Method for circulated utilization of mother liquor of alpho-naphthol, beta-naphthol ethyl naphthol production

A technology of ethyl naphthol and methyl naphthol, which is applied in the field of mother liquor recycling, can solve the problems of increased production consumption, high operating costs, and increased costs, and achieve the effects of reducing production water, reducing emissions, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

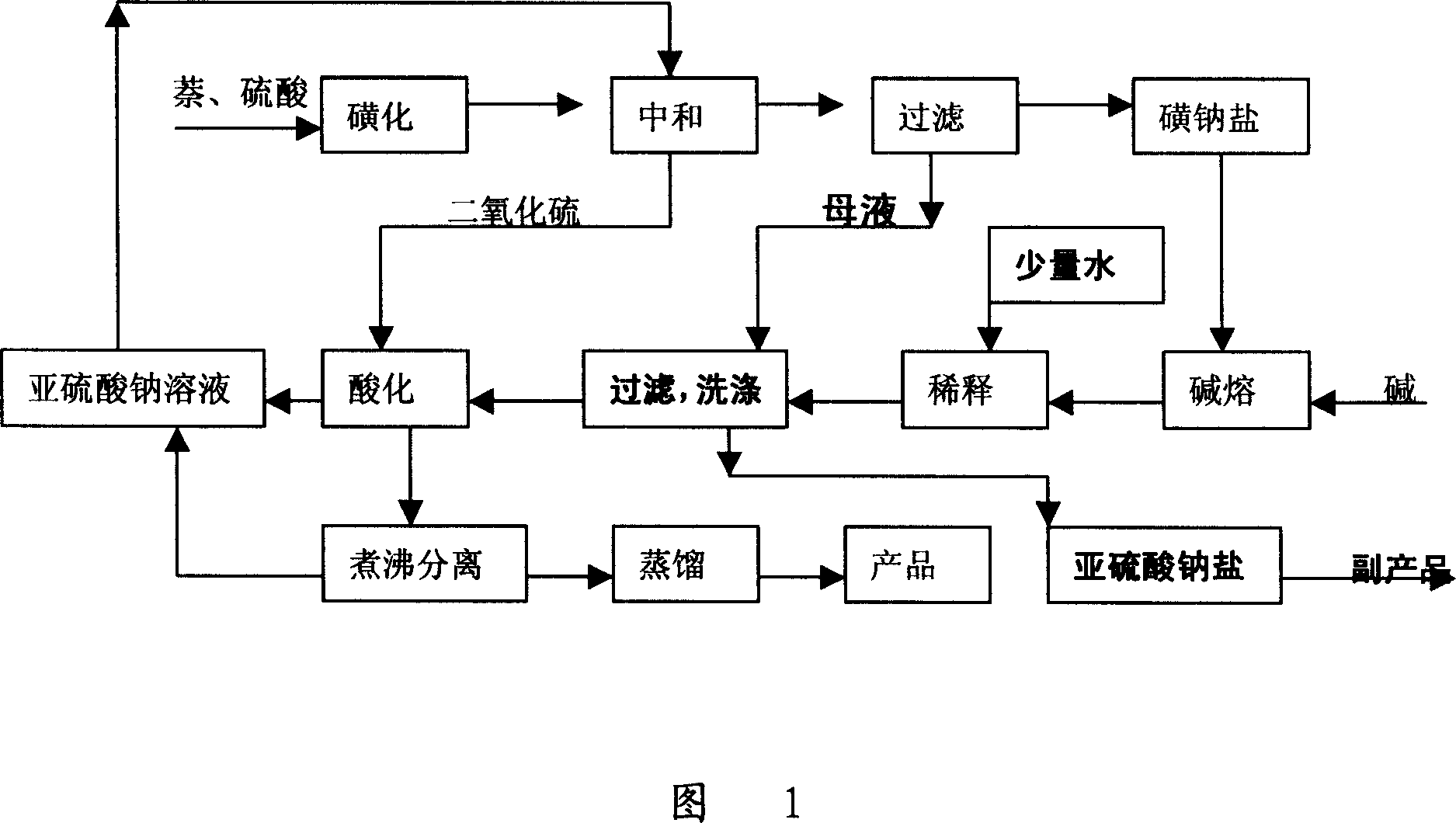

Image

Examples

Embodiment 1

[0025] Embodiment 1, in the process of preparing naphthol by sulfonation alkali fusion method, in the dilution kettle of 8 cubic meters, add water 1000L in advance, slowly add the alkali melt that alkali fusion reaction finishes (being sodium naphthol ≥ 44% and sodium sulfite ≥ 35% alkali melt) 3000kg, stirred for half an hour, the temperature is 85-95 degrees, pumped into the filter kettle, and drained. Put 6000L of sulfonium salt mother liquor preheated to 45-55 degrees in three times into the filter kettle, wash three times (a small amount for multiple times is convenient to improve the effect), drain, and combine the mother liquor to the acidification kettle for acidification reaction, then boil to separate layers, dry and distill Obtain 1110 kilograms of products at last, filter cake 800 kilograms, sodium sulfite content 93.2%.

Embodiment 2

[0026] Embodiment 2, basic steps are the same as embodiment 1, change the water 1000L into 1500L in advance, obtain 1100 kilograms of products at last. The filter cake is 650 kg, and the sodium sulfite content is 94.2%.

Embodiment 3

[0027] Embodiment 3, the basic steps are the same as in Embodiment 1, the water added in advance is increased to 500L, and finally 1101 kg of product are obtained. The filter cake is 900 kg, and the sodium sulfite content is 92.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com