Patents

Literature

286results about How to "Improve screening quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Image Tracking System and Image Tracking Method Thereof

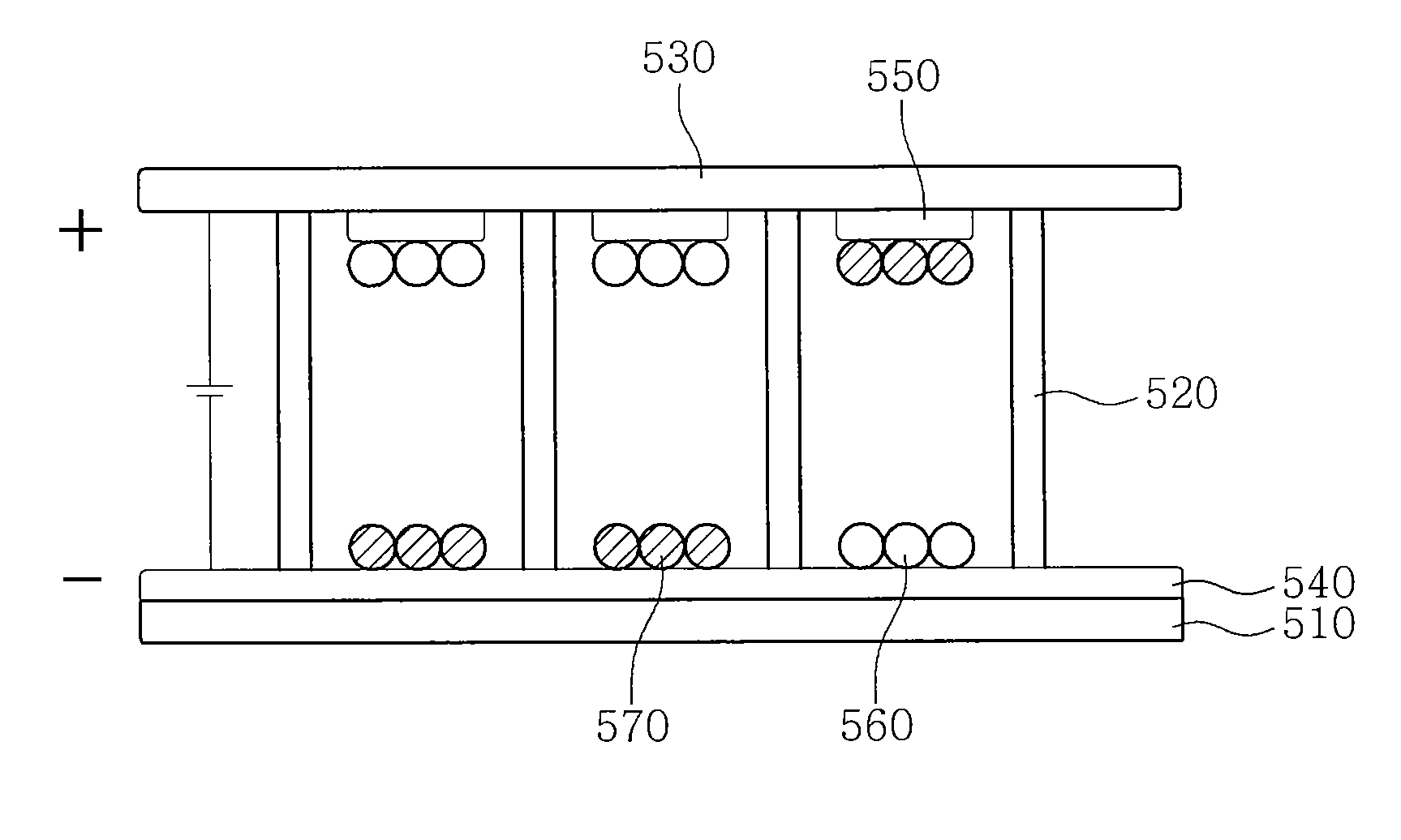

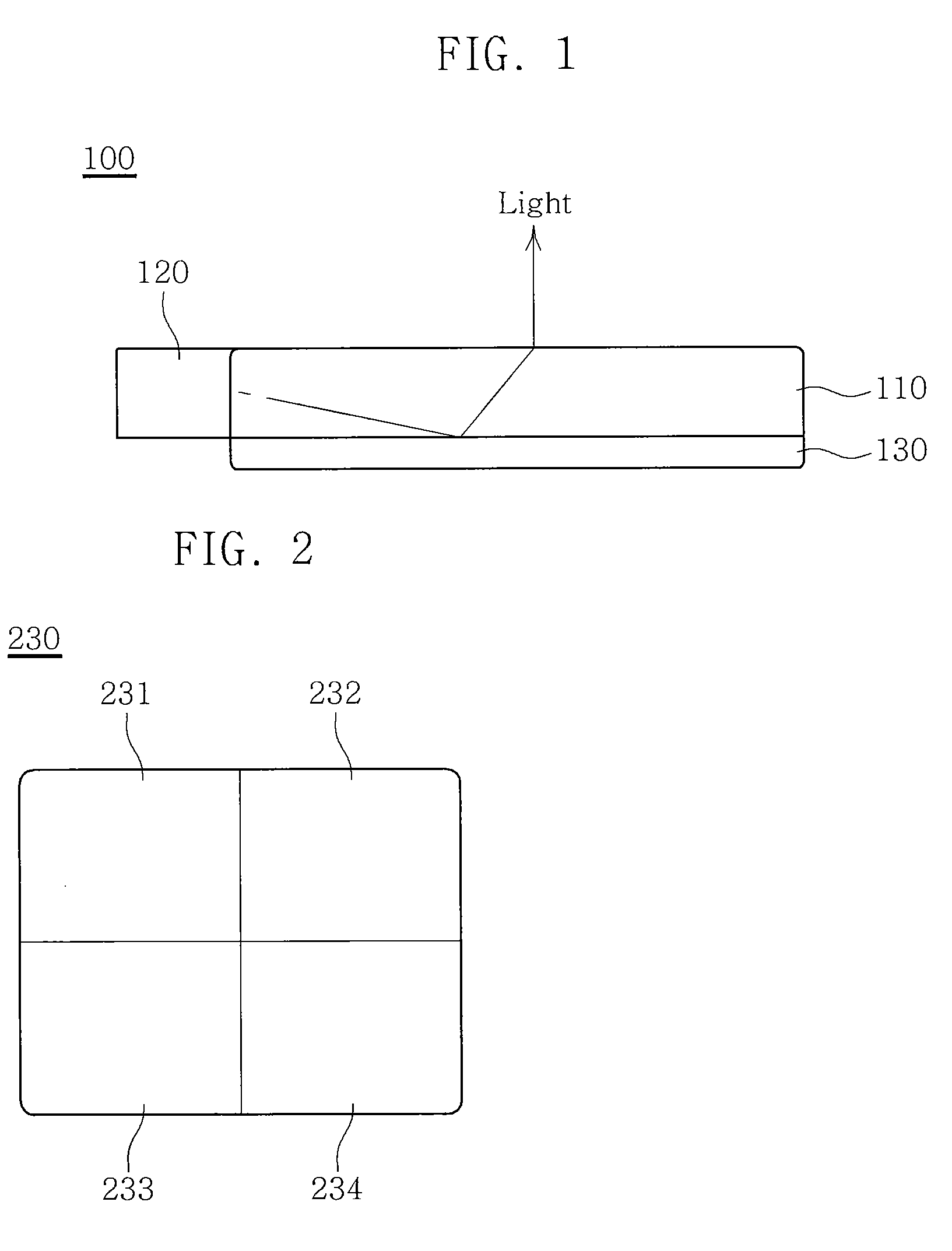

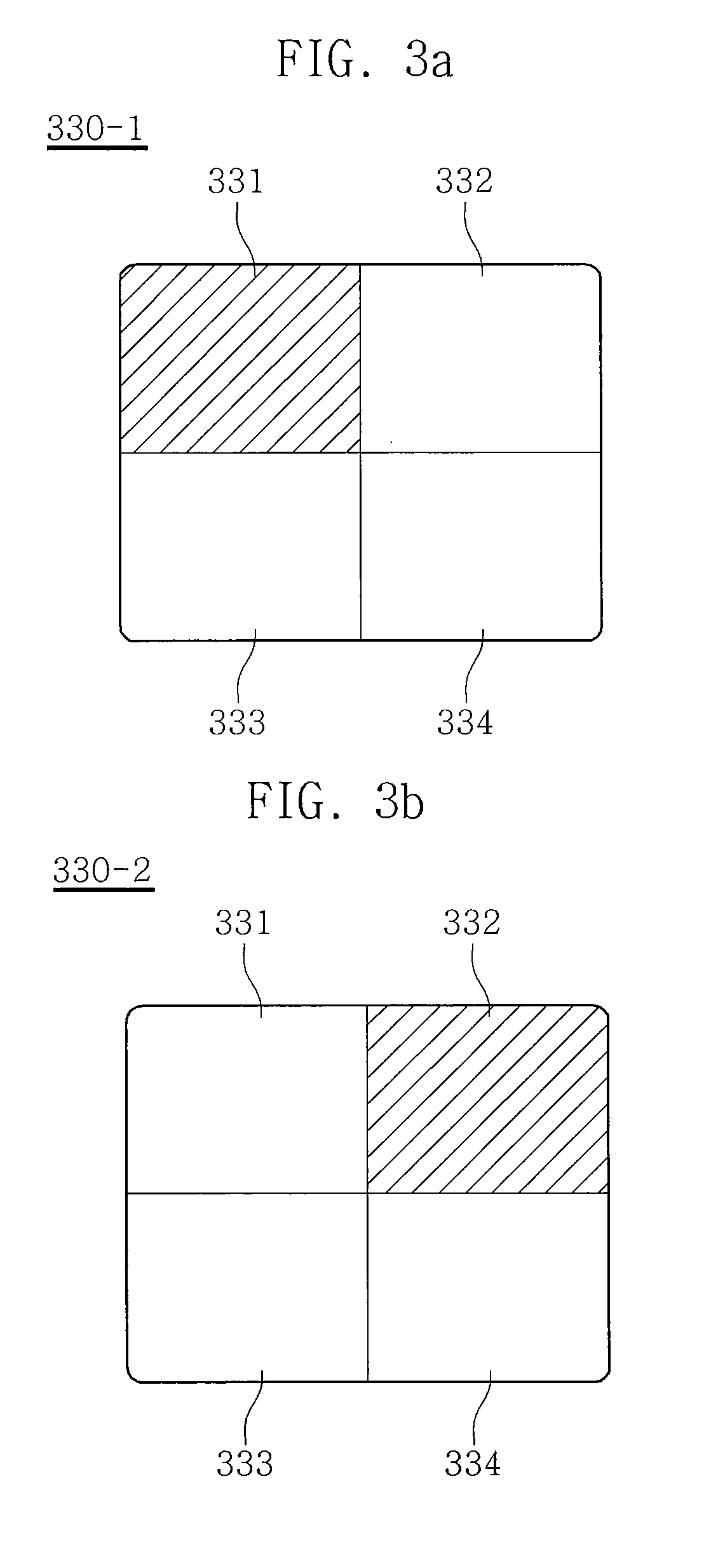

InactiveUS20140005475A1Effective trackingAvoid too much unnecessary movements of the cameraLaproscopesEndoscopesControl signalVehicle tracking system

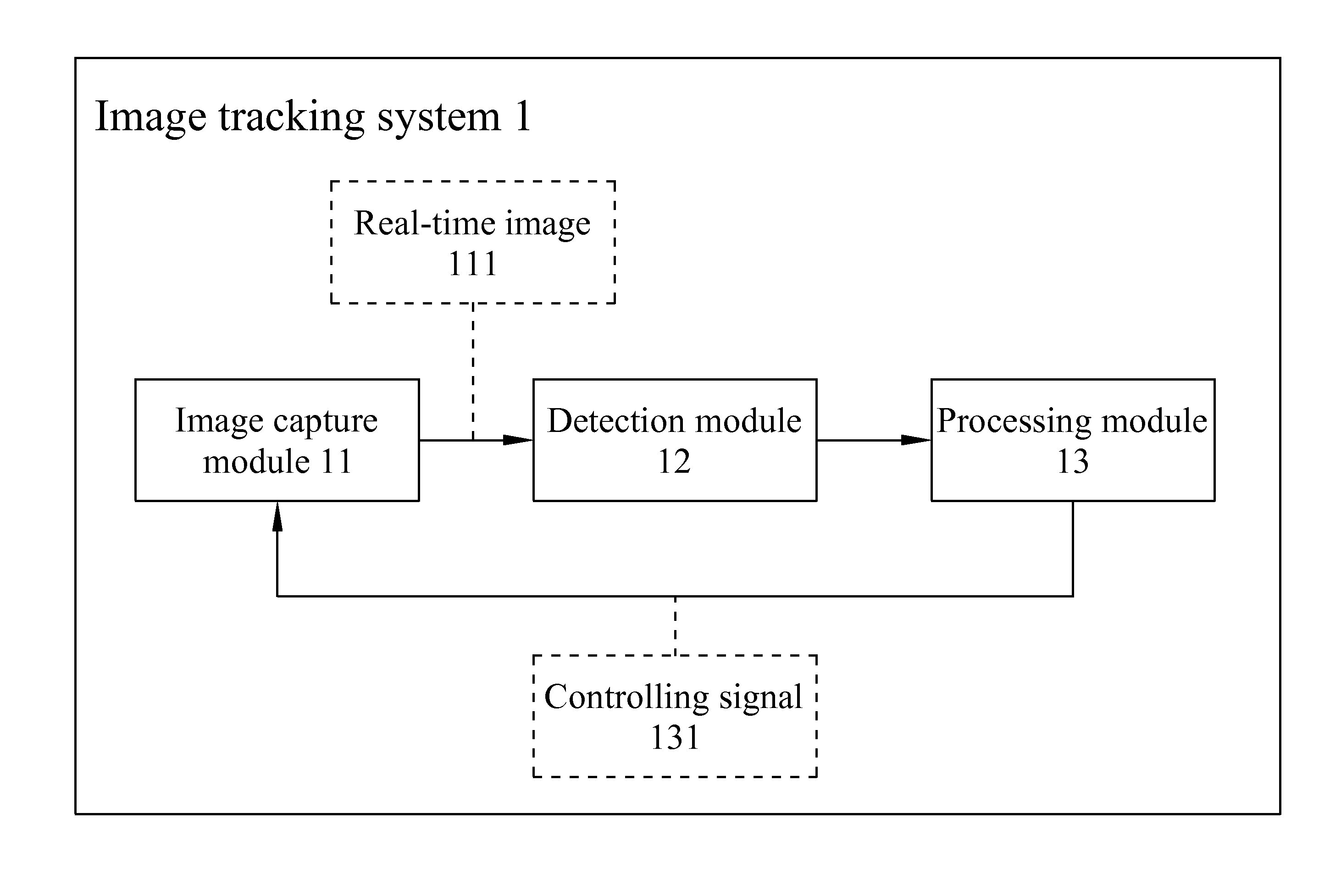

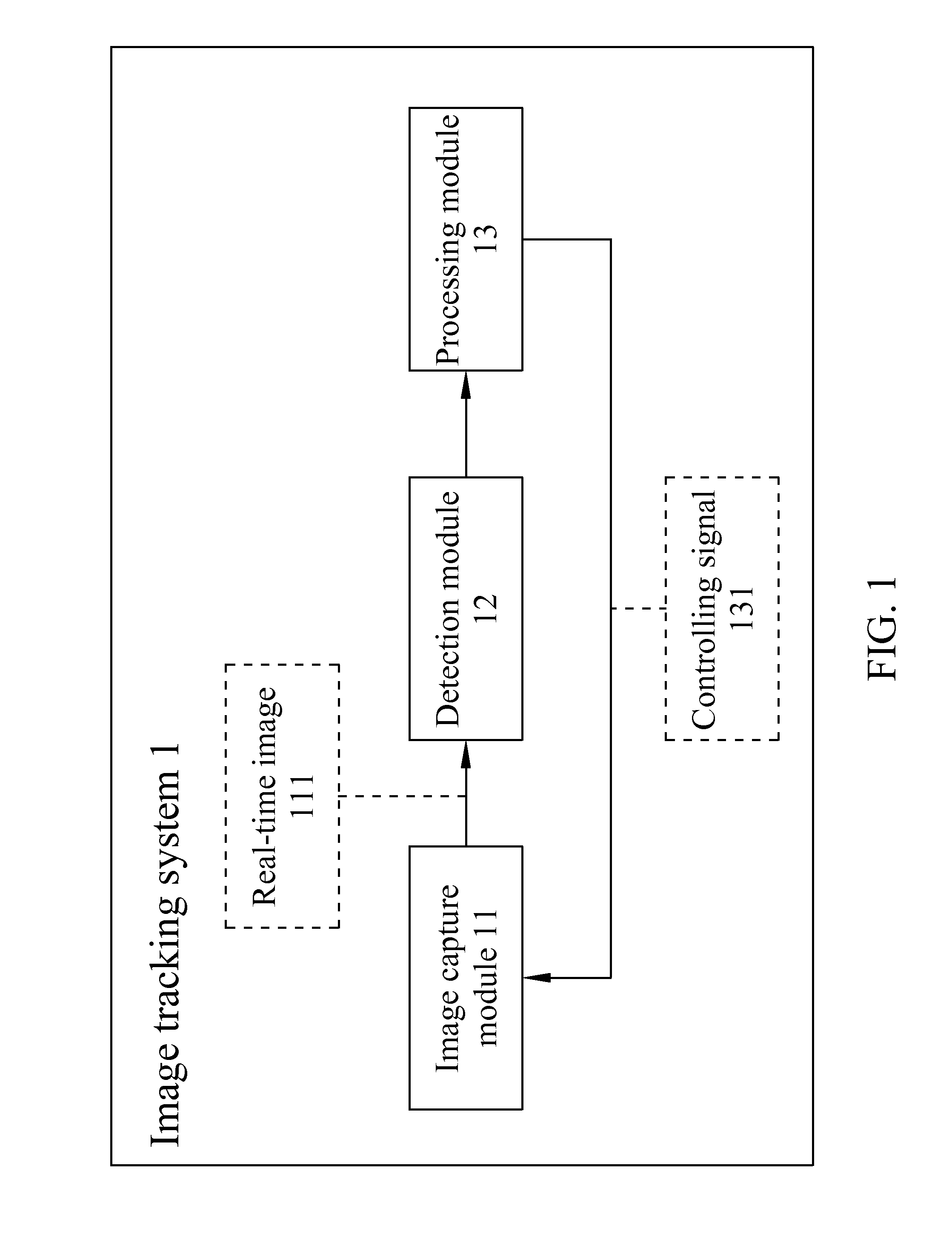

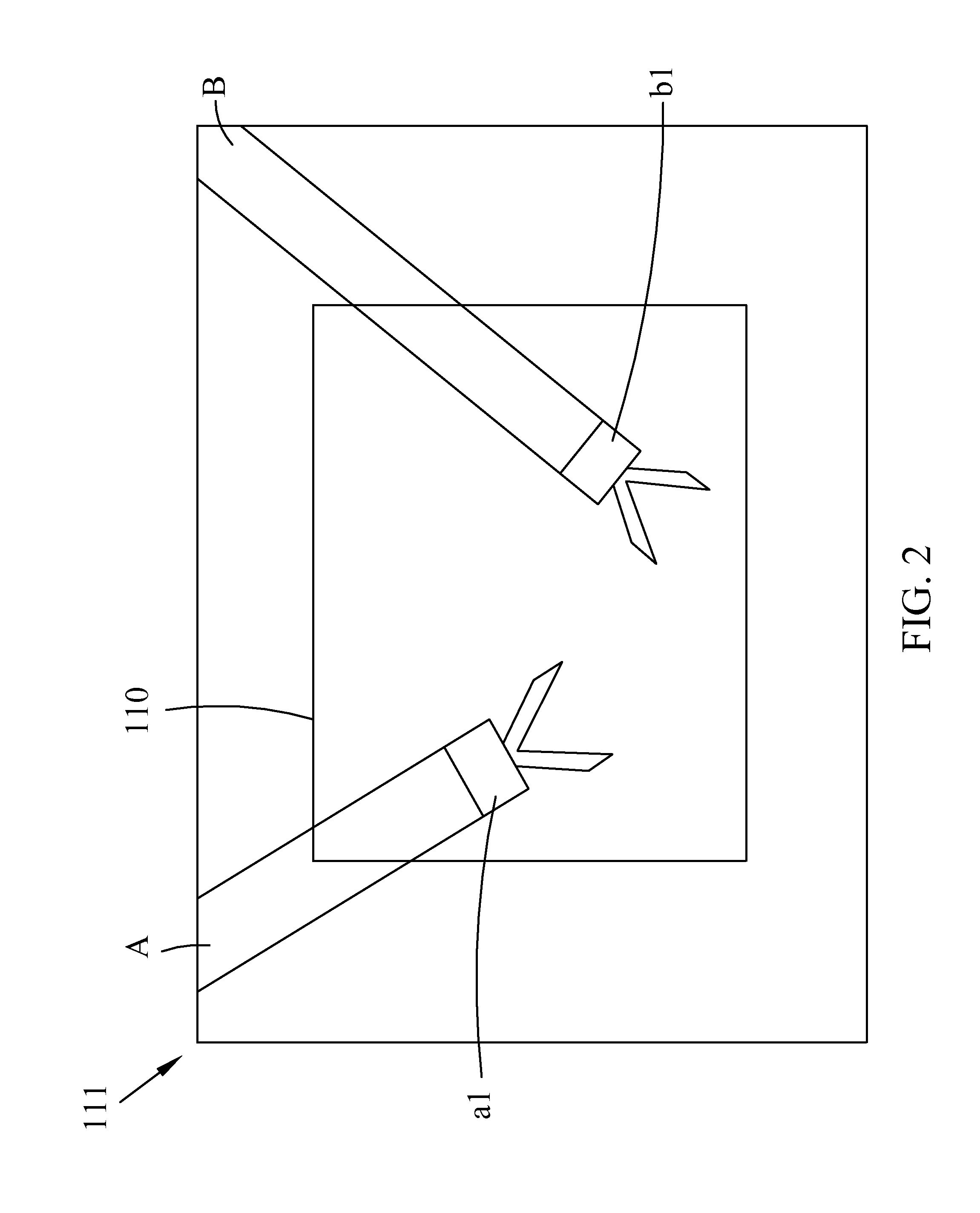

An image tracking system and an image tracking method. The image tracking system includes image capture module, detection module and processing module. The image capture module captures real-time image. The detection module analyzes the real-time image, and detects whether positions of a plurality of instruments are disposed in the real-time image. The processing module defines buffer zone in the real-time image, and analyses whether the instruments are disposed in the buffer zone based on the positions of the instruments, and determines whether spacing distance between the instruments is small than preset distance. When the spacing distance is smaller than the preset distance or the instruments are disposed outside the buffer zone, the processing module emits controlling signal to control the image capture module to move to capture position. As a result, the present invention may achieve image tracking real time and provide stable image.

Owner:NAT CHIAO TUNG UNIV

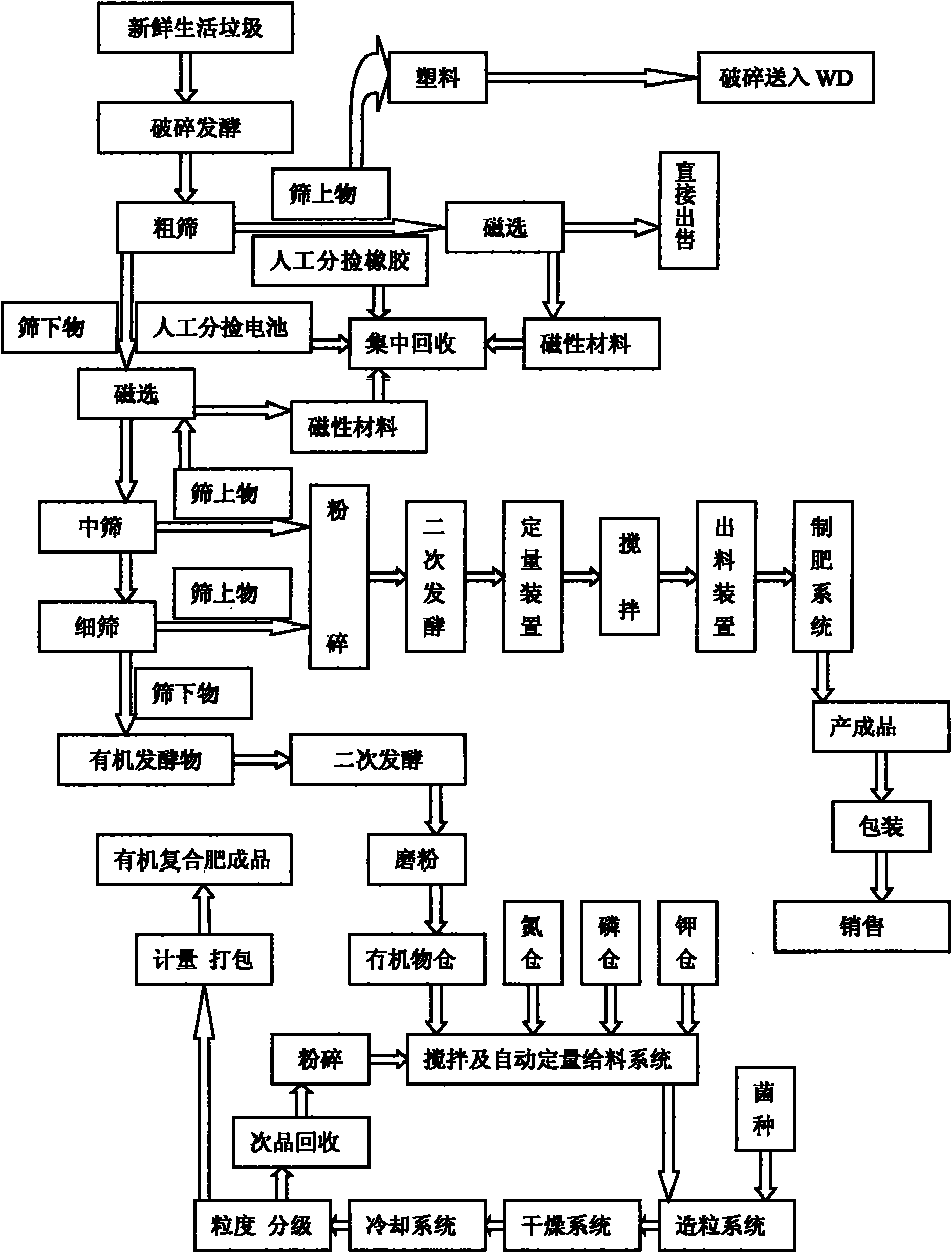

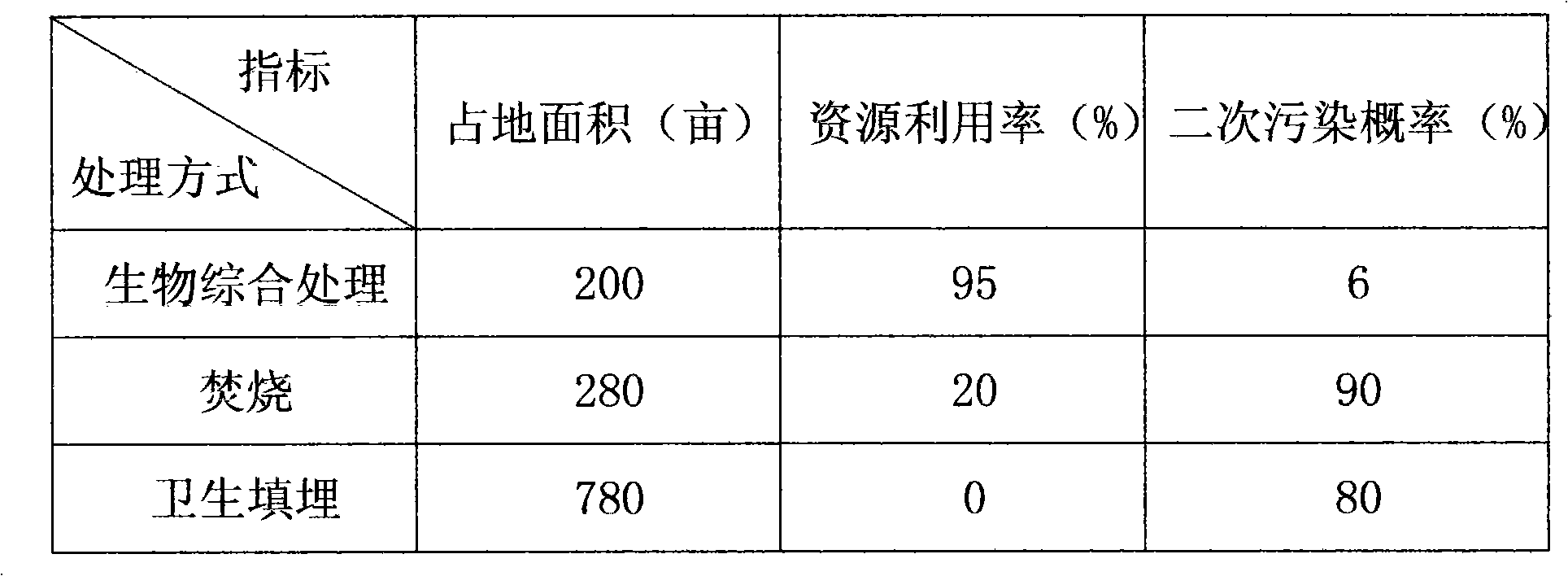

House refuse treatment method

InactiveCN102009057ASave spaceReduce the power requiredSolid waste disposalClimate change adaptationBrickCrushed stone

The invention discloses a house refuse treatment method, which comprises the following steps: crushing and fermenting refuse at normal pressure and under normal pressure; executing a screening process, crushing large or large-grain inorganic materials among oversize materials on a coarse screen, and making an urban coal material; coarsely screening, crushing stone and brick blocks among oversize materials on a medium screen, and making a roadbed material or pavior brick base material; making fertilizer by using organic materials or fermented products of the organic materials among the oversize materials and undersize materials of the medium screen and a fine screen, wherein materials with recycling value among magnetic materials screen out are sold directly, and materials without recycling value are collected and subjected to innocent treatment; and performing manual sorting, wherein materials with recycling value are directly sold. When the method is used for refuse treatment, the construction investment is small, the operation cost is low, the operation is simple, the treatment effect is desirable, and the resource recycling degree is high. The method can be widely used for treatment of refuse of different sizes and qualities without causing secondary pollution.

Owner:中山市祥源环保工程有限公司

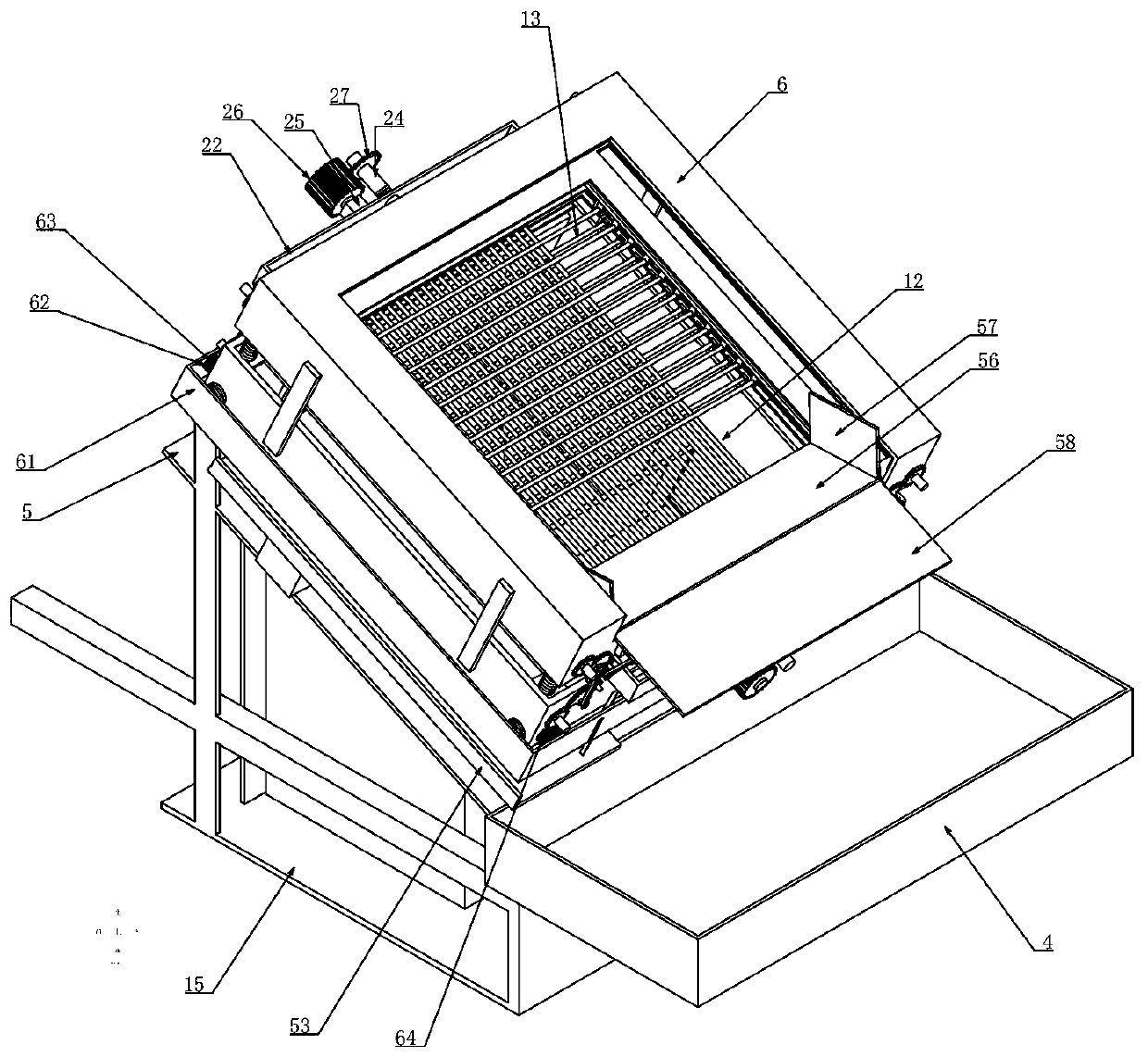

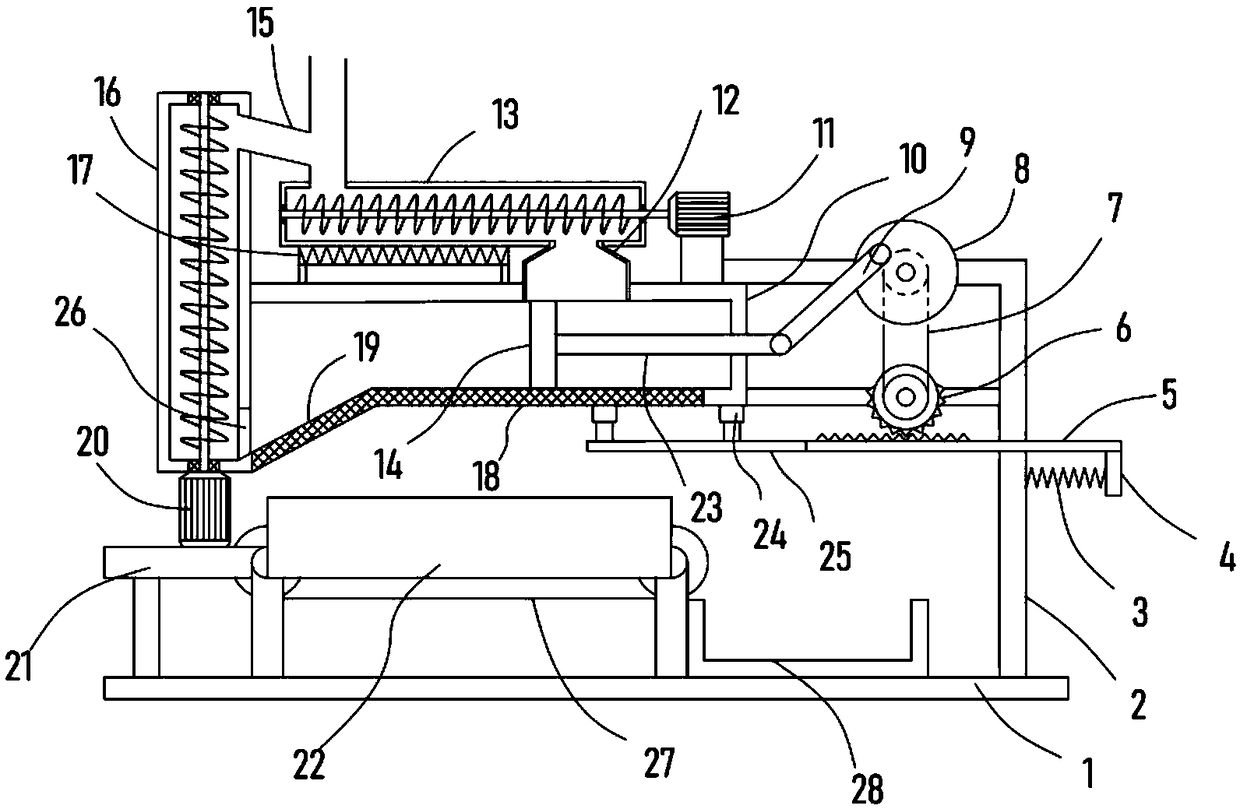

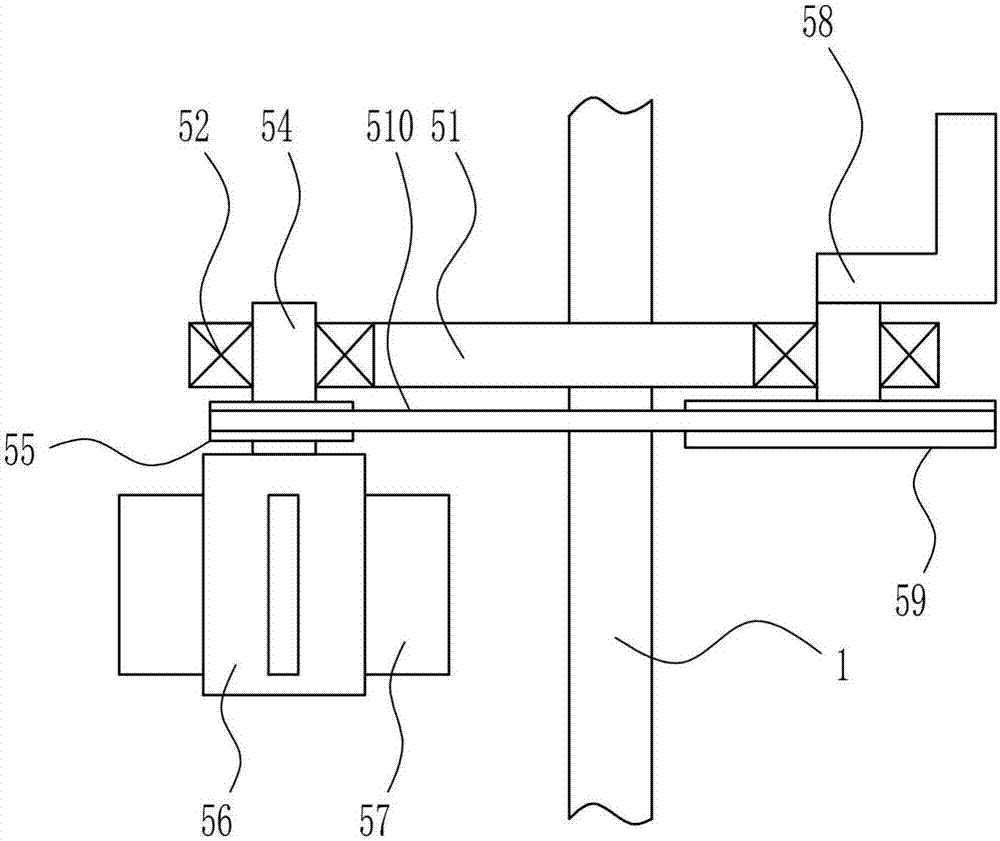

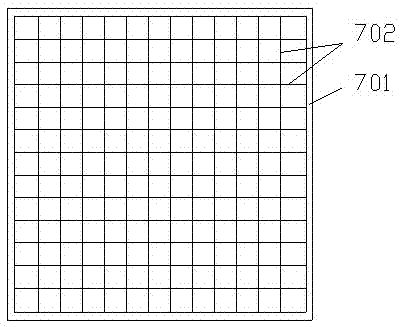

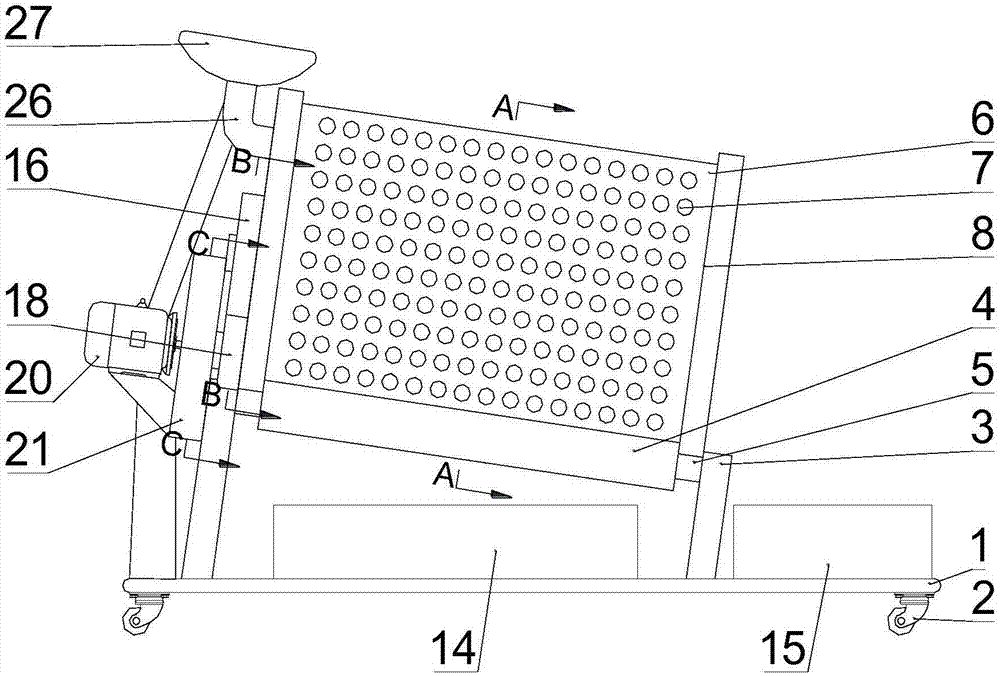

Civil engineering sand sieving device

The invention relates to a civil engineering sand sieving device. The civil engineering sand sieving device uses crosses formed by transverse rods and longitudinal rods for forming a sieving net structure, enables the transverse rods and the longitudinal rods to perform equal interval adjustment according to requirements through a transverse interval adjustment device and a longitudinal interval adjustment device, and simultaneously uses a locking function of a hydraulic telescopic rod in a hydraulic cylinder and a self-locking function of threads for achieving position locking after the equalinterval adjustment, enables the transverse rods and the longitudinal rods in the sieving net structure to be stable and reliable in the sieving process, is suitable for different grain diameters offine sand or sand stone, and avoids replacement of a sieving net, and meanwhile a power device drives the transverse rods and the longitudinal rods, which cooperate with one another, to separate whenhole blocking of the sieving net occurs or the sieving net needs to be cleaned, and then achieves cleaning effect by adjusting intervals. The civil engineering sand sieving device is simple to operateand ingenious in structure, avoids the replacement of the sieving net, and meanwhile can clean up the sieving net timely, and greatly improves sieving efficiency and quality.

Owner:ZHENGZHOU INST OF TECH

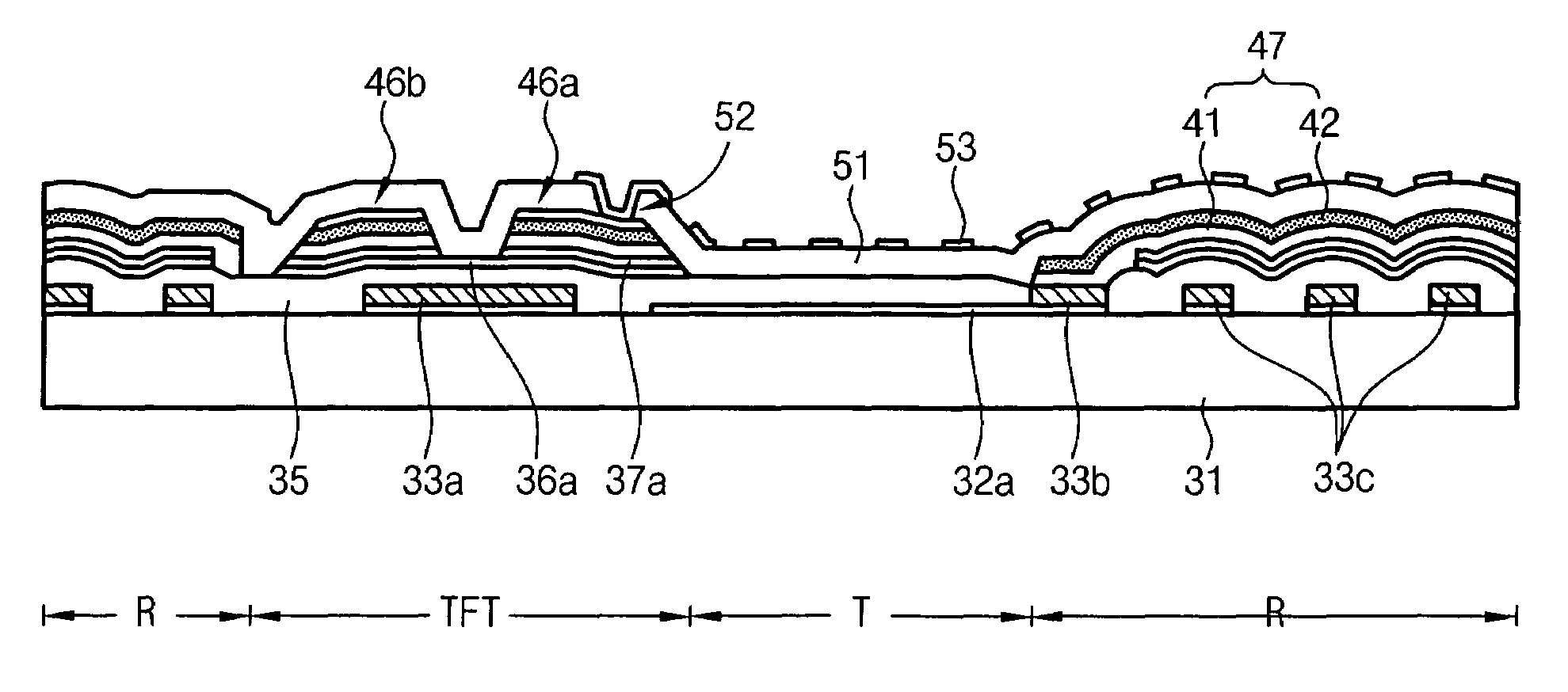

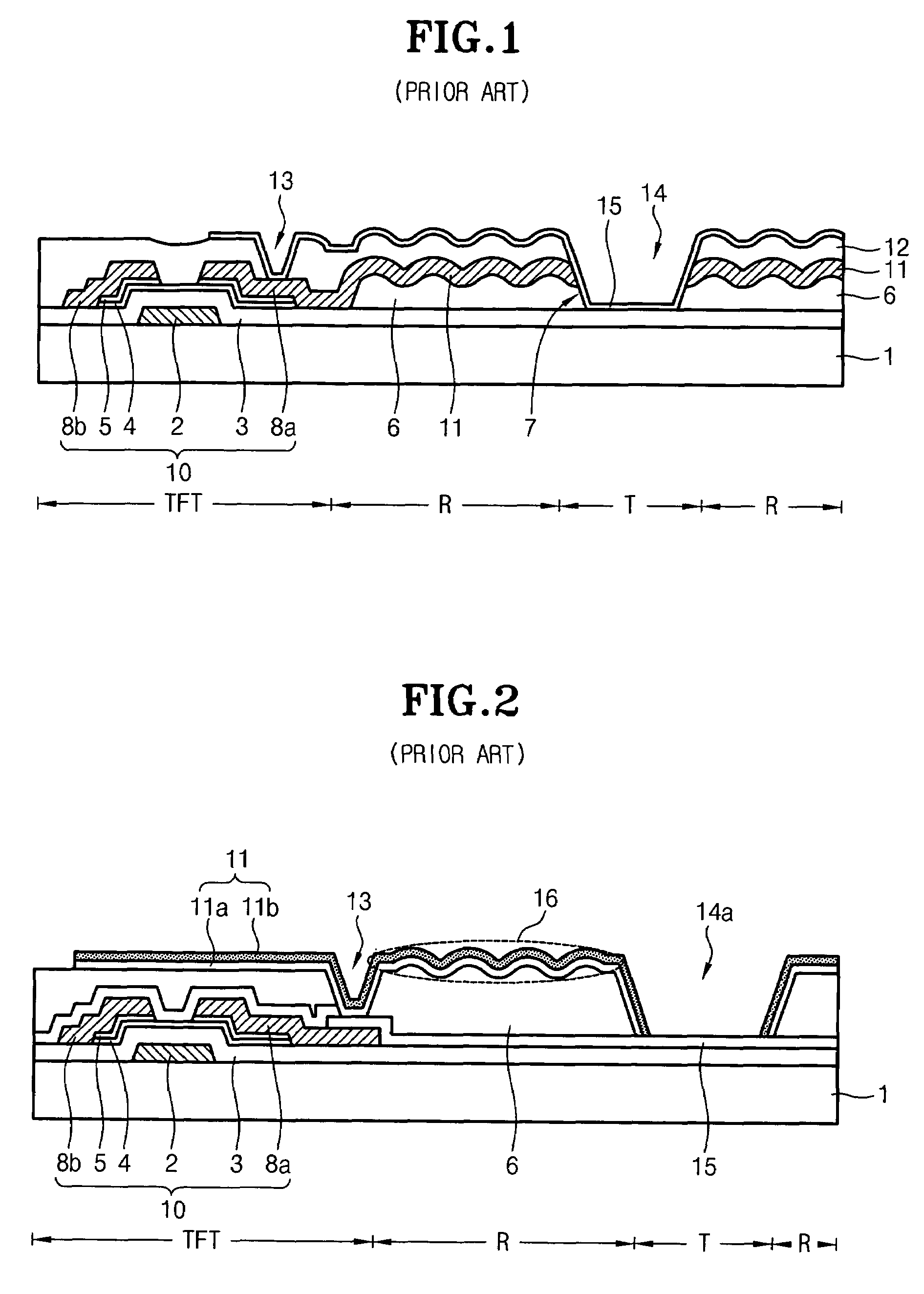

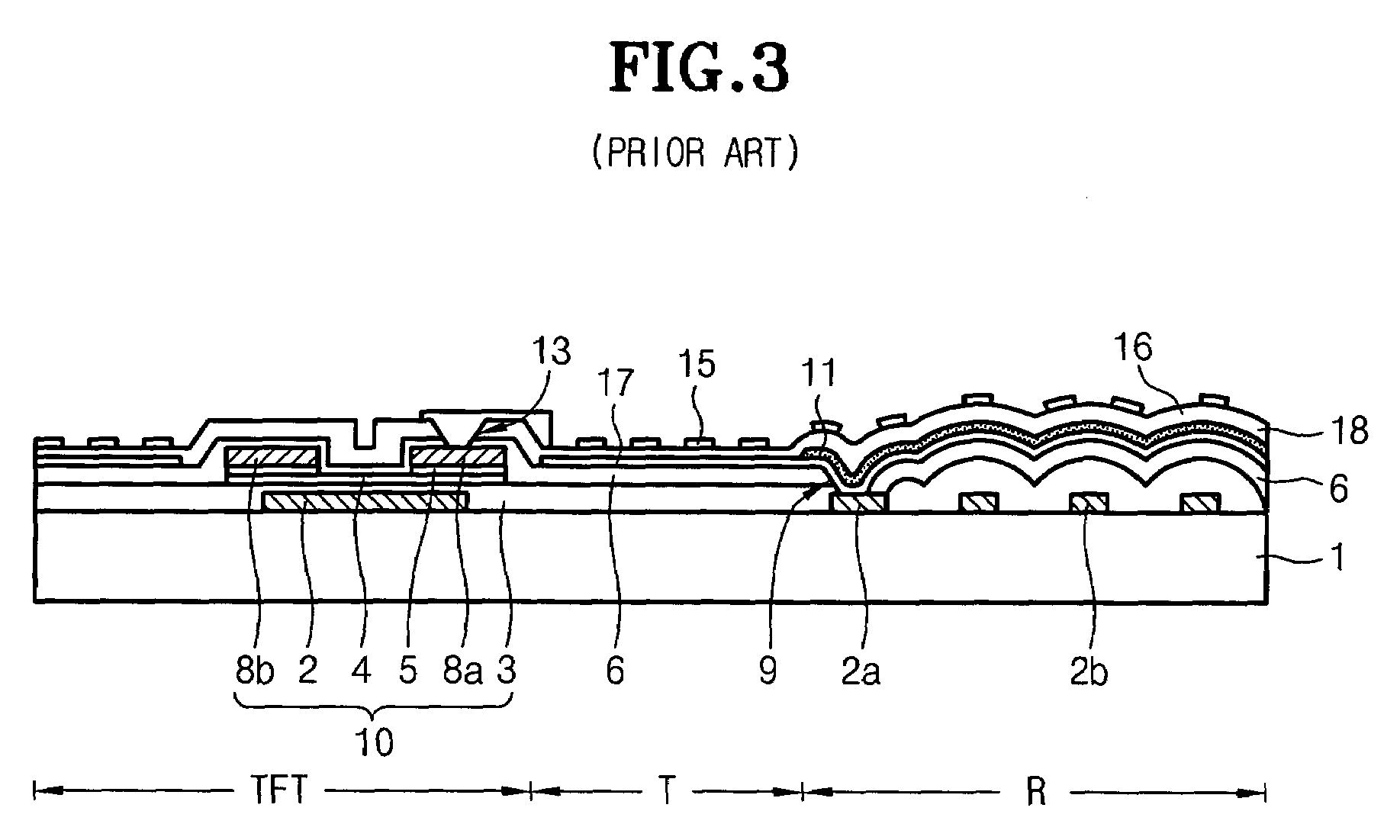

Method for manufacturing array substrate of translucent LCD

ActiveUS7480015B2Resistance in propertiesResistance in regionSemiconductor/solid-state device manufacturingNon-linear opticsElectrical resistance and conductanceReflectance properties

Owner:HYDIS TECH CO LTD

Backlight unit and display device using the same

ActiveUS20100265566A1Improve screening qualityStatic indicating devicesIlluminated signsLight guideDisplay device

An ultra-thin edge-type backlight unit allowing a local dimming driving and a scanning driving and using a low-cost light source, and a display device of excellent screen quality are provided. The backlight unit includes a light guide plate, a light source disposed in a side of the light guide plate and a reflective-type display panel disposed on an opposite side of a surface where a light radiated from the light source is extracted.

Owner:KOREA ELECTRONICS TECH INST

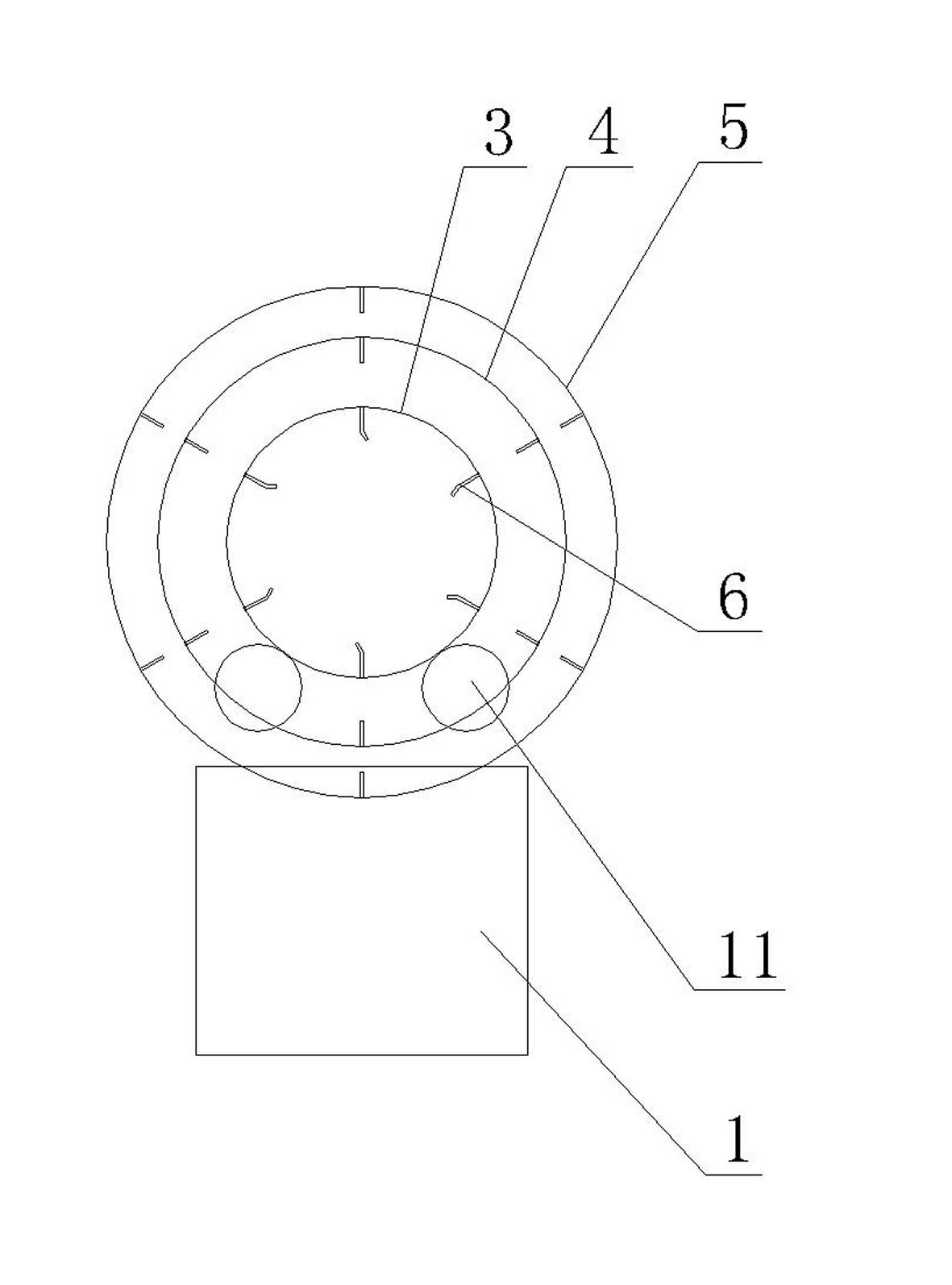

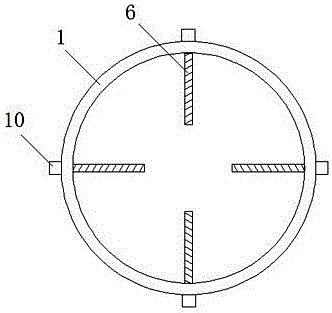

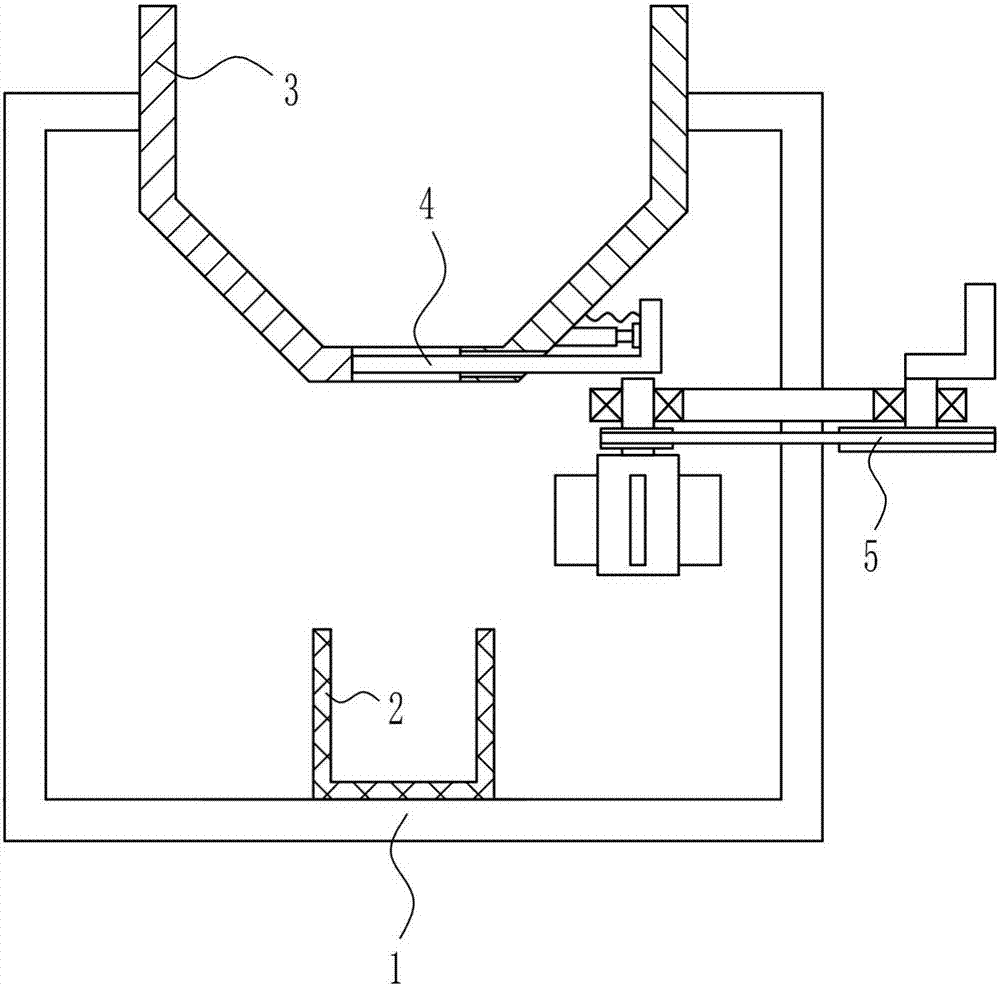

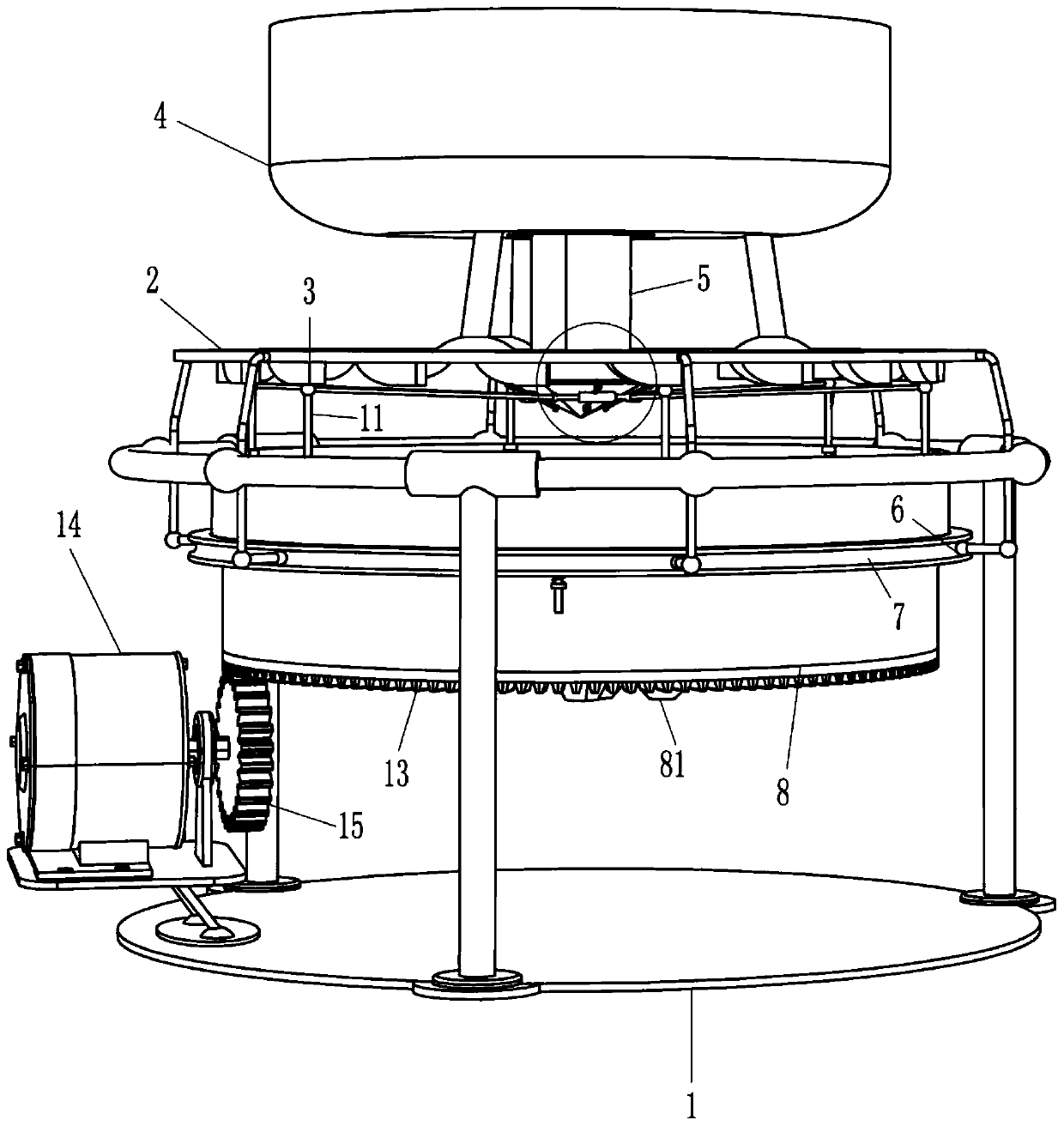

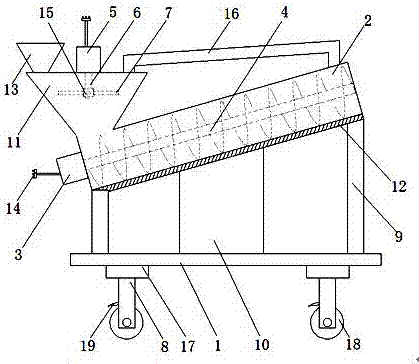

Circular building sand screening device

InactiveCN109127348AAchieve decentralizationImprove liquiditySievingScreeningScattering functionScreening effect

The invention discloses a circular building sand screening device, and relates to the technical field of building machines. The circular building sand screening device comprises a supporting bottom plate, and a transverse packing auger driven by a motor I is horizontally and fixedly mounted on the supporting frame. A dispersing barrel communicating with the transverse packing auger through a discharging pipe is arranged below the transverse packing auger. A conveying belt mounted on a supporting table is arranged below a horizontal screen, and a longitudinal packing auger driven by a motor IIis fixedly mounted on the supporting table. A lifting inlet communicating with the dispersing barrel is formed in the lower right side wall of the longitudinal packing auger, and a circulating pipe ismounted between the upper right side wall of the longitudinal packing auger and the transverse packing auger in a communicating manner. According to the circular building sand screening device, sandcan be screened through the horizontal screen and an inclined screen and passes. By means of conveying of the transverse packing auger and the longitudinal packing auger, on one hand, the scattering function on the sand is improved, the mobility of the sand during screening is improved, and the screening effect is improved; and on the other hand, repeated and circular screening of the sand can beachieved, screening can be more sufficient and thorough, and the screening quality of the sand is improved.

Owner:霸州市辉月网络技术有限公司

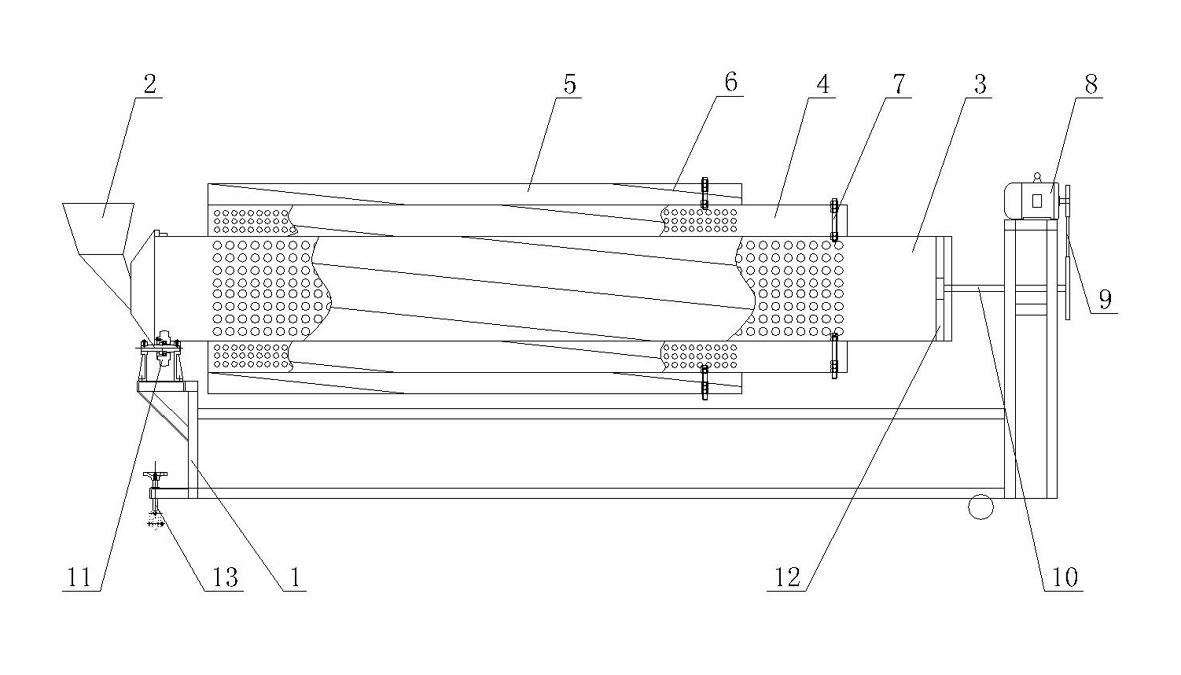

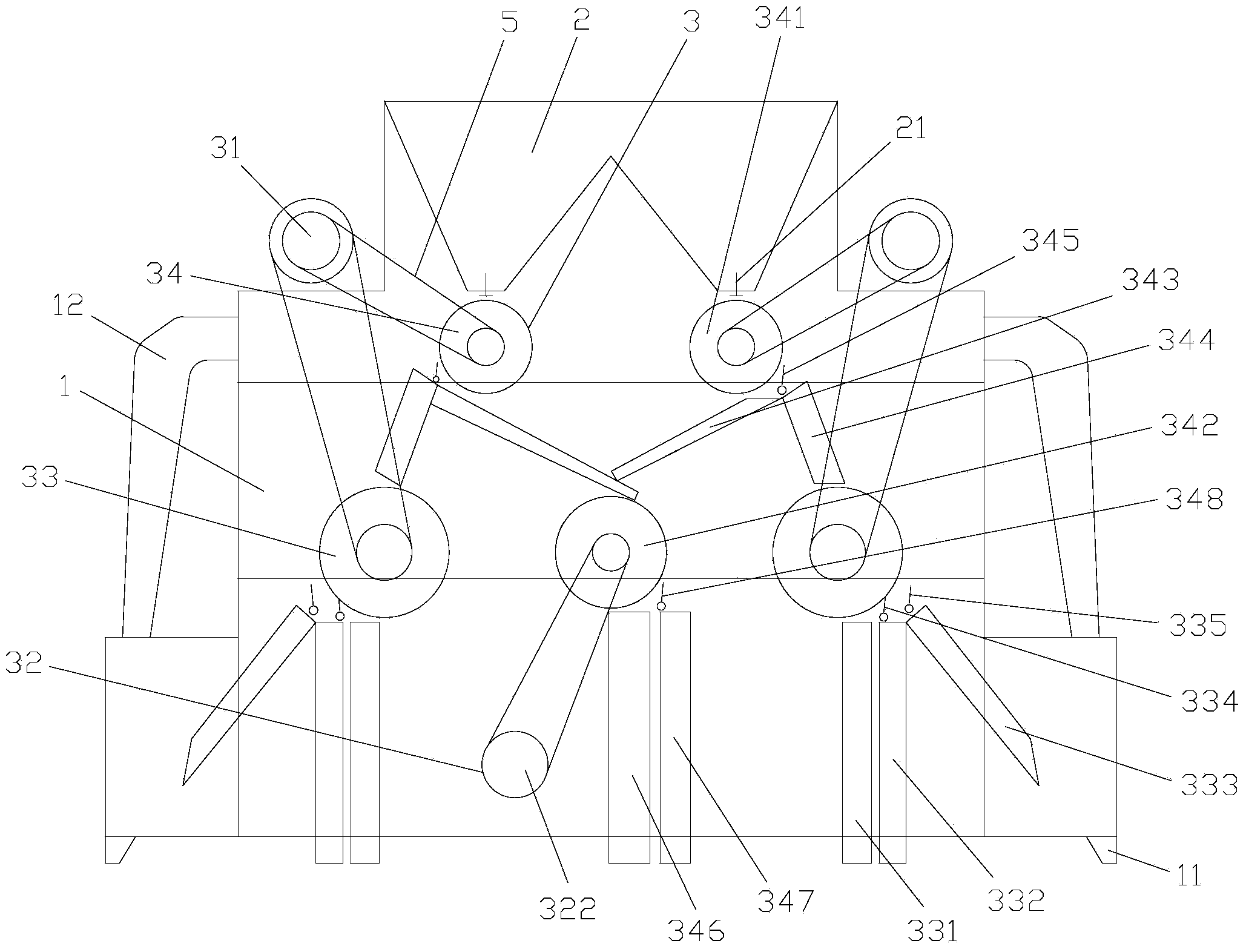

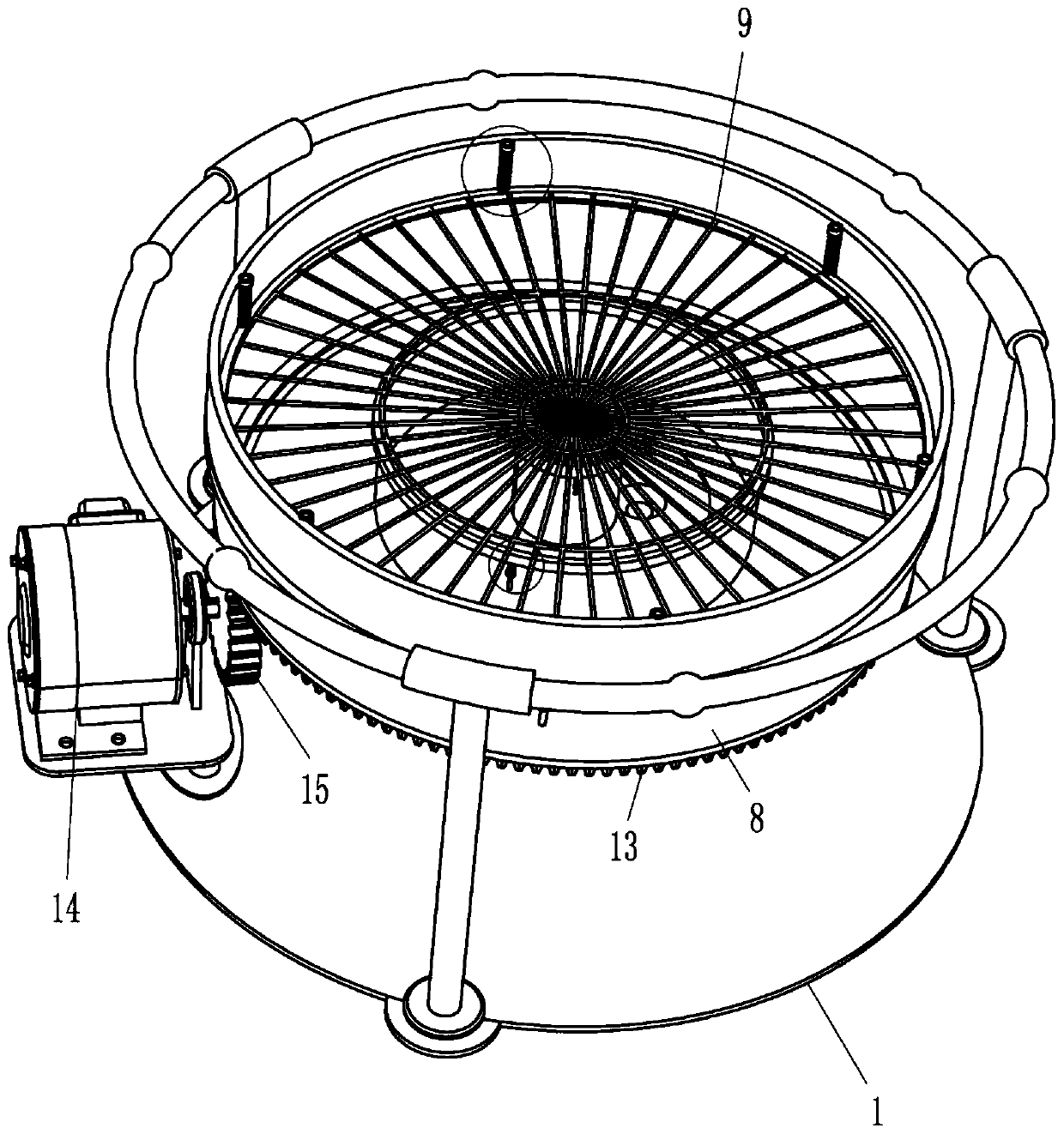

Fresh tea leaf grading machine

InactiveCN102580914AReduce labor intensityIncrease productivitySievingScreeningAgricultural engineeringTea leaf

The invention discloses a fresh tea leaf grading machine, which comprises a stander, a material feeding hopper, a power device and a screening device, wherein the screening device comprises a plurality of coaxial rotary screening barrels; a plurality of spiral material guide ribs are arranged on the inner wall of the barrel body of each screening barrel; the screening barrels are fixedly connected with one another; the apertures of screening holes of the screening barrels are reduced gradually from inside to outside; an outer barrel is coaxially arranged on the outermost screening barrel; the material feeding hopper is connected with the front end of the innermost screening barrel through a connection channel; openings are formed at the tail ends of the screening barrels; and the power device can drive the screening barrels to rotate. The fresh tea leaf grading machine has functions of turning and throwing and pushing fresh leaves to flow towards outlets at the tail ends through the material guide ribs, so that fresh tea leaves with different sizes can be graded effectively according to the sizes; the screening quality is high; the fresh tea leaf raw materials for producing qualified teas can be automatically obtained; the labor intensity is reduced greatly; and the production efficiency is improved.

Owner:ZHEJIANG ZHUFENG MACHINERY

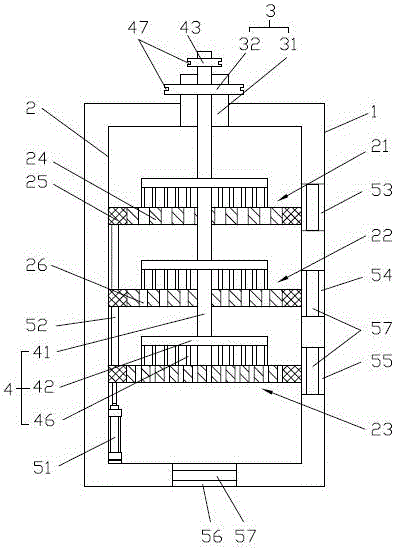

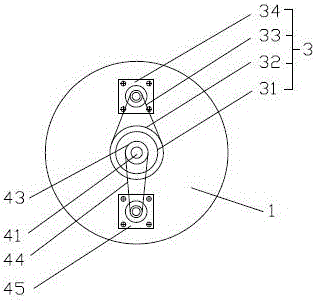

Iron-titanium ore magnetic separator

InactiveCN103447149ASimple structural designReasonable structureMagnetic separationIron powderMagnetic separator

The invention relates to an iron-titanium ore magnetic separator which comprises a rack, a magnetic separation mechanism and a feeding hopper, wherein the magnetic separation mechanism comprises a titanium concentration device, an iron-titanium separation device, a titanium selection motor and an iron-titanium separation motor; the titanium concentration device is driven by the titanium selection motor, a titanium concentrate discharging hopper, a titanium ore recovery hopper and a tailings discharging hopper are arranged at the lower side of the titanium concentration device; a titanium concentrate precision regulator is arranged at one sides of feeding ports of the titanium concentrate discharging hopper and the titanium ore recovery hopper; a tailings precision regulator is arranged at one side of a feeding port of the tailings discharging hopper; the iron-titanium separation device is driven by the iron-titanium separation motor and comprises a first iron-titanium separation device and a second iron-titanium separation device; iron-titanium separation precision regulators are arranged at one sides of an iron-titanium mixture discharging hopper and an iron-titanium powder discharging hopper which are arranged at the lower side of the first iron-titanium separation device and at one sides of a titanium-in-iron discharging hopper and an iron powder discharging hopper which are arranged at the lower side of the second iron-titanium separation device. The iron-titanium ore magnetic separator is simple and reasonable in structural design, high in magnetic separation efficiency, good in effect and capable of effectively screening and separating minerals, and is environment-friendly.

Owner:PANZHIHUA CHANGSEN IND & TRADE CO LTD

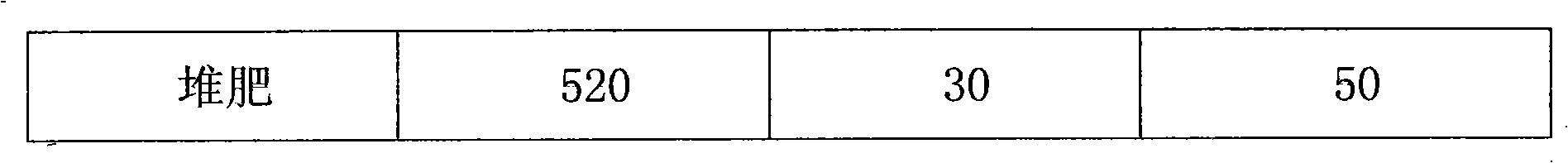

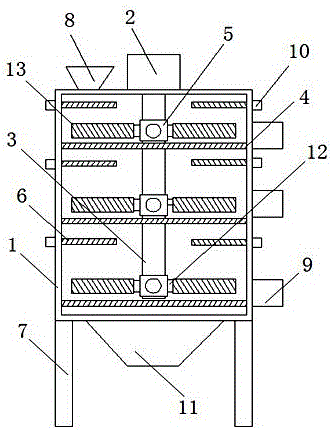

Multilayer screening machine

InactiveCN106733577ASpeed up the flowAvoid accumulationSievingScreeningAgricultural engineeringSecond screen

The invention mainly discloses a multilayer screening machine which comprises a first box, a second box, a first screen plate, a second screen plate and a third screen plate. The second box is positioned in the first box and connected with a first rotating device, the first screen plate, the second screen plate and the third screen plate are sequentially arranged in the second box from top to bottom, a stirring device is arranged in the second box and comprises a stirring rod, a stirring disk and a second rotating device, the stirring rod penetrates the second box and the first box and is connected with the second rotating device, the stirring disk is connected with the stirring rod and respectively positioned above the first screen plate, the second screen plate and the third screen plate, and combing teeth are arranged on the stirring disk. According to the multilayer screening machine, automatic multilayer screening is achieved by the aid of a plurality of screen plates, the screening machine is wide in screening range, the stirring device and the second box mutually and reversely rotate, screening of materials is accelerated, screening quality is improved, blocking of the screening machine is prevented, maintenance frequency is reduced, and the service life of the screening machine is prolonged.

Owner:张华信

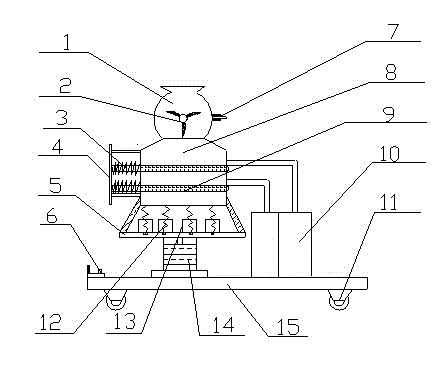

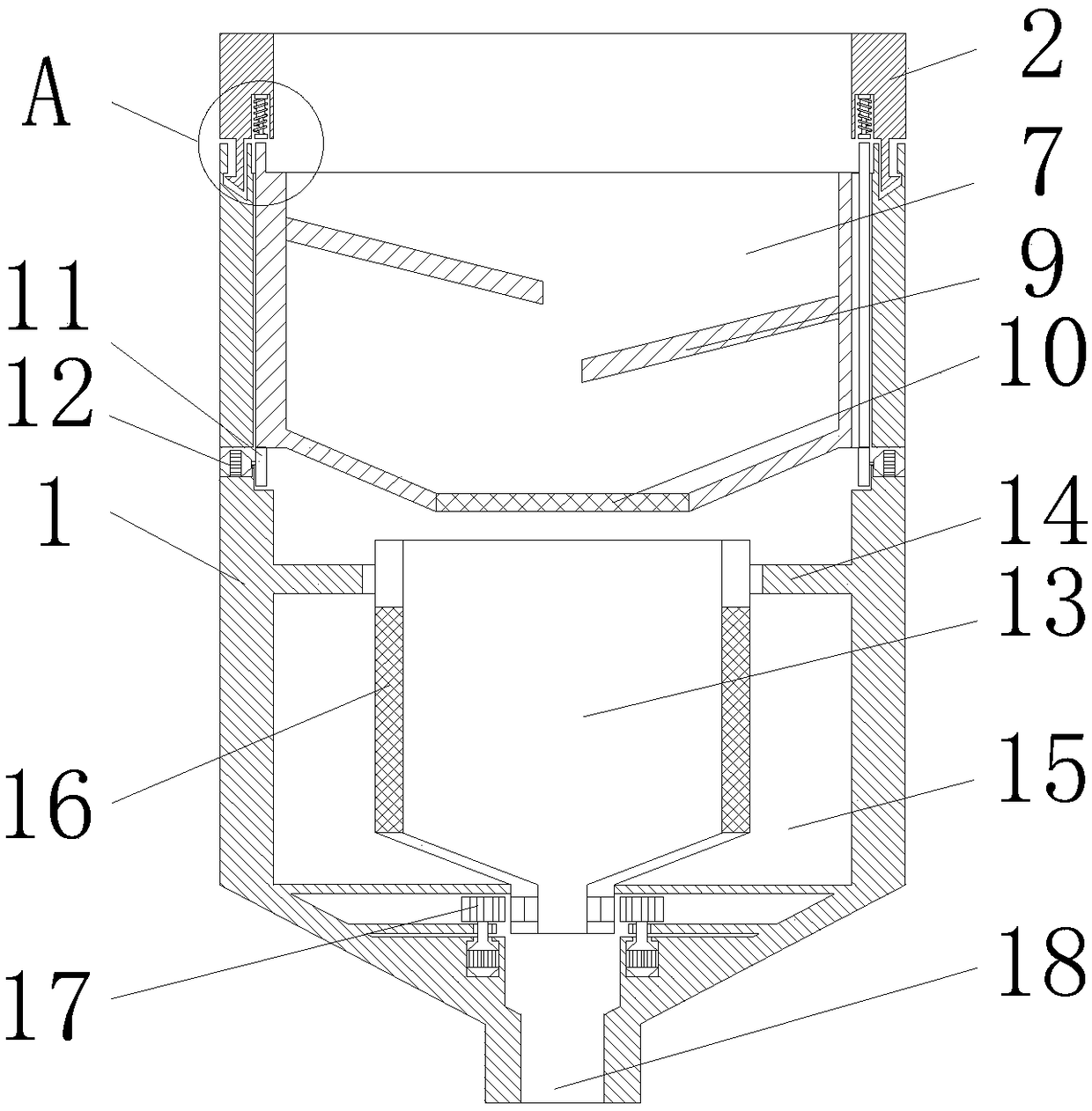

Magnetic separation device suitable for rice processing

InactiveCN106140465AImprove screening qualityImprove impurity removal rateSievingScreeningBiochemical engineeringImpurity

The invention provides a magnetic separation device suitable for rice processing. The magnetic separation device suitable for rice processing comprises a screening chamber, a motor, a rotating rod, screening plates, a mounting block and a magnetic rod, and is characterized in that the screening chamber is formed in a bracket; a feed port, a discharge pipe, a limiting block and an impurity outlet are arranged on the screening chamber; the motor is arranged on the screening chamber; the rotating rod is arranged in the screening chamber; one end of the rotating rod is connected with the motor; the screening plates are arranged in the screening chamber; the mounting block is arranged on the rotating rod; and the magnetic rod is arranged in the screening chamber, and is connected with the limiting block. Multiple screening plates are arranged in the screening chamber for classifying paddies with different sizes to improve the paddy screening quality; and a magnetic sleeve is arranged on the stirring rod, and the magnetic rod is arranged in the screening chamber, so that iron chips in the paddies can be removed through the magnetic sleeve and the magnetic rod, the paddy impurity removing rate is increased, the subsequent paddy processing is convenient, and the rice processing quality is improved.

Owner:芜湖市三山区绿色食品产业协会

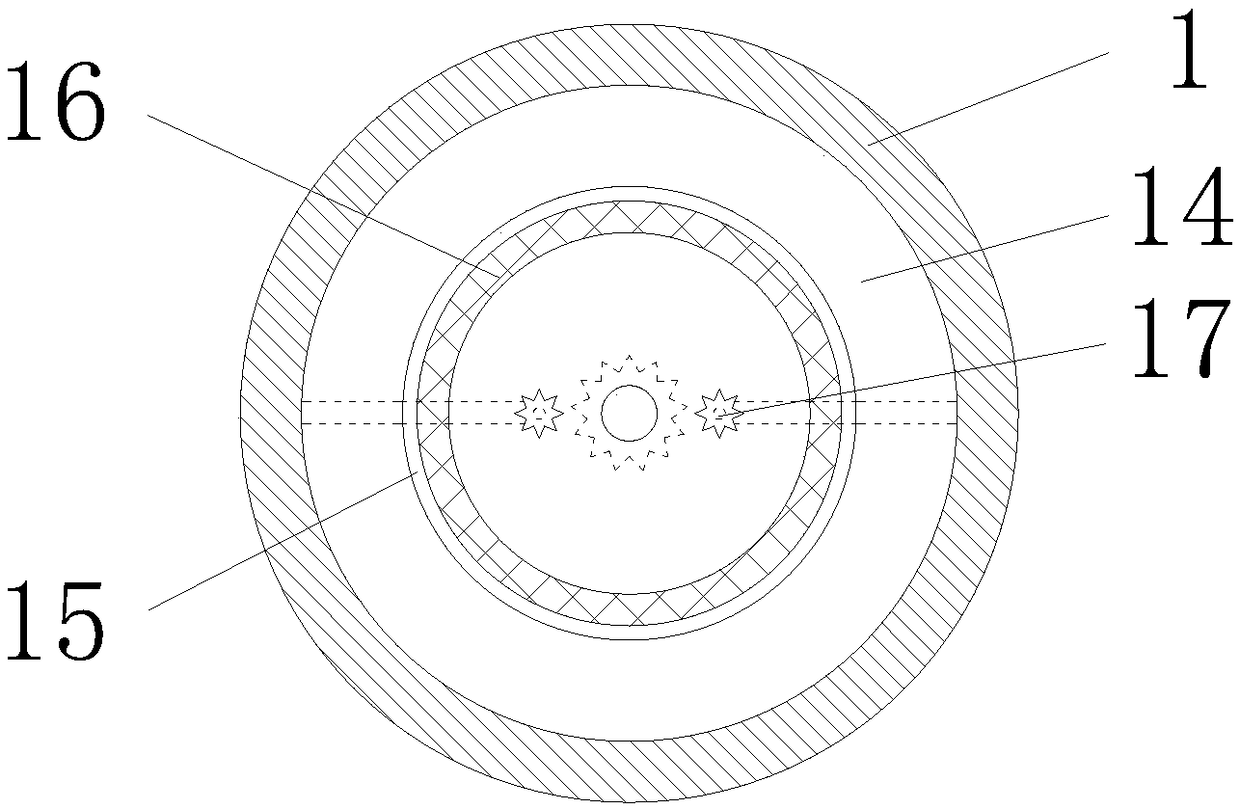

Rotary gravel vibrating screen for construction

The invention discloses a rotary gravel vibrating screen for construction. The rotary gravel vibrating screen for construction comprises a base and a screening chamber arranged on the base and further comprises a stirring chamber. A stirring impeller is arranged at the center inside the stirring chamber, the lower end of the stirring chamber is communicated with the screening chamber, two filter screens are parallelly arranged in the screening chamber, mesh holes of the filter screens are downsized from top to bottom, extending ends on one side of the filter screens are connected with compression springs, one side of the outer wall of the screening chamber is connected to a collection box arranged on the base through a collection pipe, a rotary vibrating mechanism is arranged below the screening chamber, and the base is provided with an electric control switch. The rotary gravel vibrating screen has the advantages of high screening quality, high transmission stability, reasonable structural design, convenience in use, high production efficiency, long service life and the like.

Owner:WUXI TIANYI PRINTING

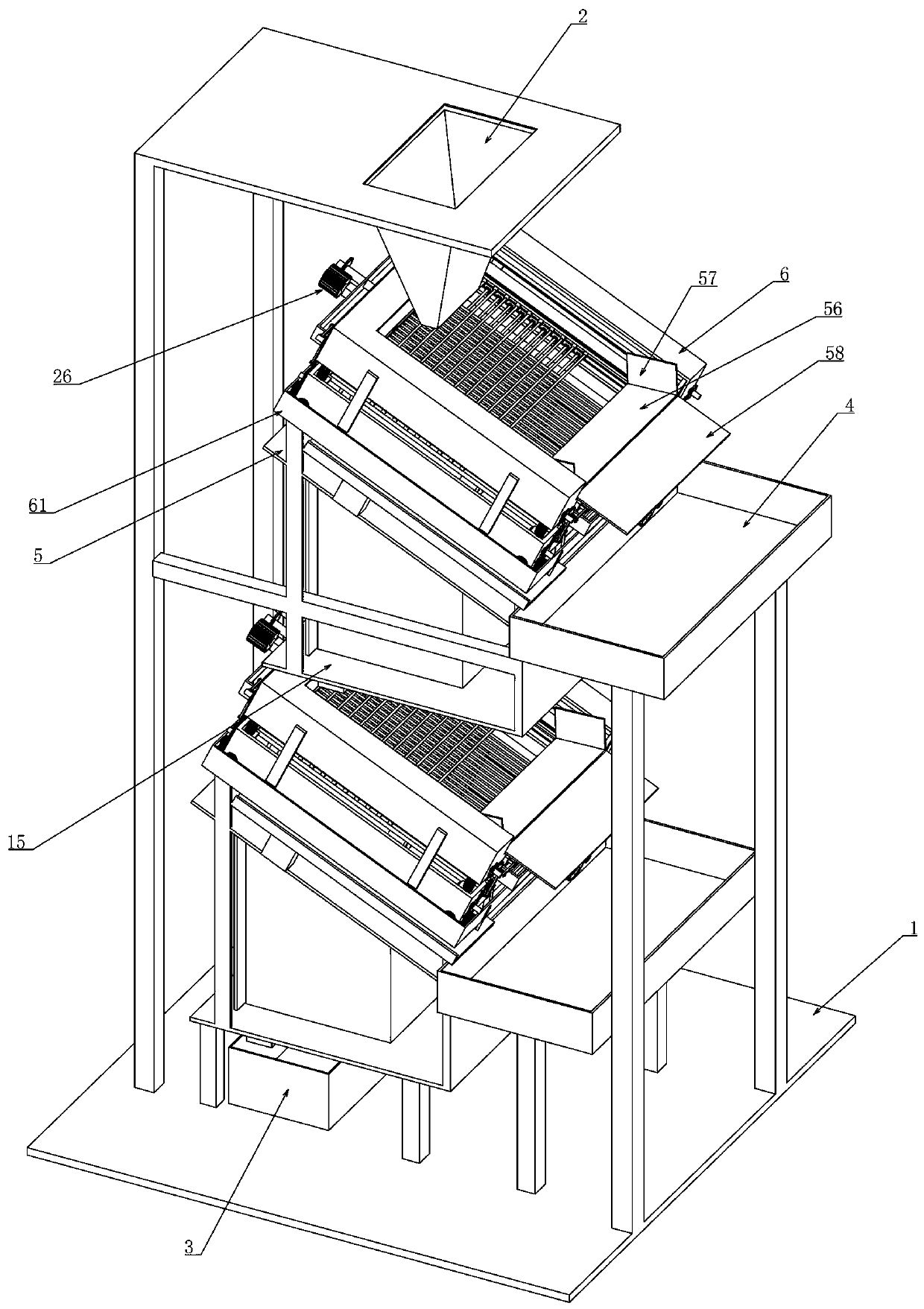

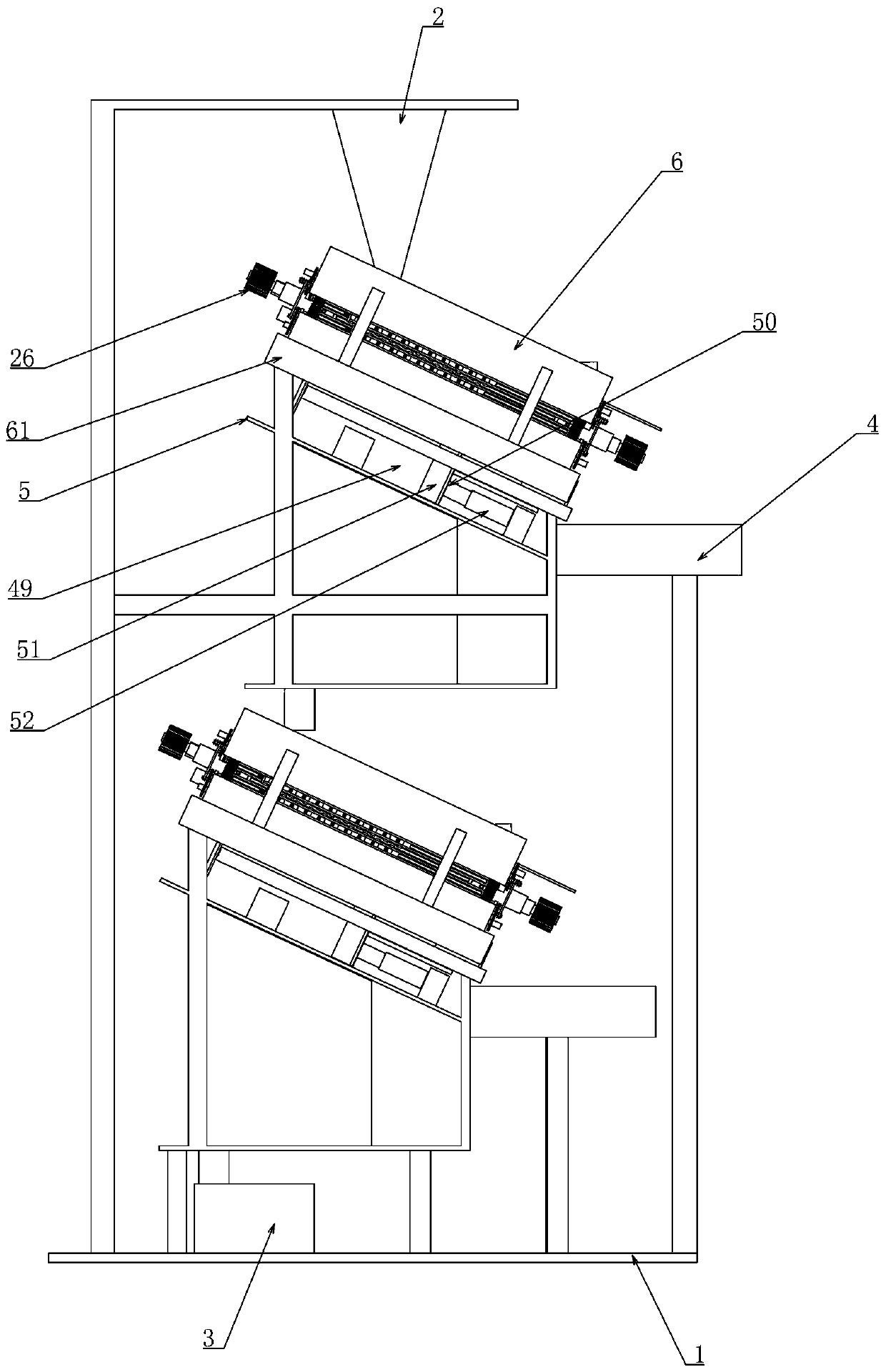

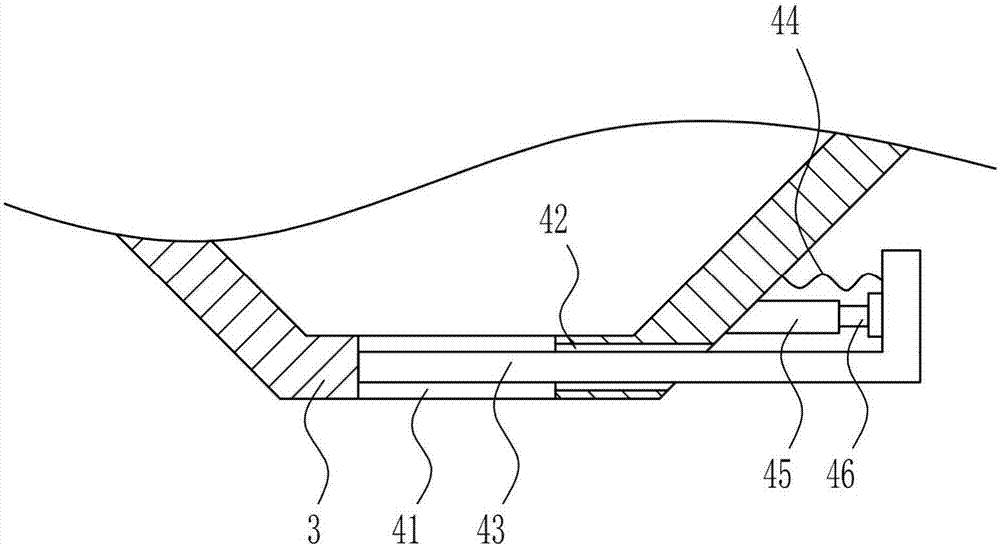

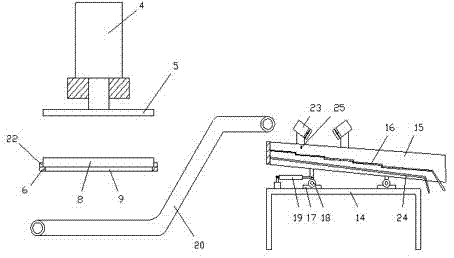

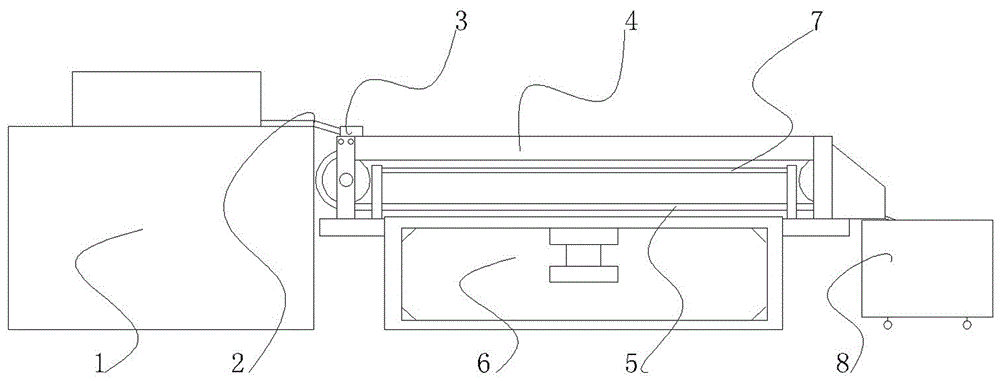

Automatic-feeding ore screening device for ore machine

InactiveCN107185819AWith automatic feeding functionNovel structureSievingConveyorsEngineeringUltimate tensile strength

The invention discloses an automatic-feeding ore screening device for an ore machine. The automatic-feeding ore screening device for the ore machine comprises a feeding device body and a screening device body. The screening device body is inclined. A first screening plate and a second screening plate are arranged in the screening device body. The first screening plate is located on the top of the second screening plate. The first screening plate and the second screening plate are provided with first screening holes and second screening holes correspondingly. Conveying rollers are connected through a conveying belt. The bottoms of the conveying rollers are provided with an installation frame. The conveying belt is further provided with feeding plates. A feeding baffle is hinged to the top of the left side face of the screening device body. The top end of the conveyer belt extends into the feeding baffle. The automatic-feeding ore screening device for the ore machine is novel in structure and convenient to operate, achieves automatic feeding, greatly lowers the labor intensity and improves the screening quality.

Owner:TAICANG QINFENG ADVERTISEMENT & MEDIA CO LTD

Screening equipment for rapeseed processing

InactiveCN107138412AImprove screening qualityAvoid distortionSievingGas current separationEngineeringRapeseed

The invention relates to a screening device, in particular to a screening device for rapeseed processing. The technical problem to be solved by the present invention is to provide a screening device for rapeseed processing which can control the screening speed and prevent the rapeseed from splashing during screening. In order to solve the above technical problems, the present invention provides such a screening equipment for rapeseed processing, which includes a mounting frame, a screen frame, a storage hopper, a discharge device and a blowing device, etc.; There is a storage hopper at the center of the top of the frame, a discharge device at the bottom of the storage hopper, and a blowing device at the middle of the right side of the installation frame. In the present invention, by changing the position of the L-shaped baffle, the falling speed of the rapeseed is controlled, and at the same time, the first baffle effectively prevents the fine rapeseed from splashing around.

Owner:马爱华

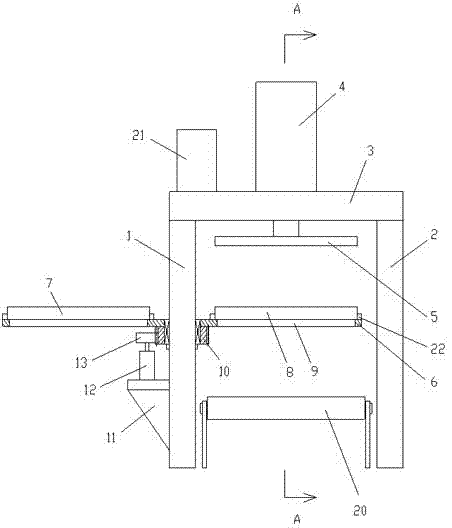

Dried tofu splitting-cutting and screening device

InactiveCN105437273AIncrease productivityConducive to mutual separationSievingScreeningMechanical engineeringEngineering

The invention discloses a dried tofu splitting-cutting and screening device. The dried tofu splitting-cutting and screening device comprises a cutting-splitting device, a sorting device, a conveyor and a controller. The cutting-splitting device comprises a first rack, an electric cylinder, a pressing plate, a rotary workbench, a left mold cutter, a right mold cutter and a servo motor. The sorting device comprises a second rack and a sorting screen which comprises a frame and a step-shaped screen face. According to the dried tofu splitting-cutting and screening device, the left mold cutter and the right mold cutter are arranged on the rotary workbench and located in a material charging position and a splitting-cutting position so that material charging and splitting-cutting can be conducted simultaneously, and the production efficiency is higher. In addition, the screen face of the sorting screen is the step-shaped screen face, so that dried tofu fall vertically when moving along the step-shaped screen face and passing steps. When falling vertically, the mutually adhesive dried tofu is more liable to be scattered and separated so that the dried tofu adhesive problem in the sorting process can be solved very well, and the good screening and sorting quality can be achieved.

Owner:CHONGQING YUPAI AGRI PROD DEV

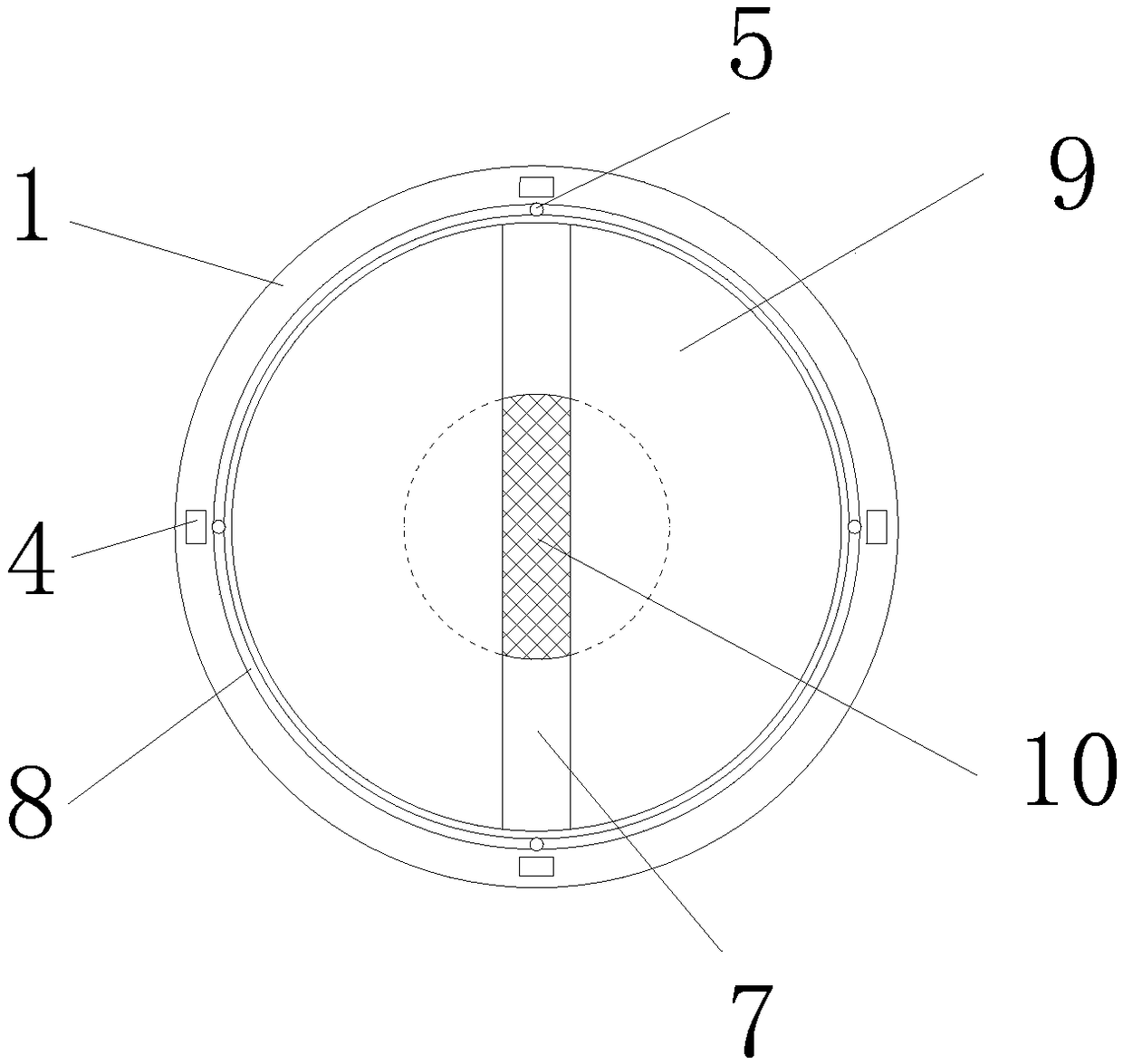

Rice eddy-vibrating sieve

InactiveCN104289443AImprove stabilityAvoid stockpilingSievingGas current separationEngineeringWaste management

The invention discloses a rice eddy-vibrating sieve. The rice eddy-vibrating sieve comprises filter sieve bodies, a sieving chamber, a base and a vibrating motor, wherein a feeding inlet is formed in the upper portion of the sieving chamber, the filter sieve bodies comprise the primary filter sieve body and the secondary filter sieve body which are arranged in a spaced mode from top to bottom, the primary filter sieve body and the secondary filter sieve body are arranged inside the sieving chamber, the mesh diameter of the primary filter sieve body is larger than that of the secondary filter sieve body, material receiving pipes matched with the primary filter sieve body and the secondary filter sieve body respectively are arranged on the same side of the sieving chamber, movable valves are arranged on the pipe openings of the material receiving pipes, and an eddy vibration mechanism is arranged below the sieving chamber. The rice eddy-vibrating sieve sieves rice in a multi-level mode, and has the advantages of being high in sieving quality, good in transmission stability, reasonable in structural design, convenient to use, high in production efficiency, long in service life and the like.

Owner:丁玉清

Lycium barbarum screening device

The invention provides a lycium barbarum screening device, and belongs to the field of agricultural product machining equipment. The lycium barbarum screening device comprises a shell, a first screening unit and a second screening unit; the first screening unit comprises a guide piece and an annular screen; the guide piece is provided with a first screen hole; the guide piece can bear materials falling from the first screen hole; the annular screen is mounted on the shell; the annular screen sleeves the guide piece; the guide piece is used for guiding the materials falling from a feed port onto the annular screen; the second screening unit comprises an exhaust mechanism; the exhaust mechanism is mounted on the shell, and is provided with multiple exhaust ports; the multiple exhaust ports are arranged in the peripheral direction of the shell at intervals; the wind direction of each exhaust port is towards the shell; each exhaust port and the inner wall of the shell are arranged at intervals; and an annular screening area for enabling the materials to fall is formed between the inner wall of the shell and the multiple exhaust ports. The lycium barbarum screening device is high in automation degree, saves both time and power in the screening work, and is high in screening quality.

Owner:宁夏全通枸杞供应链管理股份有限公司

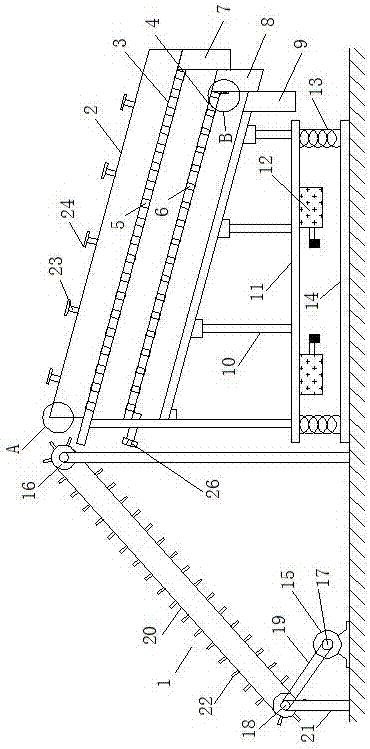

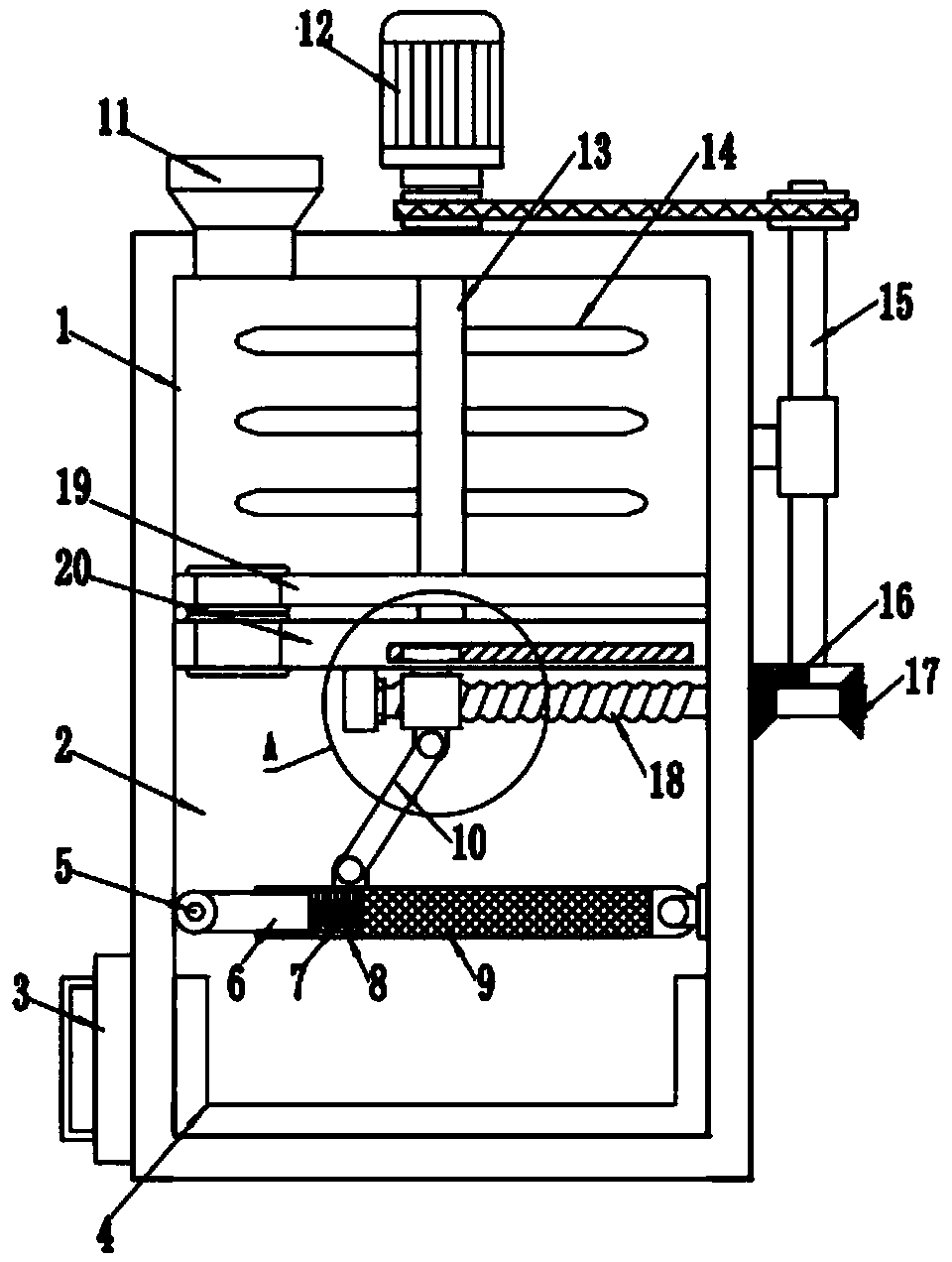

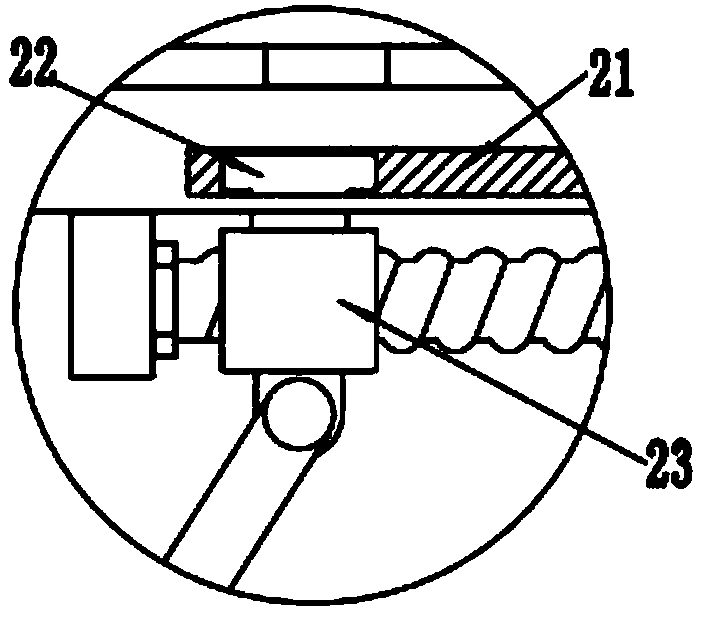

Sand screening device for municipal road construction

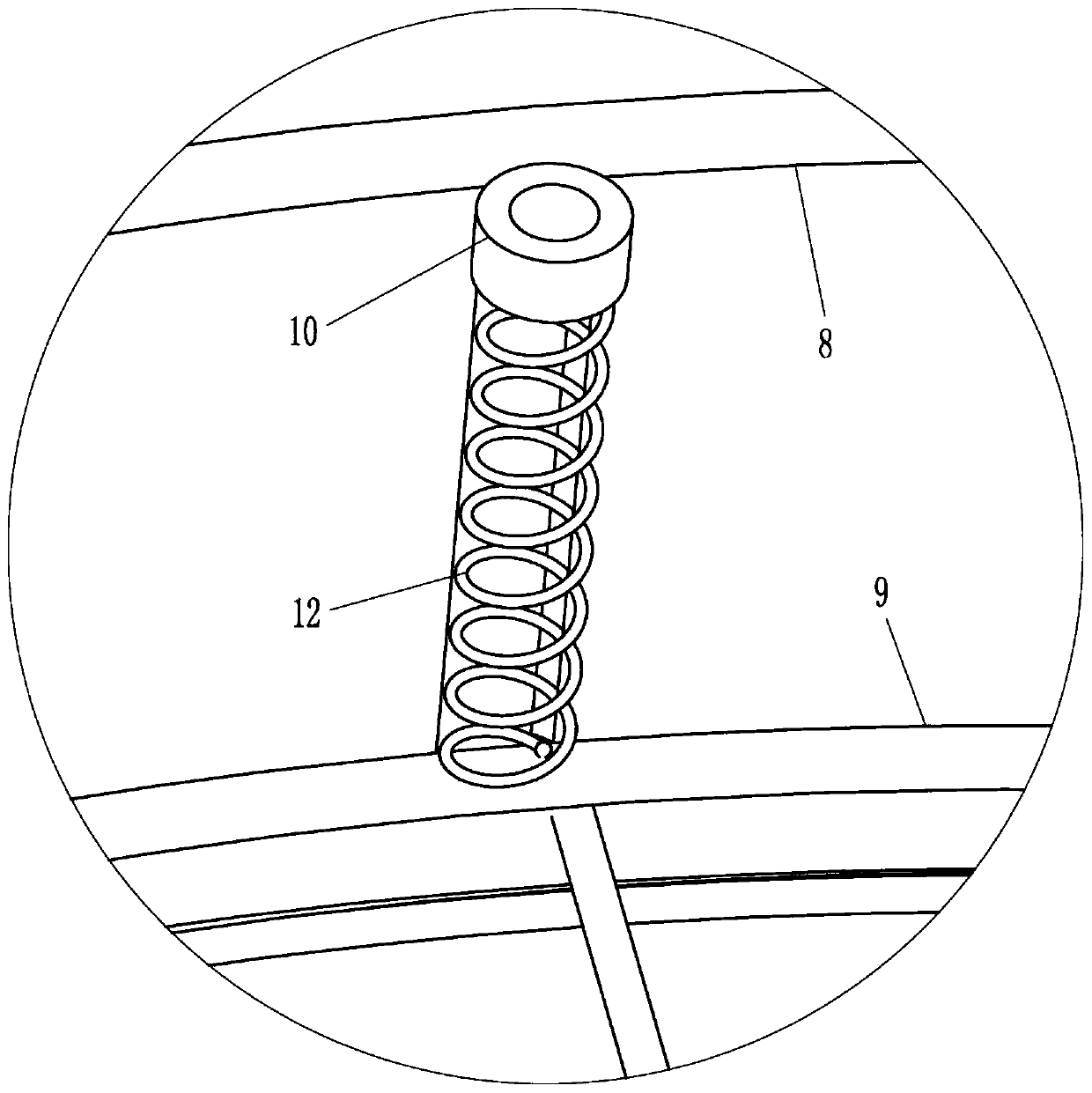

InactiveCN110152982AAvoid affecting the screening effectInnovative designSievingScreeningArchitectural engineeringScrew thread

The invention discloses a sand screening device for municipal road construction. The sand screening device comprises a stirring cavity, a screening cavity, a collecting groove and a motor, wherein thestirring cavity is separated from the screening cavity through a bottom plate, a feeding hopper is arranged at the upper end of the stirring cavity, a motor is arranged on the right side of the feeding hopper, a rotating shaft is fixedly arranged at the output end of the motor, and the rotating shaft penetrates through the upper end of the stirring cavity to extend into the stirring cavity and isconnected with the upper end of the bottom plate in a rotating mode; and a threaded rod is connected to the right side of the upper end of the screening cavity in a rotating mode, the threaded rod positioned on the inner side of the screening cavity is in threaded connection with a movable block, the lower end of the movable block is hinged to one end of a connecting rod, and the other end of theconnecting rod is hinged to a sieve plate. According to the sand screening device, the design is novel; the movable block reciprocates left and right under the action of the threaded rod, so that thesieve plate is driven to swing through the connecting rod 10, and the screening efficiency of the sieve plate is improved; and the movable plate is arranged to prevent sand from dropping from the gapat the left end of the sieve plate, so that the screening quality is improved.

Owner:ZIBO TRICKS EDUCATION TECH CO LTD

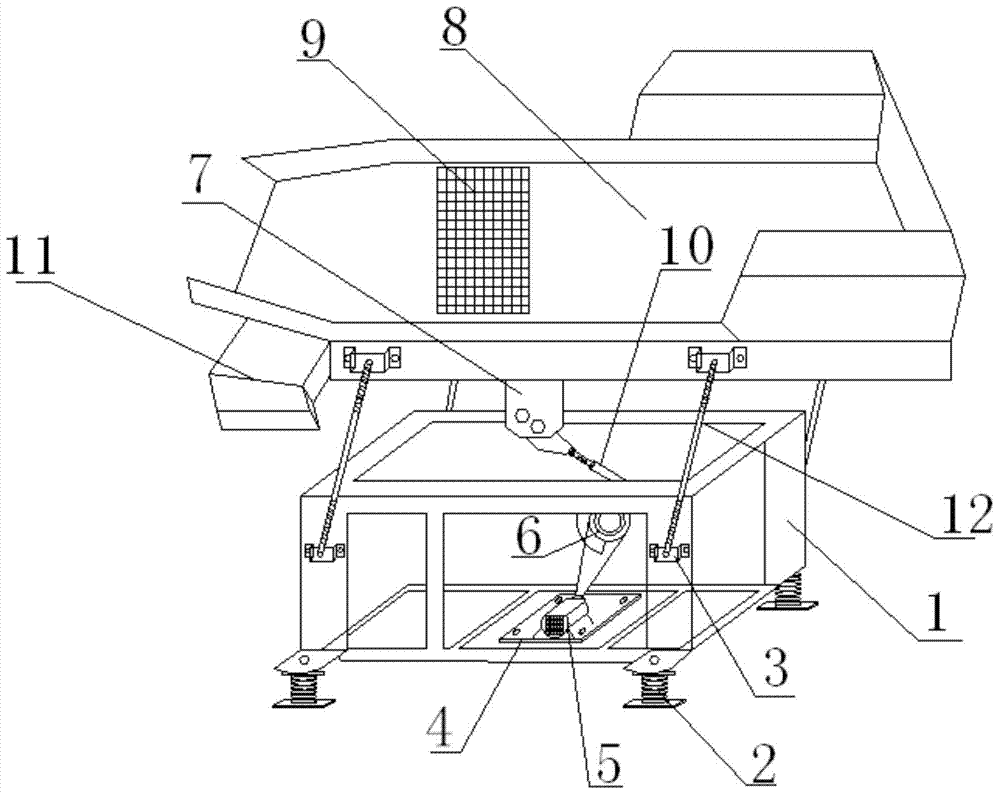

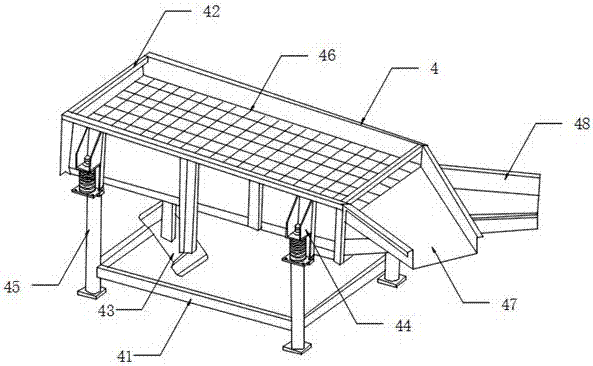

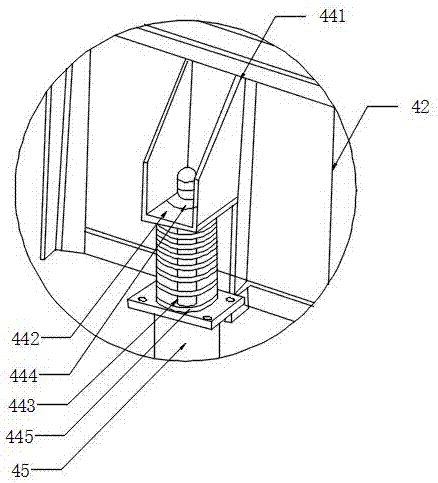

Vibration mesh screen

InactiveCN104259096ASmooth vibrationImprove screening qualitySievingScreeningEngineeringElectric motor

The invention discloses a vibration mesh screen which comprises a vibration screen frame, a shaking screen disk and a vibration mechanism, wherein spring legs are respectively arranged at four bottom legs of the vibration screen frame; connection rod fixing blocks are respectively fixed at the middle parts on the outer sides of the four frame legs of the vibration screen frame through bolts; the connection rod fixing blocks are connected with connection rods and the shaking screen disk so as to be fixed; the connection rods can swing leftwards and rightwards on the connection rod fixing blocks; the bottom of the shaking screen disk is connected with the vibration mechanism; the vibration mechanism is connected with an eccentric ball through a vibration rod so as to swing; the eccentric ball is driven to swing by a motor mounted on a fixed plate at the bottom of the vibration screen frame. The vibration mesh screen is simple in structure and high in screening efficiency, and the defect that a screening machine vibrates unstably is overcome.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

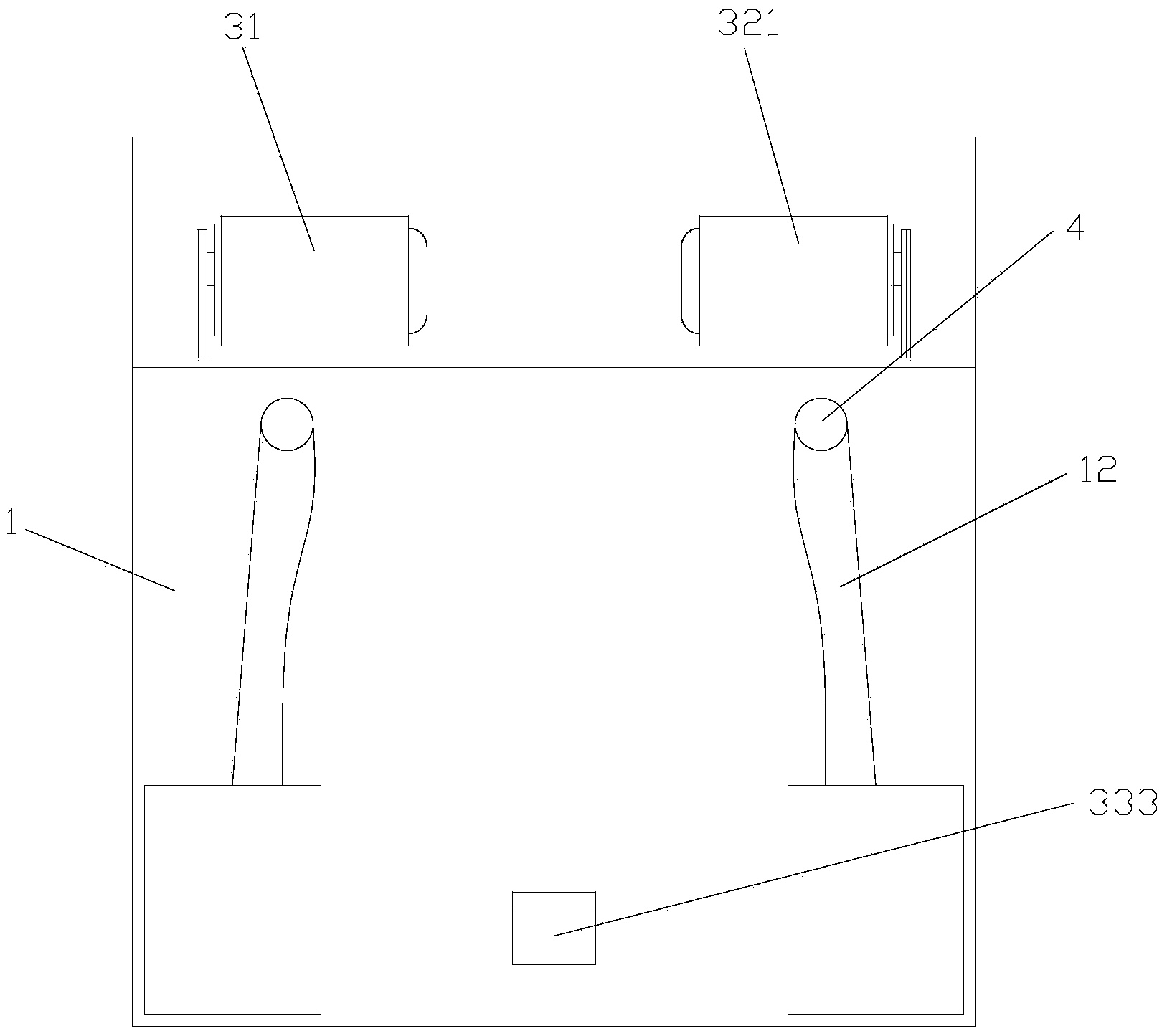

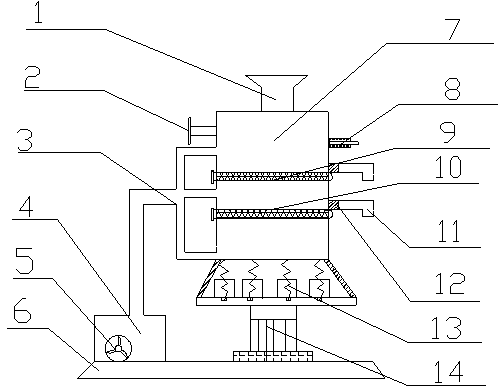

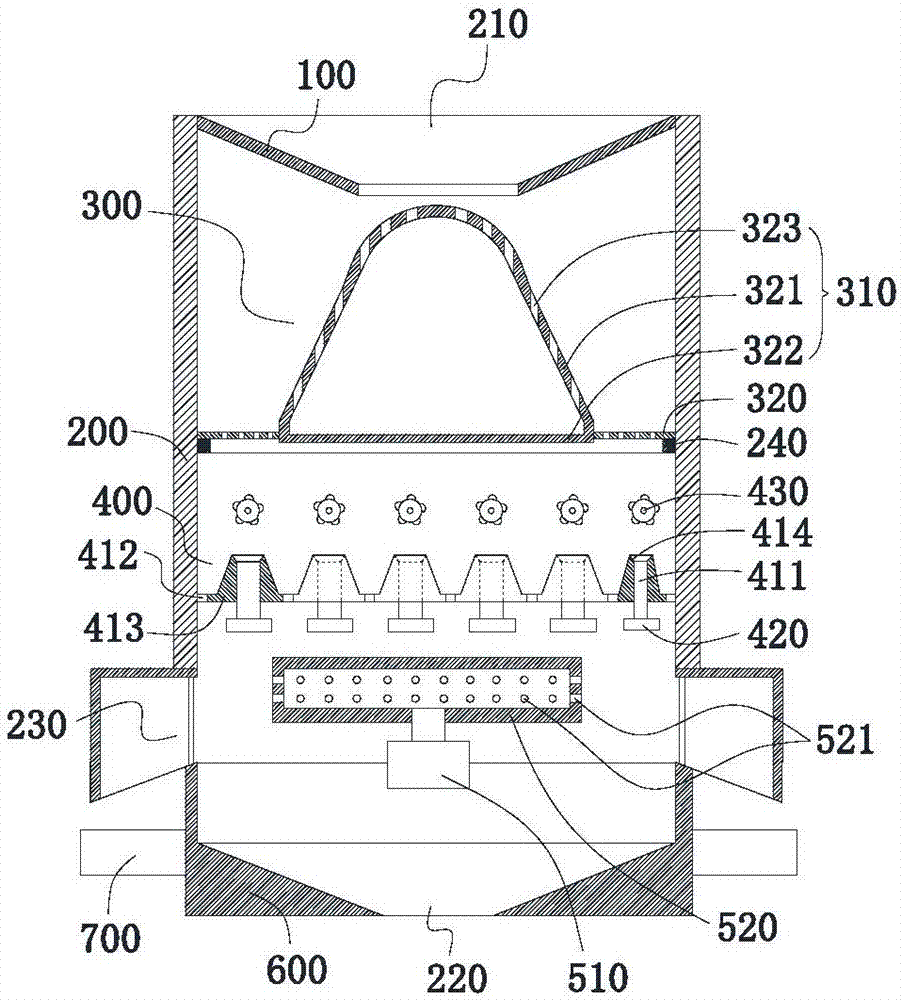

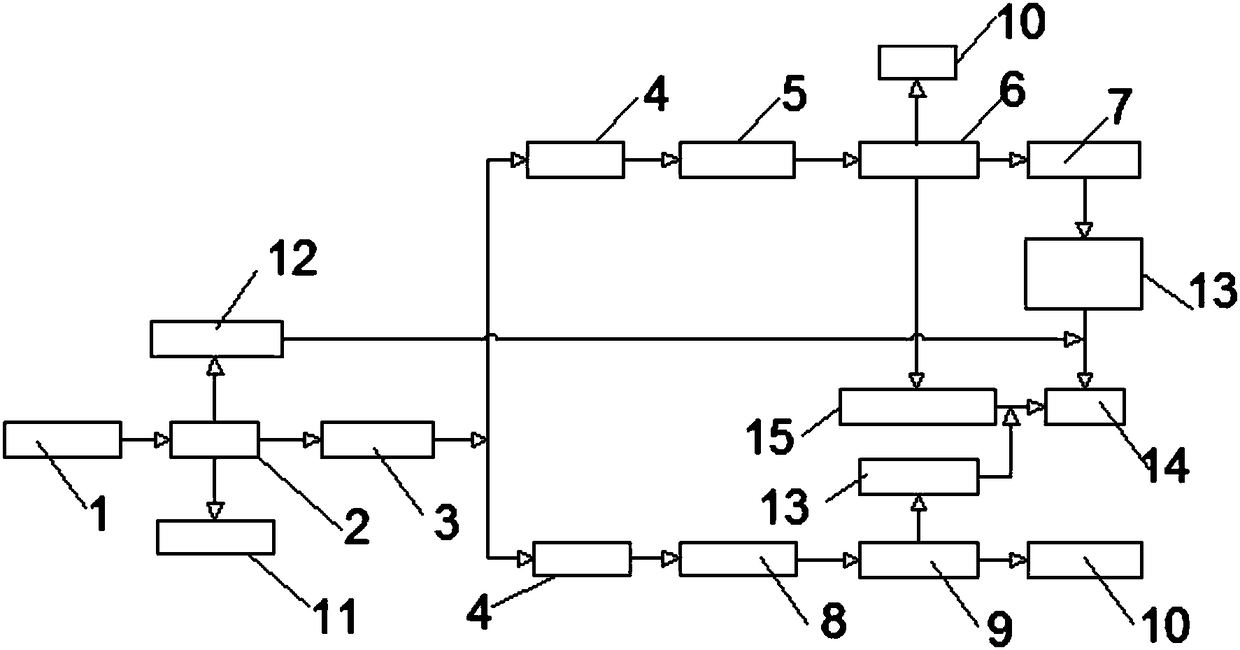

Sorting system of mineralized refuse and sorting process of mineralized refuse

PendingCN108246632AGood screening qualitySifting Quality Sifting ConvenienceGas current separationPlastic recyclingEngineeringConstruction aggregate

The invention provides a sorting system of mineralized refuse and a sorting process of the mineralized refuse, and relates to the field of mineralized refuse treatment. The sorting system includes anartificial sorting system, a screening system and a sorting system which are connected in turn; the artificial sorting system sorts out waste wood, plastic and rubber; the screening system screens outcoarse particulates with larger diameter and fine particulates with smaller diameter; the sorting system includes a coarse particulate sorting system and a fine particulate sorting system, the coarseparticulate sorting system is used for sieving out the plastic in a coarse particulate material, and the fine particulate sorting system sieves out fine aggregates in a fine particulate material. Thesorting system of the mineralized refuse can sort out the plastic and the fine aggregates through the coarse particulate sorting system and the fine particulate sorting system, and screen out the available materials such as the plastic, metal, humus soil and the like. The problem of low screening quality caused by complex composition and high humidity of the mineralized refuse is solved, and thesystem has the advantages of good screening quality, convenient screening and the like.

Owner:MEILIGUOTU BEIJING ECOLOGICAL ENVIRONMENT ENG TECH RES INST CO LTD

Raw material screening machine for orange flower cake production

ActiveCN110899106AImprove screening qualityUniform feedingSievingScreeningProcess engineeringMechanical engineering

The invention relates to a raw material screening machine, in particular to a raw material screening machine for orange flower cake production which can quickly screen orange flower cake raw materialsand improve the working efficiency. The raw material screening machine for orange flower cake production comprises a mounting frame, a mounting disc, convex blocks, a discharging hopper, a discharging pipe, L-shaped sliding rods, an annular sliding rail, a collecting cylinder and the like, wherein the mounting disc is arranged on the mounting frame, the at least two convex blocks are uniformly arranged on the peripheries of the bottom of the mounting disc at intervals, the discharging hopper is arranged on the mounting disc, and the discharging pipe is arranged between the discharging hopperand the mounting disc. According to the raw material screening machine for orange flower cake production, a screening component is matched with a transmission component, so that the orange flower cakeraw materials with different sizes are screened, and the screening quality for screening the orange flower cake raw materials by workers is improved; and through the transmission component, manpowercan be saved, and the orange flower cake raw materials can be screened and separated continuously.

Owner:江西桔娃食品有限公司

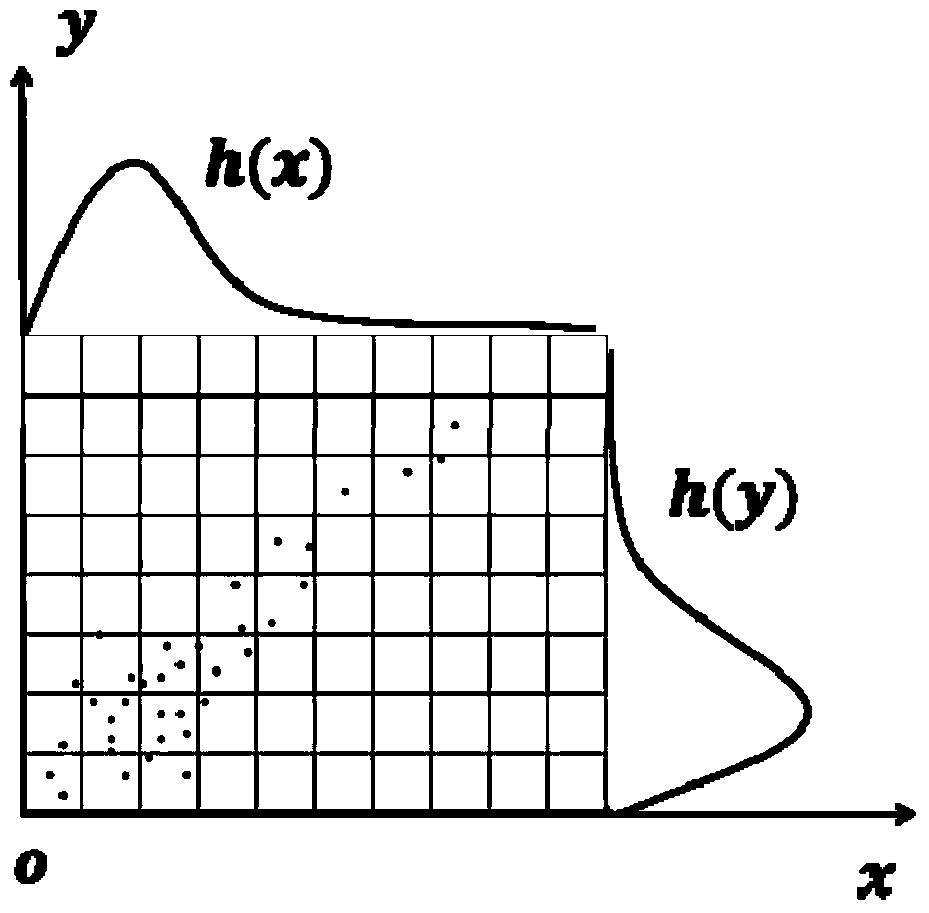

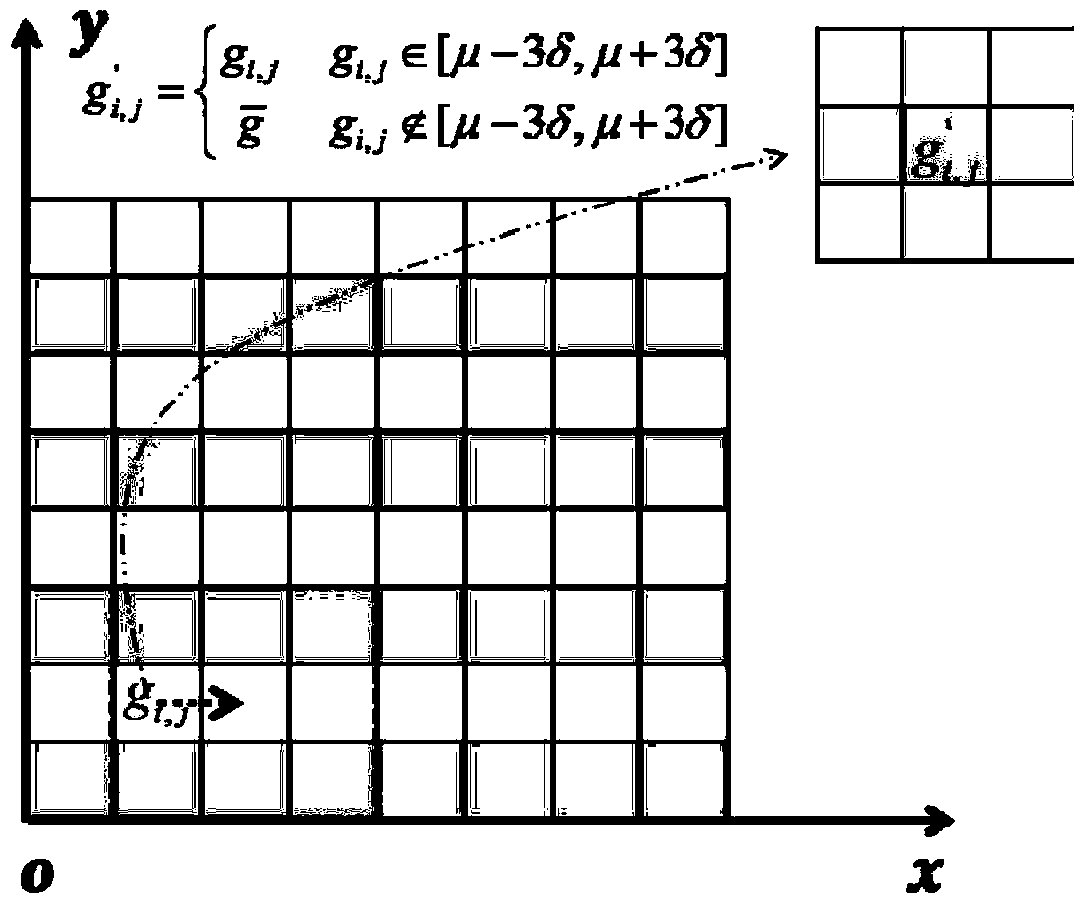

Two-dimensional scattered data density drawing method

ActiveCN104200502AHigh densityRealize visualization2D-image generationDensity distributionColor code

The invention discloses a two-dimensional scattered data density drawing method. The two-dimensional scattered data density drawing method comprises the following steps of: step (1) arranging two-dimensional density grids in an optimized manner; step (2), smoothly moving a density grid frequency number result on a plane; step (3) representing density attribute by color codes and isolines; step (4) counting and visualizing density distribution percentage. The two-dimensional scattered data density drawing method is simple, rapid and reliable, and particularly suitable for density drawing and visualization of the two-dimensional scattered data in a large data volume; the two-dimensional scattered data density drawing method realizes color code mapping of the two-dimensional scattered data density drawing through grid optimized arrangement and plane smooth movement of the density grid frequency number result, and realizes expression of the mathematical characteristic quantitative information of the two-dimensional scattered data density distribution.

Owner:HANGZHOU NORMAL UNIVERSITY

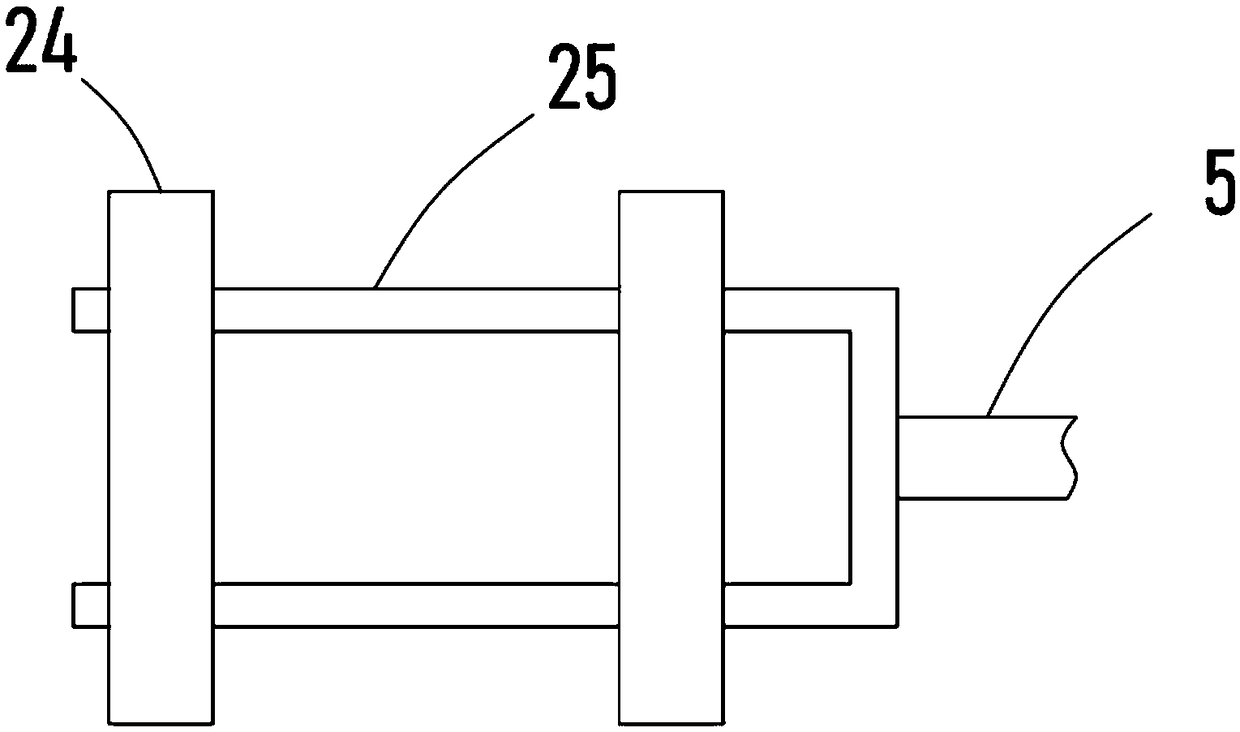

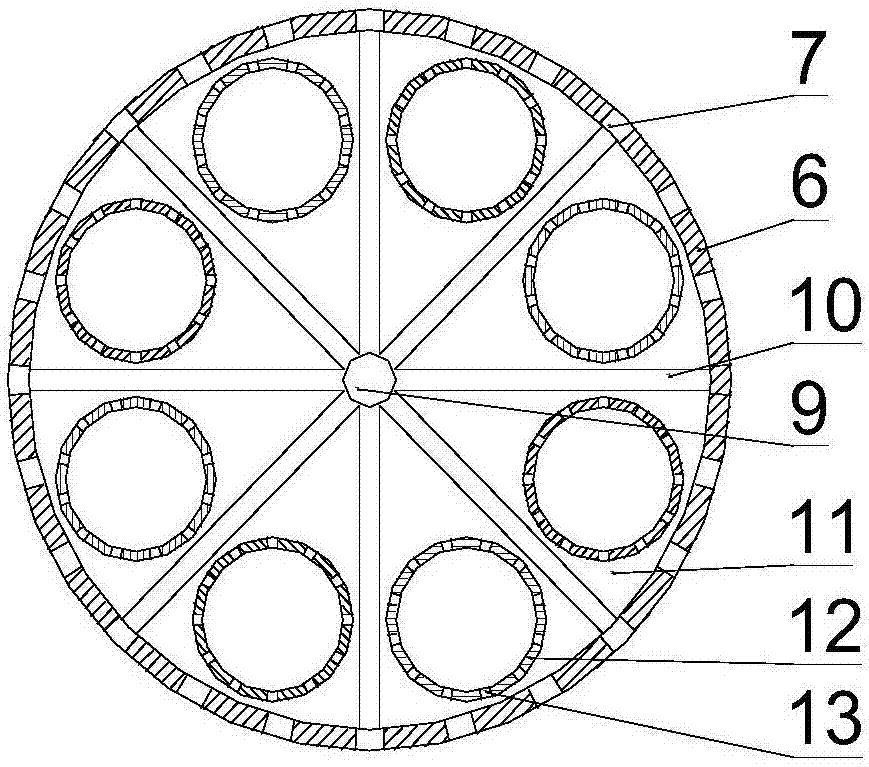

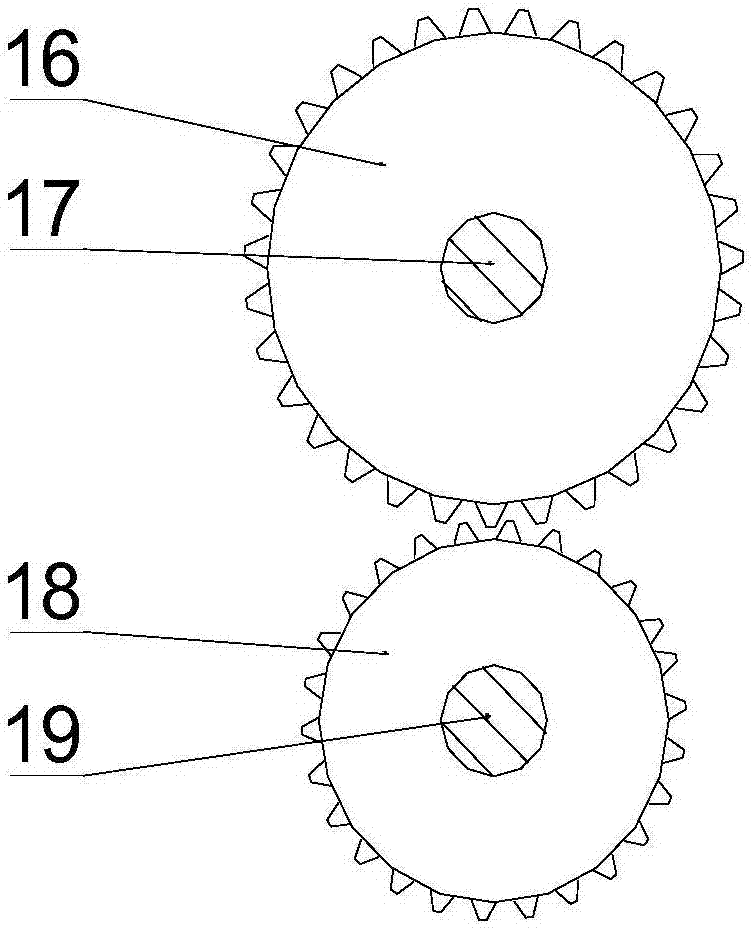

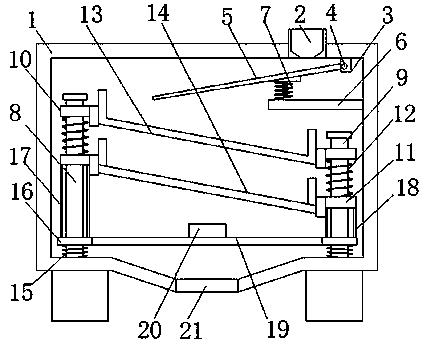

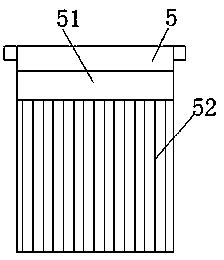

Intermittent rotating separation type drum screen for mining area of coal mine

InactiveCN107377356AImprove practicalityReduce hard-to-improvement situationsSievingScreeningGear wheelEngineering

The invention discloses an intermittent rotating separation type drum screen for a mining area of a coal mine. The intermittent rotating separation type drum screen comprises a bottom plate, mounting plates, a supporting column, a roller, inner cylinders, separation plates, a driving gear, a driven gear and an intermittent driving device. The upper portion of the bottom plate is fixedly connected with a pair of the mounting plates which are arranged in a manner of being parallel to each other. After the roller rotates intermittently every time, a discharge outlet of a feed pipe exactly corresponds to the left ends of the inner cylinders, and raw materials are uniformly scattered in the different inner cylinders. For a traditional overall large drum screen, there still exist the problems that the screening efficiency is affected by too little raw materials and the screening quality is affected by too many raw materials. According to the intermittent rotating separation type drum screen, the raw materials are located in the different inner cylinders, so that the probability of the situation that due to too many raw materials, the raw materials are mutually buried and consequently the screening quality is difficult to improve is reduced. Therefore, the intermittent rotating separation type drum screen improves the screening quality and has good practical effects as well as guaranteeing the screening efficiency.

Owner:陈旭东

Gravel screening device for building

InactiveCN109550680AExpedited screeningImprove screening efficiencySievingNon-rotating vibration suppressionEngineeringVibration motor

The invention discloses a gravel screening device for a building. The gravel screening device for the building comprises a shell, a feeding hole is formed in the right side of the upper surface of theshell, the right side of the top of an inner cavity of the shell is fixedly connected with a fixing frame, the fixing frame is movably connected with an inclined plate through a pin shaft, a supporting plate is fixedly connected above the inner wall of the right side of the shell, a buffer spring is fixedly connected to the upper surface of the supporting plate, the other end of the buffer springis fixedly connected to the lower surface of the inclined plate through a spring base, and the left side of base of the inner cavity of the shell is fixedly connected with a first guide column. According to the gravel screening device for the building, a first screening frame, a second screening frame, the first guiding column, a second guiding column, a first guide block, a second guide block, afirst spring, a second spring and a vibration motor are arranged and cooperate with one another, so that the problem that the screening efficiency is low in a construction site is solved; and the fixing frame, the pin shaft, the inclined plate, the supporting plate and the buffer spring are arranged and cooperate with one another, so that the problem that the screening speed is low when a large amount of gravels are directly screened is solved.

Owner:扬州市三祥机械制造有限公司

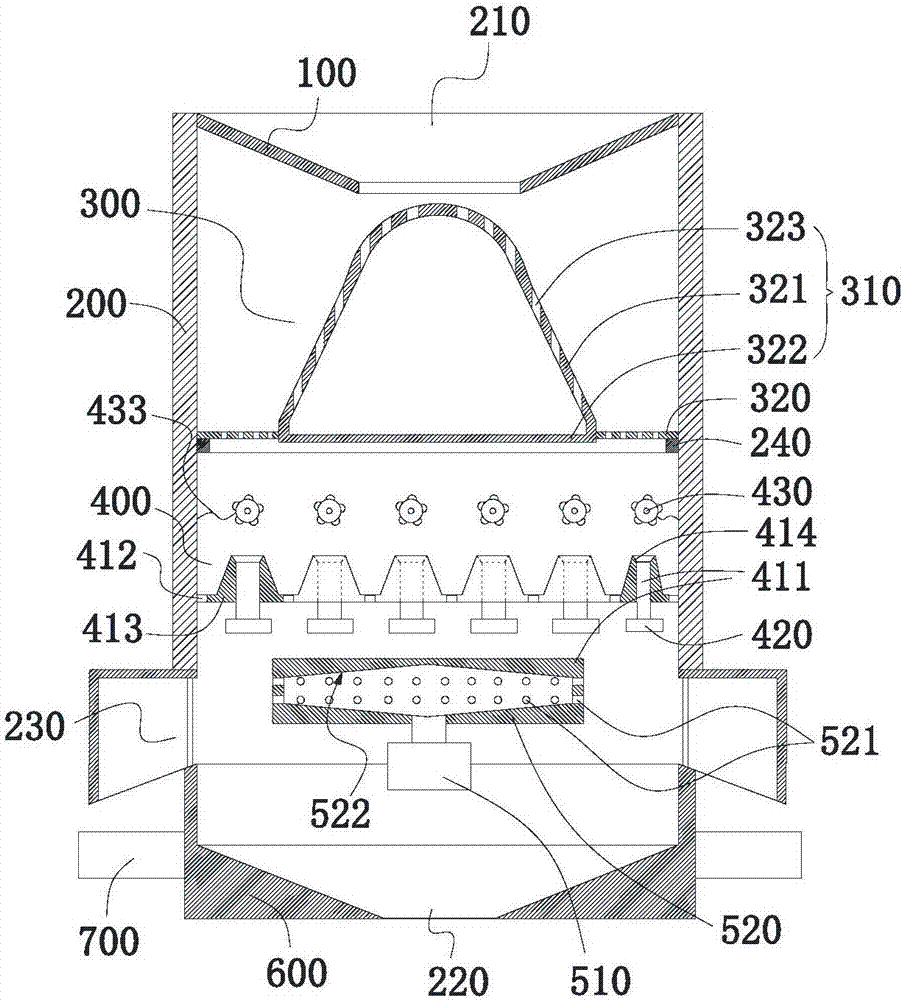

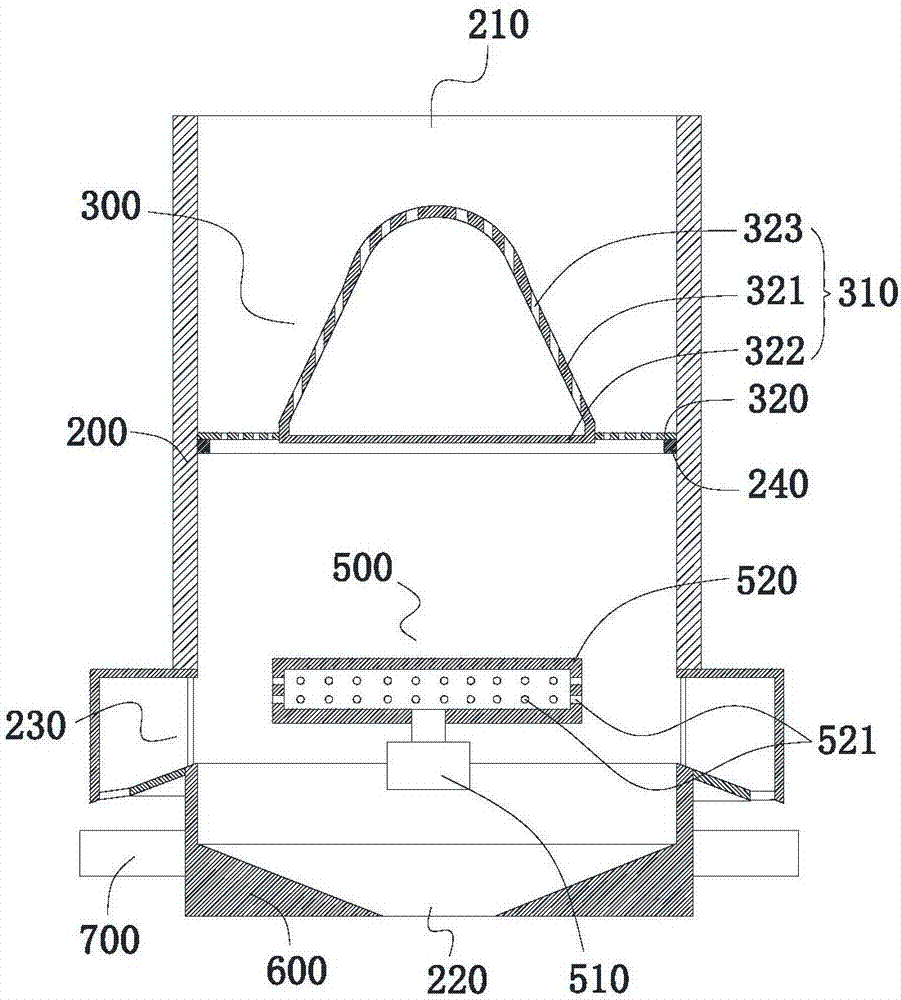

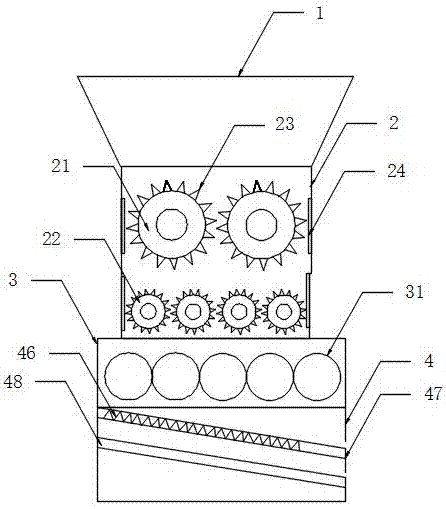

Smashing and grinding integrated raw material processing device for preparation of Relinqing tablets

InactiveCN107537649ARealize multi-stage crushingSmash thoroughlyGrain treatmentsEngineeringMaterials processing

The invention relates to the technical field of medicinal material processing, in particular to a smashing and grinding integrated raw material processing device for preparation of Relinqing tablets.The smashing and grinding integrated raw material processing device comprises a feeding inlet, a smashing box, a grinding box and a screening box; the smashing box is welded to the bottom of the feeding inlet; coarse smashing wheels and fine smashing wheels are arranged inside the smashing box; the fine smashing wheels are arranged below the coarse smashing wheels; material blocking piles are arranged on the two sides of the coarse smashing wheels and the fine smashing wheels; the grinding box is welded to the bottom of the smashing box; a plurality of grinding rollers are welded to the interior of the grinding box; and the screening box is welded to the bottom of the grinding box. The smashing and grinding integrated raw material processing device achieves multi-stage smashing, smashing is more thorough, a coarse material discharging groove outputs unqualified ground medicinal materials, unqualified medicinal materials are put into the feeding inlet again to be machined continuously till all raw materials are qualified and achieve the raw material standard of medicinal materials, a connection support makes the screening box work more stably and reliably, and noise is reduced at the same time.

Owner:HEFEI JINYUE PHARMA

Deep waste plastic particle deep purifying and screening device

InactiveCN106738469AImprove screening qualityAvoid damageUsing liquid separation agentPlastic recyclingCamImpurity

The invention discloses a deep waste plastic particle deep purifying and screening device which comprises a screening machine body, wherein an air blowing hole is formed in the right side wall of a barrel body of a feeding barrel; an air-blowing fan communicates with an inlet in the right side of the air blowing hole; a left-side end opening of a plastic bag inlet is equipped with a light impurity collecting bag in a sealing mode; a supporting mounting frame is fixedly connected below the machine body of the screening machine body; the two sides of a bottom framework of the supporting mounting frame are separately hinged with a rotary cam; a vibrating screening slot is formed in the top end of a post body of a lifting supporting post; a rolling slide wheel can be arranged on the cam periphery of the rotary cam in a sliding mode; and a dust conveying folding tube further communicates with the position above the right side wall of the screening machine body. The deep waste plastic particle deep purifying and screening device avoids the problem that follow-up screening progress is affected as a bag drops; and plastic particles in the vibrating screening slot can be continuously screened, so that a deep screening process for materials which meet specification requirements is realized, and the surrounding environment is protected.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

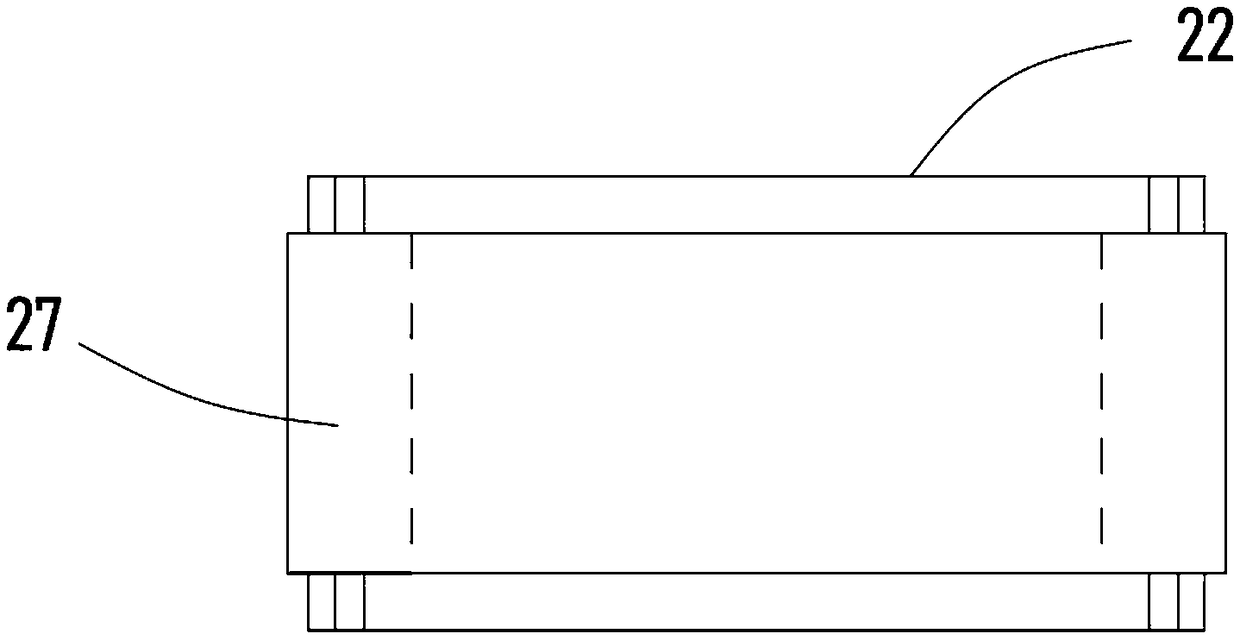

Screening equipment for organic fertilizer processing and using method of screening equipment

InactiveCN107398417AImprove screening efficiencyImprove screening qualitySievingScreeningDrive shaftAgricultural engineering

The invention discloses screening equipment for organic fertilizer processing. The screening equipment comprises a bottom plate, a screening barrel, a first motor, an auger, a second motor, a transmission shaft and a smashing rod. The screening equipment is characterized in that the bottom plate is arranged on a support, the screening barrel is arranged on a stand column, the first motor is arranged at one end of the screening barrel, the auger is arranged in the screening barrel, the second motor is arranged on a stock bin, the transmission shaft is arranged in the stock bin, the transmission shaft is connected with the second motor, and the smashing rod is arranged on a connection block. A screening plate is arranged on the screening barrel, the auger is arranged in the screening barrel, the auger is connected with the first motor, the smashing rod on the transmission shaft in the stock bin smashes organic fertilizer, and the screening working efficiency of organic fertilizer is improved.

Owner:安徽乐农环保科技有限公司

Stauntonvine screening equipment

The invention discloses stauntonvine screening equipment in the field of stauntonvine production equipment. The stauntonvine screening equipment comprises a color selector, and the color selector comprises a first outlet used for outputting lesion fruits and a second outlet used for outputting normal fruits, a conveying belt is arranged below the second outlet, and small holes used for screening small fruits are formed in the conveying belt; a small fruit collecting device is arranged between an upper belt body and a lower belt body of the conveying belt, and a large fruit collecting device is arranged at the end, away from the second outlet, of the conveying belt; the color selector is arranged to sort out picked fruits, and the lesion fruits and the normal fruits are screened out; through the conveying belt with the small holes, small fruits enter the small fruit collecting device through the small holes, and due to the fact that large fruits cannot enter the small holes, the large fruits finally enter the large fruit collecting device in a conveyed manner; and therefore screening of stauntonvine is achieved, due to automatic screening, work intensity of workers is greatly reduced, and meanwhile work efficiency is improved; and the screening standard is fixed, and the higher screening quality is ensured.

Owner:贵州天楼生物发展有限公司

Button screening device for garment processing

The invention discloses a button screening device for garment processing. The button screening device comprises a sleeve and a centrifugal barrel, the upper end of the sleeve is connected with a fixing ring through a clamping groove and a clamping block, and a connecting rod is arranged at the lower end of the fixing ring; the lower end of the connecting rod is connected with a hopper through a convex ring, and a baffle is fixed to the inner wall of the hopper; a cam is arranged on the lower side of the hopper, and a motor is connected to the outer side of the cam; the centrifugal barrel is arranged on the lower side of the hopper, a limiting ring is arranged at the upper end of the periphery of the centrifugal barrel, a waste groove is formed in the outer side of the centrifugal barrel, and a filter screen is arranged in the middle of the centrifugal barrel; the lower end of the centrifugal barrel is connected with the sleeve through a transmission wheel, a discharging opening is formed in the lower side of the centrifugal barrel, and a motor is connected to the lower end of the transmission wheel. According to the button screening device for the garment processing, impurities inbuttons can be screened according to the sizes of the impurities, and the whole device is convenient for a user to clean.

Owner:嘉兴市名汇服饰有限公司

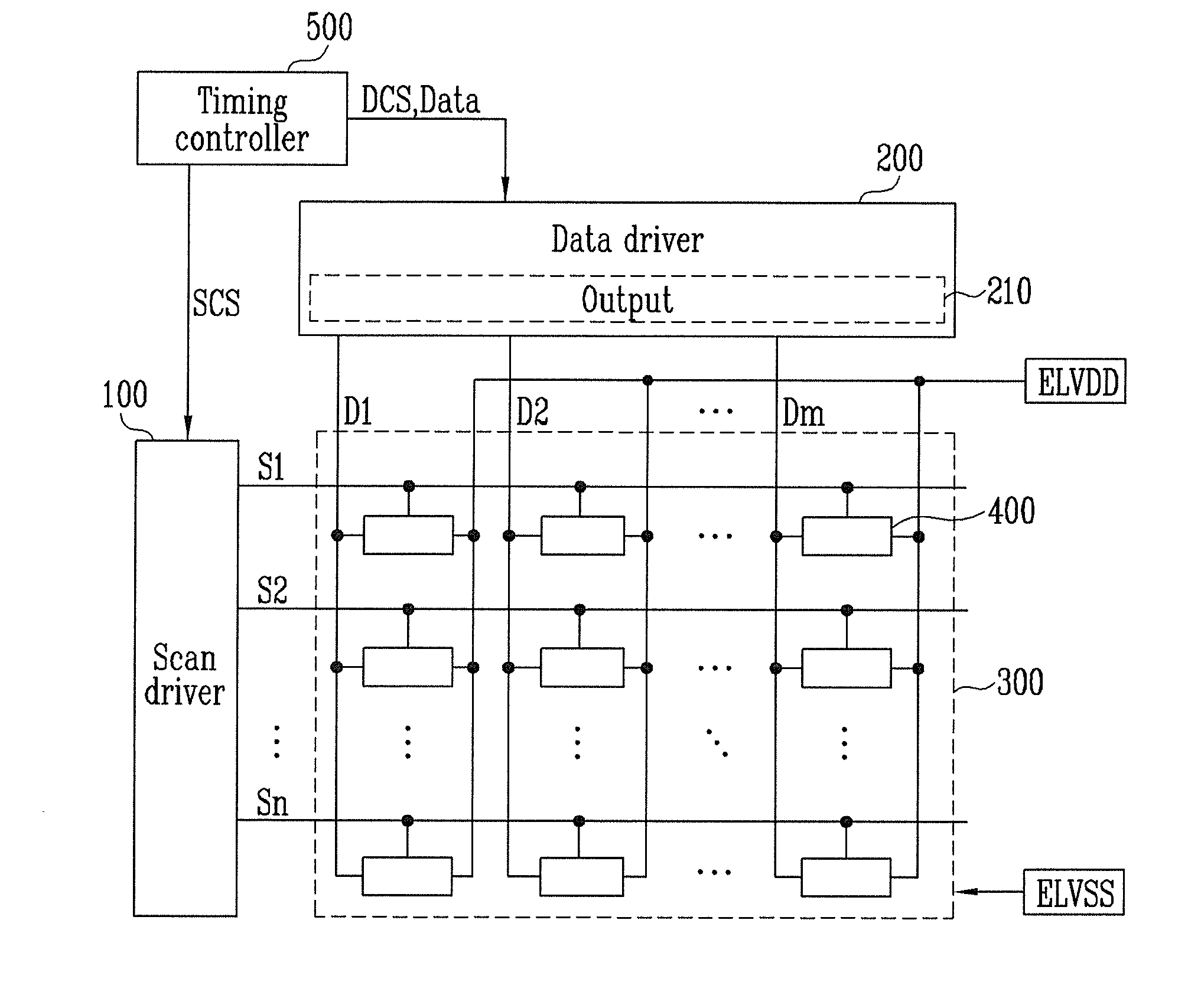

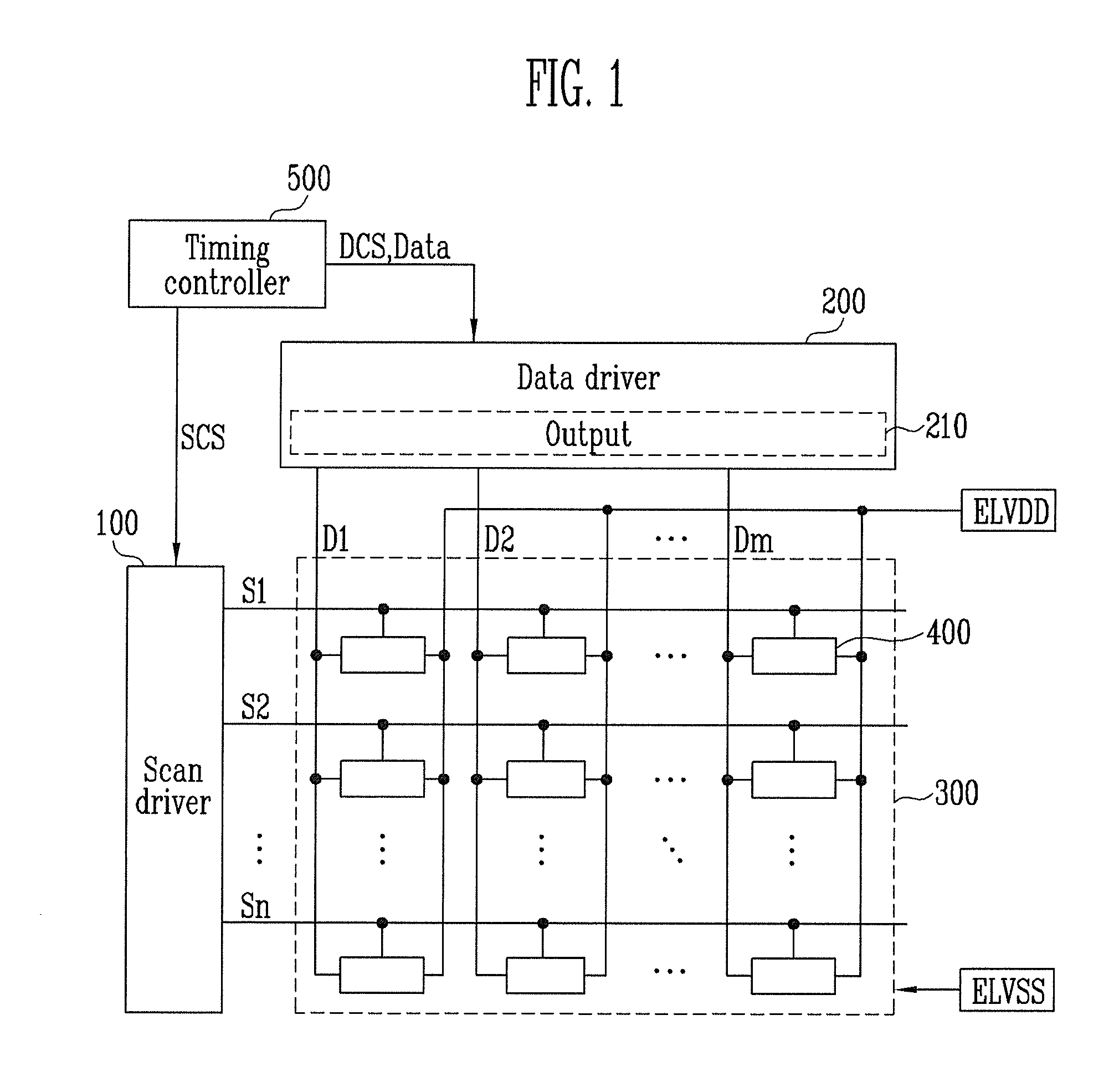

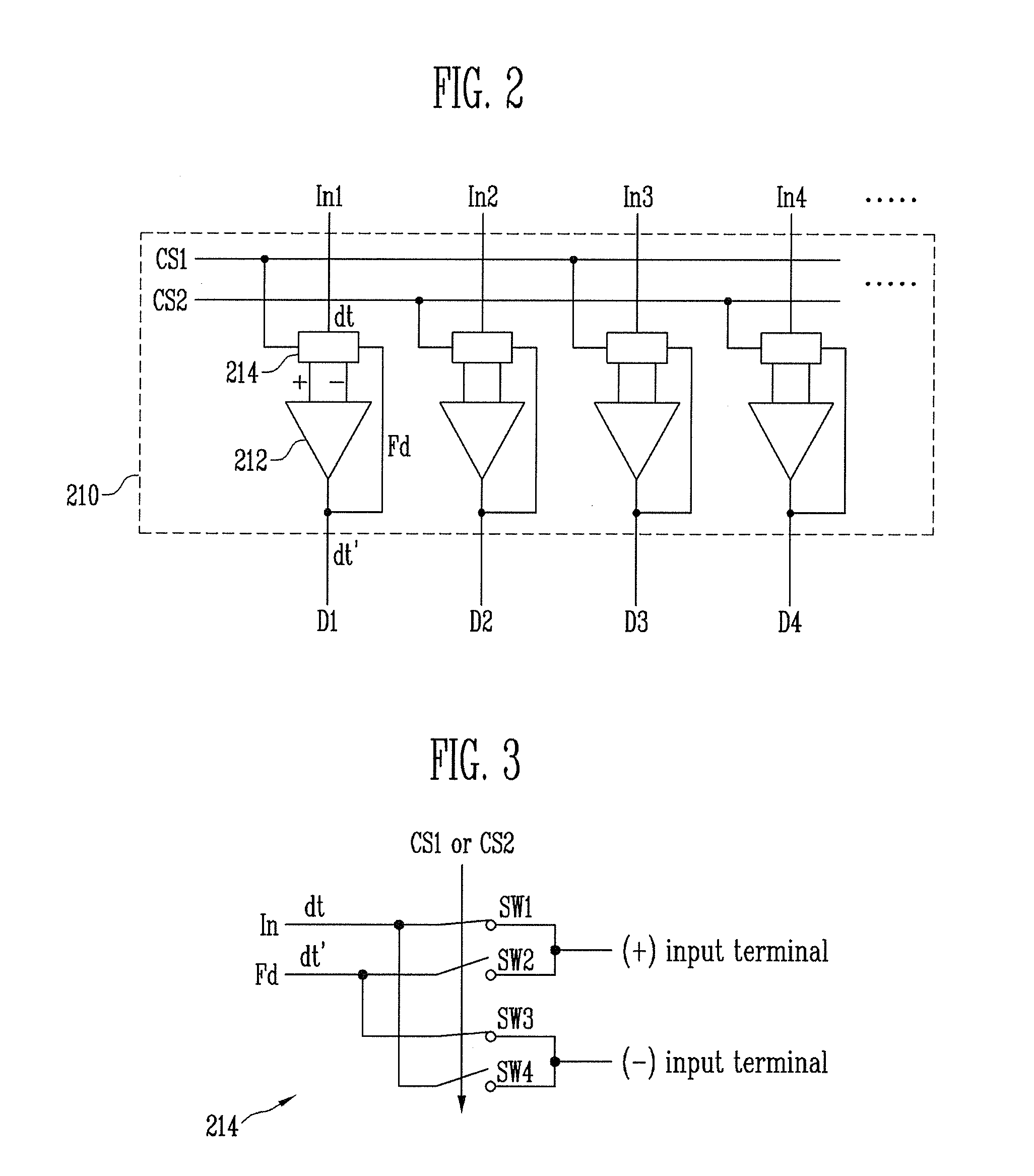

Data drive circuit of flat panel display and driving method thereof

ActiveUS20120013598A1Reduced output variationImprove screening qualityCathode-ray tube indicatorsInput/output processes for data processingAudio power amplifierControl signal

The data driver of a flat panel display includes: an output driver configured to output a plurality of amplified data signals for a plurality of channels corresponding to a plurality of data lines, the plurality of channels including: a plurality of amplifiers configured to amplify a plurality of input data signals and to supply the amplified data signals to the data lines; and a plurality of chopping controllers, each of the chopping controllers being coupled connected to a plurality of input terminals of a corresponding amplifier of the amplifiers and configured to receive a first control signal or a second control signal to periodically change signals applied to positive and negative input terminals from among the input terminals of the amplifiers.

Owner:SAMSUNG DISPLAY CO LTD

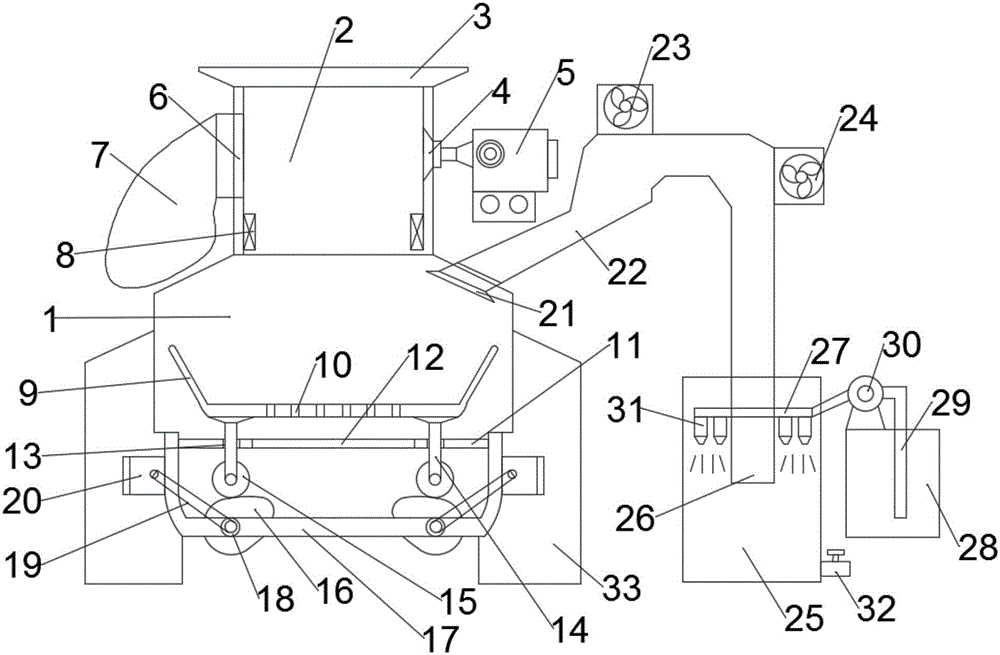

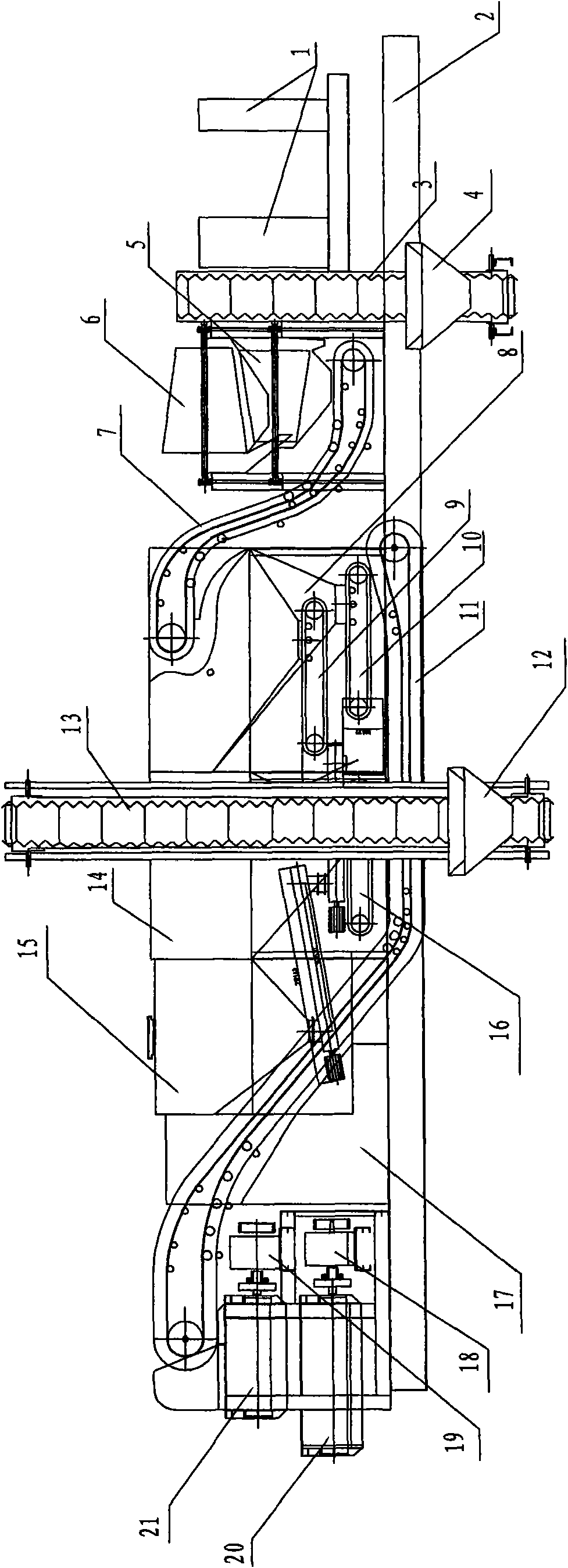

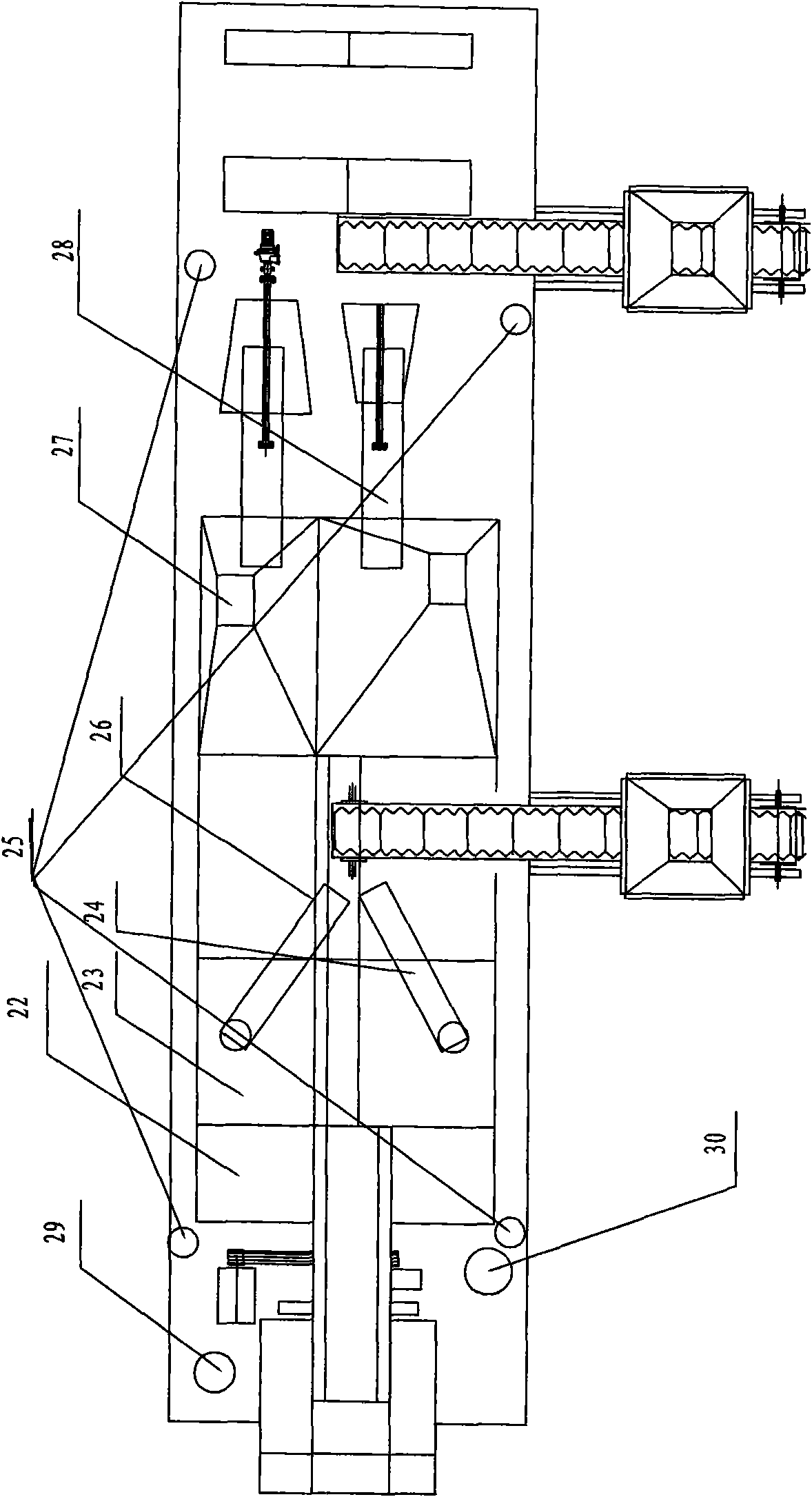

Movable asphalt cold regeneration cement gravel mixing building

InactiveCN101591885AImprove the level ofPrecise thickness controlRoads maintainenceCrushed stoneRoad surface

The invention discloses a movable asphalt cold regeneration cement gravel mixing building, which comprises a charging device capable of being loaded on a transport vehicle and consisting of a milling material charging belt, a milling material charging funnel, a new aggregate charging belt and a new aggregate charging funnel, and also comprises an asphalt cold regeneration cement gravel mixing device arranged on a stander capable of being lifted on a flat truck, wherein the asphalt cold regeneration cement gravel mixing device consists of a lifting hook arranged on the stander, a control cabinet and a milling material weighing belt, a new aggregate weighing belt, a mineral powder metering auger, a cement metering auger electrically connected with the control cabinet, and a milling material screening net, a milling material storage bin, a mineral powder bin, a cement bin, a water tank, an emulsified asphalt bin, a new aggregate bin, an asphalt pump, a water pump, an upper mixing boiler, a lower mixing boiler, a milling material semi-finished product charging belt, and a main belt; and the lower end of the lower mixing boiler is provided with a discharge port of the cold regeneration asphalt. The movable asphalt cold regeneration cement gravel mixing building recycles old road surface milling waste materials without crushing and heating, saves materials and cost, and is convenient and quick to move, lift and use.

Owner:HENAN TONGHE HIGHWAY MAINTENANCE PROJECT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com