Preparation method of tea oil anti-cracking cream composition and product thereof

A composition and technology of camellia oil, applied in the field of chemical daily necessities, can solve the problems of low content of camellia oil, can not achieve better skin maintenance and health care effects, etc., achieve skin softness, protection from oxygen free radical damage, formula reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A kind of preparation method of camellia oil anti-cracking cream composition provided by the embodiment of the present invention, it comprises the steps:

[0074] (1) According to the following component formula and weight percentage, take each raw material component:

[0075] High melting point fatty compounds 0.1-12.0%;

[0076] Emulsifier 0.1-8.0%;

[0077] Emollient 0.1-30.0%;

[0078] Humectant 0.1-30.0%;

[0079] Camellia oil 7.0-15%;

[0080] Stabilizer 0.1-10%%;

[0081] Additives 0.1-3%;

[0082] Deionized water balance

[0083] Additives include: preservatives, complexing agents, softeners, neutralizers, flavors and nutrients.

[0084] (2) Preparation of Phase A composition: Add the weighed high-melting point fatty compound, emollient, emulsifier, camellia oil, humectant, and preservative in additives into a container and heat up to 90°C-95°C while stirring. °C until all raw materials are dissolved;

[0085] (3) Preparation of phase B composition: Add...

Embodiment 2

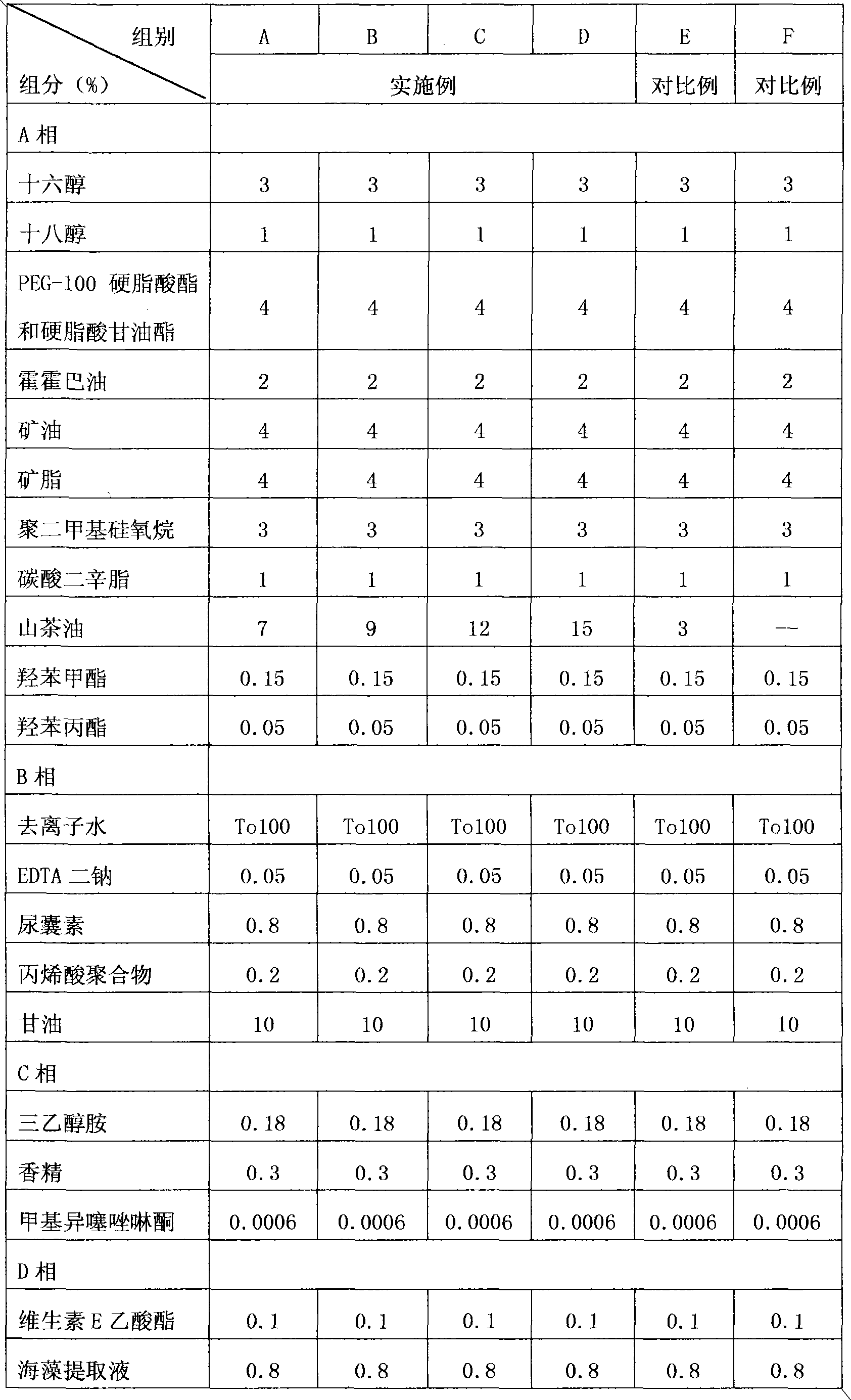

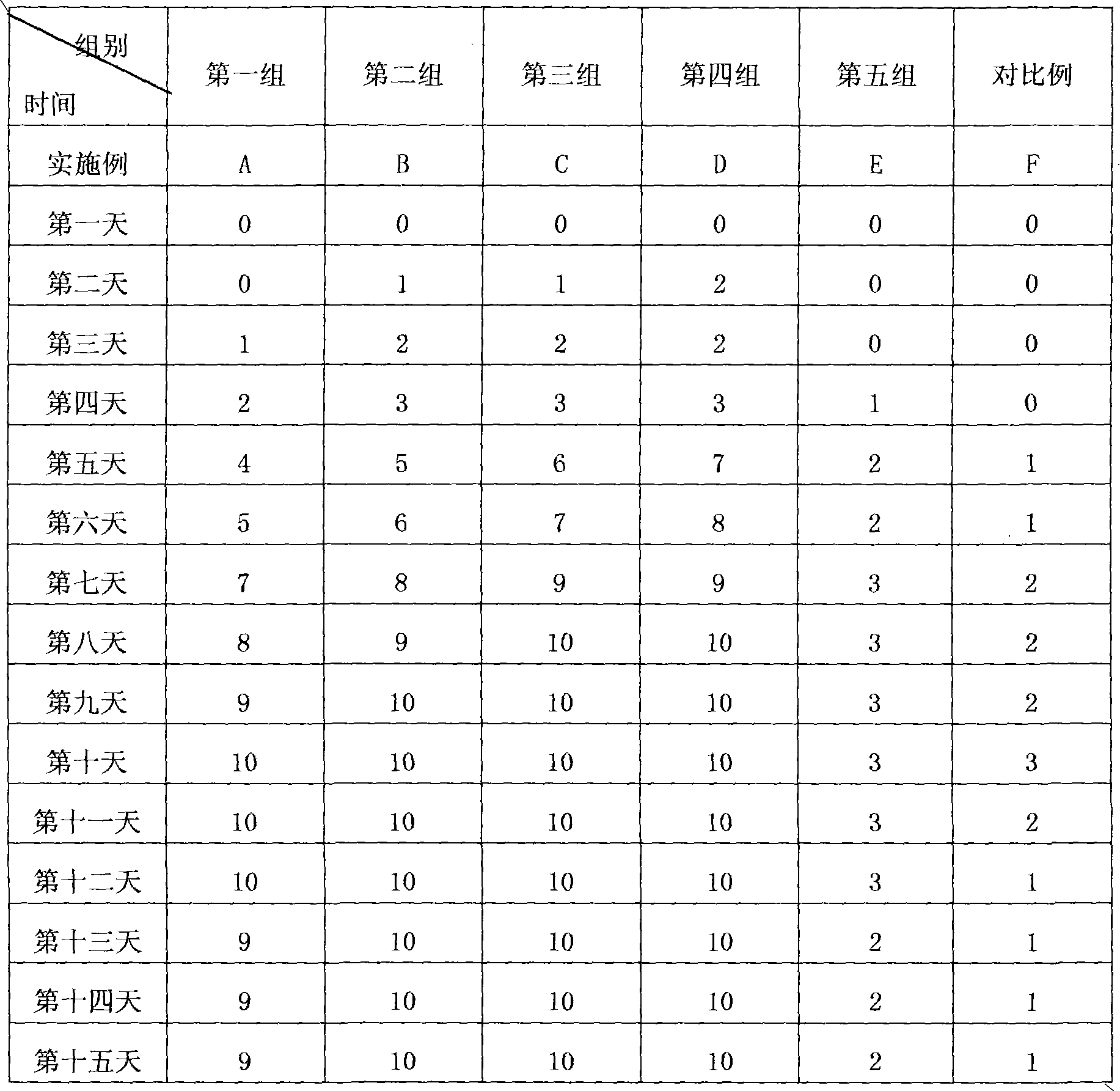

[0125] This embodiment provides a camellia oil anti-cracking cream composition, which is an anti-cracking cream containing camellia oil. Its preparation method is the same as in Example 1, except that its specific components and weight percentages are shown in Table 1. in column A. Wherein the fatty compound with a high melting point as the base is a mixture of cetyl alcohol and stearyl alcohol; the emulsifier is PEG-100 stearate and glyceryl stearate; the additives also include essence and the like.

[0126] The emulsifier suitable for the present invention is a kind of non-ionic emulsifier or anionic emulsifier between 6-15 or their mixture, and the most preferred emulsifier is the hydrophilic-lipophilic HLB value One of nonionic emulsifiers or anionic emulsifiers between 10-14 or a mixture of them. Preferred emulsifiers are selected from glycosides and esters. The glycosides are selected from cocoyl glucoside, hexadecyl glucoside, eicosyl glucoside, and C12-20 alkyl gluco...

Embodiment 3

[0134] The camellia oil anti-cracking cream composition provided in this example is a kind of anti-cracking cream containing camellia oil, and its preparation method is the same as in Example 1, the difference is that its specific components and weight percentages are shown in Table 1 Column B.

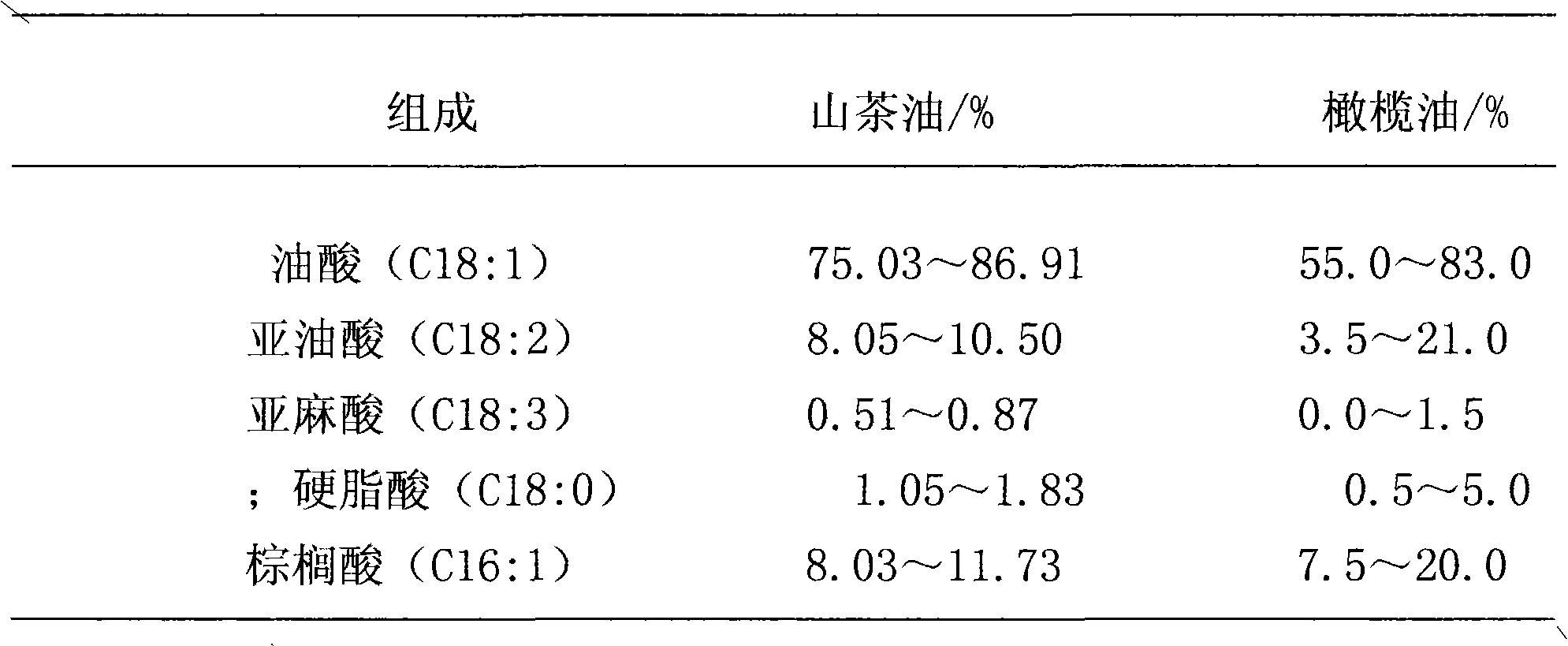

[0135] The camellia oil suitable for the present invention is selected from: Taiwan high mountain tea from the National Taiwan Farmers Pioneering Park. In recent years, Taiwanese businessmen have comprehensively promoted the technology of watering tea trees with "soy milk" in the alpine tea gardens in Zhangping, and developed organic cultivation. By improving the soil, inhibiting pathogens, and prolonging the tea picking cycle, the yield and quality of tea and tea seeds have been effectively improved. The tea oil it produces is rich in fatty acids, camellia glycosides, phospholipids, saponins, vitamin E, tannins and other components. Its unsaturated fatty acid content is rich, as hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com