Patents

Literature

37results about How to "Realize multi-stage crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

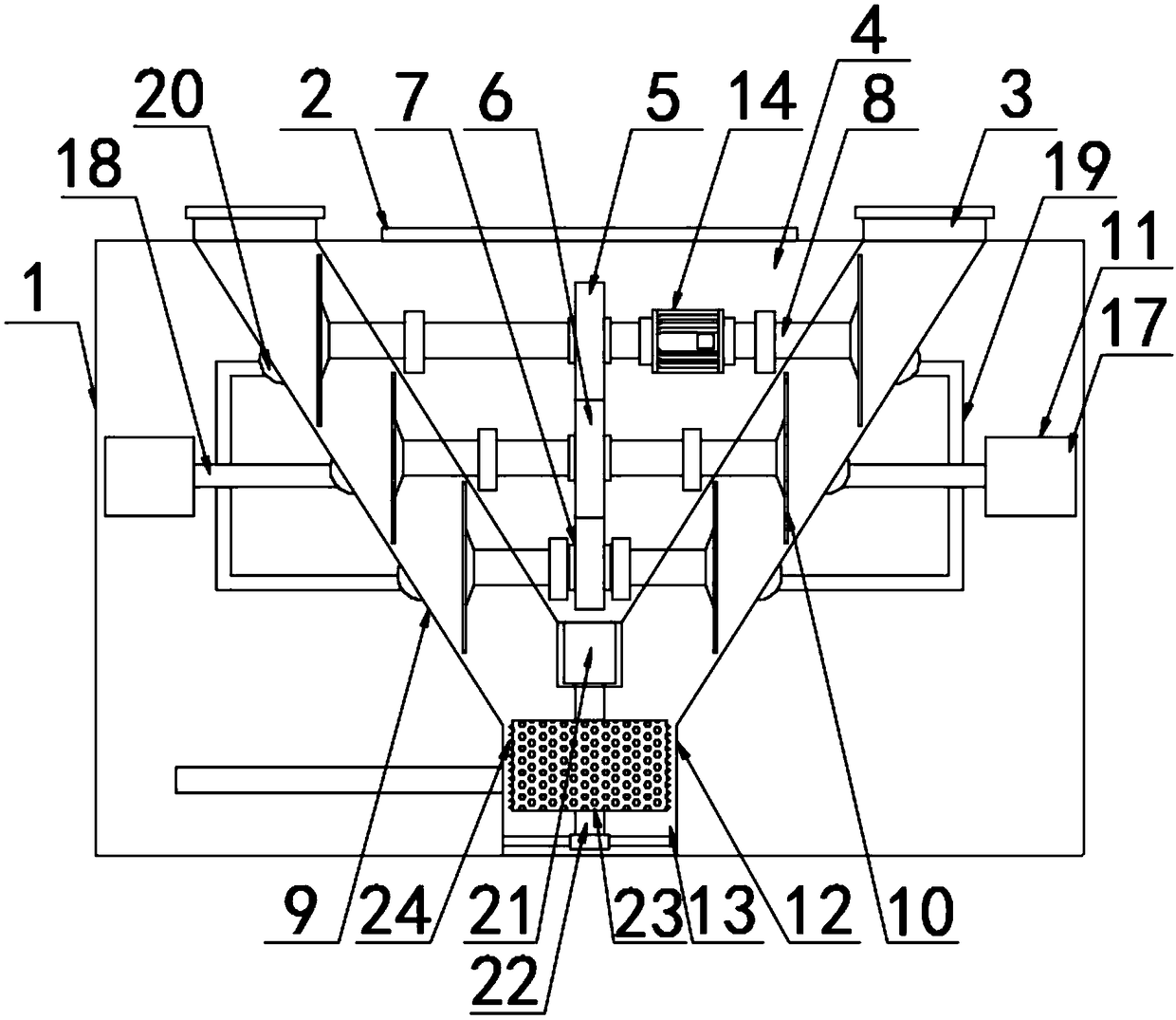

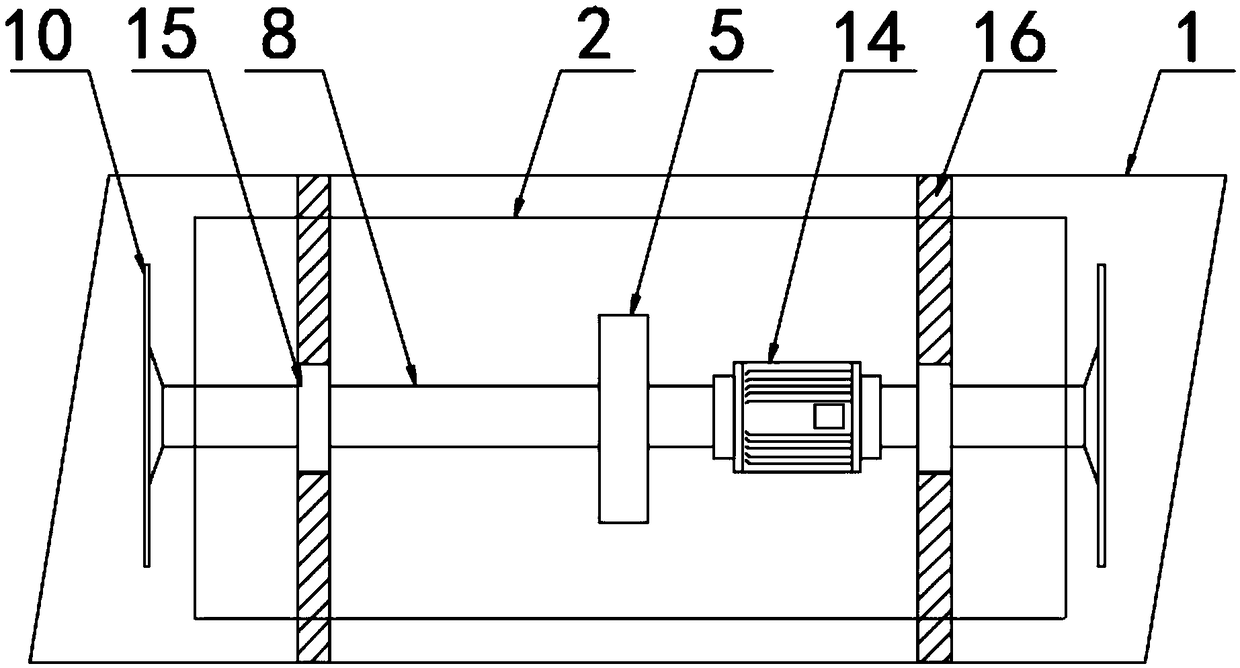

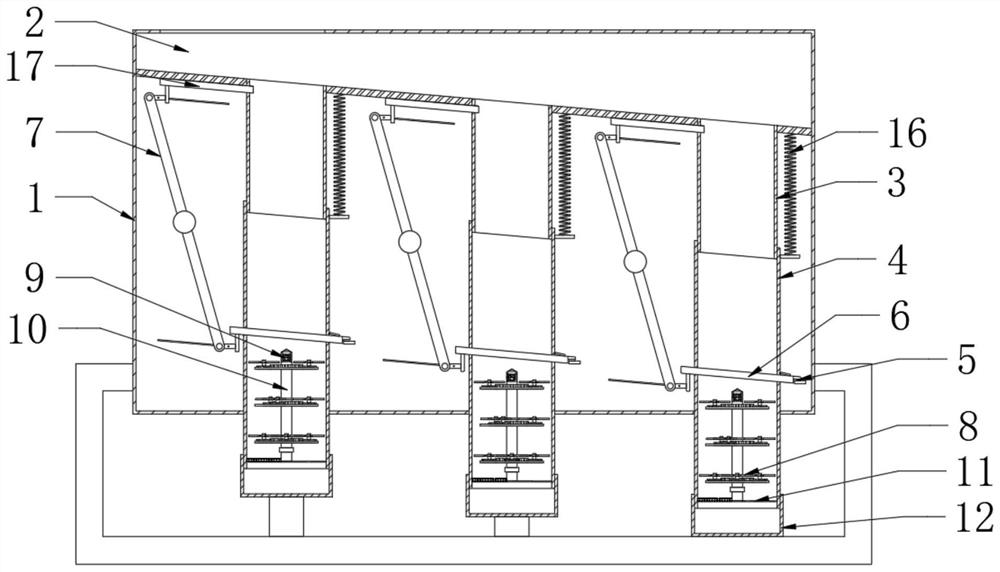

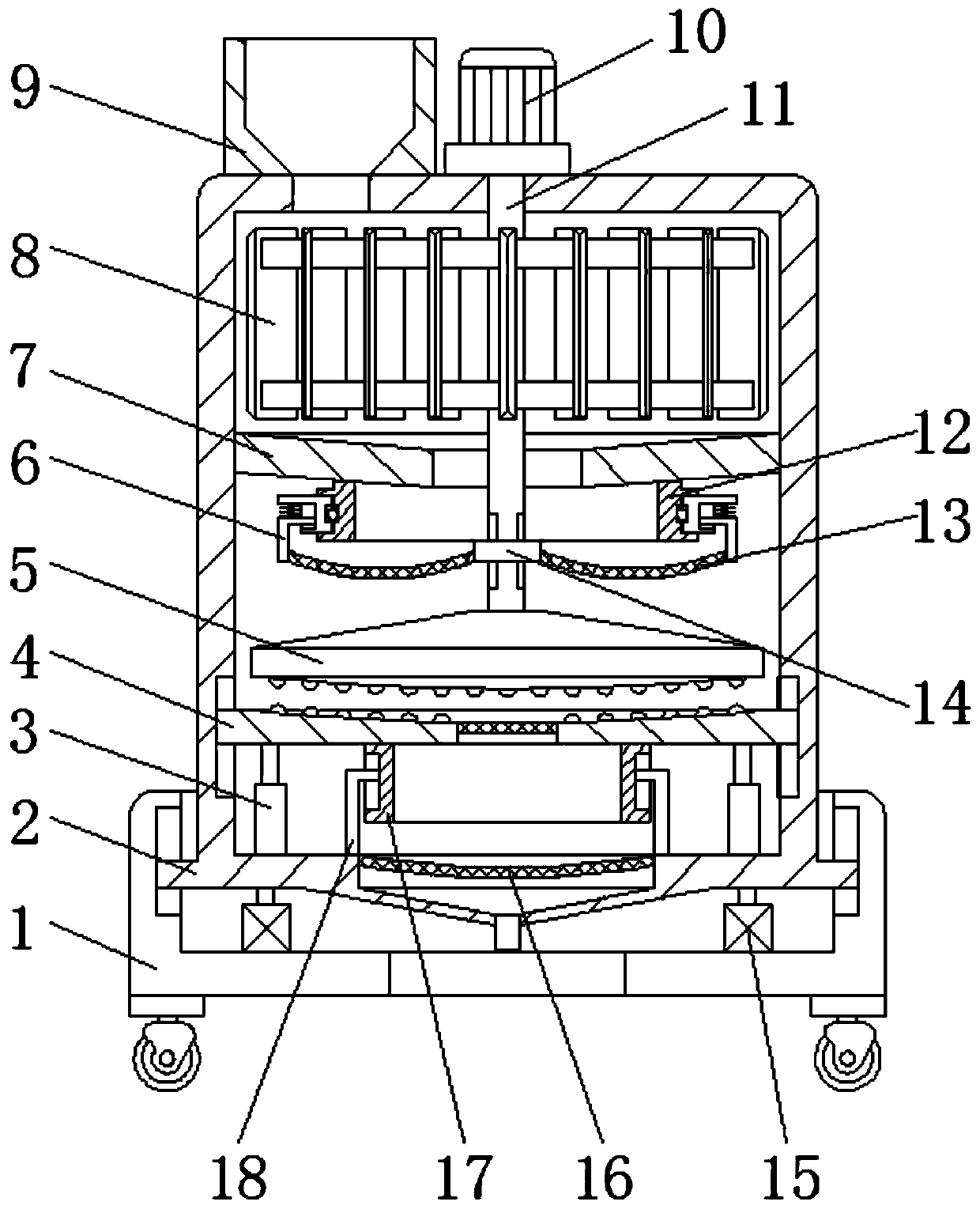

Efficient coal multi-stage crushing equipment for coal mine exploitation

InactiveCN111036376ARealize multi-stage crushingImprove crushing effectGrain treatmentsCoalMining engineering

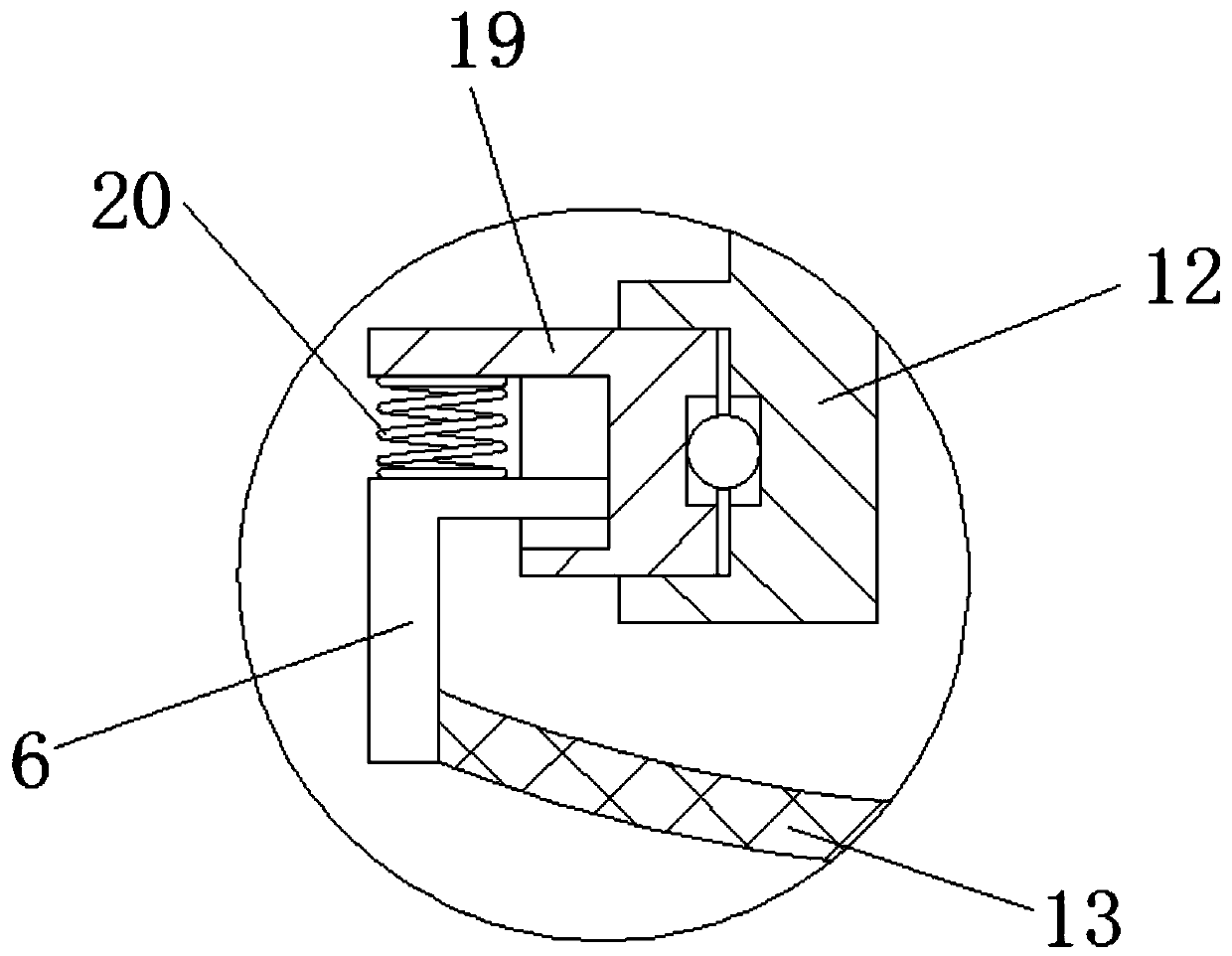

The invention relates to the technical field of coal crushing equipment, in particular to efficient coal multi-stage crushing equipment for coal mine exploitation. A first rotating shaft is driven bya servo motor to rotate, on one hand, the first rotating shaft drives a second d rotating shaft to rotate through a transmission belt, crushing cutters interact, and coal in a feeding hopper is crushed; on the other hand, the first rotating shaft directly drives a grinding end to grind coal falling into a grinding channel through a feeding pipe, and therefore multi-stage crushing is achieved, andthe crushing effect and efficiency are improved; the first rotating shaft further drives a third rotating shaft to rotate through the transmission belt, a moving block moves up and down in the axial direction, a baffle is driven to move, the feeding pipe is intermittently opened or sealed, and intermittent feeding is achieved; and a push-pull assembly is arranged, a cylinder cam rotates along withthe first rotating shaft, a wedge block is driven by a connecting rod to move up and down, a push-pull rod drives a blocking plate to work in cooperation with a spring, and blocking and material pushing are completed.

Owner:安徽信典网络科技有限公司

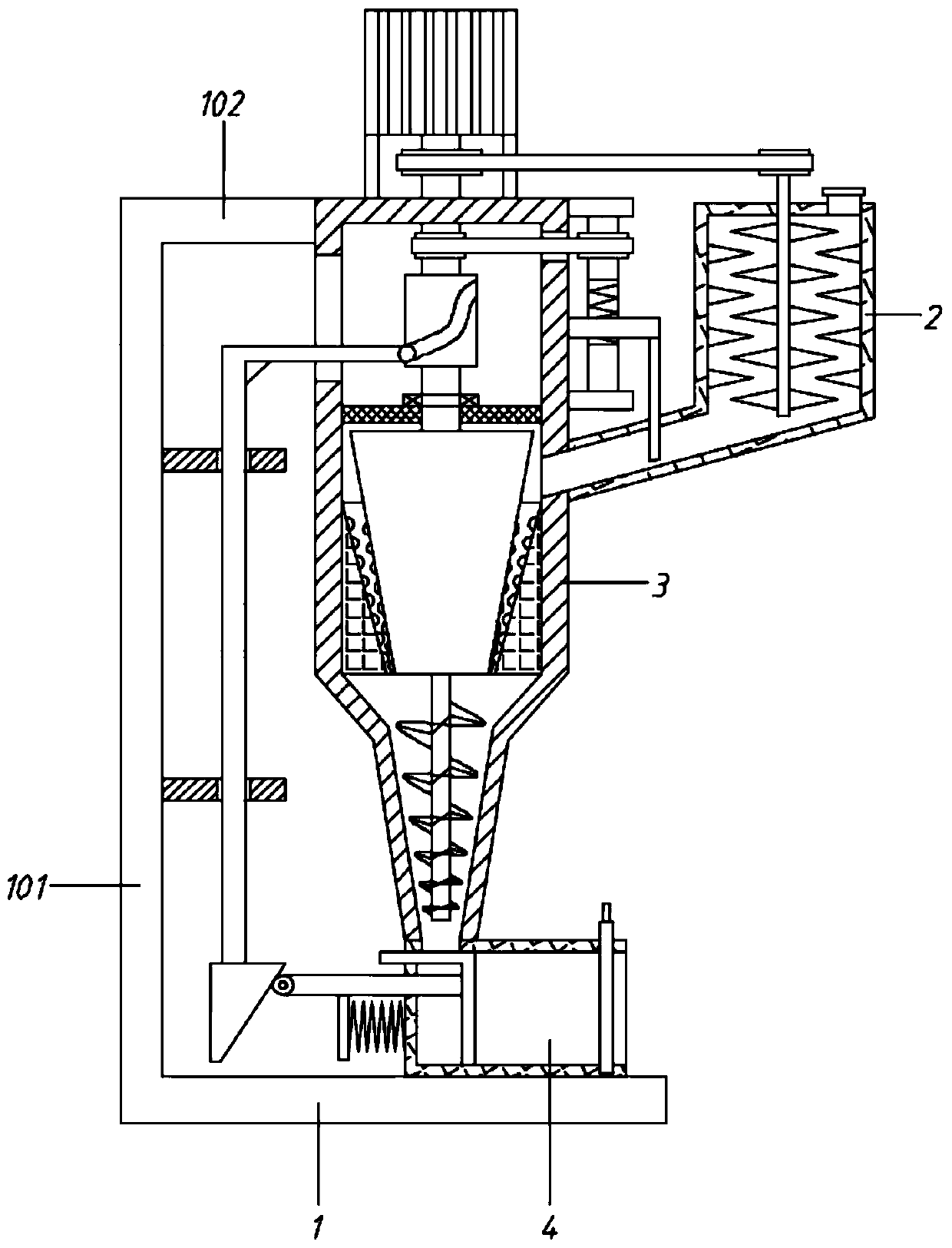

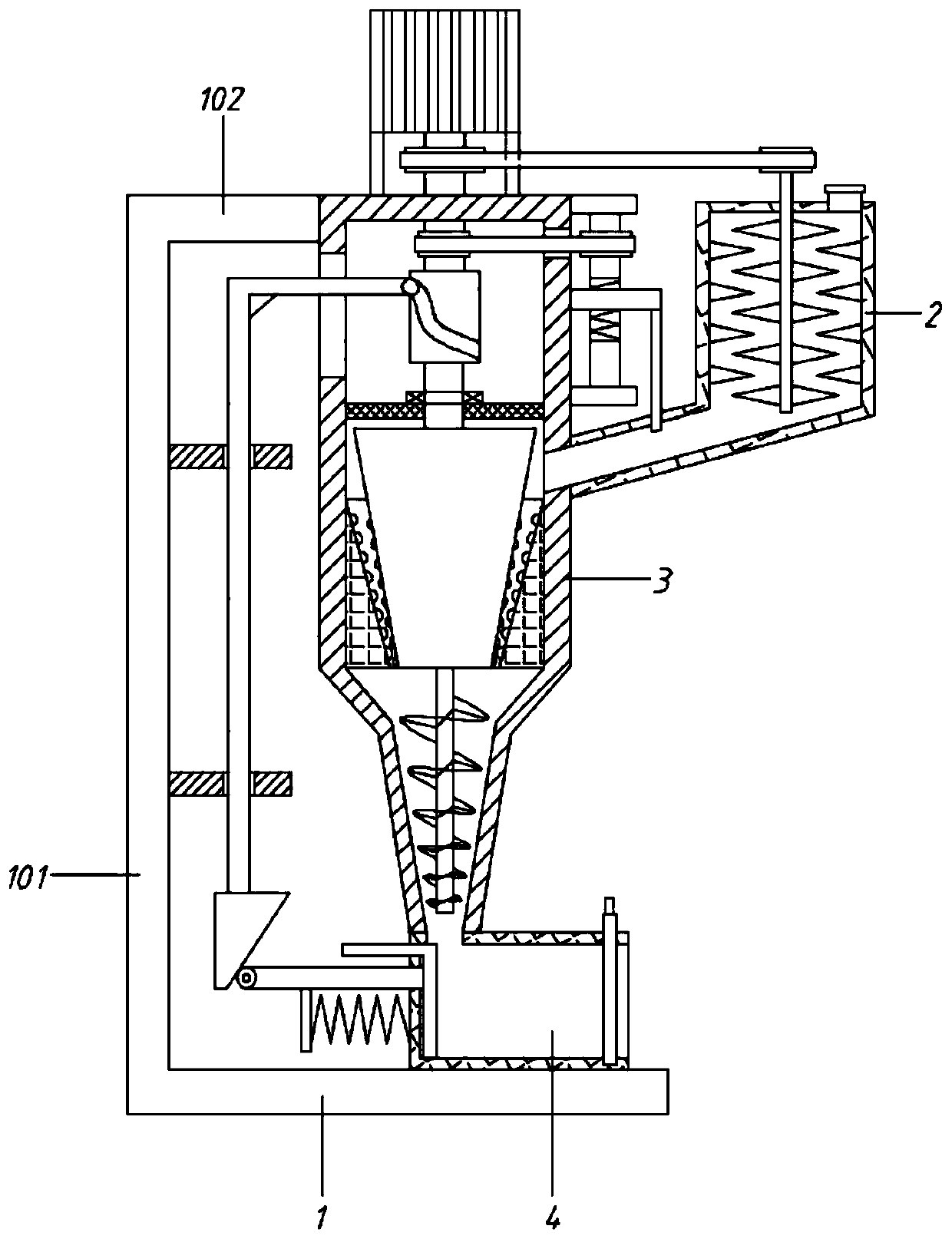

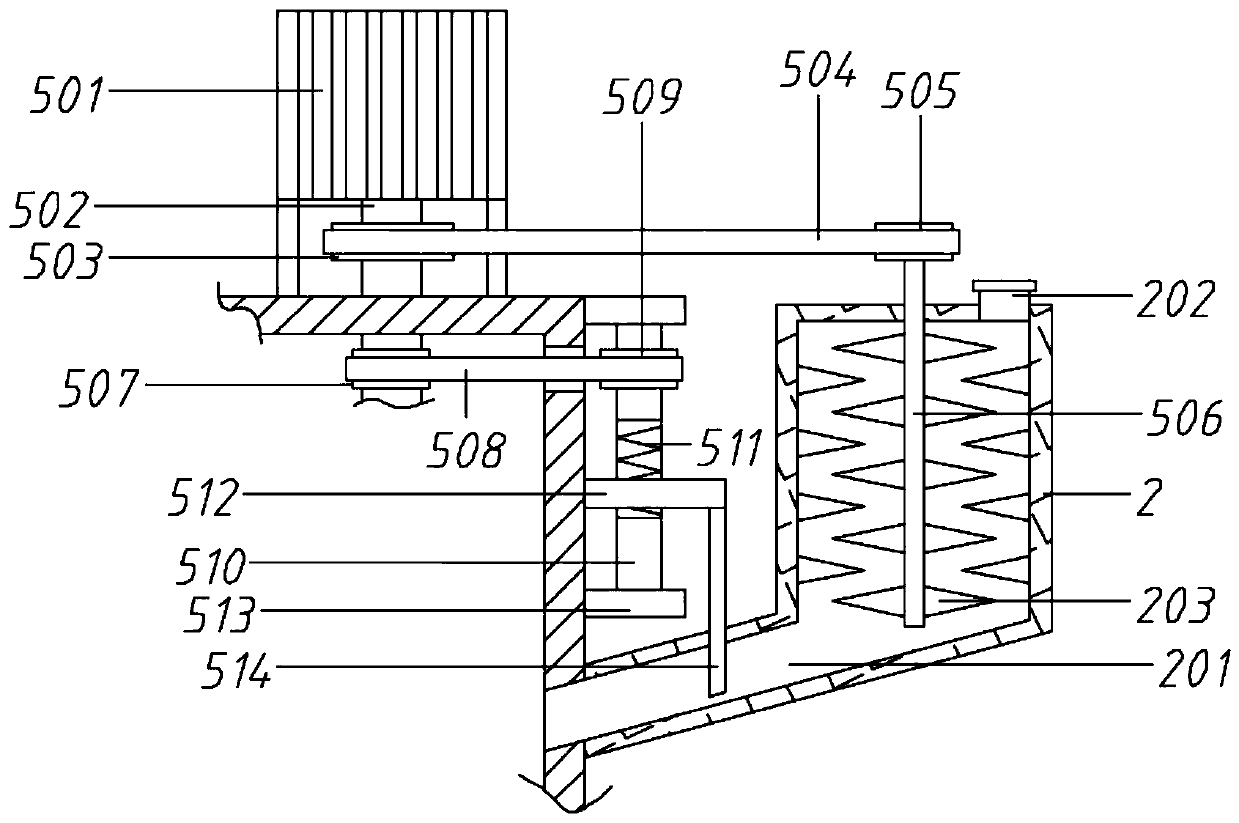

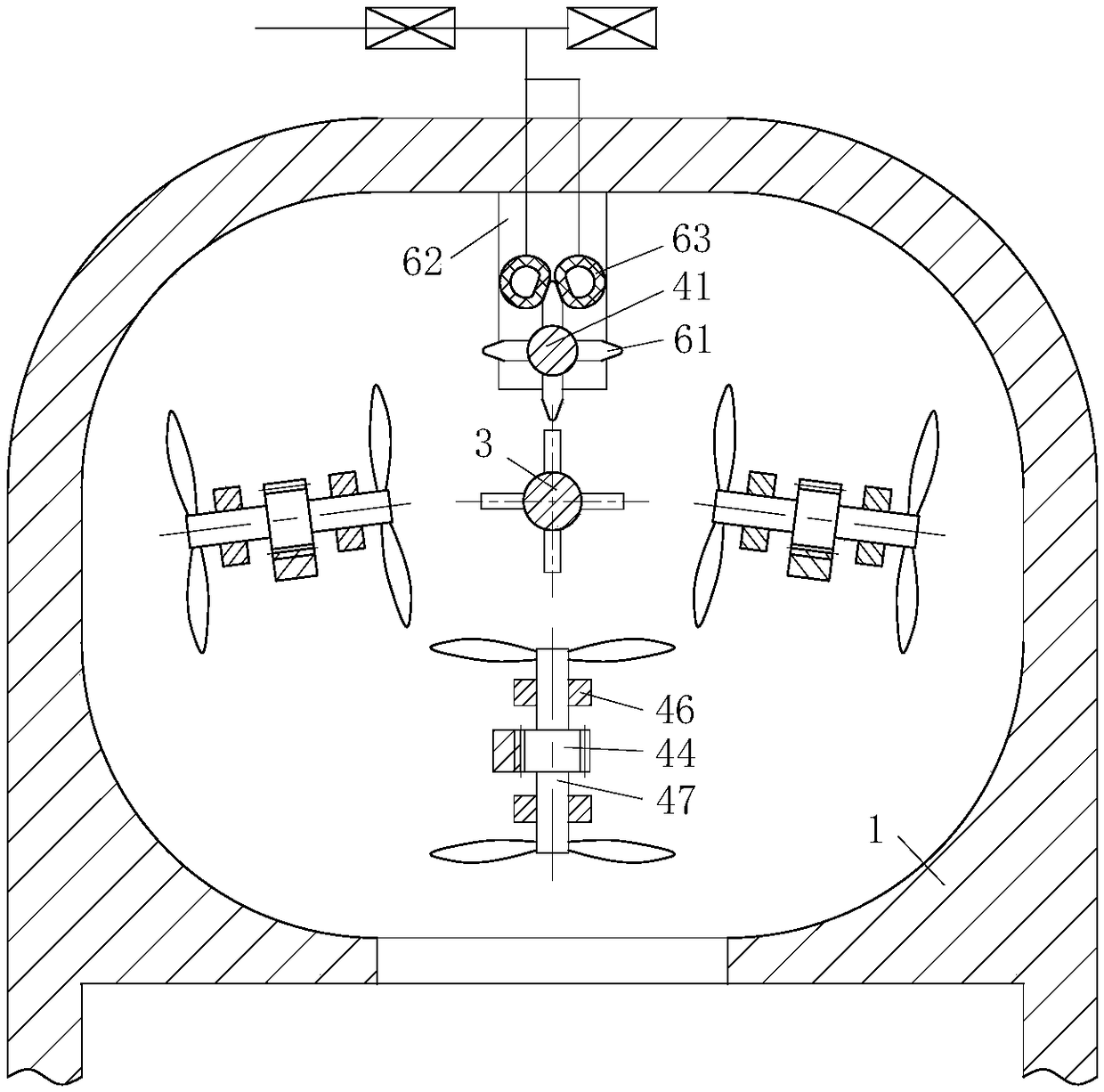

Treatment system, crushing equipment and treatment method for oily sludge

PendingCN106630515AEasy to washStir wellWaste water treatment from quariesSievingSludgeHigh pressure water

The invention discloses a treatment system, crushing equipment and a treatment method for oily sludge. The equipment comprises an inlet cylinder body, a crushing cylinder body, a double-roller type shredding mechanism, a rotating shaft type crushing mechanism, a high-pressure water spraying device and a first oil scraping device, wherein the lower part of the inlet cylinder body is connected with the crushing cylinder body; the high-pressure water spraying device is arranged above or inside the inlet cylinder body; the double-roller type shredding mechanism is arranged in the inlet cylinder body; the crushing cylinder body is provided with an oil slick space above the rotating shaft type crushing mechanism; the first oil scraping device is arranged in the oil slick space; a first oil slick draining outlet which can be opened and closed is formed in an end opposite to the first oil scraping device; an oily sludge discharging outlet is formed in the bottom of the crushing cylinder body. The oily sludge treatment equipment disclosed by the invention is formed by combining multistage crushing, multistage oil removal, high-efficiency oil binding or extraction, can be suitable for the oily sludge with different oil contents, and is particularly suitable for the oily sludge with lower oil content or serious emulsification.

Owner:仇霞霞

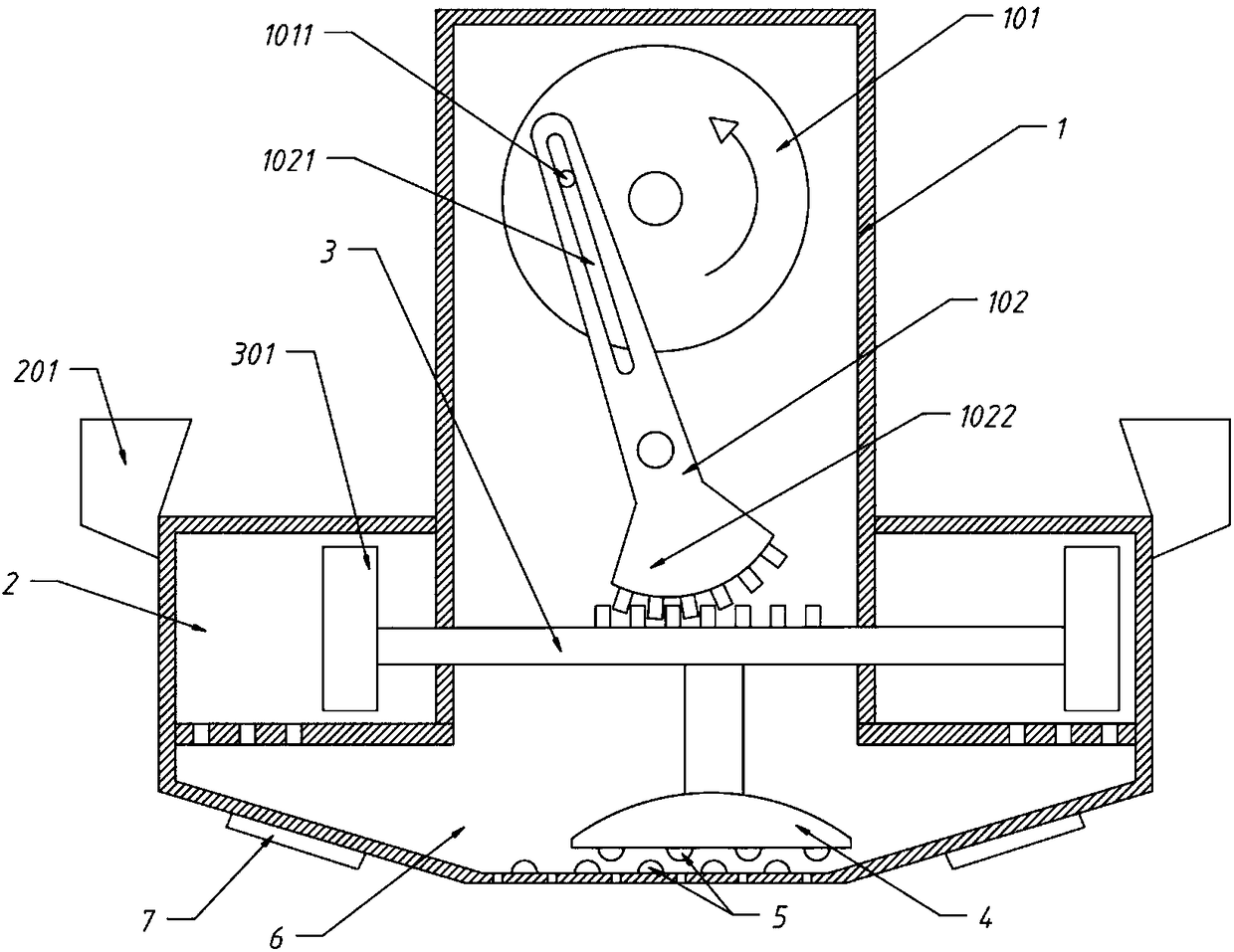

Raw material crushing grinding device for spraying device

InactiveCN108236982AImprove finenessRealize multi-stage crushingGrain treatmentsEngineeringMechanical engineering

The invention relates to the technical field of crushing and grinding, and in particular to a raw material crushing grinding device for a spraying device. The raw material crushing grinding device forthe spraying device comprises a main body cavity, a crushing cavity and a grinding cavity. The invention provides the raw material crushing grinding device for the spraying device. A rocking rod is driven to swing by utilizing a turntable, and then horizontal reciprocating movement of a reciprocating rod is realized through the engagement of a fan-shaped gear and teeth of the reciprocating rod, so that an impact hammer at an end part is driven to perform primary crushing on raw materials; simultaneously, a grinding block which is connected to the bottom of the reciprocating rod also moves reciprocally along with the reciprocating rod so as to perform secondary grinding on the primarily crushed raw materials again; and the particle fineness of particles is effectively improved. The raw material crushing grinding device for the spraying device is novel in structure and high in practicability, realizes multi-stage crushing by adopting a single power source, and is suitable for popularizing.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

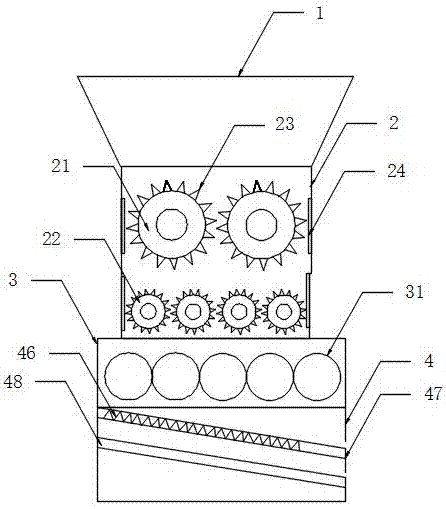

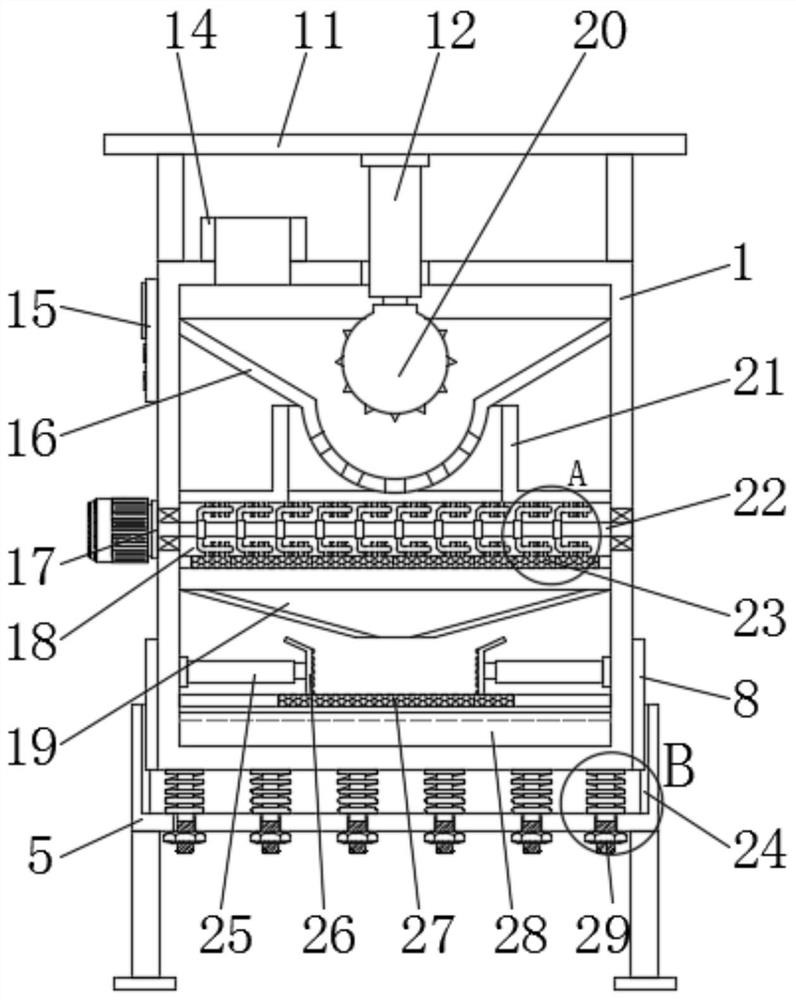

Smashing and grinding integrated raw material processing device for preparation of Relinqing tablets

InactiveCN107537649ARealize multi-stage crushingSmash thoroughlyGrain treatmentsEngineeringMaterials processing

The invention relates to the technical field of medicinal material processing, in particular to a smashing and grinding integrated raw material processing device for preparation of Relinqing tablets.The smashing and grinding integrated raw material processing device comprises a feeding inlet, a smashing box, a grinding box and a screening box; the smashing box is welded to the bottom of the feeding inlet; coarse smashing wheels and fine smashing wheels are arranged inside the smashing box; the fine smashing wheels are arranged below the coarse smashing wheels; material blocking piles are arranged on the two sides of the coarse smashing wheels and the fine smashing wheels; the grinding box is welded to the bottom of the smashing box; a plurality of grinding rollers are welded to the interior of the grinding box; and the screening box is welded to the bottom of the grinding box. The smashing and grinding integrated raw material processing device achieves multi-stage smashing, smashing is more thorough, a coarse material discharging groove outputs unqualified ground medicinal materials, unqualified medicinal materials are put into the feeding inlet again to be machined continuously till all raw materials are qualified and achieve the raw material standard of medicinal materials, a connection support makes the screening box work more stably and reliably, and noise is reduced at the same time.

Owner:HEFEI JINYUE PHARMA

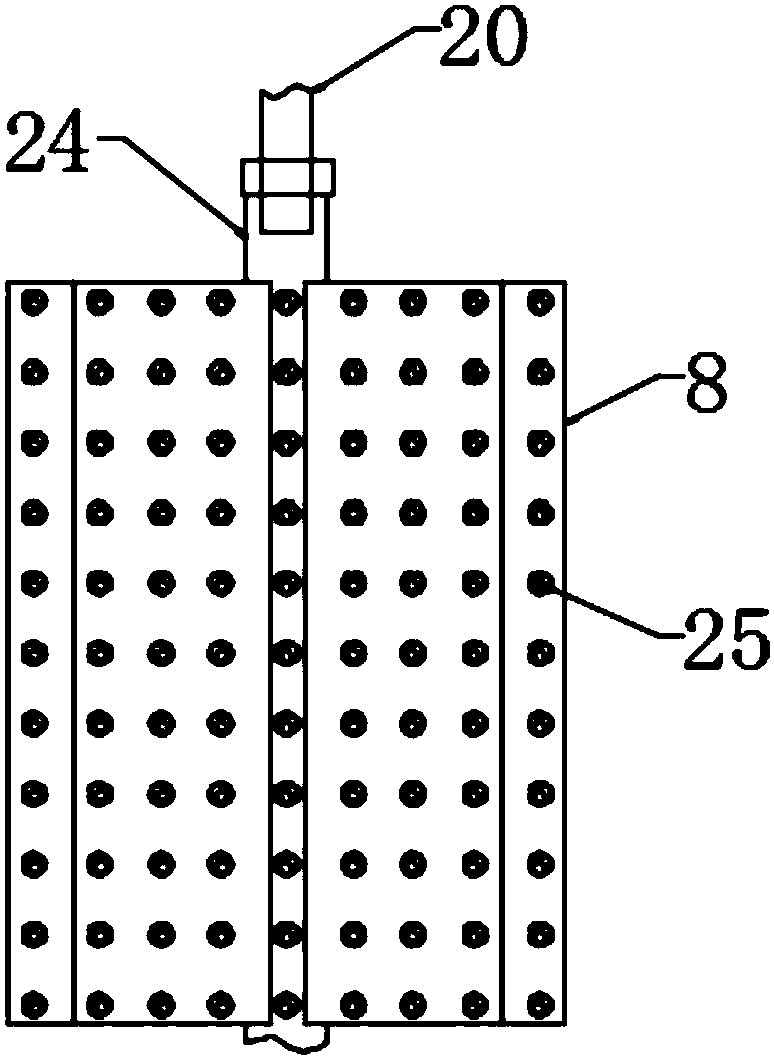

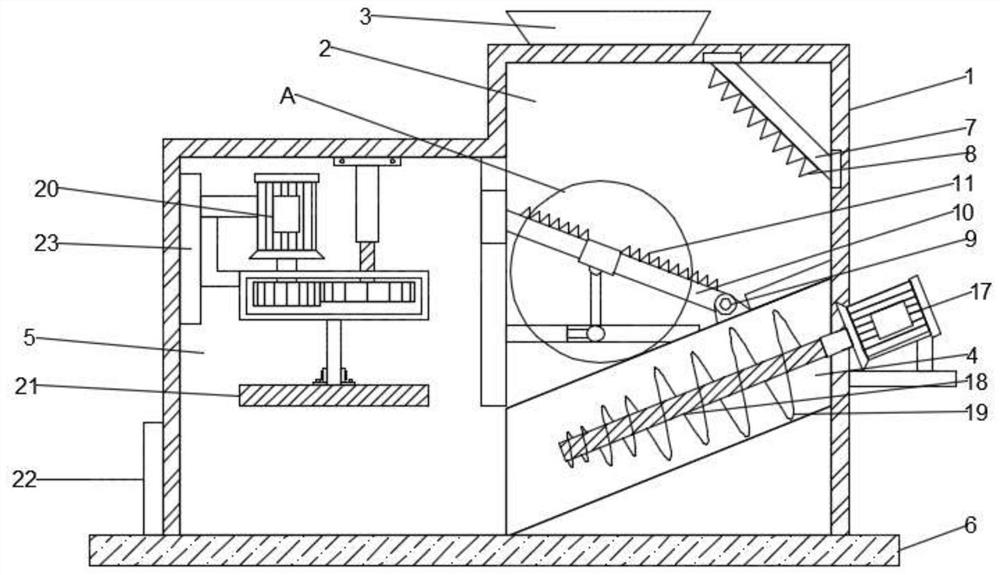

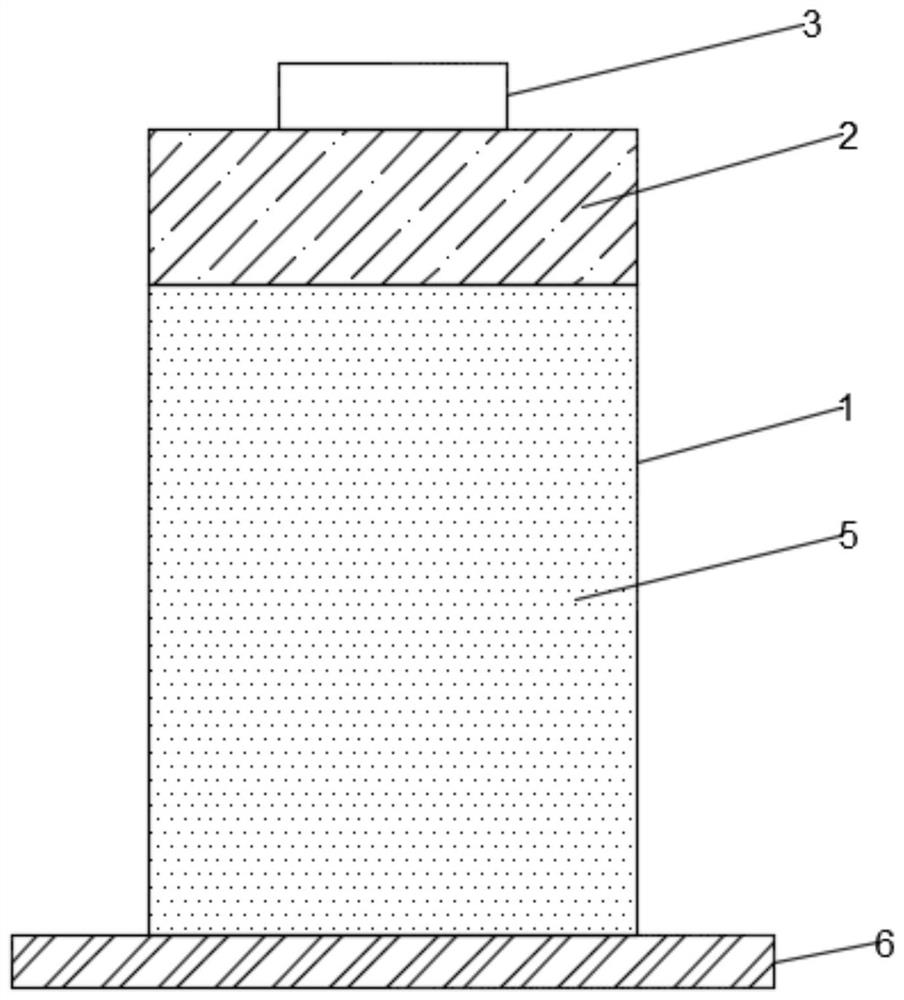

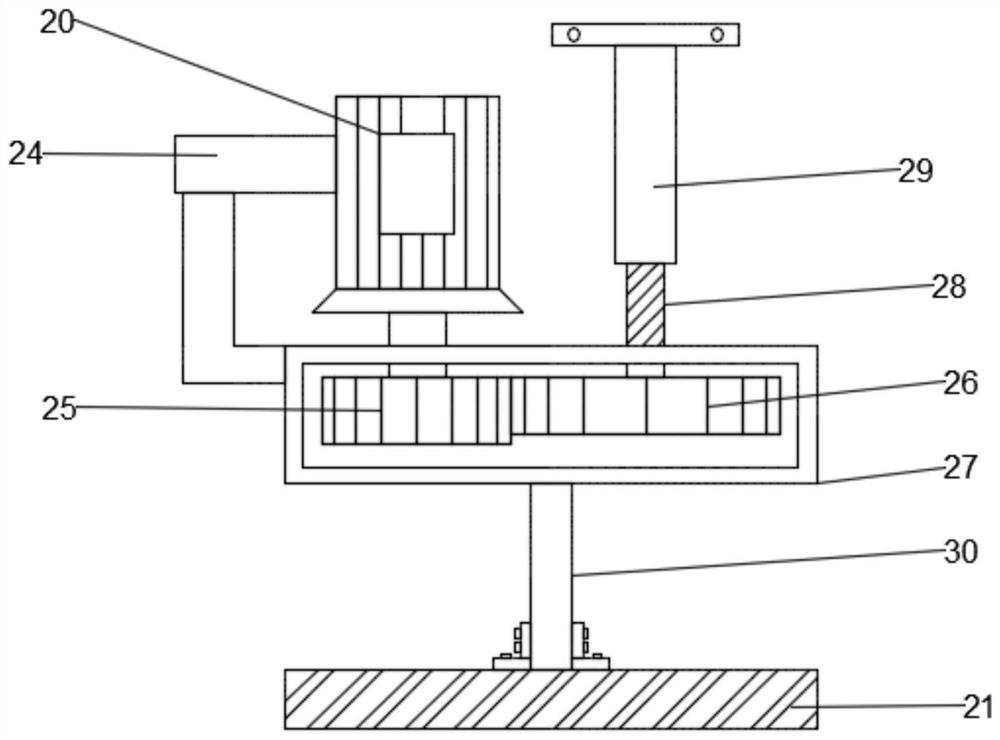

Contaminated soil remediation machine and contaminated soil remediation method

InactiveCN111842444AImplement pre-remediation processingImprove crushing effectContaminated soil reclamationGrain treatmentsSoil scienceSoil remediation

The invention relates to a contaminated soil remediation machine and a contaminated soil remediation method. The machine comprises a remediation box, a crushing box and a partition plate. A crushing chamber and a remediation chamber are defined by the upper surface and the lower surface of the partition plate and the inner wall of the remediation box correspondingly. The crushing box is arranged in the crushing chamber. Feed holes are formed in the top wall of the remediation box and the top wall of the crushing box. Discharge holes are formed in the bottom wall of the crushing box and the side wall of the partition plate. A multi-stage soil crushing assembly is arranged in the crushing box. A spraying chamber is defined between the outer wall of the crushing box and the inner wall of theremediation box, a plurality of spraying holes are evenly distributed in the side wall of the crushing box, and a primary spraying assembly for spraying a remediation agent to the spraying holes is arranged in the spraying chamber. A soil grinding assembly is arranged on the bottom wall of the partition plate, and a secondary spraying assembly for spraying the remediation agent to the soil grinding assembly is arranged on the bottom wall of the partition plate. A stirring assembly for stirring soil and the remediation agent is arranged in the remediation chamber. By crushing and grinding the soil for multiple times, the contact area of the remediation agent and the soil is increased, and the remediation effect is improved.

Owner:NANJING GIANDA ROAD & BRIDGE CONSTR +2

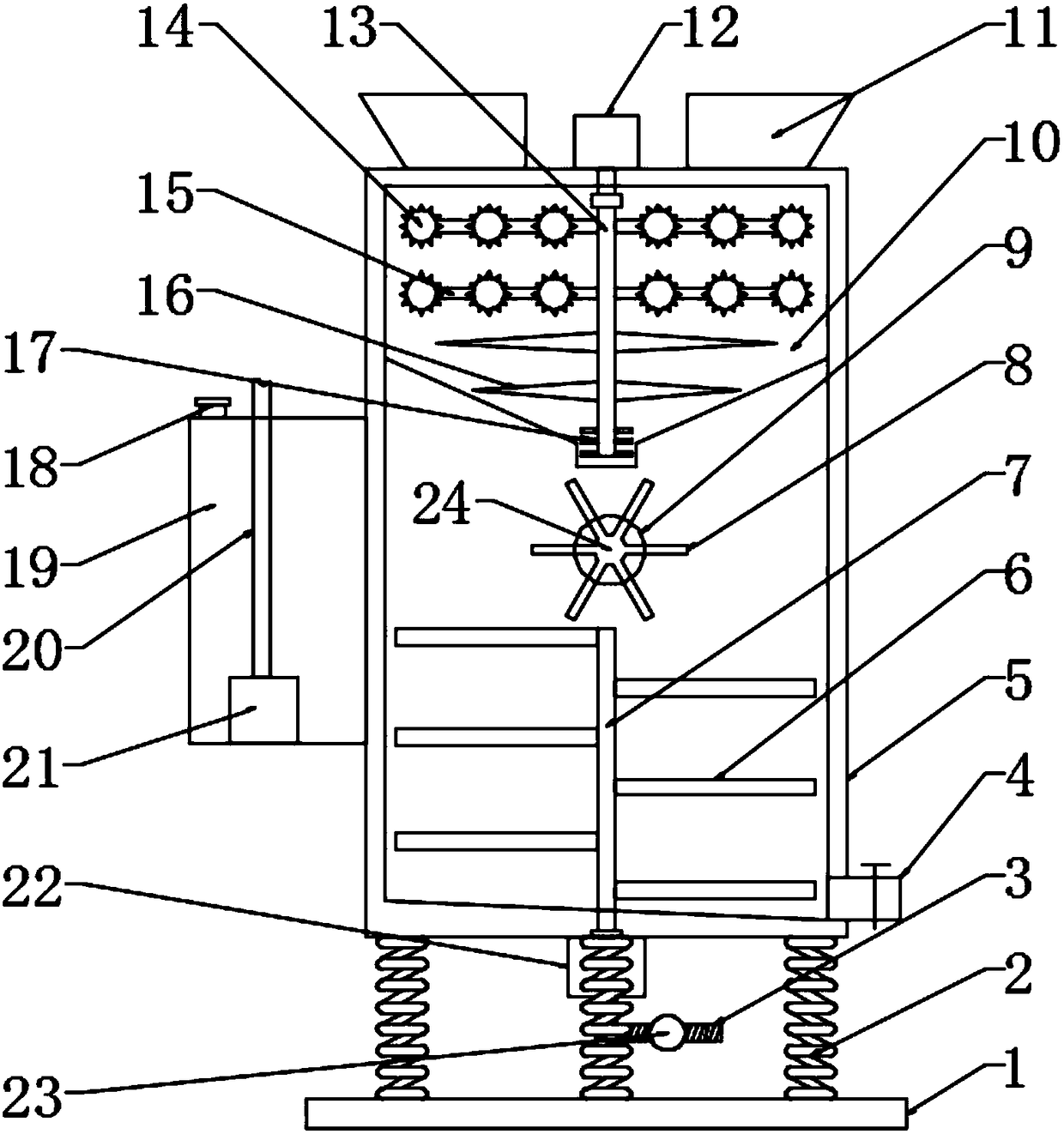

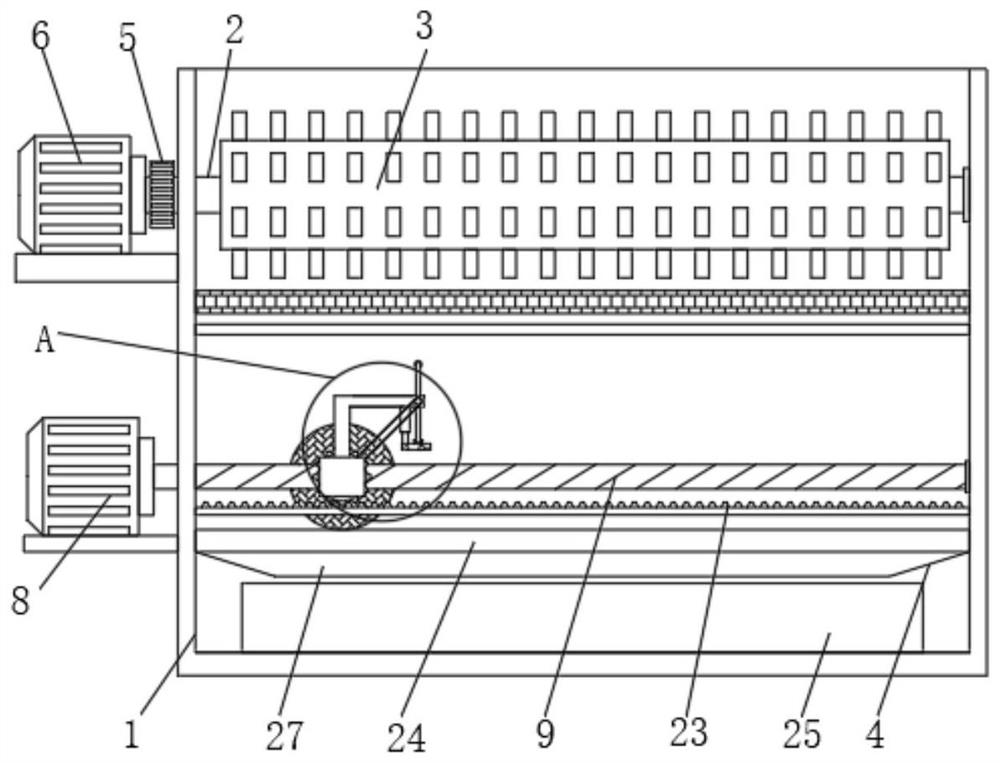

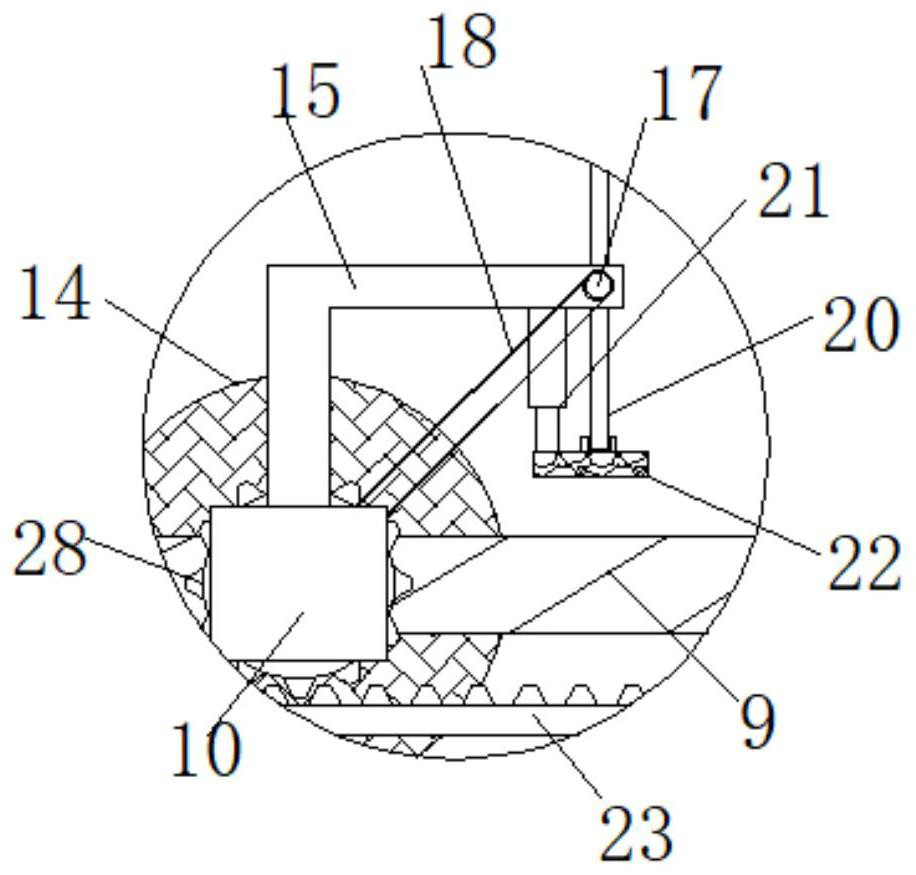

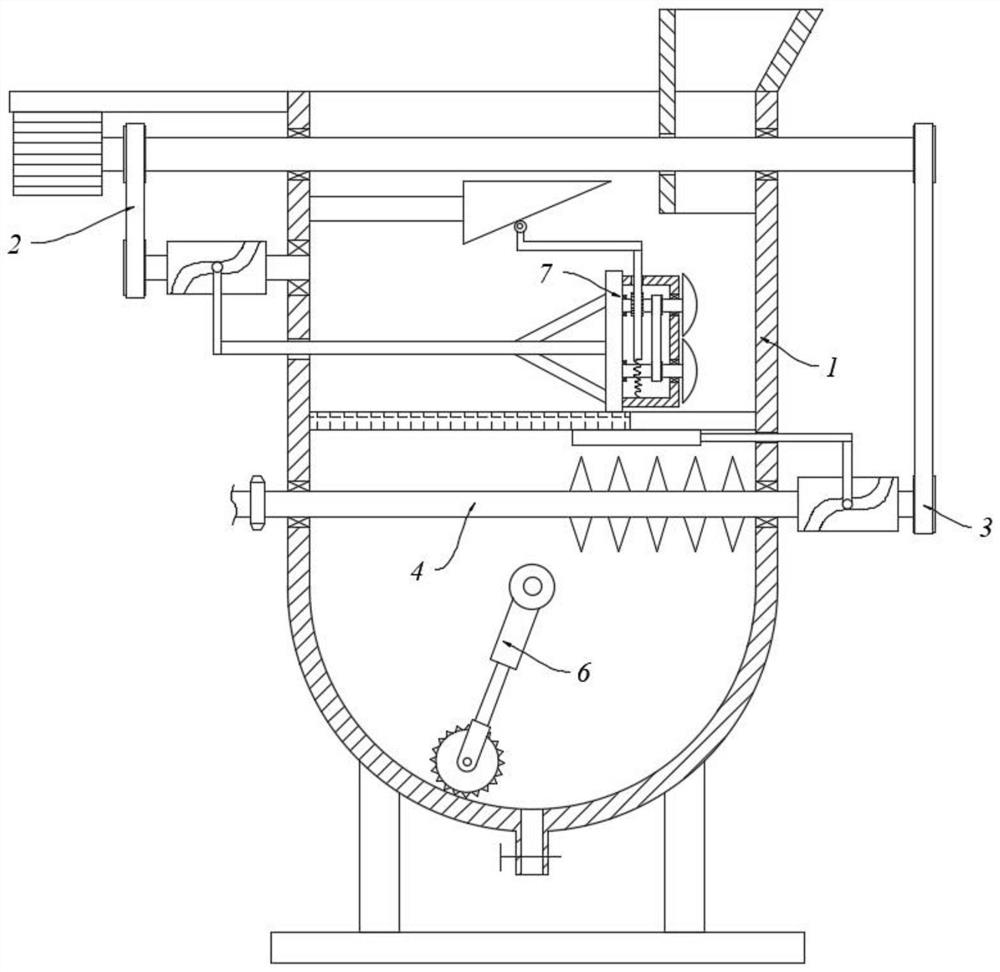

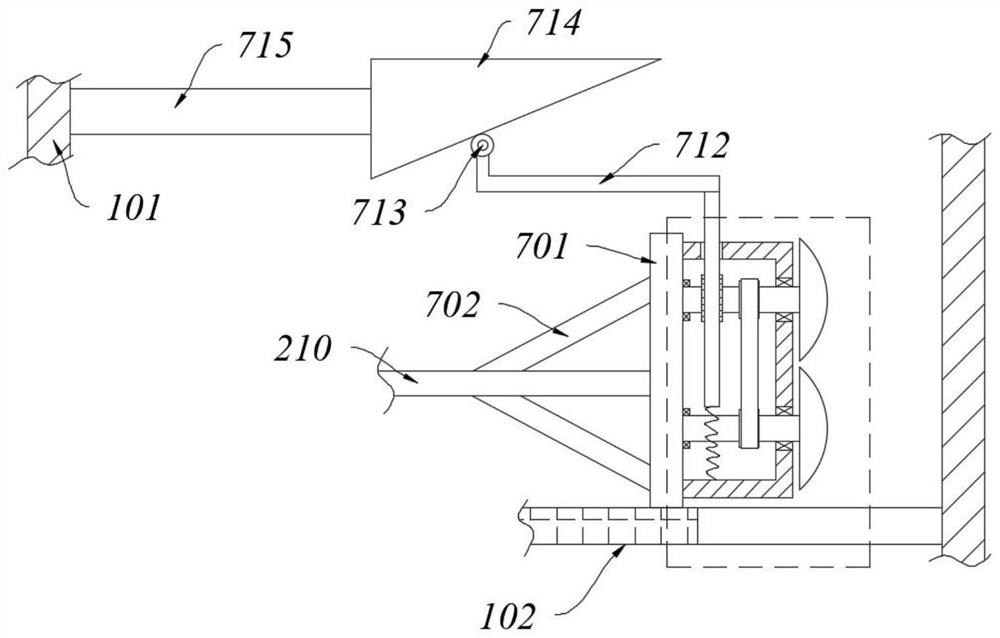

Swing type soil pollution repairing device

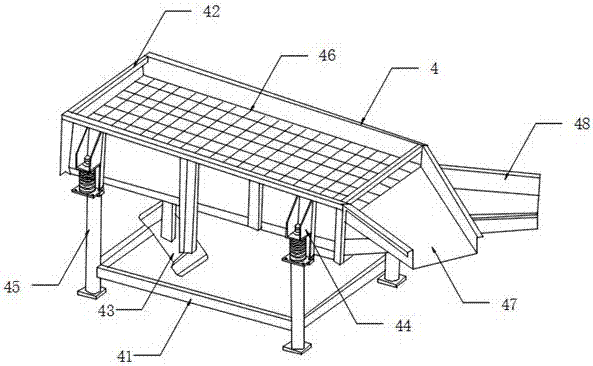

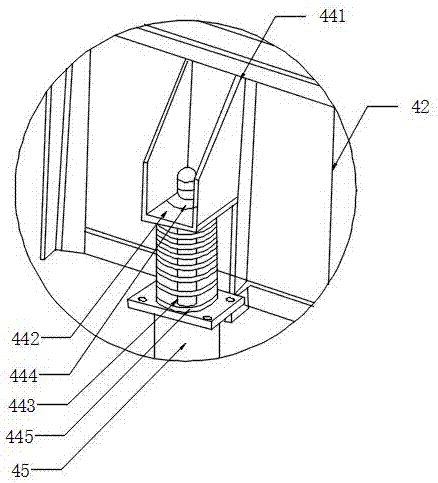

InactiveCN108188169AImprove repair efficiencyAdjust the amount of shakingContaminated soil reclamationGrain treatmentsSoil remediationEngineering

The invention discloses a swing type soil pollution repairing device. The swing type soil pollution repairing device comprises a bottom plate, a box body, a spring, a first motor, a first rotary shaft, a mounting rod, a crushing ball, a crushing blade, a soil transfer device, a second motor, a hollow shaft, a hollow fan plate, a double-shaft motor, a second rotary shaft, a stirring rod, a threadedrod, a counterweight ball, a soil repairing liquid box and a water pump. The soil transfer device comprises the second motor, the hollow shaft and the hollow fan plate. The device is further providedwith the first motor, the first rotary shaft, the mounting rod, the crushing ball and the crushing blade which are matched to achieve crushing in multiple stages, so that the device is high in crushing speed and high in efficiency. As the soil repair liquid box, the water pump and the soil transfer device are arranged, a soil repair liquid can be sprayed to falling soil fully, so that the soil repair efficiency is improved. As the double-shaft motor, the threaded rod, the counterweight ball and the spring are arranged and matched, soil in the box body swings continuously, so that the soil andthe soil repair liquid are fully mixed, and therefore, the soil repair efficiency is further improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

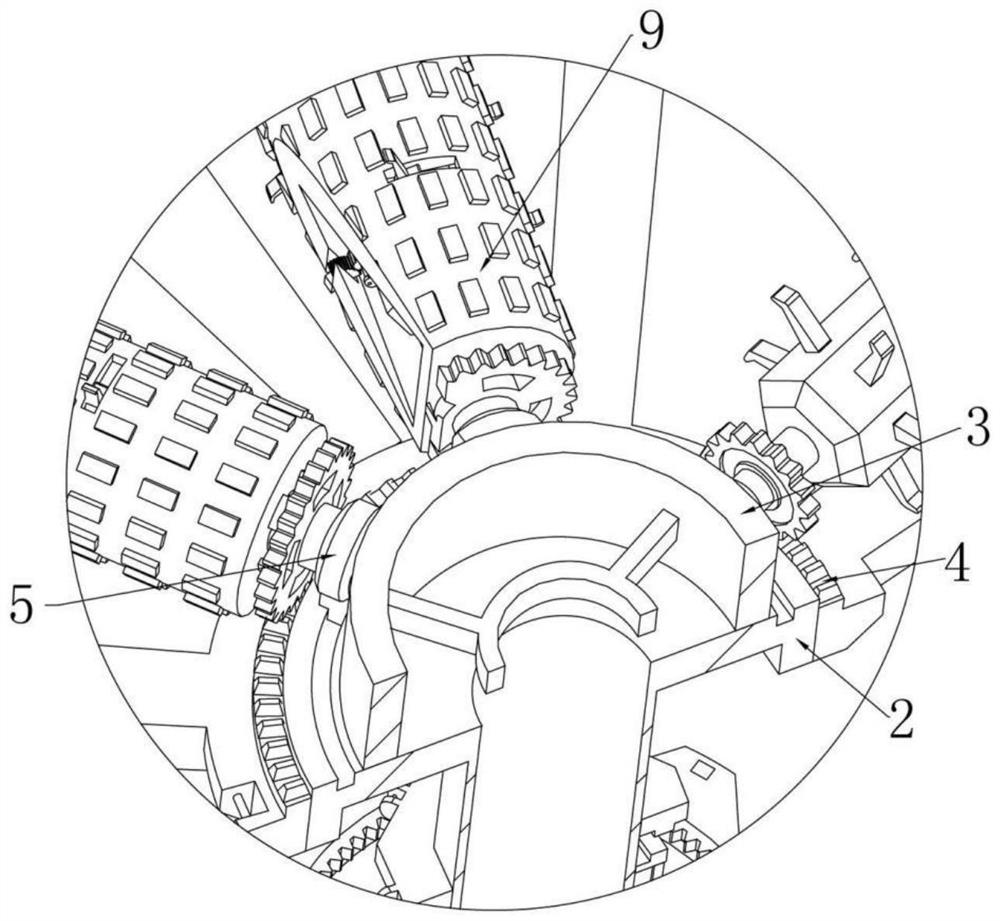

Composite manufacturing device for preparing recycled aggregate from construction waste and recycled aggregate preparation method

InactiveCN112691748AFacilitate subsequent processingHave a crushing effectGrain treatmentsAggregate (composite)Gear wheel

The invention relates to the technical field of construction waste regeneration, and discloses a method for preparing recycled aggregate from construction waste. A device comprises a shell, and further comprises two transverse rods which are respectively mounted between the left side wall and the right side wall of the interior of the shell and are arranged in parallel, crushing cutters are fixedly connected to the outer surfaces of the two transverse rods, and the left ends of the two transverse rods penetrate through and extend to the outer side of the shell and are fixedly connected with transmission gears, and the two transmission gears are meshed with each other; and the outer surface of the shell is fixedly connected with a first motor, and the output end of the first motor is fixedly connected with the left end of the transverse rod on the outer side. According to the manufacturing device for preparing the recycled aggregate from the construction waste, the waste is firstly crushed through the crushing cutters, then crushed through grinding of a grinding wheel and impacted by an impacting plate, the waste can be comprehensively crushed, aggregate particles are uniform, the particle size of the particles is small, the working requirement is met, repeated crushing is not needed, the working efficiency is high, and the working quality is good.

Owner:夏雪娟

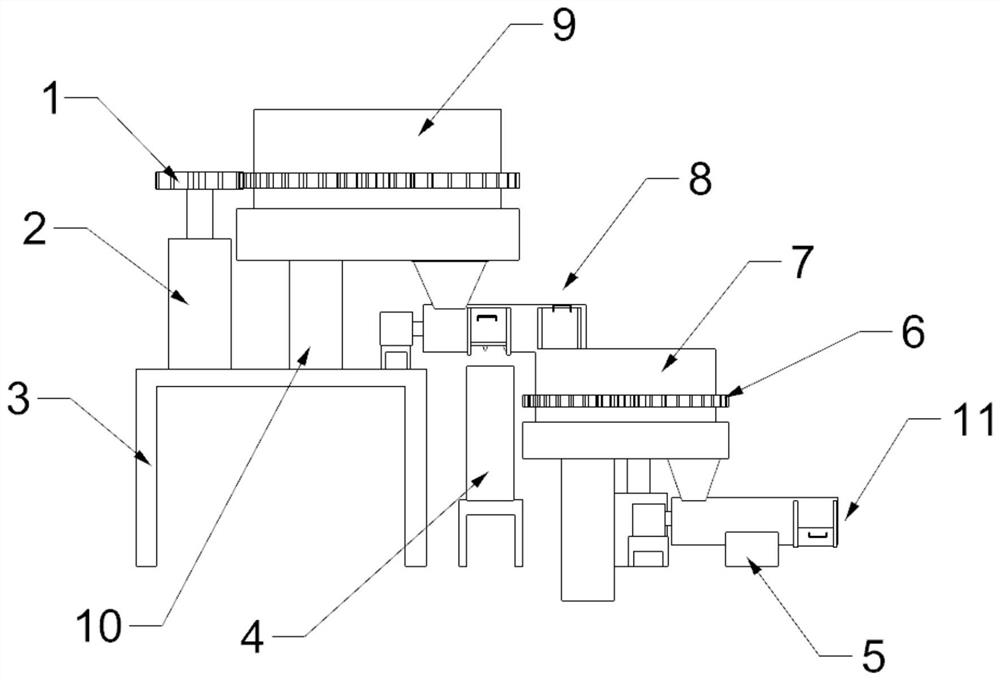

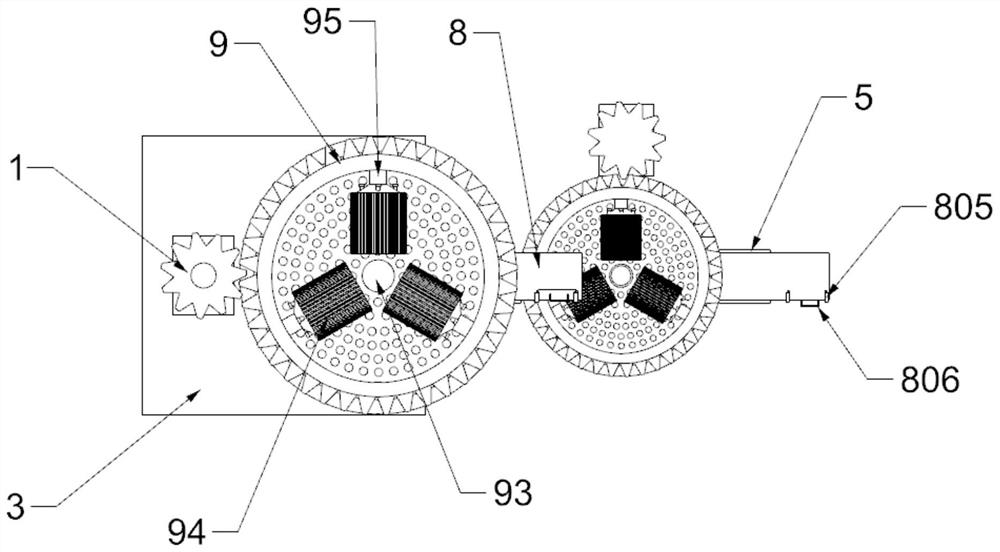

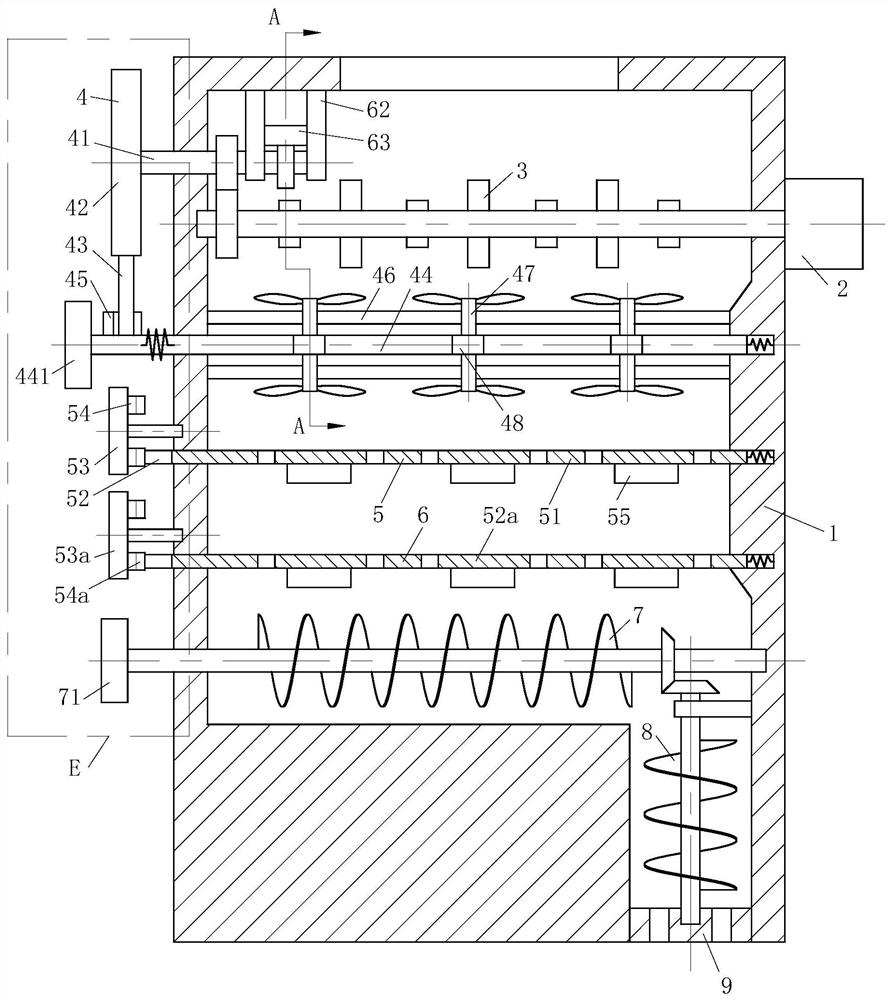

Urban solid waste disposal system

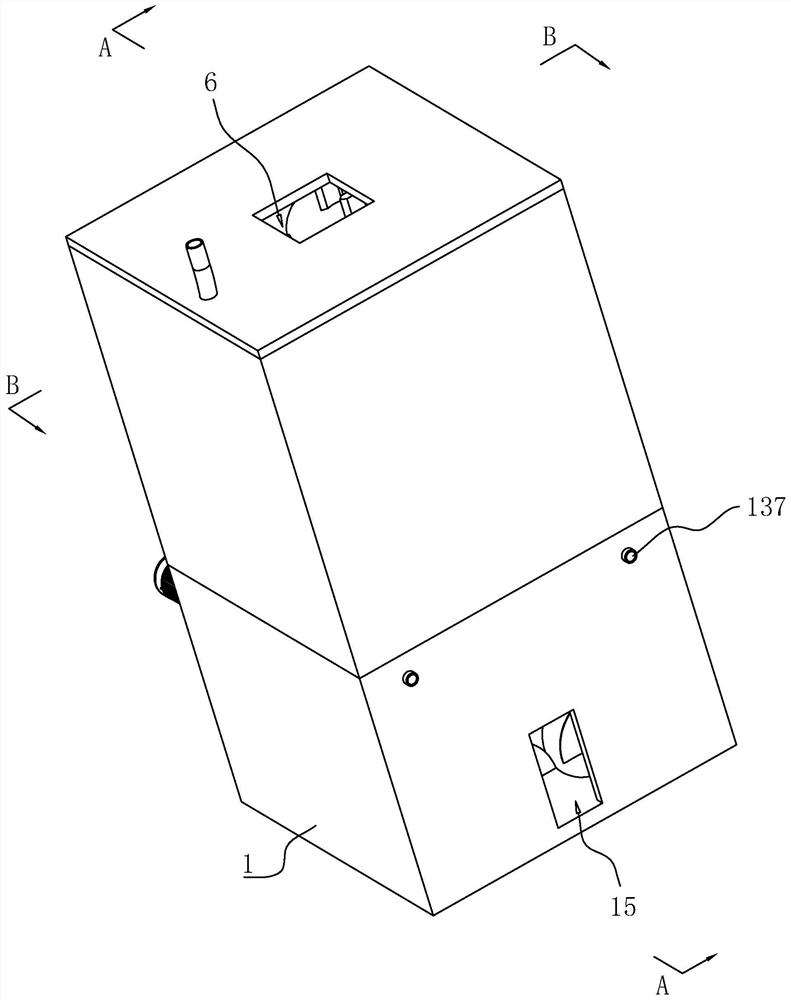

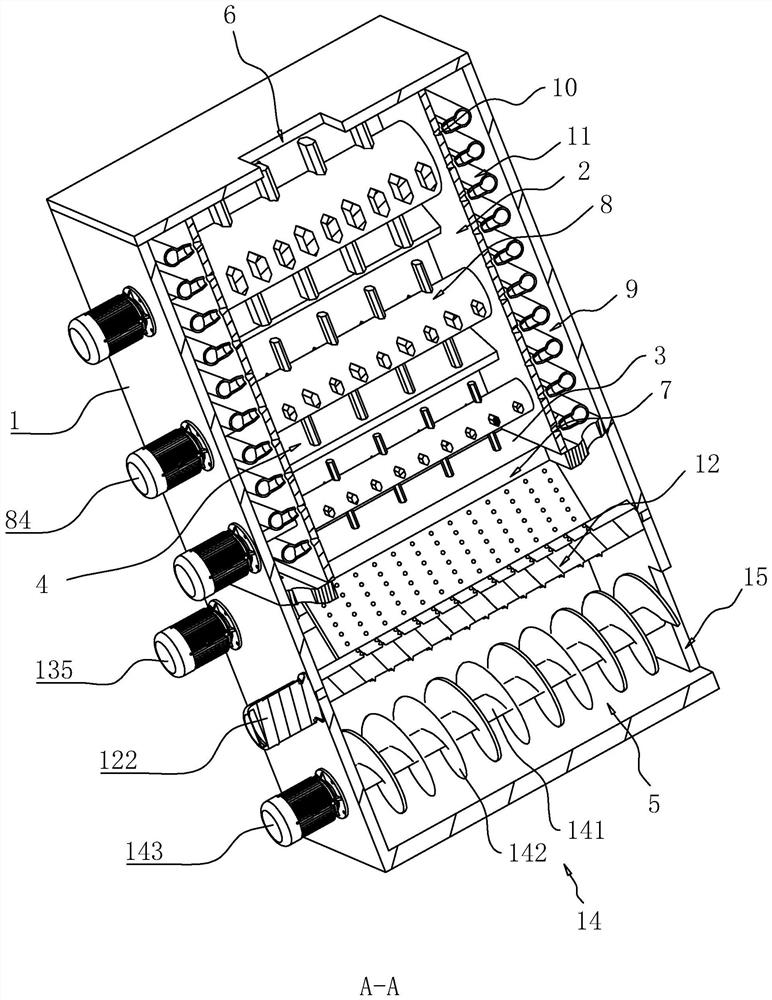

ActiveCN109092525ARealize multi-stage crushingImprove crushing efficiencyGrain treatmentsDrive shaftWaste treatment technologies

The invention belongs to the technical field of waste disposal, and particularly relates to an urban solid waste disposal system which comprises a box body, a motor, a crushing roller, a breaking module, a first vibration module, a second vibration module, a spiral feeding shaft, a spiral extrusion roller and a filter net; the crushing roller is rotatably installed on the upper portion of the interior of the box body; the breaking module comprises a driving shaft, a rotary disc, a guide column, a rack, a first inclined block, a fixing rod, a breaking cutter shaft, a driving gear, and breakingcutters; and the driving shaft is transmitted with the crushing roller through gear engagement, the rotary disc is fixedly connected to one end of the driving shaft, the outer circle of the rotary disc is fixedly connected with the guide column, the guide column is used for squeezing the first inclined block arranged on the end head of the rack, the middle of the breaking cutter shaft is fixedly connected with the driving gear, the driving gear is engaged with the rack, and the two ends of the breaking cutter shaft are correspondingly provided with the breaking cutters. According to the urbansolid waste disposal system, power of the breaking roller by the rack and the driving gear, a power source drive is used for achieving multi-stage breaking of solid waste, the breaking efficiency is improved, and energy can be saved.

Owner:国合绿材科技(江苏)有限公司

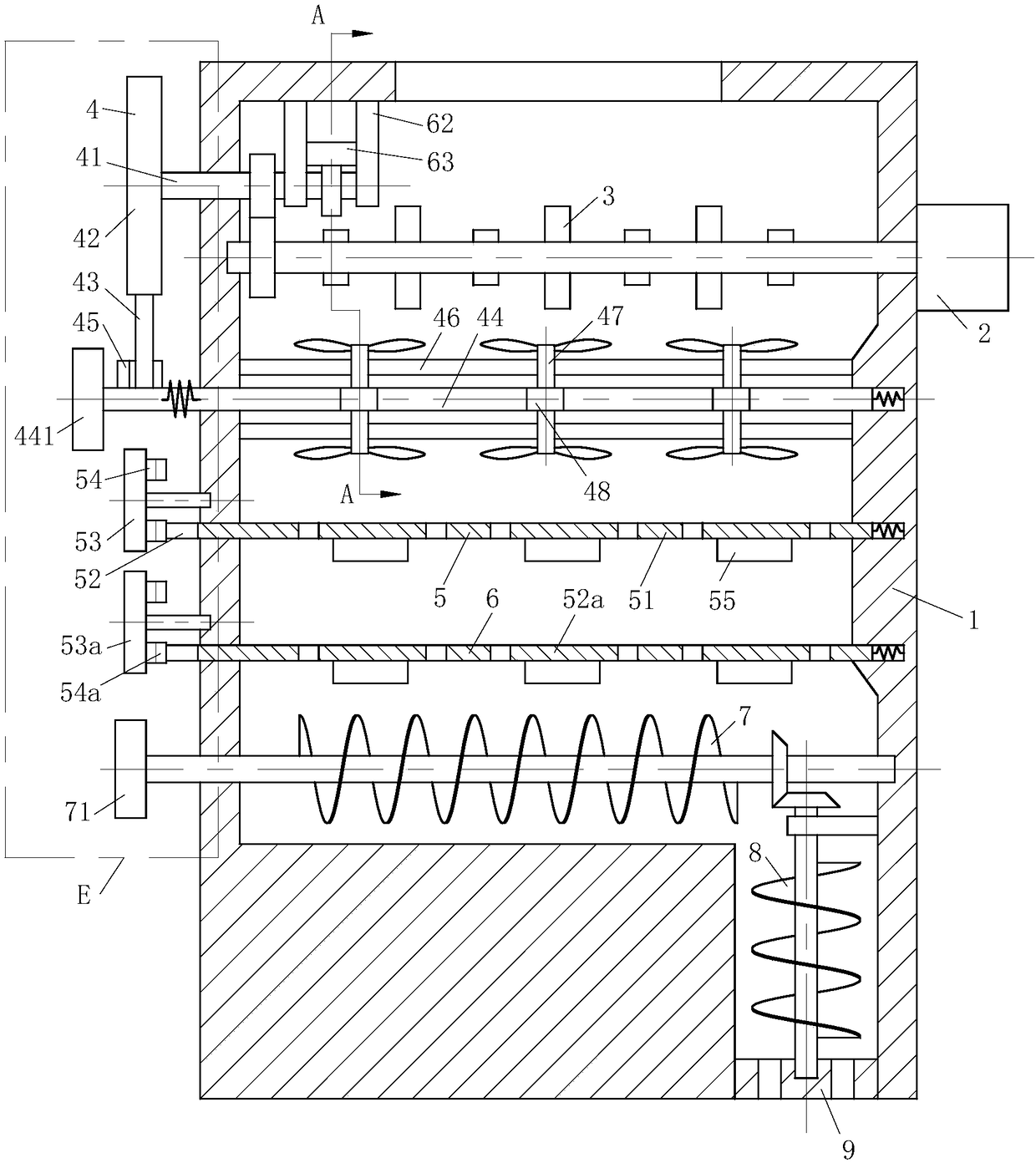

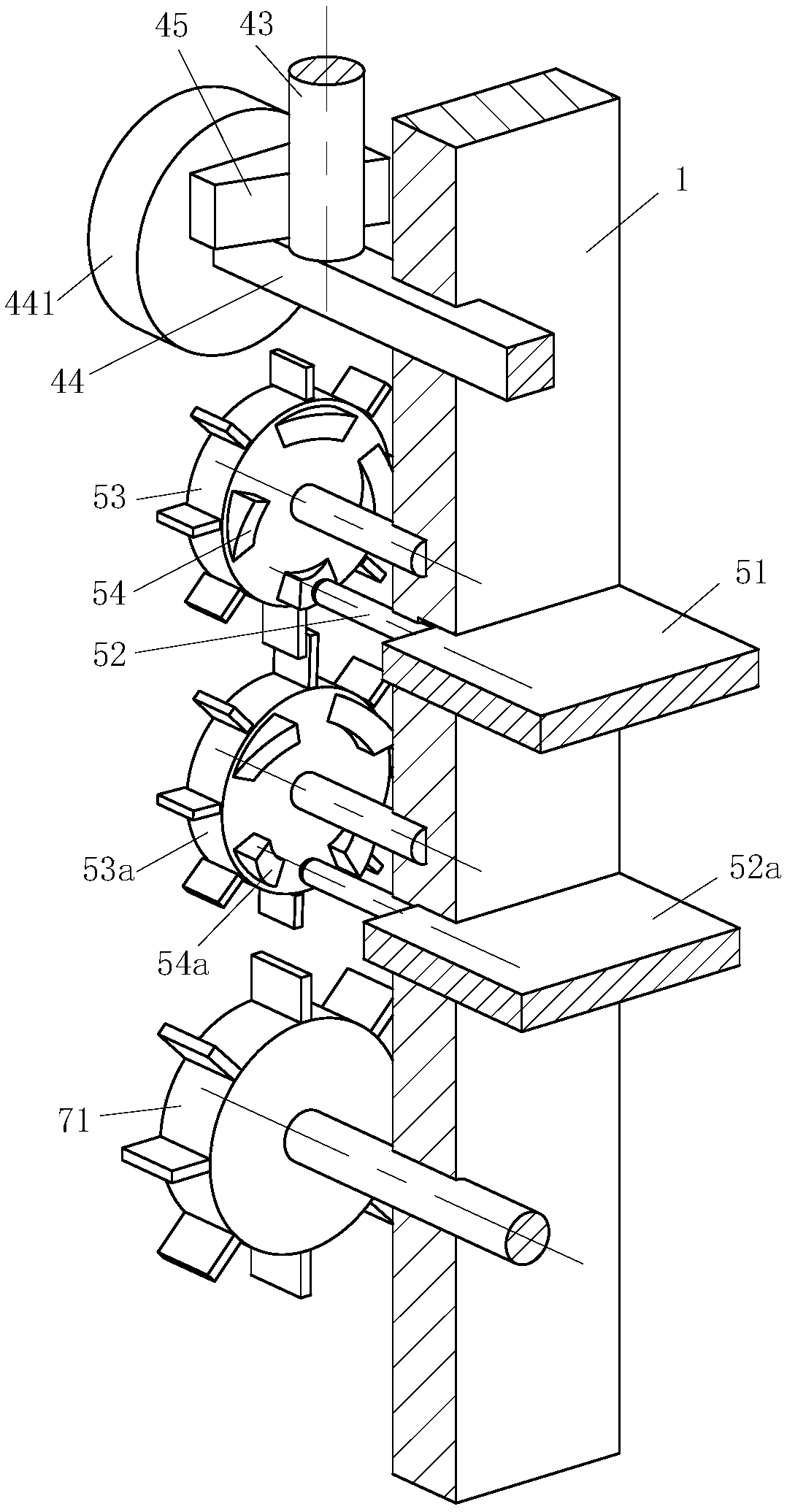

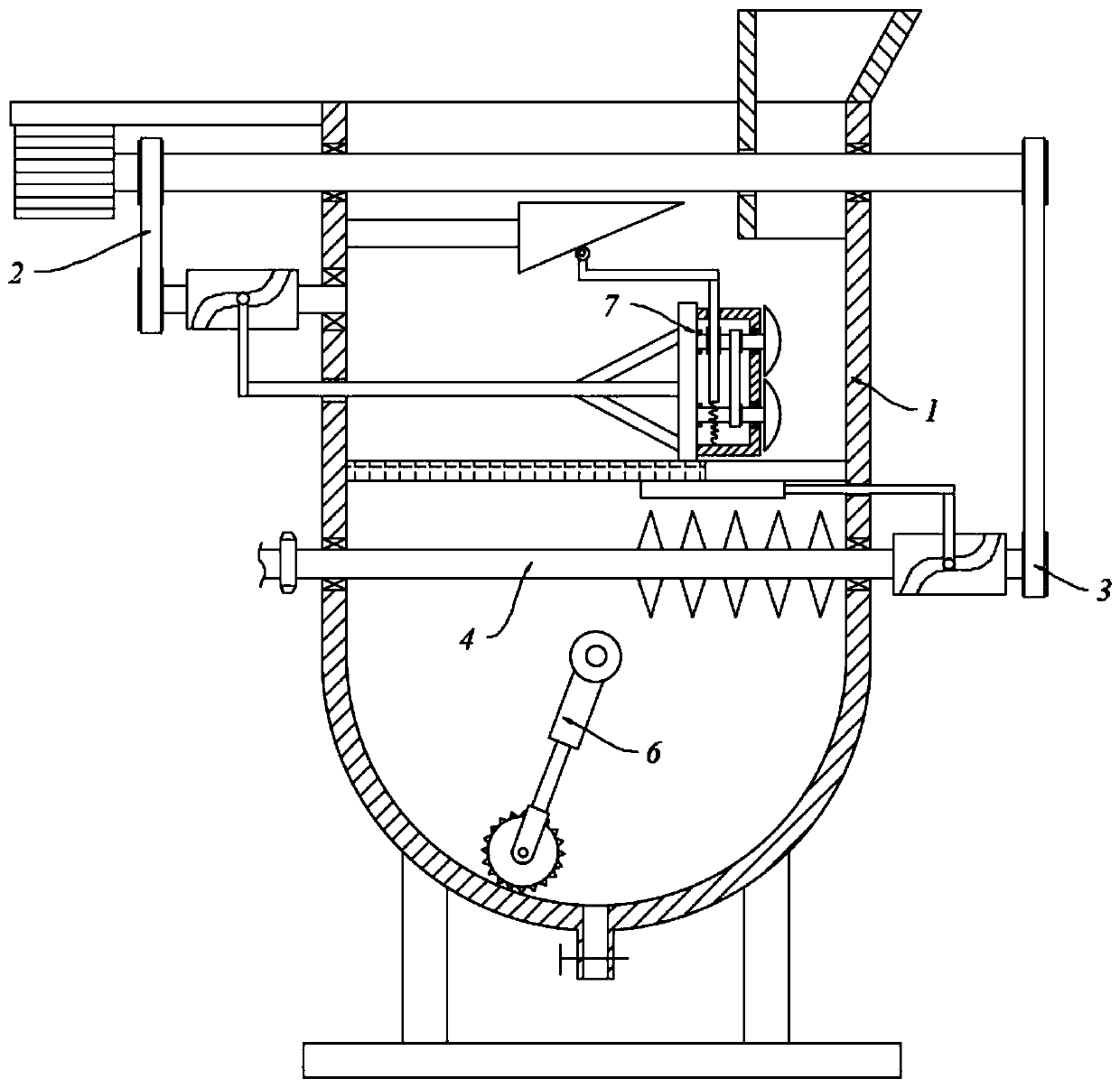

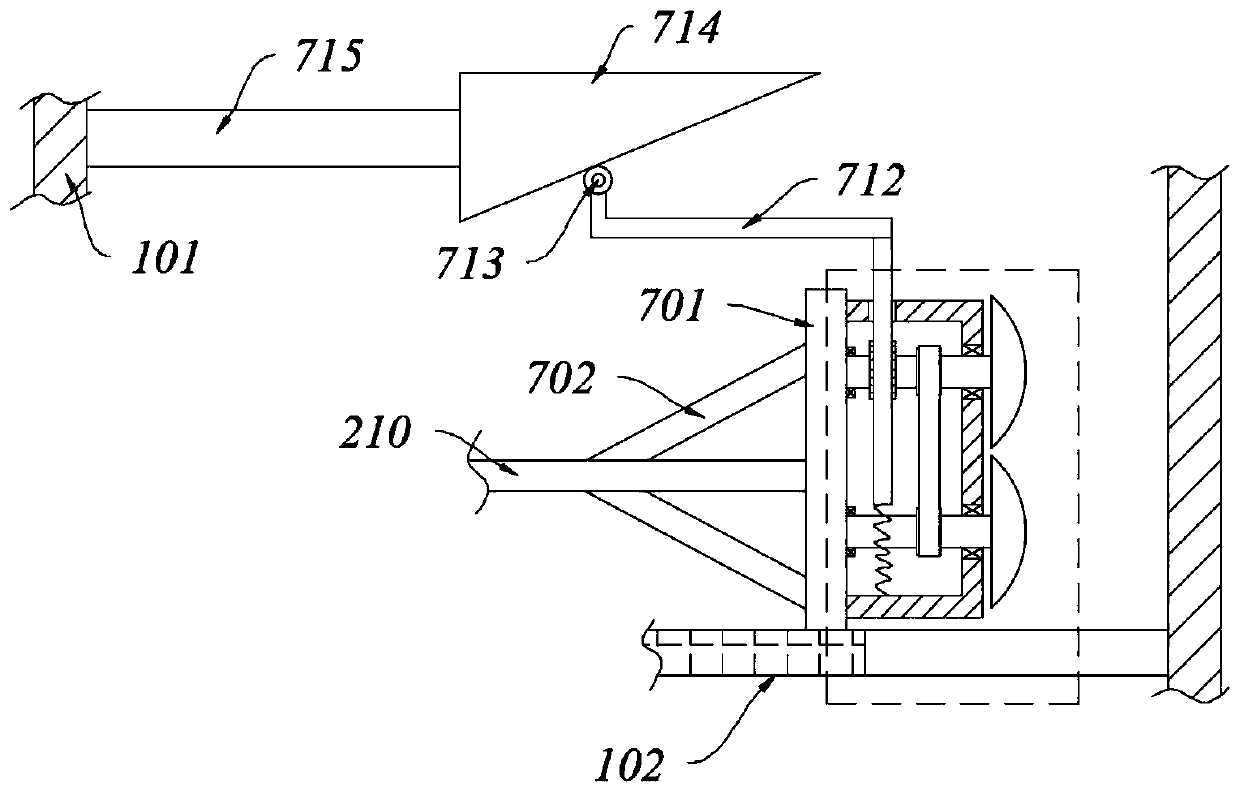

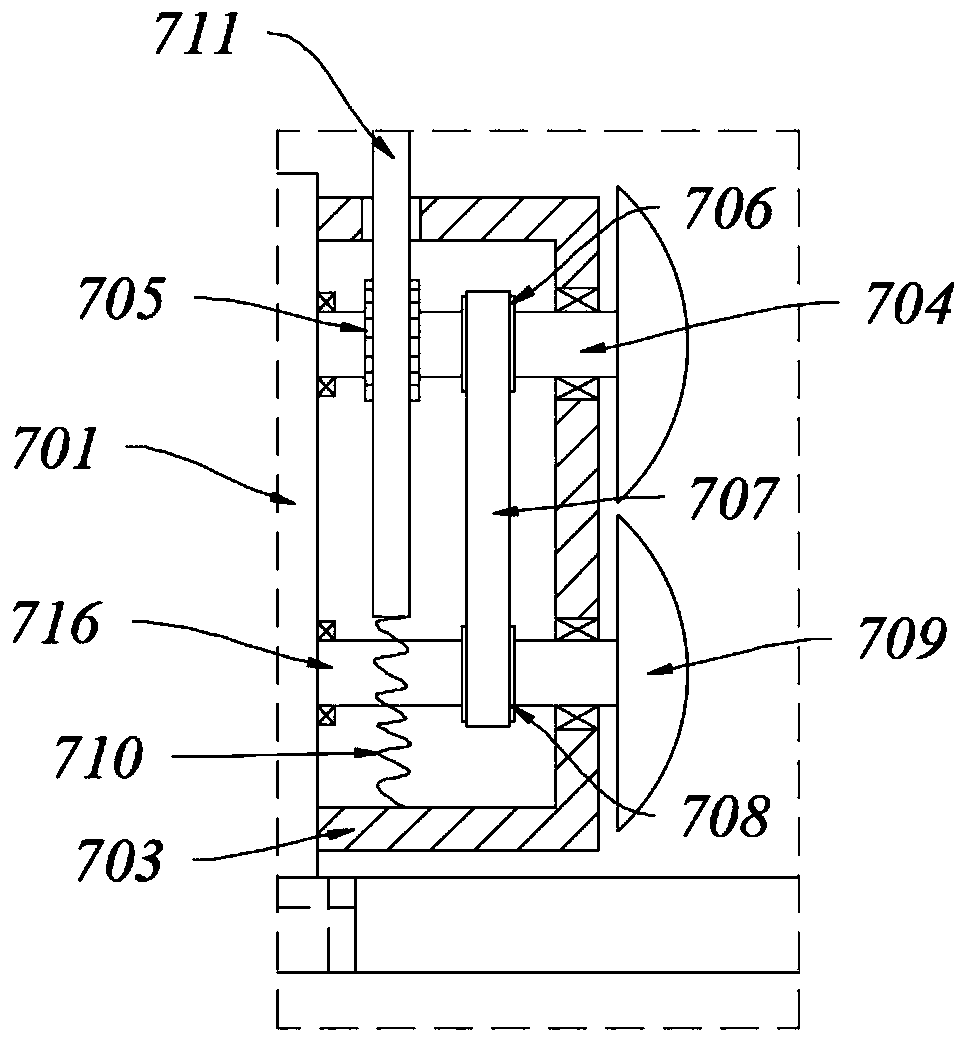

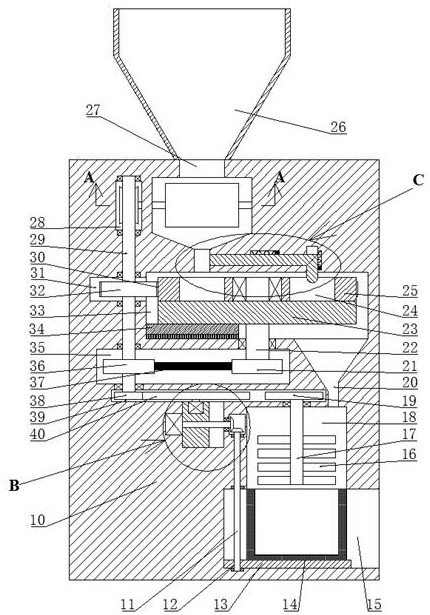

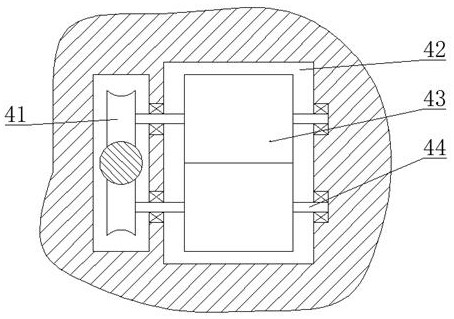

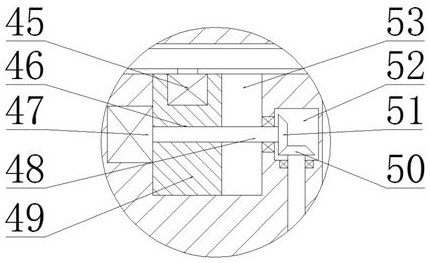

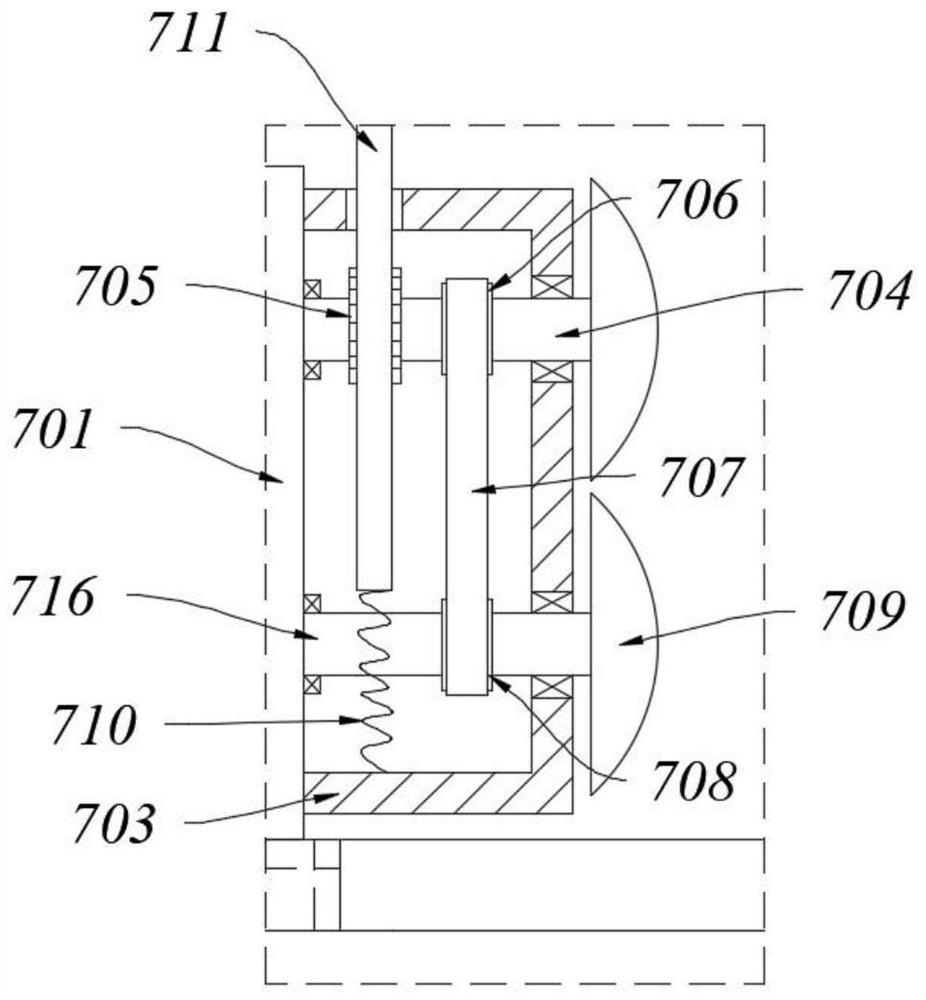

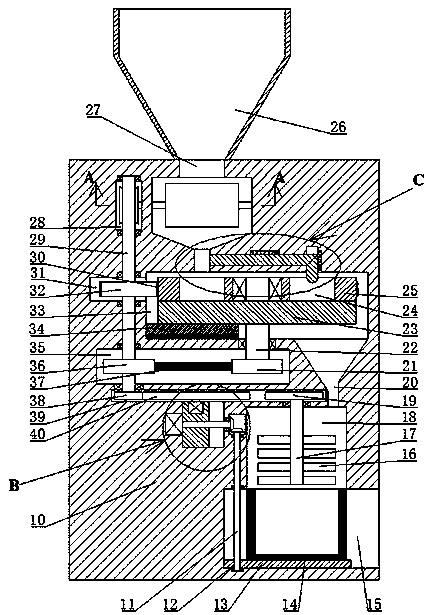

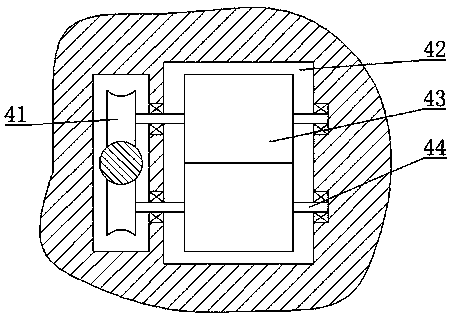

High-efficiency crushing device for refractory materials

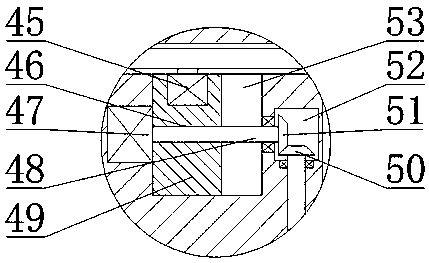

The invention relates to the technical field of refractory material crushing equipment, in particular to a high-efficiency crushing device for refractory materials. The device is based on a servo motor as a power source, and a reciprocating assembly based on a cylindrical cam cooperates with a plugging assembly, so that the materials are subjected to primary crushing through a first crushing assembly; through the transmission of the plugging assembly, the materials are subjected to secondary crushing through a secondary crushing assembly; a transmission assembly is used as the power input of athird crushing assembly to make a balance wheel drive a crushing roller to swing, and the materials are further crushed; the three treatment steps are sequentially matched to achieve multi-stage crushing, so that the crushing effect on the materials is improved. The first crushing assembly rolls along the bottom surface of a fixed wedge block through a third roll and produces a displacement in the vertical direction, so that a vertical rack moves up and down and acts on a driving gear, an upper rotating shaft rotates, a lower rotating shaft is driven through transmission to rotate together, arotating head at the right end thus rotates, and up and down grinding functions are achieved in the crushing process.

Owner:ANLI REFRACTORY MATERIAL ANSHAN CITY

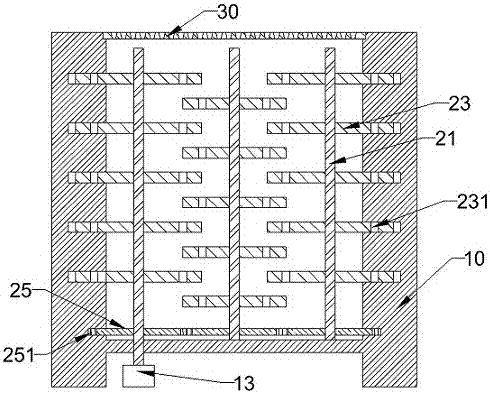

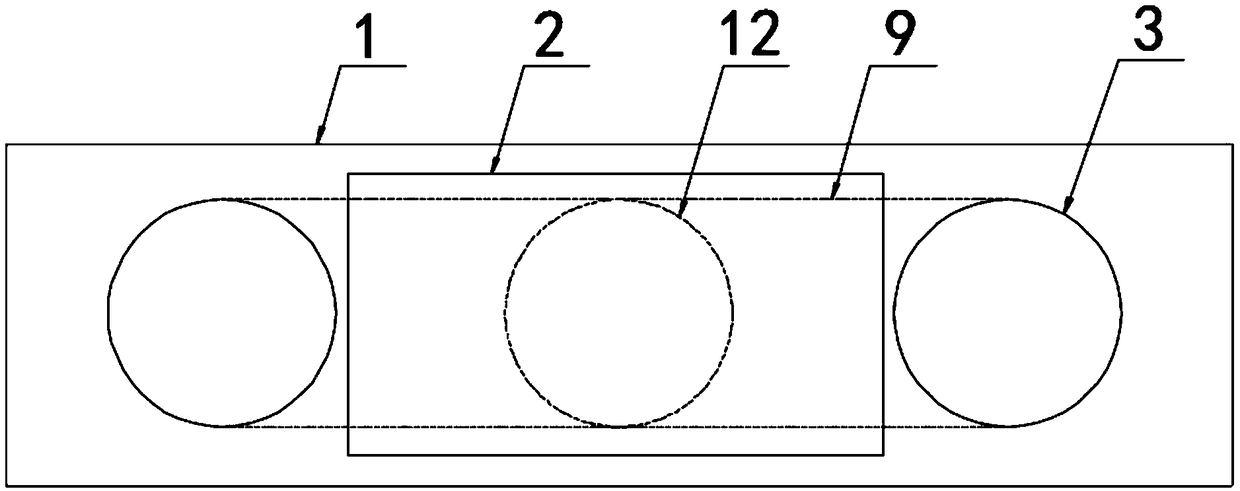

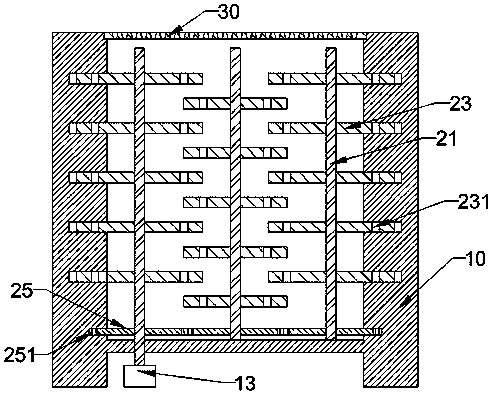

Multistage grain crushing device

The invention relates to the field of wine brewing equipment, solves the problem that a traditional grain crusher cannot fully crush grains, and provides a multistage grain crushing device. The multistage grain crushing device comprises a shell; a feed port is formed in the upper end of the shell; a crushing cavity is formed in the shell; a crushing mechanism is arranged in the crushing cavity; a screen is arranged at the upper part of the crushing cavity; the crushing mechanism comprises multiple rotating shafts vertically arranged; single rotating shaft is axially provided with blades for grain crushing at intervals; the blades are provided with through holes for enabling the grains to pass through; the through holes in the multiple blades are arranged oppositely; the apertures of the through holes are reduced along with reduction of the heights on the rotating shafts; the blades on two adjacent rotating shafts are staggered, and the through holes in the previous layer of blades are positioned rightly above the blade edges of the next layer of blades; the blade edges of the previous layer of blades are positioned rightly above the through holes in the next layer of blades; the blades in the highest place are positioned below the screen; and the crushing mechanism can generate upward air currents.

Owner:ZUNYI JINHONG METAL EQUIP

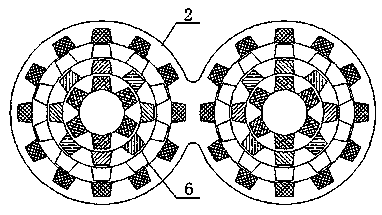

Multistage chopping and grinding machine

ActiveCN108993698AGood chopping effectReduce vibration and noiseLarge containersGrain treatmentsKnife bladesEngineering

The invention discloses a multistage chopping and grinding machine which comprises a box body, wherein a transparent top cover and feeding holes are formed on the top of the box body; the feeding holes are formed in two sides of the transparent top cover; a control cavity is formed inside the box body corresponding to the bottom of the transparent top cover; an upper gear, a middle gear and a lower gear are arranged inside the control cavity; rotating shafts are arranged on two sides of the upper gear, the middle gear and the lower gear; a chopping pipeline is arranged inside the box body corresponding to the bottom of the feeding holes; blades are arranged inside the chopping pipeline; the rotating shafts penetrate through the outer walls of the chopping pipeline to extend into the chopping pipeline so as to be fixedly connected with the blades. According to the multistage chopping and grinding machine disclosed by the invention, the diameter of the upper gear is larger than the diameter of the middle gear, and the diameter of the middle gear is larger than the diameter of the lower gear, so that the rotating speeds of the blades arranged from top to bottom can be gradually increased so as to realize multistage chopping, the materials are finely chopped, the chopping effect is excellent, the grinding workload is reduced, the chopped materials enter the grinding pipeline to beground via a conical bulge on the outer part of the grinding roller, and the materials are finely processed.

Owner:福建天源兴达生物科技有限公司

Macadam processing equipment for bridge engineering construction

ActiveCN108570906AAchieve brokenRealize extrusion crushingRoads maintainenceBridge engineeringCrushed stone

The invention discloses macadam processing equipment for bridge engineering construction. The macadam processing equipment comprises a shell, a crushing chamber, an extrusion conveying chamber and a rolling chamber, wherein the crushing chamber is arranged at the upper right side of the shell, a feeding inlet is arranged at the left side of the top of the crushing chamber, and the crushing chamberis in communication with the feeding inlet; the extrusion conveying chamber is obliquely located at the bottom of the right side of the shell, the right side of the top of the extrusion conveying chamber is in communication with the right side at the bottom of the crushing chamber, the rolling chamber is located on the left side of the bottom of the shell, the left side of the extrusion conveyingchamber is in communication with the rolling chamber, and a second working motor is located on the top of the rolling chamber; a first connecting rod is welded on the left side of the second workingmotor, a vertical guide rail is fixedly welded at the upper part of the left side wall of the rolling chamber, and the left end of the first connecting rod extends into the vertical guide rail. The macadam processing equipment has high working efficiency, saves time and labor, and can carry out multi-stage pulverization on stones and lower the difficulty of crushing stones.

Owner:天长市富春建筑工程有限公司

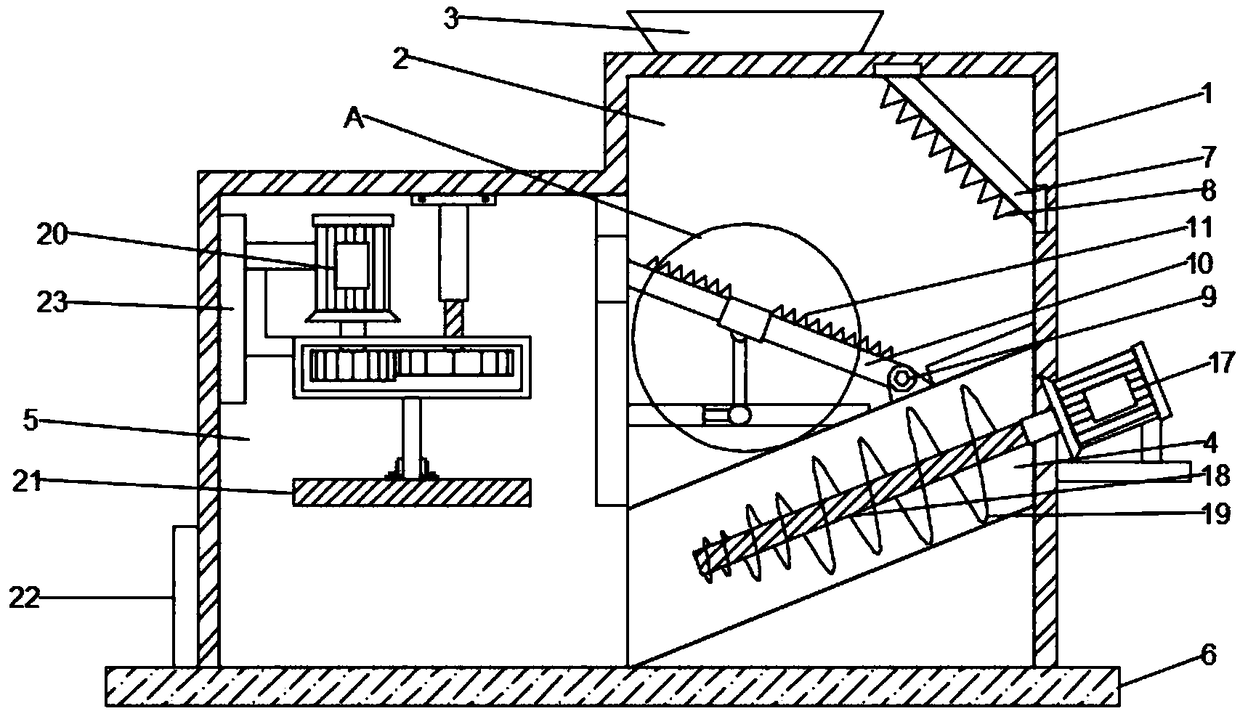

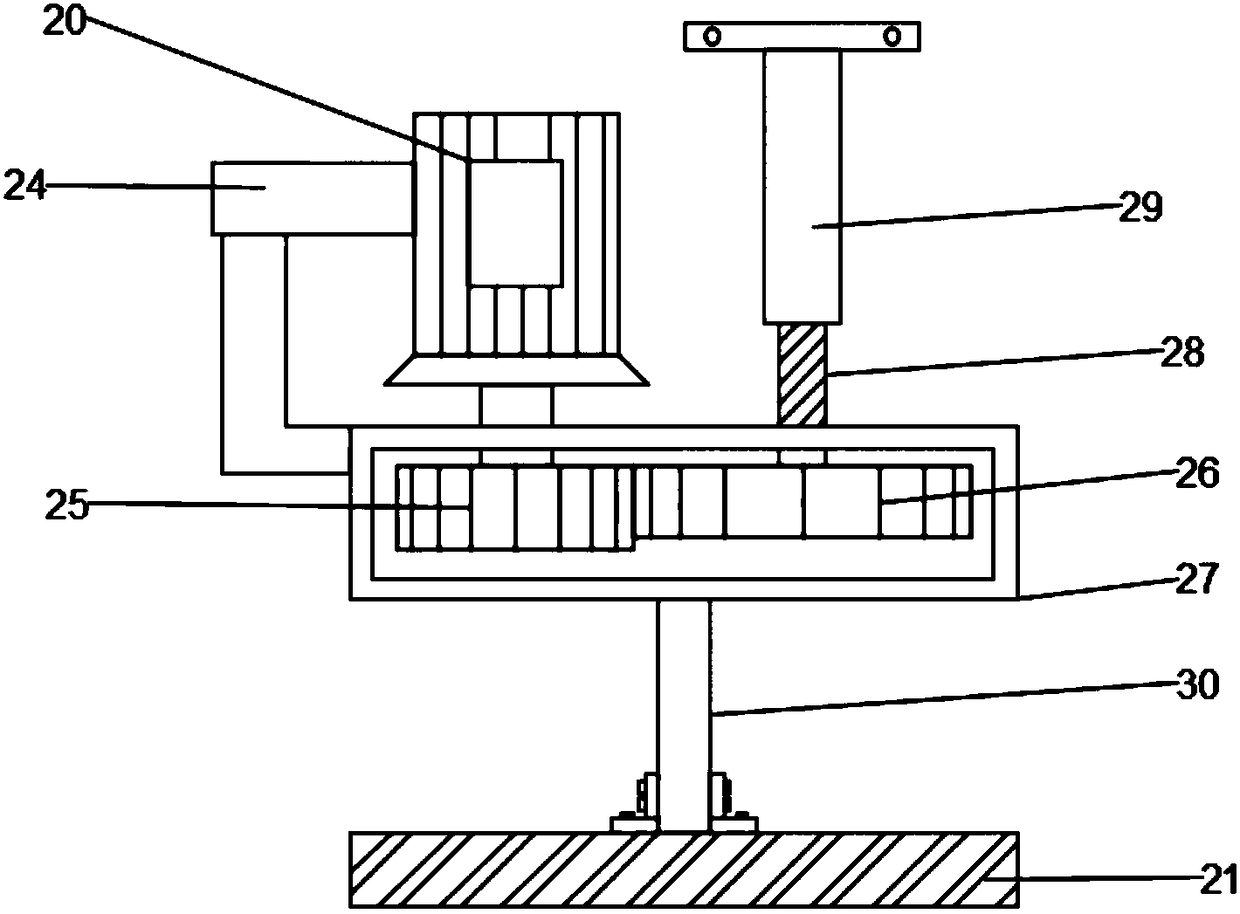

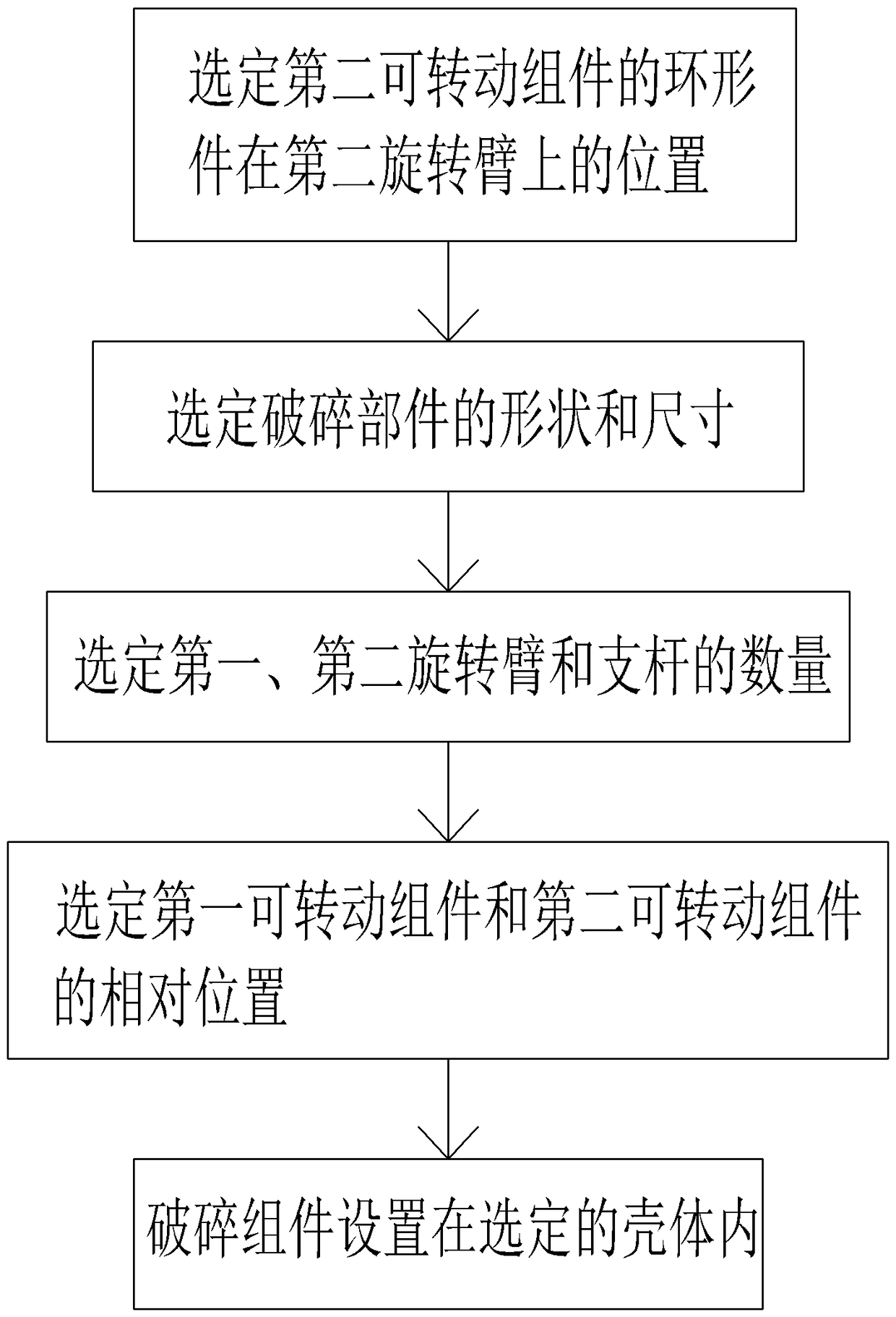

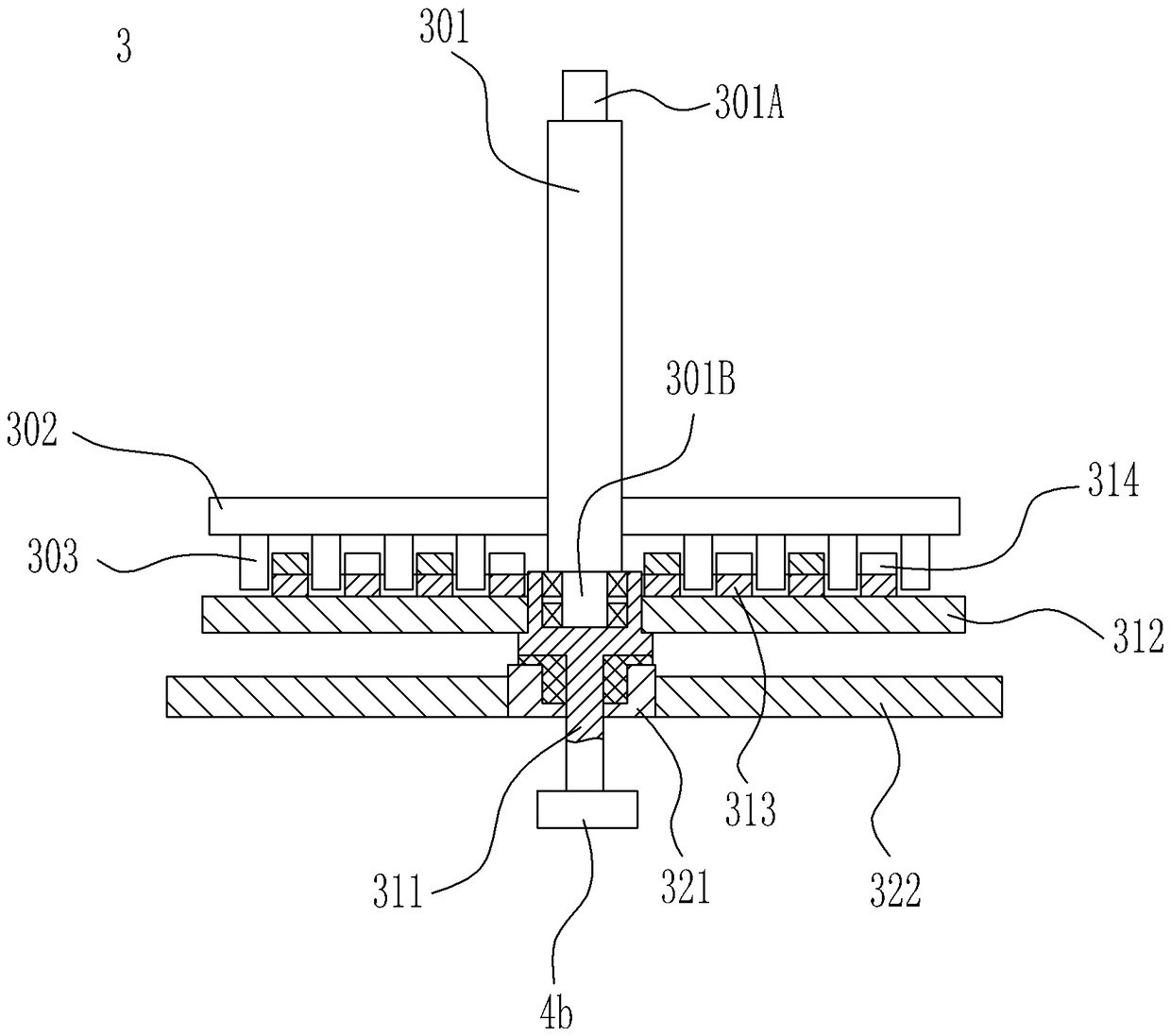

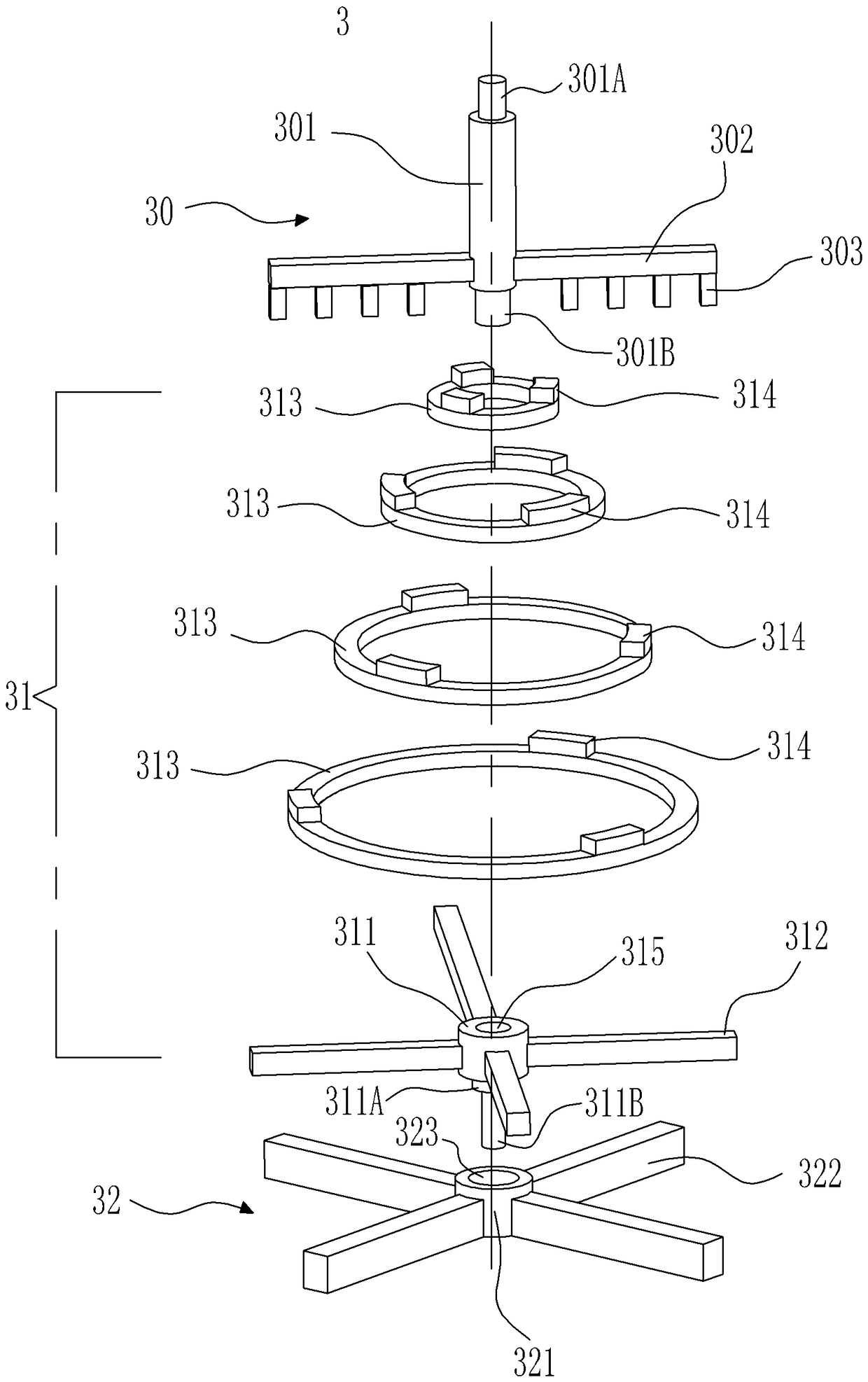

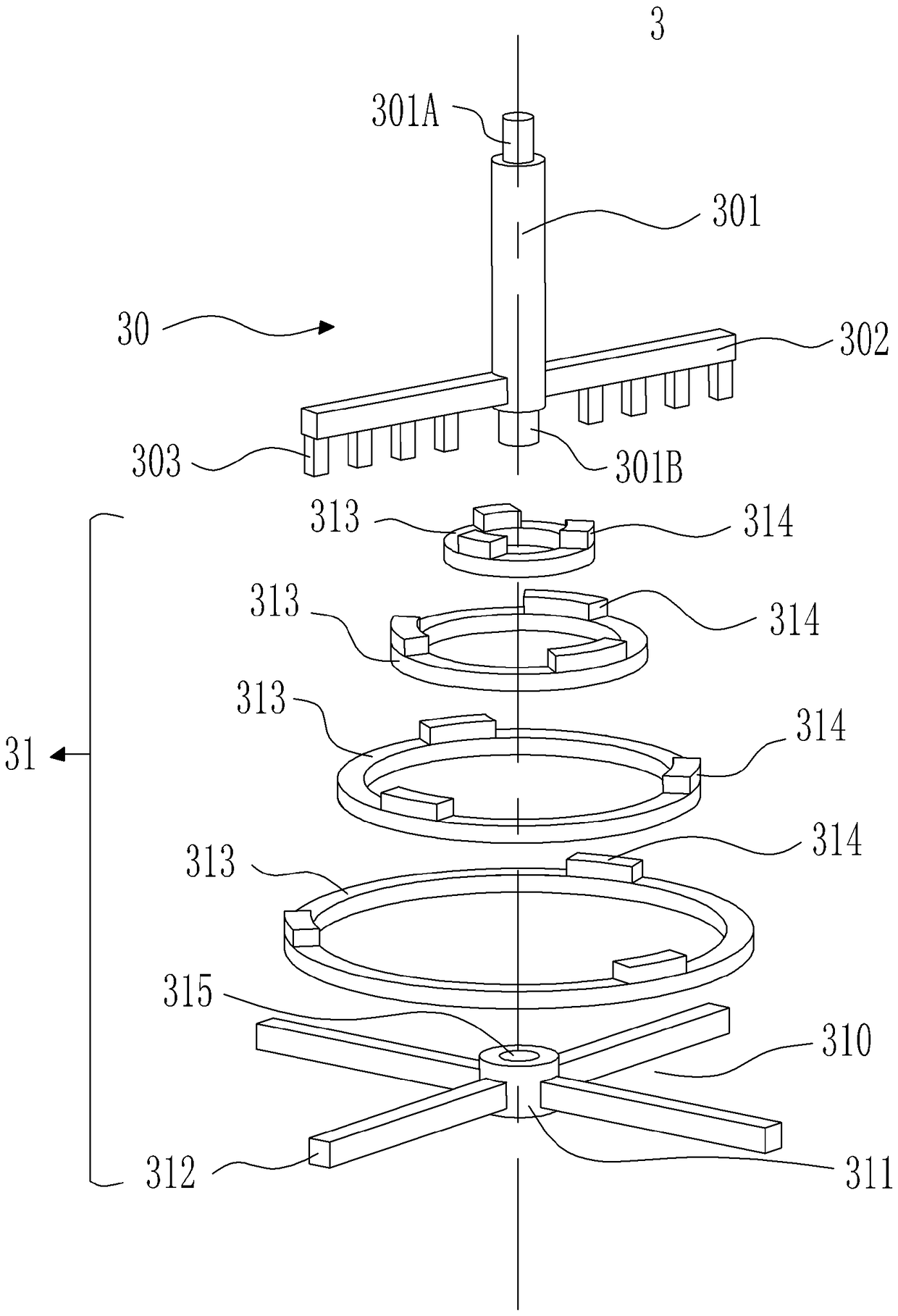

Crushing assembly for sludge crusher and construction method thereof

ActiveCN108080098ABroken continuouslyPromote fragmentationSludge treatment by de-watering/drying/thickeningGrain treatmentsSludgeEngineering

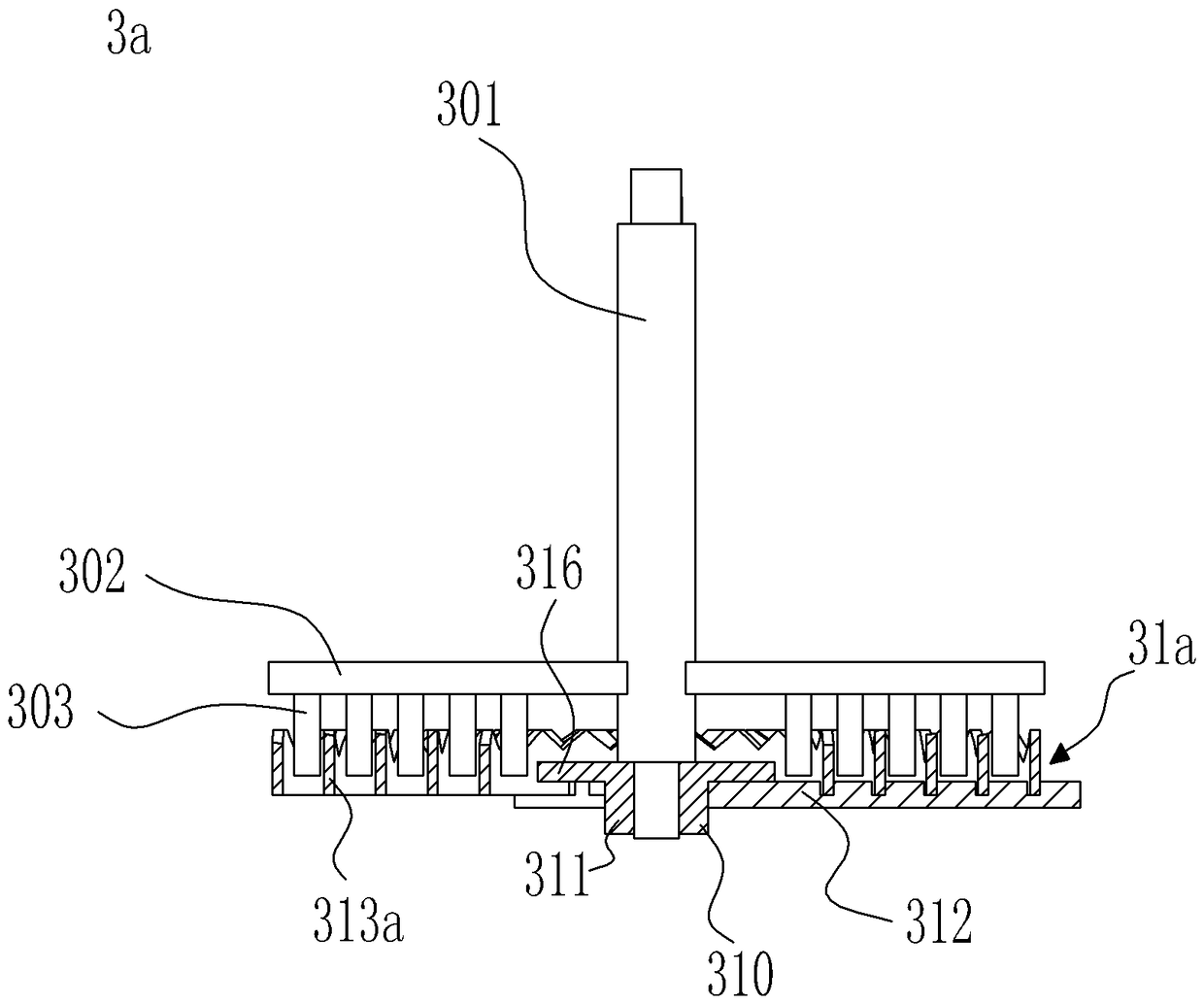

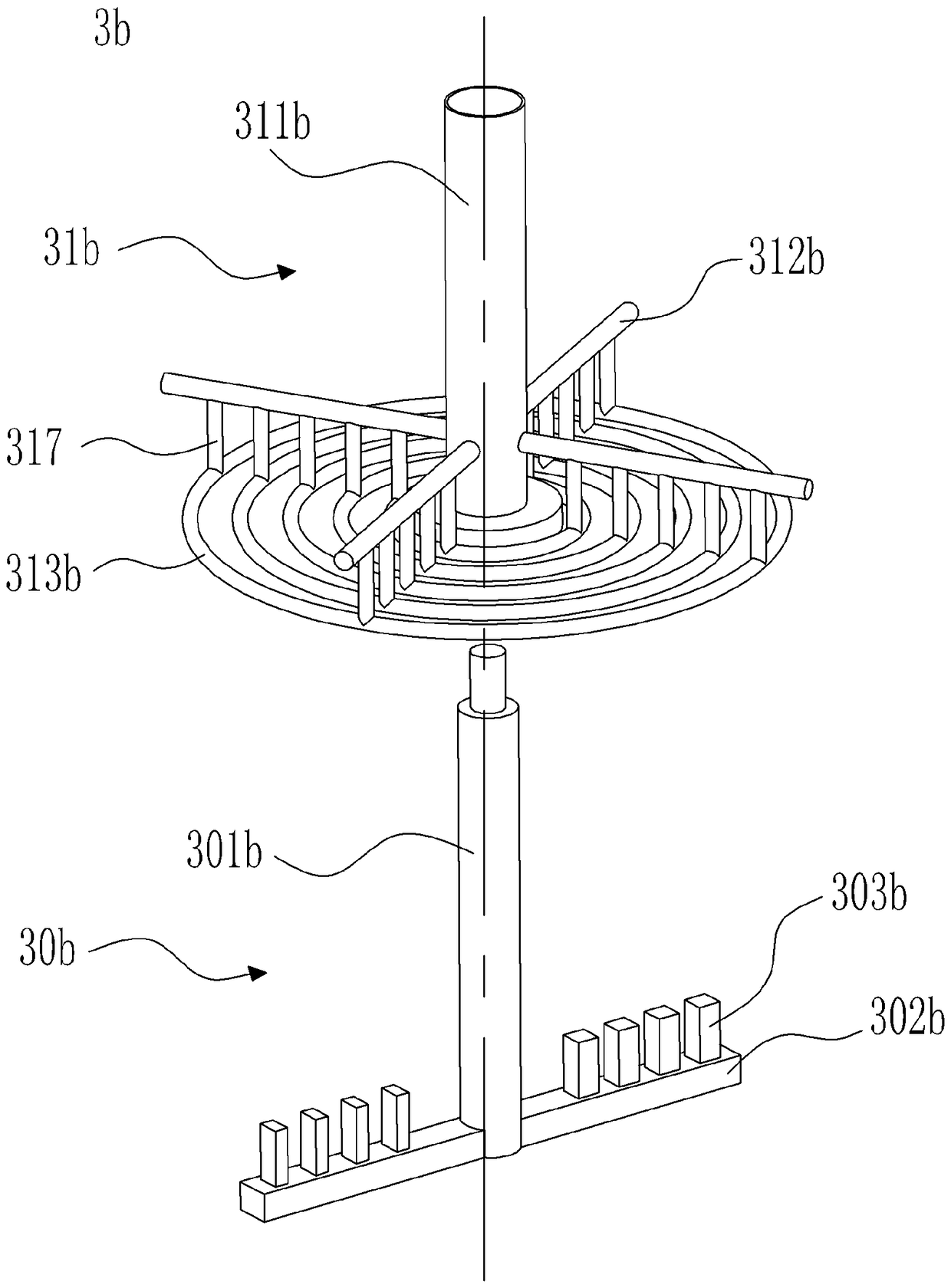

The invention relates to a crushing assembly which is used in a vertical sludge crusher. The crushing assembly is arranged in a vertical shell body and includes a first rotatable assembly, a second rotatable assembly and a fixing assembly. The first rotatable assembly is provided with a first rotating shaft, a first whirling arm which extends outward from the lower end of the first rotatable assembly and crushing parts which are arranged on the first rotating arm. The second rotatable assembly is provided with a second rotating shaft, a second whirling arm which extends outward from the secondwhirling arm and annular pieces which are arranged on the second whirling arm. The fixing assembly is provided with a center column and a support rod which extends outward from the center column. Thesecond whirling column is arranged between the first whirling assembly and the fixing assembly, the lower end of the second rotating shaft is rotatably arranged in an axle hole of the center column and extends out of the axle hole, and the crushing assembly and the annular pieces are arranged in a staggered distribution mode. The invention further relates to a method of forming the crushing assembly for the vertical sludge crusher.

Owner:广州正晟科技有限公司

Portable medicine dispensing device based on clinical pharmacy

InactiveCN114367359ASave energyImprove efficiencyPharmaceutical product form changeGrain treatmentsMedicinal herbsEngineering

The invention provides a portable medicine dispensing device based on clinical pharmacy, and effectively solves the problems that an existing grinding roller can only grind traditional Chinese medicinal materials with the surfaces in contact with the traditional Chinese medicinal materials; the problems that medicinal materials which are not in contact with the grinding roller cannot be effectively ground, the fan-shaped plate cannot be thoroughly cleaned by manually holding a corresponding tool traditionally, and multi-stage crushing cannot be achieved are solved; a supporting assembly is fixedly connected into the upper box body, a fixing ring is fixedly connected to the upper end of the middle of the supporting assembly, a synchronous ring is rotatably connected to the upper end of the middle of the fixing ring, and a reversing gear ring located on the outer side of the fixing ring is fixedly connected to the upper end of the supporting assembly. The upper end of the fixing ring is evenly and slidably connected with a plurality of driving moving discs fixedly connected with the synchronous rings correspondingly, through cooperative use of rolling claws, sliding-in holes, torsional spring rods and grinding rollers, medicinal materials on the supporting assembly can be rolled up and down, the medicinal materials are ground to be finer, blocky particles are avoided, and therefore the medicinal materials can be more effectively ground. And the medicinal materials are ground more thoroughly.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

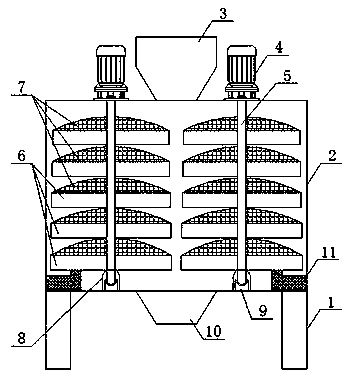

High-efficiency pulverizing device based on building materials

InactiveCN109365055ARealize multi-stage crushingAvoid residueHollow article cleaningGrain treatmentsEngineeringMechanical engineering

The invention discloses a high-efficiency pulverizing device based on building materials. The high-efficiency pulverizing device comprises a rack, the top of the rack is provided with a pulverizing box, the center portion of the top of the pulverizing box is provided with a feeding hopper, the bottom center position is provided with a discharging pipe, the feeding hopper and the discharging pipe both communicate to the pulverizing box, motors are arranged on one side of the feeding hopper, rotating shafts are fixedly connected to the ends of output shafts of the motors, the rotating shafts arearranged inside the pulverizing box, and the exteriors of the rotating shafts are fixedly sleeved with breaking gear sets. The high-efficiency pulverizing device is provided with the two motors withthe opposite output shaft rotation directions, the breaking gear sets are arranged outside the rotating shafts in a sleeving manner, and each breaking gear set is composed of a plurality of breaking gears with the gear diameters successively increased from top to bottom, wherein the centers of the multiple breaking gears are collinear in the vertical direction, every two adjacent breaking gears are arranged in parallel, multi-stage pulverizing of materials can be achieved, and the pulverizing efficiency is greatly improved.

Owner:江苏方寸元工艺制品有限公司

Multistage crushing device for iron ore mining

InactiveCN113368931ARealize multi-stage crushingImprove crushing efficiencyDispersed particle filtrationGrain treatmentsMineralogyMining engineering

The invention discloses a multistage crushing device for iron ore mining. The multistage crushing device comprises a crushing box, a feeding opening is formed in the top face of the crushing box, and a top frame is welded to the upper portion of the feeding opening. The multistage crushing device has the beneficial effects that a first air cylinder is started through a control panel, a crushing hammer with bevel teeth at one end of the first air cylinder is promoted to extend to a hemisphere part at the lower part of a material gathering hopper in a reciprocating manner, so that iron ore is crushed in the continuous hammering and tamping process until the iron ore is discharged into a cylinder through a material hole of the hemisphere part; a plurality of U-shaped crushing rods which are arranged on the surface of a shaft rod at equal intervals synchronously rotate, so that crushing teeth which are inclined and uniformly welded at the two ends of the crushing rods crush iron ore falling into the cylinder in a high-speed rotating state until the iron ore passes through a filter screen and a horn cover and falls into a filter screen plate in a gathering manner; and two crushing plates are driven to re-crush the ore through the oppositely-arranged bulges in the reciprocating attaching process.

Owner:萍乡市名胜矿业有限公司

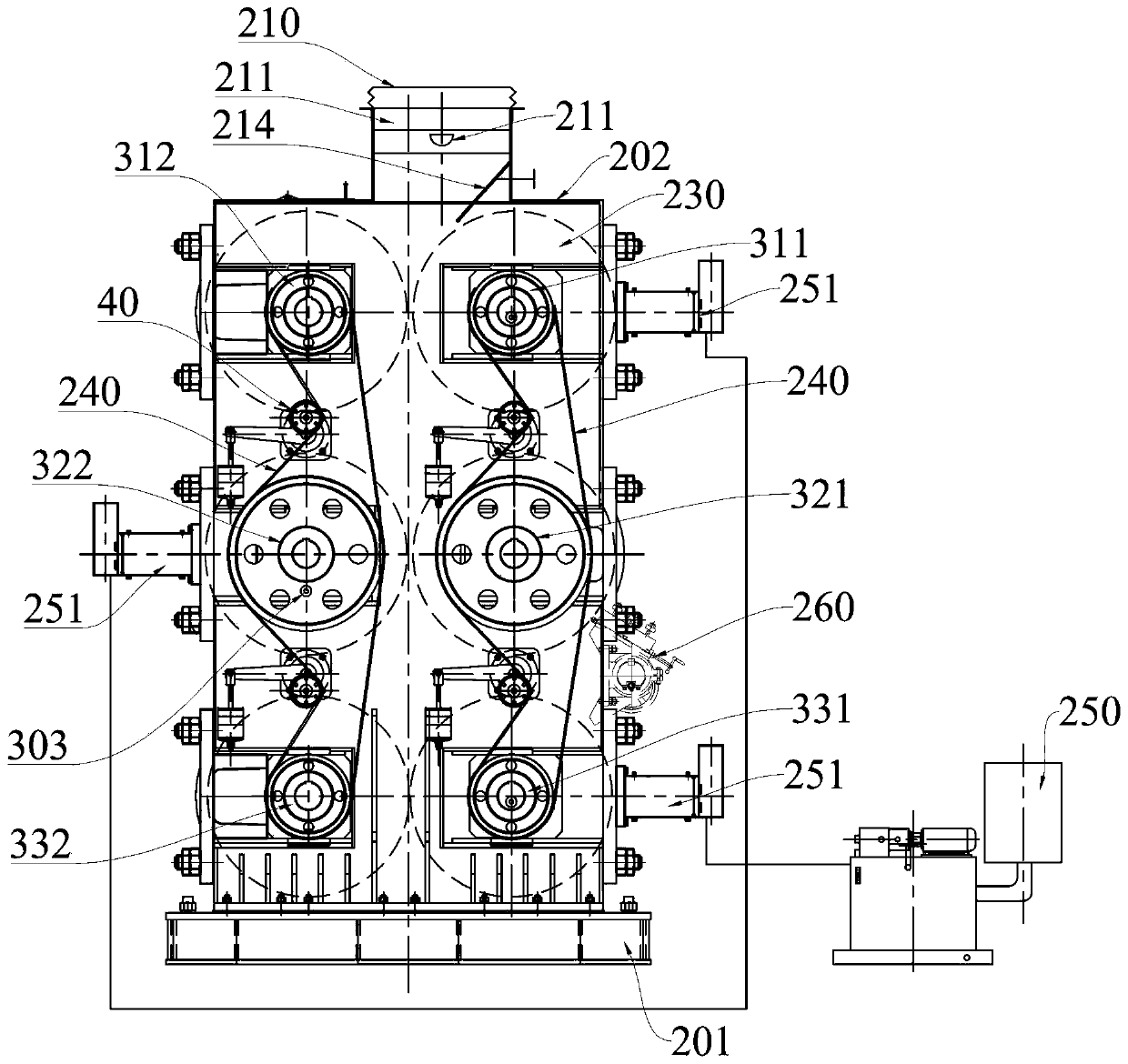

Combined crushing device and crushing system

PendingCN111330678AReduce volumeImprove versatilityGrain treatmentsStructural engineeringMechanical engineering

The invention discloses a combined crushing device and a crushing system. The combined crushing device comprises a base, a frame body arranged above the base, a feeding chute arranged above the framebody, a driving assembly and a pressing roller assembly arranged in the frame body. According to the combined crushing device, at least three pairs of pressing roller working pairs and at least threedriving pairs are arranged, multi-stage crushing can be realized, and the volumn of the crushing device is reduced; and meanwhile, driven rollers are movably fixed on the frame body, so that the distances between the driven rollers and corresponding driving rollers are adjustably arranged, the crushing particle size adjustment and selection of the combined crushing device are achieved, and the universality of the crushing device is improved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

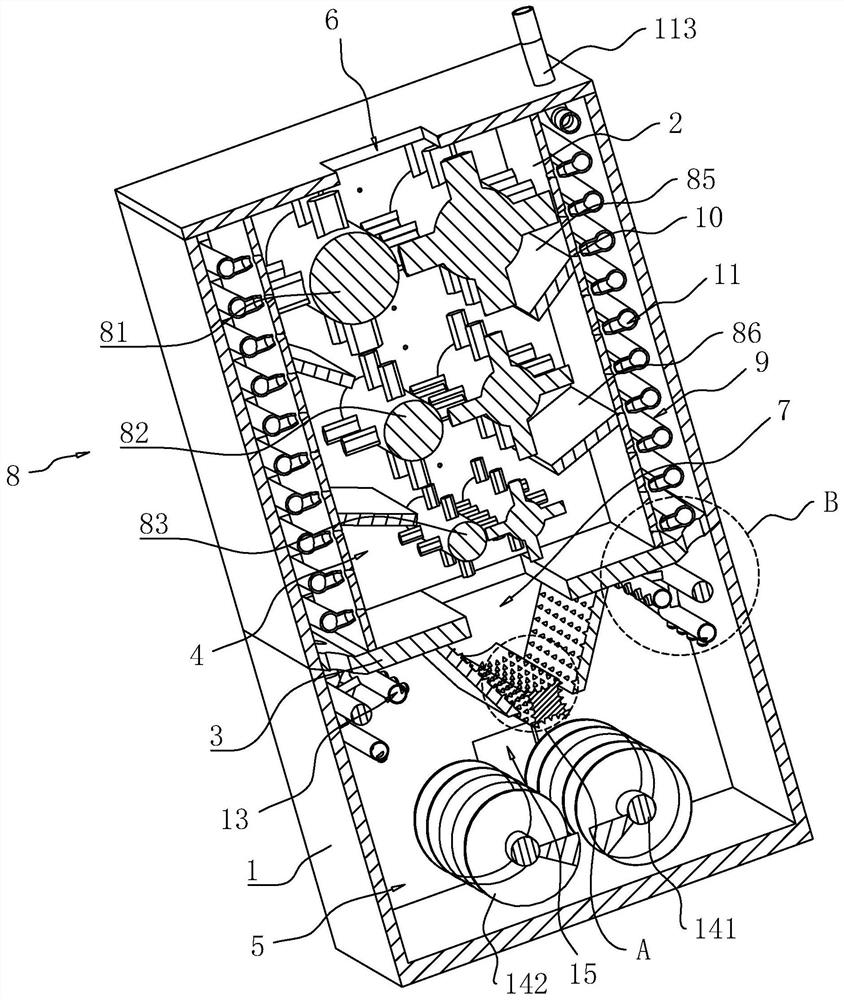

A device for preparing multi-taste silkworm chrysalis protein powder

InactiveCN110420687BRealize multi-stage crushingGreat tasteTransportation and packagingMixersFood supplementPROTEIN S HEERLEN

The invention relates to the field of food processing, in particular to a multi-taste silkworm chrysalis protein powder preparation device, which includes a body and a grinding cavity arranged in the body, a belt cavity is arranged in the bottom wall of the grinding cavity, and the belt cavity There is a first rotating shaft rotating between the grinding chamber, and a first pulley is fixed at the end of the first rotating shaft in the belt chamber. A multi-taste silkworm chrysalis protein powder preparation device provided by the present invention can realize The multi-stage crushing of silkworm chrysalis makes the crushed silkworm chrysalis smoother, thereby improving the taste of the protein powder. At the same time, the equipment can mix food additives of different tastes into the protein powder according to individual needs, so that the protein powder is easy to be accepted, and the equipment structure is simple. , easy to operate, can efficiently complete the pulverization of silkworm chrysalis and the improvement of taste, and is convenient for production and popularization.

Owner:南京溧水高新产业股权投资有限公司

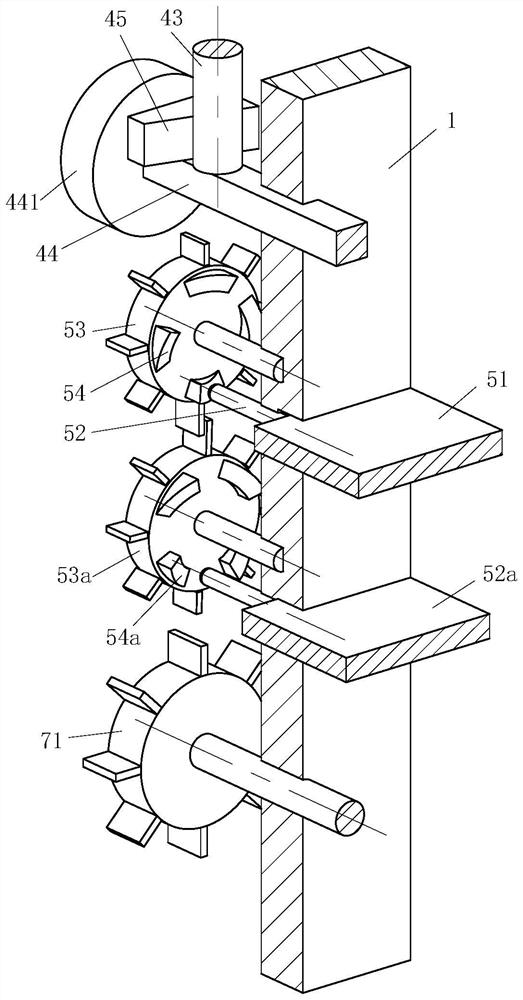

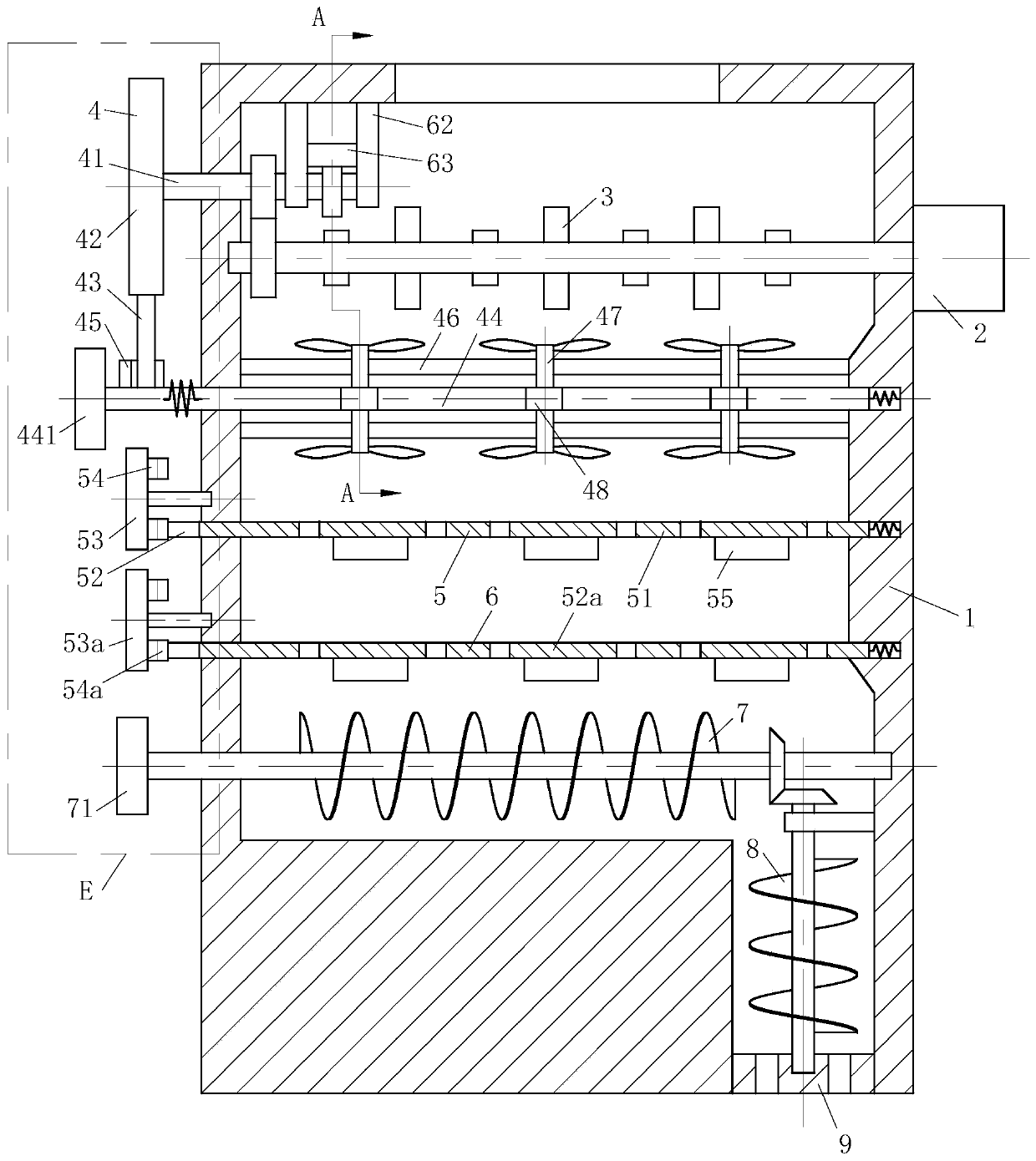

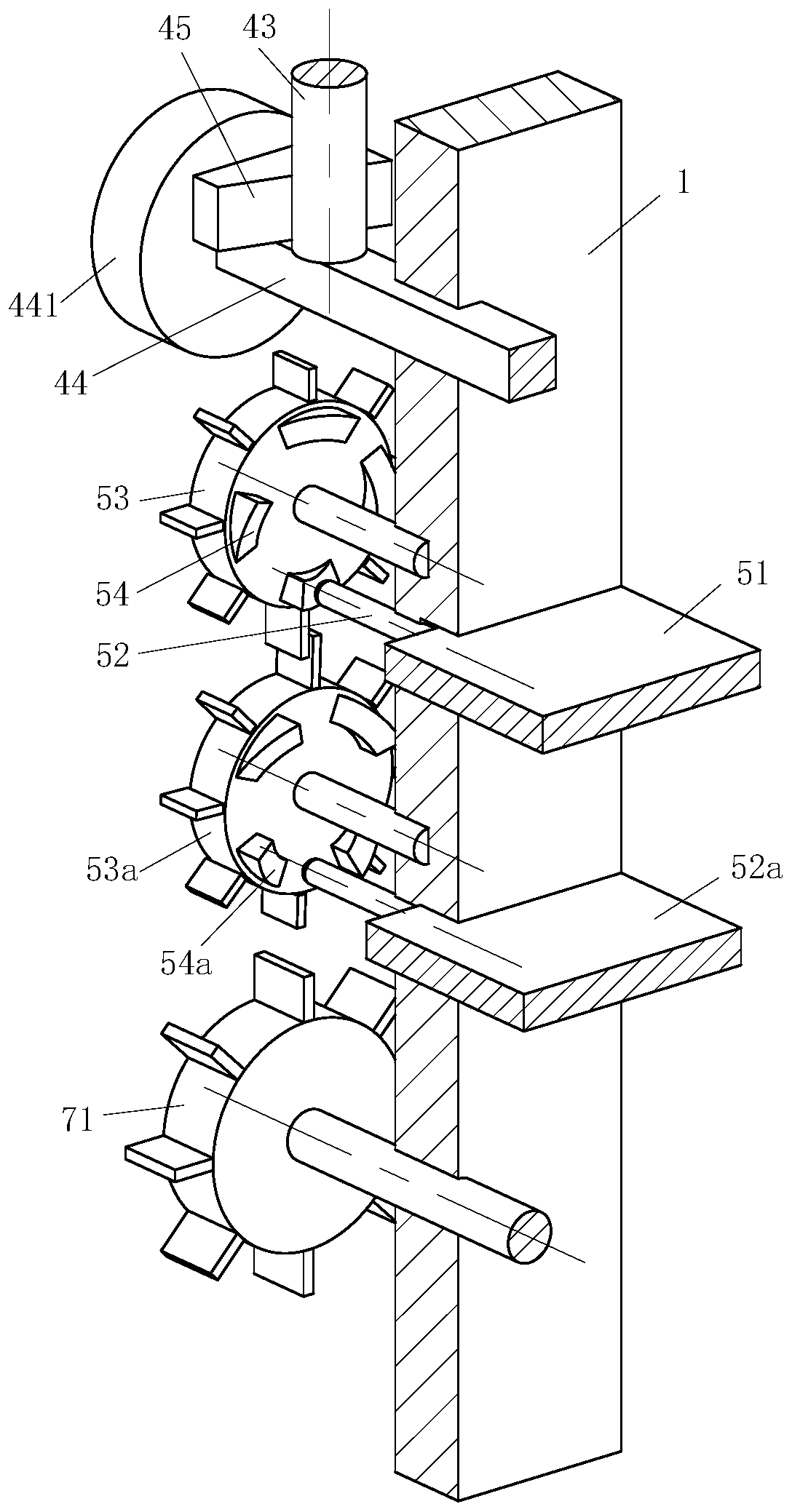

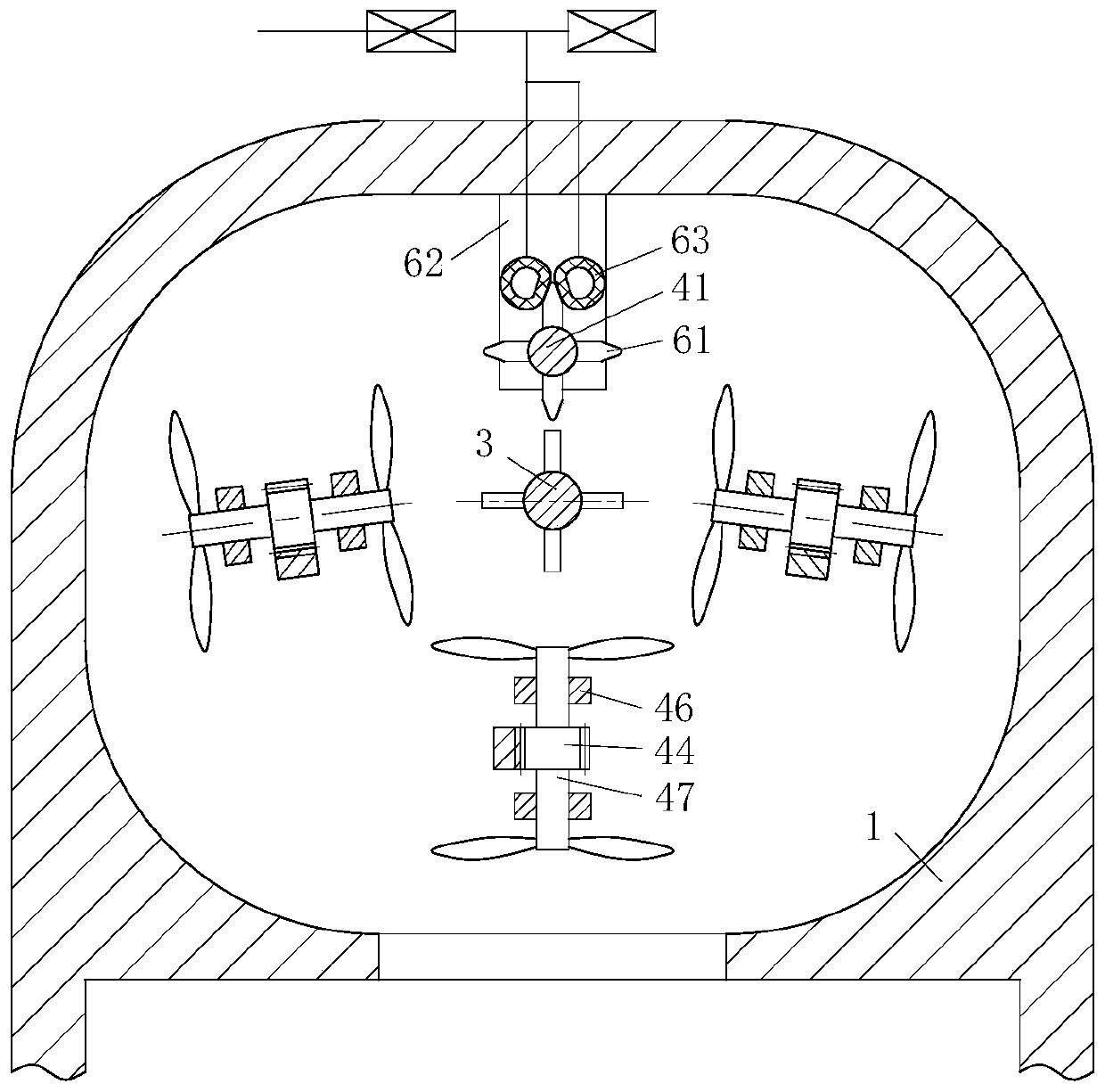

A high-efficiency crushing device for refractory materials

The invention relates to the technical field of refractory crushing equipment, in particular to a high-efficiency crushing processing device for refractory materials; based on a servo motor as a power source, through the cooperation of a reciprocating component based on a cylindrical cam and a plugging component, the first-stage crushing component is used to crush the material. Carry out primary crushing; through the transmission of the plugging component, the material passes through the secondary crushing component to achieve secondary crushing; and then through the transmission component as the power input of the third-stage crushing component, the balance wheel swings with the crushing roller to further crush the material Crushing; the three-stage processing is coordinated in sequence to achieve multi-stage crushing and improve the crushing effect on materials; the first-stage crushing component uses the No. 3 roller to roll along the bottom surface of the fixed wedge block and produces vertical displacement, so that the vertical The spur rack moves up and down, and acts on the driving gear, so that the upper shaft rotates and the lower shaft rotates through the transmission belt, so that the rotating head at the right end rotates, so that the upper and lower grinding parts are also combined during the crushing process. Function.

Owner:ANLI REFRACTORY MATERIAL ANSHAN CITY

Pulp crushing device for red raspberry fruit wine processing

ActiveCN113426513ARealize multi-stage crushingIncrease productivityGrain treatmentsHorticultureFruit wine

The invention is suitable for the technical field of red raspberry fruit wine processing, and provides a pulp crushing device for red raspberry fruit wine processing. The device comprises a device body, weighing cavities, opening and closing assemblies and crushing assemblies. The bottom of each weighing cavity is provided with a movable cylinder in a sliding manner. The opening and closing assemblies are used for driving closing plates and movable plates to move so as to achieve feeding or discharging of the weighing cavities; and each crushing assembly comprises a plurality of crushing parts. Red raspberries fall into the weighing cavities, movable barrels gradually descend under the action of gravity, the opening and closing assemblies control the closing plates and the movable plates to move so that feeding in the weighing cavities can be stopped and discharging can be started, the crushing assemblies are started to drive different numbers of crushing parts to rotate, multi-stage crushing of the red raspberries is achieved, the problem that an existing pulp crushing device for red raspberry fruit wine processing cannot automatically crush red raspberries in batches according to the weight in a multi-stage mode is effectively solved, the pulp of the red raspberries is crushed more sufficiently, and therefore the production efficiency of the red raspberry fruit wine is improved.

Owner:天津市天裕东来生物科技有限公司

Preparing device for multiflavor silkworm chrysalis protein powder

InactiveCN110420687ARealize multi-stage crushingGreat tasteTransportation and packagingMixersFlavorFood additive

The invention relates to the field of food processing, in particular to a preparing device for multiflavor silkworm chrysalis protein powder. The preparing device comprises a machine body and a grinding cavity arranged in the machine body; a belt cavity is formed in the bottom wall of the grinding cavity; a first rotating shaft is rotationally arranged between the belt cavity and the grinding cavity; and a first belt pulley is fixedly arranged at the tail end of the first rotating shaft in the belt cavity. The preparing device for the multiflavor silkworm chrysalis protein powder, provided bythe invention can realize multistage crushing of silkworm chrysalis and enables the crushed silkworm chrysalis to be finer and smoother, so that the mouthfeel of the protein powder is improved; meanwhile, by use of equipment, food additives with different flavors can be mixed into the protein powder according to personal demands, and thereby the protein powder is accepted more easily; and the equipment is simple in structure and convenient to operate, can efficiently crush the silkworm chrysalis and improve the flavor and is convenient to produce and popularize.

Owner:南京溧水高新产业股权投资有限公司

Multi-stage grain crushing device

The invention relates to the field of wine brewing equipment, solves the problem that a traditional grain crusher cannot fully crush grains, and provides a multistage grain crushing device. The multistage grain crushing device comprises a shell; a feed port is formed in the upper end of the shell; a crushing cavity is formed in the shell; a crushing mechanism is arranged in the crushing cavity; a screen is arranged at the upper part of the crushing cavity; the crushing mechanism comprises multiple rotating shafts vertically arranged; single rotating shaft is axially provided with blades for grain crushing at intervals; the blades are provided with through holes for enabling the grains to pass through; the through holes in the multiple blades are arranged oppositely; the apertures of the through holes are reduced along with reduction of the heights on the rotating shafts; the blades on two adjacent rotating shafts are staggered, and the through holes in the previous layer of blades are positioned rightly above the blade edges of the next layer of blades; the blade edges of the previous layer of blades are positioned rightly above the through holes in the next layer of blades; the blades in the highest place are positioned below the screen; and the crushing mechanism can generate upward air currents.

Owner:ZUNYI JINHONG METAL EQUIP

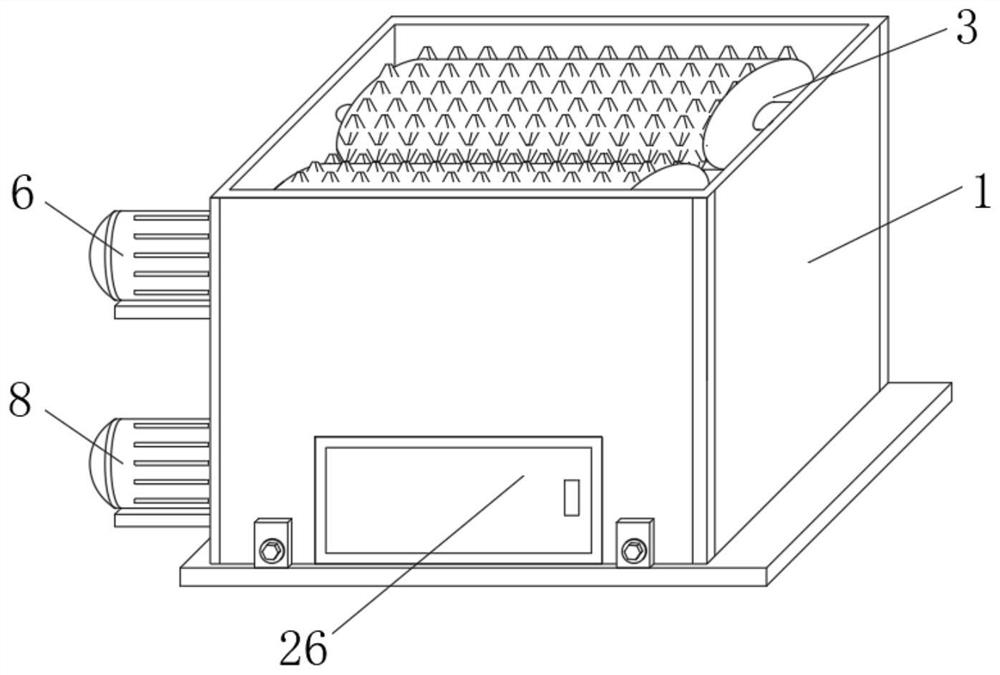

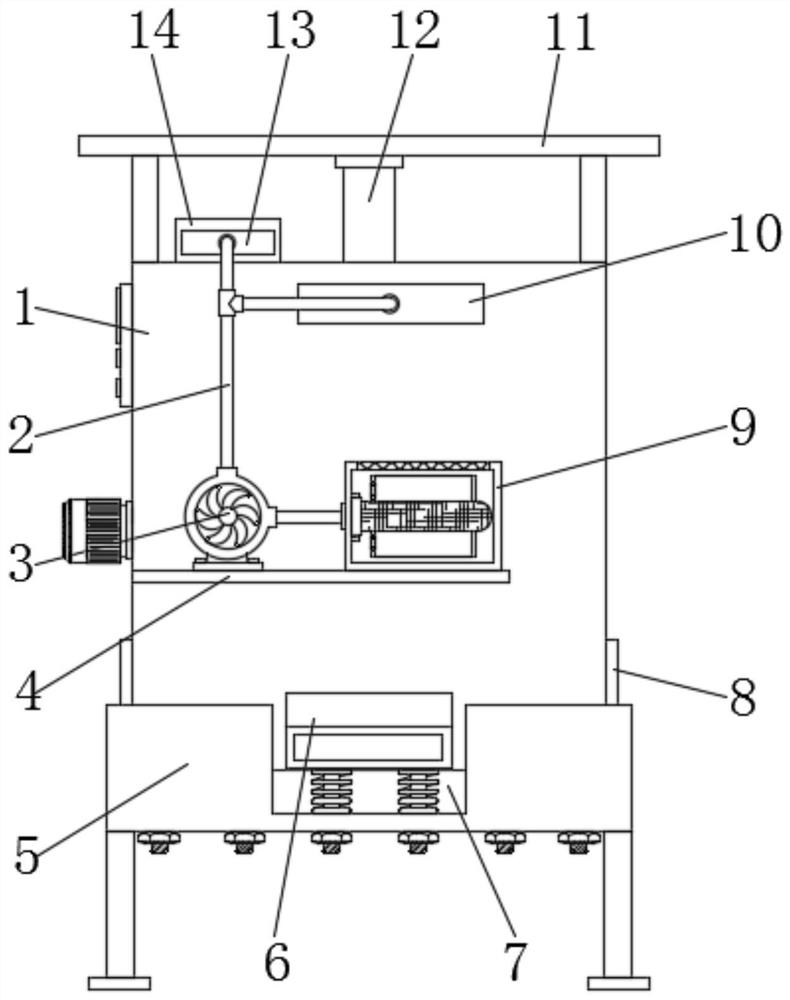

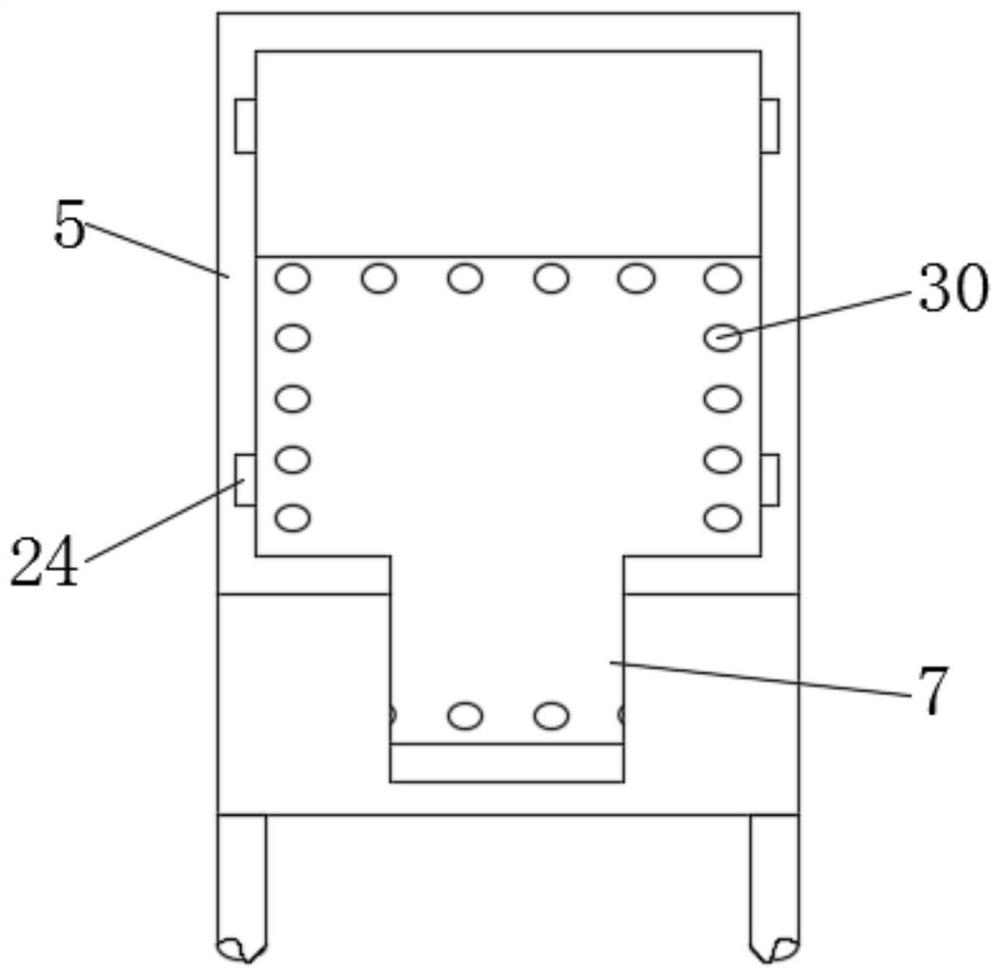

A multi-stage crushing device for waste materials for interior decoration

ActiveCN109127091BRealize multi-stage crushingReduce manual labor intensitySievingScreeningHydraulic cylinderElectric machinery

The invention discloses a multi-level smashing device for waste materials for indoor decoration. The device comprises a base, smashing box sliding grooves are formed in the inner walls of the sides ofthe base, and a smashing box is slidably connected with the inner walls of the smashing box sliding grooves; vibration motors are fixed to the inner wall of the bottom of the base through screws, output shafts of the vibration motors are fixed to the outer wall of the bottom of the smashing box through screws, and a lower grinding plate sliding groove is formed in the bottom of the inner wall ofone side of the smashing box; a lower grinding plate is slidably connected with the inner wall of the lower grinding plate sliding groove, hydraulic cylinders are fixed to the inner wall of the bottomof the smashing box through screws, and the ends of piston rods of the hydraulic cylinders are fixed to the outer wall of the bottom of the lower grinding plate through screws. Multi-level smashing can be achieved, the device is beneficial for relieving the manual labor intensity and improving the production efficiency, the sieving filtering efficiency and the feeding speed, the probability of blocking a first-level screen, a filtering screen and a second-level screen can be reduced, and particles of different sizes can be obtained according to the need.

Owner:圣安隆环境建设有限公司

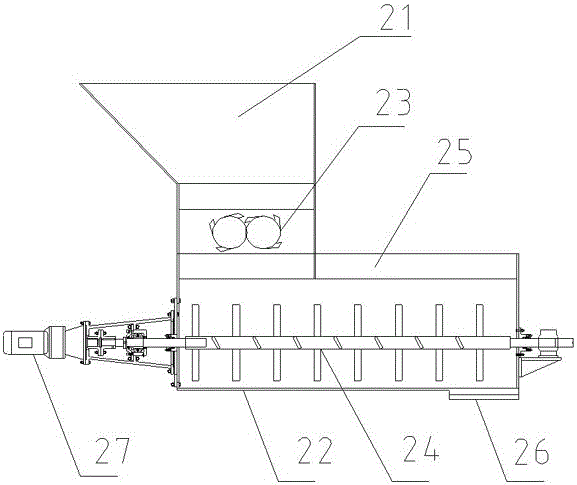

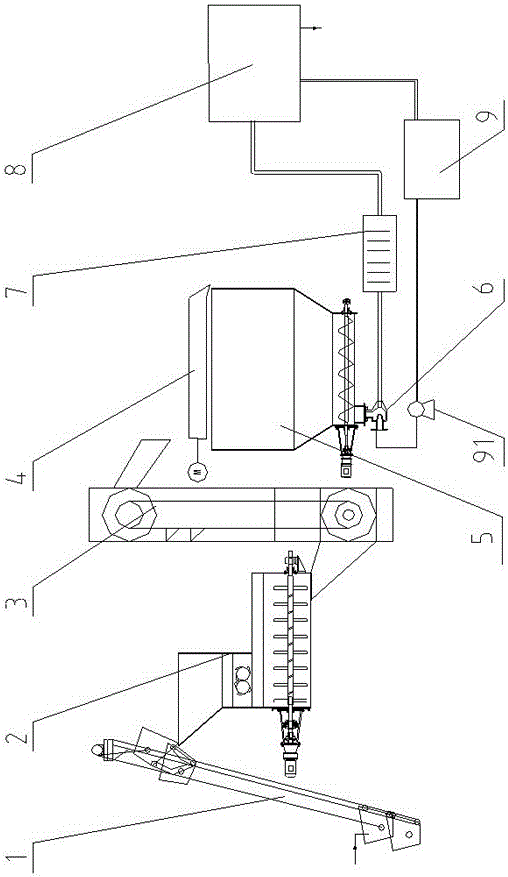

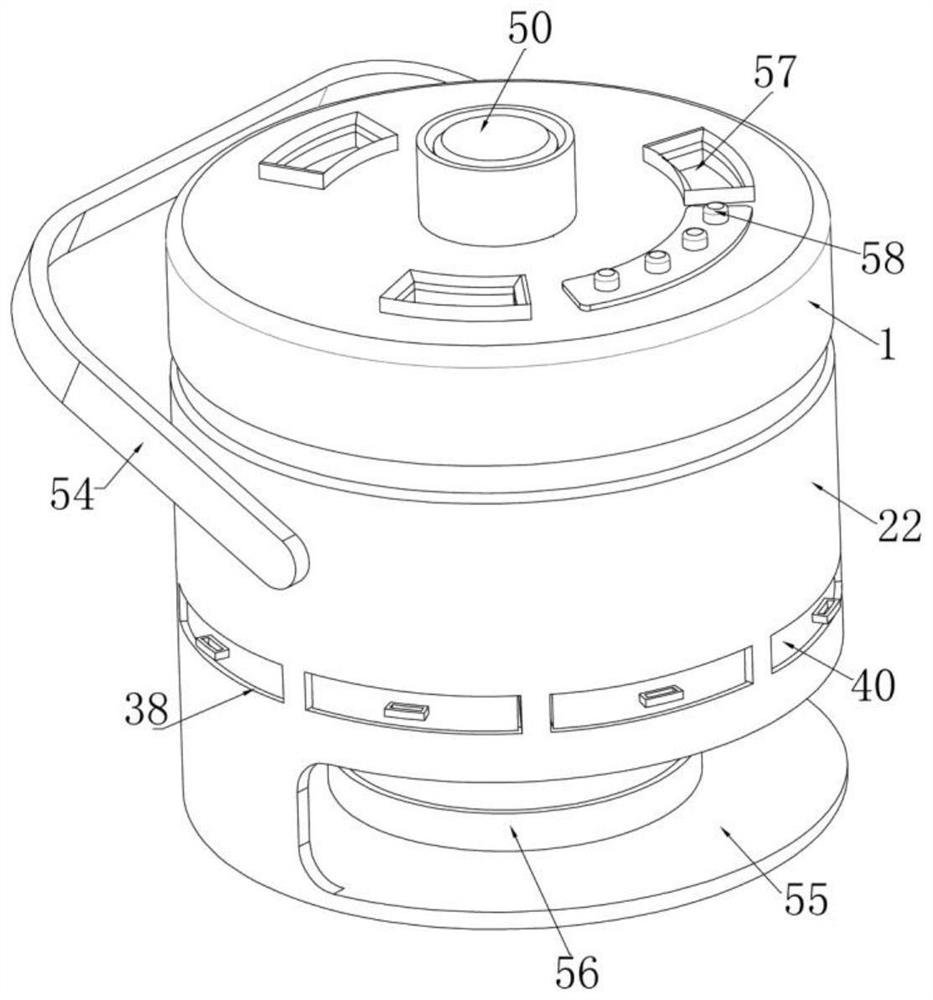

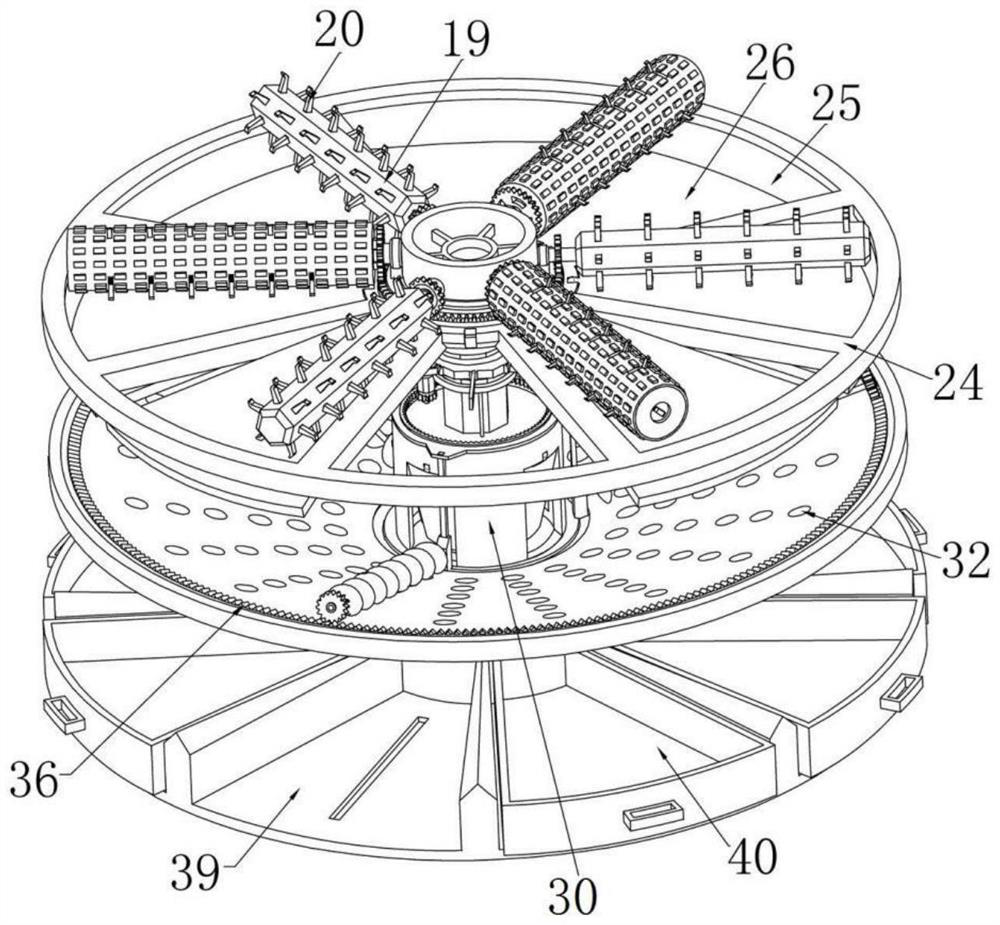

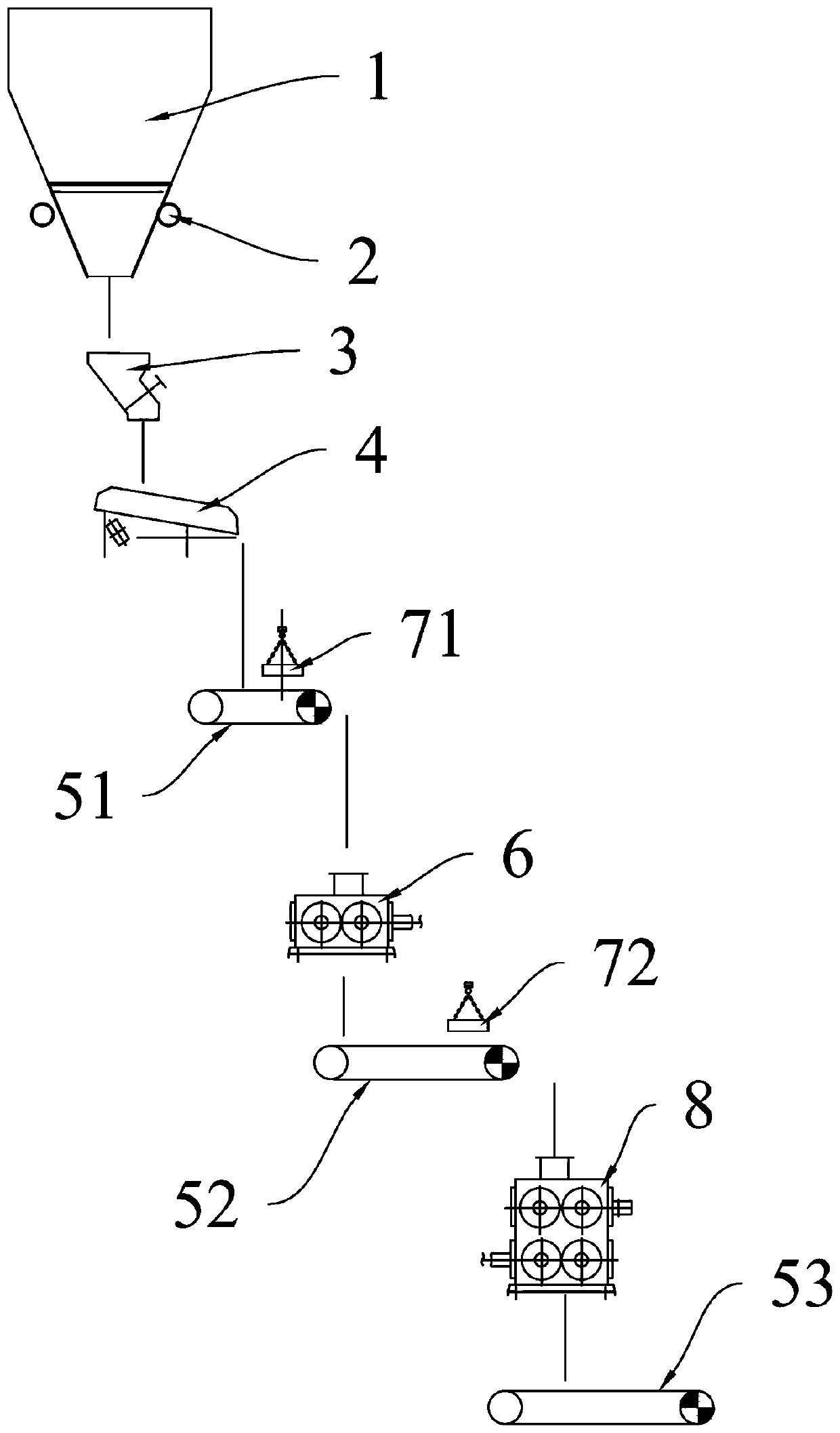

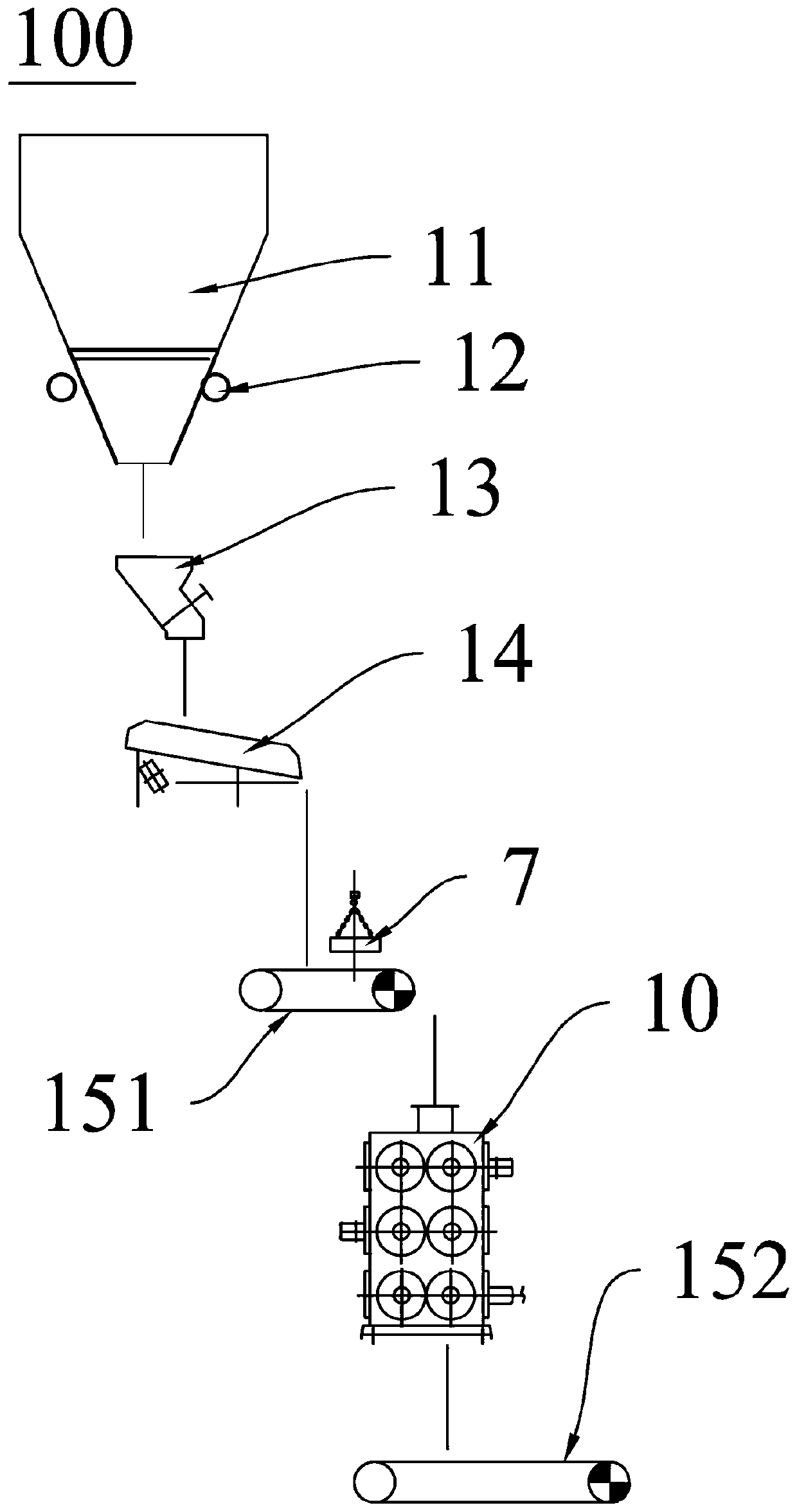

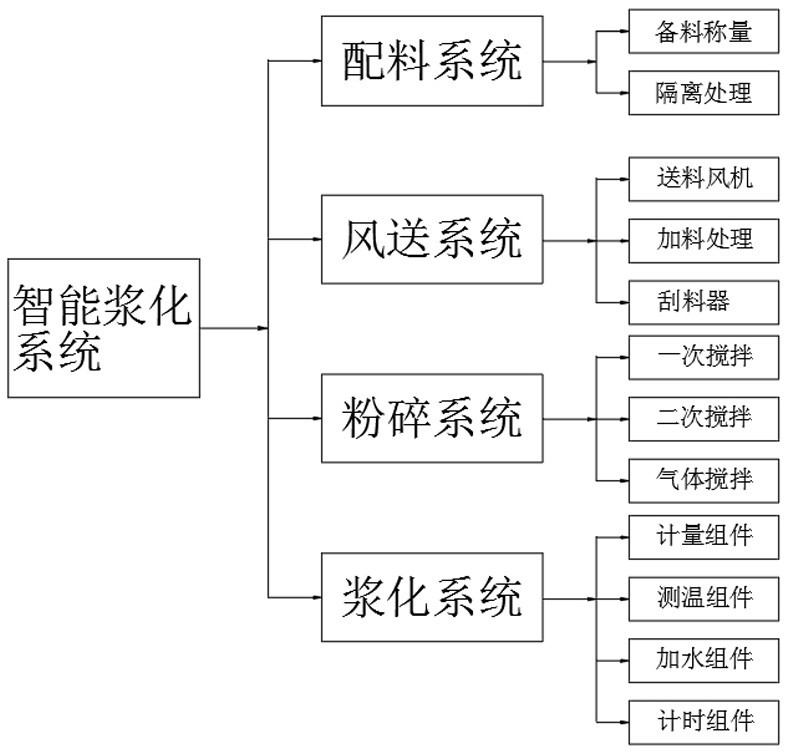

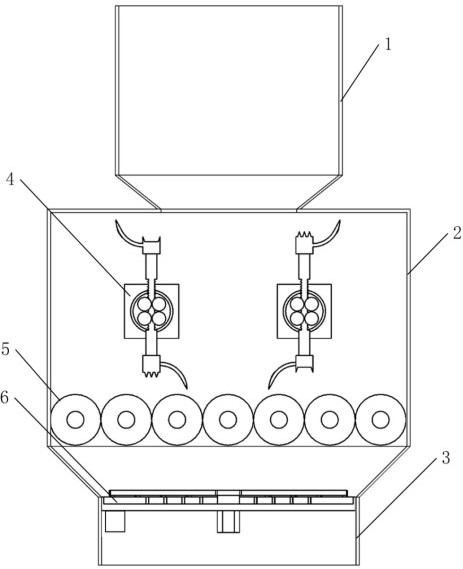

An intelligent pulping system for producing vermicelli

ActiveCN108967466BEfficient use ofReduce manufacturing costDough processingProcess engineeringIndustrial engineering

Owner:HUNAN YUXIANG FOODS

Crushing assembly used for sludge crushing device and construction method of crushing assembly

The invention provides a crushing assembly used for a vertical sludge crushing device. The crushing assembly is arranged in a vertical shell body and includes a rotatable assembly and a fixing assembly and ring pieces. The rotatable assembly includes a rotation shaft and a rotation arm extending outwards vertically from the lower end of the rotation shaft. The rotation arm is provided with crushing assemblies arranged at intervals and expanding parallel to the rotation arm in the length direction of the rotation arm. The fixing assembly includes a fixing supporting seat. The fixing supportingseat is provided with a central column and supporting rods vertically extending outwards from the central column. One end of each supporting rod is fixed to the central column. The ring pieces can bearranged on the supporting rods at certain intervals around the central column and in the length direction of the supporting rods. The rotatable assembly and the fixing assembly are arranged up and down, and the crushing assemblies on the rotation arm are in staggered arrangement relative to the ring pieces on the supporting rods. Each crushing assembly is corresponding to the corresponding spacebetween the two adjacent ring pieces and can extend into the space. The invention further relates to a method of constitution of the crushing assembly used for the vertical sludge crushing device.

Owner:广州正晟科技有限公司

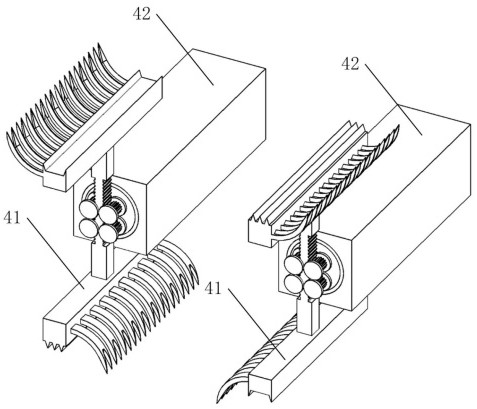

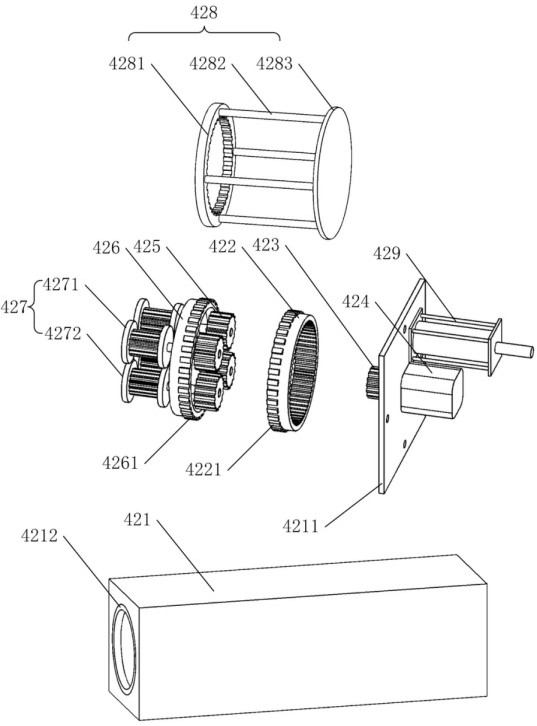

Polyester waste silk crushing device and using method thereof

PendingCN114536600AImprove continuityRealize multi-stage crushingPlastic recyclingPolyesterPolymer chemistry

The invention relates to the technical field of production of dioctyl terephthalate from waste polyester filaments, in particular to a waste polyester filament crushing device and a using method thereof.The waste polyester filament crushing device comprises a stock bin, a crushing bin and a discharging port which are sequentially communicated from top to bottom; a feeding mechanism, a first crushing mechanism and a second crushing mechanism are sequentially arranged in the crushing bin from top to bottom, and the feeding mechanism is arranged under the stock bin and comprises two feeding rods which are symmetrically arranged and a driving assembly for driving the feeding rods to relatively rotate in the polyester waste yarn conveying direction; and the second crushing mechanism comprises a filter screen, and the discharge port is formed below the filter screen. Automatic feeding can be achieved, and the labor intensity of workers is reduced; in the automatic feeding process, waste polyester filaments are preliminarily cut, the waste polyester filaments are prevented from winding a roller, and the production continuity and safety are improved; the waste polyester filaments subjected to multi-stage crushing are small in granularity and uniform in size, and the process requirement for producing dioctyl phthalate through alcoholysis of the waste polyester filaments is fully met.

Owner:SHANDONG TONGYUAN ENVIRONMENTAL MATERIAL CO LTD

Crushed stone processing equipment for bridge engineering construction

ActiveCN108570906BAchieve brokenRealize extrusion crushingRoads maintainenceBridge engineeringCrushed stone

The invention discloses macadam processing equipment for bridge engineering construction. The macadam processing equipment comprises a shell, a crushing chamber, an extrusion conveying chamber and a rolling chamber, wherein the crushing chamber is arranged at the upper right side of the shell, a feeding inlet is arranged at the left side of the top of the crushing chamber, and the crushing chamberis in communication with the feeding inlet; the extrusion conveying chamber is obliquely located at the bottom of the right side of the shell, the right side of the top of the extrusion conveying chamber is in communication with the right side at the bottom of the crushing chamber, the rolling chamber is located on the left side of the bottom of the shell, the left side of the extrusion conveyingchamber is in communication with the rolling chamber, and a second working motor is located on the top of the rolling chamber; a first connecting rod is welded on the left side of the second workingmotor, a vertical guide rail is fixedly welded at the upper part of the left side wall of the rolling chamber, and the left end of the first connecting rod extends into the vertical guide rail. The macadam processing equipment has high working efficiency, saves time and labor, and can carry out multi-stage pulverization on stones and lower the difficulty of crushing stones.

Owner:天长市富春建筑工程有限公司

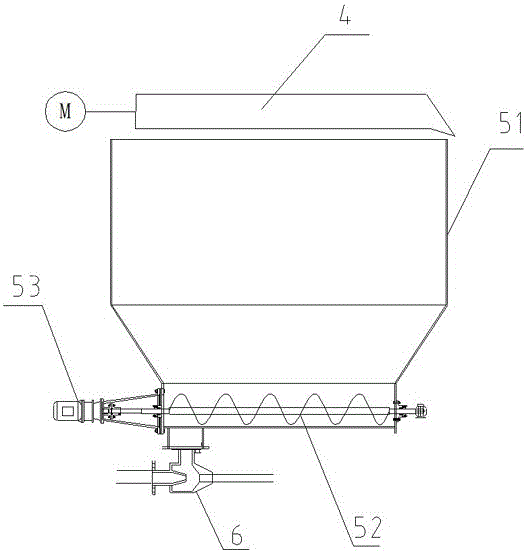

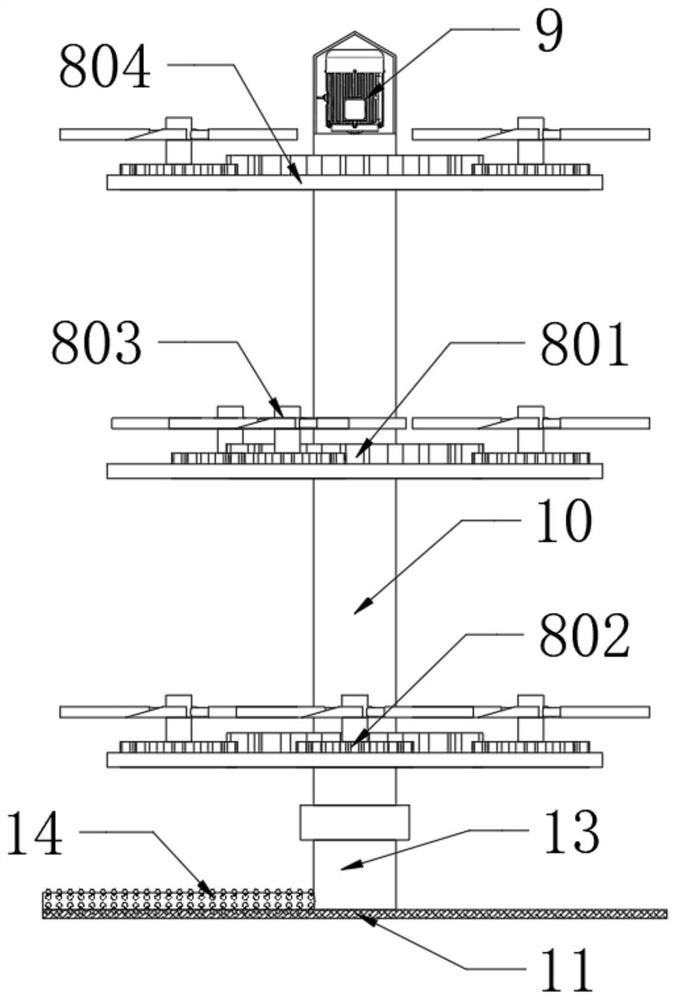

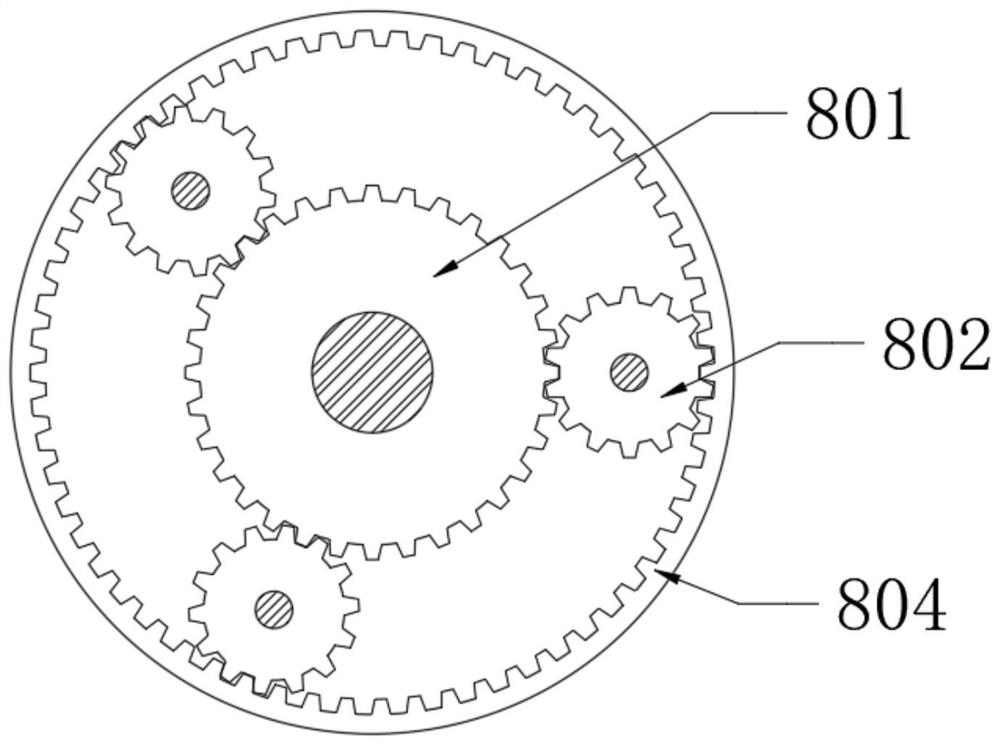

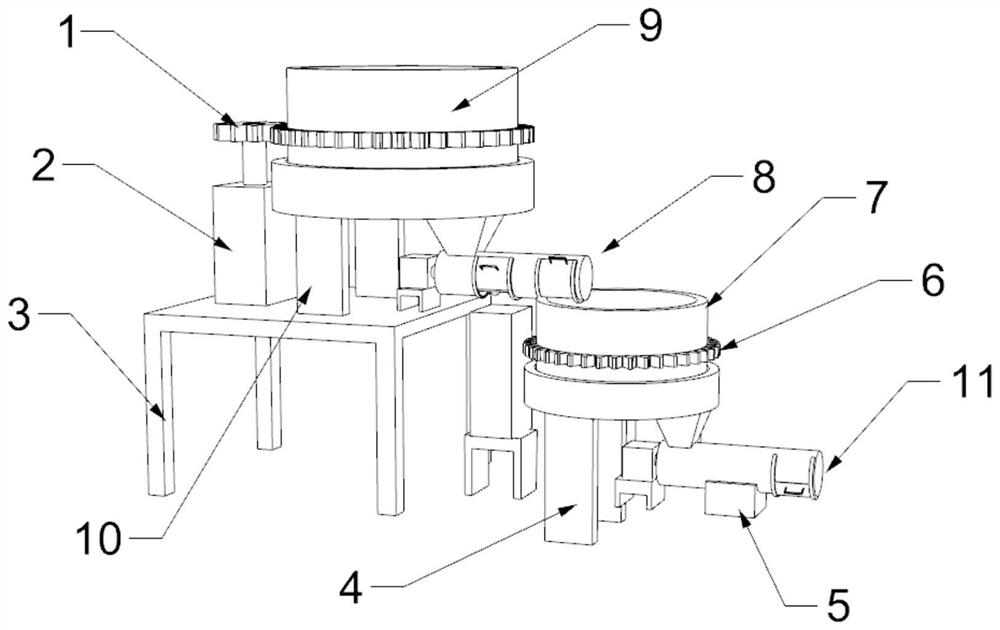

Raw material rotating disc type multi-stage crushing device for veterinary drug processing

InactiveCN111957412AIncrease productivityThe crushing process is continuousGrain treatmentsBiotechnologyVeterinary Drugs

The invention relates to the technical field of veterinary drug crushing devices, in particular to a raw material rotating disc type multi-stage crushing device for veterinary drug processing. The rawmaterial rotating disc type multi-stage crushing device comprises a support frame; a first motor device and a first crushing device are arranged on the support frame, a first stirring and conveying device is arranged below the first crushing device, a second crushing device is arranged below the first stirring and conveying device, and a second stirring and conveying device is arranged below thesecond crushing device. The raw material rotating disc type multi-stage crushing device has the beneficial effects that the first crushing device and the second crushing device are arranged, so that the novel structure can be subjected to multi-stage crushing, different combinations can be adopted to crush raw material, so that the crushed raw material can meet the preparation standards of different veterinary drugs, and the effect of improving the production efficiency is achieved; the stirring and conveying device is arranged, on the one hand, the processed raw material can be stirred and collected, and on the other hand, the raw material can be conveyed to the second crushing device, so that multi-stage crushing is achieved, the raw material can be continuously crushed, manual carryingis not needed, and the effect of accelerating production is achieved.

Owner:江苏大地动物保健品有限公司

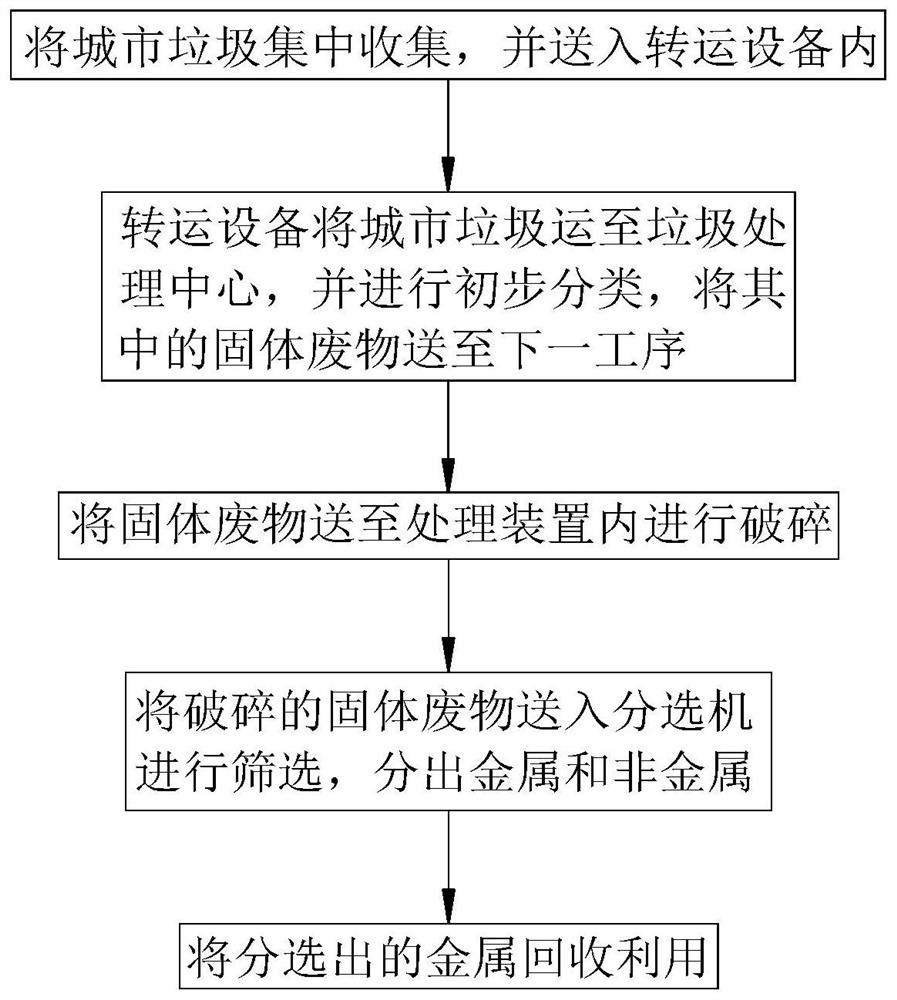

A kind of municipal waste treatment process

ActiveCN109047286BRealize multi-stage crushingImprove crushing efficiencySolid waste disposalGrain treatmentsDrive shaftGear wheel

The invention belongs to the technical field of waste treatment, and particularly relates to an urban waste treatment process. The urban waste treatment process adopts a treatment device. The treatment device comprises a box, a motor, crushing rollers, a crushing module, a first vibration module, a second vibration module, a spiral conveying shaft, a spiral squeezing roller and a filter screen. The crushing rollers are rotatably mounted on the upper portion of the interior of the box. The crushing module comprises a driving shaft, a rotary disc, a guide column, a rack, a first oblique block, afixing rod, a crushing cutter shaft, a driving gear and crushing cutters. The driving shaft is in engaged transmission with a crushing roller shaft though a gear. The rotary disc is fixedly connectedto one end of the driving shaft. The guide column is fixedly connected to the outer circle of the rotary disc and is used for squeezing the first oblique block arranged at the end of the rack. The driving gear is fixedly connected to the middle of the crushing cutter shaft and is engaged with the rack. The crushing cutters are arranged at the two ends of the crushing cutter shaft correspondingly.According to the treatment device, the rack and the driving gear are used for transmitting power of the crushing rollers, one power source is used for driving to achieve multi-stage crushing of solidwaste, and thus, energy can be saved.

Owner:浙江正浩智能制造有限公司

A municipal solid waste treatment system

ActiveCN109092525BRealize multi-stage crushingImprove crushing efficiencyGrain treatmentsGear wheelDrive shaft

The invention belongs to the technical field of waste disposal, and particularly relates to an urban solid waste disposal system which comprises a box body, a motor, a crushing roller, a breaking module, a first vibration module, a second vibration module, a spiral feeding shaft, a spiral extrusion roller and a filter net; the crushing roller is rotatably installed on the upper portion of the interior of the box body; the breaking module comprises a driving shaft, a rotary disc, a guide column, a rack, a first inclined block, a fixing rod, a breaking cutter shaft, a driving gear, and breakingcutters; and the driving shaft is transmitted with the crushing roller through gear engagement, the rotary disc is fixedly connected to one end of the driving shaft, the outer circle of the rotary disc is fixedly connected with the guide column, the guide column is used for squeezing the first inclined block arranged on the end head of the rack, the middle of the breaking cutter shaft is fixedly connected with the driving gear, the driving gear is engaged with the rack, and the two ends of the breaking cutter shaft are correspondingly provided with the breaking cutters. According to the urbansolid waste disposal system, power of the breaking roller by the rack and the driving gear, a power source drive is used for achieving multi-stage breaking of solid waste, the breaking efficiency is improved, and energy can be saved.

Owner:国合绿材科技(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com