High strength and high modulus para-aramid fiber and preparation method thereof

A para-aramid fiber, high-strength and high-modulus technology, applied in fiber treatment, single-component copolyamide artificial filament, artificial filament cleaning/drying, etc., can solve the problem of high manufacturing cost, achieve physical performance improvement, Wide range of applications and the effect of reducing corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 : A high-strength and high-modulus para-aramid fiber (CyPPTA), which is prepared from a polymer with an intrinsic viscosity of 7.0dL / g, and its intrinsic viscosity is less than 0.5dL / g lower than that of the polymer. The specific indicators of the fiber include: tensile strength 24g / d, initial modulus 700g / d, elongation at break 3.5%, monofilament fineness 1.5D, bundle yarn fineness 1000D.

[0022] 1. Polymerized spinning slurry:

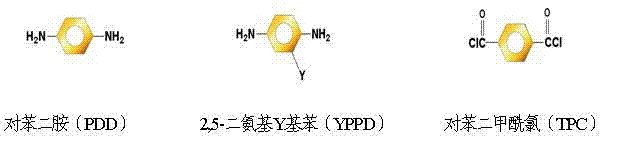

[0023] Pass nitrogen into the dried reaction kettle to create a nitrogen environment. According to the molar ratio of TPC:PPD:CyPPD=10:3:7, first put 4.676kg of high-purity (above 99.9%) p-phenylenediamine (PPD) and 2,5-diaminobenzonitrile (CyPPD) 13.435kg of two diamine monomers are added to 200 liters (L) of N-methylpyrrolidone (NMP) and 20.238kg of calcium chloride CaCl2 solvent system, where CaCl 2 The content is 8wt%, then stir to completely dissolve PPD and CyPPD, use the freezing jacket of the reaction kettle to cool ...

Embodiment 2

[0030] Example 2 : A high-strength and high-modulus para-aramid fiber (CyPPTA), which is prepared from a polymer with an intrinsic viscosity of 9.0dL / g, and its intrinsic viscosity is less than 0.5dL / g lower than that of the polymer. The specific indicators of the fiber include: tensile strength 27g / d, initial modulus 850g / d, elongation at break 2.7%, monofilament fineness 1.5D, bundle yarn fineness 1500D.

[0031] 1. Polymerized spinning slurry:

[0032] Put nitrogen gas into the dried reaction kettle to create a nitrogen environment. According to the molar ratio of TPC:PPD:CyPPD=10:1:9, first put 0.967kg of high-purity (99.9% or more) p-phenylenediamine (PPD) and 2,5-diaminobenzonitrile (CyPPD) 10.713kg of two diamine monomers were added to 200 liters (L) of N-methylpyrrolidone (NMP) and 6.064kg of calcium chloride LiCl solvent system, where LiCl The content is 2.58wt%, then stir to completely dissolve PPD and CyPPD, use the freezing jacket of the reaction kettle to...

Embodiment 3

[0039] Example 3 : A high-strength and high-modulus para-aramid fiber (CyPPTA), which is prepared from a polymer with an intrinsic viscosity of 7.0dL / g, and its intrinsic viscosity is less than 0.5dL / g lower than that of the polymer. The specific indicators of the fiber include: tensile strength 24g / d, initial modulus 750g / d, elongation at break 3.3%, monofilament fineness 1.5D, bundle yarn fineness 1500D.

[0040] 1. Polymerized spinning slurry:

[0041] Put nitrogen gas into the dried reaction kettle to create a nitrogen environment. According to the molar ratio of TPC:PPD:CyPPD=10:3:7, first put 5.362kg of high-purity (above 99.9%) p-phenylenediamine (PPD) and 2,5-diaminobenzonitrile (CyPPD) 15.405kg of the two diamine monomers were added to 200 liters (L) of dimethylacetamide (DMAc) and 18.343kg of calcium chloride CaCl 2 In the solvent system, where CaCl 2 The content is 7.6wt%, then stir to completely dissolve PPD and CyPPD, use the freezing jacket of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Initial modulus | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com