Raw material screening machine for orange flower cake production

A technology of orange flower cake and screening machine, which is applied in the direction of sieve, solid separation, grille, etc., can solve the problems of low efficiency, turning orange flowers, etc., and achieve the effect of improving screening quality, uniform cutting and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

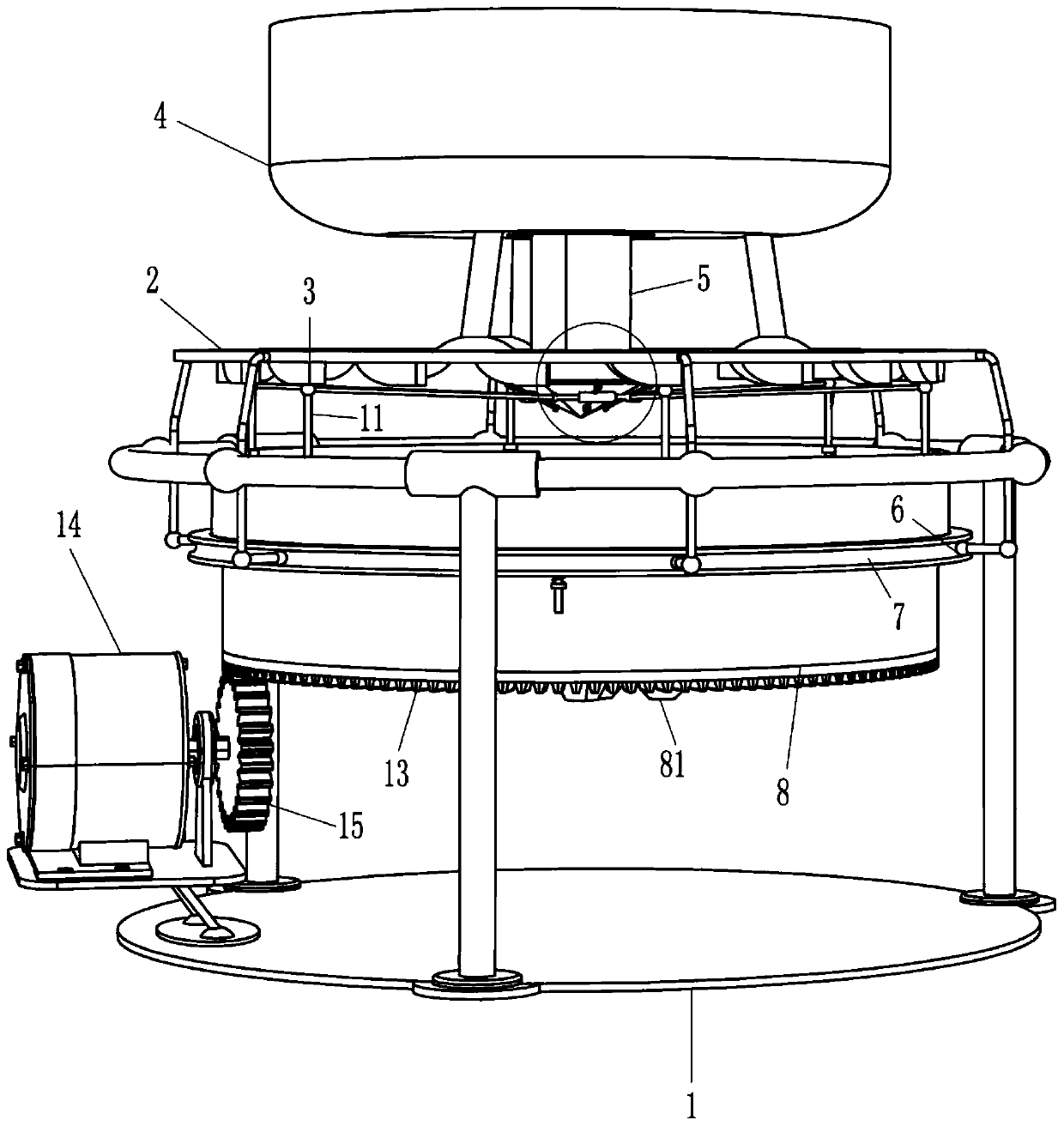

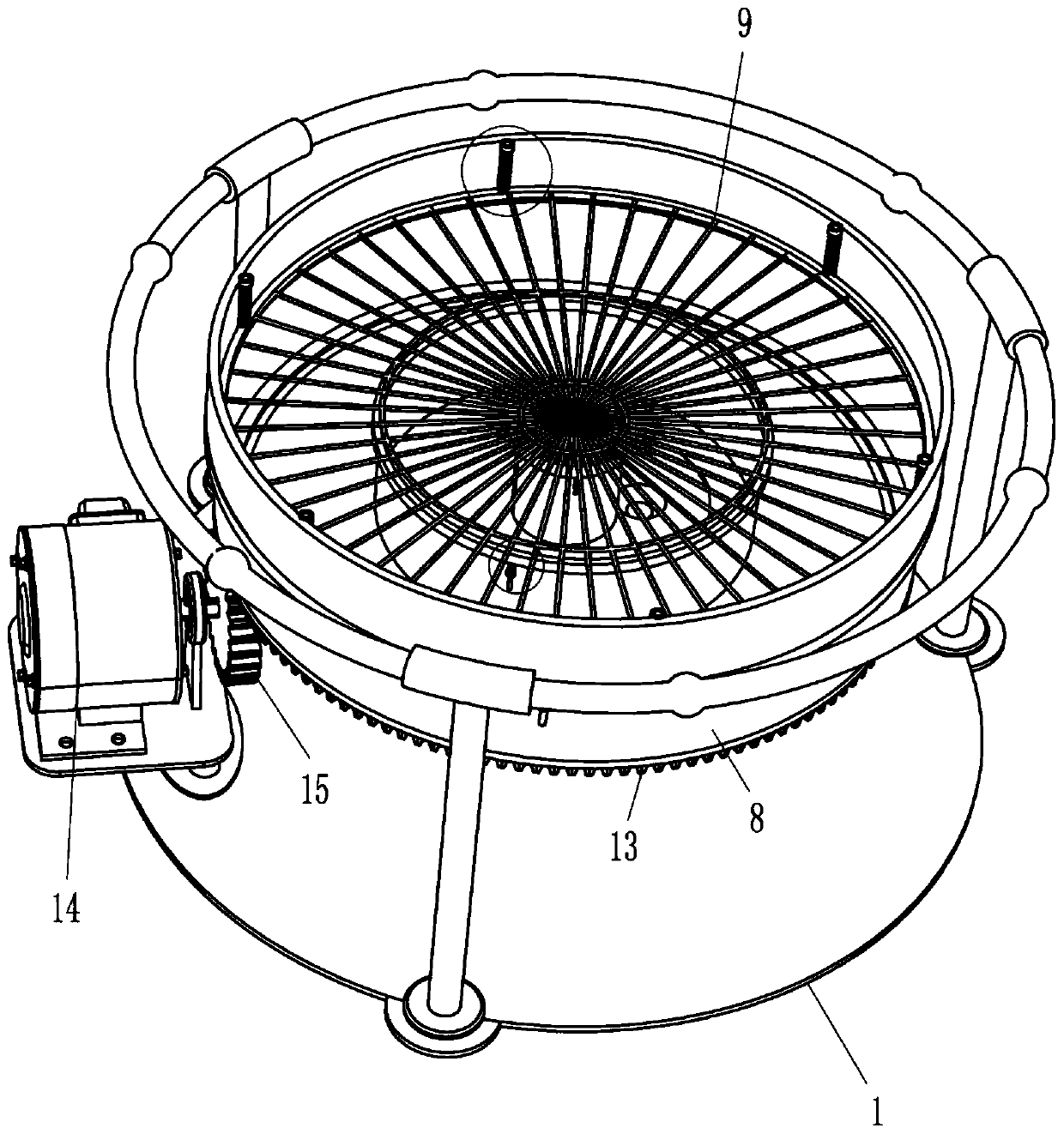

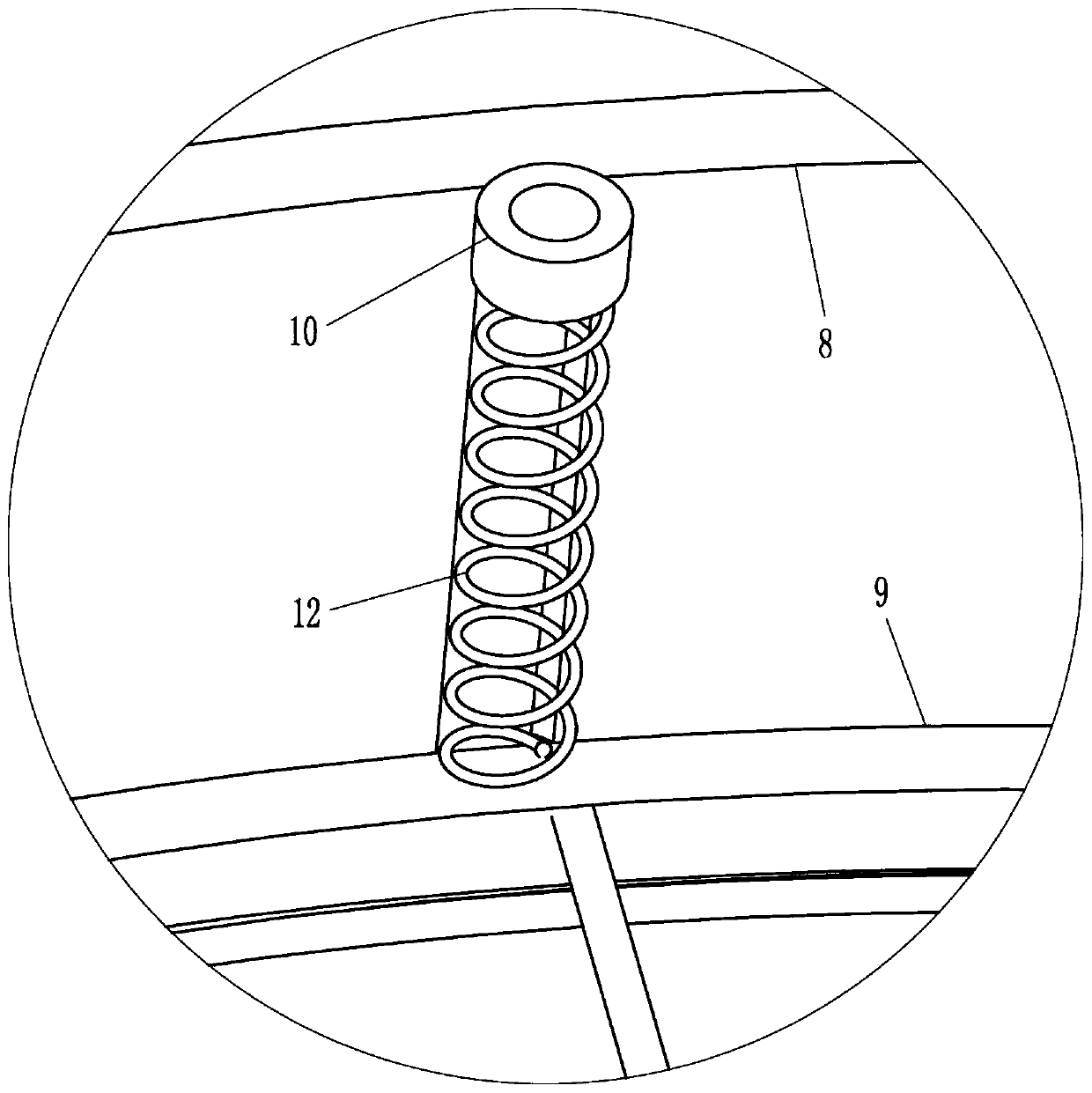

[0020] A raw material screening machine for the production of orange blossom cake, such as Figure 1-3 As shown, it includes a mounting frame 1, a mounting disc 2, a bump 3, a hopper 4, a feeding pipe 5, an L-shaped sliding rod 6, an annular sliding rail 7, a collecting cylinder 8, a screening assembly and a transmission assembly. The rack 1 is provided with an installation disc 2, a circle of bumps 3 are evenly spaced around the bottom of the installation disc 2, a discharge hopper 4 is arranged on the installation disc 2, and a blanking material is arranged between the discharge hopper 4 and the installation disc 2. Tube 5, the upper part of the inner side of the mounting frame 1 is evenly provided with a circle of L-shaped sliding rods 6, the inner end of the L-shaped sliding rod 6 is slidably provided with an annular sliding rail 7, and the inner side of the annular sliding rail 7 is provided with a collecting cylinder 8, and the collecting cylinder 8 There are two dischar...

Embodiment 2

[0027] On the basis of Example 1, as Figure 4 As shown, in order to intermittently put down the raw materials, it also includes a conical baffle 16, a guide rod 17, a sliding sleeve 18, a ring connecting rod 19 and a connecting rod 20. The bottom of the installation disc 2 is rotatably provided with four cones. The outer side of the tapered baffle 16 is provided with guide rods 17. The guide rods 17 are all slidably provided with sliding sleeves 18. The sliding sleeves 18 are connected with annular connecting rods 19, which are installed around the annular connecting rods 19. There is a circle of connecting rods 20 , and the outer ends of the connecting rods 20 are all connected with the top of the first sliding rod 11 .

[0028] like Figure 5 As shown, it also includes a second guide sleeve 21, a second sliding rod 22, a second spring 23 and a ring sleeve 24. The upper part of the collecting cylinder 8 is evenly spaced with a circle of second guide sleeves 21. Inside the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com