Profile modification agent for epoxy resin emulsion

A technology of epoxy resin emulsion and profile control water blocking agent, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor selectivity and achieve suitable particle size, high viscosity and small particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1. Optimal design of epoxy resin emulsion profile control and water blocking agent formula:

[0025] 1. Establishment of epoxy resin concentration:

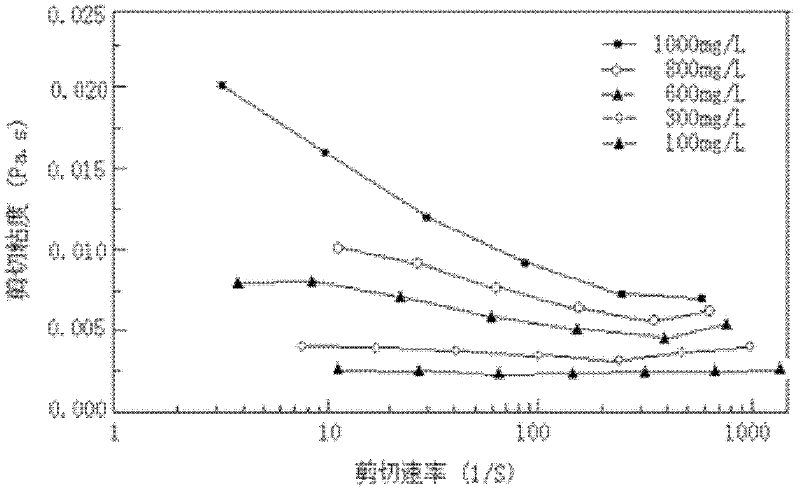

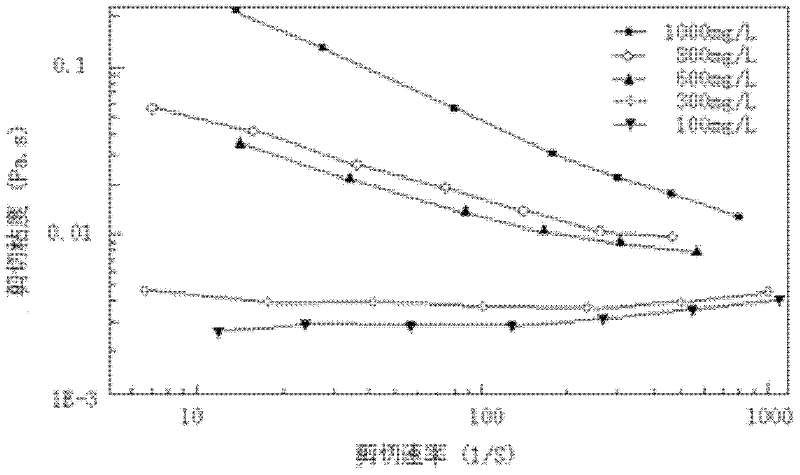

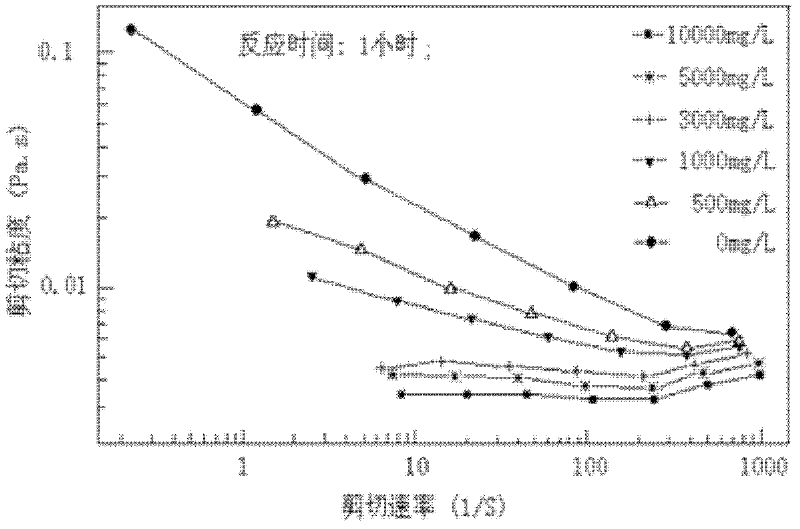

[0026] Because the concentration of epoxy resin is an important factor for whether the crosslinking system can form an emulsion, it is first necessary to establish the concentration of epoxy resin and measure the viscosity of the system after crosslinking different concentrations of epoxy resin and acrylic acid for different times. Experimental data Such as figure 1 and figure 2 shown.

[0027] Depend on figure 1 and figure 2 Shown: the viscosity of the crosslinking system increases with the increase of the epoxy resin concentration after the reaction is carried out for 1 hour. When the epoxy resin concentration is greater than 600mg / L, there is no obvious shear thinning phenomenon. When the rate is very large, it shows the behavior of shear thickening. During the reaction, the cross-linking system with epoxy resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com