Magnetic separation device suitable for rice processing

A magnetic separation device and rice processing technology, applied in the directions of magnetic separation, solid separation, sieve, etc., can solve the problems of low impurity removal rate and low work efficiency of rice, and achieve the improvement of screening quality, processing quality, and impurity removal. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

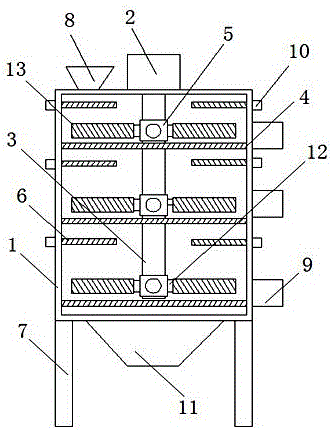

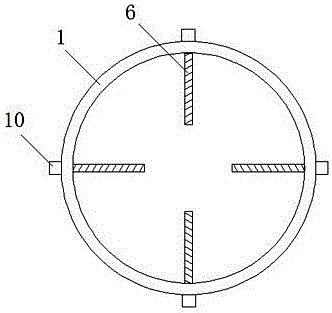

[0012] The present invention will be described in more detail below with reference to the accompanying drawings.

[0013] As shown in the accompanying drawings, a magnetic separation device suitable for rice processing includes a screening chamber 1, a motor 2, a rotating rod 3, a sieve plate 4, a mounting block 5 and a magnetic bar 6, and is characterized in that: the screening chamber is characterized in that: 1 is arranged on the bracket 7, and the screening chamber 1 is provided with a feeding port 8, a discharging pipe 9, a limit block 10, and a miscellaneous outlet 11. Through the feeding port 8, it is convenient for the rice to enter the screening chamber 1. The feeding pipe 9 is convenient for discharging different sizes of paddy from different discharging pipes 9, which improves the screening quality of the paddy, and facilitates the discharge of impurities such as gravel in the paddy through the miscellaneous outlet 11, thereby improving the impurity removal rate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com