Preparation method of polyester plasticizer

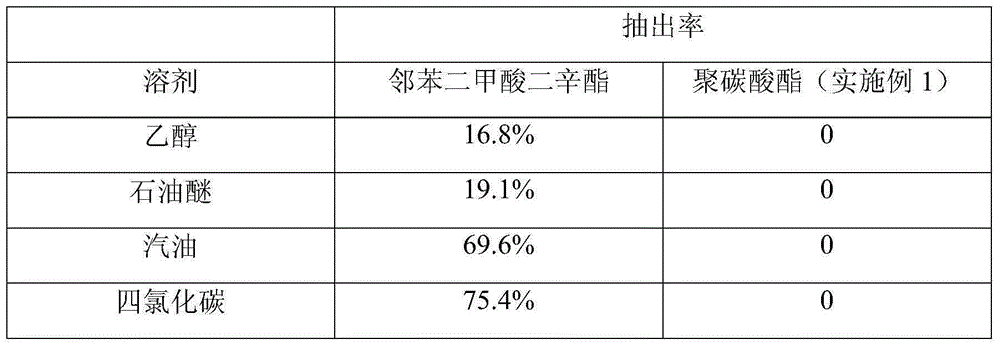

A technology of polyester plasticizer and polycarbonate, applied in the field of plastic additives, can solve problems such as interference with human endocrine, damage to reproduction and development, and small molecular weight, and achieve the effects of high molecular weight, good extraction resistance, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) dry monomer

[0037] The epoxy compound was mixed with CaH at room temperature 2 Mix and stir, evaporate under reduced pressure, degas three times to remove oxygen, and then store under anhydrous and oxygen-free conditions. The purity of the carbon dioxide used is 99.99%. Before the reaction, the gas is passed through a purification column for removing water and oxygen, and then passes into the reaction system.

[0038] (2) Synthesis of polycarbonate

[0039] Add 40mg of catalyst (zinc cobalt cyanide complex, ligand is tert-butanol, ultrasonic power 50W, time 60s) into the cleaned autoclave, then vacuum dry at 80°C for 12h, then cool to room temperature. Add treated 80mL propylene oxide under negative pressure conditions, pass in a certain pressure of carbon dioxide under stirring conditions, then heat to 60°C, adjust the pressure of the amount of carbon dioxide added to 4.0MPa, react for 12 hours, cool down, and release the unreacted in the kettle carbon dioxide...

Embodiment 2

[0041] (1) dry monomer

[0042] The epoxy compound was mixed with CaH at room temperature 2 Mix and stir, evaporate under reduced pressure, degas three times to remove oxygen, and then store under anhydrous and oxygen-free conditions. The purity of the carbon dioxide used is 99.99%. Before the reaction, the gas is passed through a purification column for removing water and oxygen, and then passes into the reaction system.

[0043] (2) Synthesis of polycarbonate

[0044] Add 10 mg of catalyst (same as Example 1) into the cleaned autoclave, then vacuum dry at 80° C. for 12 h, and then cool to room temperature. Add treated 30mL propylene oxide under negative pressure conditions, pass in a certain pressure of carbon dioxide under stirring conditions, then heat to 70°C, adjust the pressure of carbon dioxide addition to 5.0MPa, react for 6 hours, cool down, and release the unreacted in the kettle carbon dioxide, the crude product was dissolved, precipitated, filtered, and dried t...

Embodiment 3

[0046] (1) dry monomer

[0047] The epoxy compound was mixed with CaH at room temperature 2Mix and stir, evaporate under reduced pressure, degas three times to remove oxygen, and then store under anhydrous and oxygen-free conditions. The purity of the carbon dioxide used is 99.99%. Before the reaction, the gas is passed through a purification column for removing water and oxygen, and then passes into the reaction system.

[0048] (2) Synthesis of polycarbonate

[0049] Add 12.5 g of catalyst (same as Example 1) into the cleaned autoclave, then vacuum dry at 80° C. for 12 h, and then cool to room temperature. Add treated 30mL propylene oxide under negative pressure conditions, pass in a certain pressure of carbon dioxide under stirring conditions, then heat to 30°C, adjust the pressure of carbon dioxide addition to 8.0MPa, react for 10 hours, cool down, and release the unreacted in the kettle carbon dioxide, the crude product was dissolved, precipitated, filtered, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com