Polyester copolymer with hindered amine group-containing main chain and preparation method thereof

A technology of hindered amines and copolymers, applied in the field of polyester copolymers, which can solve the problems of decreased mechanical properties of polyester, poor compatibility of polyester, unsatisfactory compatibility, etc., and achieve low volatility and good processing stability non-toxicity, excellent migration resistance and extraction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail now in conjunction with embodiment.

[0030] The technical solution adopted by the present invention to solve its technical problems is:

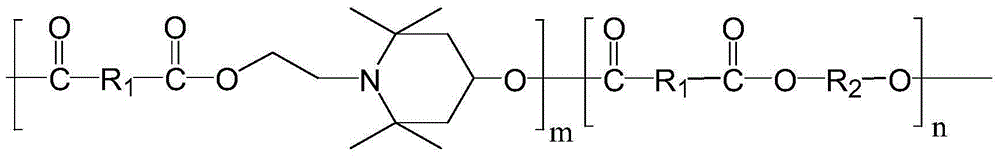

[0031] A kind of main chain contains the polyester copolymer of hindered amine group, and its molecular structural formula is as follows:

[0032]

[0033] Among them, R 1 is a benzene ring or a naphthalene ring, R 2 is ethyl, propyl, butyl or cyclohexyl;

[0034] Among them, m:n=0.1-80:99.9-20.

[0035] Specifically, the intrinsic viscosity of the polyester copolymer ranges from 0.2 to 1.2 dL / g.

[0036] A kind of preparation method of the polyester copolymer that main chain contains hindered amine group, comprises the steps:

[0037] 1) Esterification reaction: 1-(2'-hydroxyethyl)-2,2,6,6-tetramethyl-4 - Add piperidinol and catalyst into the reaction kettle, heat to 245-265°C for 2-12 hours; terephthalic acid or terephthalic acid, aliphatic diol and hindered amine )-2,2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com