Preparation method of ultraviolet ray resistant antibacterial fabric

An antibacterial fabric and UV-resistant technology, which can be used in plant fibers, animal fibers, textiles and papermaking, etc., can solve problems such as loss and bond breaking reactions of compounds, and achieve high catalytic efficiency, good wearing performance, and high washing stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

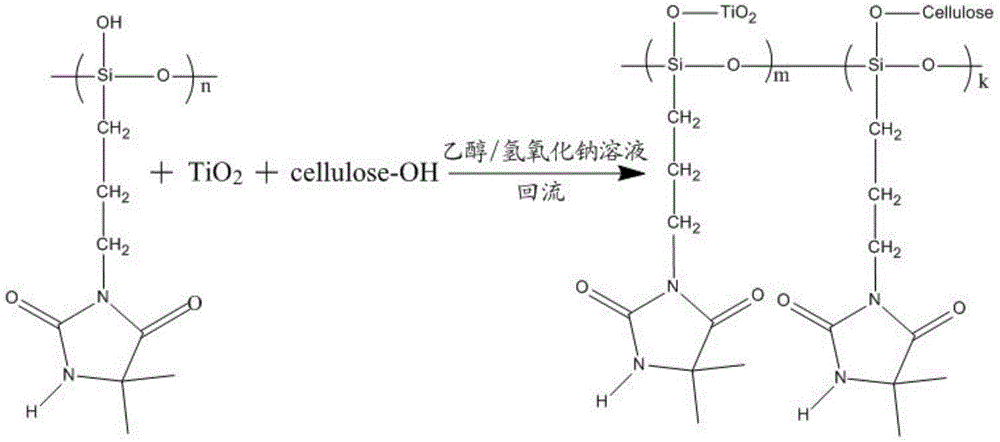

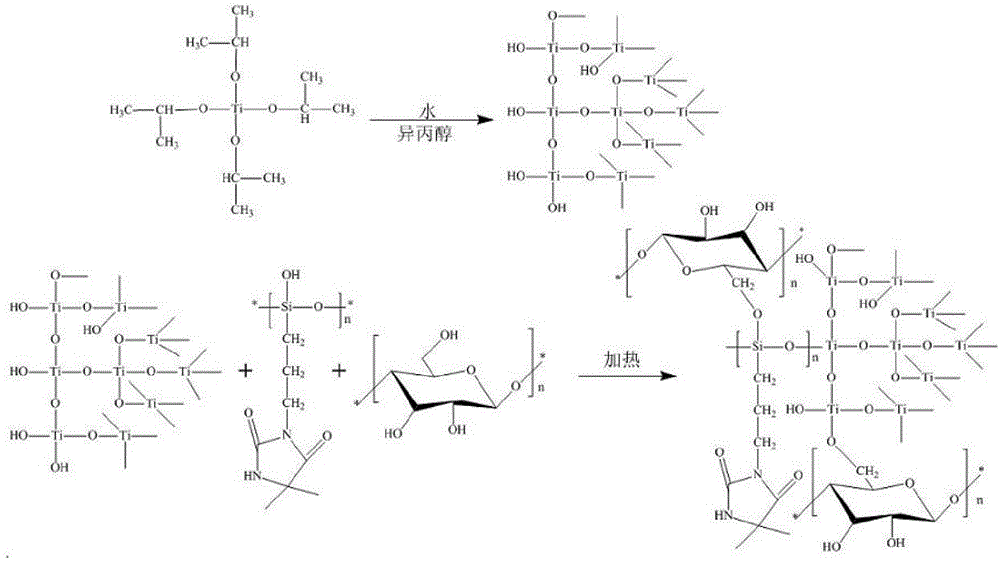

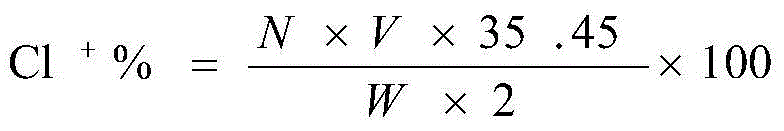

[0037] (1) Method (1) Preparation of siloxane haloamine compound / nano-titanium dioxide finishing solution:

[0038] Add 5,5-dimethyl-3-(3'-triethoxysilylpropyl)-hydantoin to the mixed solution of ethanol and water with a mass ratio of 1:0.8 to make it dissolve in the mixed solution of ethanol and water The final concentration in the solution is 6wt%; or add 5,5-dimethyl-3-(3'-triethoxysilylpropyl)-hydantoin polymer to make its final concentration in the mixed solution of ethanol and water The concentration is 4wt%; stir to form a transparent liquid; then add nano-titanium dioxide so that the final concentration in the mixed solution of ethanol and water is 3wt%, and ultrasonically vibrate for 10 minutes to obtain the product;

[0039] The preparation method of the 5,5-dimethyl-3-(3'-triethoxysilylpropyl)-hydantoin is:

[0040] Mix equimolar amounts of 5,5-dimethylhydantoin and sodium hydroxide in absolute ethanol, react at 90°C for 8 minutes, remove the solvent ethanol and dry ...

Embodiment 2

[0046] (1) Method (1) Preparation of siloxane haloamine compound / nano-titanium dioxide finishing solution:

[0047] Add 5,5-dimethyl-3-(3'-triethoxysilylpropyl)-hydantoin to a mixed solution of ethanol and water with a mass ratio of 1:1 to make it dissolve in the mixed solution of ethanol and water The final concentration in the solution is 10wt%; or add 5,5-dimethyl-3-(3'-triethoxysilylpropyl)-hydantoin polymer to make its final concentration in the mixed solution of ethanol and water The concentration is 6wt%; stir to form a transparent liquid; then add nano-titanium dioxide to make the final concentration in the mixed solution of ethanol and water to be 5wt%, and ultrasonically vibrate for 20 minutes to obtain; the 5,5-dimethyl-3 The preparation method of -(3'-triethoxysilylpropyl)-hydantoin and its polymer is the same as in Example 1.

[0048] (2) Siloxane haloamine compound / nano-titanium dioxide finishing process:

[0049] Take a portion of the cotton fiber fabric and s...

Embodiment 3

[0051] (1) Method (1) Preparation of siloxane haloamine compound / nano-titanium dioxide finishing solution:

[0052] Add 5,5-dimethyl-3-(3'-triethoxysilylpropyl)-hydantoin to the mixed solution of ethanol and water with a mass ratio of 1:1.2, so that it is in the mixed solution of ethanol and water The final concentration in the solution is 15wt%; or add 5,5-dimethyl-3-(3'-triethoxysilylpropyl)-hydantoin polymer to make its final concentration in the mixed solution of ethanol and water The concentration is 8wt%; stir to form a transparent liquid; then add nano-titanium dioxide to make the final concentration in the mixed solution of ethanol and water to be 7wt%, and ultrasonically vibrate for 30 minutes to obtain; the 5,5-dimethyl-3 The preparation method of -(3'-triethoxysilylpropyl)-hydantoin and its polymer is the same as in Example 1.

[0053] (2) Siloxane haloamine compound / nano-titanium dioxide finishing process:

[0054] Take a portion of the hemp fiber fabric and soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com