Crushing assembly used for sludge crushing device and construction method of crushing assembly

A crusher and component technology, applied in grain processing and other directions, can solve the problems of increasing difficulty, poor continuity, uneven size of small blocks, etc., and achieve the effect of promoting crushing or shearing, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be understood that the drawings herein are not drawn to scale in order to clearly show the contents thereof, and the same or similar reference numerals indicate the same or similar parts or parts.

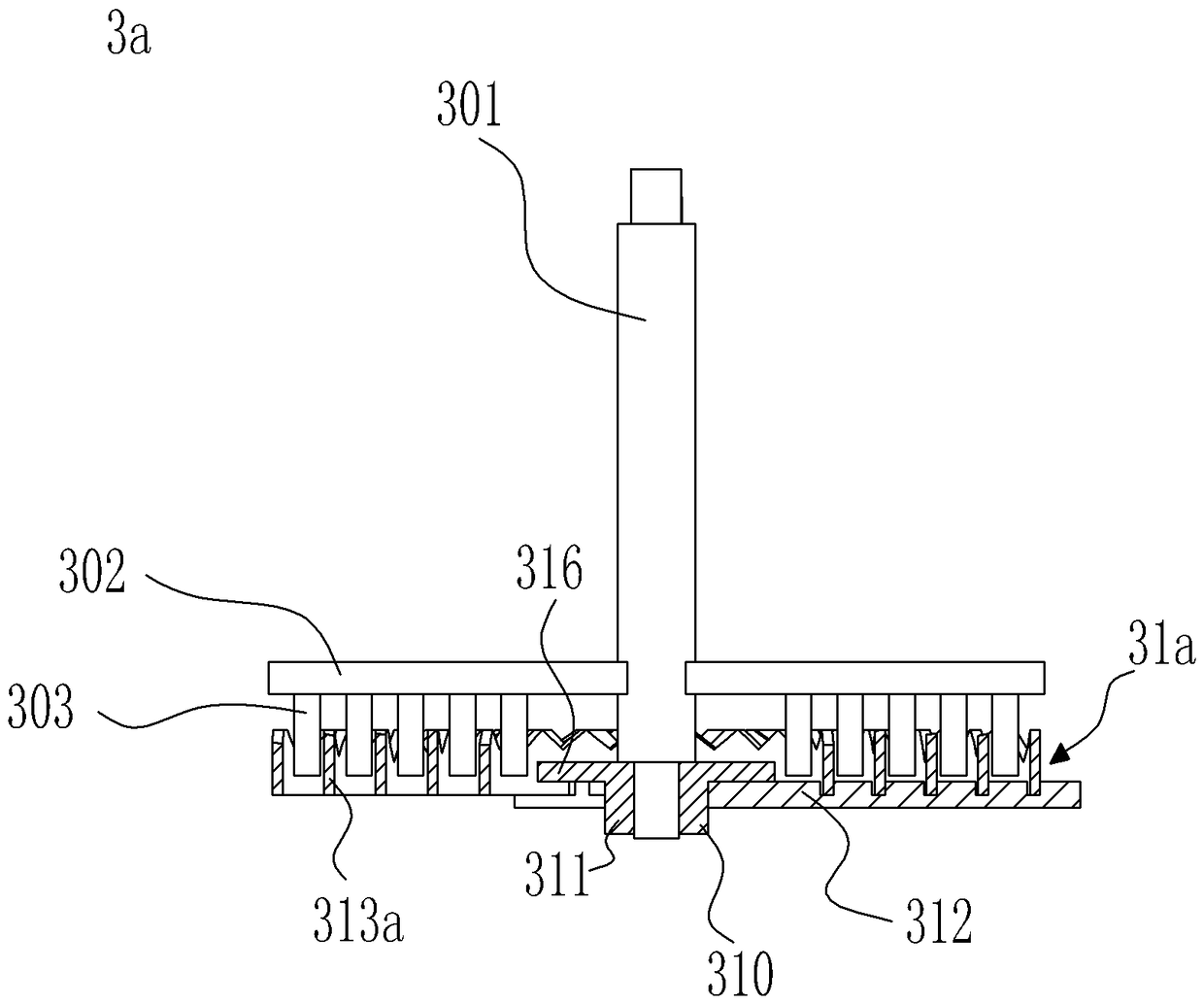

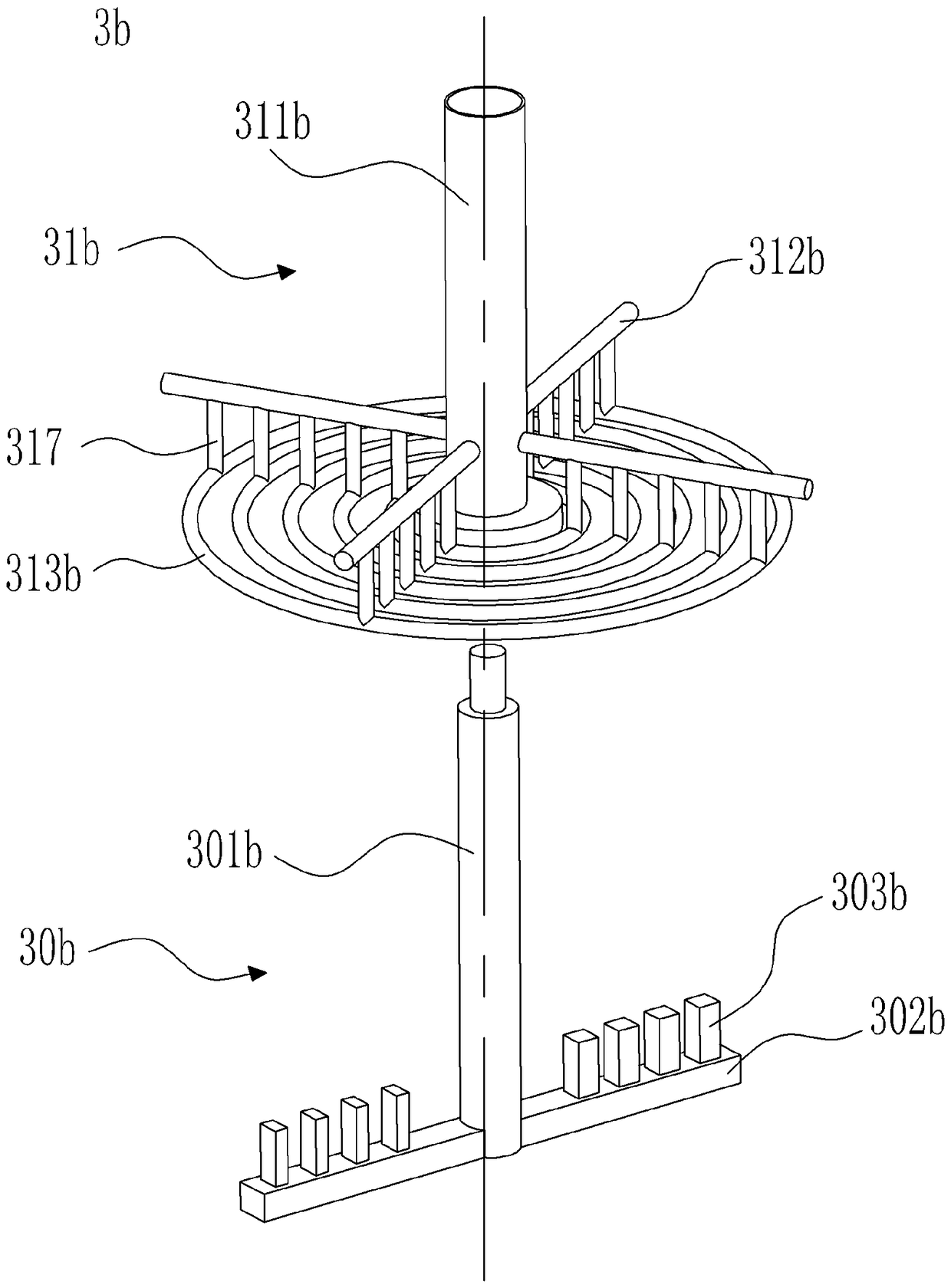

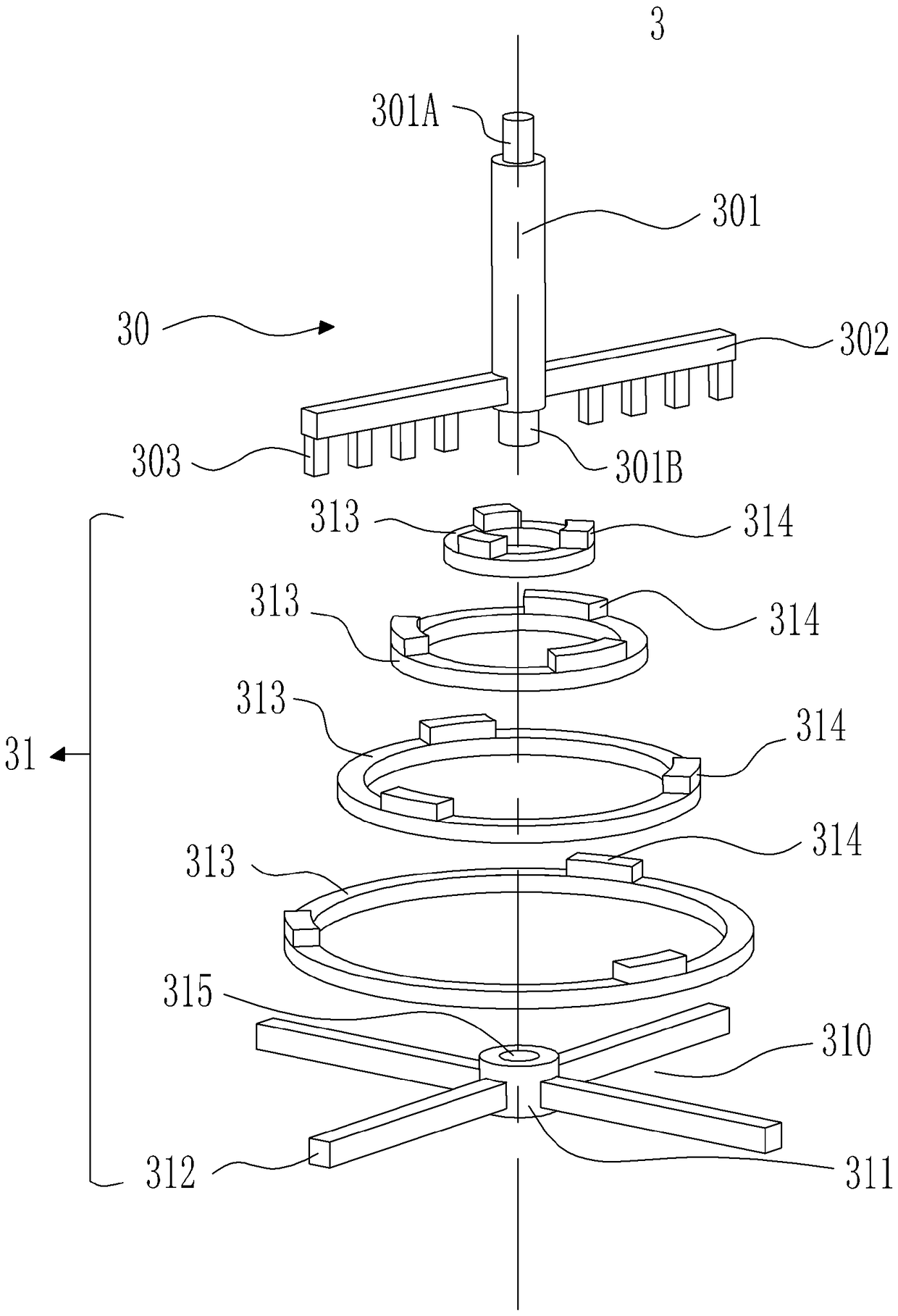

[0024] figure 1 A vertical crusher is schematically shown in a perspective view, wherein a preferred embodiment of the crushing assembly for crushing sludge lumps according to the invention is used in the vertical crusher. figure 2 shown in cross-sectional view figure 1 Broken components in. As shown in the figure, a crushing assembly 3 for crushing sludge lumps is arranged in the casing 2 of the vertical crusher 1 . The casing 2 is generally arranged vertically, and may include a cylinder body 202 and a top cover 201 located at the upper end of the cylinder body, wherein the bottom of the cylinder body 202 is opened downward. In addition, the housing 2 can be constructed in other forms, for example, the cylinder body 202 and the top cover 201 of the housing 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com