Thermal plastic processing available polyvinyl alcohol resin, as well as preparation method and application thereof

A polyvinyl alcohol resin, thermoplastic processing technology, applied in the field of polymer science, can solve the problems that affect the stable use of materials, high viscosity of ionic liquids, and uncommon ionic liquids, etc., achieve no yellowing, good thermal stability, and easy processing Excellent fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

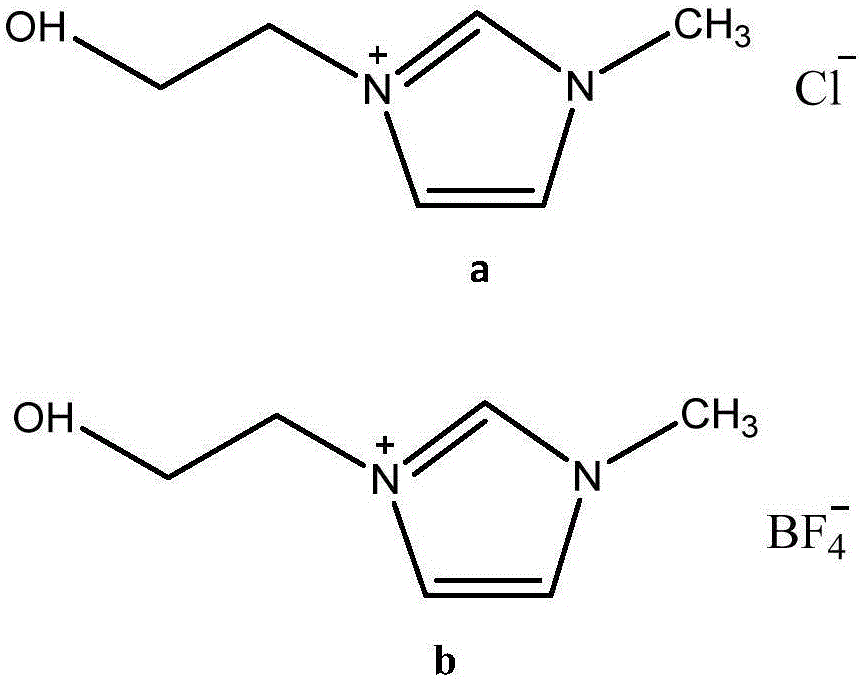

[0023] The preparation method of thermoplastically processable polyvinyl alcohol resin comprises the following steps: adding 15 to 45 parts of imidazole ionic liquid into an appropriate amount of water to fully dissolve and ionize according to the mass ratio, then adding 100 parts of polyvinyl alcohol and stirring evenly , place the mixture obtained by stirring evenly at 65-90° C. for plasticization for more than 1 hour, and then dry to remove the moisture in the mixture.

[0024] The inventor also found that the amount of imidazole ionic liquid added has a certain impact on product performance. When the amount of imidazole ionic liquid added is less (below 15 parts), the destruction of a large amount of hydrogen bonds in polyvinyl alcohol is limited, and thermoplastic processing Poor performance; when the amount of imidazole ionic liquid is added more (more than 50 parts), although the intramolecular and intermolecular hydrogen bonds in polyvinyl alcohol can be completely dest...

Embodiment 1

[0031] Dissolve 15 parts of imidazole ionic liquid in an appropriate amount of water to fully ionize, then add 100 parts of polyvinyl alcohol, stir evenly, plasticize the stirred mixture at 65°C for 2 hours, and then dry the water in the mixture, That is, a thermoplastically processable polyvinyl alcohol resin is obtained. The ionic liquid is 1-octyl-3-methylimidazolium tetrafluoroborate, the degree of polymerization of polyvinyl alcohol is 300, and the degree of alcoholysis is 80%.

[0032] The dried mixture is subjected to thermoplastic processing at 140°C, such as extrusion, injection molding, film blowing, spinning, foaming, and fused deposition molding.

[0033] The polyvinyl alcohol product obtained in this example has good transparency, no yellowing phenomenon, smooth surface, uniform and bubble-free inside, the tensile strength is 30MPa, and the electrical conductivity is 3.5×10 -4 S / cm.

Embodiment 2

[0035] Dissolve 20 parts of imidazole ionic liquid in an appropriate amount of water to fully ionize, then add 100 parts of polyvinyl alcohol, stir evenly, plasticize the stirred mixture at 70°C for 2 hours, and then dry the water in the mixture, That is, a thermoplastically processable polyvinyl alcohol resin is obtained. The ionic liquid is 1-octyl-3-methylimidazolium chloride, the degree of polymerization of polyvinyl alcohol is 500, and the degree of alcoholysis is 88%.

[0036] The dried mixture is subjected to thermoplastic processing at 130°C, such as extrusion, injection molding, film blowing, spinning, foaming, and fused deposition molding.

[0037] The polyvinyl alcohol product obtained in this example has good transparency, no yellowing phenomenon, smooth product surface, uniform and bubble-free inside. The tensile strength is 26MPa, and the electrical conductivity is 2.1×10 -3 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com