Maleic acid tributyl citrate diester compound and preparation method thereof

A technology of butenedioic acid citric acid and tributyl citrate, which is applied in the field of plastic plasticizers, can solve problems such as thermal stability and poor volatility, and achieve improved anti-aging performance, high yield, and good anti-bleeding sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

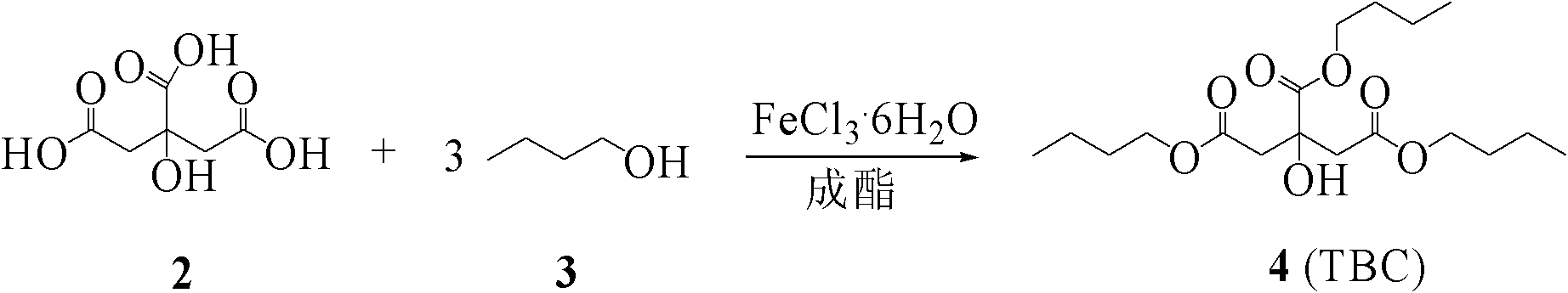

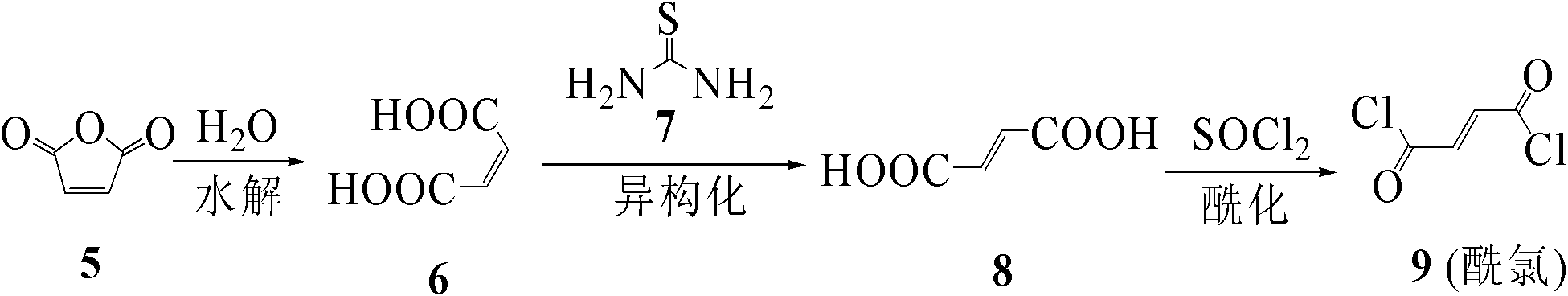

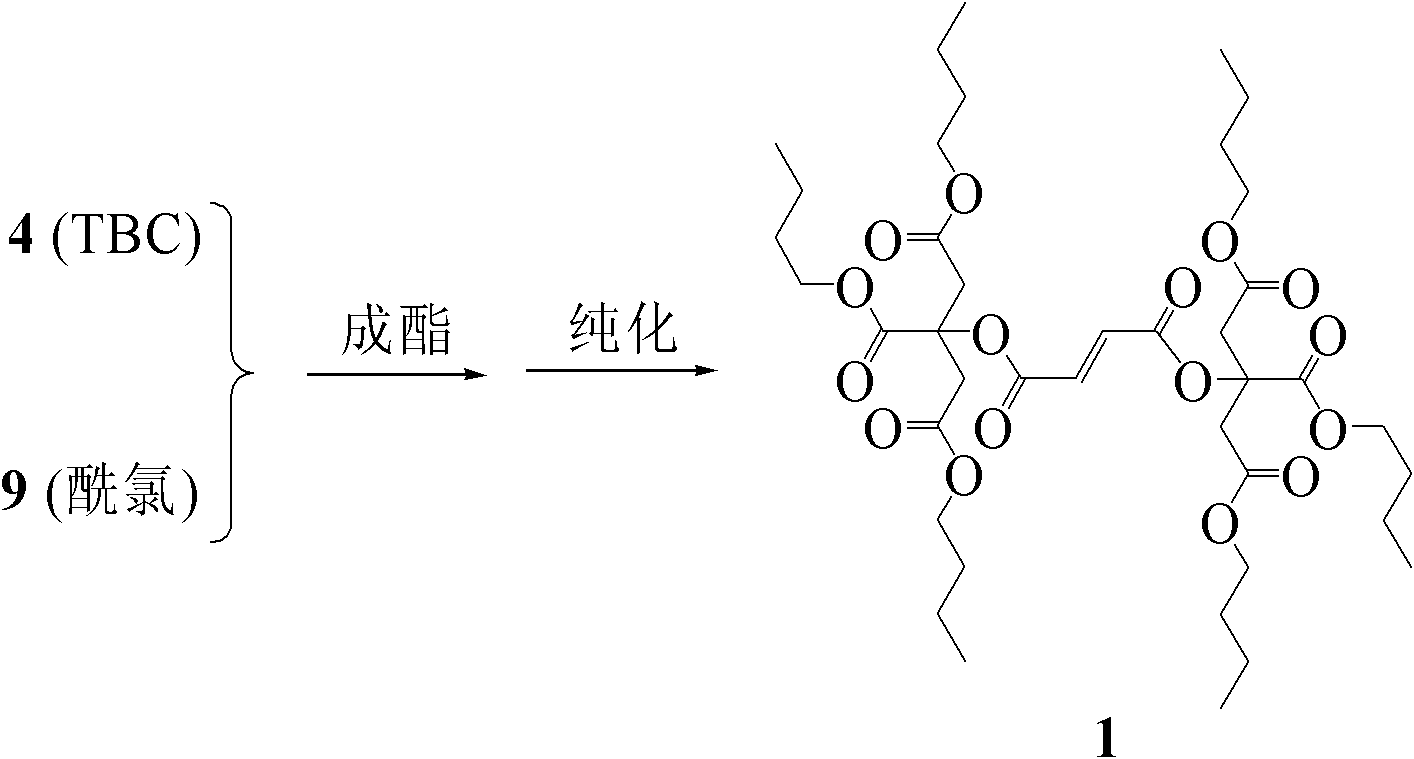

[0031] see Figure 1~3 , the preparation method of butenedioic acid tributyl citrate diester, comprises the following steps:

[0032] 1) Synthesis of tributyl citrate: add citric acid (2) and excess n-butanol (3) in the reaction kettle, then add iron trichloride hexahydrate (FeCl 3 ·6H 2 O) as a catalyst, stir and heat up to 108-115° C., reflux reaction until anhydrous is generated, and recover the residual n-butanol (3) by distillation to obtain tributyl citrate (4);

[0033] 2) Synthesis of fumaric acid: Add maleic anhydride (5) and water 2 to 2.5 times its mass in the reaction kettle, stir until the solution is clear and carry out hydrolysis reaction to generate maleic anhydride (6 ), then add thiourea (7) with 2% maleic anhydride mass as a catalyst, stir and heat to 70°C and keep it for 0.5-0.8h, cool to room temperature, filter, wash the solid with distilled water, and obtain trans Butenedioic acid (8);

[0034] 3) Synthesis of trans-butene dichloride: add fumaric aci...

Embodiment 1

[0037] The preparation of butenedioic acid tributyl citrate diester comprises the following steps:

[0038] 1) Synthesis of tributyl citrate: in parts by mass, add 35 parts of citric acid and 58 parts of n-butanol (excessive) in the reactor, then add citric acid quality 4% (1.4 parts) of six Ferric trichloride hydrate is used as a catalyst for esterification reaction, stirred and heated to 108 ° C, and refluxed with a serpentine condenser tube, reacted to anhydrous (H 2 O) generate, after distillation reclaims excess n-butanol remaining, obtain tributyl citrate;

[0039] 2) Synthesis of fumaric acid: in parts by mass, add 95 parts of maleic anhydride and 190 parts of water in the reactor, stir and carry out hydrolysis reaction until the solution is clear without separation, and then Add 1.8 parts of thiourea directly to the system as a catalyst (2% of the mass of maleic anhydride), stir and heat to 70°C, the system quickly becomes cloudy, keep the reaction at 70°C for 0.5h, coo...

Embodiment 2

[0043] The preparation of butenedioic acid tributyl citrate diester comprises the following steps:

[0044] 1) Synthesis of tributyl citrate: in parts by mass, add 38.6 parts of citric acid and 59.4 parts of n-butanol (excessive) in the reactor, then add citric acid quality 5.1% (2.0 parts) of six Ferric trichloride hydrate is used as a catalyst for esterification reaction, stirred and heated to 115 ° C, and refluxed with a serpentine condenser tube, reacted to anhydrous (H 2 O) generate, after distillation reclaims excess n-butanol remaining, obtain tributyl citrate;

[0045] 2) Synthesis of fumaric acid: in parts by mass, add 98 parts of maleic anhydride and 200 parts of water in the reactor, stir and carry out hydrolysis until the solution is clear without separation, and then Add 2.0 parts of thiourea directly to the system as a catalyst (2% of the mass of maleic anhydride), stir and heat to 70°C, the system quickly becomes cloudy, keep the reaction at 70°C for 0.5h, cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com