Rolling method capable of reducing hot-rolled hardness and curvature of 42CrMo

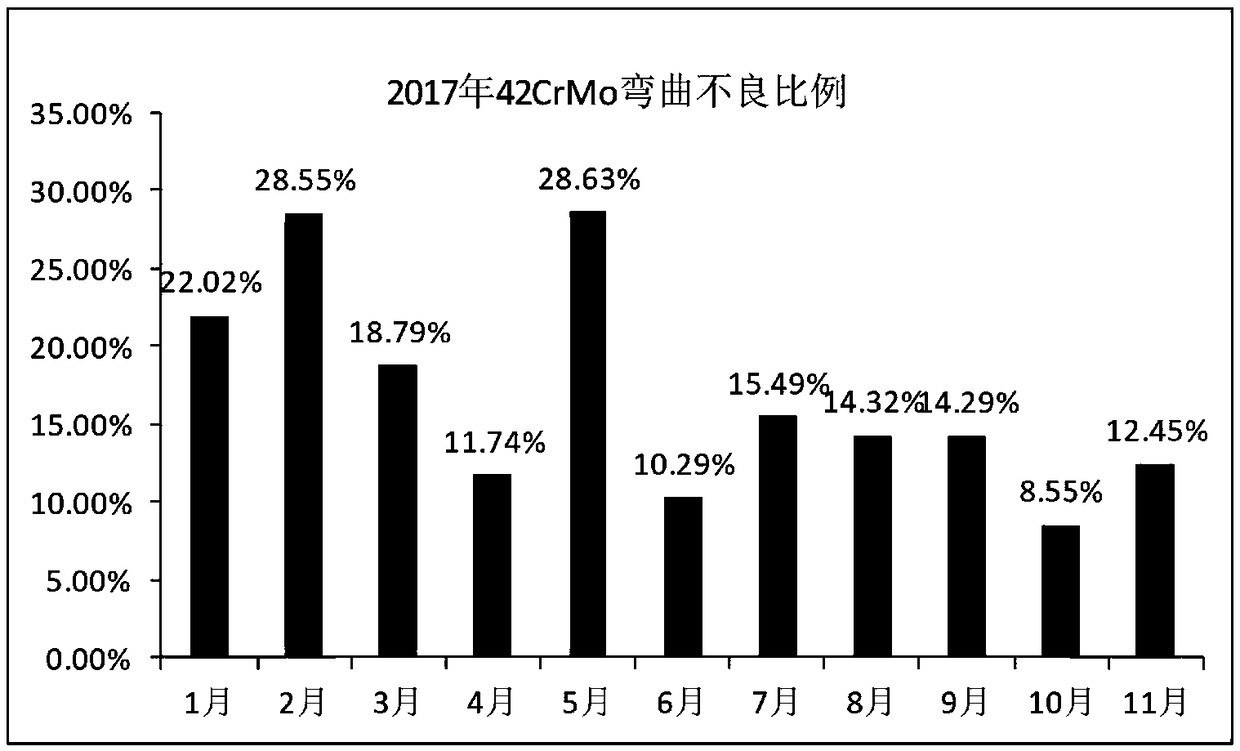

A curvature and hardness technology, applied in the field of rolling to reduce the hardness and curvature of 42CrMo in the hot-rolled state, can solve the problems of production organization and downstream users, easy formation of cracks, fractures, and large curvature in the hot-rolled state, etc. The effect of shortening the production cycle, improving the hardness of the hot-rolled state, and improving the bending degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

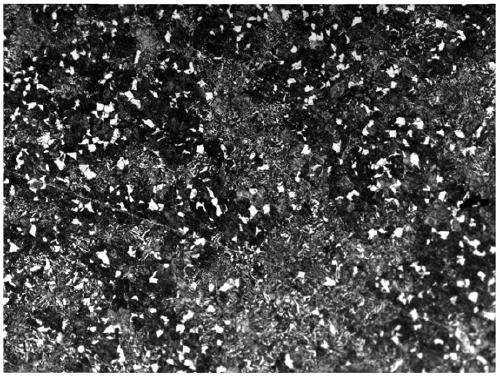

[0015] Below, the present invention will be described in further detail in conjunction with the accompanying drawings.

[0016] A rolling method that reduces 42CrMo hot-rolled state hardness and curvature, comprises the steps:

[0017] (1) Heating: The purpose of this step is to heat the billet to the temperature range of the austenite single-phase solid solution structure, and have enough time to homogenize and dissolve carbides, thereby improving the shaping of the steel, reducing deformation resistance, and improving the internal structure. and performance for easy rolling. The specific requirement is to carry out step-by-step heating on the blank, and the step-by-step heating includes a non-heating section, a preheating section, a heating section, a heating section, a soaking section, and a soaking section; The temperature of the heating section is 600-850°C, the heating rate is 0.180-0.254°C / s, the temperature of the preheating section is 800-1020°C, the heating rate is ...

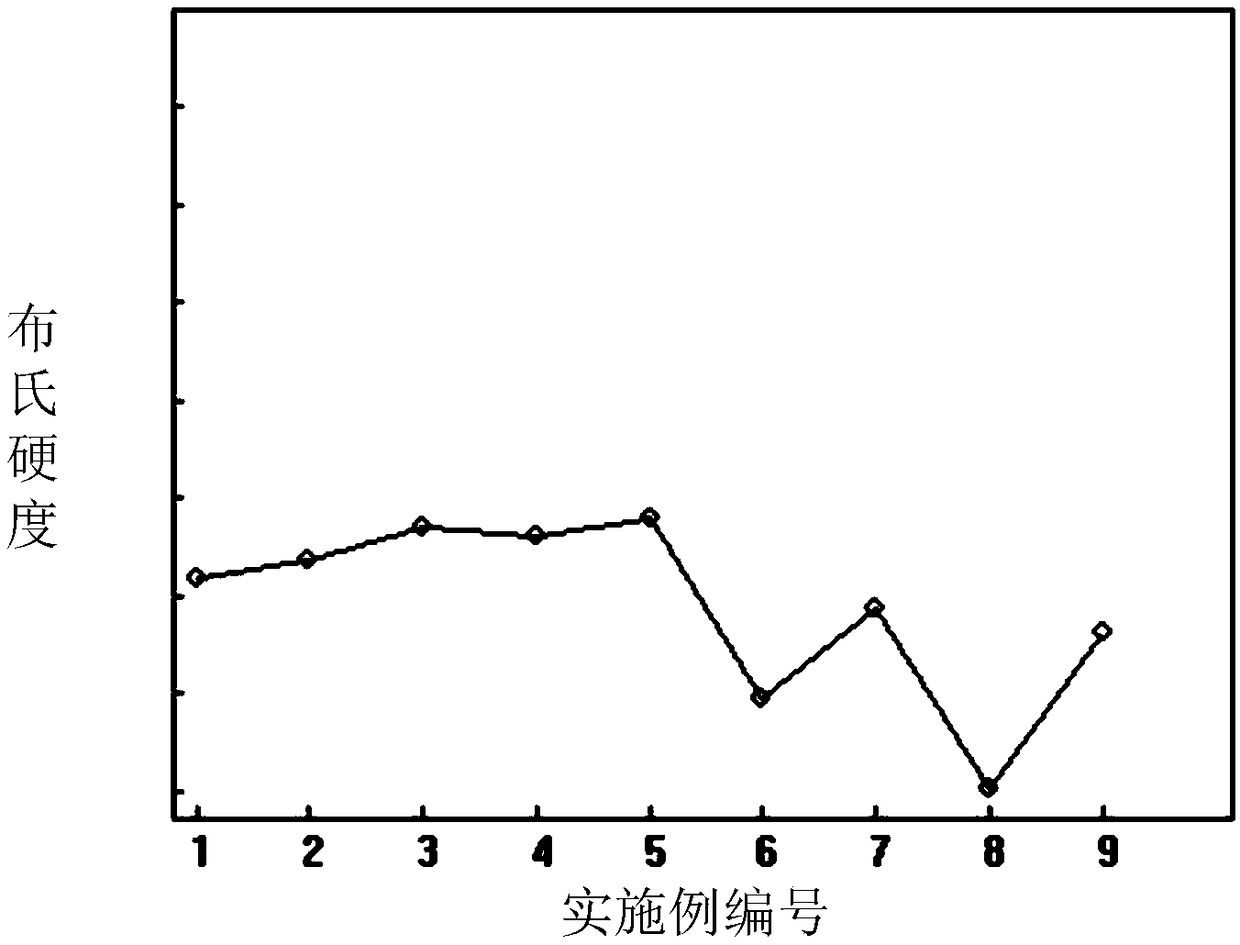

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com