Polymer type anti-oxidant, preparation method thereof, and application thereof

An antioxidant and polymer technology, applied in the field of polymer antioxidants and their preparation, can solve the problems of low relative content of low molecular compounds, difficulty in large-scale industrial production, and unsatisfactory antioxidant performance, and achieve excellent The effect of resistance to extraction, easy process control, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 10.00 g of hydroxyl-terminated polybutadiene (Krayville (Guangzhou) Chemical Co., Ltd., brand LBH2000, number average molecular weight 1.8- 2.5×10 3 ) and 5.00g of toluene, after stirring evenly, raise the temperature to 40°C, add 0.01g of dibutyltin dilaurate, add 2.02g of isophorone diisocyanate dropwise to the above reactant within 30min, keep the temperature for 270min , to prepare adducts. Subsequently, the temperature of the adduct was raised to 75°C, 0.31g of dibutyltin dilaurate was added, and 3.26g of 2,2'-thiobis(4-methyl-6-tert-butylphenol) and 10.00 A solution of g toluene was added dropwise to the above-mentioned adduct, and the reaction was kept for 360 minutes. After the reaction, excess methanol was added to the reaction system to precipitate the product, and the supernatant was removed to obtain a light yellow emulsion. Dissolved in toluene, precipitated in methanol, and filtered cyclically for 5 times, and dried in vacuum to obtain a polymer-typ...

Embodiment 2

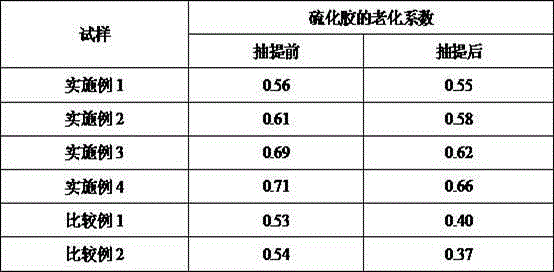

[0041] According to the method and process conditions in Example 1, the reaction temperature of hydroxyl-terminated polybutadiene and isophorone diisocyanate is increased to 45°C, and the adduct and 2,2'-thiobis(4-methyl- 6-tert-butylphenol) The reaction temperature was reduced to 60°C, and the amount of 2,2'-thiobis(4-methyl-6-tert-butylphenol) was increased to 6.53g. The experimental results are shown in Table 1. It can be seen that the prepared polymer antioxidant has excellent resistance to thermo-oxidative aging and extraction resistance.

Embodiment 3

[0043] According to the method and process conditions in Example 1, 2,2'-thiobis(4-methyl-6-tert-butylphenol) becomes 2,2'-methylenebis(4-methyl-6- tert-butylphenol), its consumption is 3.10g; in the reaction of adduct and 2,2'-methylene bis(4-methyl-6-tert-butylphenol), the consumption of dibutyltin dilaurate is reduced to 0.23 g, the reaction temperature is increased to 80°C, and the amount of the prepared polymer-type antioxidant polybutadiene with hydroxyl-terminated polybutadiene connected to 2,2'-methylene bis(4-methyl-6-tert-butylphenol) in natural rubber Makes 6 servings. The experimental results are shown in Table 1.

[0044] It can be seen that the aging coefficient of natural rubber vulcanizate added with 1 part of 2,2′-methylene bis(4-methyl-6-tert-butylphenol) is 0.54, and it drops to 0.37 after 24 hours of boiling water extraction at 100°C (See Comparative Example 2), while the aging of natural rubber vulcanizate with polymer-type antioxidant polybutadiene term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com