Acrylic polyurethane silicofluoride coating as well as preparation method and application method thereof

A technology of acrylic polyurethane and fluorine siliconization, which is applied in polyurea/polyurethane coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., to achieve good anti-tarnish performance, good long-term protection performance, and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

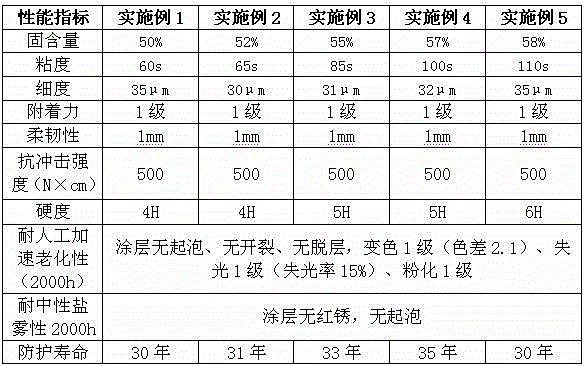

Examples

Embodiment 1

[0074] A kind of fluorine siliconized acrylic polyurethane coating of the present embodiment comprises the raw material of following percentage by weight:

[0075] Hydroxy Acrylic Resin 52%

[0076] Solvent 20%

[0077] Fluorine micropowder 0.2%

[0078] Pigment 5%

[0079] High hardness oxide 3%

[0080] Auxiliary 2.8%

[0081] Blocked isocyanate curing agent 17%

[0082] Wherein, the hydroxyacrylic resin is a hydroxyacrylate copolymer with a solid content of 59% and a specific gravity of 0.95g / cm 3 , the viscosity is 5500cp (25°C), the acid value is 5mgKOH / g (100%), and the hydroxyl value is 53mgKOH / g.

[0083] Wherein, the solvent is any one of dehydrated xylene, butyl ester, ethylene glycol ether acetate, dimethyl nylonate, dimethyl glutarate, dimethyl adipate and diacetone alcohol or a mixture of more than one species;

[0084] Wherein, the fluorine-containing micropowder is polytetrafluoroethylene micropowder;

[0085] Wherein, the pigment is a mixture of any tw...

Embodiment 2

[0107] A kind of fluorine siliconized acrylic polyurethane coating of the present embodiment comprises the raw material of following percentage by weight:

[0108] Hydroxy Acrylic Resin 55%

[0109] Solvent 18%

[0110] Fluorine micropowder 0.8%

[0111] Pigment 4%

[0112] High hardness oxide 2.5%

[0113] Auxiliary 3.7%

[0114] Blocked isocyanate curing agent 16%

[0115] Wherein, the hydroxyacrylic resin is a hydroxyacrylate copolymer with a solid content of 60% and a specific gravity of 1 g / cm 3 , the viscosity is 5800cp (25°C), the acid value is 7mgKOH / g (100%), and the hydroxyl value is 54mgKOH / g.

[0116] Wherein, described solvent comprises the raw material of following weight percent:

[0117] Xylene 35%

[0118] Butyl ester 13%

[0119] Ethylene glycol ether acetate 15%

[0120] Dimethyl Nylate 6%

[0121] Dimethyl glutarate 12%

[0122] Dimethyl Adipate 8%

[0123] Diacetone Alcohol 11%;

[0124] Wherein, the fluorine-containing micropowder is polyvinyl...

Embodiment 3

[0147] A kind of fluorine siliconized acrylic polyurethane coating of the present embodiment comprises the raw material of following percentage by weight:

[0148] Hydroxy Acrylic Resin 60%

[0149] Solvent 15%

[0150] Fluorine micropowder 1.2%

[0151] Pigment 3%

[0152] High hardness oxide 1.8%

[0153] Auxiliary 4%

[0154] Blocked isocyanate curing agent 15%

[0155] Wherein, the hydroxyacrylic resin is a hydroxyacrylate copolymer with a solid content of 60% and a specific gravity of 1.01g / cm 3 , the viscosity is 6000cp (25°C), the acid value is 9mgKOH / g (100%), and the hydroxyl value is 55mgKOH / g.

[0156] Wherein, described solvent comprises the raw material of following weight percent:

[0157] Xylene 40%

[0158] Butyl ester 12%

[0159] Ethylene glycol ether acetate 10%

[0160] Dimethyl Nylate 15%

[0161] Dimethyl glutarate 6%

[0162] Dimethyl Adipate 5%

[0163] Diacetone Alcohol 12%;

[0164] Wherein, the fluorine-containing micropowder is polyper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com