Patents

Literature

284results about How to "No yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

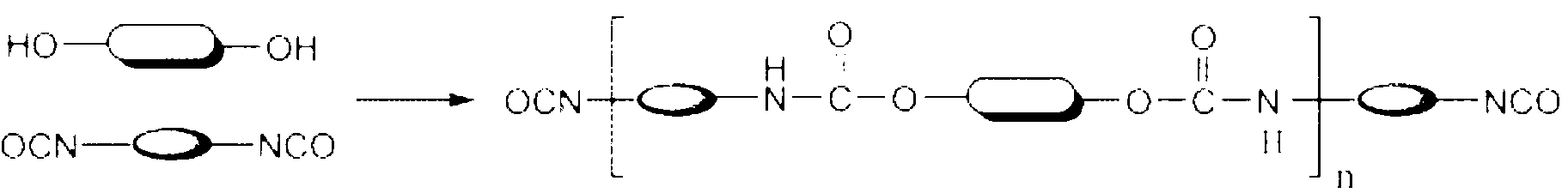

Non-yellowing thermoplastic polyurethane hot melt adhesive and preparation method thereof

InactiveCN101760166ASolve the problem of yellowing and agingNo yellowingPolyureas/polyurethane adhesivesIsocyanate compoundXenon lamp

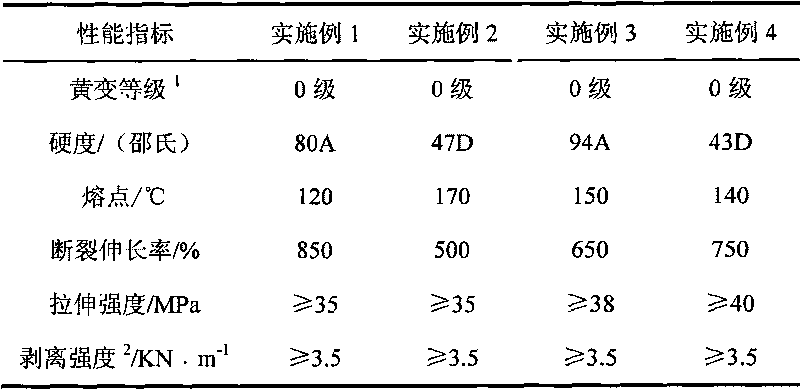

The invention discloses non-yellowing thermoplastic polyurethane hot melt adhesive which is calculated by weight percentage; the prescription comprises the following components: 40 to 55 percent of polyester polyol, 30 to 45 percent of polyether polyol, 1 to 4 percent of chain extendor, 12 to 24 percent of aliphatic isocyanates, 0.2 to 2 percent of coupling agent, 0.5 to 4 percent of inorganic nano-sized powder, and 0.02 to 0.05 percent of catalyst which are prepared through bulk polymerization. The invention adopts aliphatic isocyanates as the raw material, thereby fundamentally solving the problem that the polyurethane hot melt adhesive on sale yellows and is aged in a short time; the prepared polyurethane hot melt adhesive does not yellow in 504 hours under the irradiation of an xenon lamp, is particularly applicable in the bonding of products with appearance in light color or in white or with quite high grade, does not contain organic solvent, has no harm to the environment and the human body when in use and belongs to environment-friendly hot melt adhesive; and in addition, the preparation method has the advantages of little equipment investment, simple process, easy operation, stable product quality and the like.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Tile glue

ActiveCN102206066ANo yellowingThere will be no pan-alkaline vomiting phenomenonEmulsionPortland cement

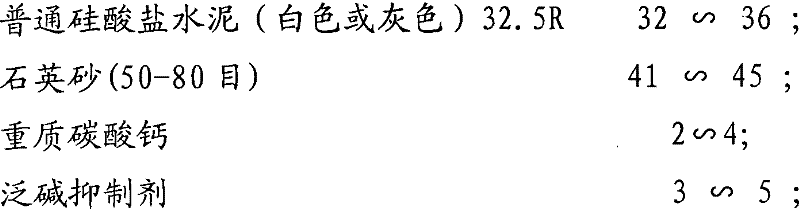

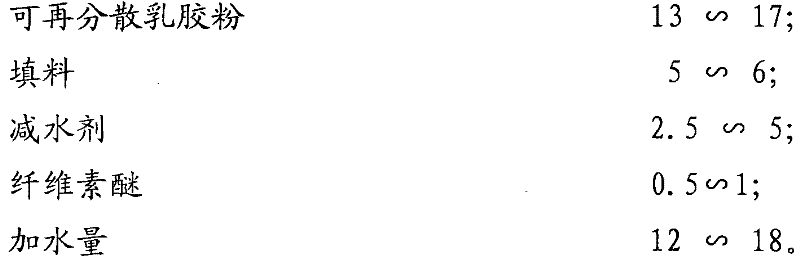

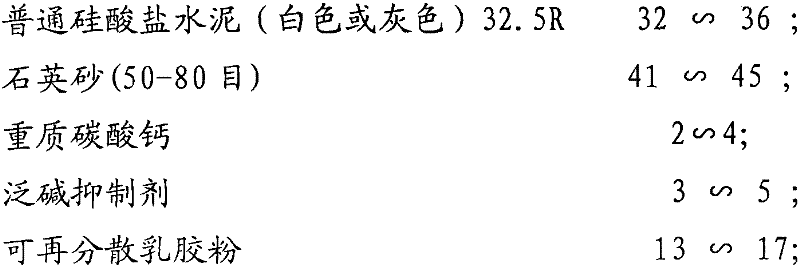

The invention discloses a tile glue, comprising ordinary portland cement, quartz sand, re-dispersible emulsion powder, heavy calcium carbonate, water reducer, cellulose ether and efflorescence inhibitor. By utilizing the technical scheme, since the efflorescence inhibitor is added, there is no yellowing and efforescence phenomenon after construction; and the portion of the re-dispersible emulsionpowder is increased, so that the technical effect of pasting glass onto glass directly can be achieved.

Owner:XIAMEN LIKASAM WATERPROOF ENG

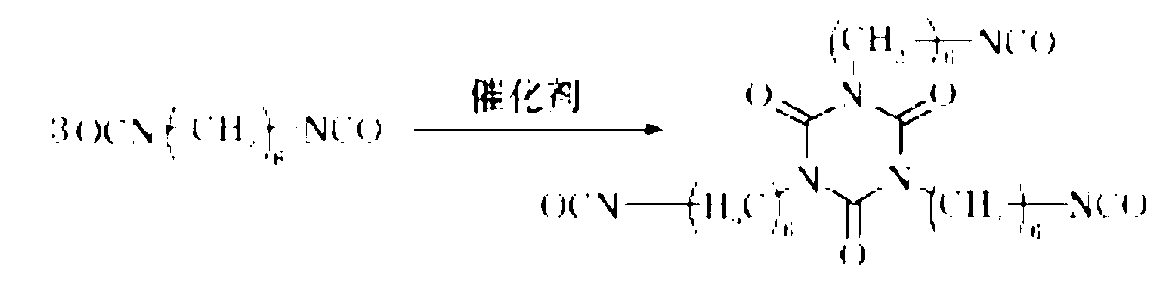

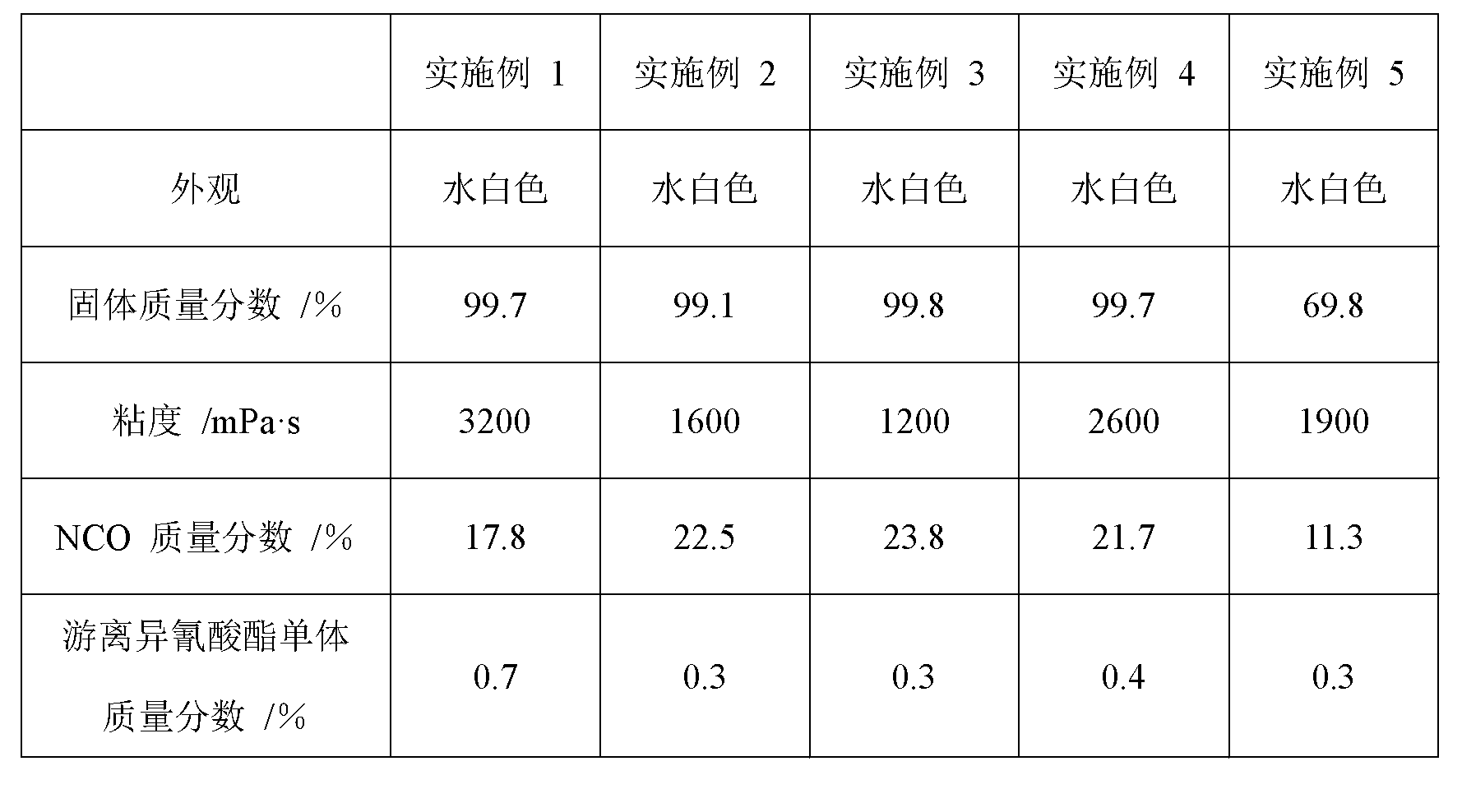

Polyurethane curing agent with low free isocyanate monomer and preparation method thereof

InactiveCN103224605AAdd one step polymerization reactionLow free HDI contentPolyurea/polyurethane coatingsPolymer scienceMeth-

The present invention relates to a polyurethane curing agent with low free isocyanate monomer and a preparation method thereof. The polyurethane curing agent comprises the raw materials in weight percentage as following: 80 - 88 parts of hexamethylene diisocyanate monomer; 12 - 20 parts of polyhydric alcohol; 0.1-0.5 part of catalyst; and 0.1-1.0 part of terminating agent. The invention adopts a two-step chemical conversion reaction, namely, adds one step of polymerization reaction based on one-step addition reaction to remove free isocyanate monomer by a trimer method so as to obtain the 100% solid content, wherein the NCO content is between 21 and 22 %, and the free HDI content is between 0.1 and 1.0 %. According to the present invention, the preparation process of polyurethane curing agent is simplified without post-processing . The polyurethane curing agent of the invention is matched with hydroxyl acrylic resin and polyester resin etc., and the paint film will not be yellowed, and has excellent light resistance, weathering resistance, chemical resistance and gorgeous gloss.

Owner:HUBEI TRASION CHEM IND CO LTD

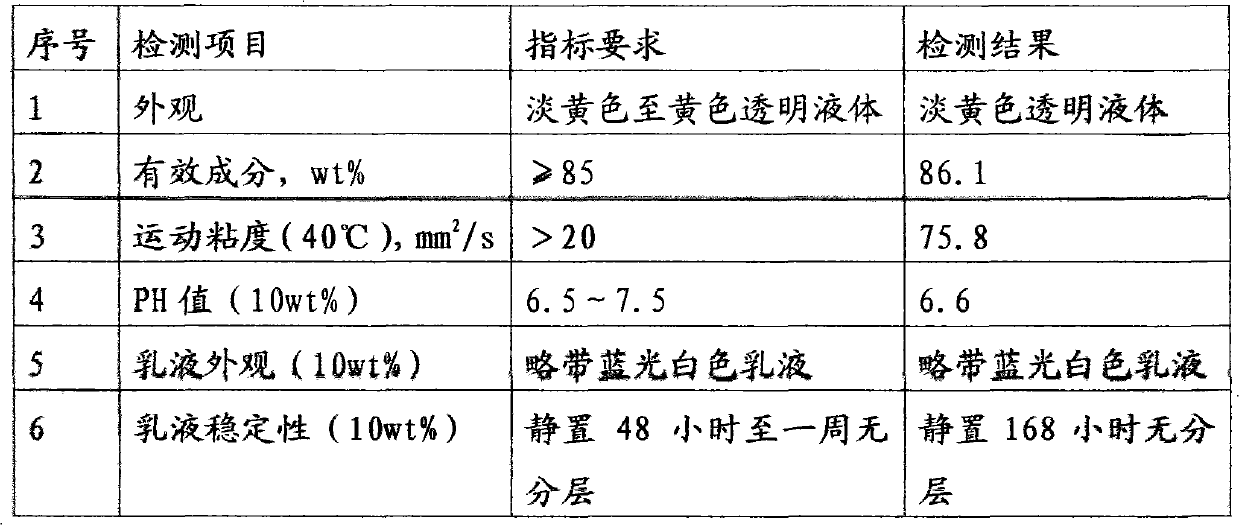

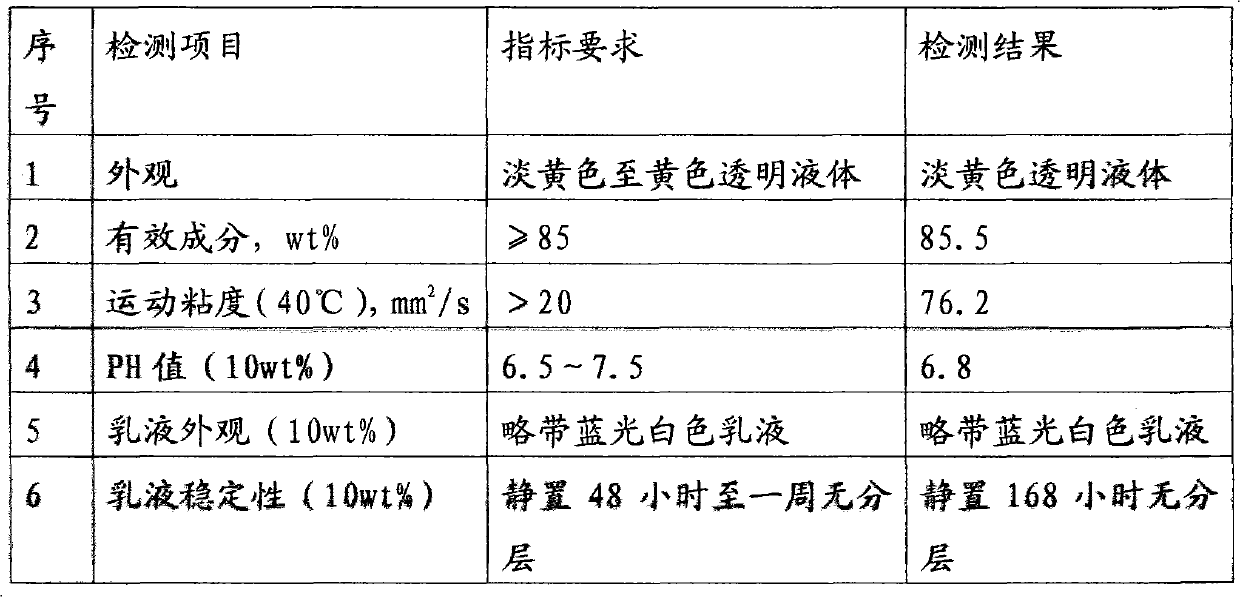

Environment-friendly polypropylene filament yarn oil agent and production method thereof

The invention discloses a preparation method of an environment-friendly polypropylene filament yarn oil agent, comprising the following steps of: weighing 40 to 60 parts by weight of fatty alcohol ether phosphate potassium salt, 2 to 8 parts by weight of polysiloxane polyether copolymer, 3 to 12 parts by weight of pentaerythritol oleate, 4 to 10 parts by weight of fatty alcohol polyoxyethylene ether, 2 to 12 parts by weight of ethylene oxide-epoxypropane block polyether, 20 to 45 parts by weight of polyethylene glycol laurate, 10 to 20 parts by weight of butter alcohol amine phosphate salt and 5 to 10 parts by weight of high-carbon heterogeneous alcohol phosphate potassium salt, heating to 40 to 80 DEG C, reacting under the stirring condition, then adding 20 to 40 parts of emulsifying agent EL-40, 1 to 5 parts of methyl-1-hydroxyethyl-2-stearyl imidazoline ammonium methosulfate, 5 to 15 parts of dimethyl silicon oil, 2 to 40 parts of deionized water and 0.001 to 0.02 part of preservative, reacting under the stirring condition at 50 to 70 DEG C, and separating to obtain the environment-friendly polypropylene filament yarn oil agent.

Owner:青岛荣达新材料研究所

Production method of formaldehyde-free non-ironing shirt

ActiveCN102808322AShort production processSimple process controlFibre treatmentFormaldehyde freeProcess control

The invention relates to a production method of a formaldehyde-free non-ironing shirt. The production process is as follows: spraying of finishing liquid, drying, stereoscopic molding, shaping of a drying tunnel, and dehumidifying and dampening, wherein the drying temperature is set to be 80 DEG C to 90 DEG C, and the humidity is controlled to be 30-50%; in the stereoscopic molding step, a stereoscopic combined type press process is adopted, the temperature is controlled to be 140 DEG C to 160 DEG C the time is controlled to be 1-2min, and force of 6-10 kg / cm<2> is applied; and in the step of shaping of the drying tunnel, the design of circular blowing and heat insulation as well as a band-type drying tunnel of a ternary-form gradually-heated system are adopted, the shaping temperature of different segments is set to be 110 DEG C to 140 DEG C, 130 DEG C to 160 DEG C and 150 DEG C to180 DEG C, and the total shaping time is 3-6min. The non-ironing shirt produced by the invention is free from formaldehyde and belongs to a real formaldehyde-free non-ironing shirt, the production process flow is short, the process control is simple, the production reproducibility is good, and the product quality is stable.

Owner:SUQIAN BAOZITOU GARMENTS TECH

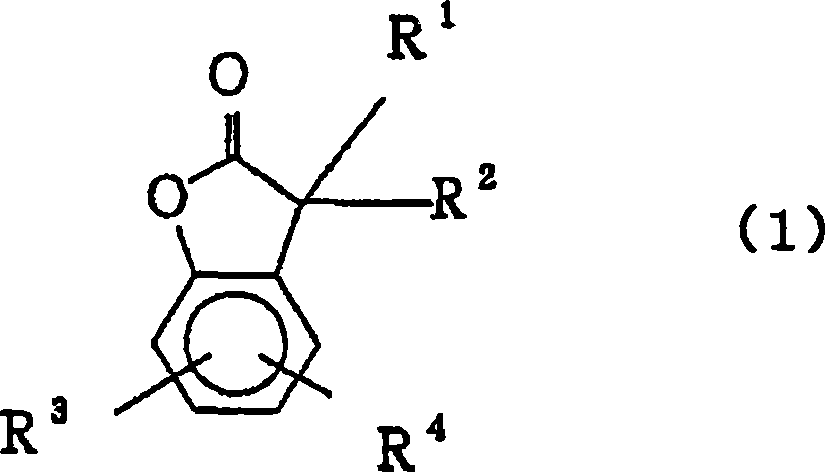

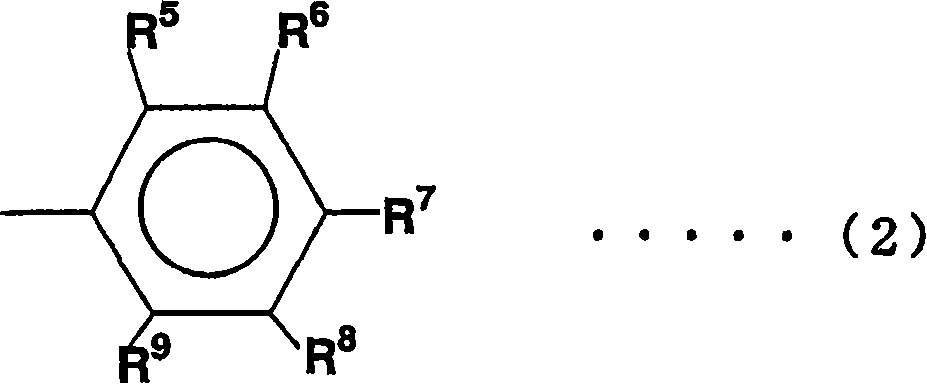

Lens for glasses and process for producing the same

InactiveCN1910503AImprove impact resistanceHigh transparencyOptical partsOptical elementsPolymer scienceChlorobenzene

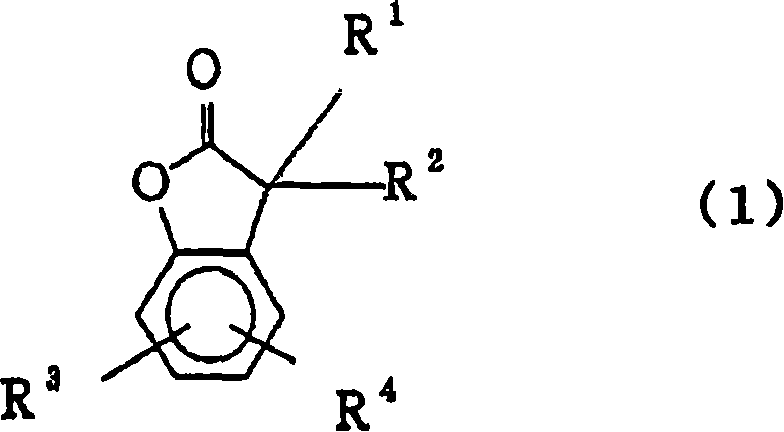

A spectacles lens and an optical transparent molded article are provided that are formed from a polycarbonate resin composition comprising: (1) 100 parts by weight of polycarbonate resin (A), (2) 0.05 to 0.5 parts by weight of at least one ultraviolet absorber (B) selected from the group consisting of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole (B-1) and 2-(2'-hydroxy-5'-tert-octylphenyl)benzotriazole (B-2), (3) 0.01 to 0.3 parts by weight of at least one ultraviolet absorber (C) selected from the group consisting of 2-(3-tert-butyl-5-methyl-2-hydroxyphenyl)-5-chlorobenzotriazole (C-1), 2,2'-methylenebis[4-(1,1,3,3-tetramethylbutyl)-6-(2H-benzotriazole)-2-ylphenol] (C-2) and 2-[2-hydroxy-3,5-bis(+-,+--dimethylbenzyl)phenyl]-2H-benzotriazole (C-3), and (4) 0.0005 to 0.1 parts by weight of lactone compound having a specific structure.

Owner:TEIJIN CHEM LTD

Full-dull polyamide 6 fibre and method for producing the same

ActiveCN101463506AAvoid yellowingImprove structural uniformityFilament/thread formingHeating/cooling textile fabricsYarnPolymer science

The invention relates to a chemical fiber and a manufacturing method thereof, in particular to a full-dull daiamid 6 fiber added with titanium dioxide and a manufacturing method thereof. The full-dull daiamid 6 fiber and the manufacturing method thereof which have less polymer degradation, even yarn levelness, less filoplume and uniform dyeing aim at solving the disadvantages of easy degradation of high polymer fusant, poor evenness of the yarn levelness, high fluctuation of oiling rate, easy occurrence of more filoplume, bad uniformity of dyeing, etc. The invention mainly has the technical proposal that daiamid 6 particle with more than or equal to 1.6% of TiO2 is taken as raw material, treated by melt spinning and cross air blasting through twice of rectification and oiling, and is wound; finally, the full-dull daiamid 6 fiber is obtained.

Owner:YIWU HUADING NYLON

Vinyl acetate-acrylate copolymer emulsion, its synthesis method and application

ActiveCN103059211ALow coating viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesAdhesiveSynthesis methods

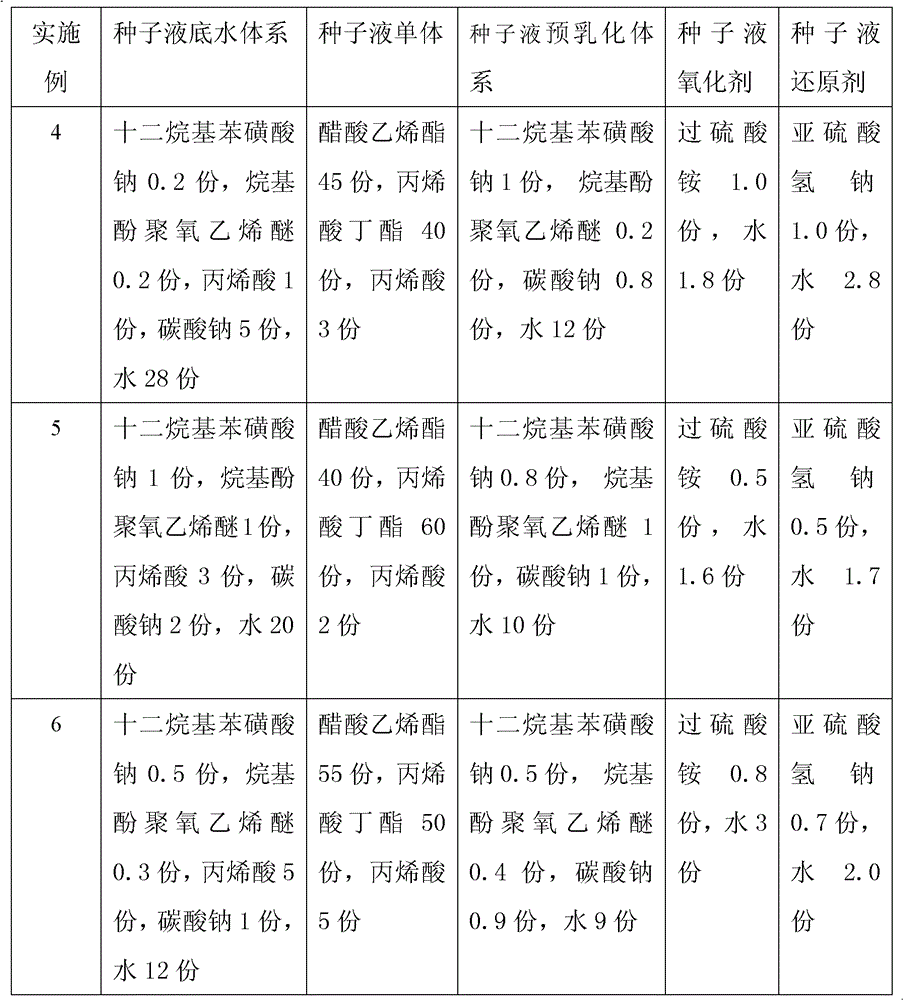

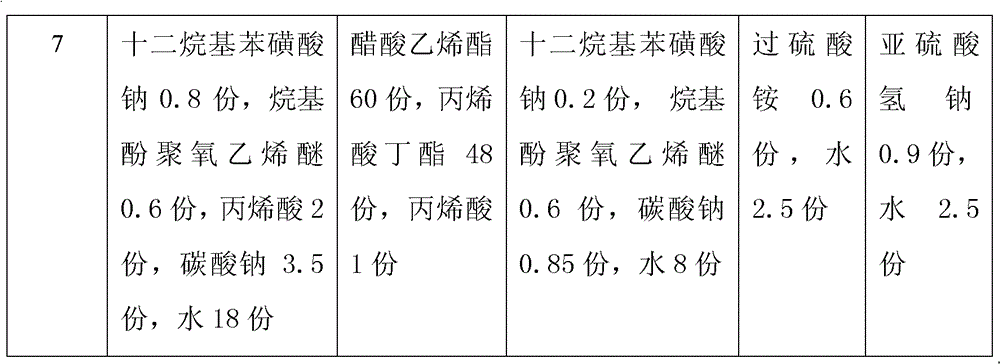

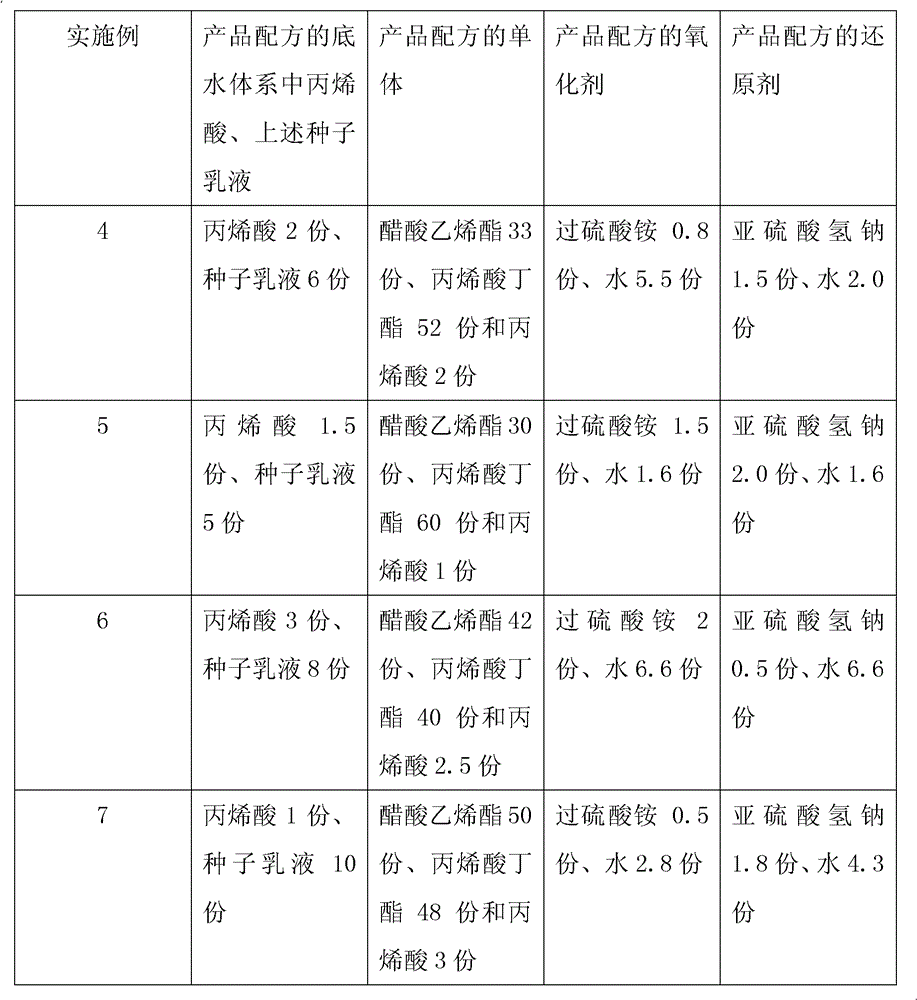

The invention relates to a vinyl acetate-acrylate copolymer emulsion, which is prepared by adopting OP-10, SDBS, SVS, water, acrylic acid and a seed emulsion as the bottom water system, taking VAc, BA and AA as the monomer, employing ammonium persulfate as the oxidant, and using sodium bisulfite as the reducing agent. Specifically, the seed emulsion in the bottom water system is prepared by using SDBS, OP-10, AA, sodium carbonate and water as the base solution, adopting VAc, BA and AA as the monomer, employing SDBS, OP-10, sodium carbonate and water as the pre-emulsification system, taking ammonium persulfate as the oxidant, and adopting sodium bisulfite as the reducing agent. The emulsion provided in the invention has a solid content of 40%-45%, viscosity (in terms of a 4-cup application amount) of 20S-26S, bonding peel strength (N / 2.5cm) of 1.4-2.5, a surface tension force of 32-37 dyne, and a film contact angle of 25-29 degrees, thus being particularly suitable for application in dry paper-plastic or plastic-plastic composite adhesives. The preparation method of the vinyl acetate-acrylate copolymer emulsion has the characteristics of mild reaction conditions and safety reaction system, thus being conducive to factory mass production.

Owner:CHINA PETROCHEMICAL CORP +2

LED lighting unit

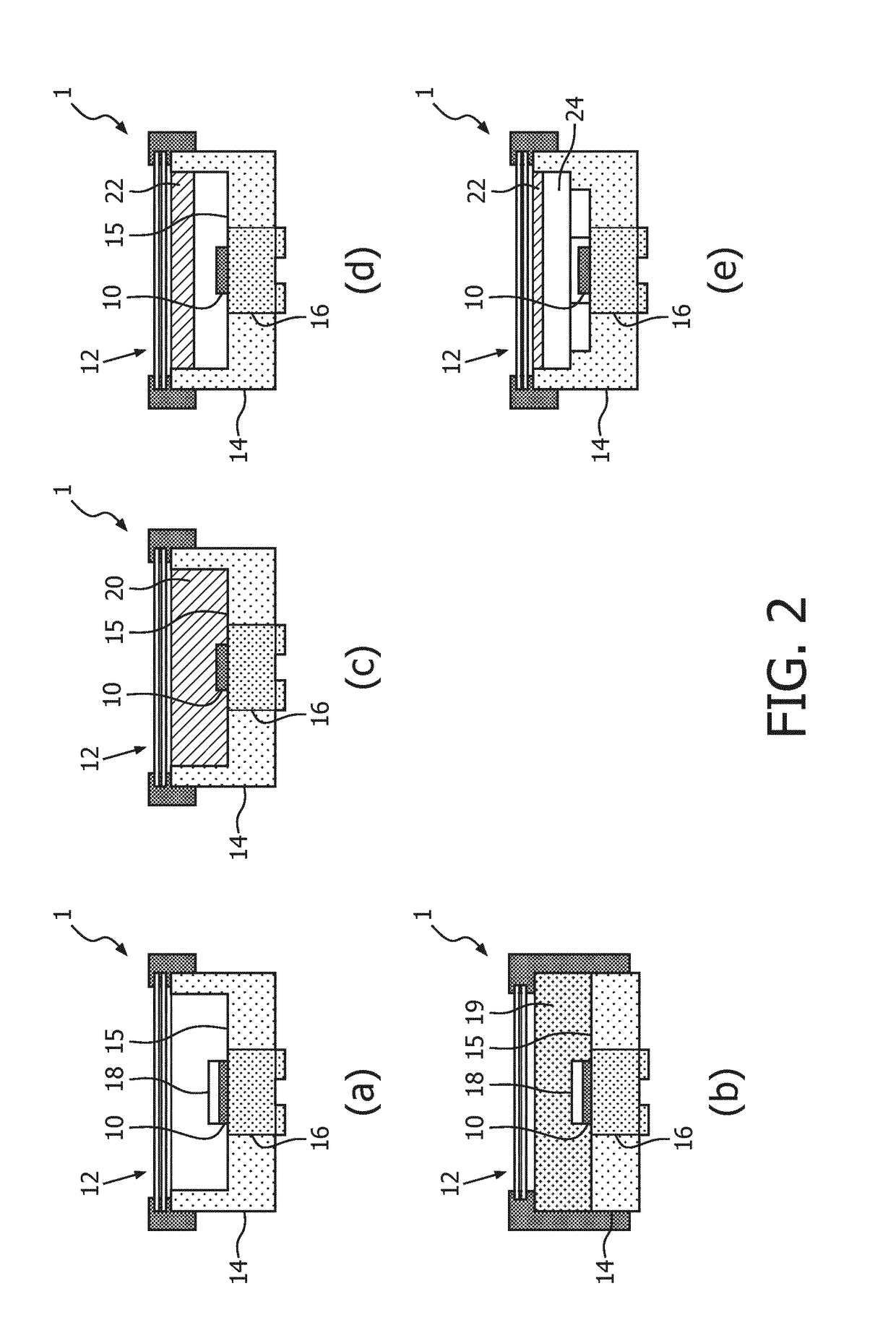

ActiveUS20170126944A1Size lossNo wrinkling or bulgingTelevision system detailsLighting elementsEffect lightEngineering

An LED lighting unit comprising a support structure (14), an LED-based light emitting structure (10) mounted within the support structure and an optical beam shaping arrangement (50, 52) over the top of the support structure. The optical beam shaping arrangement comprises an optically transparent and thermally stable material, and the support structure supports the microstructured layer at a small height above the LED-based light emitting structure. This height may for example be less than 0.5 mm. The optical beam shaping arrangement enables a compact and low height lighting unit to be mounted on a carrier by reflow soldering without damaging the optical beam-shaping component.

Owner:KONINKLJIJKE PHILIPS NV

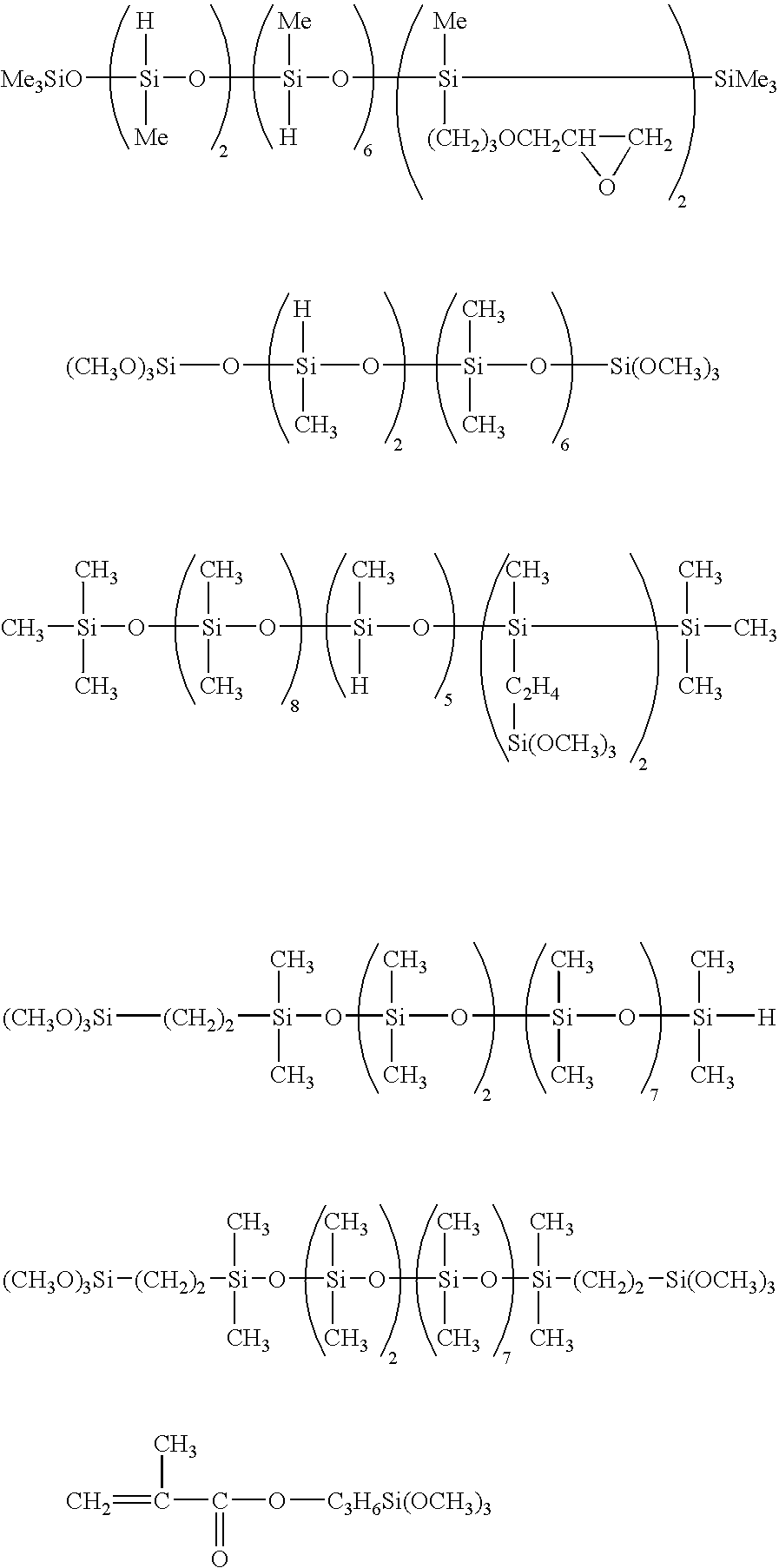

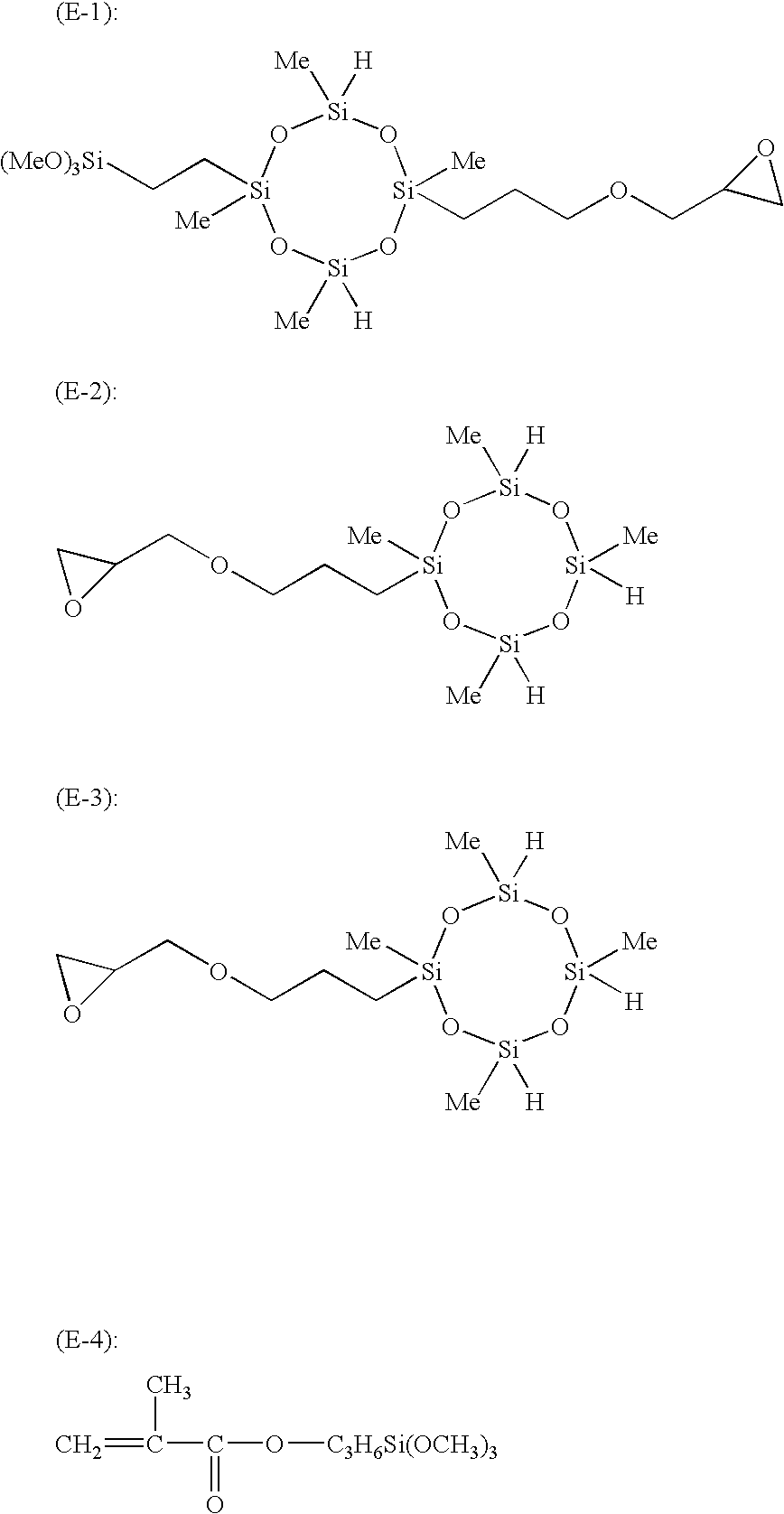

Addition curable silicone adhesive composition and cured product thereof

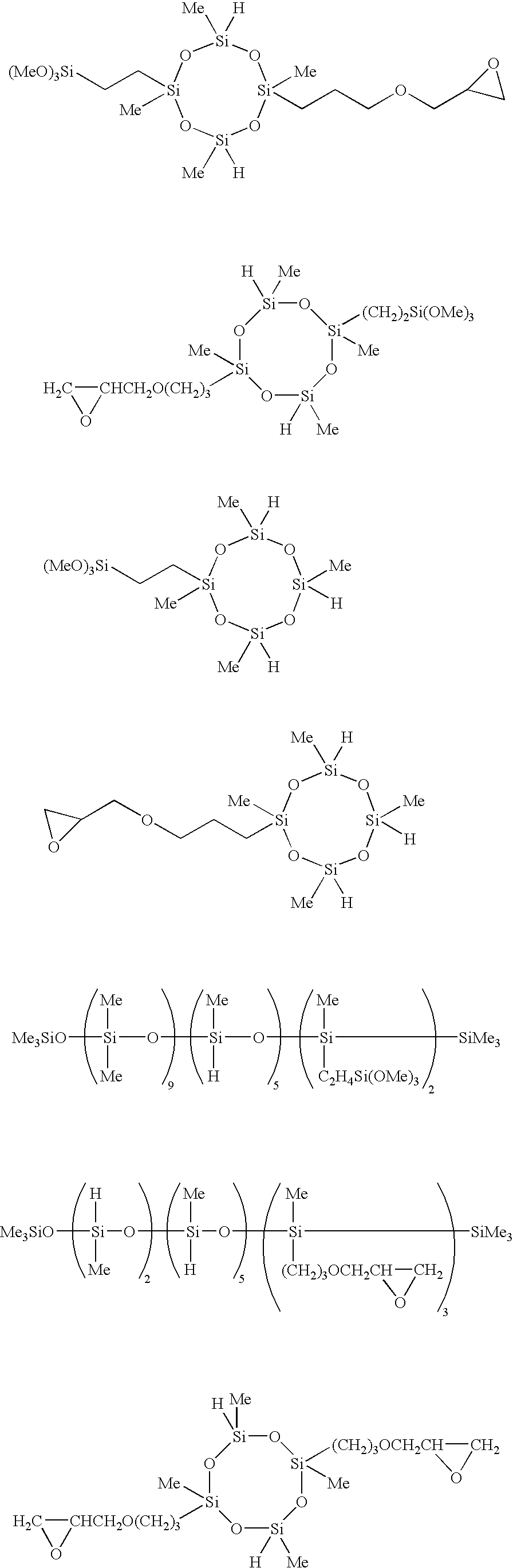

InactiveUS20080146709A1Improve adhesionTransparent highGroup 4/14 element organic compoundsAdhesivesHydrogen atomHydrogen

An addition curable silicone adhesive composition that can be cured at room temperature, exhibits favorable adhesiveness, and yields a cured product upon curing that exhibits excellent transparency and a suitable degree of hardness. The addition curable silicone adhesive composition of the present invention comprises: (A) a diorganopolysiloxane containing at least two silicon atom-bonded alkenyl groups, (B) a three dimensional organopolysiloxane resin that comprises trifunctional siloxane units and / or tetrafunctional siloxane units represented by SiO4 / 2, (C) an organohydrogenpolysiloxane containing at least two silicon atom-bonded hydrogen atoms, (D) a hydrosilylation reaction catalyst, (E) an organosilicon compound as an adhesion-imparting agent, and (F) an acid anhydride that is liquid at room temperature.

Owner:SHIN ETSU CHEM IND CO LTD

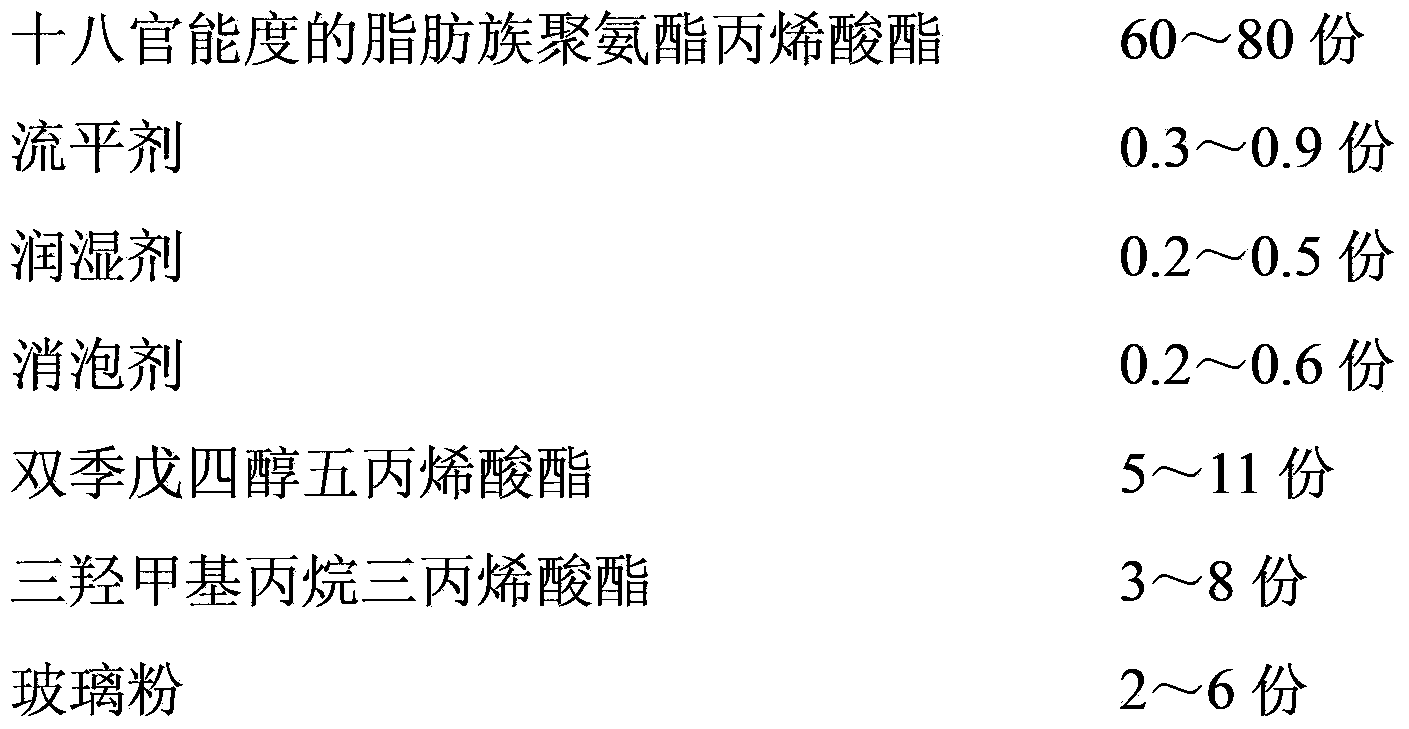

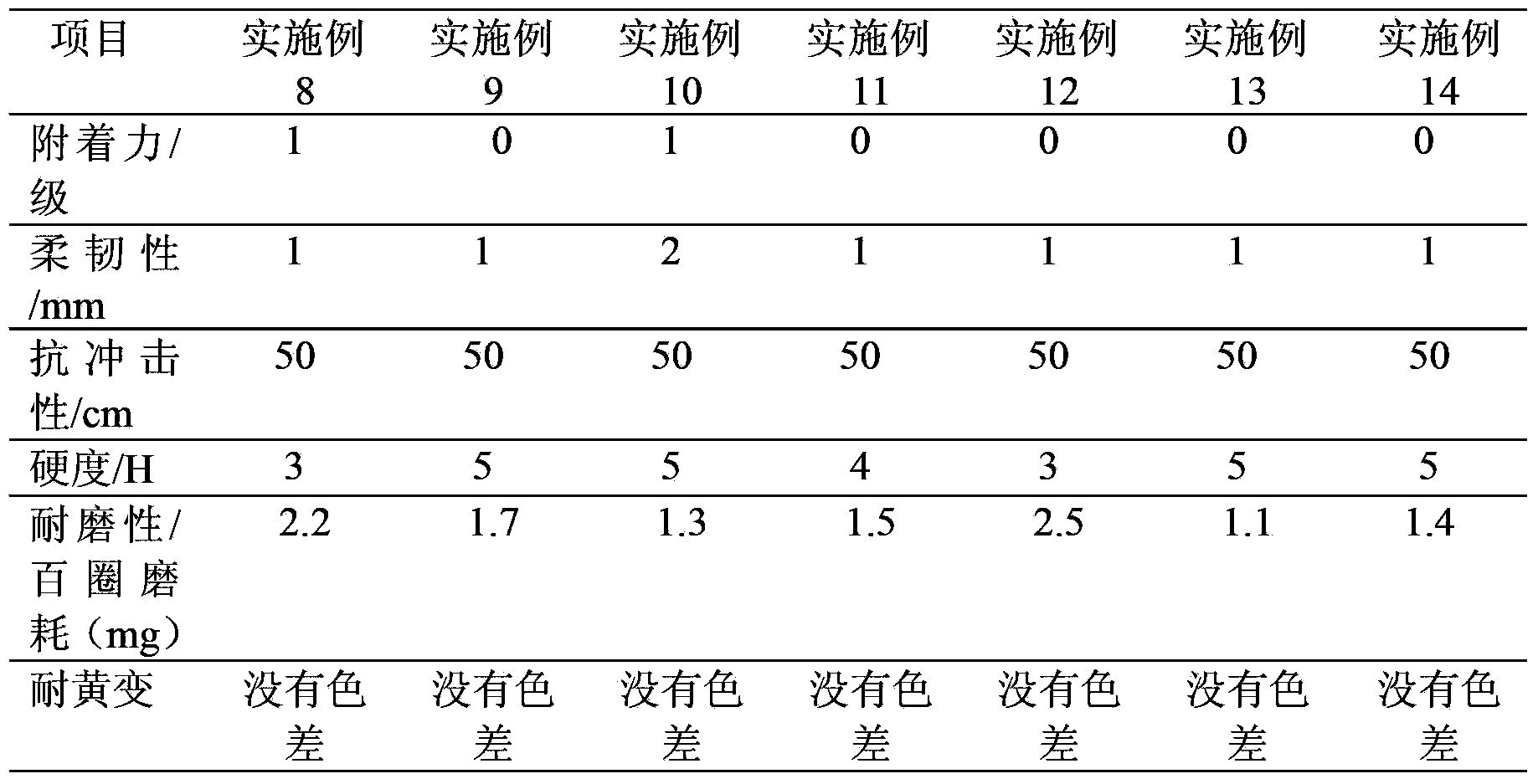

Non-yellowing ultraviolet light curing abrasion resistant paint and preparation method thereof

ActiveCN103409058ANo yellowingHigh hardnessPolyurea/polyurethane coatingsPentaerythritolUltraviolet lights

The invention provides a non-yellowing ultraviolet light curing abrasion resistant paint and a preparation method thereof, belongs to the technical field of ultraviolet light paints and aims to solve the problem of yellowing in a conventional ultraviolet light abrasion resistant paint caused by that an aromatic ultraviolet light resin with rigid construction is adopted as a matrix resin. The paint is prepared by the following components in parts by weight: 60 to 80 parts of aliphatic urethane acrylate with eighteen degree of functionality, 0.3 to 0.9 part of flatting agent, 0.2 to 0.5 part of wetting agent, 0.2 to 0.6 part of antifoaming agent, 5 to 11 parts of dipentaerythritol pentaacrylate, 2 to 6 parts of glass powder, 1 to 5 parts of ceramic powder, 1 to 3 parts of polyethylene wax, and 1.8 to 4 parts of photoinitiator. The invention further provides the preparation method of the non-yellowing ultraviolet light curing abrasion resistant paint. The hardness of the non-yellowing ultraviolet light curing abrasion resistant paint is 3 to 5H, and the abrasive resistance is 1.1 to 2.5 mg per hundred laps.

Owner:CHANGCHUN SANHUA IND

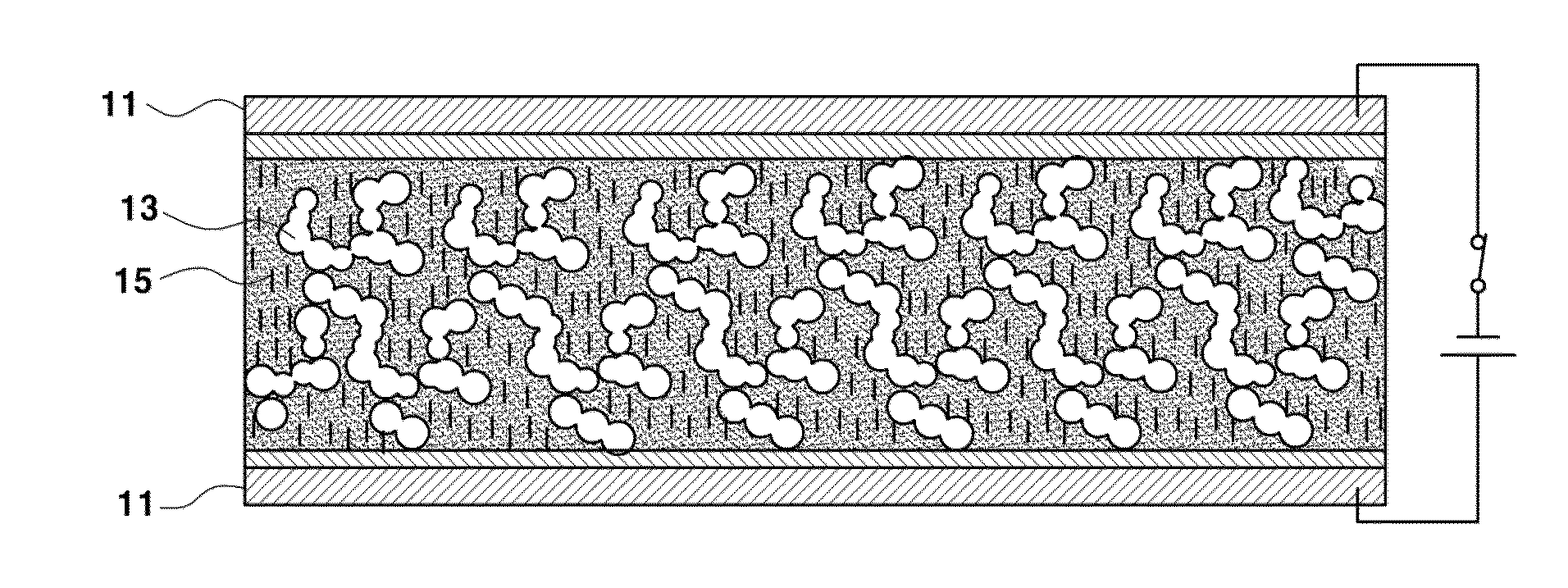

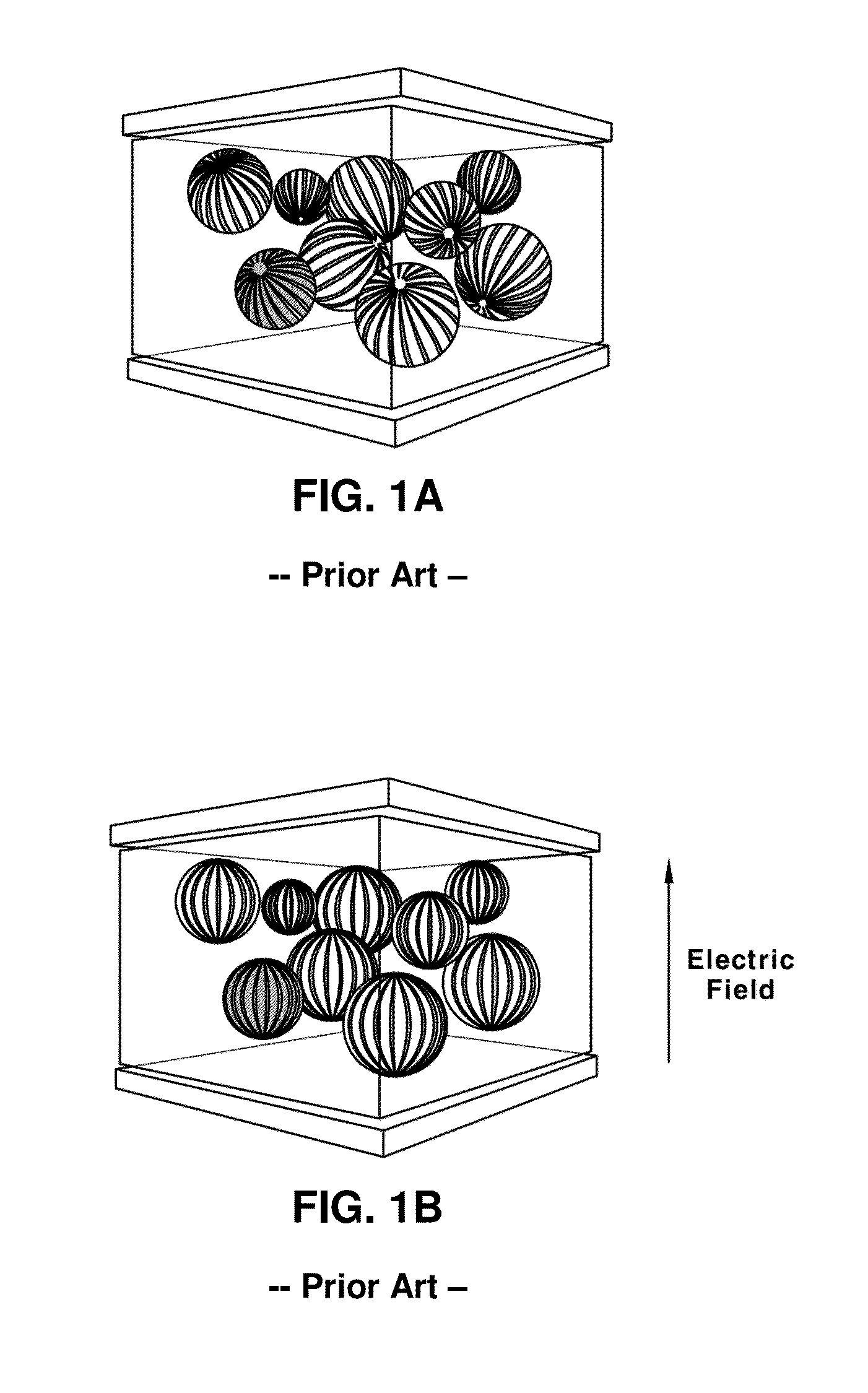

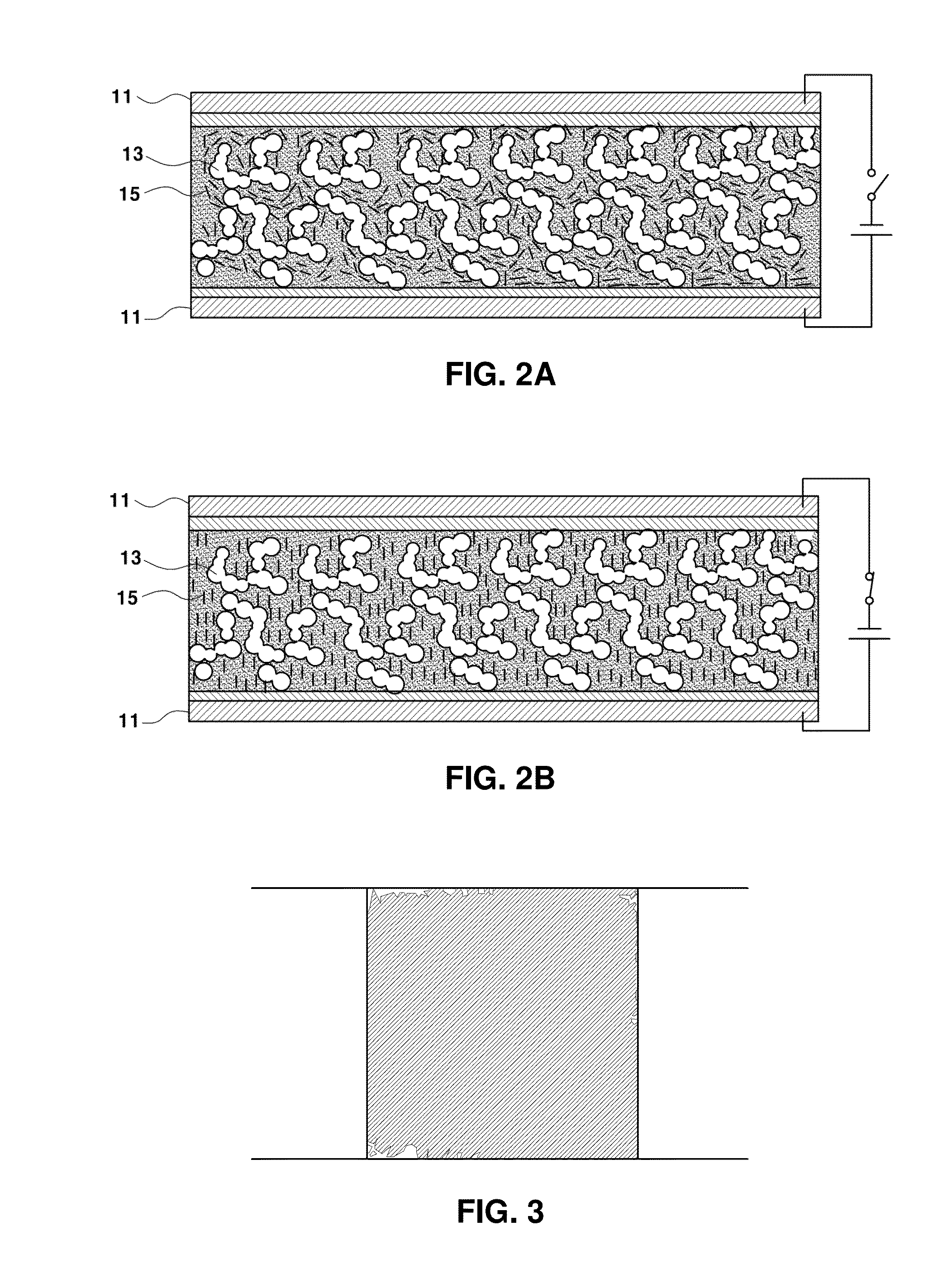

Smart window using aerogel

InactiveUS20160160557A1Low haze valueNo yellowingLayered productsLight protection screensLiquid crystalAerogel

A smart window includes a pair of transparent electrodes spaced apart to face each other. Porous aerogel is interposed between the pair of transparent electrodes. Liquid crystal is interposed between the pair of transparent electrodes and filliping pores of the aerogel. The smart window scatters more light because an interface between the aerogel and liquid crystal is maximized by filling pores of the aerogel with the liquid crystal.

Owner:HYUNDAI MOTOR CO LTD +2

Liquid mixed fertilizer

InactiveCN104686303APromote growthPrevent water quality from deterioratingCultivating equipmentsSoilless cultivationCinnamomum camphoraDistilled water

The invention provides a liquid mixed fertilizer. Main raw materials of the liquid mixed fertilizer comprise fresh crabapple leaves, phoenix tree leaves and Cinnamomum camphora leaves. The liquid mixed fertilizer is prepared by the following steps: adding the leaves into a mixer, smashing the leaves through stirring, adding distilled water into the treated leaves and carrying out soaking for 24 hours, wherein the addition amount of the distilled water is subject to the amount of water capable of completely submerging the leaves and usually is 2 to 3 times of the mass of the leaves; transporting the soaked leaves and the distilled water to a microwave extracting tank, wherein a weight ratio of the leaves to the distilled water is 1: 5; and carrying out heating to 80 DEG C, carrying out extracting for 20 minutes, carrying out cooling, then releasing the obtained extract, and carrying out filtering so as to obtain a hydroponic plant culture solution. The liquid mixed fertilizer provided by the invention contains a plurality of sugar or has bacteriostatic effects, so nutrients can be provided for hydroponic plants, and deterioration of water quality due to root rot can be inhibited; meanwhile, seedling plants cultured by using the liquid mixed fertilizer grow well, do not need changing of water and are free of root rot and leaf yellowing.

Owner:钱佩霞

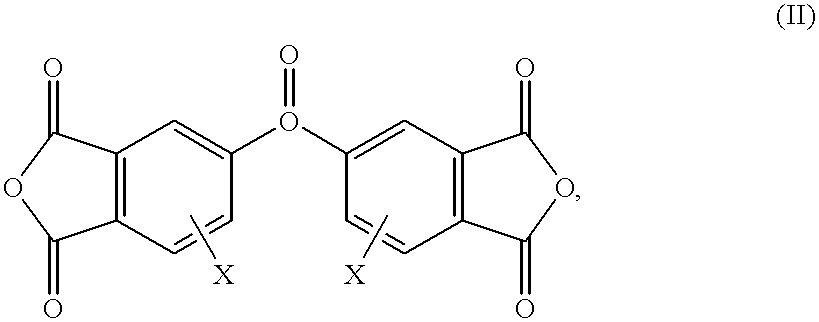

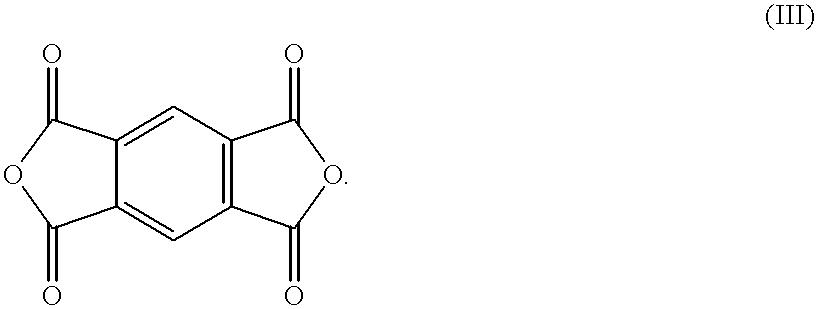

Coating agent, the manufacture and uses thereof

InactiveUS6200639B1High hardnessImprove application reliabilityPretreated surfacesPolyester coatingsPolyesterMeth-

Coating composition suitable for multi-layer lacquerings, with a binder composition which comprises: A) 25 to 75 wt. % of carboxyl-functional (meth)acrylic copolymers and / or carboxyl-functional polyesters, the carboxyl functionality of which corresponds to an acid number of 15 to 300 mg KOH / g, B) 25 to 75 wt. % of epoxide-functionalized crosslinker resins, at least one of which is a (meth)acrylic copolymer which has been prepared co-using tert-butyl (meth)acrylate, C) 0 to 50 wt. % of polyols which have at least two hydroxyl functions in the molecule, D) 0 to 40 wt. % of components which crosslink with hydroxyl groups to form ethers, and / or of a crosslinking agent based on triazine, E) 0 to 40 wt. % of polyisocyanates, F) 0 to 50 wt. % of at least one organic polyanhydride with at least two cyclic carboxylic acid anhydride groups per molecule, G) 0 to 20 wt. % of reactive thinners with an epoxide function, H) 0 to 10 wt. % of one or more catalysts for the reaction of carboxyl and epoxide groups.

Owner:HERBERTS GMBH

Preparation method of long-acting slow-release fragrance silk quilt

The invention relates to a preparation method of a long-acting slow-release fragrance silk quilt. The preparation method comprises the following steps of: (1) refining, bleaching, rinsing and dewatering cocoon strippings to obtain silks with the cleanliness of 99 percent; (2) putting the silks treated in the step (1) into a reaction tank, injecting a fragrance mixed solution of which the temperature is 50 to 60 DEG C into the reaction tank, keeping the temperature for 30 to 40 minutes, and performing pliancy and fragrance treatment on the silks; (3) taking out the silks subjected to the pliancy and fragrance treatment, dewatering the silks until the water content is less than 25 percent, and taking out and drying the silks; (4) carding the dried silks into a silk quilt batt, attaching a gauze fabric to the silk quilt batt, and performing fixed-point fixation to ensure that the gauze fabric is fully attached to the silks; and (5) covering the silk quilt batt by using a fabric, and quilting. By the preparation method, the original taste of the conventional silks is changed, the prepared silk quilt has a lasting fresh fragrance and better hand feeling, the silks cannot cause silk loss and make people feel fresh, and during preparation, an adhesive is not added, so that the silk quilt is soft in hand feeling in use and cannot generate yellowing.

Owner:SHANGHAI SHUIXING HOME TEXTILE

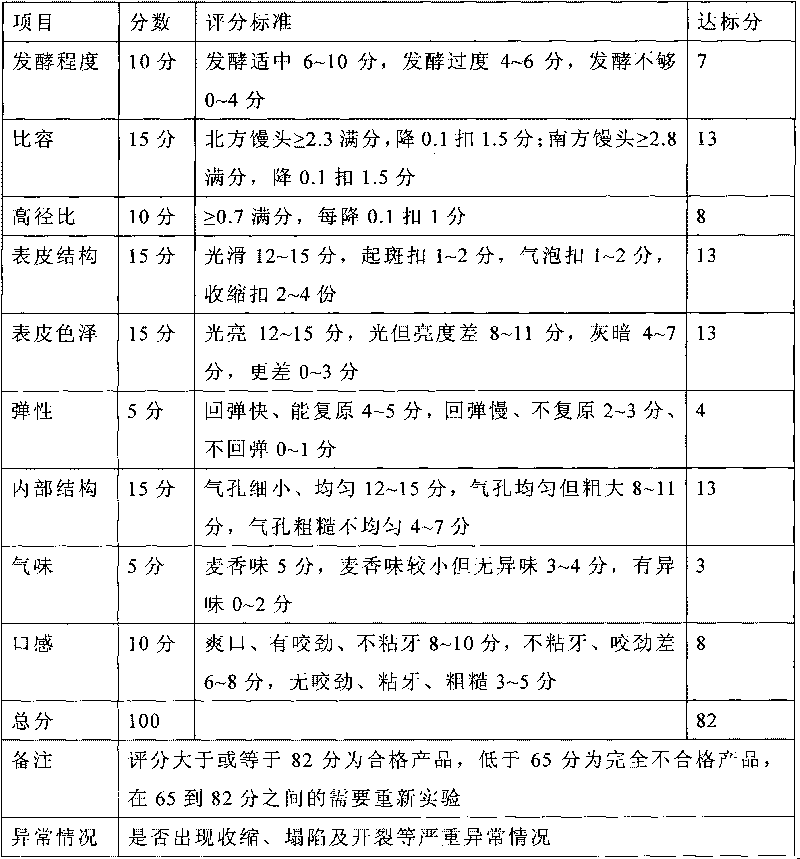

Domestic instantly-fermenting steamed bread modifier

InactiveCN101731299ANo yellowingNo retractionDough treatmentPre-baking dough treatmentSodium bicarbonateFood additive

The invention belongs to the technical field of compound food additives and in particular discloses a domestic instantly-fermenting bread modifier, which is mainly prepared by uniformly mixing the following raw materials in a certain weight ratio: yeast, emulsifier, sodium bicarbonate, citric acid, alpha-amylase, glucose oxidase, lipoxidase and modified starch. The modifier can be conveniently used without additional yeast and other additives, makes domestic operation more convenient, the skin the steamed bread smooth and the taste of the steamed bread fragrant and sweet, and delays ageing caused by water loss.

Owner:刘全卫

Water-soluble composite containing thermoplastic PVA (polyvinyl alcohol) and preparation method of water-soluble composite containing thermoplastic PVA

ActiveCN107266838AReduce crystallinityExcellent melt processing fluidityThermoplasticPolyvinyl alcohol

A water-soluble composite containing thermoplastic PVA (polyvinyl alcohol) is finely particulate, the particle size is 0.0015-2.0 mm, and the composite is prepared from thermoplastic PVA resin and a linear random polymer in a weight ratio of (80-99.9): (0.1-20). The water-soluble composite containing thermoplastic PVA is characterized in that the melt index is 8-35 g / 10 min, the melt temperature is 120-280 DEG C, and the water solution temperature is 20-80 DEG C. The water-soluble composite has lower crystallinity and excellent melt processing fluidity, overcomes defects of high crystallinity and poor melt flowability of existing blended modified PVA resin, and a preparation method is simple and easy to implement.

Owner:CHINA PETROCHEMICAL CORP +1

Functional inorganic mineral wall material

InactiveCN106892636AGuaranteed normal generationKeep dry and cleanCovering/liningsSodium BentoniteMetakaolin

The invention belongs to the field of building coatings and particularly relates to a functional inorganic mineral wall material. The functional inorganic mineral wall material is prepared from, by mass, 20-40 parts of ground calcium carbonate, 10-20 parts of ash calcium powder, 0-10 parts of washed kaolin, 0-10 parts of metakaolin, 0-10 parts of calcined kaolin, 0-5 parts of calcium bentonite, 5-15 parts of diatomaceous earth, 0-10 parts of zeolites, 10-30 parts of modified gypsum, 0-20 parts of magnesium oxide, 0-10 parts of magnesium sulfate, 0-5 parts of titanium dioxide, 0-5 parts of white cement, 0-5 parts of sepiolite, 0-5 parts of attapulgite, 2-5 parts of talcum powder, 0-5 parts of wollastonite, 0.5-1 part of water-retaining agent and 0-2 parts of nano titanium dioxide photocatalyst.

Owner:陈锦

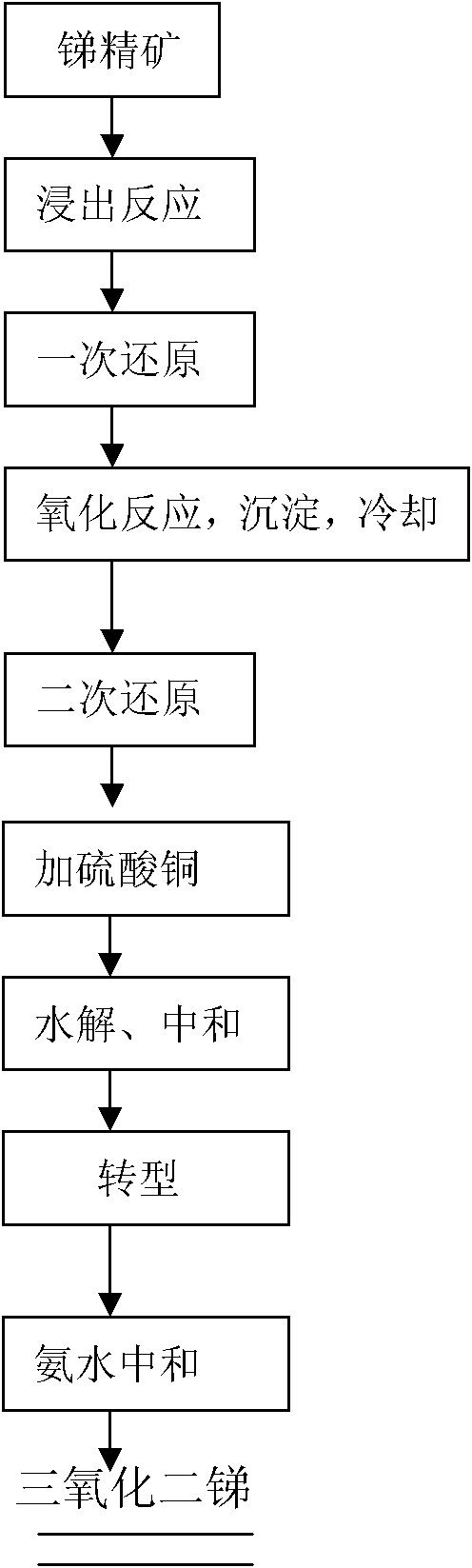

Method for producing antimonous oxide by wet method to improve whiteness

ActiveCN102070194APrecipitate thoroughlyDoes not affect elevationAntimony compoundsAntimony trioxideHydrolysis

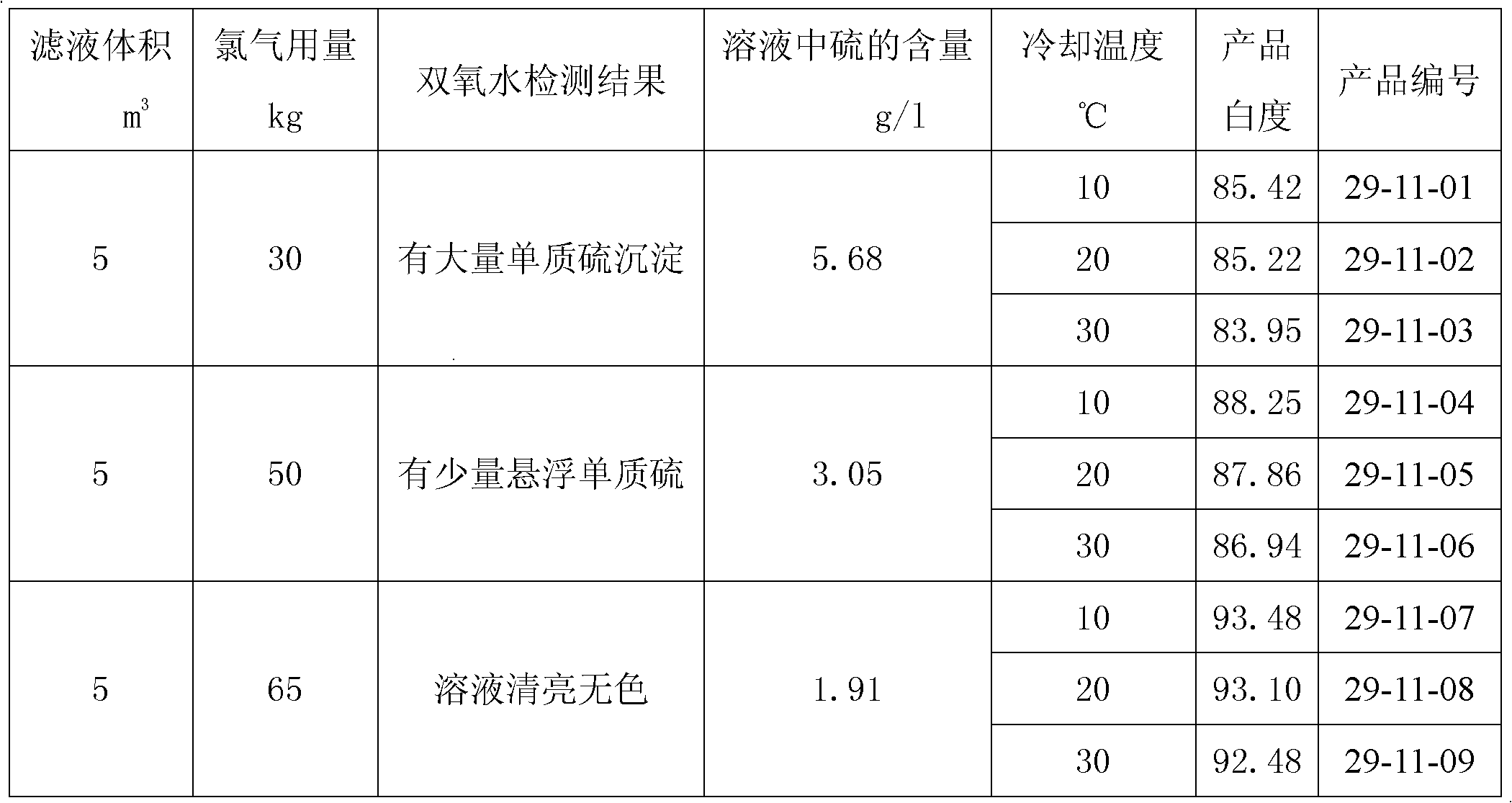

The invention discloses a method for producing high-purity antimonous oxide by treating antimony sulfide concentrate to improve product whiteness, which comprises the following steps of: performing leaching and primary reduction, rising the temperature of solution, introducing chlorine for oxidation, performing precipitation for at least 2 hours, performing secondary reduction, adding copper sulfate into the secondary reduction solution for reaction, filtering the reaction solution, adding water for hydrolysis, adding a transformation agent for transformation, and drying the transformed solution to obtain the product with the whiteness of 93 to 95.

Owner:HUNAN CHENZHOU MINING CO LTD

Method for producing negative ion silk quilt

The invention discloses a method for producing a negative ion silk quilt, which comprises the following steps: manufacturing a silk wadding comforter batt; fixing the silk wadding comforter batt in a coating plus material to perform check point quilting so as to sew a comforter batt; jacketing a quilt cover outside the comforter batt; and adhering negative ions to silk wadding. The method has the advantages of simple process, time saving and labor saving, and the negative ion silk quilt produced by the method has good softness and is comfortable to use, the silk has no yellow discoloration, and the releasing quantity of the negative ions is large.

Owner:LIAONING YIXING FLOSS SILK

Profile modification agent for epoxy resin emulsion

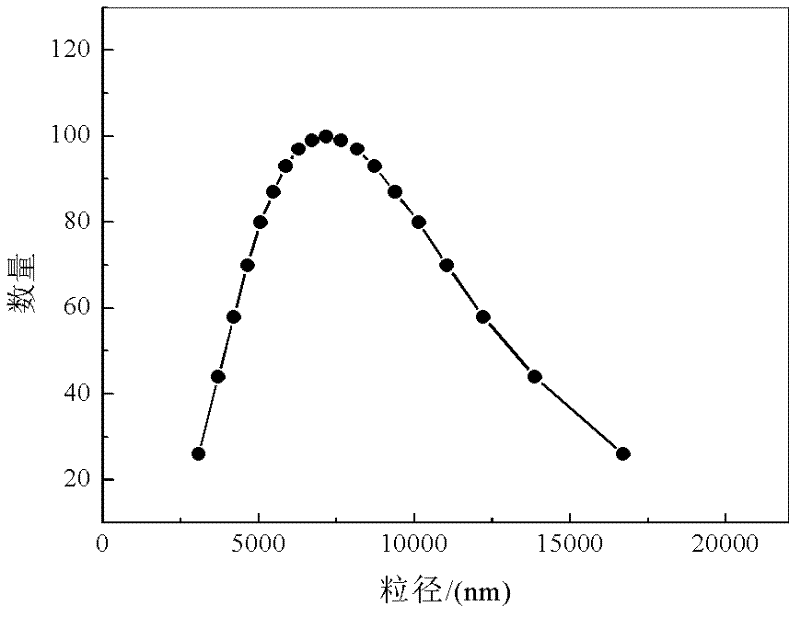

InactiveCN102443111ASmall particle sizeAppropriate particle sizeDrilling compositionLarge porePolymer chemistry

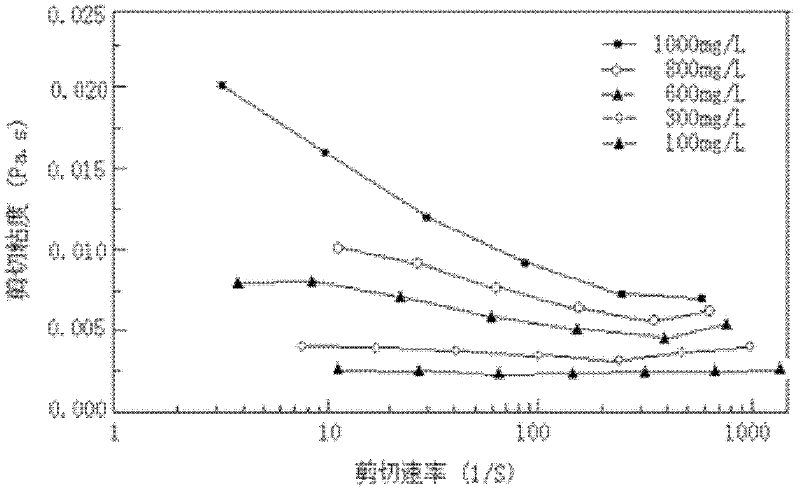

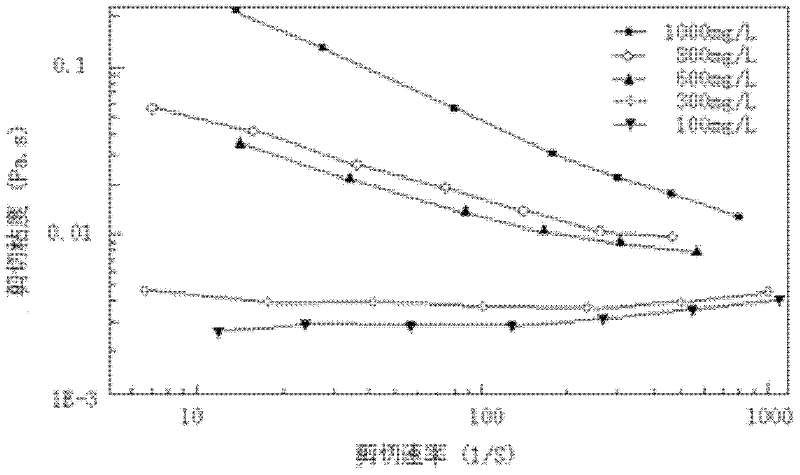

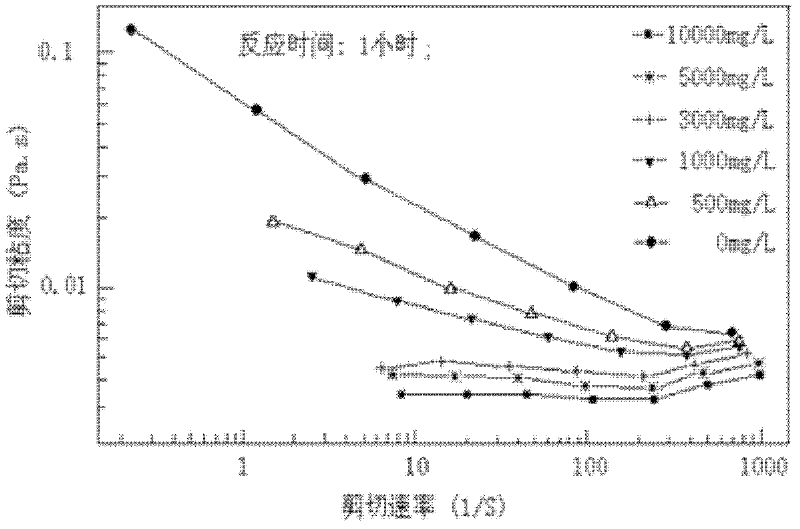

The invention relates to a profile modification agent for an epoxy resin emulsion, which is used for solving the problem of poor selectivity of the conventional organic resin plugging agent. The profile modification agent for an acrylic monomer grafted epoxy resin emulsion is obtained by polymerizing epoxy resin with an acrylic monomer, neutralizing with N,N-dimethylethanolamine and emulsifying with deionized water, wherein the concentration of the epoxy resin in an emulsion system is 300-600 mg / L, the concentration of the N,N-dimethylethanolamine is 3,000-5,000 mg / L, and the crosslinking ratio is 10:1 or 20:1 or 40:1. When the profile modification agent is in use, a large quantity of gel particles of the emulsion enter large pore canals while a small quantity of or no gel particle enterssmall pore canals, the resistance coefficients of the large pore canals are increased, and the resistance coefficients of the small pore canals are increased at a lower frequency in comparison to thelarge pore canals, so that selective plugging can be realized; and moreover, the profile modification agent has high temperature resistance and high salt resistance, and the emulsion system is stable.

Owner:NORTHEAST GASOLINEEUM UNIV

Printed synthetic leather and method for manufacturing same

InactiveCN102605635AImprove breathabilityGood resistance to extractionLamination ancillary operationsSynthetic resin layered productsCooking & bakingUltraviolet lights

The invention relates to a printed synthetic leather and a method for manufacturing the printed synthetic leather. The printed synthetic leather comprises a base cloth layer; the base cloth layer is coated with a water PU (polyurethane) foaming layer; and the surface of the water PU (polyurethane) foaming layer is printed directly to form a printed layer. The method for manufacturing the printed synthetic leather comprises the following steps: preparing a slurry; feeding the slurry into a foaming machine; adjusting the proportion of the slurry amount to the air intake to determine the size of needed foam holes; feeding a piece of base cloth, heating to iron, feeding, and putting into a baking oven to finish processing the base cloth; and finally printing directly on the surface of the synthetic leather taken out of the baking oven. The printed synthetic leather manufactured by adopting the method has good breathability and extraction resistance, can resist the irradiation of ultraviolet light, hydrolysis, cold bending and wear, can not become yellow, age and mildew and reaches the international advanced flame resistance standard. The process for manufacturing the printed synthetic leather is simple and has the advantages of saving energy and reducing consumption.

Owner:YIXING XINGUANG SYNTHETIC LEATHER

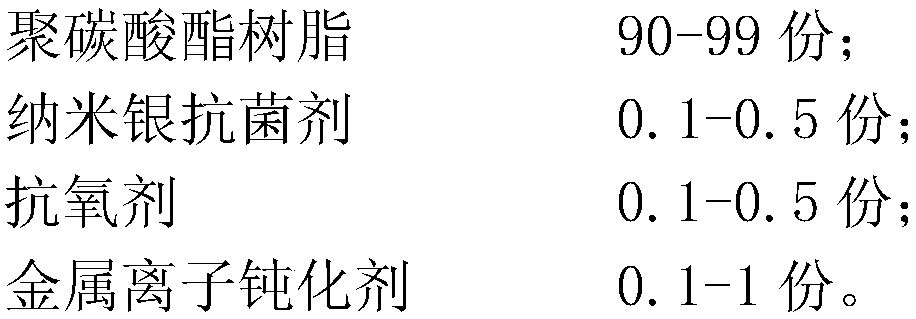

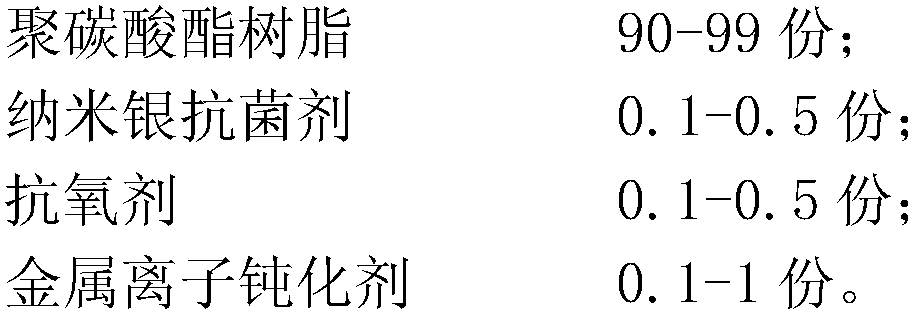

Anti-yellowing nano-silver antibacterial polycarbonate material and formed product thereof

The invention relates to the technical field of high polymer materials, in particular to an anti-yellowing nano-silver antibacterial polycarbonate material and a formed product thereof. The anti-yellowing nano-silver antibacterial polycarbonate material comprises polycarbonate resin, nano-silver antibacterial agents, antioxidants and metal ion passivators, and the formed product is a product generated after the anti-yellowing nano-silver antibacterial polycarbonate material is formed. According to the anti-yellowing nano-silver antibacterial polycarbonate material, the antioxidants, the metalion passivators, the nano-silver antibacterial agents and the polycarbonate resin are blended, so that the polycarbonate resin cannot be yellowed under the processing condition of 300-330 DEG C.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

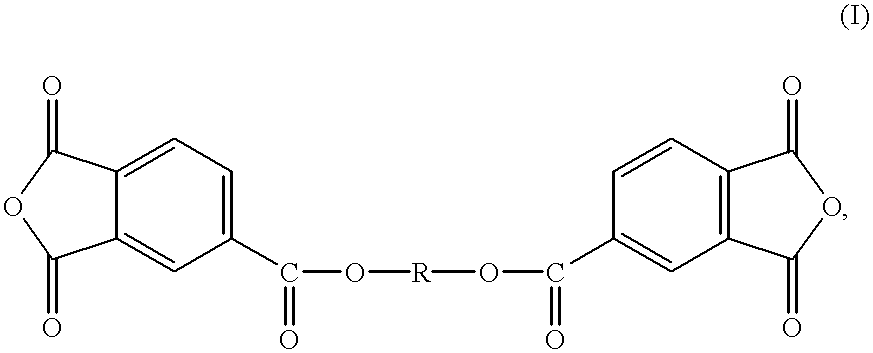

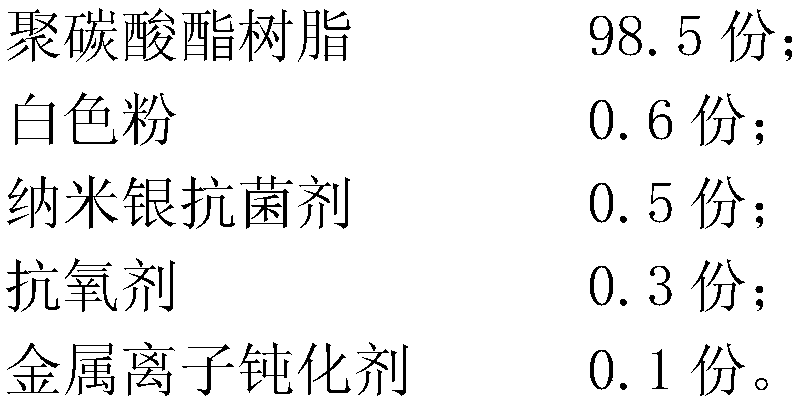

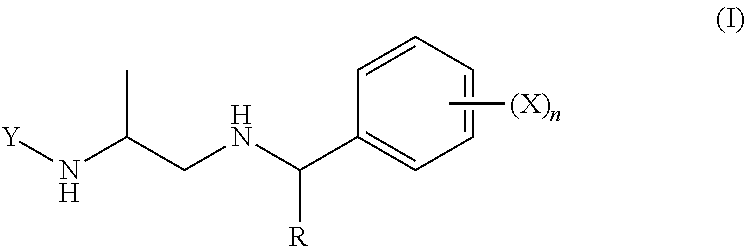

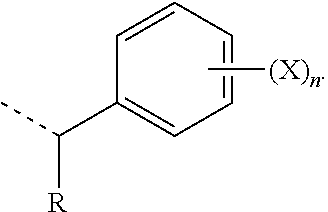

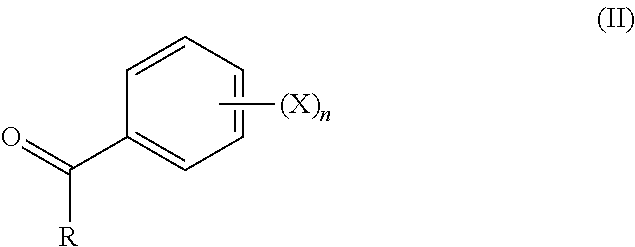

Amine for low-emission epoxy resin compositions

ActiveUS20170218114A1High hardnessImprove surface qualityOrganic chemistryEpoxy resin coatingsEpoxyPolymer science

An amine of the formula (I) for use as hardener for epoxy resins, hardeners for epoxy resins containing the amine of the formula (I) and resultant epoxy resin compositions which more particularly can be used as low-emission room-temperature-curing epoxy-resin coatings with high hardness and surface quality. The amine of the formula (I) has little odour and is a very successful diluent for epoxy resin compositions. It is more particularly obtained by reductive alkylation from 1,2-propylenediamine and an aldehyde or ketone.

Owner:SIKA TECH AG

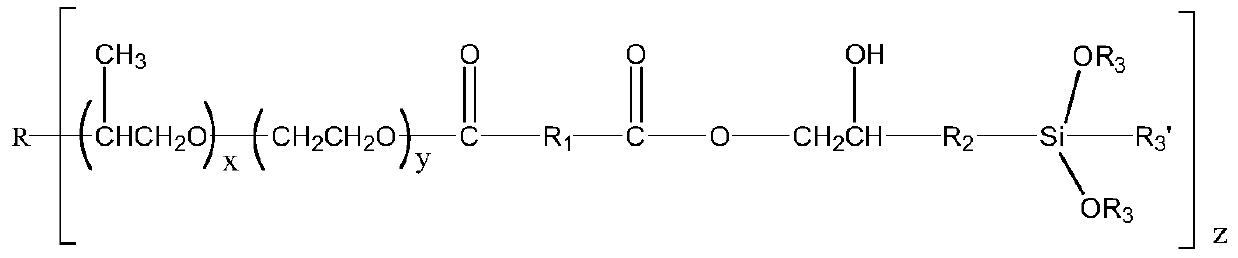

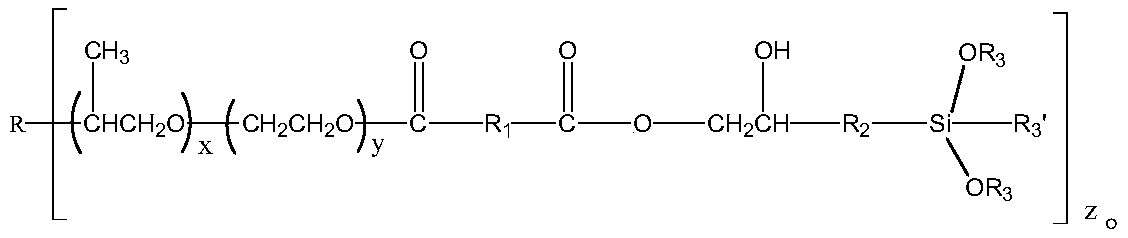

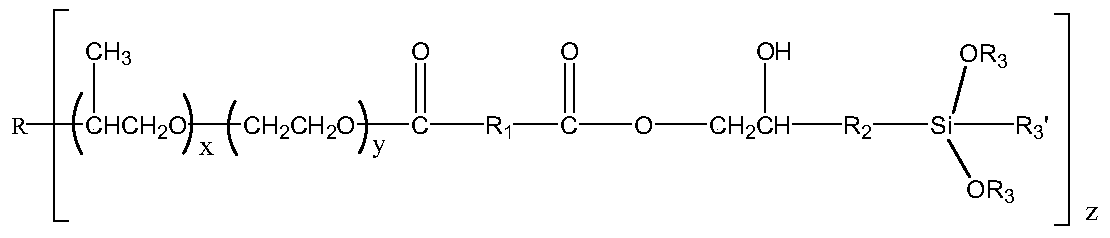

Silane-terminated polyether and preparation method thereof

ActiveCN110028664AThe production process is simple and safeRaw materials are readily availablePolyether adhesivesSilanesTriphenylphosphine

The invention provides a silane-terminated polyether, which has a structural general formula shown in the description. The invention also provides a preparation method of the silane-terminated polyether, and the preparation method comprises the following steps: adding hydroxyl-terminated polyether into a reaction kettle; vacuumizing at the high temperature of 80-120 DEG C to remove water for 2 hours; adjusting the temperature to 90-150 DEG C, and adding anhydride to prepare carboxyl-terminated polyether; adjusting the temperature to 100-120 DEG C, adding glycidyl ether alkoxy silane and a triphenylphosphine or ammonia catalyst, and continuously reacting; and cooling and discharging to obtain silane-terminated polyether resin. The preparation method provided by the invention is simple and safe in production process, and common, easily available and low in purchasing cost in production raw materials.

Owner:杭州大牛新材料有限公司

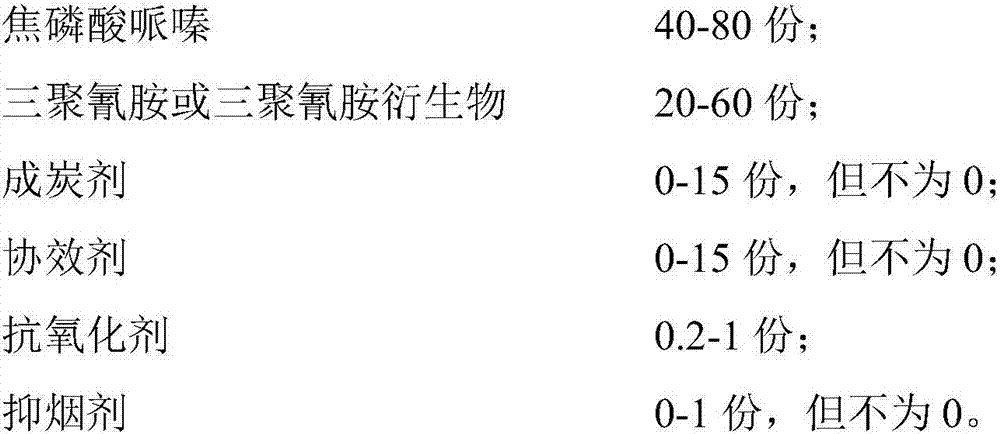

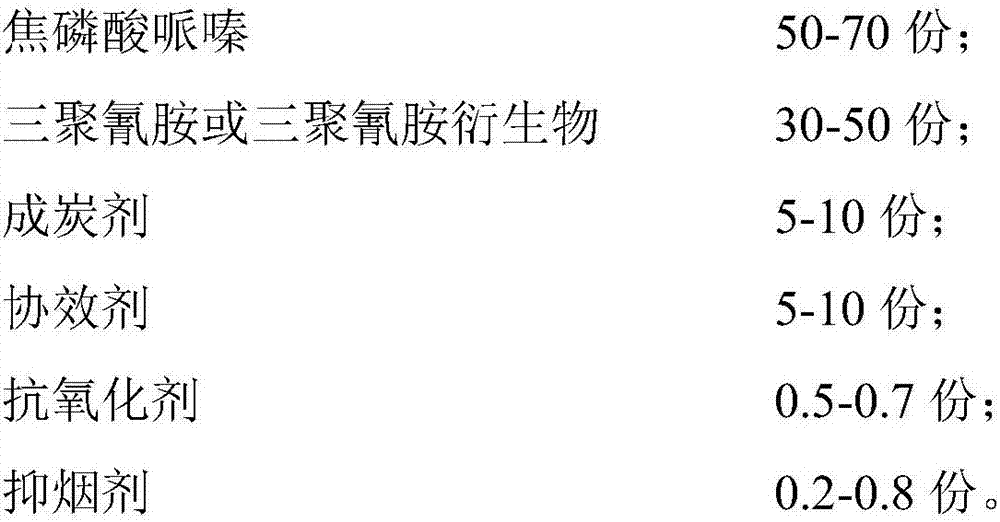

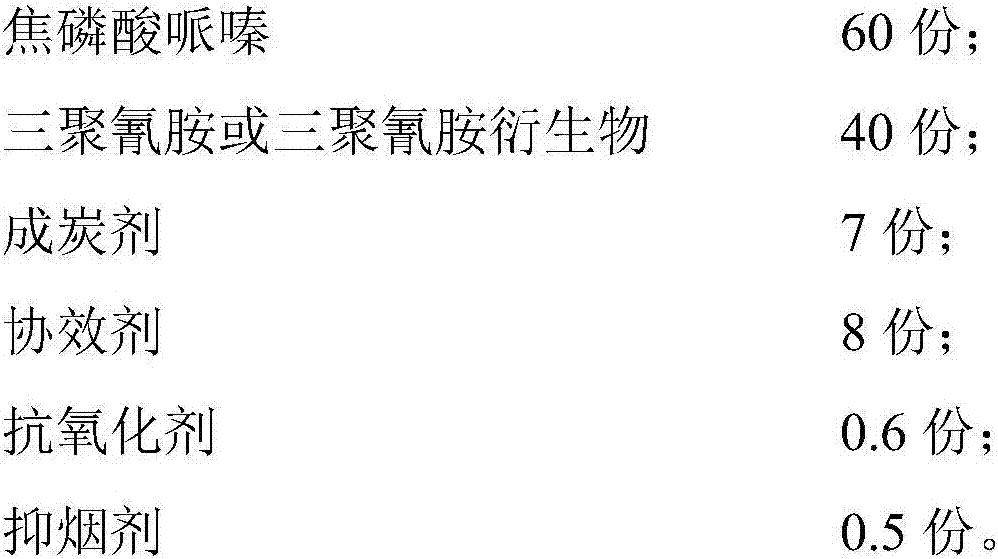

Intumescent flame retardant used for outer cover of ABS (acrylonitrile-butadiene-styrene) appliance switch as well as preparation and application of intumescent flame retardant

The invention relates to an intumescent flame retardant used for an outer cover of an ABS (acrylonitrile-butadiene-styrene) appliance switch as well as a preparation and an application of the intumescent flame retardant. The flame retardant is prepared from components in parts by weight as follows: 40-80 parts of piperazine pyrophosphate, 20-60 parts of melamine or a melamine derivative, 0-15 (except 0) parts of a charring agent, 0-15 (except 0) parts of a synergist, 0.2-1 part of an antioxidant and 0-1 (except 0) part of a smoke inhibitor. During preparation, substances are mixed and stirred uniformly, and the product is obtained; during application, 0.4-0.5 g of the flame retardant is added to every 1 g of ABS resin. Compared with the prior art, the flame retardant is easy to prepare and has good compatibility with an ABS matrix, the surface of a flame-retardant ABS material prepared from the flame retardant does not absorb moisture and does not migrate, and the flame-retardant ABS material can reach the UL94V-0 level, has remarkably reduced specific optical density Ds10 of smoke and can be used for processing and preparation of the outer cover of the ABS appliance switch with an injection molding process and can pass tests of 750 DEG C glowing filaments.

Owner:SHANGHAI RES INST OF CHEM IND +1

Digital printing advertisement base material and preparation method thereof

ActiveCN105017548ASame protective effectImprove the degree of automated productionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesDigital printingHot-melt adhesive

The invention provides a digital printing advertisement base material and a preparation method thereof. The preparation method comprises the steps: preparing anti-ultraviolet hot melt glue for digital printing and putting a base layer on a coil-feeding rack of a coating machine for corona treatment; coating the anti-ultraviolet hot melt glue and drying the base layer at 60-120 DEG C, wherein the thickness of the cooled hot melt glue is 20-100 [mu]m; coating a 10-50 [mu]m thick ink-receptive coating on the cooled anti-ultraviolet hot melt glue, and printing a pattern; carrying out hot press, wherein the pressure is 1-5 kg, the temperature is 120-200 DEG C, the time is 2-50 seconds, and the anti-ultraviolet hot melt glue is melted and permeates among particles of the ink-receptive coating and the printed pattern and covers above and quickly congeals to a film to form a protective layer; and cooling and rolling. The advertisement base material prepared by the invention is bright in pattern, smooth and level, rainproof and sun-proof and strong in anti-ultraviolet ability, and is free of yellowing phenomenon if being used outdoors for one year.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

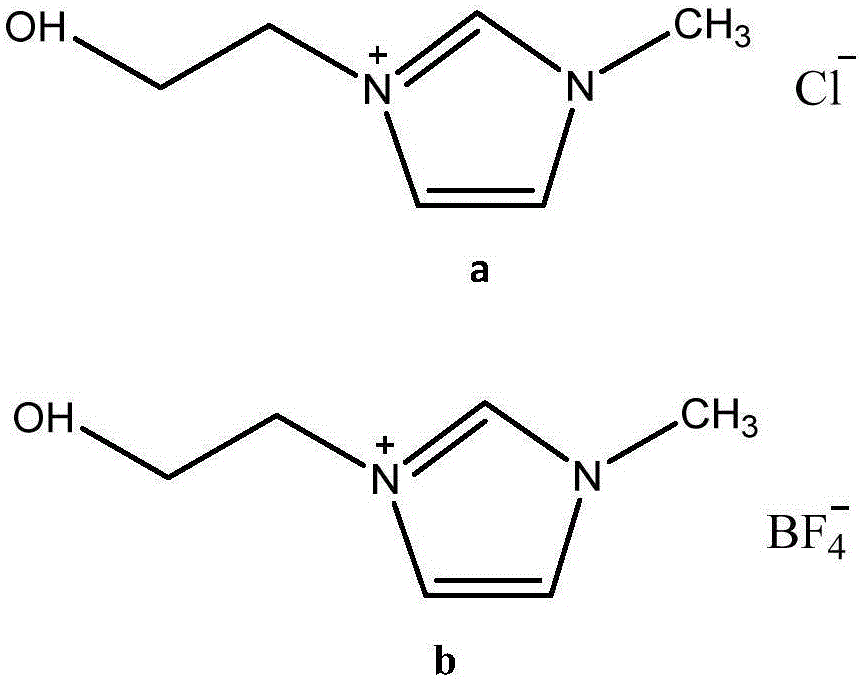

Thermal plastic processing available polyvinyl alcohol resin, as well as preparation method and application thereof

The invention belongs to the field of high molecules, and particularly relates to thermal plastic processing available polyvinyl alcohol resin, as well as a preparation method and application thereof. To solve the technical problems, the method comprises the following steps: based on mass percentage, adding 15-45 parts of imidazole ionic liquid into water, sufficiently dissolving and ionizing; then, adding 100 parts of polyvinyl alcohol, uniformly mixing to obtain a mixture, and standing at 65-90 DEG C for plasticizing; and removing moisture. The thermal plastic processing available polyvinyl alcohol resin can be applied to the fields of thermal plastic processing, such as extrusion, injection molding, membrane blowing, spinning, foaming and fused deposition modeling. The preparation method is simple and efficient, has strong operability, and is easy for industrial implementation. Products prepared by adopting the polyvinyl alcohol resin as a raw material has excellent mechanical performance and excellent conductive performance.

Owner:SICHUAN UNIV

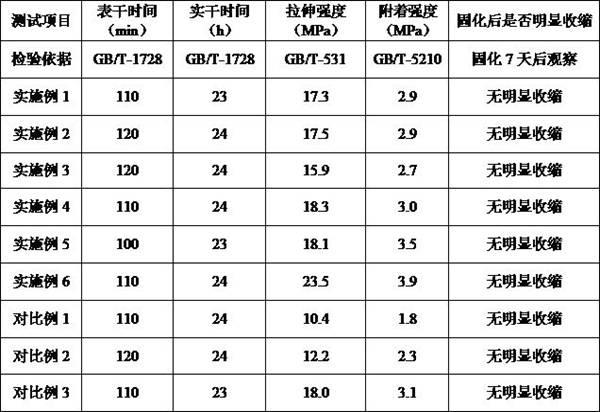

Two-component polyaspartic acid ester sealant and preparation method thereof

ActiveCN113025255AEasy to useEasy maintenanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceSolvent free

The invention relates to the technical field of sealant, and provides a two-component polyaspartic acid ester sealant and a preparation method thereof. The two-component polyaspartic acid ester sealant comprises a component A and a component B, wherein the component A comprises a prepolymer containing polyisocyanate, fumed silica, Portland cement, lime powder, a defoaming agent, a flatting agent and isocyanate silane; and the component B is prepared from polyaspartic acid ester, titanium dioxide, a molecular sieve, fumed silica, a silane coupling agent, a dispersing agent, a defoaming agent, a flatting agent and a pigment. The two-component polyaspartic acid ester sealant provided by the invention is a solvent-free two-component sealant, and is environment-friendly, non-toxic, simple and convenient to use, small in shrinkage rate and good in maintenance and recoatability; the matrix resin does not contain an aromatic structure easy to yellow, does not yellow when being used outdoors or used for a long time, and is excellent in weather resistance; and the sealant is firm in interface bonding, high in adhesive strength, excellent in mechanical toughness, good in wear resistance and not prone to being scratched.

Owner:山东卓高新材料有限公司

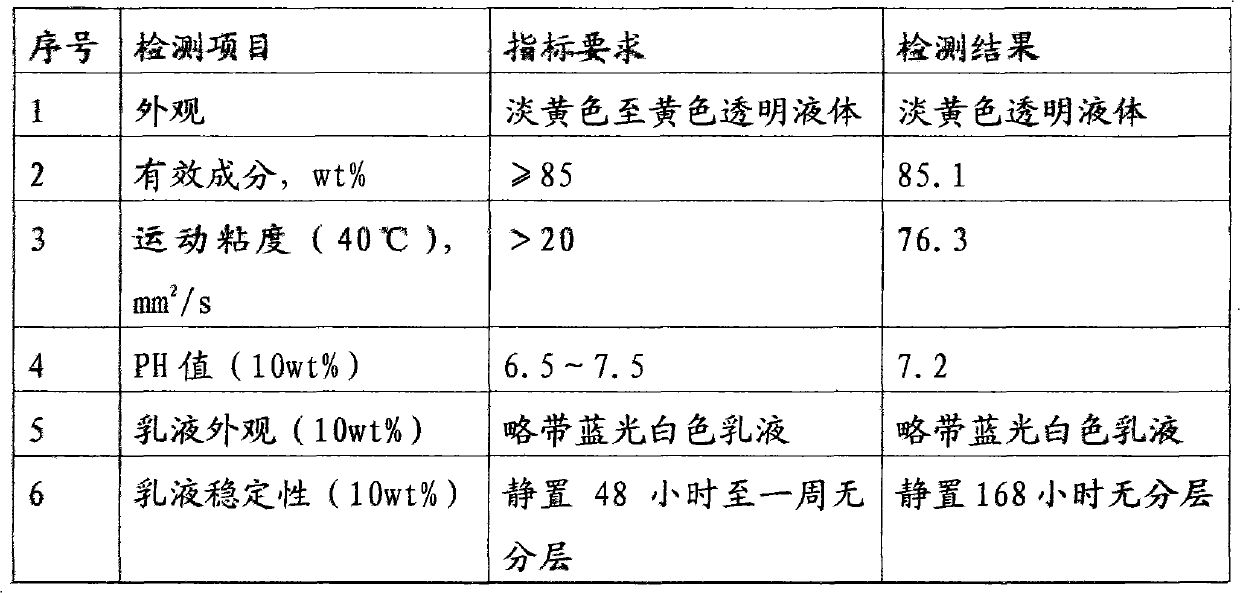

Preparation method for closed-type aliphatic-series isocyanate water dispersoid

InactiveCN102417598ASystem stabilitySimple to usePolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsSolventIsocyanate

The invention discloses a preparation method for closed-type aliphatic-series isocyanate water dispersoid, which aims to solve the technical problems of low cementing or splicing strength existing in the traditional closed-type aliphatic-series isocyanate. The preparation method for the closed-type aliphatic-series isocyanate water dispersoid comprises the following steps: 1. drying polyatomic alcohol; 2. adding the polyatomic alcohol and dimethylolpropionic acid into compound solvent, stirring, introducing nitrogen, and keeping warm for 15-45 minutes after heating; 3. dripping aliphatic-series isocyanate; 4. adding blocking agent; 5. adding triethylamine, then adding deionized water, emulsifying, and stopping introducing the nitrogen; and 6. removing the compound solvent. The closed-typehexamethylene diisocyanate (HDI) water dispersoid prepared with the preparation method can be used for high-grade cementing and finishing fields, such as wood lacquers, leather finishing agent, aqueous adhesive and the like, also can serve as the crosslinking curing agent and the accessory ingredient for film forming resin and is applied to the fields, such as enamelled wires, paper treating agent and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com