High-efficiency crushing device for refractory materials

A high-efficiency pulverizing and processing device technology, applied in grain processing and other directions, can solve problems such as the improvement of pulverizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

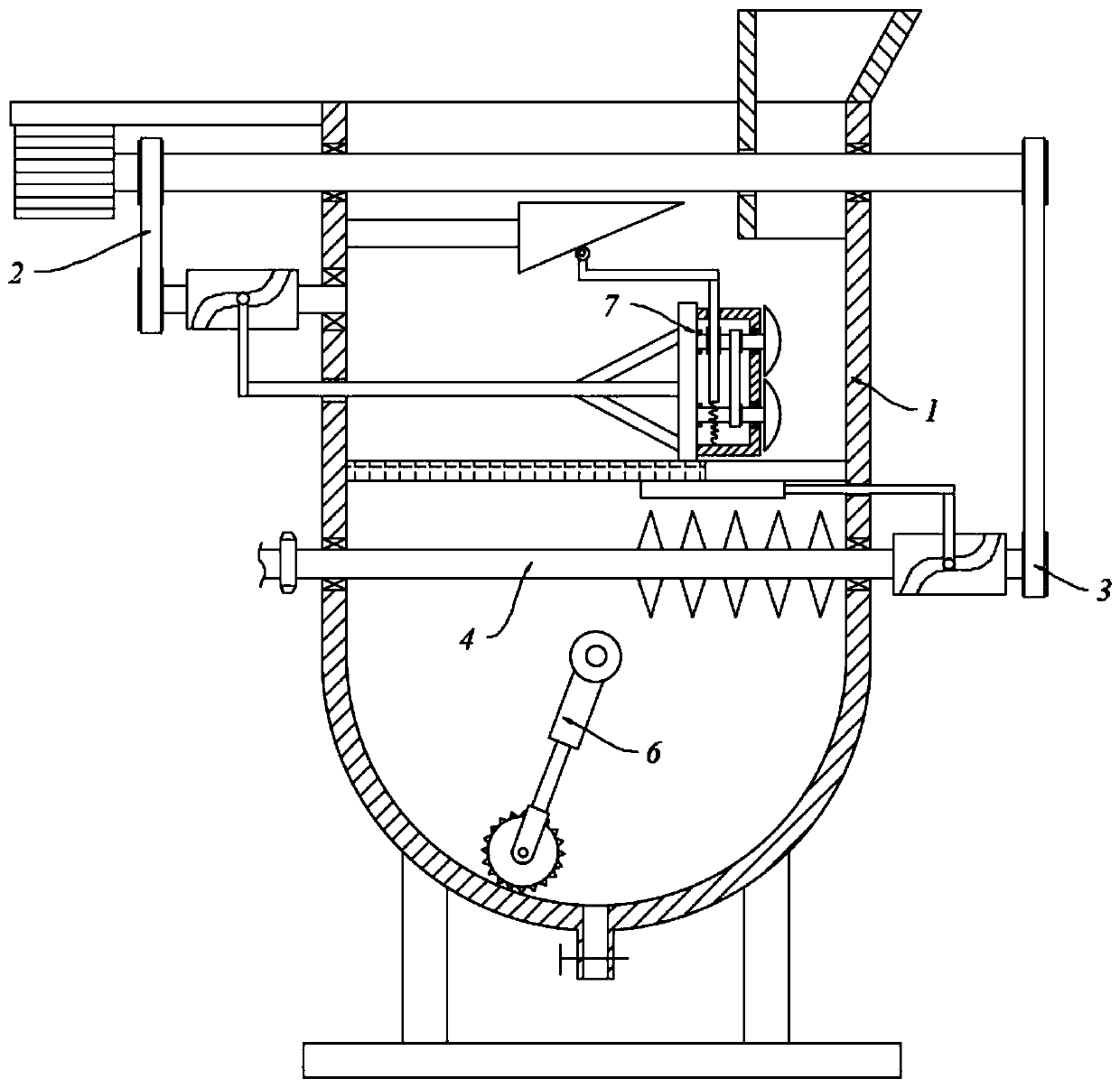

[0050] Referring to the accompanying drawings, a high-efficiency crushing treatment device for refractory materials includes a housing 1, a reciprocating assembly 2, a primary crushing assembly 7, a plugging assembly 3, a secondary crushing assembly 4, a transmission assembly 5, and a tertiary rolling assembly 6 ;

[0051] The housing 1 includes an upper processing chamber 101 and a lower processing chamber 105, the middle part of the upper processing chamber 101 is fixedly connected with a partition 102, the right end of the partition 102 is provided with a discharge port 103, and the discharge port 103 is provided with a blocking assembly 3;

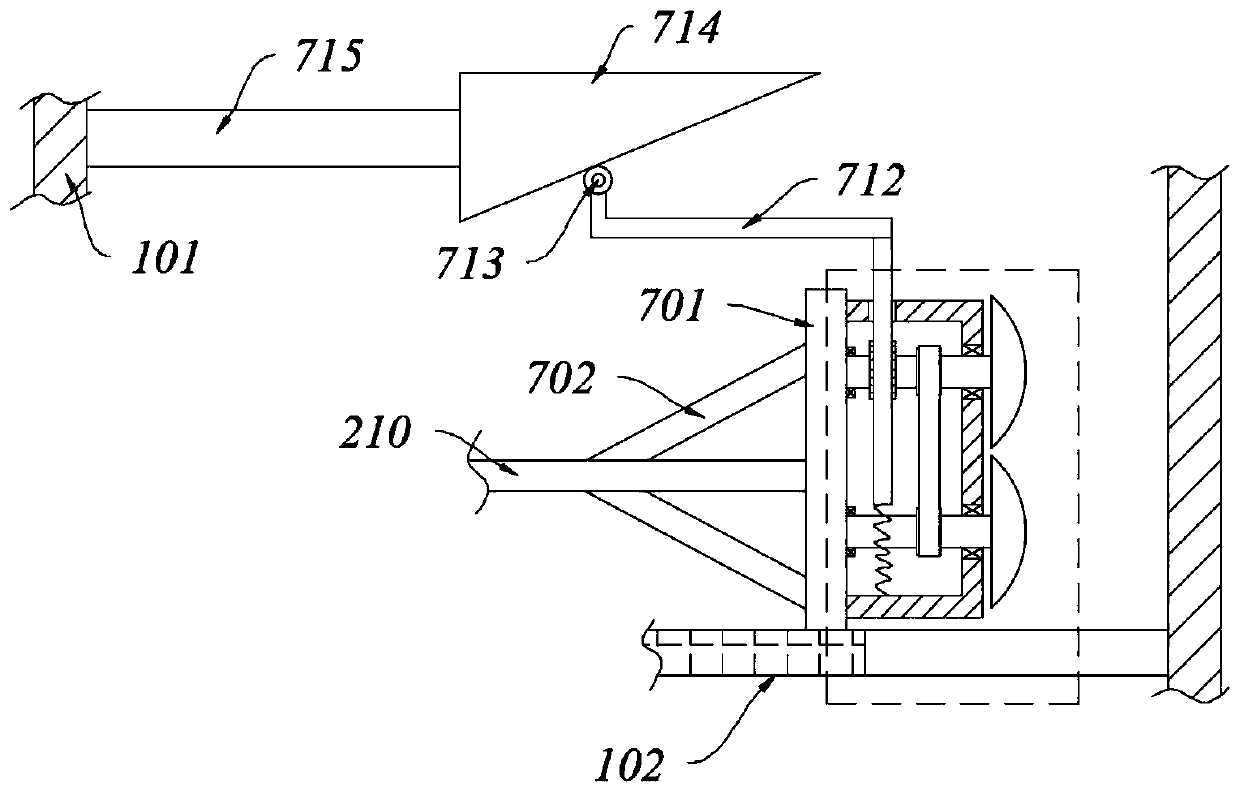

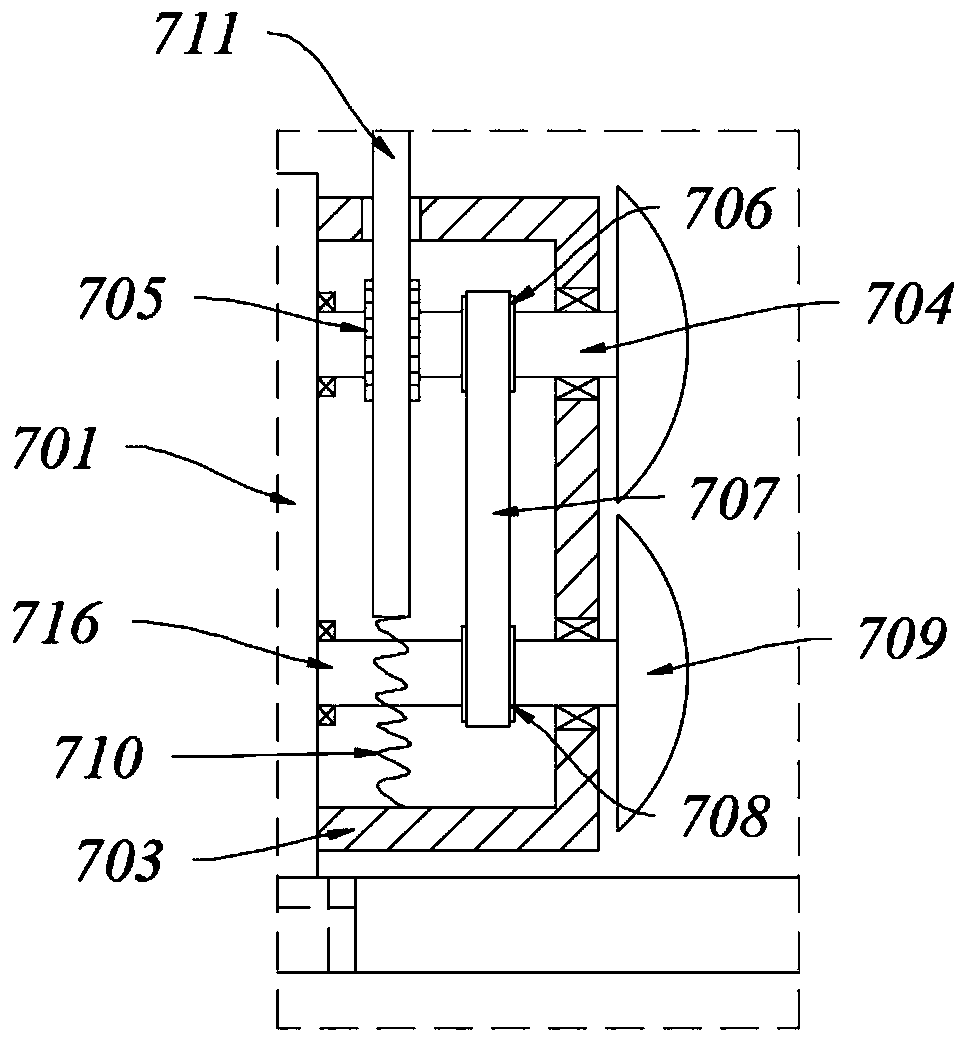

[0052] The primary crushing assembly 7 is arranged above the partition 102; the primary crushing assembly 7 includes a base plate 701, a transmission box 703, an upper shaft 704, a driving gear 705, a fifth transmission wheel 706, a third transmission belt 707, and a sixth transmission belt. No. drive wheel 708, end block 709, No. 3 sp...

Embodiment 2

[0055] Referring to the accompanying drawings, a high-efficiency crushing treatment device for refractory materials includes a housing 1, a reciprocating assembly 2, a primary crushing assembly 7, a plugging assembly 3, a secondary crushing assembly 4, a transmission assembly 5, and a tertiary rolling assembly 6 ;

[0056] The housing 1 includes an upper processing chamber 101 and a lower processing chamber 105, the middle part of the upper processing chamber 101 is fixedly connected with a partition 102, the right end of the partition 102 is provided with a discharge port 103, and the discharge port 103 is provided with a blocking assembly 3;

[0057] The primary crushing assembly 7 is arranged above the partition 102; the primary crushing assembly 7 includes a base plate 701, a transmission box 703, an upper shaft 704, a driving gear 705, a fifth transmission wheel 706, a third transmission belt 707, and a sixth transmission belt. No. drive wheel 708, end block 709, No. 3 sp...

Embodiment 3

[0076] Wherein, the same or corresponding components as in Embodiment 1 and Embodiment 2 adopt the reference numerals corresponding to Embodiment 1 and Embodiment 2. For the sake of brevity, only the differences from Embodiment 2 are described below. The difference between this embodiment and embodiment two is:

[0077] Wherein, a reinforcing rod 702 is connected between the second rod 210 and the base plate 701 to improve the firmness of the connection; the right part of the end plate 709 is processed with a protrusion to improve the grinding effect.

[0078] Wherein, the connecting rod 712 is an L-shaped bent rod, one end is fixedly connected to the vertical rack 711, and the other end is equipped with a No. 3 roller 713. In this way, the fixed wedge 714 can be arranged in the upper processing chamber Left, to avoid impact on blanking.

[0079] The electrical components mentioned above are all equipped with a power supply, and the control means and circuits are all prior ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com