Dry anti-seepage material and preparation method thereof

A dry, coal gangue technology, applied in the field of anti-seepage materials, can solve the problems of high production cost, long logistics, no market competitiveness, etc., and achieve the effect of uniform and stable quality and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

[0020] A kind of dry anti-seepage material among the present invention, the raw material composition of each embodiment and comparative example is shown in the following table:

[0021] serial number Experimental case coal gangue andalusite Binding agent 1 Example 1 70 10 20 2 Example 2 60 15 15 3 Example 3 80 8 12 4 Comparative example 1 50 30 20 5 Comparative example 2 90 5 5 6 Comparative example 3 70 10 20 7 Comparative example 4 70 10 20

[0022] The preparation method of the scheme of above-mentioned serial number 1-5 all comprises the following steps:

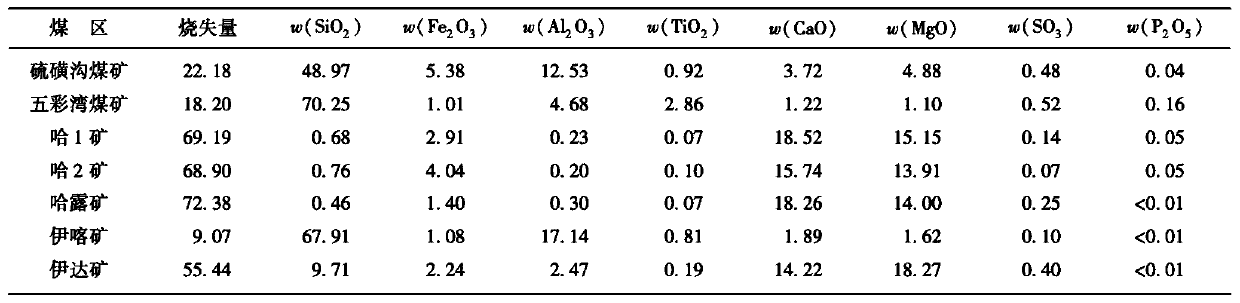

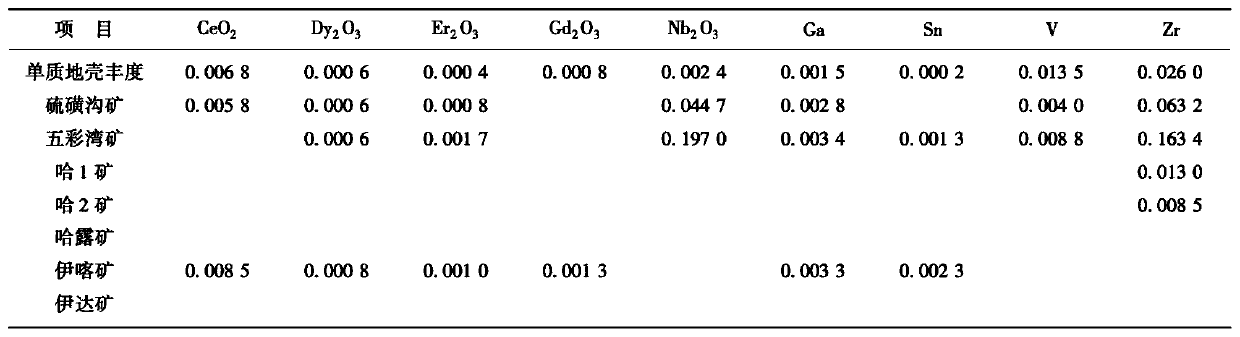

[0023] The first step is to select the local coal gangue in Xinjiang, remove the surface impurities, then crush it, grind it into fine powder, and pass the fine powder through a 325-mesh sieve;

[0024] In the second step, add andalusite fine powder and CA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com