Production line for self-insulation building blocks

A self-insulating block and production line technology, which is applied in ceramic molding workshops, auxiliary molding equipment, unloading devices, etc., can solve the problems of high investment costs, messy working environment, and large staffing, and achieve less plant occupation , reduce manual handling, less demand for pallets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

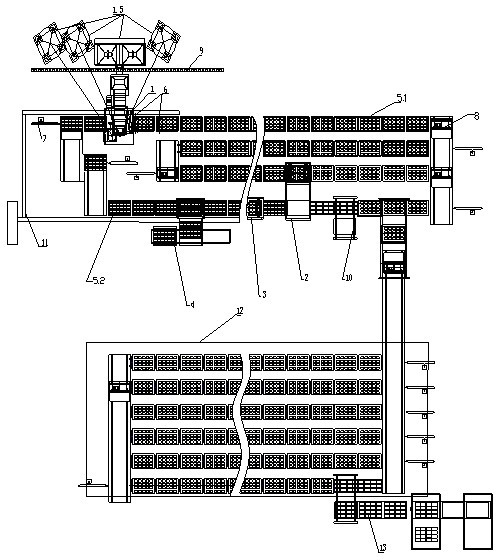

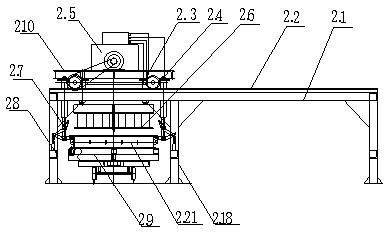

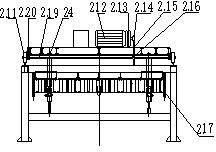

[0024] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a mixer, an automatic feeding device is provided between the mixer and the raw material bin, and a material distributing port is provided below the mixer, and it is characterized in that: the feeding port and the bottom of the mixer are equipped with an automatic metering device, so A production track 5.1 for automatically transporting molds is provided below the material opening of the mixer, and a demoulding machine 2 is also provided on the production track at an appropriate distance from the mixer. The return track 5.2 that returns to the mixer and a track that enters the maintenance area, the return track passes through the cleaning area, the fuel injection area and the lower core area in turn, the cleaning area is provided with a cleaning machine 3, and the lower core area is provided with a core lowering machine 4. The other end of the maintenance area 12 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com