Preparation method for reactive polyamidoamine dendrime rubber antioxidant

A technology of rubber anti-aging agent and polyamidoamine, which is applied in the field of preparation of reactive rubber anti-aging agent, can solve the problems of poor effect and toxicity, and achieve the effects of simple preparation method, improved rubber aging performance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] According to the 1.0 generation of dendritic polyamidoamine and allyl glycidyl ether, the primary amino group / epoxy group is reacted in a molar ratio of 1:0.5. First, the 1.0 generation of dendritic polyamidoamine is dissolved in methanol, and then stirred dropwise Add allyl glycidyl ether and react at 50°C for 12 hours to obtain reactive polyamidoamine rubber antioxidant R-1.

[0020] The prepared anti-aging agent R-1 was added to NBR to prepare a rubber compound; at the same time, traditional rubber anti-aging agents 4010NA, 4020, MB, and ODA were used as comparisons. The rubber formula is: NBR: 100phr, N220 carbon black: 40phr, zinc oxide: 5phr, stearic acid: 2phr, CZ: 1.5phr, DM: 0.5phr, sulfur: 2phr, antioxidant: 2phr. After the prepared mixed rubber is parked for a period of time, determine the best positive vulcanization time for vulcanization. The mechanical properties are tested according to GB / T-528-2006; the samples are aged in an air aging box at 100°C accor...

Embodiment 2

[0022] According to the 2.0 generation of dendritic polyamidoamine and maleic anhydride in the primary amino group / acid anhydride molar ratio of 1:0.2 to react, the 2.0 generation of dendritic polyamidoamine dissolved in dimethyl sulfoxide to a homogeneous state , dropwise added dimethyl sulfoxide solution of maleic anhydride, reacted at 30°C for 0.5h, and distilled off dimethyl sulfoxide under reduced pressure to obtain reactive polyamidoamine rubber antioxidant R-2.

[0023] The prepared anti-aging agent R-2 was added to NBR, and traditional rubber anti-aging agents 4010NA, 4020, MB, and ODA were used as comparisons to prepare compound rubber. The rubber formulation, vulcanized rubber preparation, aging conditions and tests are all the same as in Example 1. The test results are given in Tables 1, 2, and 3.

Embodiment 3

[0025] React according to the molar ratio of hyperbranched polyamidoamine / 2-methyl-3-butenoic acid of 1:0.4, fully dissolve the hyperbranched polyamidoamine in N,N-dimethylformamide until it becomes After the homogeneous state, slowly drop the N,N-dimethylformamide solution of 2-methyl-3-butenoic acid under stirring conditions, and react at 60°C for 18 hours to obtain a reactive polyamidoamine rubber antioxidant R-3.

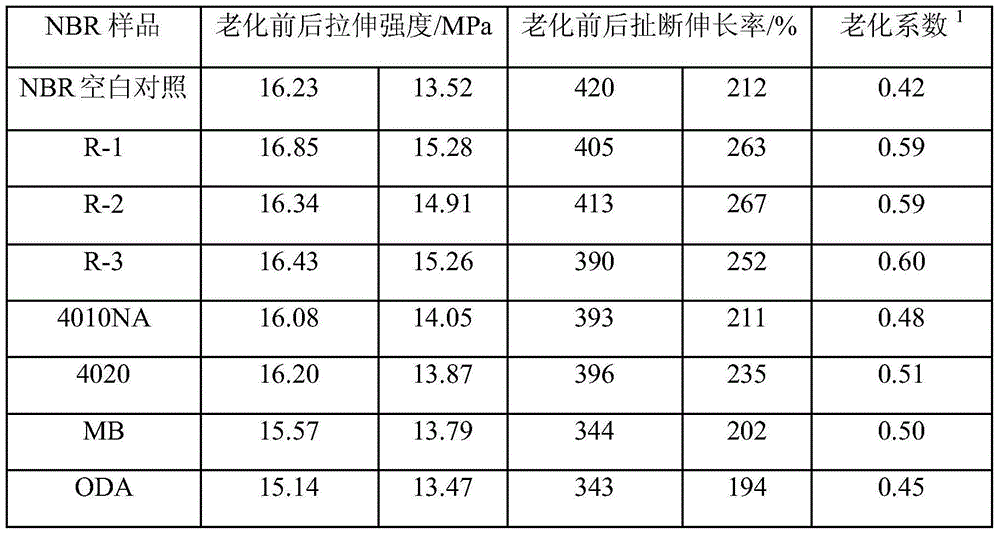

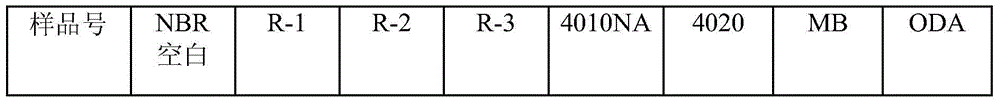

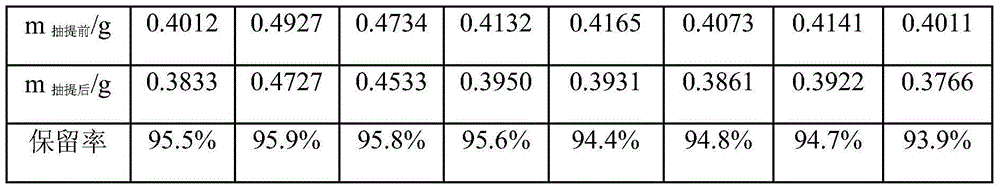

[0026] Add the prepared antiaging agent R-3 into NBR to prepare a rubber compound. The rubber formulation, vulcanized rubber preparation, aging conditions and tests are all the same as in Example 1. The test results are given in Tables 1, 2, and 3 (the aging coefficient in Table 1 1 Aging coefficient=(tensile strength after aging*elongation at break after aging) / (tensile strength before aging*elongation at break before aging)).

[0027] Table 1 Mechanical properties of NBR vulcanizates containing different antioxidants before and after aging

[0028]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com