Civil engineering sand sieving device

A technology of civil engineering and sand screening, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of reducing the life of the screen, difficult to grasp the installation accuracy, and destroying the screen, so as to improve the screening efficiency and quality, and the structure is ingenious , to avoid the effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

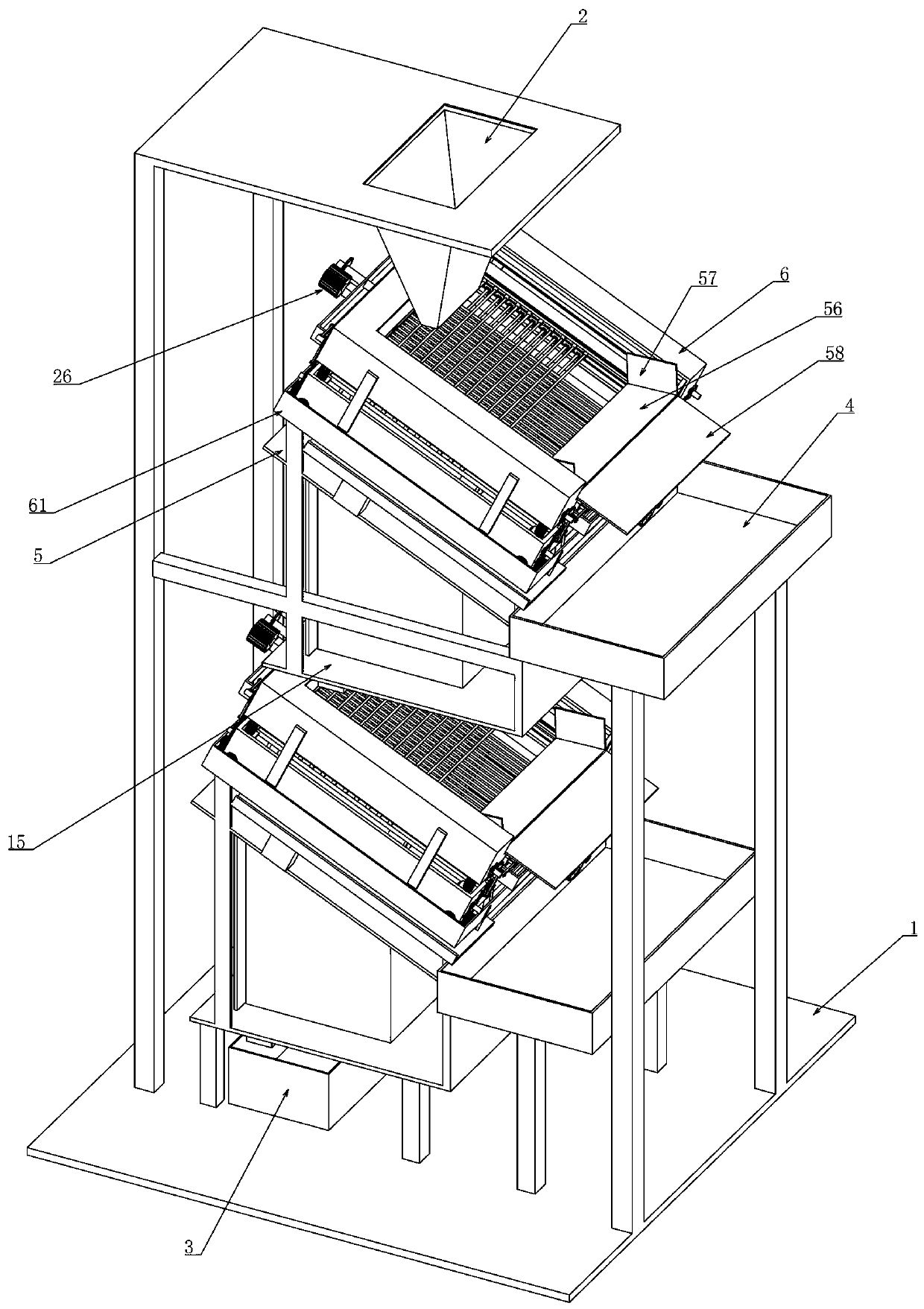

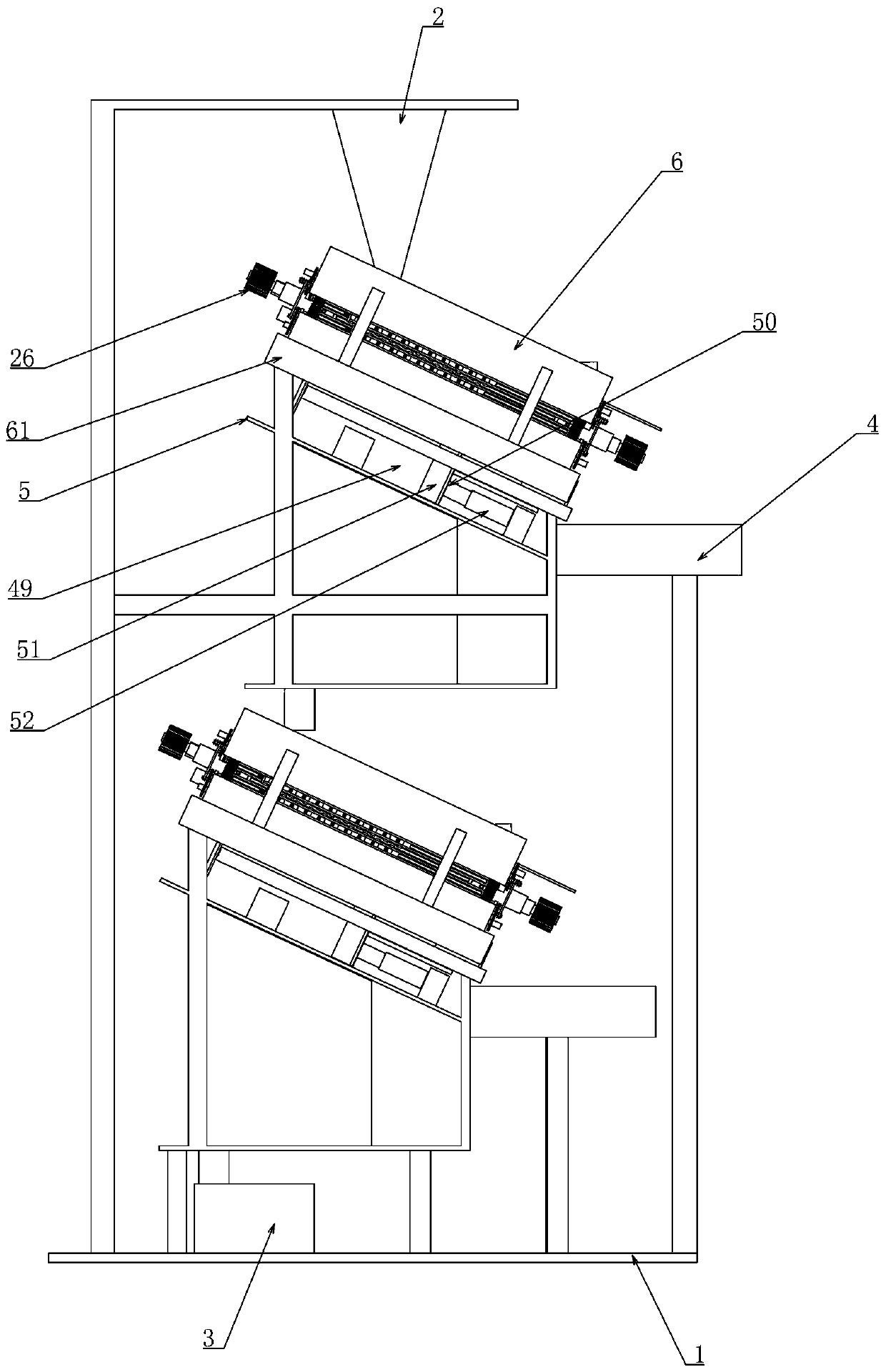

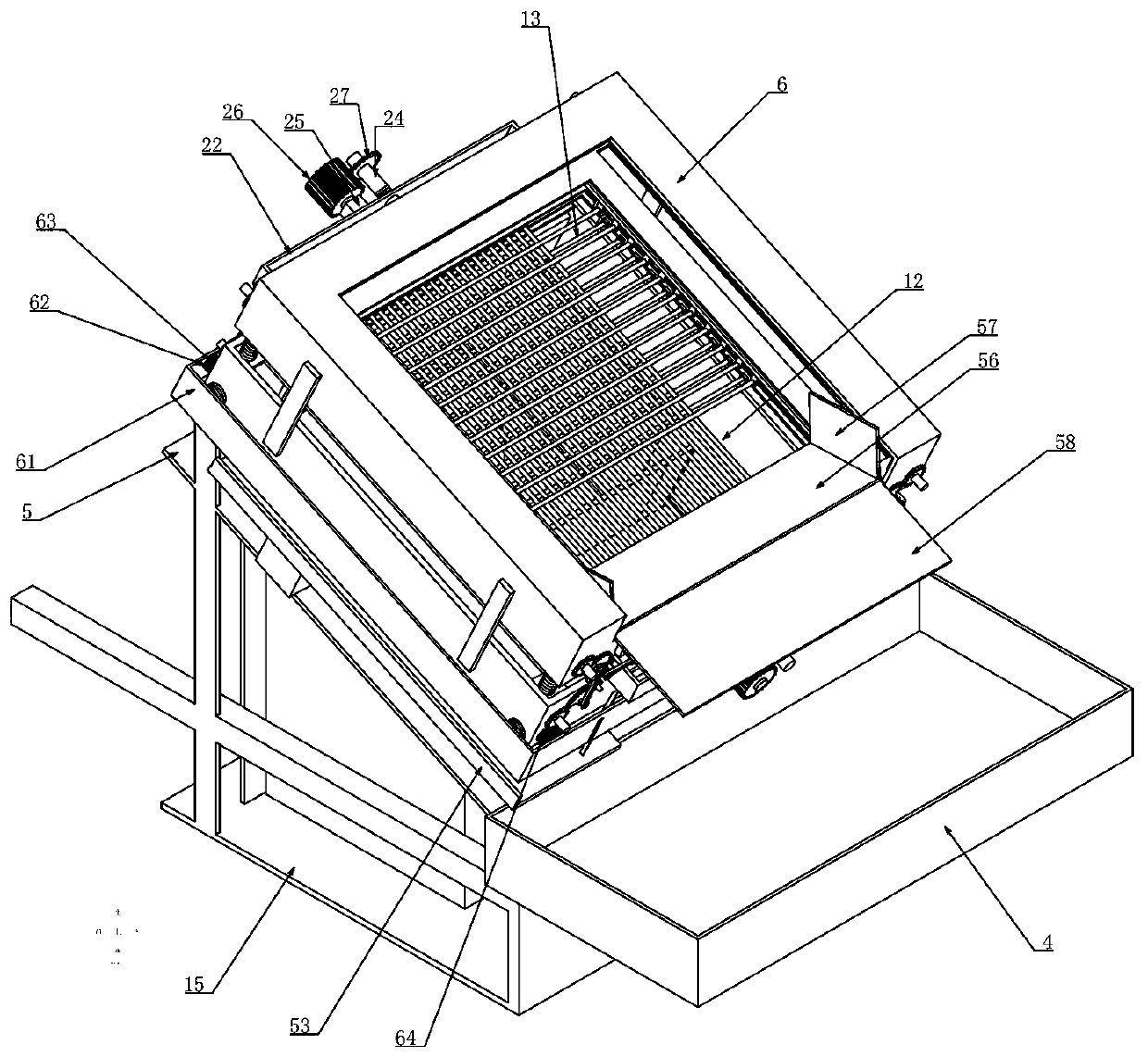

[0035] Embodiment one, combined with the attached Figure 1-17 , a civil engineering sand screening device, including a bracket 1, the bracket 1 can be fixed and installed in the area where it needs to be applied through anchor bolts, and it is characterized in that the upper end of the bracket 1 is connected from top to bottom with multiple groups of vertically arranged Sand screening device, the discharge end of the upper sand screening device is connected to the feed end of the lower sand screening device, the sand screened by each layer of sand screening device enters the sand screening device below, and the sand screening device on the uppermost layer The upper end of the device is connected to a raw material storage box 2, and the discharge end of the raw material storage box 2 is connected to the feeding end of the uppermost sand screening device. The raw material storage box 2 can be used to hold sand or gravel to be screened , the discharge end of the sand screening d...

Embodiment 2

[0038] Embodiment two, on the basis of embodiment one, in conjunction with the attached Figure 1-17 , the two ends of the transverse bar 12 are connected with a fixed block 17, the fixed block 17 is longitudinally slid between the two square frames 11, and a limit device is set so that it can only be carried out along the longitudinal direction of the square frame 11. To move, the ends of the fixed blocks 17 are respectively provided with front and rear symmetrical slopes, and the longitudinal spacing adjustment device includes a triangular wedge that is vertically limited by the square frame 11 and is horizontally slidable between two adjacent groups of fixed blocks 17. 18. The triangular wedge 18 cooperates with the side wall and the inclined surface of the fixed block 17. With the movement of the triangular wedge 18, the distance between adjacent fixed blocks 17 is adjusted. At the same time, due to the existence of the inclined surface, the triangular wedge 18 does not As...

Embodiment 3

[0040] Embodiment three, on the basis of embodiment one, in conjunction with the attached Figure 1-17 , the two ends of the transverse bar 12 are respectively connected with a second slider 32, and the second slider 32 is horizontally slidably fitted between the square frame 11 and the rectangular frame 7, and the upper end of the second slider 32 is connected to the section It is a T-shaped slide block, and there is a T-shaped chute matching it on the rectangular frame 7, so that the second slide block 32 can only move along the lateral direction of the rectangular frame 7. The lateral spacing adjustment device It includes a plurality of sets of through holes 33 provided by the second slider 32, one side of the through holes 33 is rotatably connected to a second lead screw 34 which is hollow inside, and the other side of the through holes 33 is coaxially connected to a set of The sleeve 35, the sleeve 35 is provided with an internal thread that is threadedly matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com