Method for sealing large-dip-angle downward gas pressure determination drill hole

A technology of gas pressure and large inclination angle, which is applied in the direction of gas discharge, measurement, earthwork drilling and mining, etc., can solve problems affecting pressure measurement work, complicated operation, easy air leakage, etc., and achieve improved sealing quality, strong operability and low price cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

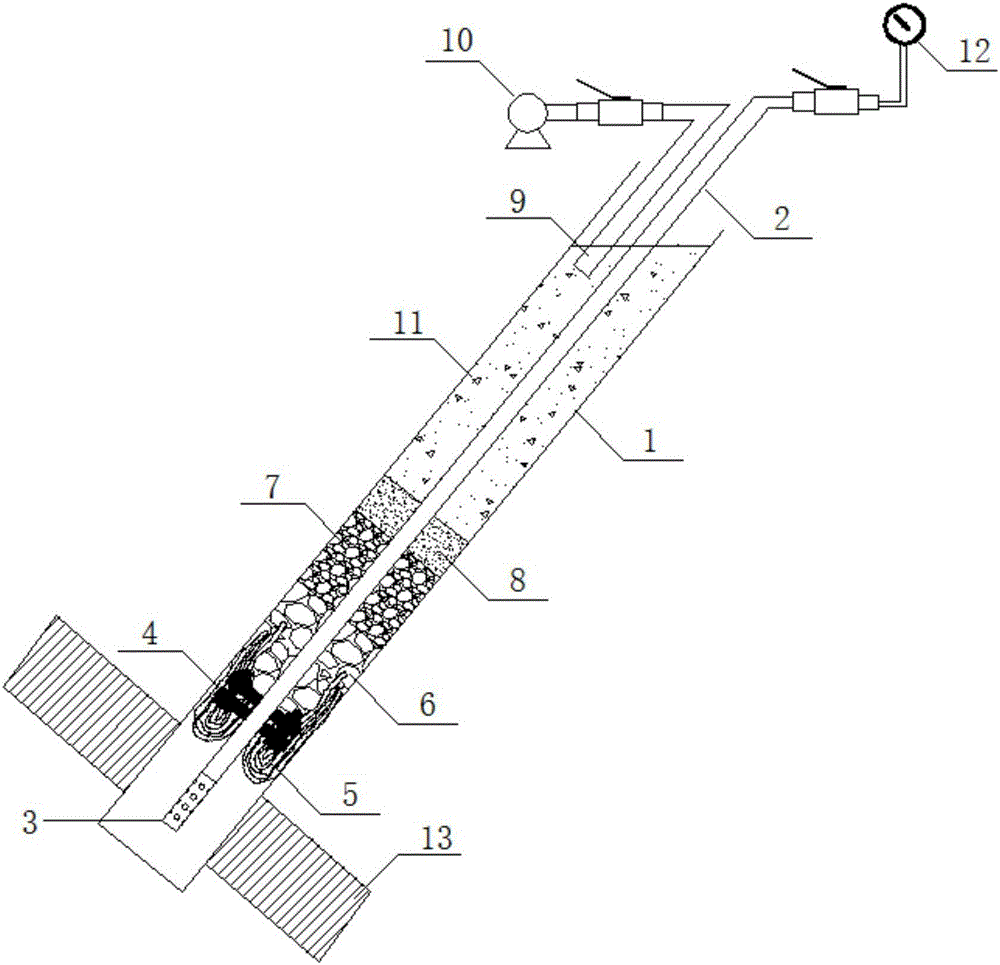

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] A drilling sealing method for measuring downward gas pressure at a large inclination angle, the schematic diagram of the sealing is as follows figure 1 As shown, the method includes the following steps:

[0027] 1) Construct a high-inclination borehole 1 with a diameter of 75mm from the roadway to the target coal seam 13 below. Stop drilling when the drilling reaches 2m from the bottom of the coal seam, withdraw the drill pipe, and use the compressed air method to clean the high-inclination borehole 1. scum.

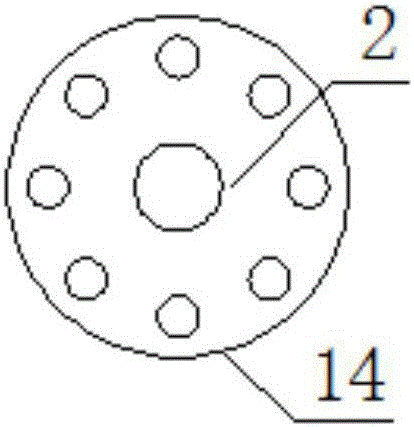

[0028] 2) A disc I4 with a diameter of 50 mm is welded at the position 2 m from the end of the pressure measuring tube 2, and eight bolt holes with a diameter of 6 mm are uniformly arranged on the edge of the disc I4, as shown in figure 2 shown.

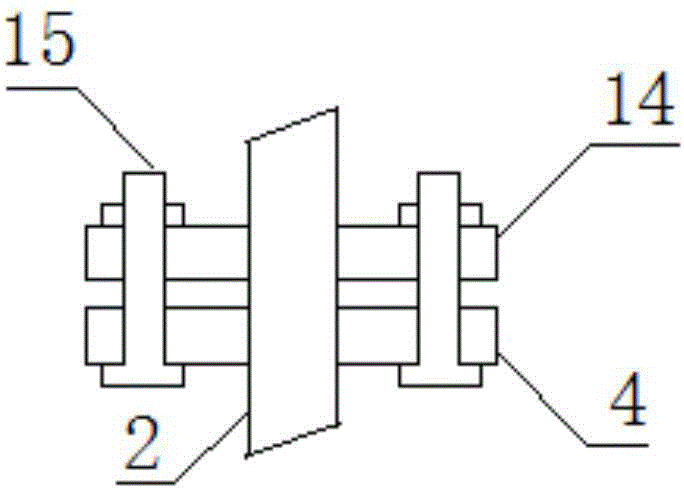

[0029] 3) Put another movable disk II14 identical to the disk I4 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com