Automatic terminal insertion device of stators

An automatic insertion and terminal technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of inability to adjust, laborious and laborious, and low degree of automation, so as to achieve stable and uniform output quality, ensure product quality, and save equipment resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Refer to attached picture.

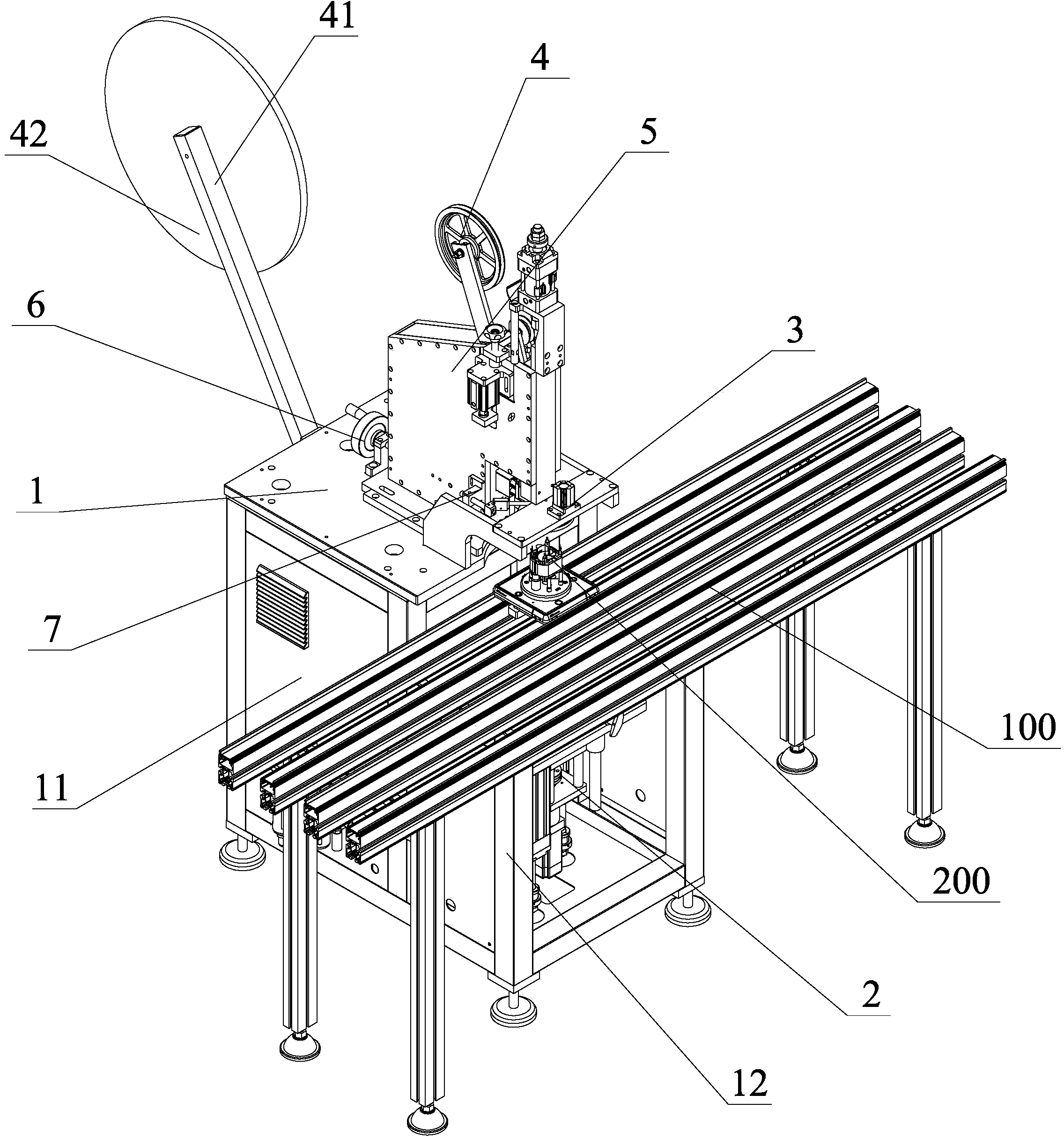

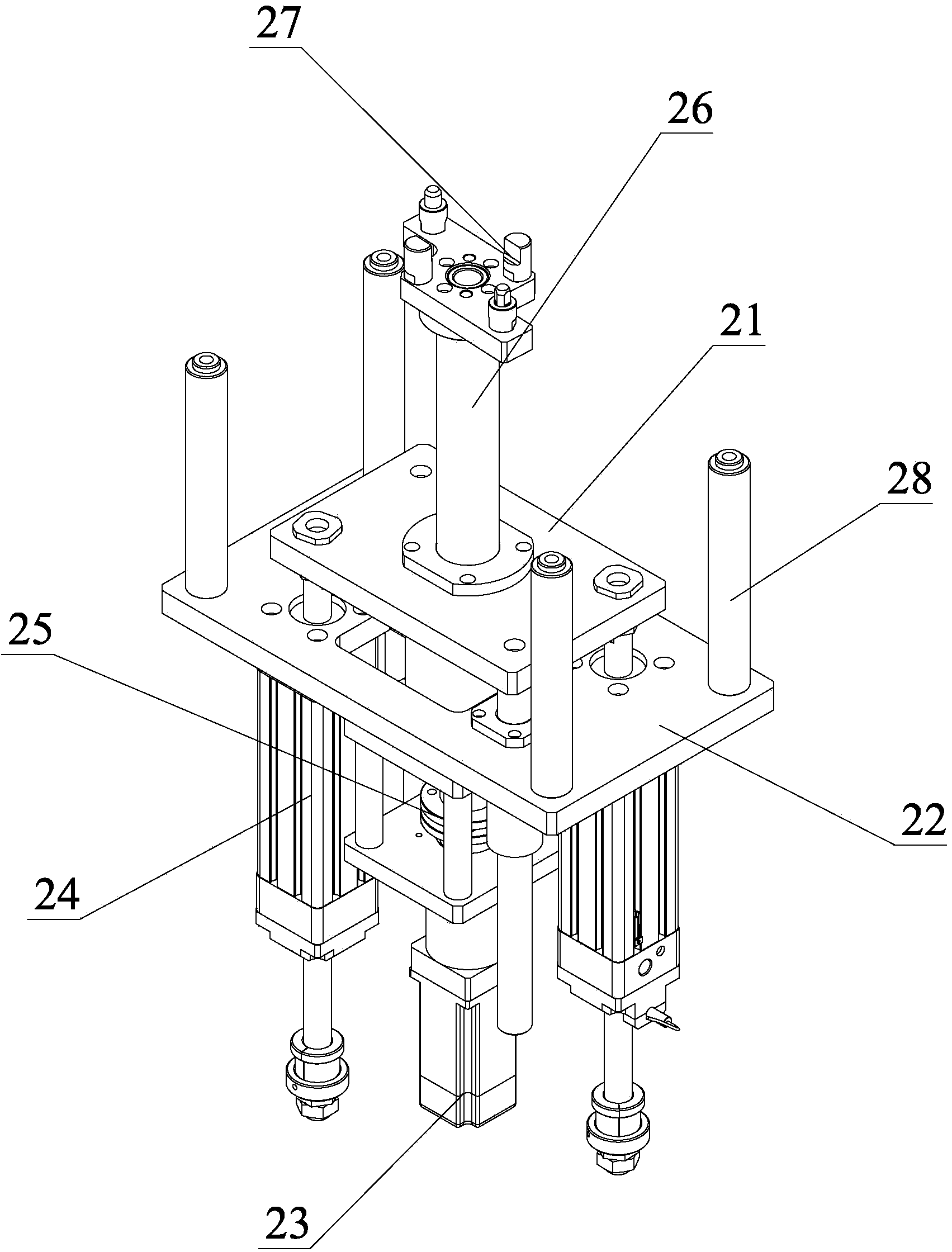

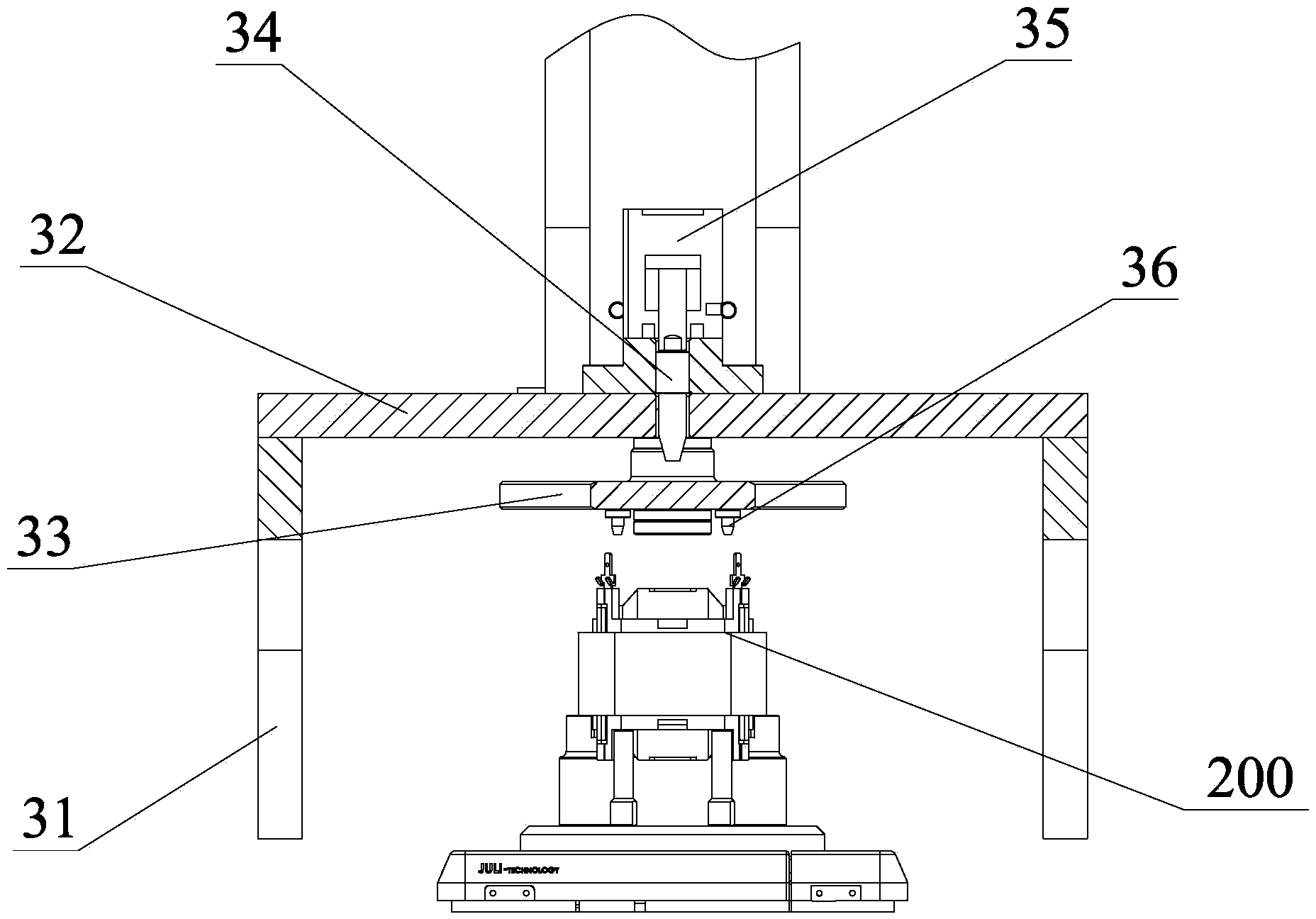

[0025] The present invention provides a stator terminal automatic insertion device, which includes a frame platen part 1, a lifting and feeding part 2, a positioning and rotating part 3, a terminal aisle part 4, a machine head part 5 and a terminal position adjustment part 6, the top The lifting and feeding part 2 is installed under the stator conveying line 100, and is used to lift the stator 200 on the line up to the corresponding station for terminal insertion operation, and the positioning rotating part 3 is used to rotate the stator 200 to switch the terminal insertion hole, The terminal aisle part 4 is used to provide the feeding channel of the terminal. The head part 5 includes a head frame plate 51, a terminal sending mechanism 52, a terminal cutting mechanism 53 and a terminal insertion mechanism 54. The head frame plate 51 is vertically installed on the frame platform. On the plate part 1, the terminal sending mechanism 52 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com