Patents

Literature

58results about How to "Good resistance to extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-silica immobilized hindered phenol antioxidant as well as preparation method and application of antioxidant

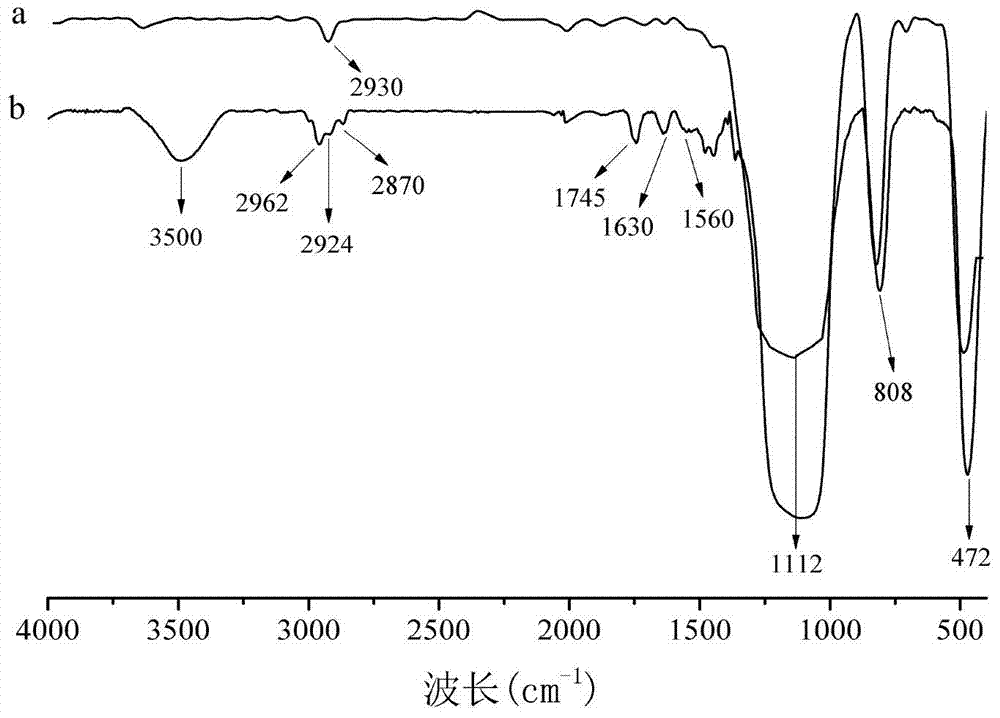

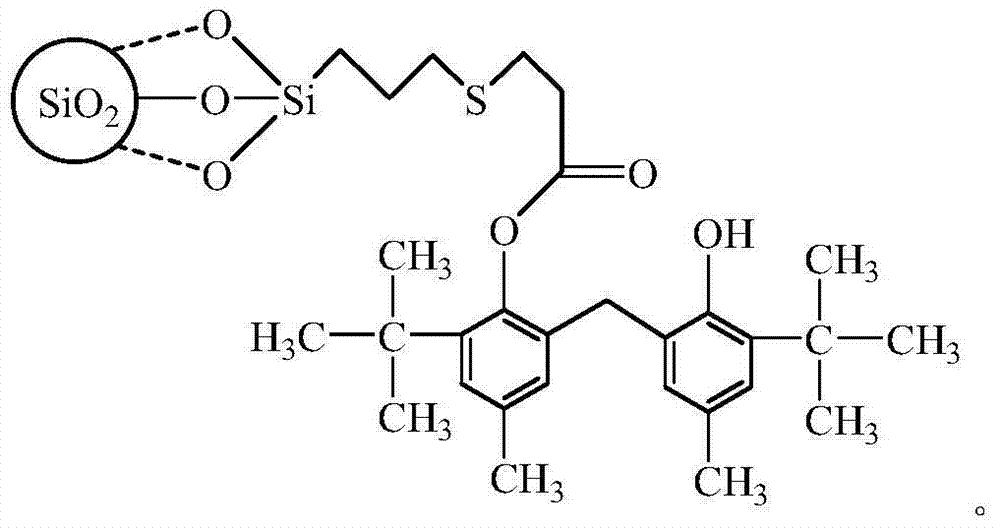

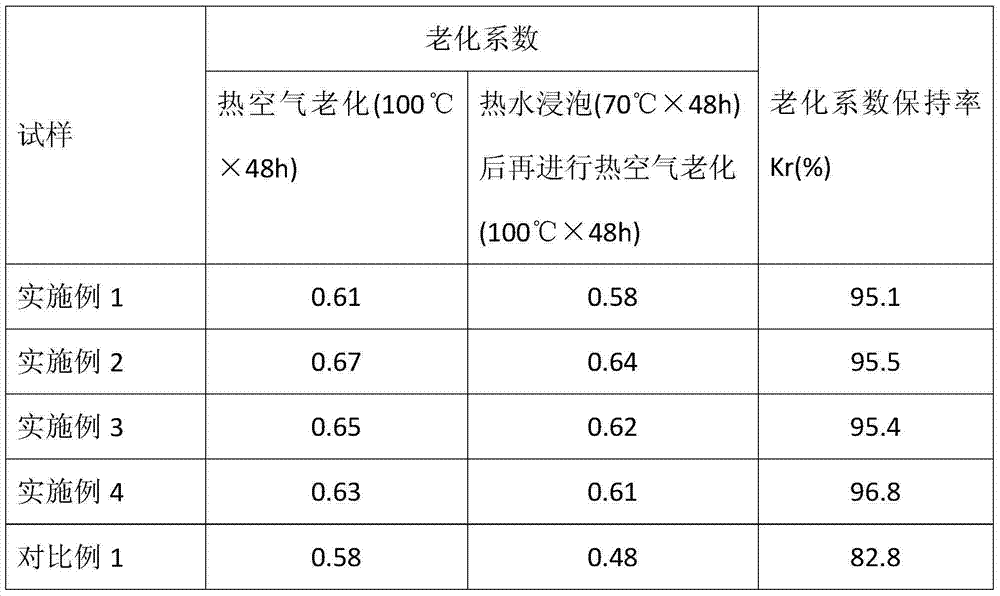

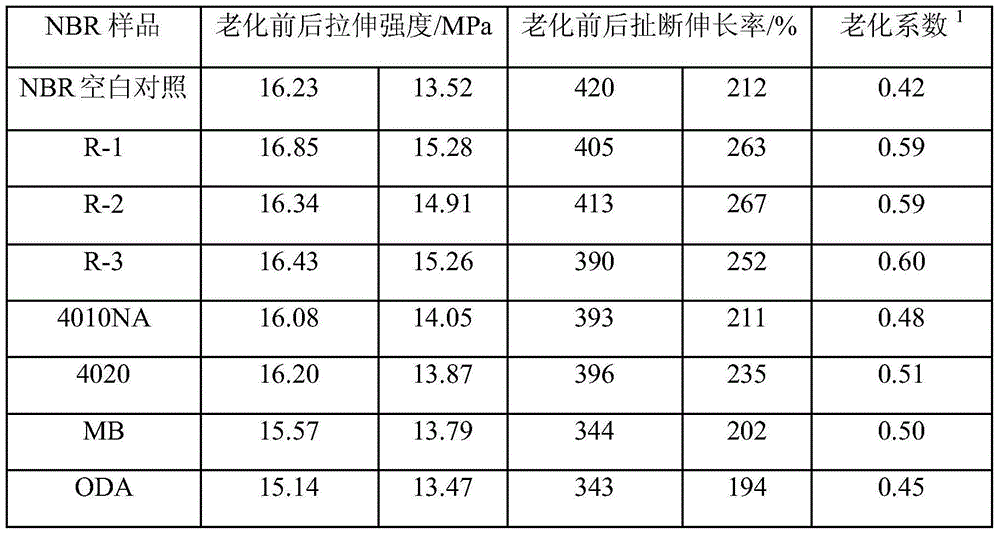

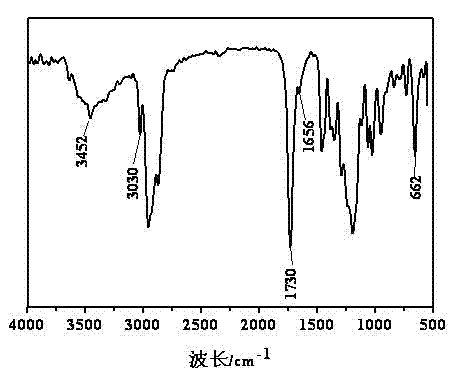

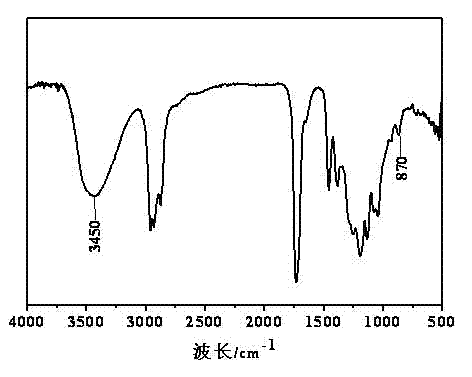

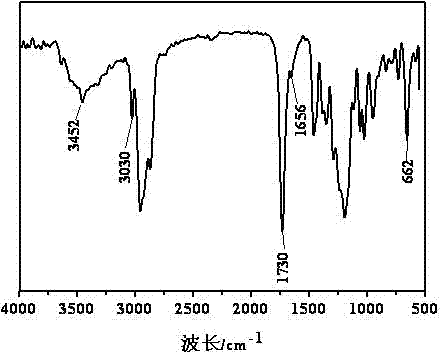

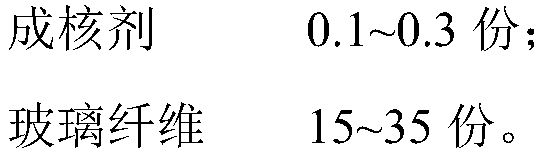

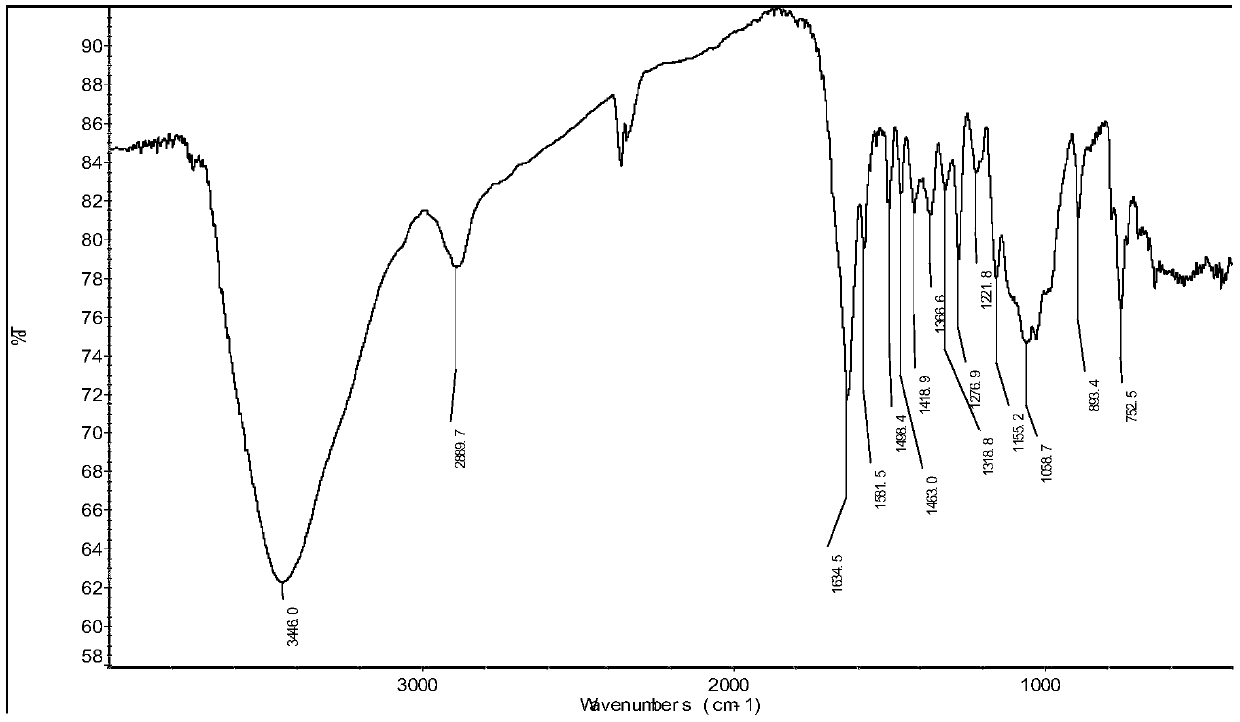

The invention discloses a nano-silica immobilized hindered phenol antioxidant as well as a preparation method and an application of the antioxidant. According to the preparation method, ethanol water is taken as a dispersion medium, a silane coupling agent kh590 is hydrolyzed to generate hydroxyls which join in condensation polymerization with the hydroxyls of nano-silica, and then the KH590 modified nano-silica containing the sulfydryl can be obtained after suction filtration, washing and drying; under the action of ultrasonic, the KH590 modified nano-silica and the hindered phenol antioxidant GM are dispersed into toluene; under the action of a catalyst, the sulfydryl reactions with the double bond C=C of the GM, and finally, the nano-silica immobilized hindered phenol antioxidant can be obtained after suction filtration, washing and drying. The suction filtration, washing and drying prepared is capable of overcoming the defects of poor extraction resistance of a traditional small molecular antioxidant and also advantageous for improving the mechanical properties of a matrix material, and can be widely applied to natural rubber, butadiene rubber and butadiene styrene rubber.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for reactive polyamidoamine dendrime rubber antioxidant

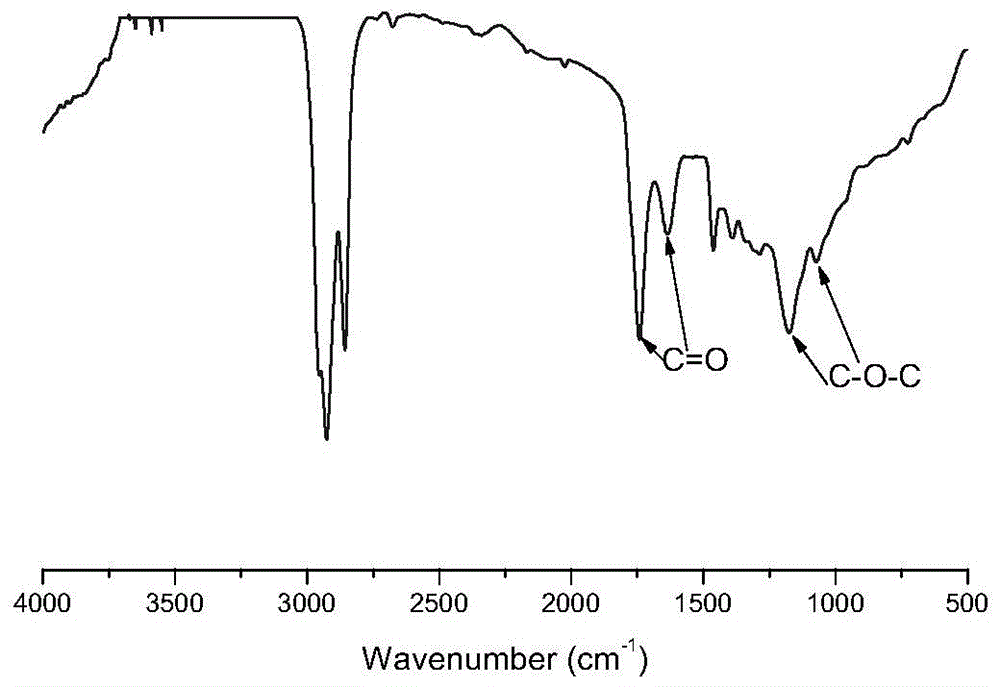

ActiveCN104403109AGood anti-aging performanceGood resistance to extractionOrganic solventDistillation

The invention discloses a preparation method for a reactive polyamidoamine dendrime rubber antioxidant. The preparation method comprises the following steps: fully dissolving polyamidoamine in an organic solvent until polyamidoamine is in a uniform state, dropwise adding a reactant pre-dissolved in the organic solvent while stirring, reacting at 10-60 DEG C for 0.5-24 hours, and performing reduced pressure distillation to remove the organic solvent to obtain a reactive polyamidoamine rubber antioxidant with unsaturated double bonds, which is the reactive polyamidoamine dendrime rubber antioxidant, wherein the reactant is unsaturated carboxylic acid, unsaturated carboxylic ester, an epoxy compound containing double bonds or unsaturated anhydride. The antioxidant prepared by the method can be crosslinked with a rubber matrix and has remarkable advantages of good antioxidant effect, high relative molecular weight, good compatibility with a polymer matrix, extraction resistance, good environmental protection and the like.

Owner:SOUTH CHINA UNIV OF TECH

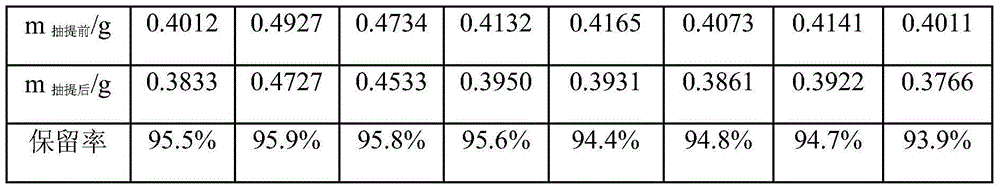

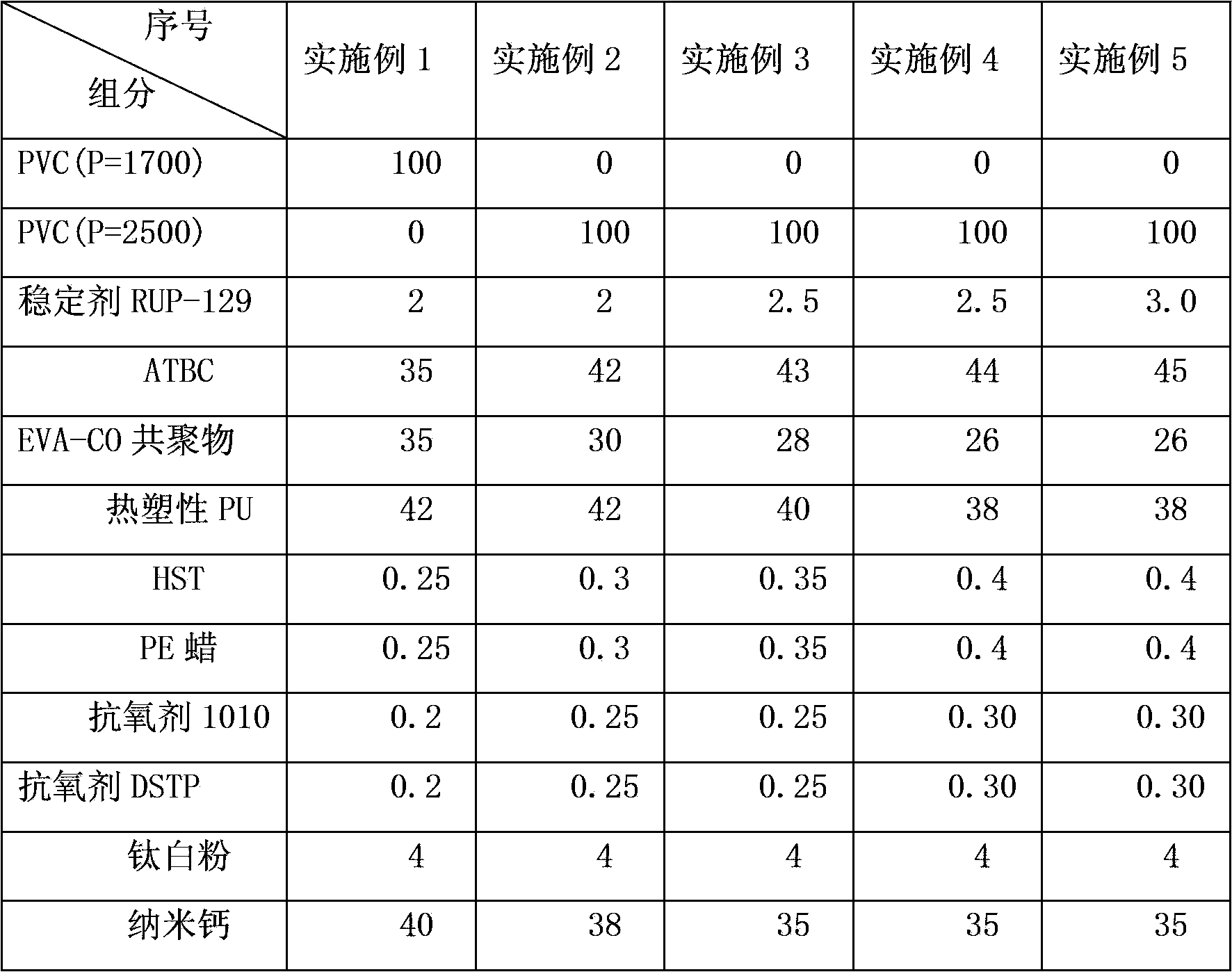

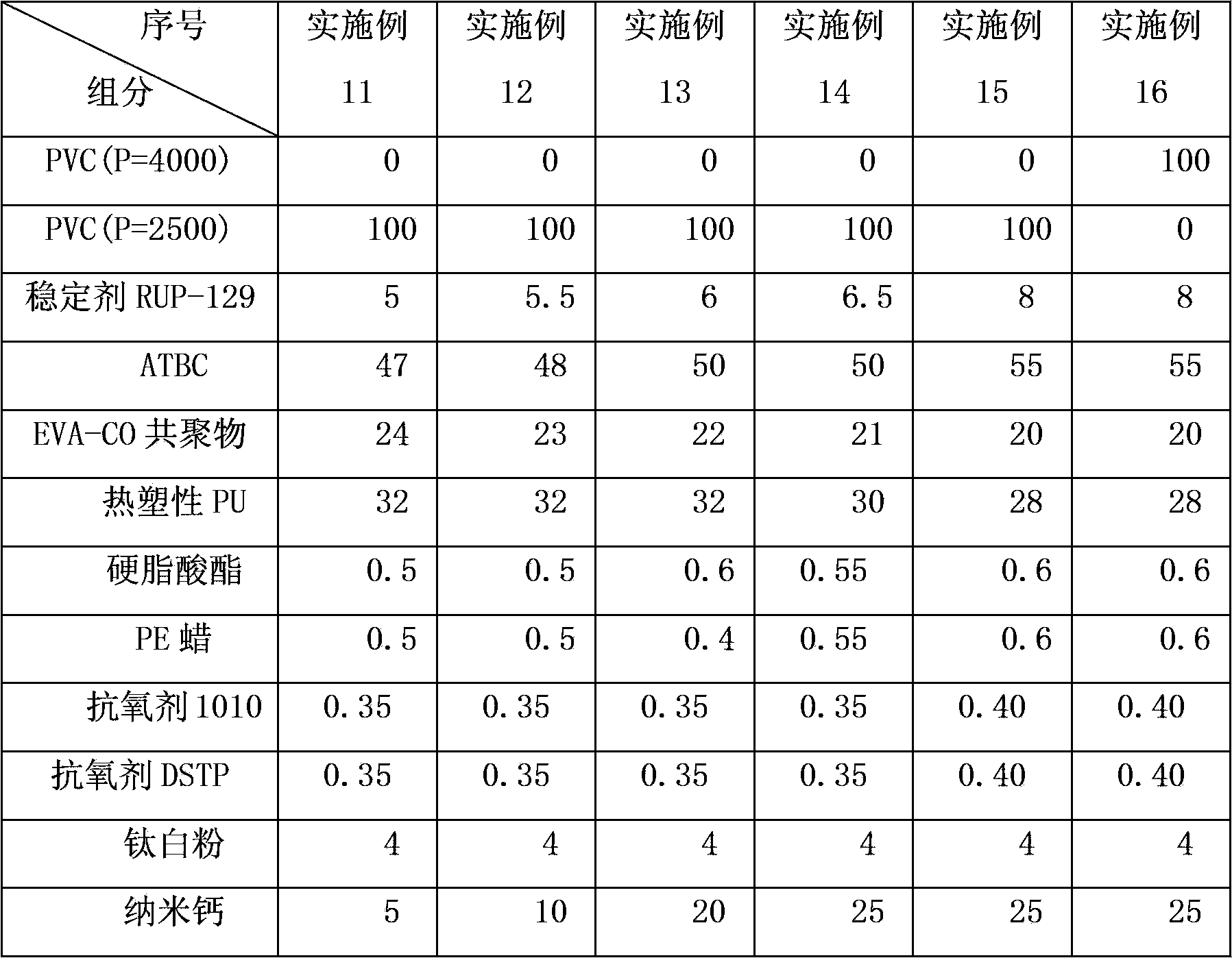

Polyvinyl chloride sealing strip composition for refrigerator

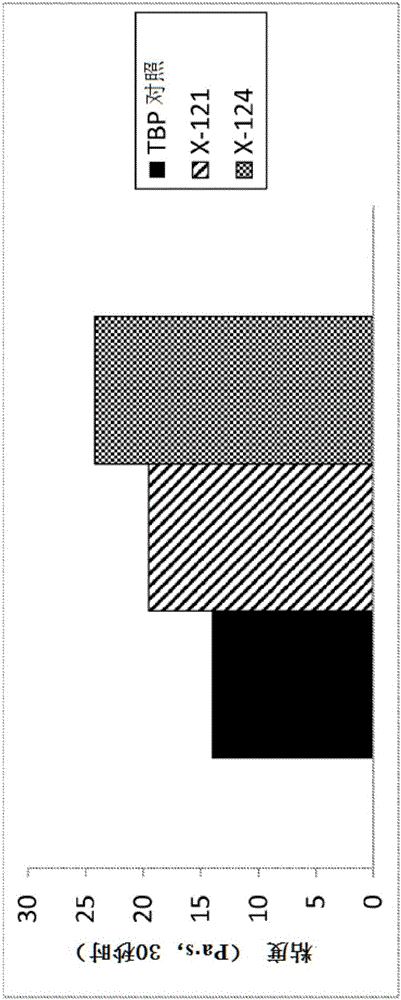

ActiveCN103524917AImprove mechanical propertiesImprove processing fluidityOther chemical processesPlasticizerPolyvinyl chloride

The invention discloses a polyvinyl chloride sealing strip composition for a refrigerator, belongs to the field of processing and application of macromolecular materials, and mainly relates to a polyvinyl chloride sealing strip composition for a refrigerator. The polyvinyl chloride sealing strip composition is prepared from the following components in parts by weight: 100 parts of polyvinyl chloride, 35-55 parts of a plasticizer, 20-35 parts of modified ethylene vinyl acetate copolymer, 28-42 parts of a thermoplastic polyurethane elastomer, 2-8 parts of a thermal stabilizer, 0.5-1.2 parts of a lubricant, 0.4-0.8 part of an antioxidant and 9-44 parts of a filling agent. A polyvinyl chloride sealing strip, produced from the polyvinyl chloride sealing strip composition, for a refrigerator is cold-resistant and oil-resistant, has good elastic resilience and durability, and is of great significance in energy conservation and consumption reduction.

Owner:CHINA PETROLEUM & CHEM CORP

Polymer type anti-oxidant, preparation method thereof, and application thereof

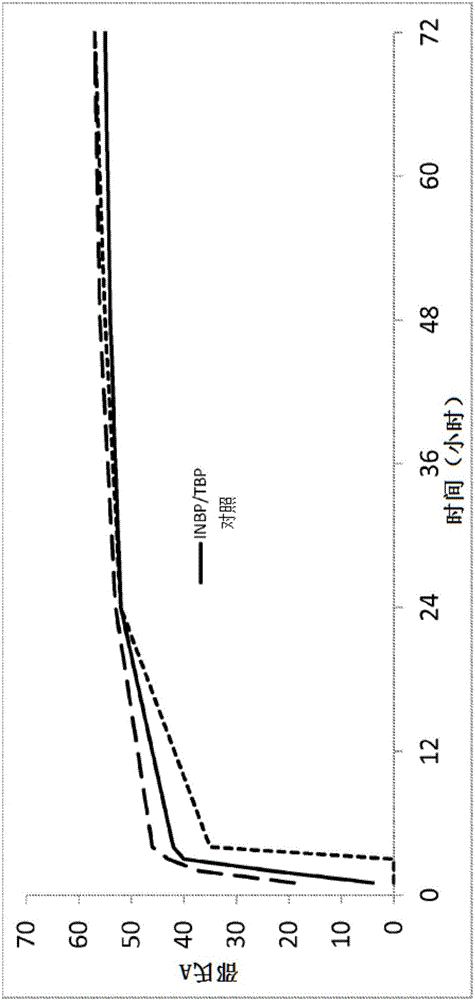

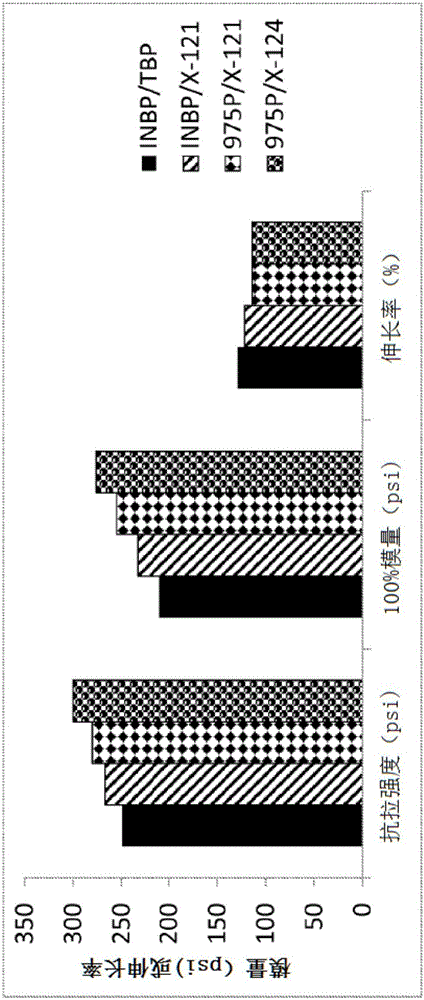

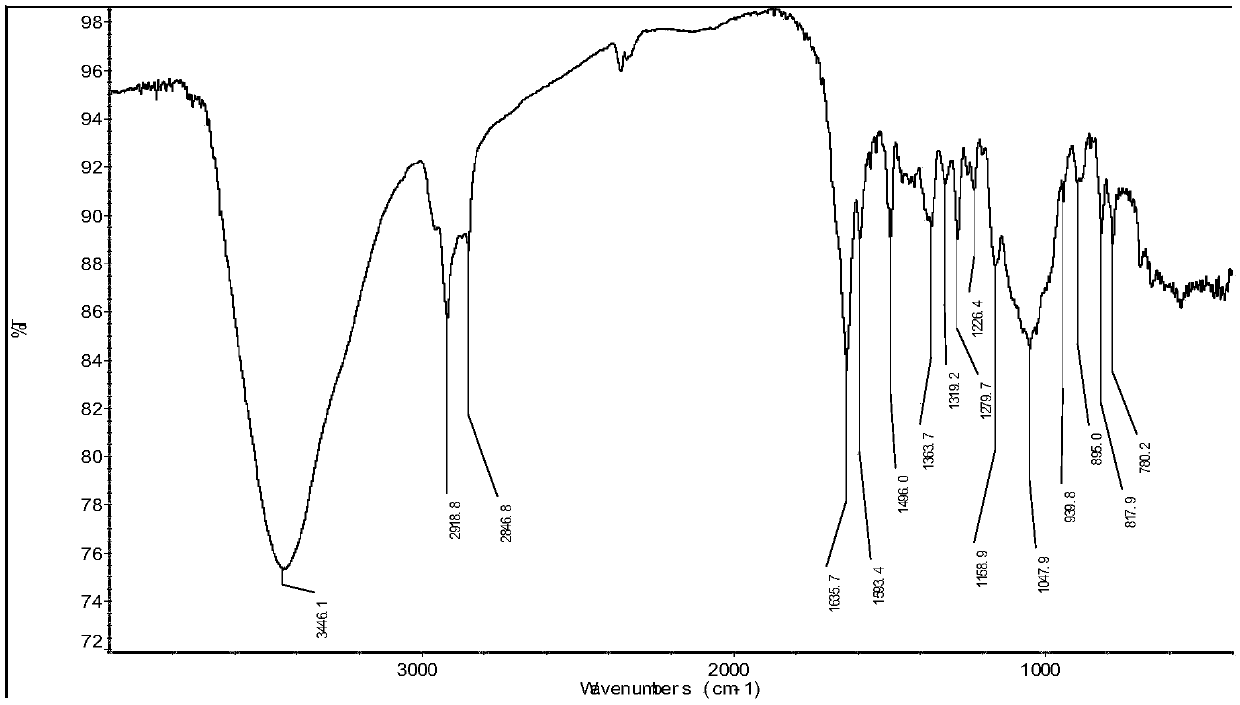

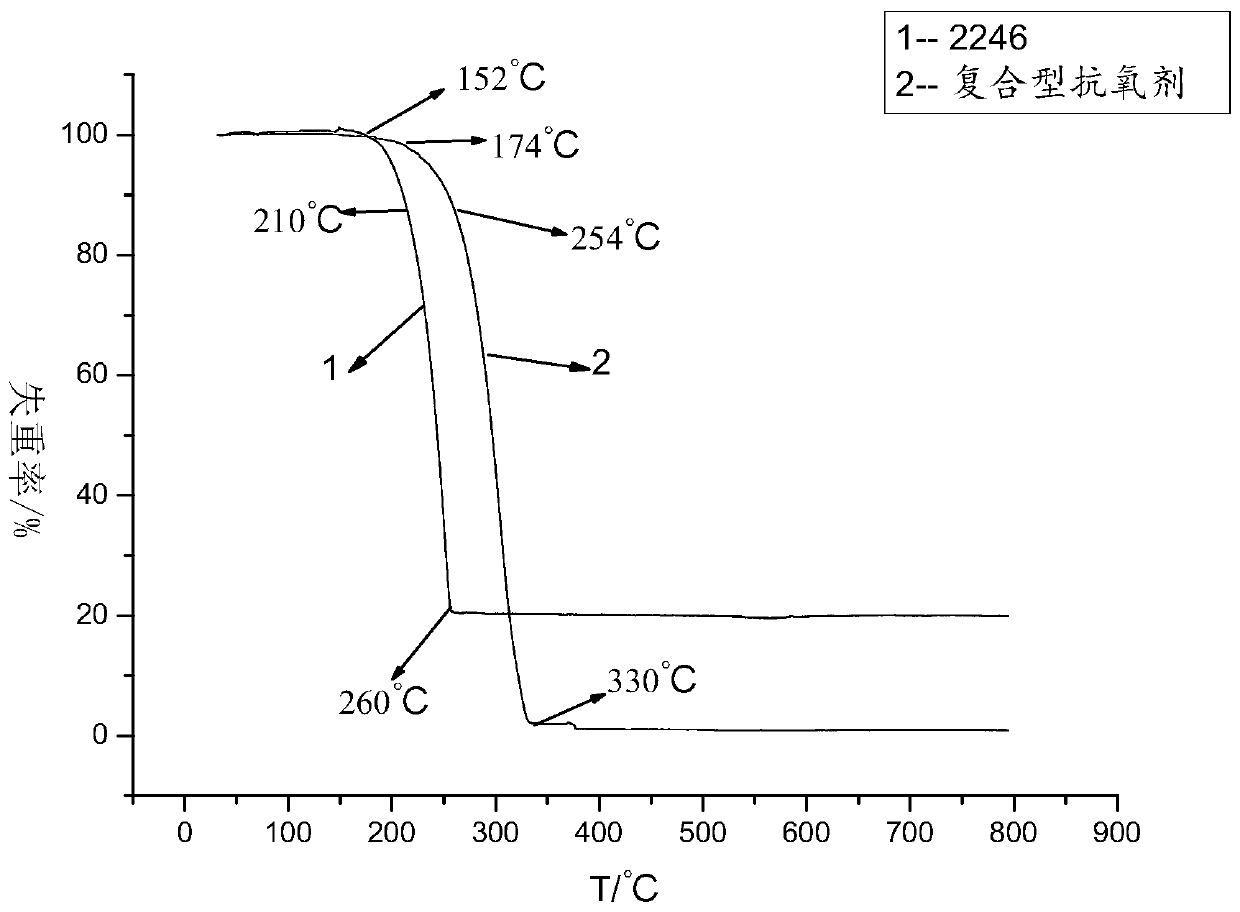

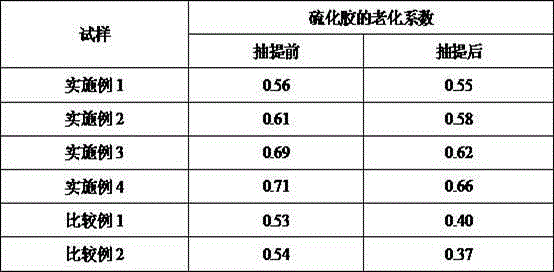

ActiveCN102516488AImprove antioxidant capacityExcellent thermal and oxidative aging resistanceRubber materialPolymer science

The invention relates to the field of a polymer type anti-oxidant, and provides a polymer type anti-oxidant, a preparation method thereof, and an application thereof. According to the invention, under the effect of a catalyst dibutyltin dilaurate, hydroxyl-terminated polybutadiene and isophorone diisocyanate are subject to a reaction under a temperature of 30 to 50 DEG C, such that an adduct is synthesized; the adduct is subject to a reaction with a low-molecular bisphenol anti-oxidant under a temperature of 60 to 80 DEG C, such that the polymer type anti-oxidant is prepared. The thermal oxidative aging resistance of the polymer type anti-oxidant is better than that of the corresponding low-molecular bisphenol anti-oxidant. Also, the polymer type anti-oxidant has an excellent extraction resistance. The anti-oxidant can be widely applied in rubber materials.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for epoxy polyester plasticizer

The invention relates to a preparation method for an epoxy polyester plasticizer, belonging to the technical field of chemical synthesis. The preparation method comprises the following steps of: firstly carrying out reaction on an unsaturated dicarboxylic anhydride and a saturated dibasic alcohol under catalysis action to generate a polyester with a certain molecular weight, and then carrying out epoxidation reaction on the polyester under the conditions of introducing an oxygen source and using formic acid as a carrier to obtain the epoxy polyester plasticizer with a certain epoxide number. The product provided by the invention has the characteristics of light color and luster, low residual iodine value and high heat stability and are basically nontoxic; and the reaction process is short, is easy to operate, is low in energy consumption and cost, and meets pollution-free and clean production process.

Owner:JIANGNAN UNIV

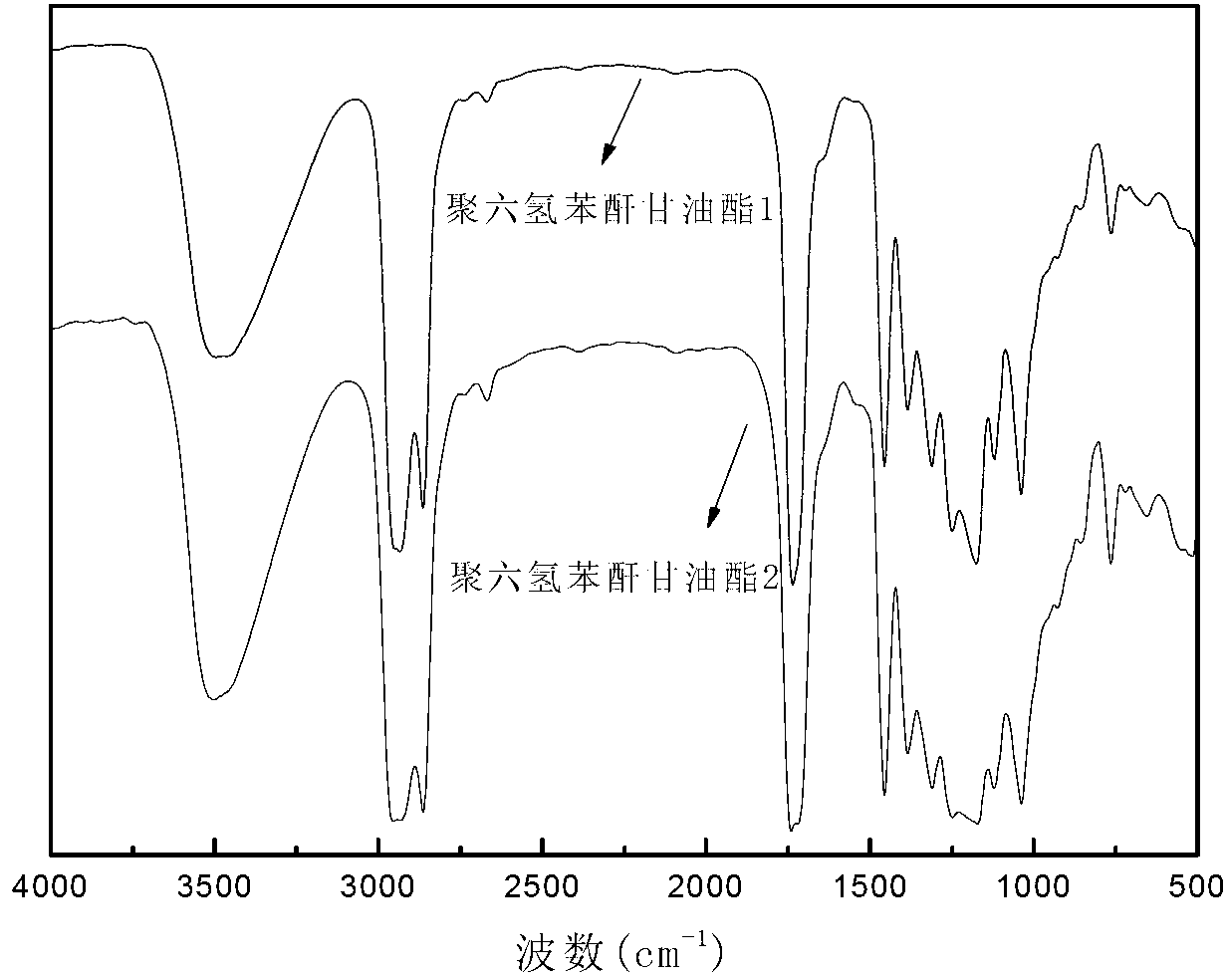

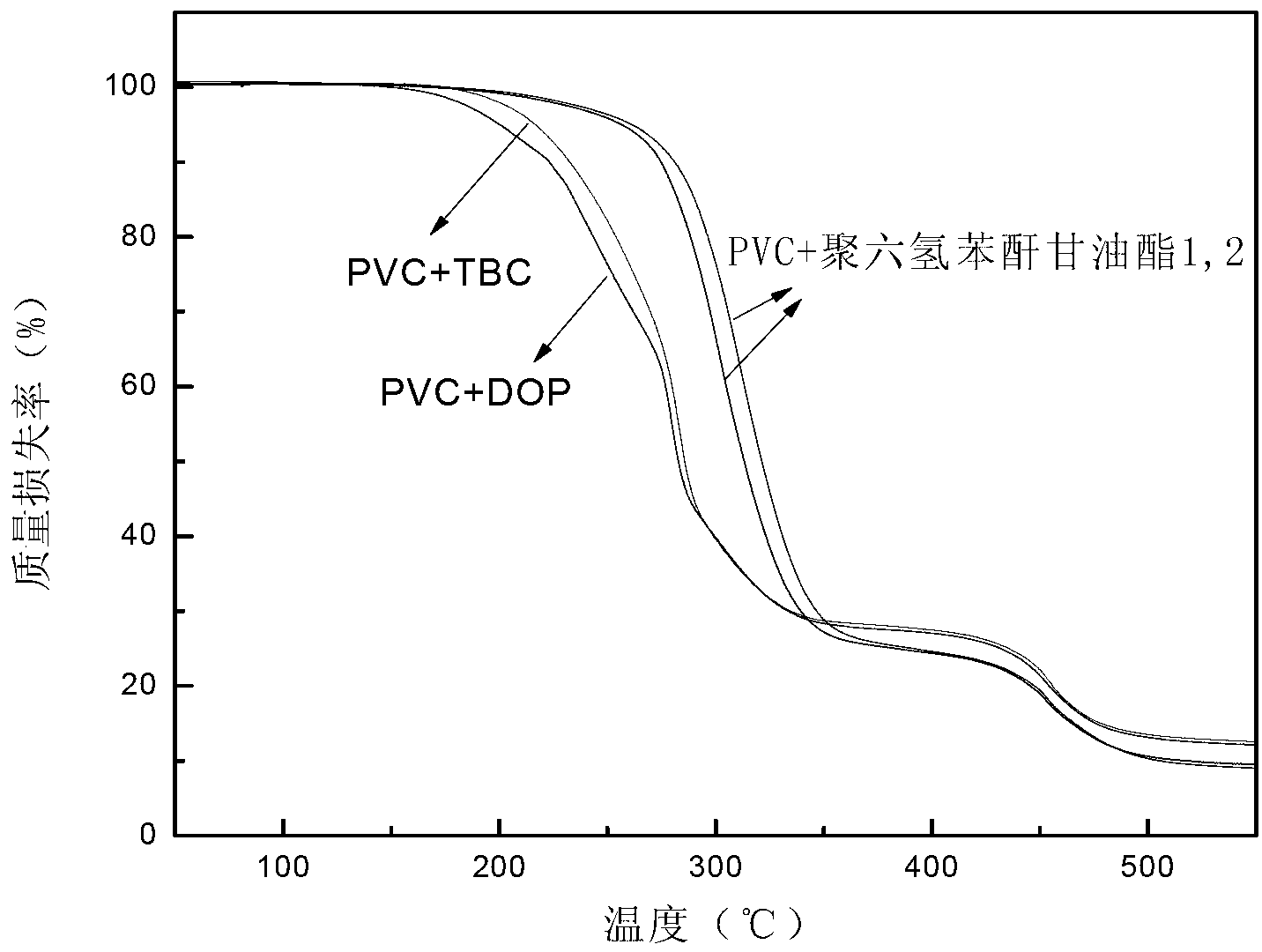

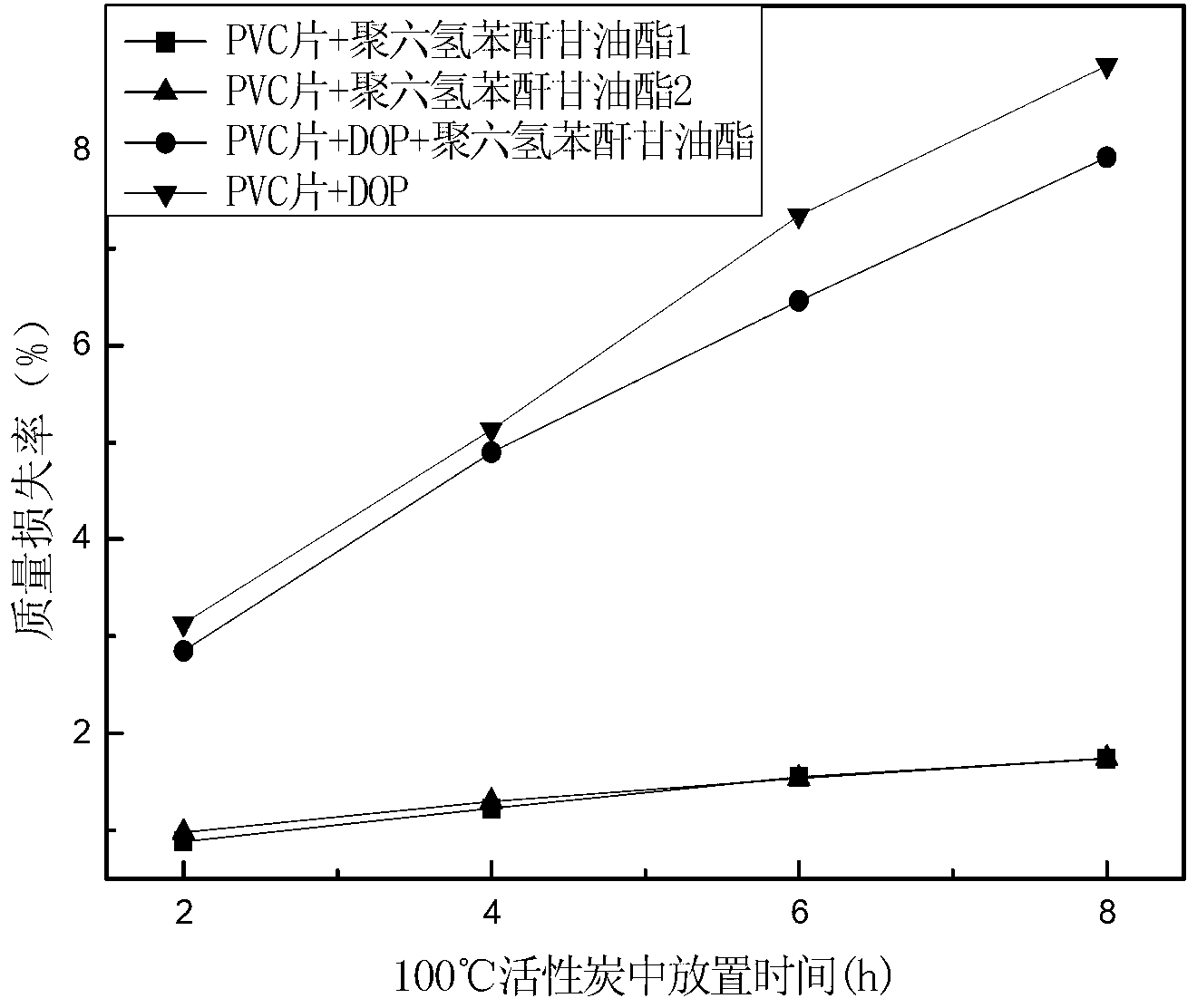

Preparation method of glyceryl polyester used as PVC (Polyvinyl Chloride) plasticizer

InactiveCN103242516AThe synthesis process is simpleReduce energy consumptionDispersion coefficientChemical synthesis

The invention discloses a preparation method of glyceryl polyester used as a PVC (Polyvinyl Chloride) plasticizer and belongs to the technical field of chemical synthesis. The preparation method comprises the following steps of: synthesizing by a one-step process under the combined action of a catalyst, an end-capping reagent and a water-carrying agent by using cheap bio-based glycerol, non-orthophthalic binary acid (for example hexahydrophthalic anhydride, adipic acid or the like) as the materials; and carrying out the post-treatment processes including dehydration poly-condensation, reduced pressure distillation and the like to obtain the poly-binary acid glyceride plasticizer. The glyceride plasticizer has a final acid value of 0.7mgKOH.g<-1>-2mgKOH.g<-1>, an esterification rate higher than 97%, relative molecular weight of about 5000, a dispersion coefficient of 1.00-1.13, appropriate viscosity and stable physical and chemical characteristics; the glyceride plasticizer is added to the PVC according to a certain formula to be refined into a PVC plastic test block, so that application performances including heat stability, drawing resistance, tensile performance and the like of the test block are tested; and the test block has good heat stability, tensile performance and excellent mobility resistance. The preparation method of the glyceryl polyester used as the PVC plasticizer is low in material price, simple in preparation process, low in energy consumption, excellent in product performance and good in application prospect.

Owner:JIANGNAN UNIV

Printed synthetic leather and method for manufacturing same

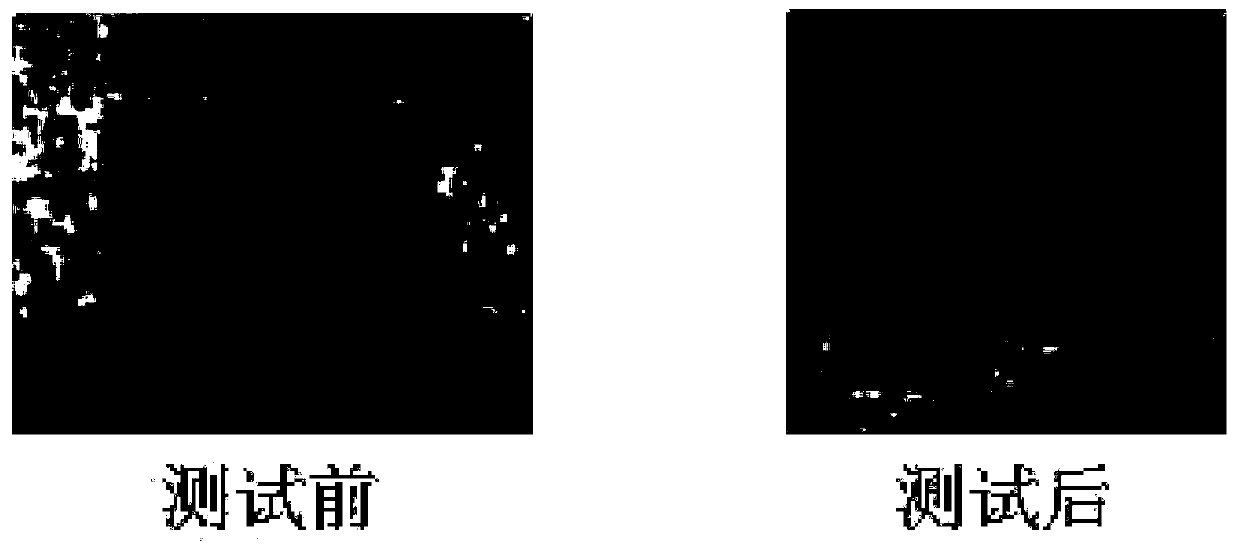

InactiveCN102605635AImprove breathabilityGood resistance to extractionLamination ancillary operationsSynthetic resin layered productsCooking & bakingUltraviolet lights

The invention relates to a printed synthetic leather and a method for manufacturing the printed synthetic leather. The printed synthetic leather comprises a base cloth layer; the base cloth layer is coated with a water PU (polyurethane) foaming layer; and the surface of the water PU (polyurethane) foaming layer is printed directly to form a printed layer. The method for manufacturing the printed synthetic leather comprises the following steps: preparing a slurry; feeding the slurry into a foaming machine; adjusting the proportion of the slurry amount to the air intake to determine the size of needed foam holes; feeding a piece of base cloth, heating to iron, feeding, and putting into a baking oven to finish processing the base cloth; and finally printing directly on the surface of the synthetic leather taken out of the baking oven. The printed synthetic leather manufactured by adopting the method has good breathability and extraction resistance, can resist the irradiation of ultraviolet light, hydrolysis, cold bending and wear, can not become yellow, age and mildew and reaches the international advanced flame resistance standard. The process for manufacturing the printed synthetic leather is simple and has the advantages of saving energy and reducing consumption.

Owner:YIXING XINGUANG SYNTHETIC LEATHER

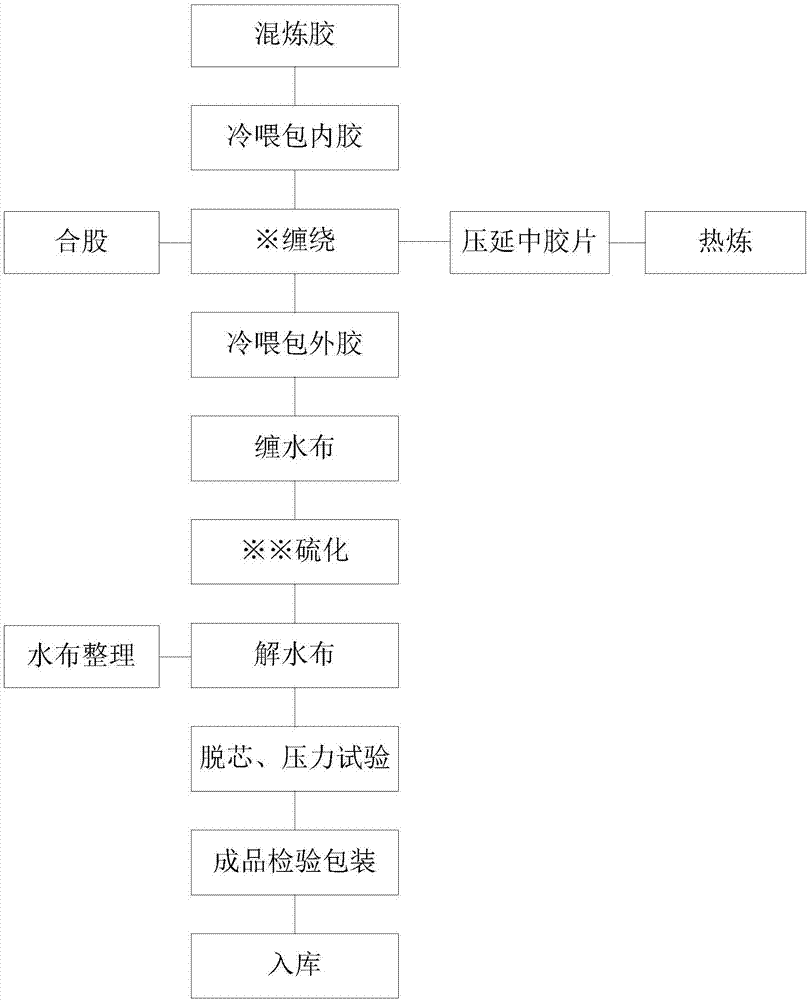

Rubber compound, rubber product, hydraulic rubber hose and preparation method of hydraulic rubber hose

ActiveCN106987040AImprove aging resistanceImproved liquid resistanceFlexible pipesRubber materialPolymer science

The invention relates to a rubber compound, a rubber product, a hydraulic rubber hose and a preparation method of the hydraulic rubber hose. The rubber compound comprises (i) hydrogenated butadiene-acrylonitrile rubber, (ii) thermal cracking carbon black and (iii) other selectable matching agents. A rubber material prepared by the rubber compound has excellent oil resistance and temperature resistance.

Owner:XIANYANG KELONG SPECIAL RUBBER PROD

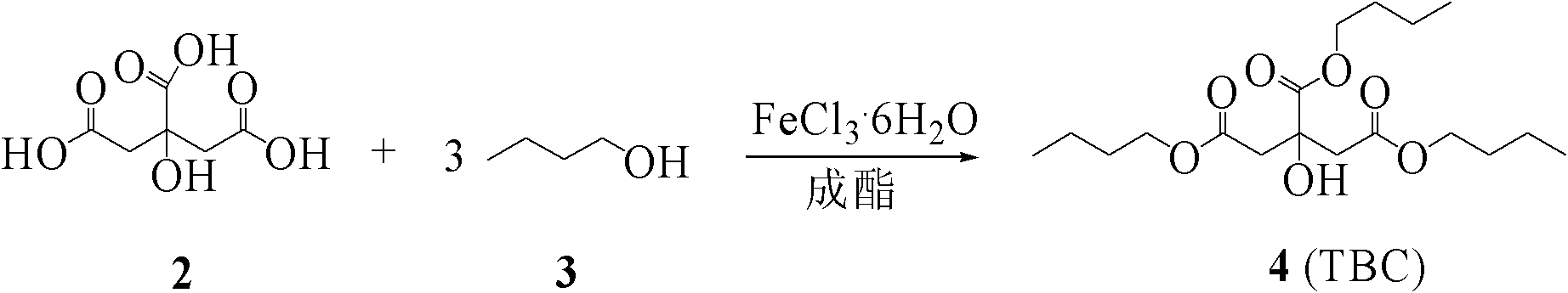

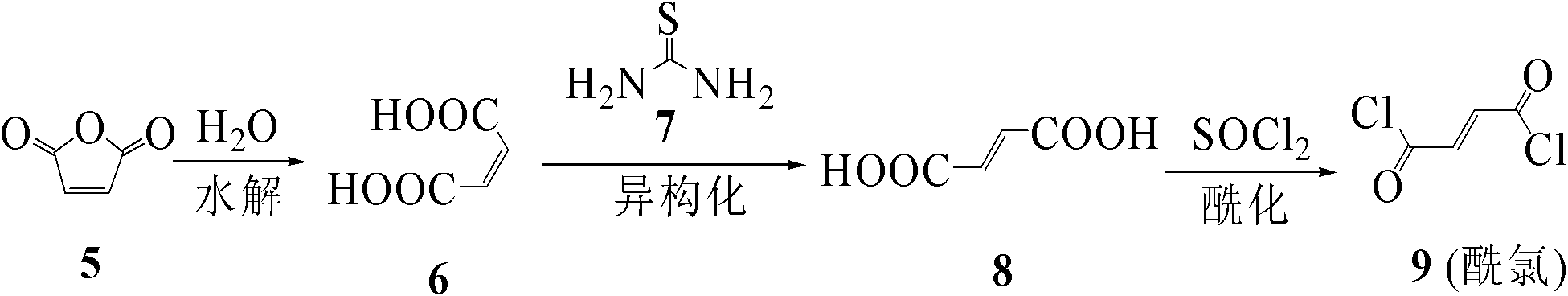

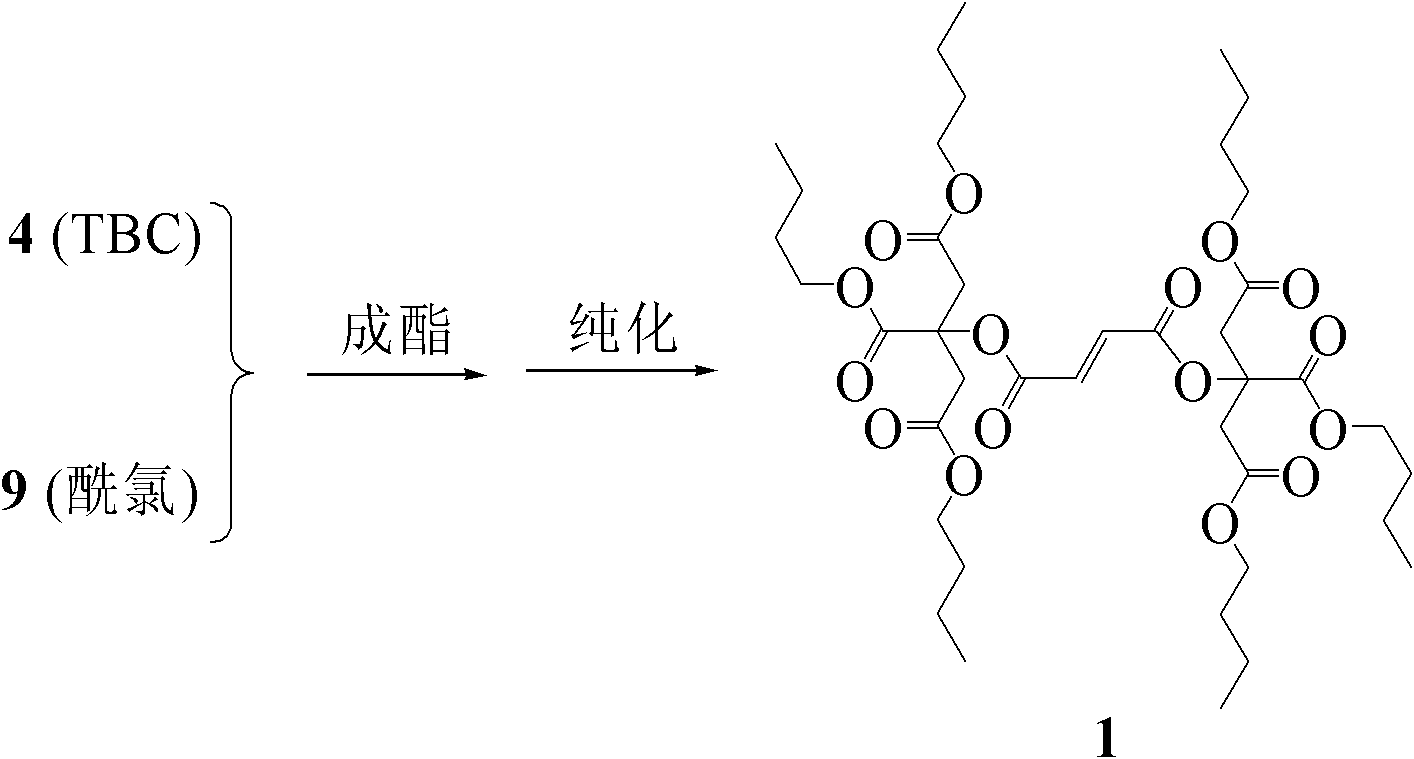

Maleic acid tributyl citrate diester compound and preparation method thereof

InactiveCN101781213AReduce volatilityGood seepage resistancePreparation from carboxylic acid halidesChlorideTributyl citrate

The invention discloses a new type green environmental protection type plastic plasticizer, which belongs to the technical field of plastic plasticizers and has the chemical name of maleic acid tributyl citrate diester. The invention also discloses a preparation method of the compound. Tributyl citrate and trans-maleic acid chloride are synthesized into a whole by a converging method, thereby effectively preparing a final product of the maleic acid tributyl citrate diester. The Maleic acid tributyl citrate diester as the plastic plasticizer has the advantages of small volatility, high stability, good anti-migration, good anti-extraction performance, good low-temperature flexibility, safety and no toxicity.

Owner:XI AN JIAOTONG UNIV

Non-toxic environmentally friendly nadic anhydride polyester plasticizer and preparation method thereof

ActiveCN102391482AShorten the reaction time of esterification and polycondensationImprove reactor efficiencyPlasticizerDistillation

The invention relates to a non-toxic environmentally friendly nadic anhydride polyester plasticizer and a preparation method thereof, and relates to the technical field of polyester plasticizers. The non-toxic environmentally friendly nadic anhydride polyester plasticizer comprises nadic acid polymethyl propylene glycol ester, nadic acid poly-1,4-butanediol ester, nadic acid poly-diglycol ester and nadic acid poly-triethylene glycol ester. The preparation method comprises the following steps that: nadic anhydride and diol are subjected to esterification and polycondensation reactions at a temperature of 170 DEG C to 220 DEG C under the conditions that 2-ethylhexanol is used as an end-capping agent, tetra-n-butyl titanate is used as a catalyst and cyclohexane is used as a water-carrying agent; and after the completion of the reactions, excess alcohols and micromolecular esters are removed by reduced pressure distillation to finally obtain a polyester product. The product has an acid value reduced to 0.31-0.53mgKOH . g<-1>, an iodine value of 71.98% - 74.35%, a saponification value of 501.9-593.4mgKOH . g<-1>, viscosity of 801.9-846.5mPa. S, a number average molecular weight of 7052-8612g . mol<-1>, and an esterification rate of 99.68% - 99.81%. The product is non-toxic and environmental friendly, the preparation process is short, the energy consumption is low, 'three wastes' (waste gas, waste water, solid waste) are not generated, and the preparation method meets the green process requirements.

Owner:安徽新鸿药业有限公司

Preparation method for composite type phosphate ester leather fat-liquoring agent of polyurethane containing nonionic structures

The invention provides a preparation method for a composite type phosphate ester leather fat-liquoring agent of polyurethane containing nonionic structures. P2O5 is effectively dispersed through low-melting-point polyoxypropylene ether at first and then is subjected to compound esterification with the composite polyurethane containing the nonionic structures and high alcohols, and the composite type phosphate ester leather fat-liquoring agent is obtained. The preparation method has the advantages that polyurethane phosphate ester which serves as both a nonionic surfactant and an anionic surfactant is adopted as an emulsifier of the fat-liquoring agent, so that the emulsifying capacity and the permeability of the fat-liquoring agent are improved; meanwhile, the characteristic that a PO bond in the phosphate ester can be subjected to complexation with active groups on leather fibers is used, so that the stability and the combining capacity with chrome tanning leather collagen fibers of emulsion of the fat-liquoring agent are improved.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Aqueous PU (Poly Urethane) synthetic leather and manufacture method thereof

InactiveCN102605636AImprove breathabilityGood resistance to extractionTextiles and paperManufacturing technologyAging resistance

The invention relates to an aqueous PU (Poly Urethane) synthetic leather and a manufacture method thereof. The aqueous PU synthetic leather comprises a base cloth layer, wherein the base cloth layer is coated with an aqueous PU foaming layer. The manufacture method for the aqueous PU synthetic leather comprises the following steps: preparing slurry, and putting the slurry into a foaming machine; regulating the ratio of the slurry and air inflow to determine the size of a required bubble hole; adding the base cloth; and finishing processing the aqueous PU synthetic leather by the working procedures of heating, ironing, loading, sending into an oven. The synthetic leather manufactured with the manufacture method has the advantages of good air permeability, excellent extraction resistance, yellowing resistance, ultraviolet radiation resistance, ageing resistance, mildewing resistance, hydrolysis resistance, cold and bending resistance, high abrasive resistance, simple and clear manufacture technology and obvious energy-saving and consumption reduction effect, and the fire resistance reaches the international advanced standard.

Owner:YIXING XINGUANG SYNTHETIC LEATHER

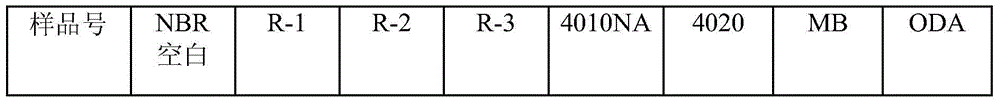

Low-VOC polyvinyl chloride/powder nitrile butadiene rubber thermoplastic elastomer sealing strip and preparation method thereof

The invention relates to a sealing strip, in particular to a low-VOC polyvinyl chloride / powder nitrile butadiene rubber thermoplastic elastomer sealing strip and a preparation method thereof. The low-smoke zero-halogen flame-retardant sealing strip is prepared from the following raw materials in parts by weight: 100 parts of PVC, 10 to 60 parts of PNBR (powder nitrile butadiene rubber), 10 to 70 parts of plant oil based polyester plasticizer, 5 to 30 parts of epoxidized soybean oil, 10 to 80 parts of calcium carbonate superfine powder, 10 to 30 parts of carbon black, 1 to 5 parts of stearic acid, 2 to 10 parts of zinc oxide, 3 to 8 parts of calcium and zinc composite stabilizer, 0.5 to 3 parts of bis(1-(tert-butylperoxy)-1-methylethyl)-benzene and 0.5 to 2 parts of antiager 4010NA. The low-VOC polyvinyl chloride / powder nitrile butadiene rubber thermoplastic elastomer sealing strip disclosed by the invention has the characteristics of good resilience, low VOC emission, excellent comprehensive performance and the like and is suitable for use in industries of automobiles, buildings, cables, household appliances and the like.

Owner:ZHEJIANG XINGYU AUTO PARTS CO LTD

Anti-ageing shock-resistant modified butyl-rubber cable material

A disclosed anti-ageing shock-resistant modified butyl-rubber cable material comprises the following raw materials: butyl rubber, natural rubber, poly(4-methyl-1-pentene), stearic acid, zinc oxide, 2,5-dimethyl-2,5-di-(benzoyl peroxy)hexane, carbon black, carbon nanotube, modified white carbon black, polyethylene micro powder, 2,4-di-tert-butyl-6-cycloheximide phenol, 3,5-di-tert-butyl-4-hydroxylbenzyl methyl ether, promoter CZ, promoter TMTD, propanediol sebacate polyester, coumarone resin, di-(2-ethylhexyl)4,5-epoxy tetrahydrophthalate, N-[3-(trimethoxysilyl)propyl]ethylenediamine, isopropyl tri(dioctylpyrophosphate) titanate, and calcium stearate. The anti-ageing shock-resistant modified butyl-rubber cable material is fast in curing speed, high in strength, and excellent in ageing resistance and impact resistance.

Owner:繁昌县菲德通讯材料设计有限公司

Environment-friendly type high-resilience PVC (Polyvinyl Chloride)/NBR (Nitrile-Butadiene Rubber)/BR (Butadiene Rubber) elastomer sealing strip and preparation method thereof

The invention relates to environment-friendly sealing strips, and in particular to an environment-friendly type high-resilience PVC (Polyvinyl Chloride) / NBR (Nitrile-Butadiene Rubber) / BR (Butadiene Rubber) elastomer sealing strip and a preparation method thereof. The environment-friendly type high-resilience PVC / NBR / BR elastomer sealing strip is mainly prepared from the following raw materials: 100 parts of PVC, 10 to 70 parts of NBR, 10 to 50 parts of modified BR, 10 to 60 parts of a polyester plasticizing agent, 5 to 20 parts of epoxidized soybean oil, 10 to 60 parts of superfine white carbon black, 10 to 40 parts of carbon black, 1 to 3 parts of stearic acid, 2 to 8 parts of zinc oxide, 2 to 6 parts of a calcium-zinc composite stabilizing agent, 1 to 5 parts of ditert-butyl cumene peroxide and 1 to 3 parts of an anti-aging agent 4010NA. The environment-friendly type high-resilience PVC / NBR / BR elastomer sealing strip disclosed by the invention has the characteristics of good resilience, low mobility, good comprehensive performance and the like, and is suitable for industries such as automobiles, buildings, electric wires and cables and household appliances to use.

Owner:浙江仙居星峰汽车零部件有限公司

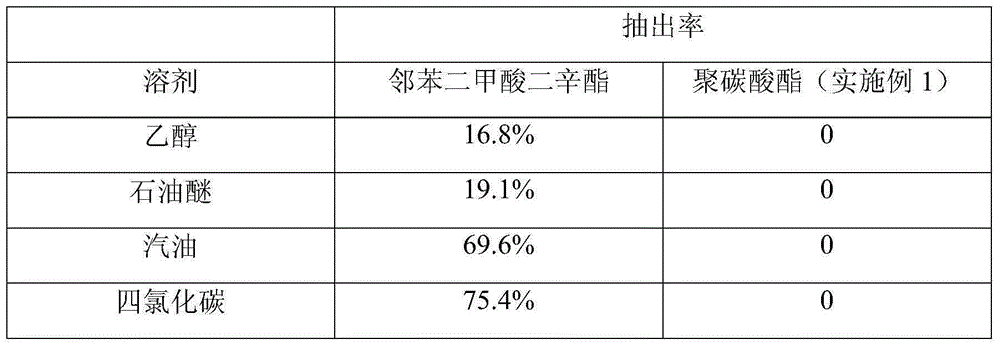

Preparation method of polyester plasticizer

The invention belongs to the technical field of plastic additives and particularly relates to a preparation method of a polyester plasticizer. In a high-pressure reaction kettle, with a bi-metal cyanide complex prepared through an ultrasonic method as a catalyst, CO2 and an epoxy compound are subjected to a catalytic copolymerization reaction to synthesize polycarbonate. The preparation method has wide selection range and wide source of raw material and can effectively reduce production cost. The polycarbonate has a transparent appearance and low viscosity, and can satisfy the demands on plasticizers in PVC processing. The polycarbonate is higher than a conventional monomer-type phthalate plasticizer in molecular weight, and has excellent extraction resistance and thermal stability.

Owner:CHINA PETROLEUM & CHEM CORP

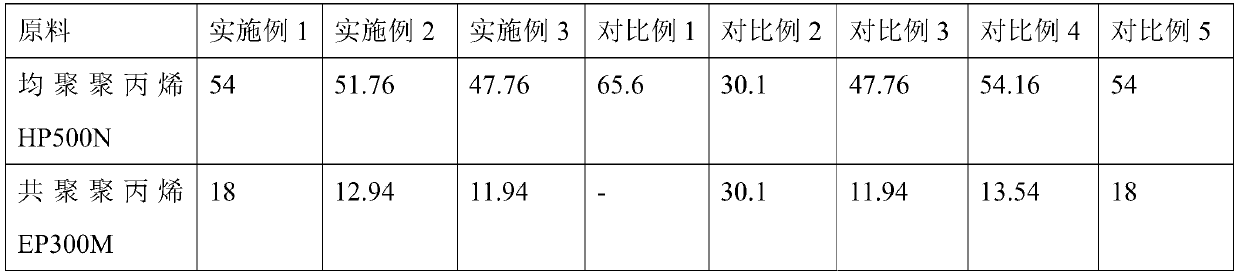

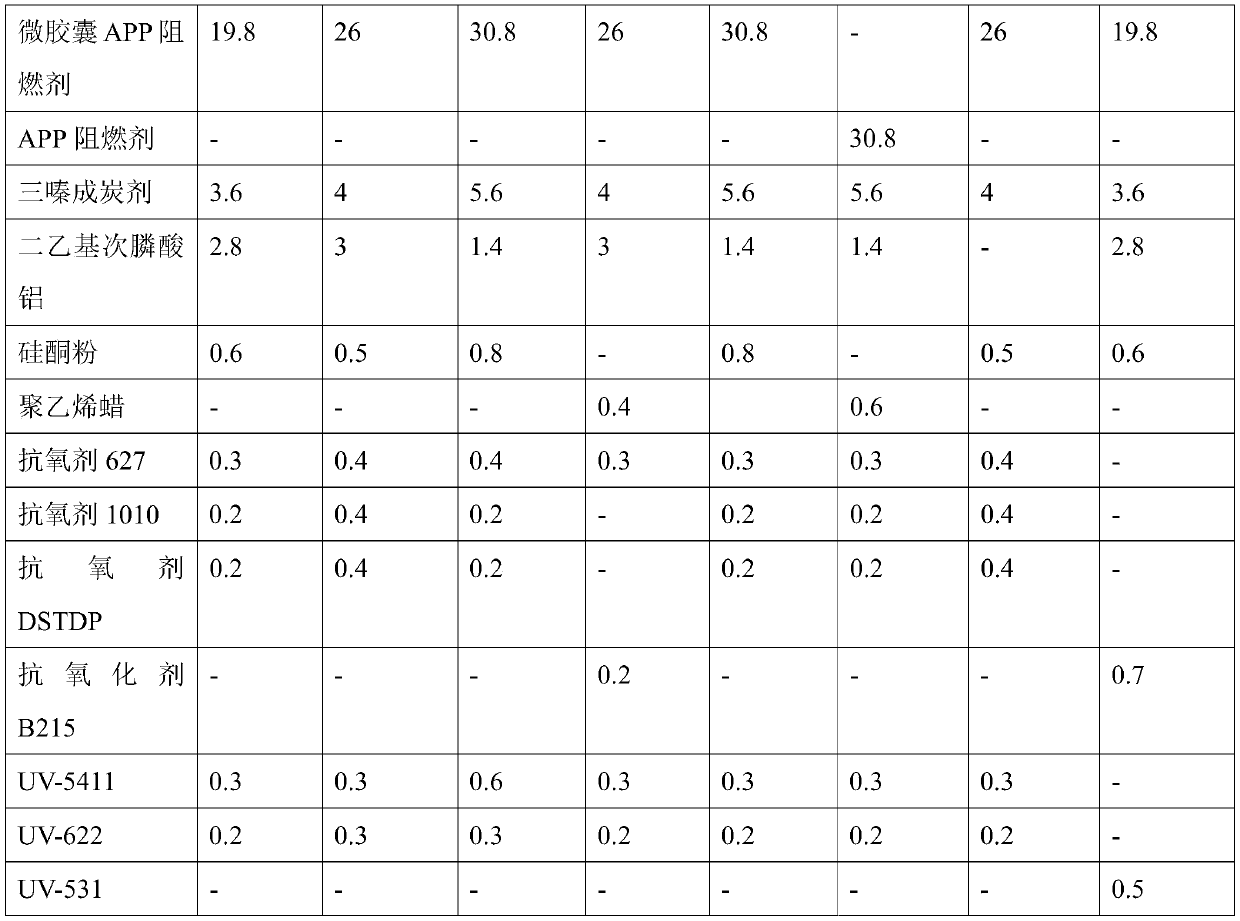

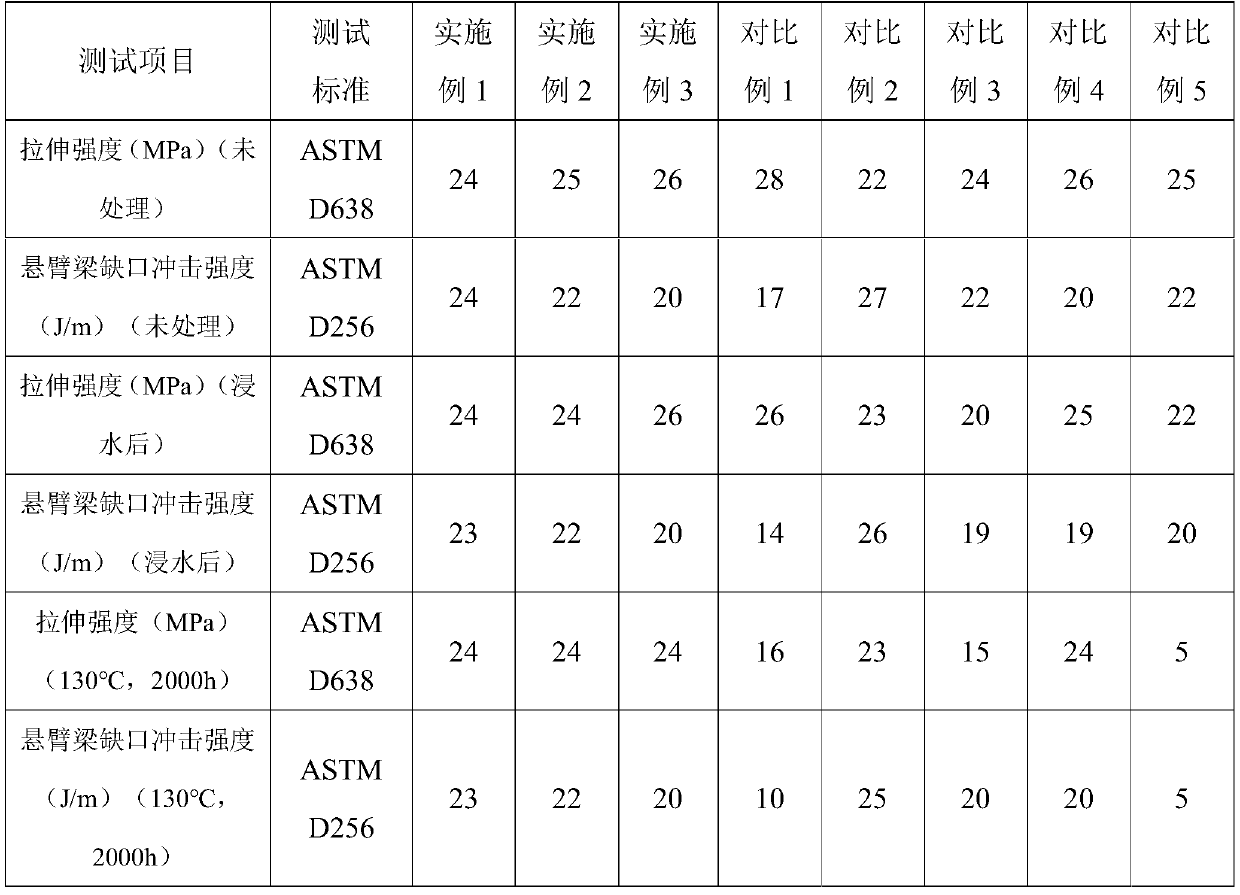

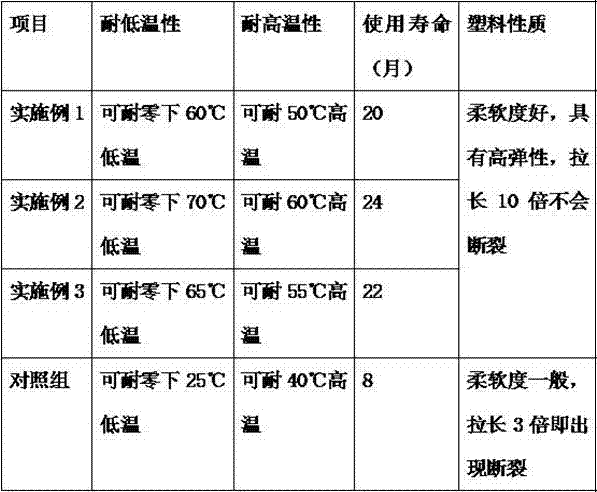

Weather-resistant halogen-free flame-retardant polypropylene material as well as preparation method and application thereof

PendingCN111548559AImprove flame retardant performanceImprove water resistancePolymer sciencePolypropylene

The invention provides a weather-resistant halogen-free flame-retardant polypropylene material as well as a preparation method and application thereof. The weather-resistant halogen-free flame-retardant polypropylene material is prepared from the following raw materials in parts by mass: 55-75 parts of polypropylene resin, 20-38 parts of halogen-free flame retardant, 1-3 parts of a flame-retardantsynergist, 0.5-0.8 part of a lubricant, 0.5-1.2 parts of an antioxidant and 0.3-1 part of a light stabilizer; wherein the halogen-free flame retardant comprises microcapsule ammonium polyphosphate and a charring agent. The weather-resistant halogen-free combustion-supporting polypropylene material has a high flame retardant performance (UL94 V-0 and UL1694 SC-0 with a thickness of 0.75 mm), and after being soaked in water at 70 DEG C for 7 days, at least 90% of mechanical properties are still maintained. After the material is irradiated by a xenon lamp for 1000 hours, at least 90% of mechanical properties are maintained. In addition, the preparation method is simple and easy to control. The material is applied to a soft core of decorative lighting.

Owner:GUANGDONG JUSHI CHEM CO LTD

Manufacturing process of high-weather-resistance reflective film

InactiveCN112080216AHigh plasticizing efficiencyImprove cold resistanceFilm/foil adhesivesPaints with free metalsPolyvinyl chlorideETHYLHEXYL ACETATE

The invention discloses a manufacturing process of a high-weather-resistance reflective film. The reflective film comprises a transparent protective layer, a microprism layer, a packaging layer, a pressure-sensitive adhesive layer and a release layer which are sequentially arranged from top to bottom, the transparent protective layer is prepared from the following raw materials in parts by weight:polyvinyl chloride paste resin, acetyl tributyl citrate, tributyl citrate, di(2ethylhexyl)phthalate, a plasticizer TXIB, a heat stabilizer, epoxidized soybean oil, diatomite, titanium dioxide, lightcalcium carbonate, ground calcium carbonate, a foaming agent, a coupling agent, an impact modifier and zinc oxide. By limiting plasticizers such as acetyl tributyl citrate, tributyl citrate, di(2ethylhexyl) phthalate and a plasticizer TXIB to be matched with polyvinyl chloride paste resin, the transparent protective layer formed on a microprism is high in plasticizing efficiency, low in plasticizer mobility, good in cold resistance and extraction resistance and high in wear resistance, so that the weather resistance of the reflective film is improved, and the service life of the reflective film is prolonged.

Owner:JINJIANG LIANXING REFLECTIVE MATERIAL

Polyester plasticizers with benzoic acid end-caps

ActiveCN105873978AGood compatibilityEasy to processNon-macromolecular adhesive additivesOther chemical processesBenzoic acidPolyester

Polyester plasticizer compositions for adhesives, caulk, sealants, vinyl and other polymeric compositions comprising low molecular weight oligomeric dibenzoates prepared by end-capping a polyester plasticizer, having alternating units of glycols or diols and dibasic acids, with benzoic acid. Methods for preparing oligomeric dibenzoates include steps to reduce or eliminate residual hydroxyl content and improve plasticizer performance by adding acetic anhydride are also disclosed. Propylene glycol adipate and propylene glycol succinate polyesters with benzoic acid end-caps are particularly useful, as are hybrid benzoate / acetate end-capped polyesters formed in the process with acetic anhydride. The invention further relates to vinyl resin compositions comprising the oligomeric end-capped polyesters.

Owner:EMERALD KALAMA CHEM

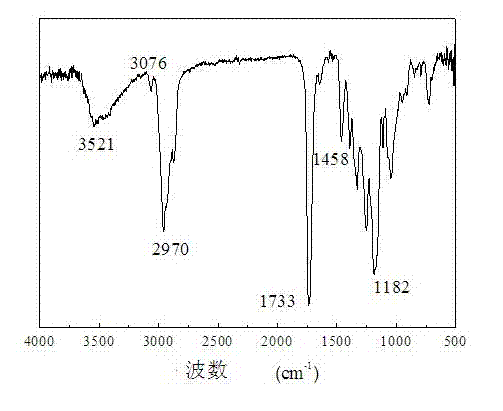

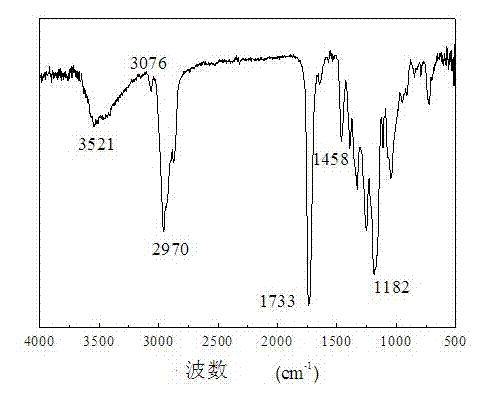

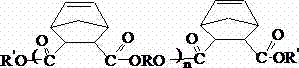

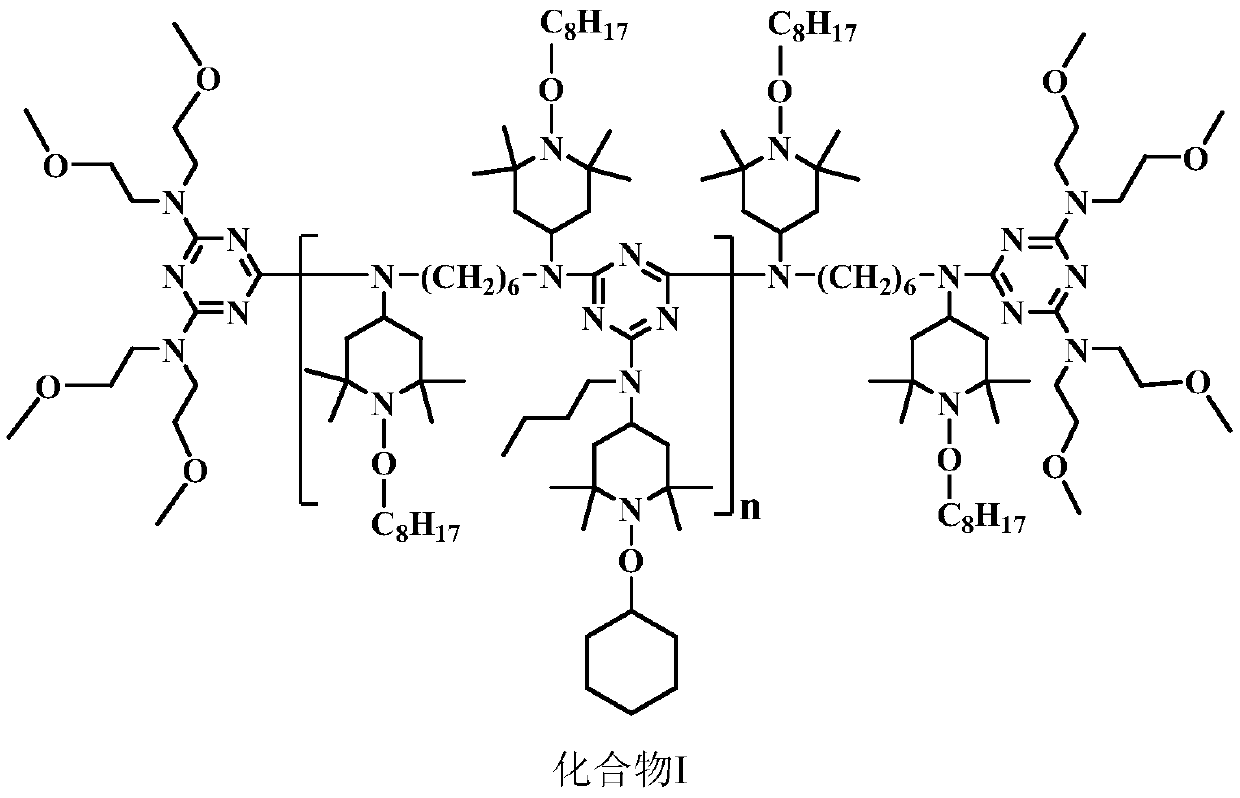

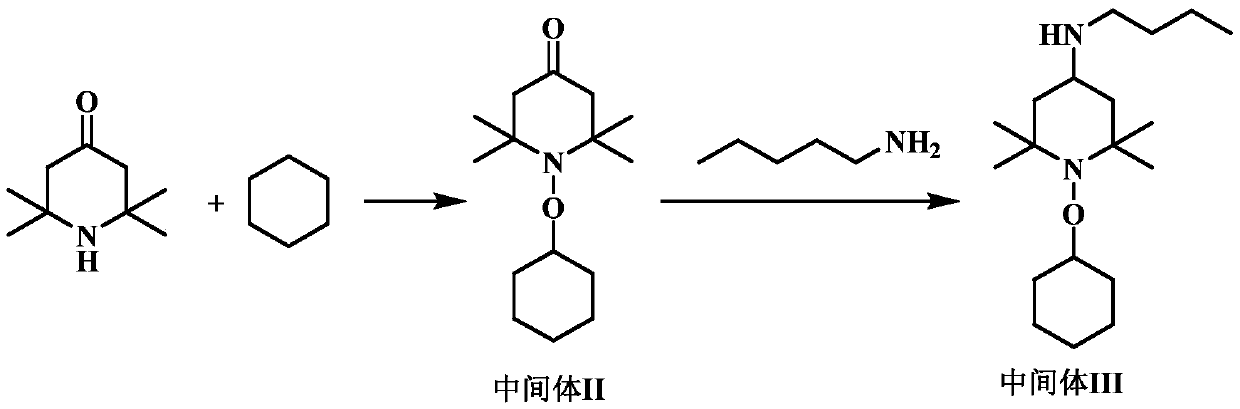

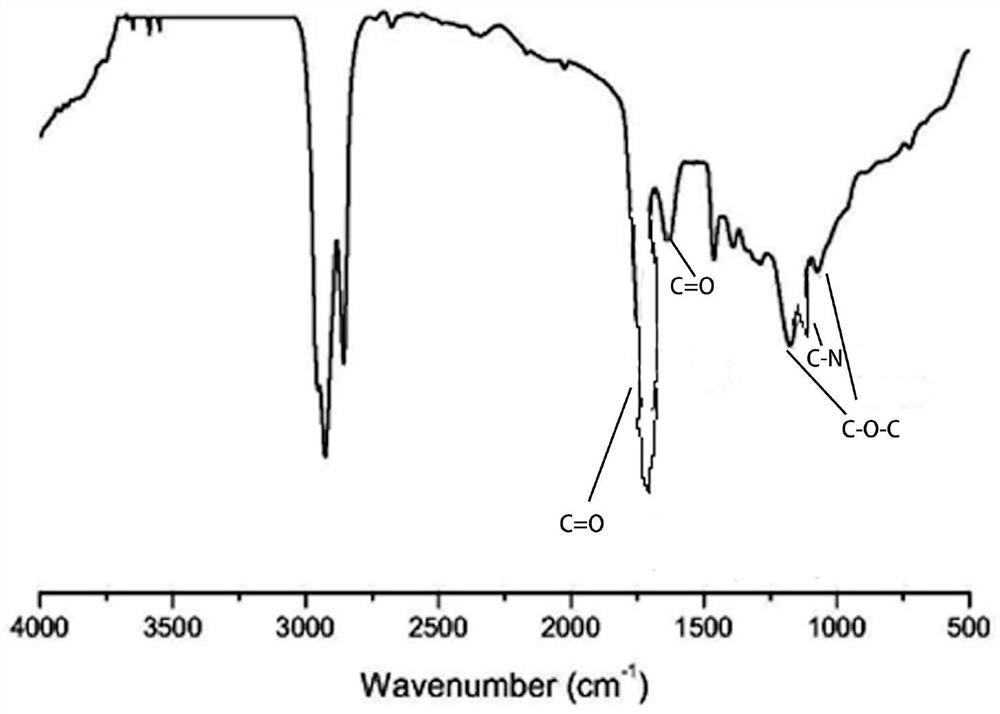

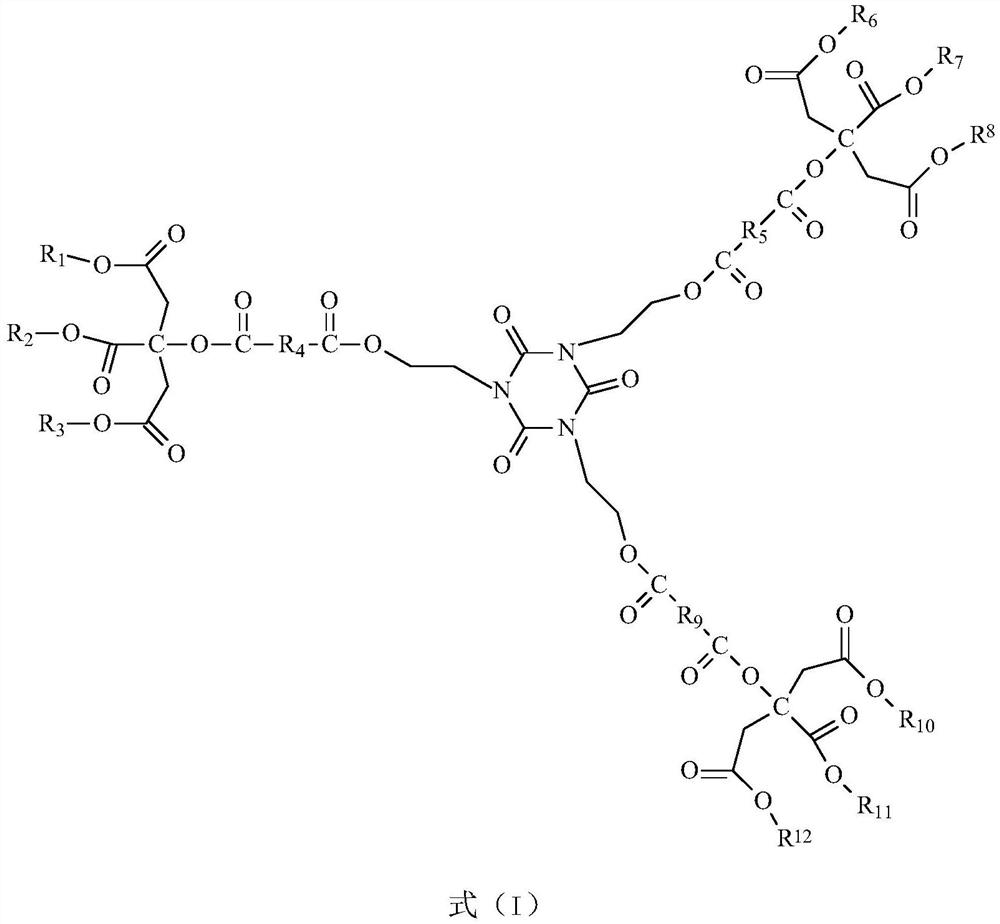

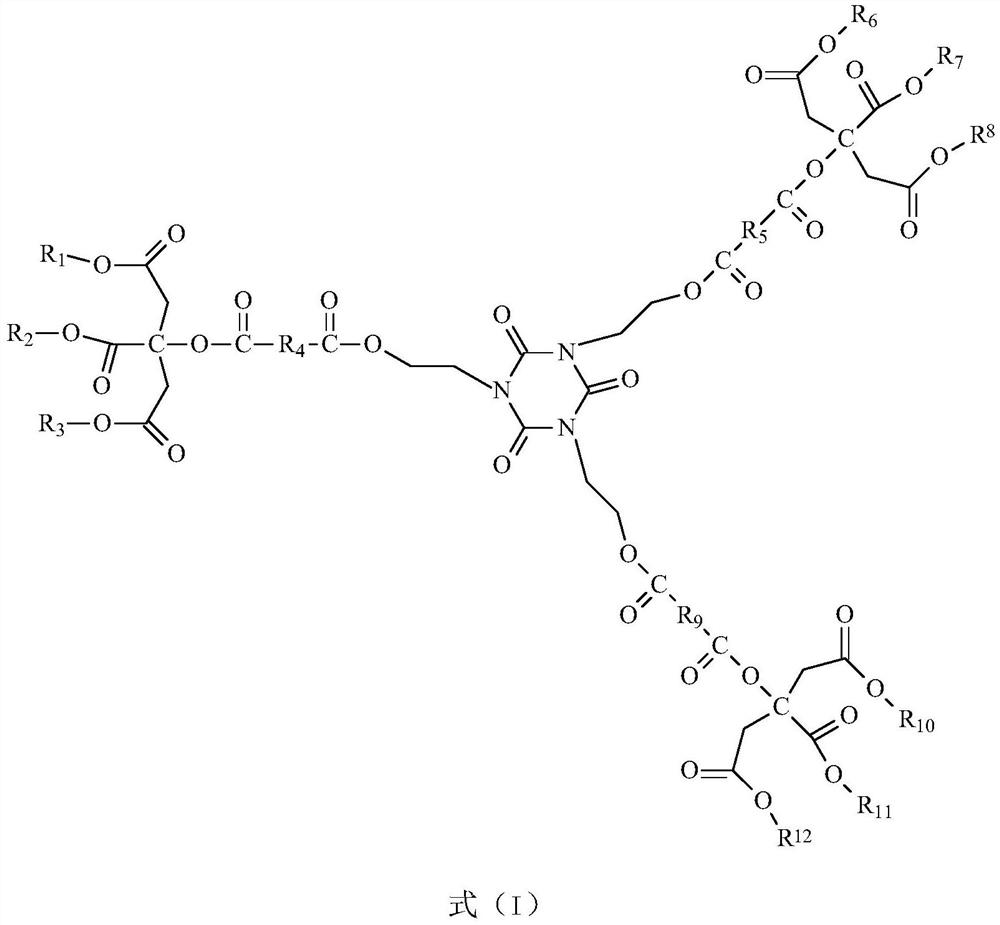

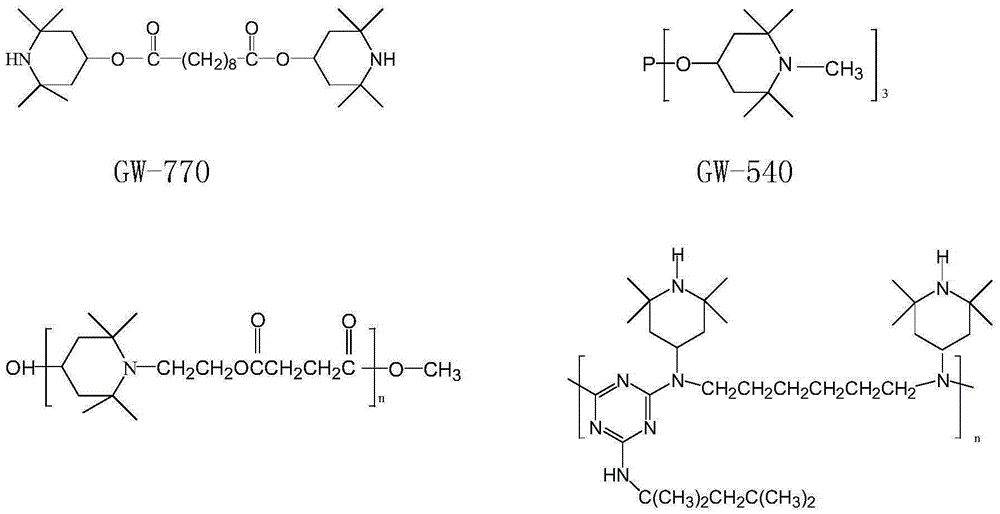

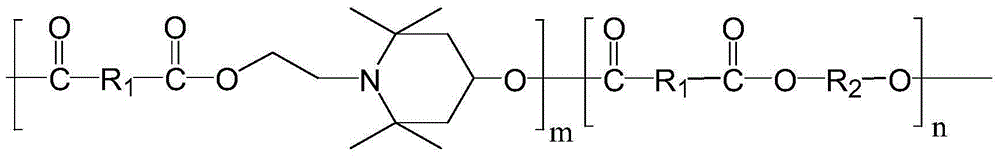

High-molecular-weight low-alkalinity light stabilizer as well as preparation and application thereof

InactiveCN110845729AGood extraction resistancePrevent migration and volatilizationBulk chemical productionSide productOrganic chemistry

The invention belongs to the field of light stabilizers and preparation thereof, and particularly relates to a high-molecular-weight low-alkalinity light stabilizer and preparation and application thereof. The structure of the light stabilizer is shown as a compound I. The light stabilizer has high molecular weight, good extraction resistance, narrow molecular weight distribution and excellent light stability, volatilization and migration in the using process can be effectively prevented, the molecular weight is about 2000-10000, and the molecular weight distribution is below 2.0. The preparation method of the light stabilizer is simple, mild in synthesis condition, easy to operate, high in product yield, free of by-products, clean and environmentally friendly.

Owner:SHENYANG RES INST OF CHEM IND

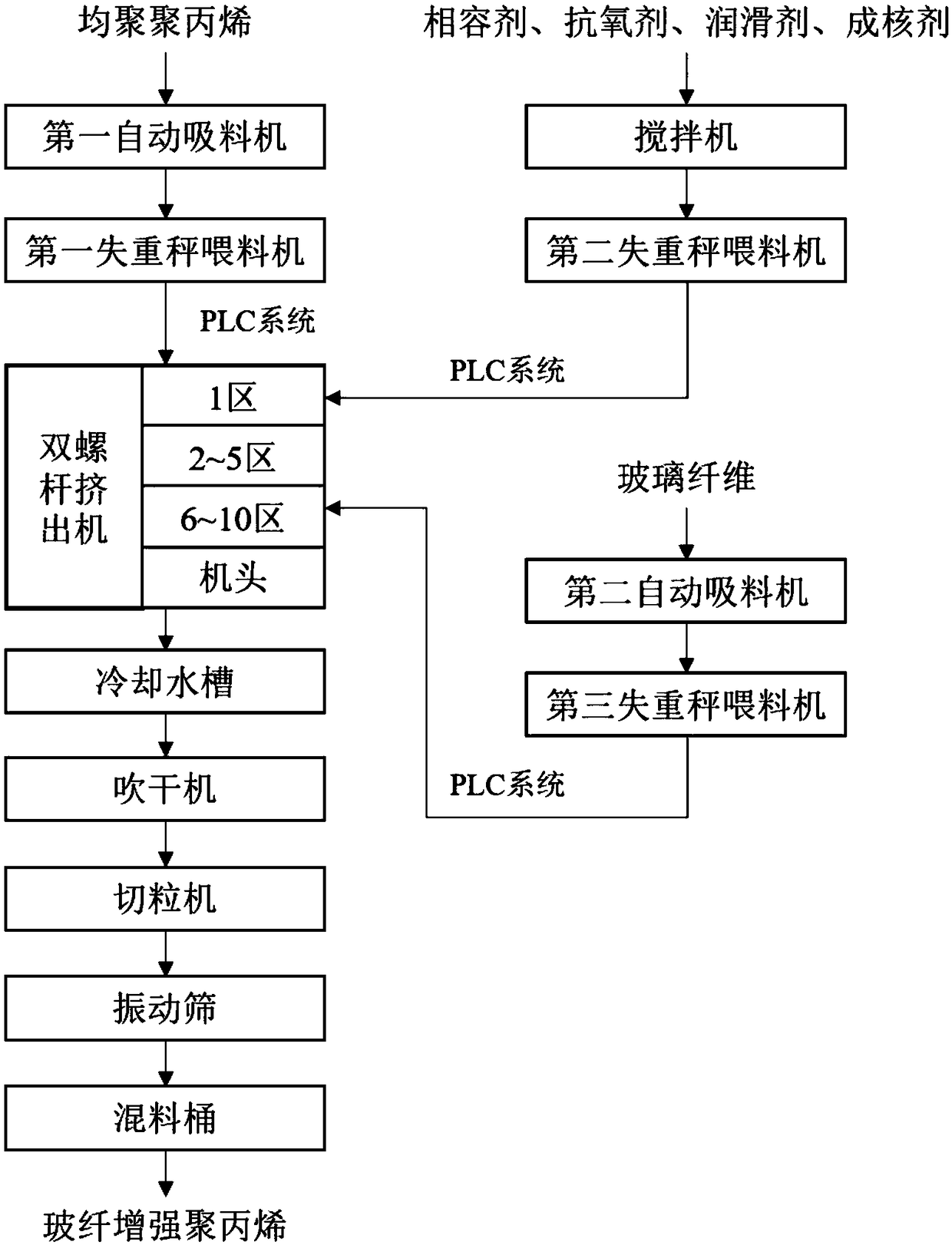

High-rigidity glass fiber reinforced polypropylene material and preparation equipment and preparation method thereof

The invention discloses a high-rigidity glass fiber reinforced polypropylene material and preparation equipment and a preparation method thereof. The high-rigidity glass fiber reinforced polypropylenematerial consists of the following raw materials: homo-polypropylene, a compatilizer, an antioxidant, a lubricating agent, a nucleating agent and glass fibers. Meanwhile, the invention discloses theequipment for preparing the polypropylene material and a method for preparing the high-rigidity glass fiber reinforced polypropylene material by using the equipment. In addition, the invention furtherdiscloses application of the high-rigidity glass fiber reinforced polypropylene material. The polypropylene material has high bending strength and modulus, is excellent in anti-impact property and good in thermal stability, resists hydrolysis, and can be widely applied to automotive panels, washing machine drums, handles of thermal jugs and the like.

Owner:GUANGDONG JUSHI CHEM CO LTD

Polymeric hindered phenolic antioxidant and preparation method thereof

The invention discloses a polymeric hindered phenolic antioxidant and a preparation method thereof. The polymeric hindered phenolic antioxidant comprises a compound having a structure of formula (1) (shown in the specification where m is 7-80, n is 3-80 and R1 and the R2 are respectively independently selected from H, CH3, and C(CH3)). According to the method, the polymeric antioxidant containinga plurality of hindered phenol structures is obtained by nucleophilic addition of amine groups and aldehyde groups. The antioxidant disclosed by the invention has the advantages of good stability, high antioxidant efficiency, large molecular weight, migration resistance, large proportion of antioxidant groups in molecules and low additive amount; the preparation method is simple in process and mild in condition and the large-scale industrialized production is easy; and therefore, the antioxidant has broad development prospects in the fields of oil products, rubber, plastic and the like.

Owner:JILIN INST OF CHEM TECH

Citrate plasticizer

InactiveCN112794825AIncrease the relative molecular massReduce volatilityOrganic chemistryPolymer scienceCITRATE ESTER

The invention discloses a citrate plasticizer and a preparation method thereof, and the preparation method of citrate comprises the following steps: firstly, citric acid and alcohol react to prepare citric acid triester, and then dianhydride acylation is carried out to prepare carboxyl-containing citric acid triester. After chlorination, the carboxyl-containing citric acid triester and the tris(2-ethoxyl) isocyanurate are subjected to esterification reaction to prepare triester citrate containing the isocyanurate. According to the present invention, the preparation method has characteristics of simple operation, wide raw material source and mild reaction condition, and meets the industrial production, the prepared triester citrate containing isocyanurate has a good plasticizing effect and excellent thermal stability, low-temperature flexibility, solvent extraction resistance, migration resistance and flame retardance, and can be widely applied to plastic rubber plasticizers.

Owner:马海社

Bio-based solvent-resistant plasticizer and preparation method thereof

ActiveCN114591537AHigh efficiency and low toxicityMeet the requirements of green chemistryPolymer scienceButyrate

The invention discloses a bio-based solvent-resistant plasticizer and a preparation method thereof. The bio-based solvent-resistant plasticizer is formed by combining modified isosorbide dioleate, tri (ethyl butyrate) isocyanurate and tetrabutylammonium chloride. The components of the bio-based solvent-resistant plasticizer prepared by the invention cooperate with one another, so that the bio-based solvent-resistant plasticizer not only has a good plasticizing effect, but also can improve the flexibility, tensile strength, extraction resistance and degradability of polyethylene resin and endow polyethylene with good flame retardant property, and meanwhile, the preparation raw materials are green and environment-friendly and have good biocompatibility.

Owner:昕亮科技(深圳)有限公司

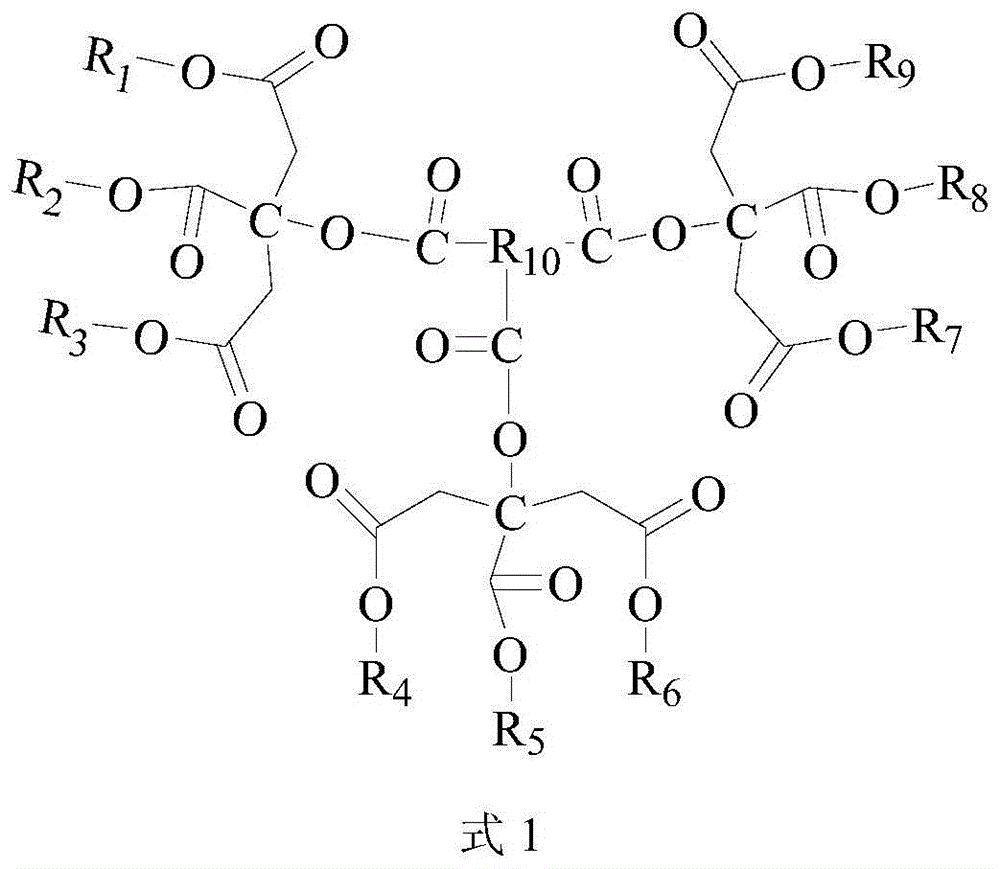

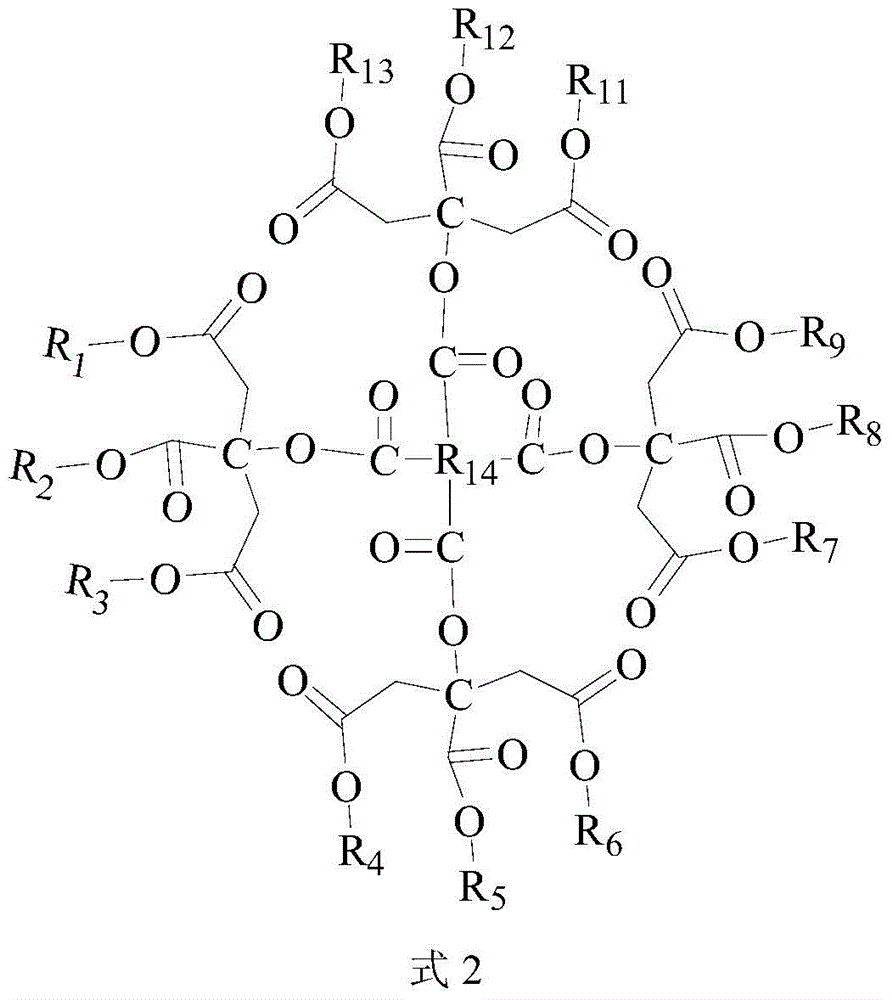

A kind of polycitrate triester and preparation method thereof

InactiveCN104163760BIncrease the relative molecular massMeet plasticizing requirementsPreparation from carboxylic acid halidesCITRATE ESTERAlcohol

The invention discloses a polycitrate triester and a preparation method thereof. The preparation method of the polycitrate triester is to prepare the citrate triester by reacting citric acid and alcohol, and then prepare polybasic acid chloride by acylation of polybasic carboxylic acid. Polyacyl chlorides and citrate triesters are prepared by esterification to obtain polycitrate triesters. The preparation method is simple to operate, has wide sources of raw materials, mild reaction conditions, and meets industrial production requirements. The obtained polycitrate triesters have good growth Plastic effect and excellent thermal stability, low temperature flexibility, solvent extraction resistance and migration resistance, can be widely used in plastic rubber plasticizers.

Owner:CENT SOUTH UNIV

Polyester copolymer with hindered amine group-containing main chain and preparation method thereof

The invention provides a polyester copolymer with hindered amine group-containing main chain, polycondensation is carried out for aromatic acids, aliphatic diols and 1-(2'-hydroxyethyl)-2,2,6,6-tetramethyl-4-pipradrol, wherein, the mol ratio between 1-(2'-hydroxyethyl)-2,2,6,6-tetramethyl-4-pipradrol and aliphatic diols is (0.1:99.9)-(20:80). The aromatic acids contain terephthalic acid and 2,6-naphthalenedicarboxylic acid, and the aliphatic diols contain glycol, propylene glycol, butylene glycol or cyclohexanediol. Compared with the prior art, the invention has the advantages that the polyester copolymer of the present invention has excellent ultraviolet light stability of the hindered amine compound, simultaneously has excellent mechanical properties, and overcomes the disadvantage that in the prior art after the polyester is added with the hindered amine light stabilizing agent, the mechanical properties decrease.

Owner:JIANGSU YUXING FILM TECH

Durable PVC (polyvinyl chloride) bionic bait

The invention relates to the technical field of research, development and processing of fishing gear and discloses durable PVC (polyvinyl chloride) bionic bait. The bait is prepared from the components as follows: PVC, DHP (dihexyl phthalate), dibutyl sebacate, epoxidized soybean oil, tricresyl phosphate, citrate, diol fatty acid ester, dipentaerythritol, diol benzoate, zinc stearate, calcium stearate, ash calcium powder, talcum powder, an aluminate coupling agent, titanium dioxide and an antibacterial agent, the PVC is used as the main material, the rest components are added to enhance the performance of PVC, the PVC has excellent low-temperature resistance, the brittle temperature of a product can be decreased to subzero 70 DEG C-subzero 30 DEG C, the low-temperature softness is better, the heat resistance and weather resistance are higher, the service life of the bionic bait can be prolonged, the recycling rate is high, and the used inorganic antibacterial agent can be dispersed uniformly in the biotic bait and can play the antibacterial role for a long term.

Owner:界首市汇珠渔具有限公司

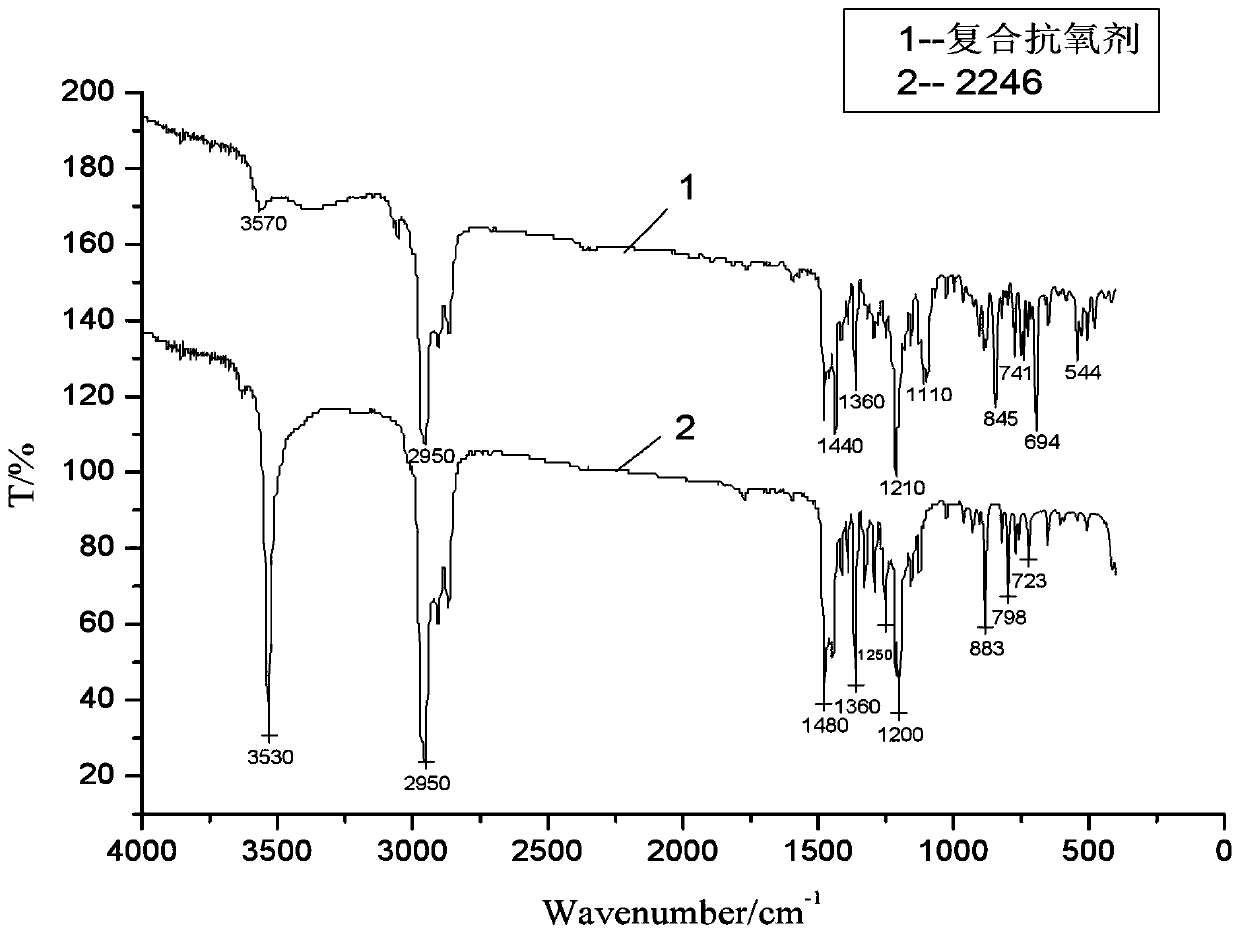

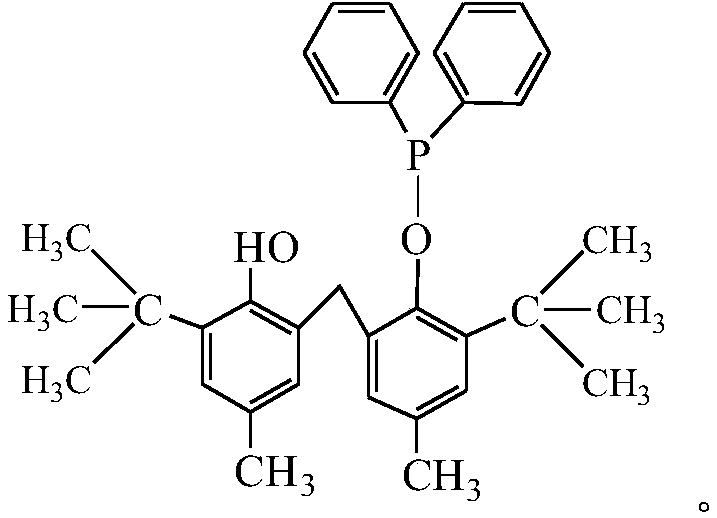

Intramolecular compound antioxidant and preparation method thereof

InactiveCN110078760AHigh molecular weightNot volatileGroup 5/15 element organic compoundsPolyolefinDual effect

The invention discloses an intramolecular compound antioxidant and a preparation method thereof. The obtained intramolecular compound antioxidant has good hydrolysis resistance, high oxidation resistance efficiency and dual effects of hindered phenol and phosphite antioxidants, can replace an existing compound system of hindered phenol and phosphite antioxidants and can meet the function requirement for antioxidants during synthesis and processing of ABS resin and polyolefin.

Owner:JILIN INST OF CHEM TECH

Preparation method for foamed wallpaper

InactiveCN108547171AImprove migration resistanceGood resistance to extractionCoatings with pigmentsSpecial paperAdhesivePolyvinyl chloride

The invention discloses foamed wallpaper, and belongs to the field of decorative materials. According to the wallpaper disclosed by the invention, sodium polyacrylate, tourmaline powder and inorganicnano anti-mold powder are used as raw materials, and an adhesive, a hardening agent, tackifying resin polyacrylate, polyamide and hydrogenated rosin are added to prepare a compound emulsion, so that mildew of a wallpaper adhesive is inhibited, and a long-lasting antibacterial effect is achieved; the hardening agent is added, so that ability of a base film to solidify and pulverize a wall surface is improved, and the wallpaper does not fall off in a large area; the tourmaline powder has a degradation effect on harmful gases and protects the environment and human bodies, moisture and alkaline substances of a construction wall surface are effectively prevented from being infiltrated to the outside, and an occurrence of phenomena that the wallpaper gets damp, gets mildew, gets black and is discolored is prevented. The method disclosed by the invention solves the problems that in current wallpaper, a stronger-pollution flame retardant is added into a printing layer and a foaming agent containing polyvinyl chloride is added into a foaming layer, so that produced pure paper wallpaper has a higher content of harmful substances, and surfaces of foaming holes are rough and easy to fall off.The invention provides a preparation method for the foamed wallpaper.

Owner:张芸

Polymer type anti-oxidant, preparation method thereof, and application thereof

ActiveCN102516488BImprove antioxidant capacityExcellent thermal and oxidative aging resistanceRubber materialPolymer science

The invention relates to the field of a polymer type anti-oxidant, and provides a polymer type anti-oxidant, a preparation method thereof, and an application thereof. According to the invention, under the effect of a catalyst dibutyltin dilaurate, hydroxyl-terminated polybutadiene and isophorone diisocyanate are subject to a reaction under a temperature of 30 to 50 DEG C, such that an adduct is synthesized; the adduct is subject to a reaction with a low-molecular bisphenol anti-oxidant under a temperature of 60 to 80 DEG C, such that the polymer type anti-oxidant is prepared. The thermal oxidative aging resistance of the polymer type anti-oxidant is better than that of the corresponding low-molecular bisphenol anti-oxidant. Also, the polymer type anti-oxidant has an excellent extraction resistance. The anti-oxidant can be widely applied in rubber materials.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com