Nano-silica immobilized hindered phenol antioxidant as well as preparation method and application of antioxidant

A technology of nano-silica and hindered phenols, which is applied in the field of antioxidants and can solve the problems of dark product color and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

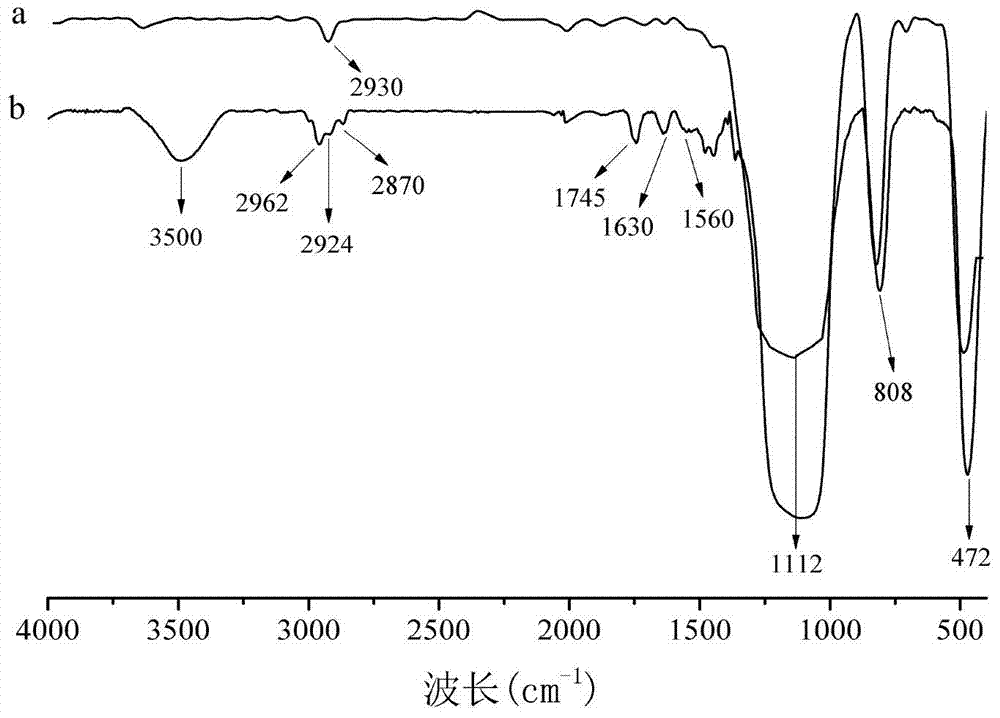

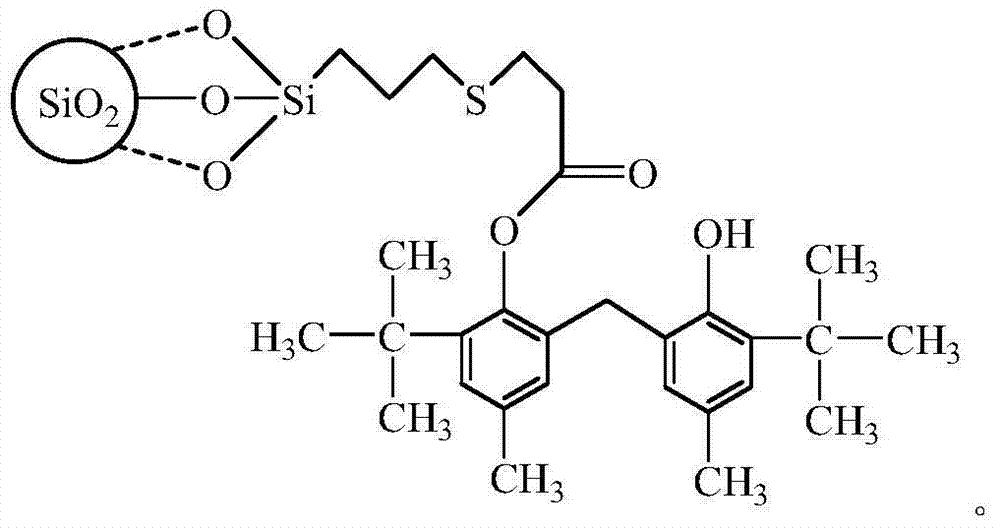

Method used

Image

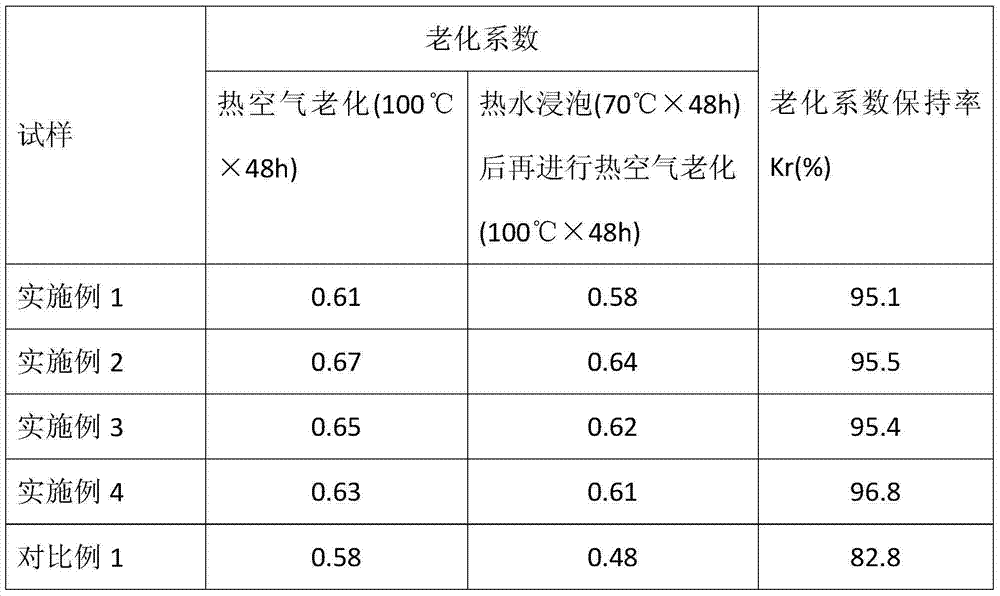

Examples

Embodiment 1

[0031] Add 20g of nano-silica with a particle size of 100nm to 100g of ethanol aqueous solution (75g of ethanol and 25g of water), and disperse by ultrasonic wave for 30min (ultrasonic frequency is 20kHz, power is 300W); then adjust the pH value to 4 with hydrochloric acid, and add 1g Silane coupling agent KH590, and stirred at a speed of 120rpm / min for 20min; heated to 70°C, stirred at a speed of 80rpm / min for 90min, then cooled to room temperature, filtered under reduced pressure, washed with ethanol and dried at 50°C After 12 hours, KH590 modified nano-silica was obtained. KH590 modified nano silica and 2g antioxidant GM (2‐tertbutyl‐6‐(3‐tertbutyl‐2‐hydroxy‐5‐cresylmethyl)‐4‐methylphenol acrylate, Guangzhou Synthetic Materials Research Institute Co., Ltd.) into 100g toluene, ultrasonically dispersed for 20min (ultrasonic frequency is 25kHz, power is 200W), heated to 80°C; 0.4g triethylamine was added, and reacted for 2h under stirring at 120rpm / min; After cooling to room ...

Embodiment 2

[0036] Add 40g of nano silicon dioxide with a particle size of 150nm to 160g of ethanol aqueous solution (120g of ethanol and 40g of water), ultrasonically disperse for 10min (ultrasonic frequency is 40kHz, power is 400W); then adjust the pH value to 5 with hydrochloric acid, add 5g Silane coupling agent KH590, and stirred at a speed of 160rpm / min for 15min; heated to 80°C, stirred at a speed of 120rpm / min for 60min, then cooled to room temperature, filtered under reduced pressure, washed with ethanol and dried at 80°C After 6 hours, KH590 modified nano-silica was obtained. Add KH590 modified nano-silica and 10g antioxidant GM to 150g toluene, ultrasonically disperse for 10min (ultrasonic frequency is 20kHz, power is 400W), heat up to 90°C; add 2.0g hexamethylenediamine, at 80rpm / min React for 1 h under the action of stirring; cool to room temperature, filter under reduced pressure, wash with toluene and ethanol respectively, and dry at 80°C for 6 h to obtain the nano-silica-i...

Embodiment 3

[0039] Add 30g of nano-silica with a particle size of 10nm to 80g of ethanol aqueous solution (60g of ethanol and 20g of water), and disperse by ultrasonic wave for 60min (ultrasonic frequency is 20kHz, power is 40W); then adjust the pH value to 4 with hydrochloric acid, and add 4g Silane coupling agent KH590, and stirred at a speed of 80rpm / min for 20min; heated to 50°C, stirred at a speed of 110rpm / min for 80min, then cooled to room temperature, filtered under reduced pressure, washed with ethanol and dried at 70°C After 8 hours, KH590 modified nano-silica was obtained. Add KH590 modified nano-silica and 9g antioxidant GM to 120g toluene, ultrasonically disperse for 15min (ultrasonic frequency is 30kHz, power is 300W), heat up to 60°C; add 1.0g diethylenetriamine, at 100rpm / React for 3 hours under stirring for 1 min; cool to room temperature, filter under reduced pressure, wash with toluene and ethanol respectively, and dry at 70°C for 8 hours to obtain the nano-silica-immo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com