Patents

Literature

62results about How to "High growth rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

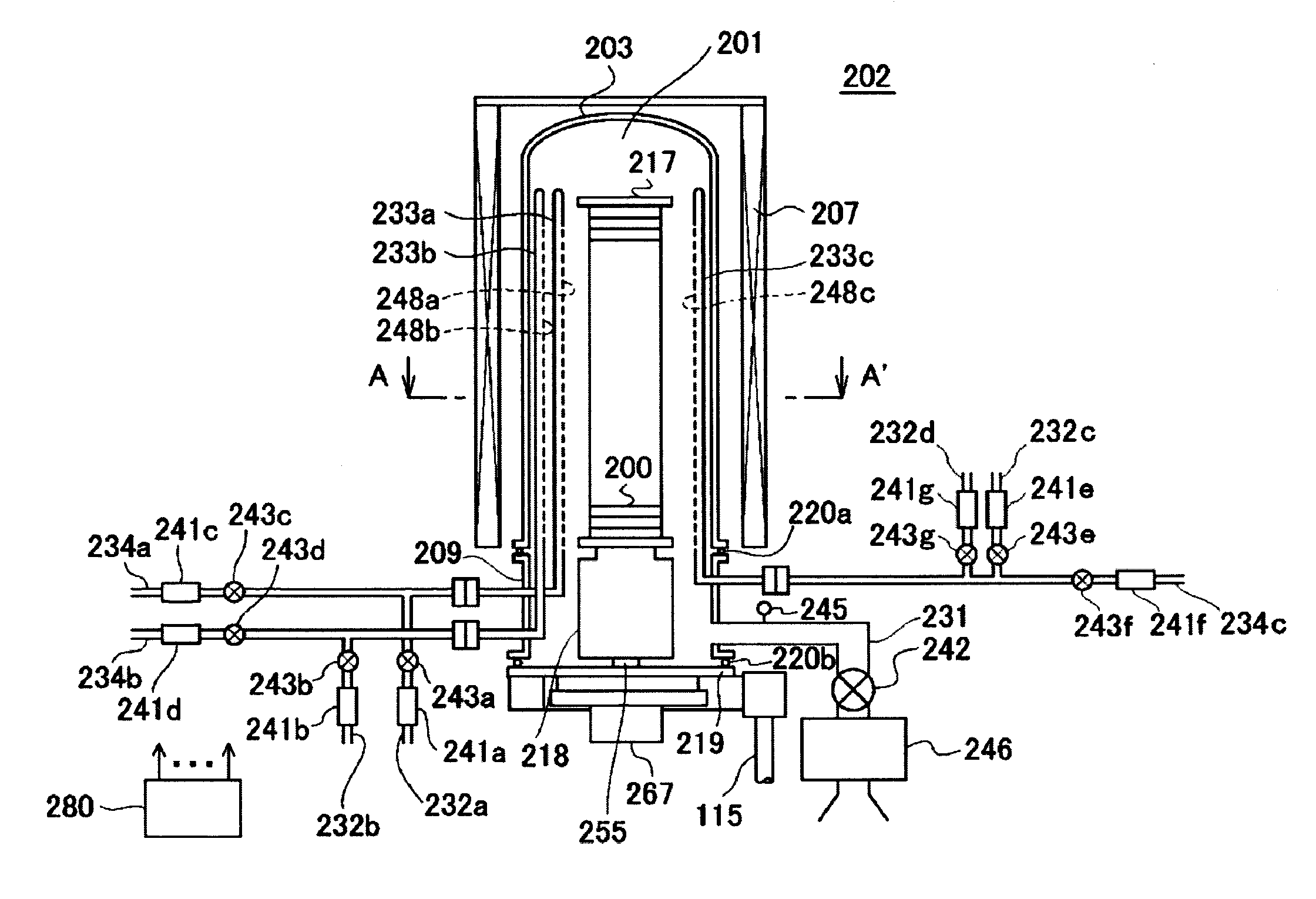

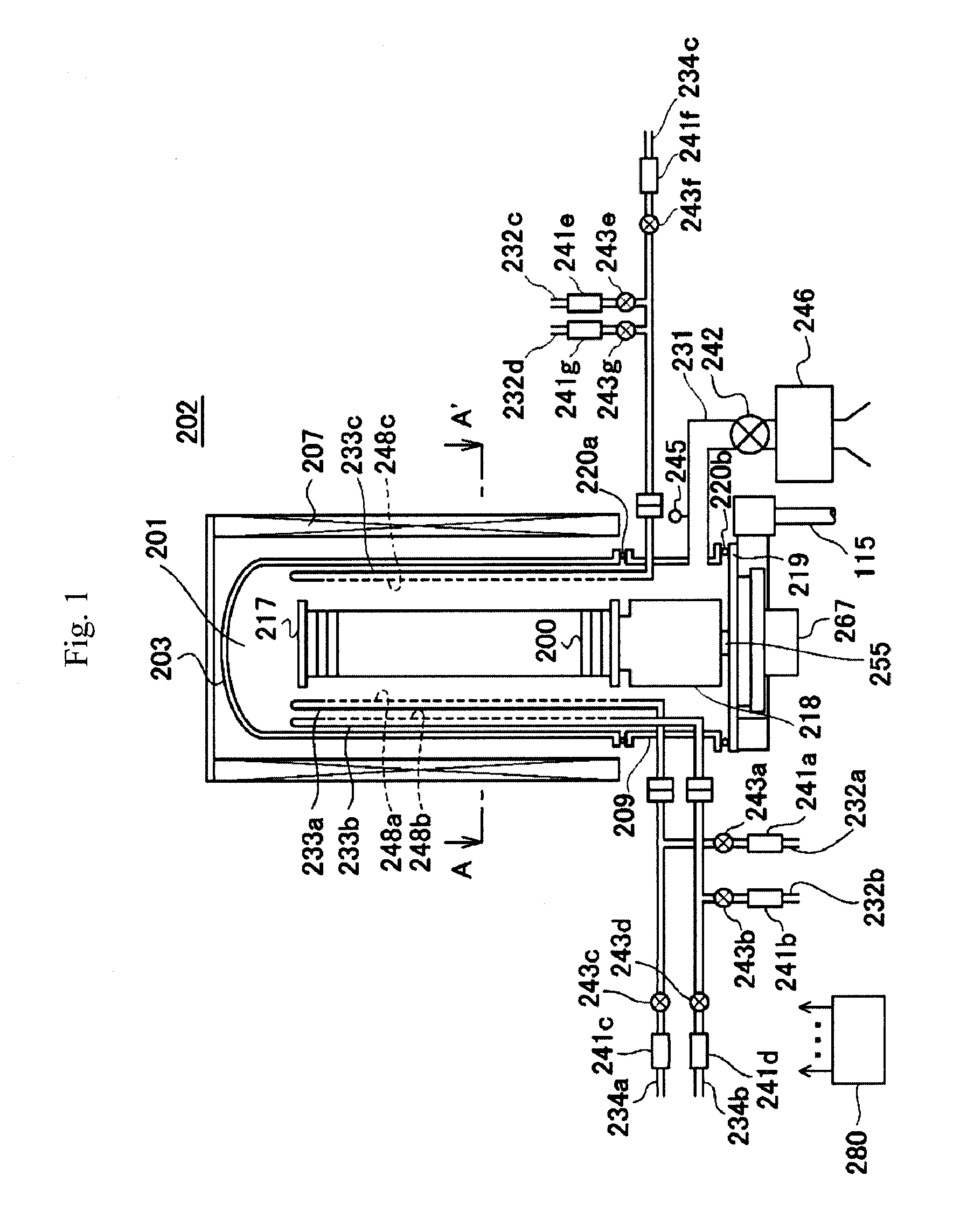

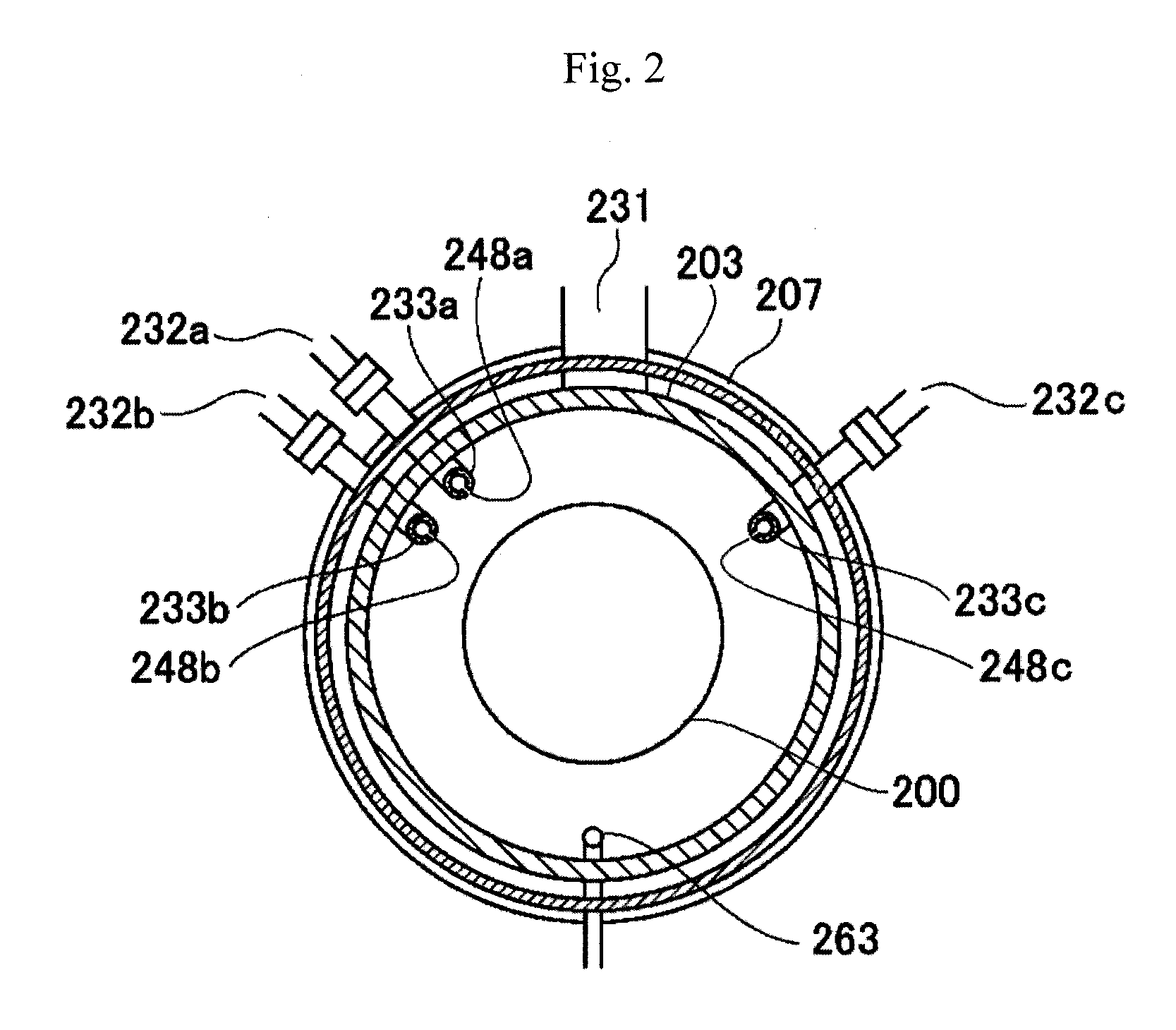

Method of manufacturing semiconductor device and substrate processing apparatus

ActiveUS20110076857A1High growth rateLow costSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringOxide

Provided is a method of manufacturing a semiconductor device. The method includes: loading a substrate into a process vessel; performing a process to form an oxide, nitride, or oxynitride film on the substrate by alternately repeating: (a) forming a layer containing a predetermined element on the substrate by supplying and exhausting first and second source gases containing the element into and from the process vessel; and (b) changing the layer containing the element into an oxide, nitride, or oxynitride layer by supplying and exhausting reaction gas different from the first and second source gases into and from the process vessel; and unloading the substrate from the process vessel. The first source gas is more reactive than the second source gas, and an amount of the first source gas supplied into the process vessel is set to be less than that of the second source gas supplied into the process vessel.

Owner:KOKUSA ELECTRIC CO LTD

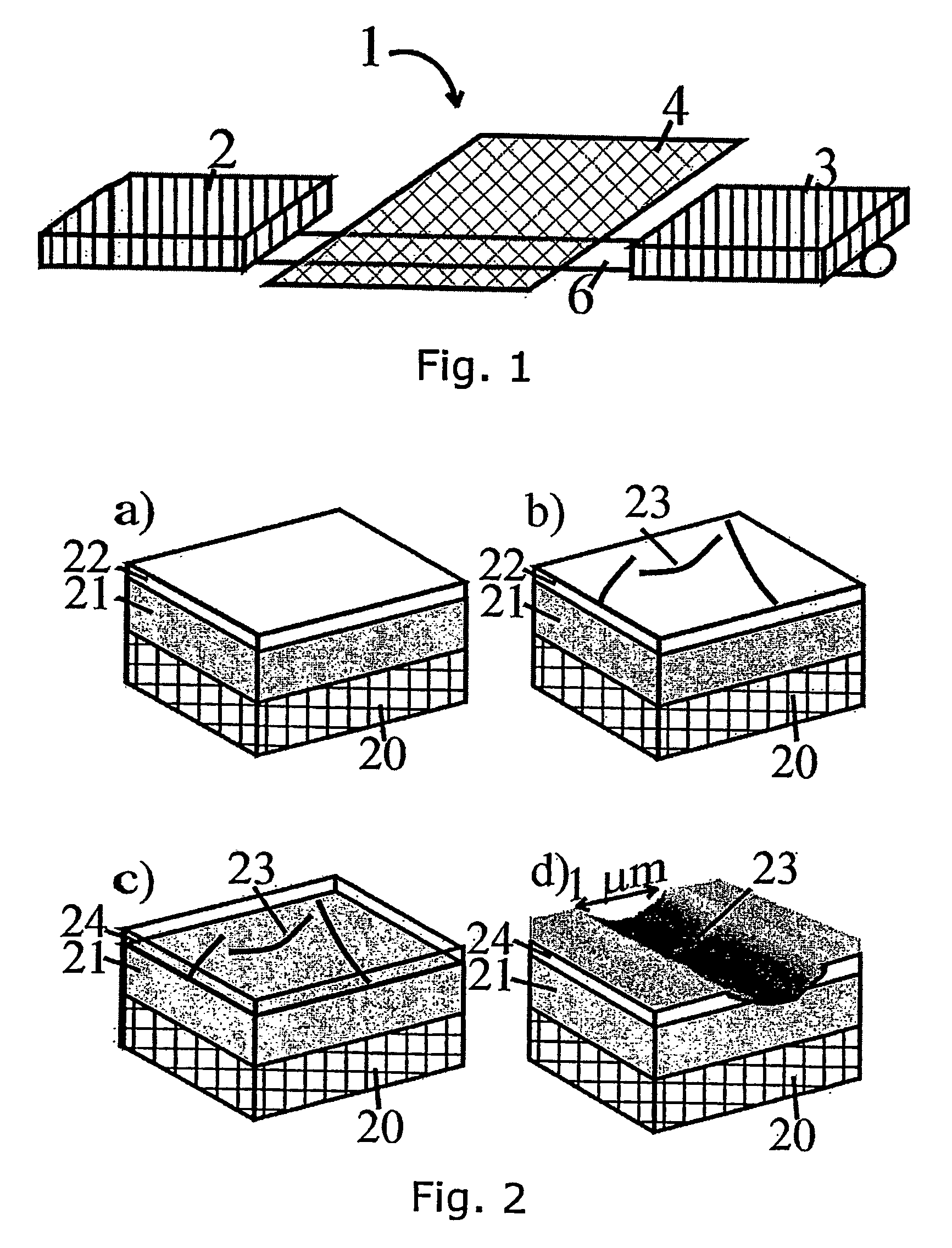

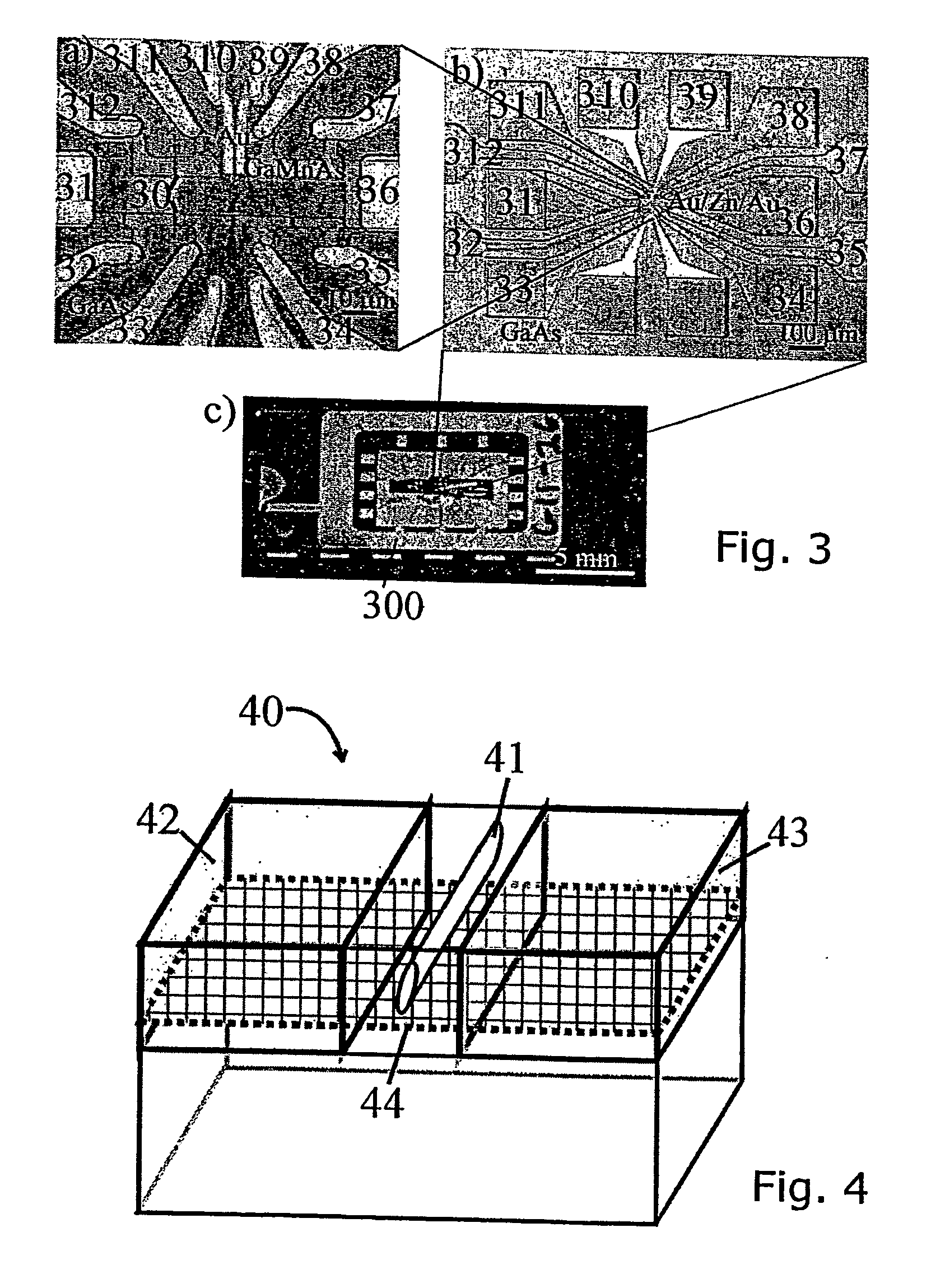

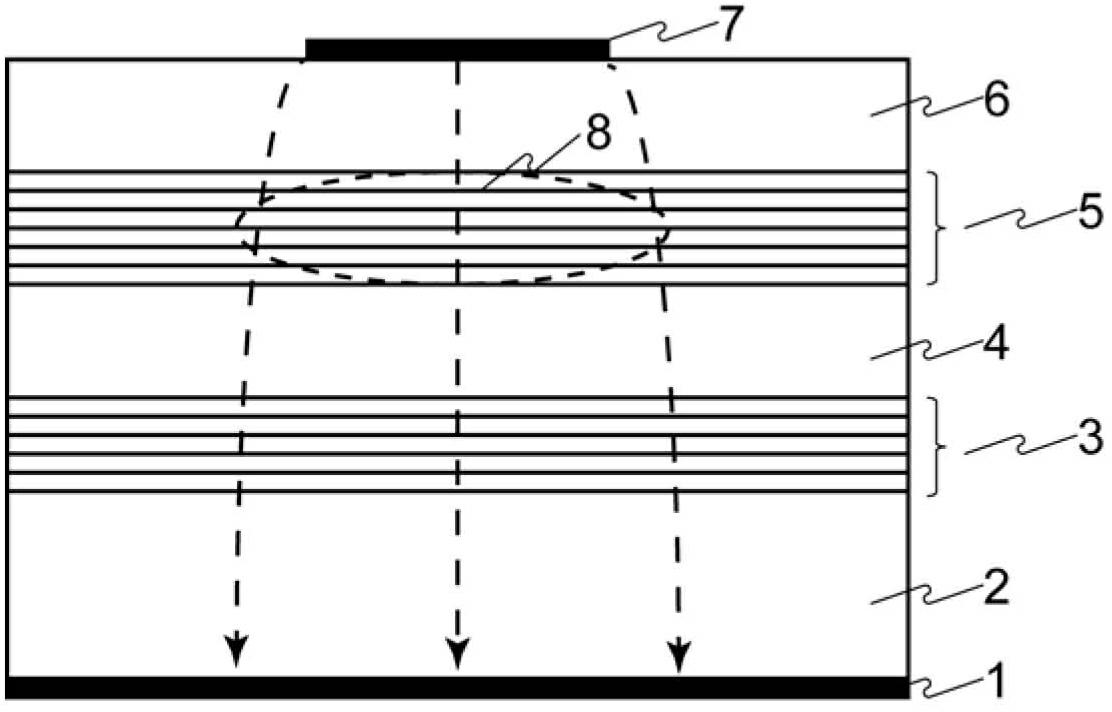

Method of fabrication and device comprising elongated nanosize elements

InactiveUS20070157873A1Precise and very well-defined interfaceHigh growth ratePolycrystalline material growthBy zone-melting liquidsCarbon nanotubeSemiconductor

A method of fabricating devices comprising elongated nanosize elements as well as such devices are disclosed. The devices comprise epitaxially grown layers into which elongated nanosize elements, such as carbon nanotubes, are incorporated. A substrate supporting epitaxial growth of an epitaxial layer is provided, elongated nanosize elements is provided onto the substrate and epitaxially overgrown with an epitaxial layer. The elongate nanosize elements are thereby at least partly encapsulated by the epitaxially grown layer. One or more components are prepared in the layer, the one or more components being prepared by means of lithography. Devices with carbon nanotubes as the active element may thereby be provided. The method is suitable for hybrid devices, hybrid between conventional semiconductor devices and nano-devices.

Owner:UNIVERSITY OF COPENHAGEN

Method for controlling seeding form in process of preparing large-sized sapphire single crystal by Kyropoulos method

ActiveCN102154698AQuality improvementImprove growth success ratePolycrystalline material growthBy pulling from meltSeed crystalSapphire

The invention provides a method for controlling seeding form in process of preparing a large-sized sapphire single crystal by a Kyropoulos method. By using the method, four technical processes of preparation work, roasting a seed crystal, diameter shrinkage and multiple-seeding are finished in the process of growing the large-sized sapphire single crystal. Based on a Kyropoulos seeding method, the method is greatly improved and has the advantages that a grown crystal has higher quality and larger size, the success rate of the crystal growing is higher and the like.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

Composite moisture holding agent of humic acid and preparation method

InactiveCN1687193APromote rootingStable growth rateOrganic fertilisersSoil conditioning compositionsPotassiumPotassium hydroxide

The present invention provides a method for preparing compounded type humic acid water-retaining agent. Said method includes the following steps: adopting acrylic acid, starch and potassium hydroxide as main agent, compounding humic acid protective function group, controlling by items, respectively modifying and improving humate and potassium polyacrylate water-absorbing resin to make both them have reaction activity, then uniformly mixing them, and under the condition of heating and melting them making them implement compounding reaction so as to obtain the invented water-retaining agent with the function of promoting plant rooting, germination and growth.

Owner:师进

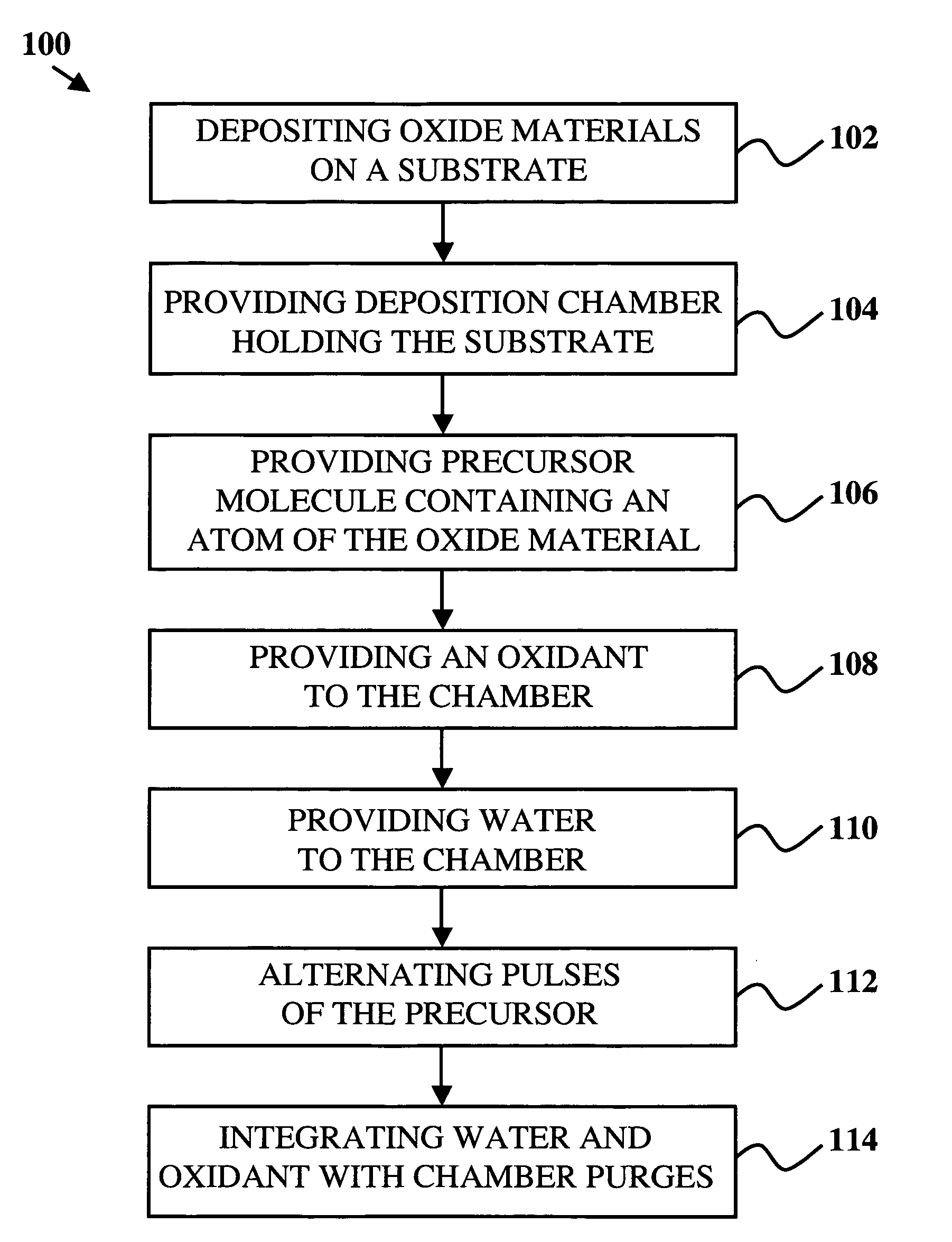

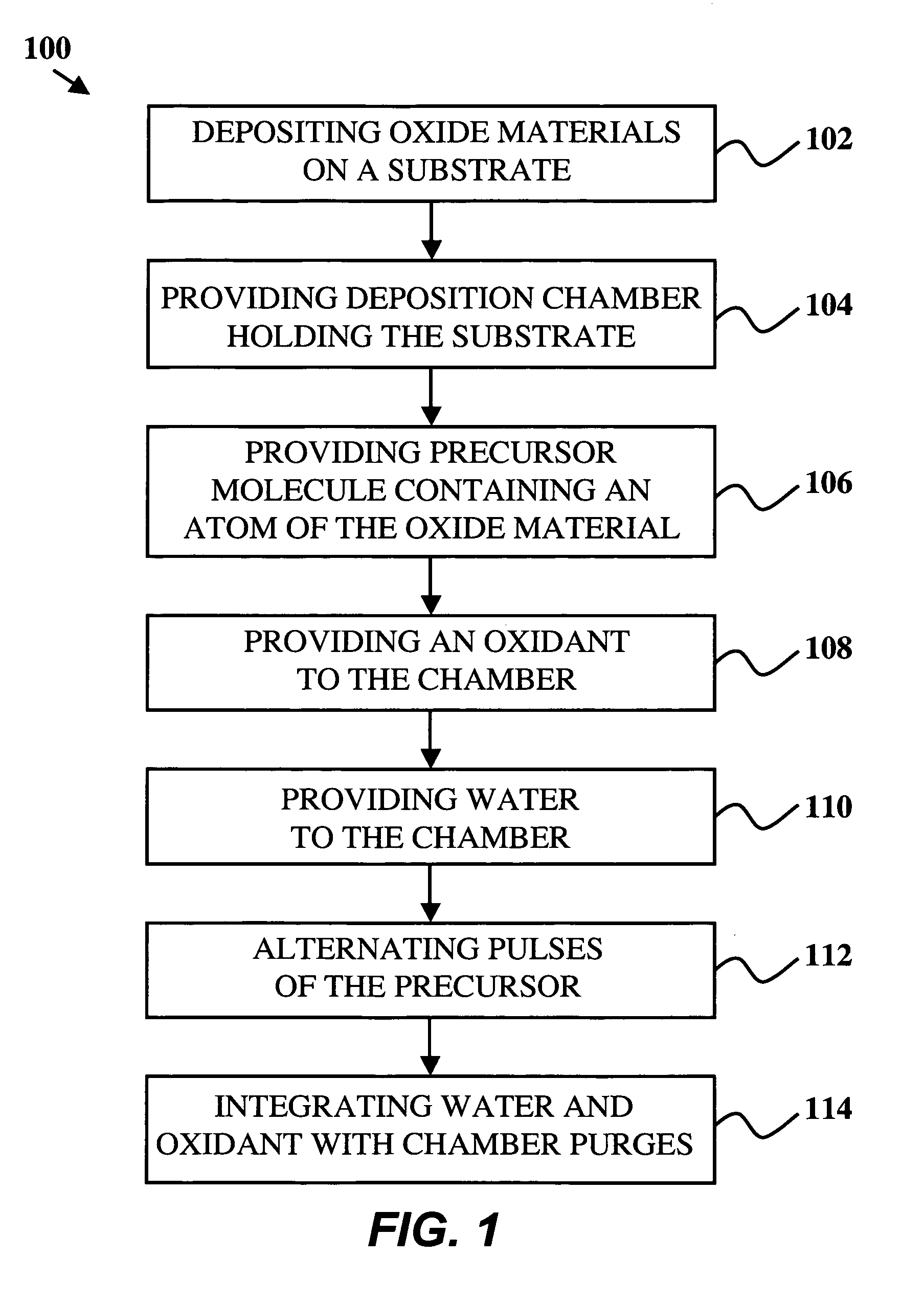

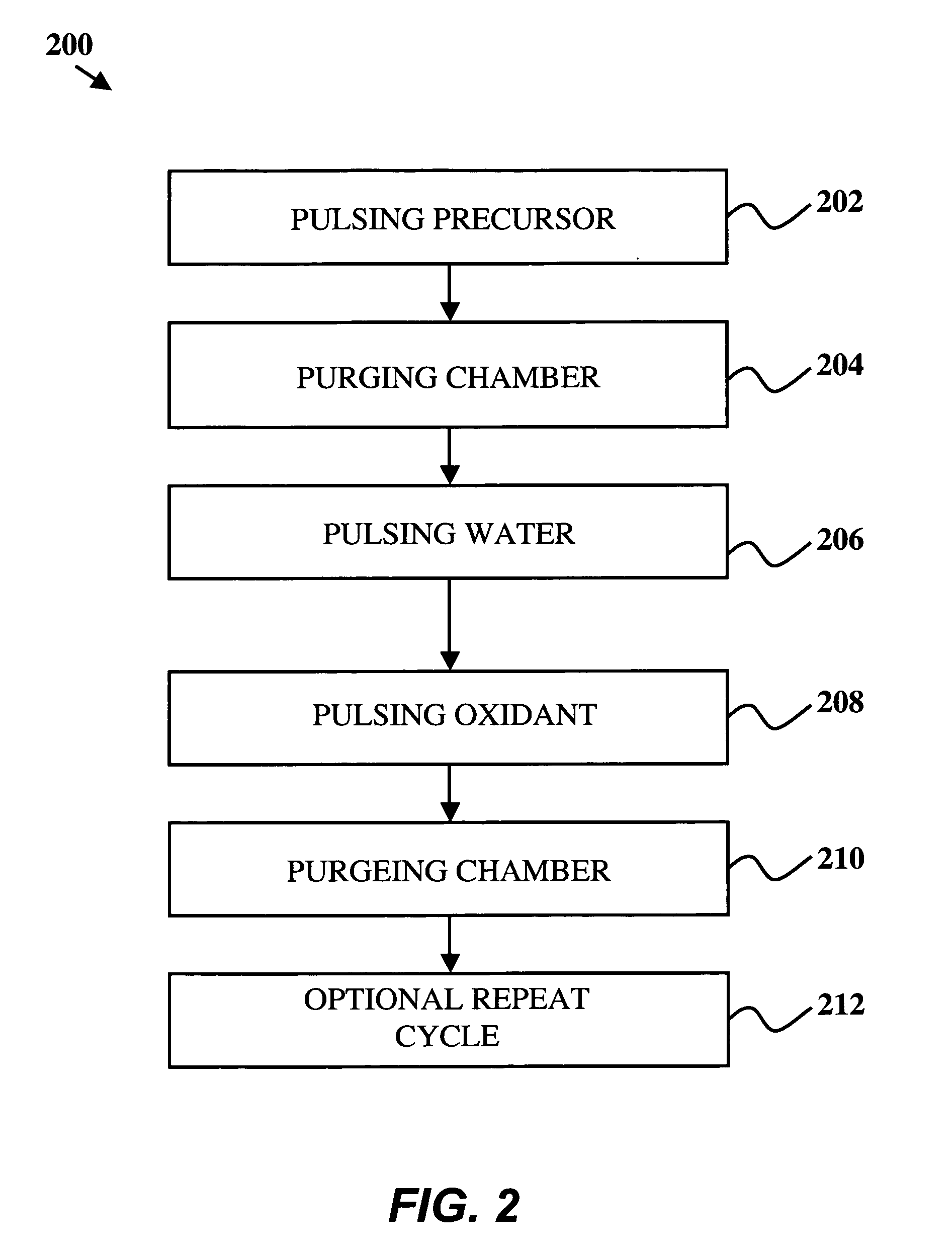

Atomic layer deposition of strontium oxide via n-propyltetramethyl cyclopentadiendyl precursor

InactiveUS20080242111A1Increase relative volatilityLower operating temperatureSemiconductor/solid-state device detailsSolid-state devicesChamber pressureStrontium oxide

A method of depositing oxide materials on a substrate is provided. A deposition chamber holds the substrate, where the substrate is at a specified temperature, and the chamber has a chamber pressure and wall temperature. A precursor molecule containing a cation material atom is provided to the chamber, where the precursor has a line temperature and a source temperature. An oxidant is provided to the chamber, where the oxidant has a source flow rate. Water is provided to the chamber, where the water has a source temperature. By alternating precursor pulses, the water and the oxidant are integrated with purges of the chamber to provide low contamination levels and high growth rates of oxide material on the substrate, where the pulses and the purge have durations and flow rates. A repeatable growth cycle includes pulsing the precursor, purging the chamber, pulsing the water, pulsing the oxidant, and purging the chamber.

Owner:HONDA MOTOR CO LTD +1

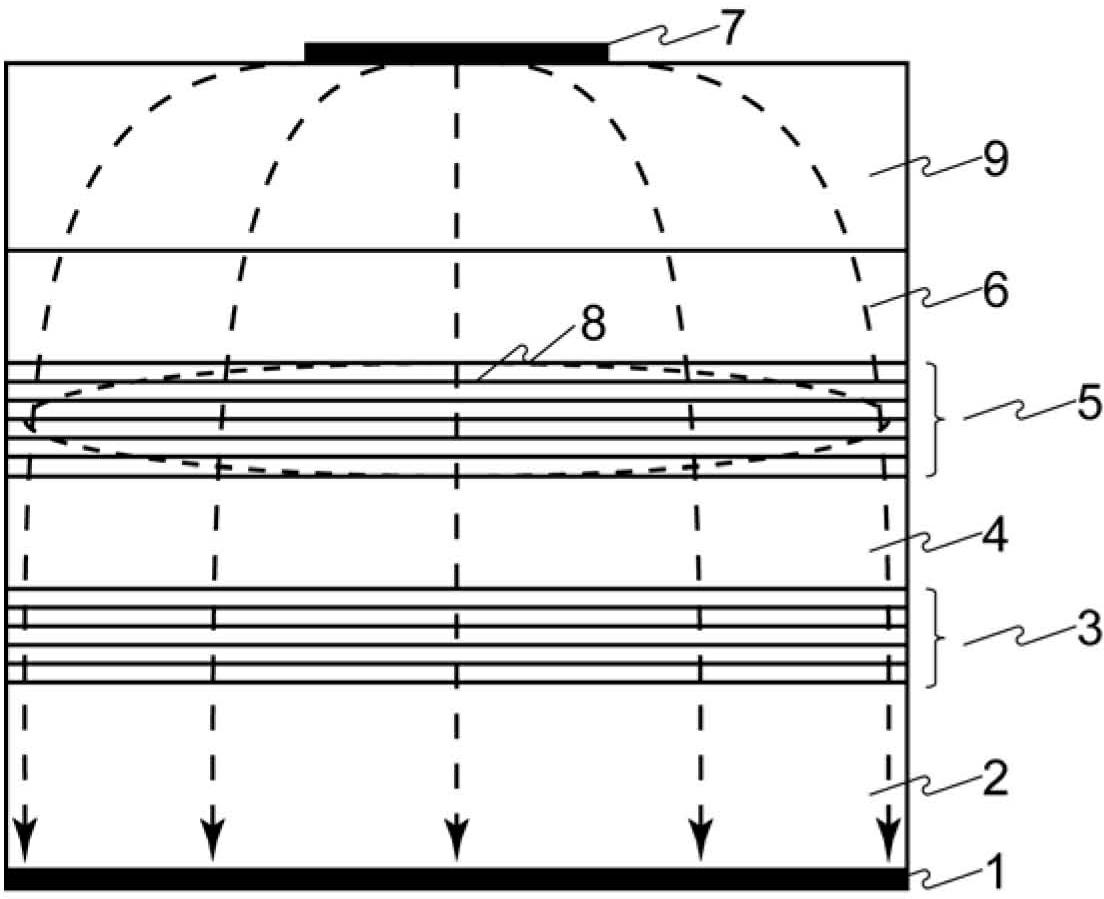

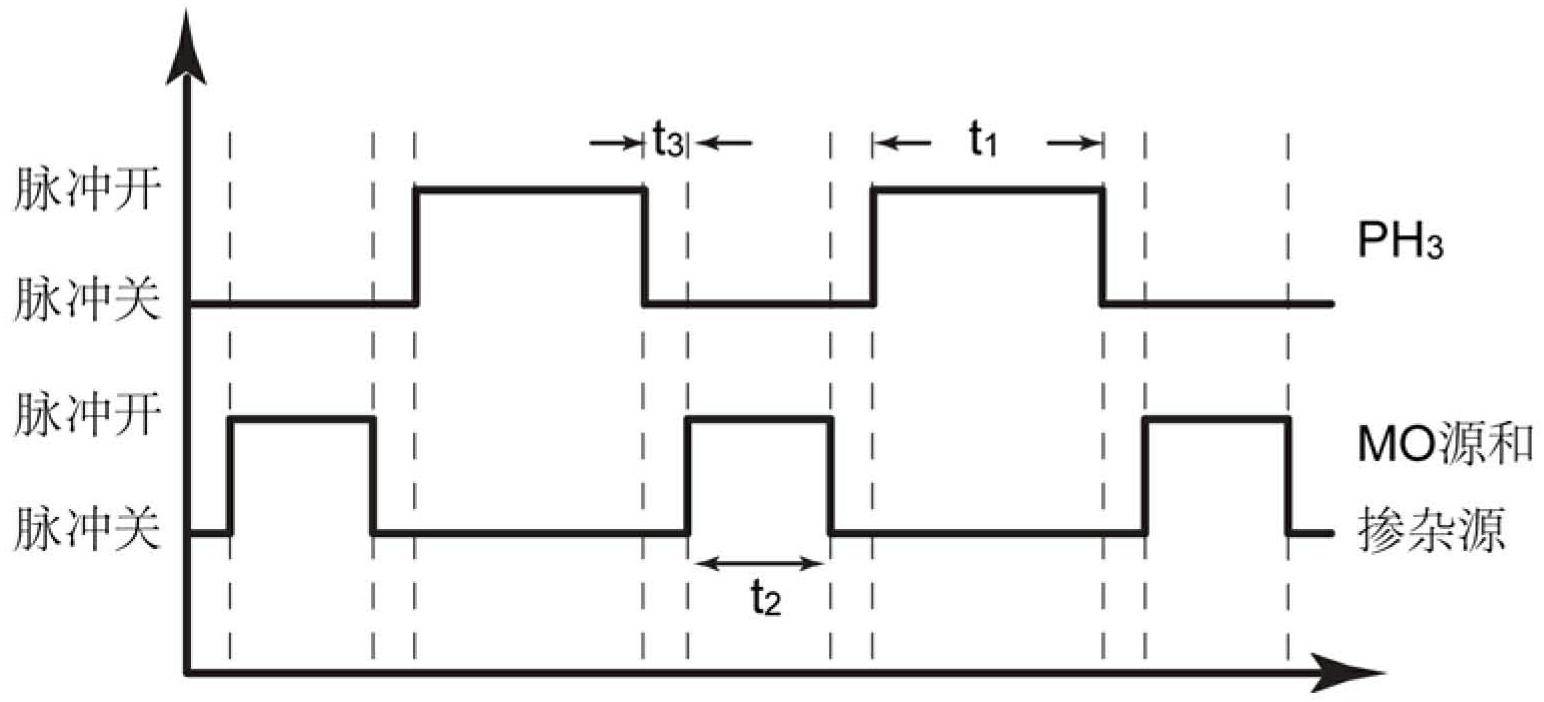

Method by adopting impulse airflow method to grow gallium phosphide (GaP) current extension layer

ActiveCN102593274AImprove efficiencyExtend your lifePolycrystalline material growthFrom chemically reactive gasesGas phaseChemical vapor deposition

The invention discloses a method by adopting an impulse airflow method to grow a gallium phosphide (GaP) current extension layer, which is characterized in that: a molybdenum (MO) source containing gallium atoms, phosphorane and a doping source are alternatively introduced into a reaction chamber of a metal organic chemical gas-phase precipitation system in a pulse way, or the flow-rate of the phosphorane is maintained constant, the MO source containing t he gallium atoms and the doping source are introduced in a pulse way. Due to adoption of the method, transition time of gallium atoms and phosphorus atoms on the surface of an extension layer can be increased, so that the gallium atoms and the phosphorus atoms can adequately cover the surface of the extension layer, and a GaP current extension layer with high quality can be obtained.

Owner:XIAMEN CHANGELIGHT CO LTD

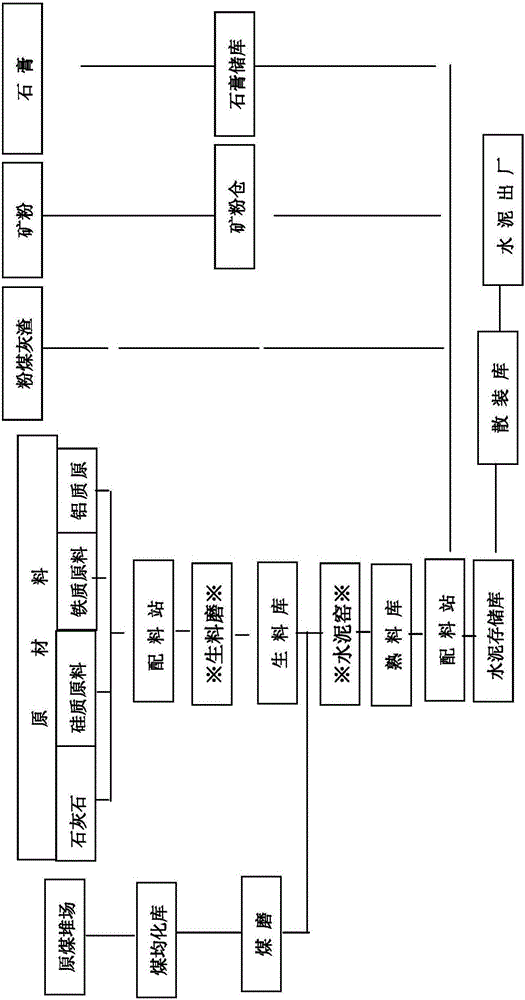

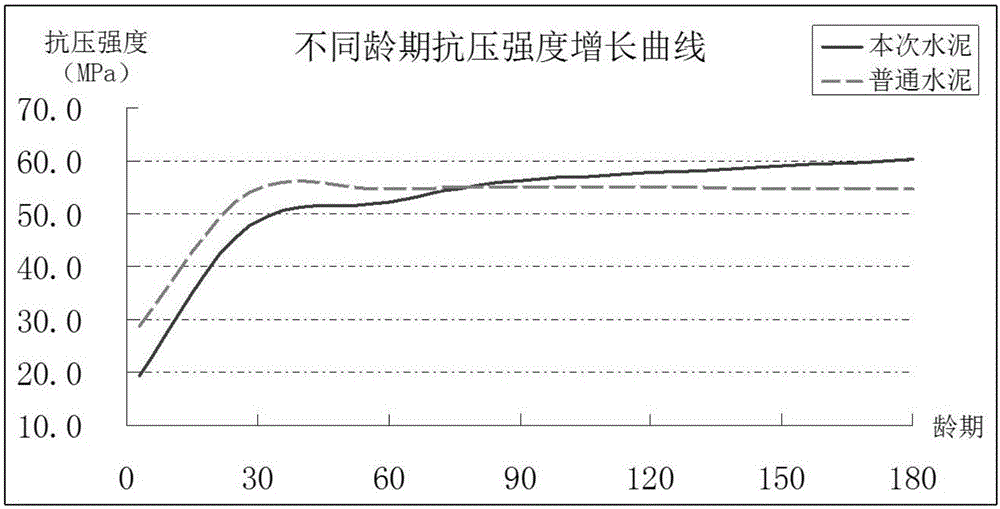

Highly-durable cement and production method thereof

InactiveCN106587670AReduce contentSmall specific surface areaCement productionSlagUltimate tensile strength

The invention relates to highly-durable cement and a production method thereof. The production method includes mixing calcareous raw materials, aluminous raw materials, silica raw materials and iron raw materials, calcining to obtain highly-durable clinker, and grinding the highly-durable clinker as well as natural gypsum, coal ash and blast-furnace slag powder so as to obtain the highly-durable cement. The highly-durable cement produced by the production method has the advantages that the C3S content in the cement can be decreased below 50% by weight, the C3A content in the cement can be decreased below 4% by weight, C2S content in the cement can be increased above 25% by weight, the specific surface area of the cement is decreased below 350 m<2> / kg, final setting time of the cement is prolonged to 250 minutes, and 3-day strength of the cement is reduced around 20 MPa, so that the increasing range of the later cement strength is increased, concrete project cracks are reduced, and project service life is prolonged greatly.

Owner:杨文科

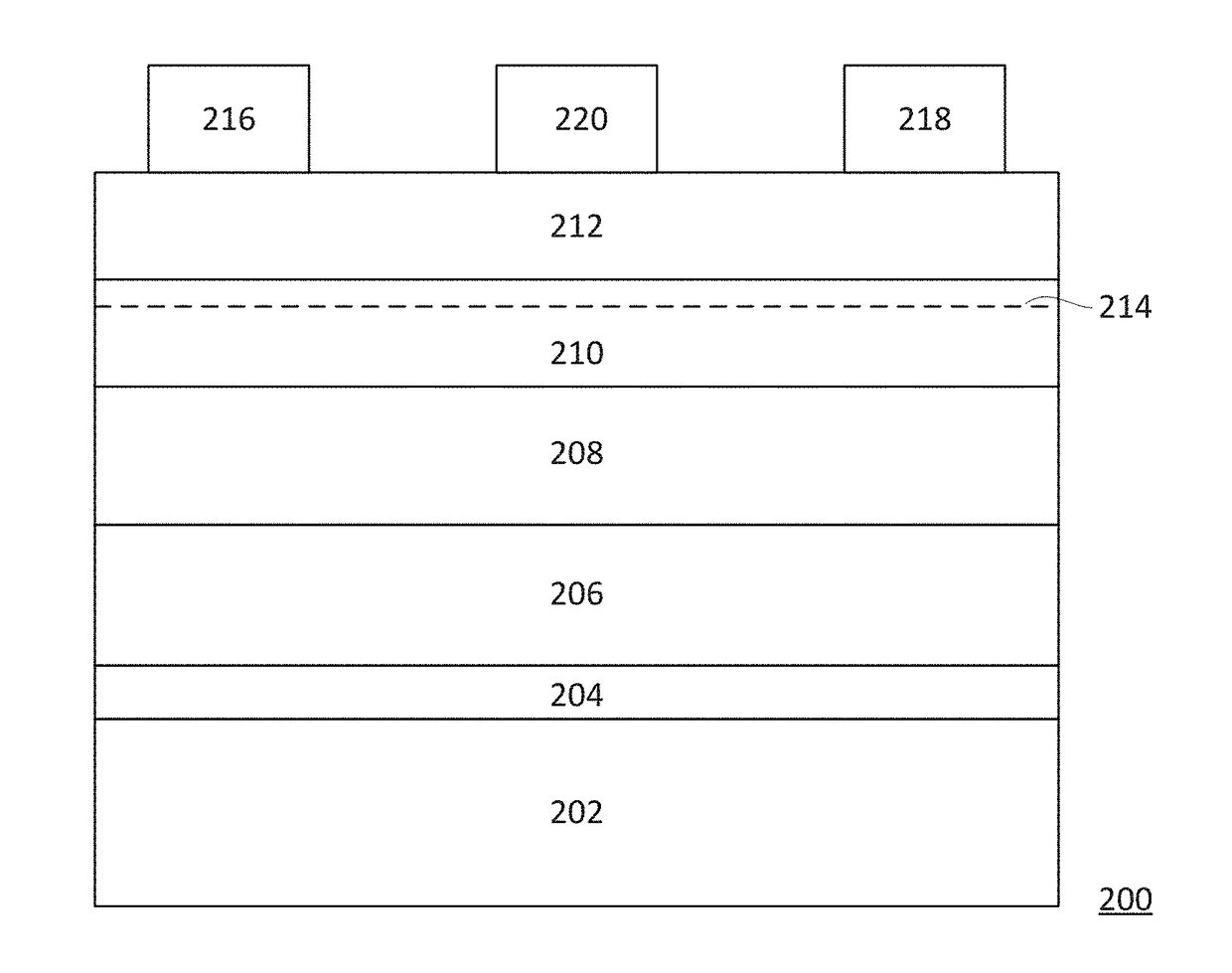

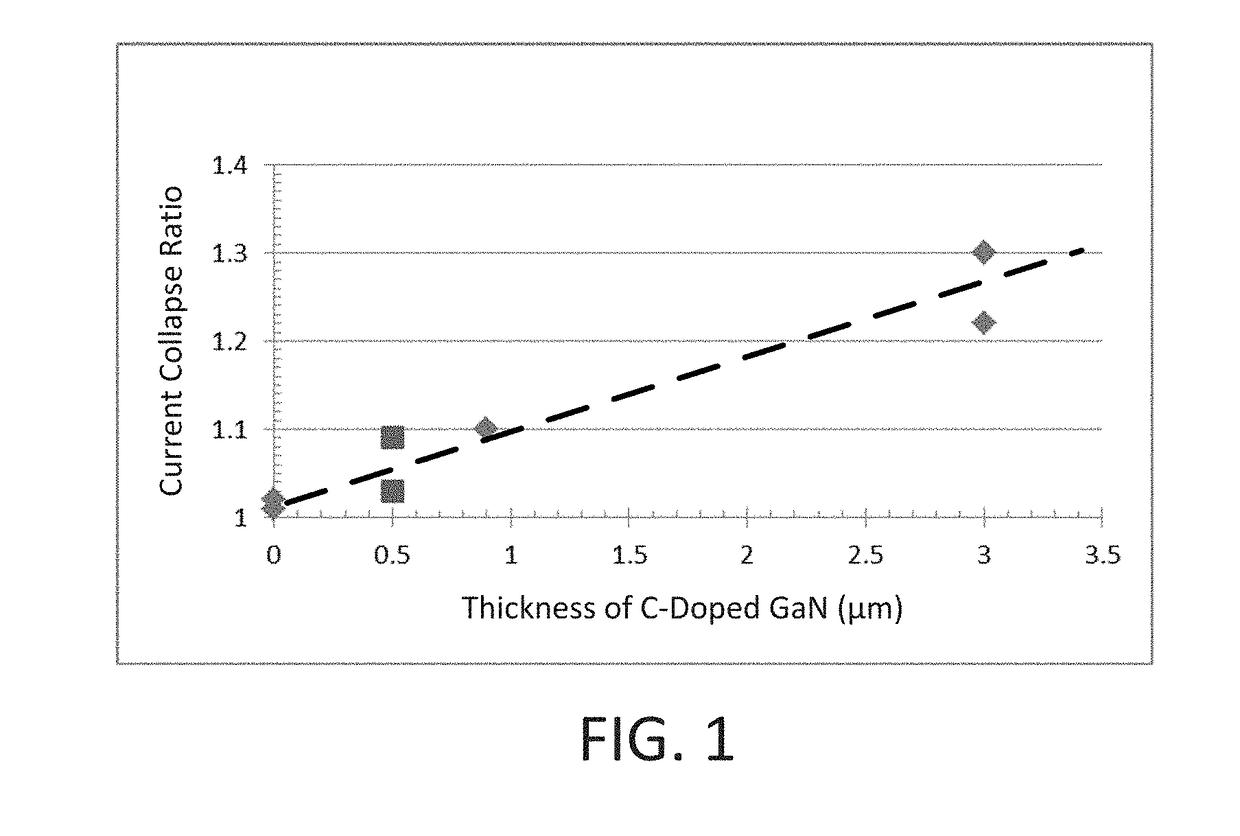

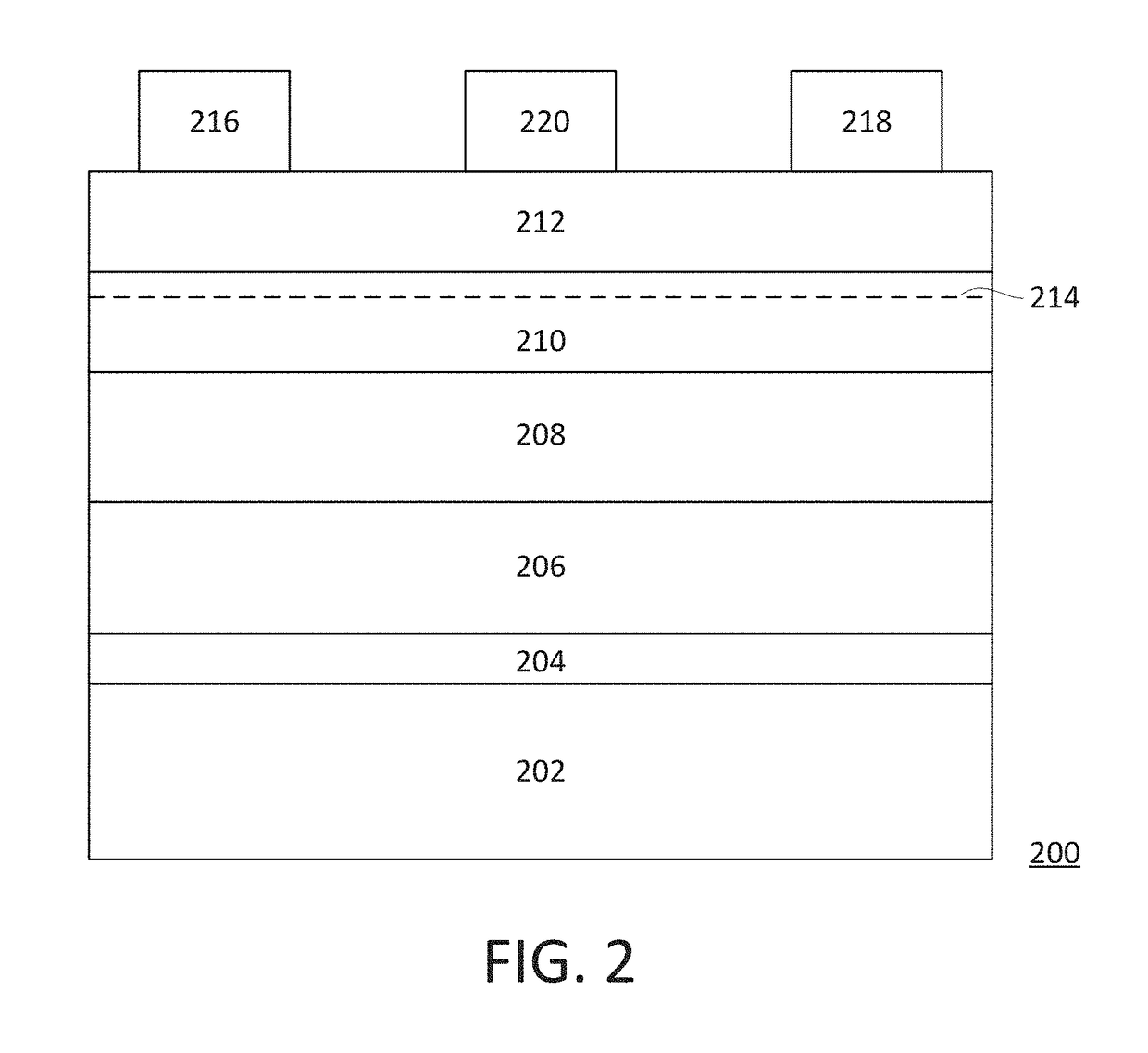

High electron mobility transistor (HEMT)

ActiveUS20170179271A1Low ratioHigh growth rateTransistorGallium nitrideHigh-electron-mobility transistor

A high electron mobility transistor (HEMT) device with a highly resistive layer co-doped with carbon (C) and a donor-type impurity and a method for making the HEMT device is disclosed. In one embodiment, the HEMT device includes a substrate, the highly resistive layer co-doped with C and the donor-type impurity formed above the substrate, a channel layer formed above the highly resistive layer, and a barrier layer formed above the channel layer. In one embodiment, the highly resistive layer comprises gallium nitride (GaN). In one embodiment, the donor-type impurity is silicon (Si). In another embodiment, the donor-type impurity is oxygen (O).

Owner:KK TOSHIBA

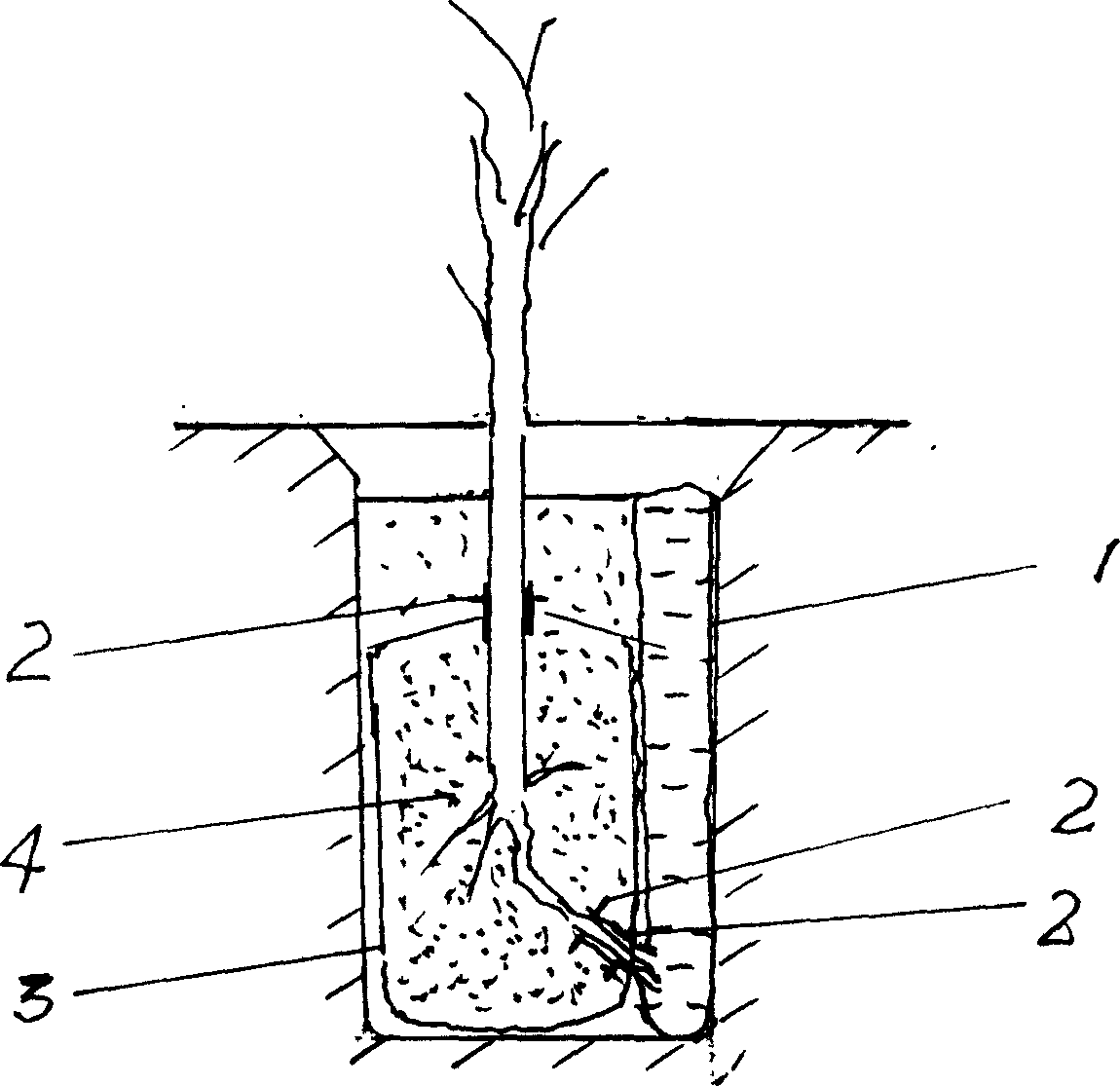

Drought region tree transplanting method

InactiveCN1555679AEffective water supplyHigh growth rate of treesRoot feedersForestryBiologyHigh survival rate

A method for transplanting tree in dye region features that a degradable water storage bag is bound onto one of its root branches, a degradable moisture preserving bag is bound at surround whole root, and whole root of tree is buried in soil pit. Its advantage is high survival rate.

Owner:安教全

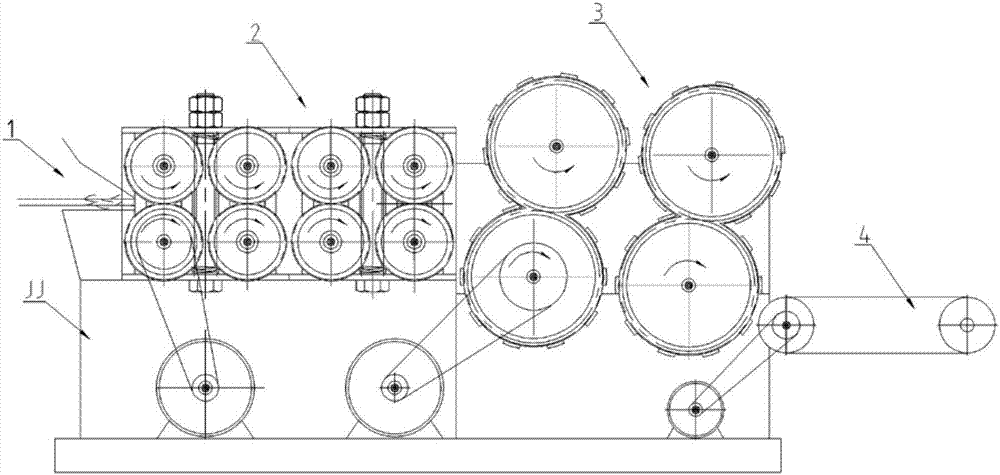

Industrial hemp scapus fiber separator

ActiveCN107164804AImprove efficiencyImprove the effect of broken stemsTextile disintegration and recoveryMechanical fibre separationCardingCombing

The invention discloses an industrial hemp scapus fiber separator which comprises a material feeding table, a stalk rolling device and a hemp combing carding device, sequentially arranged, wherein the stalk rolling device comprises multiple pairs of upper and lower meshed rollers; every two adjacent rollers meshed with each other through convex teeth and grooves in the outer walls of roller bodies to efficiently roll stalks, so as to separate peels from scapuses, and hemp scapuses are rolled into tiny hemp combings which are attached to the surface of fiber; the rolled hemp scapuses are conveyed to the hemp combing carding device; the hemp combing carding device comprises multiple pairs of upper and lower meshed carding drums; a plurality of rows of carding components are arranged on the outer wall of each carding drum along the axial direction; a splayed carding gap is formed between every two adjacent rows of carding component; a carding strip is arranged on the side wall of each carding component; the carding components repeatedly tap and card the hemp combings to enable the hemp combings to be separated from the surface of the fiber, thus obtaining clean hemp fiber; the stalk rolling device is applicable to feeding the stalks along a direction both parallel to the axial direction of the rollers and perpendicular to the axial direction of the rollers; and the carding components can guarantee high efficiency and increase the hemp growth rate.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

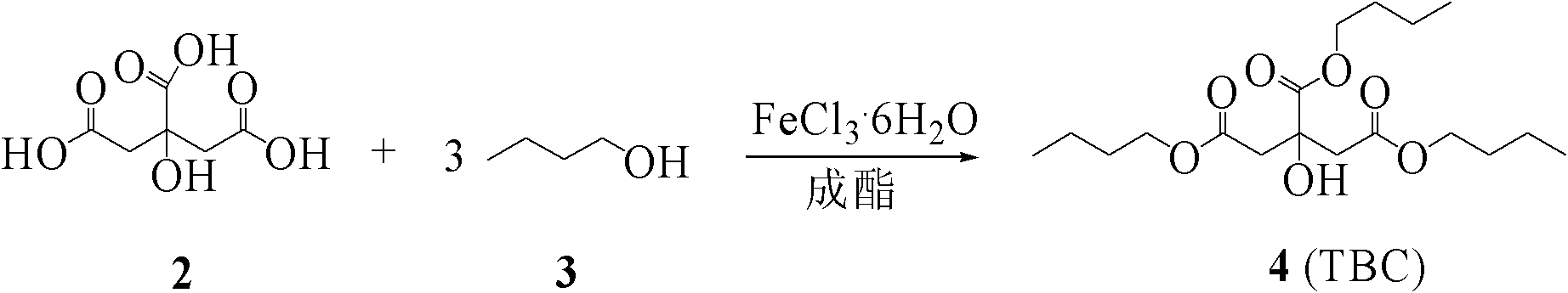

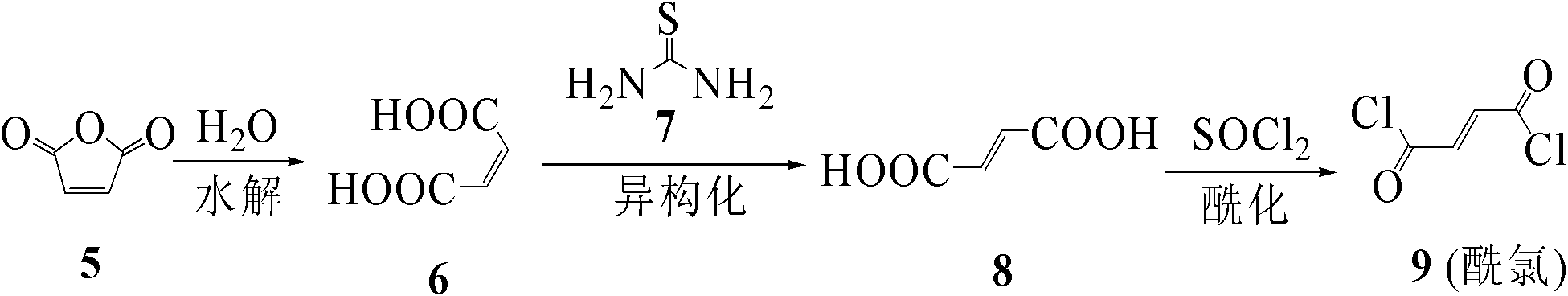

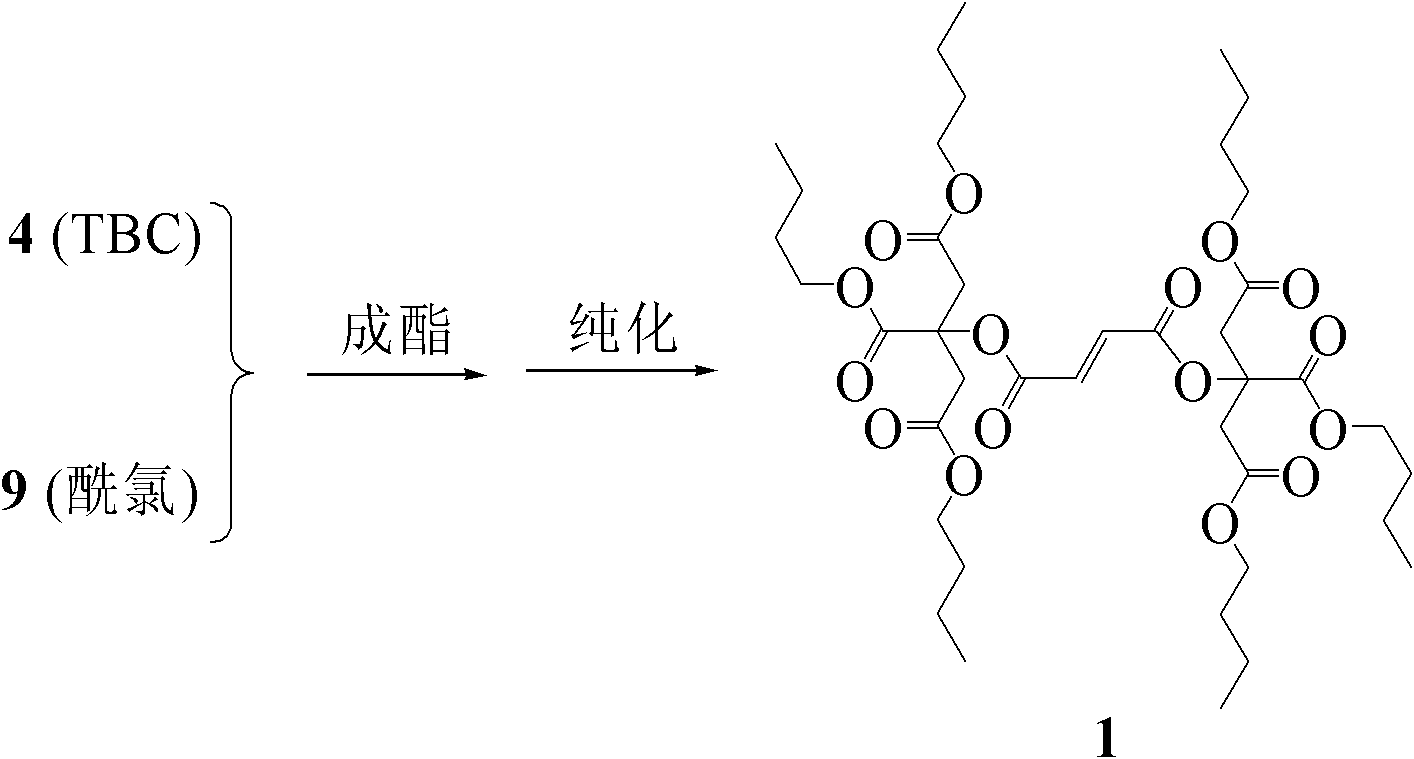

Maleic acid tributyl citrate diester compound and preparation method thereof

InactiveCN101781213AReduce volatilityGood seepage resistancePreparation from carboxylic acid halidesChlorideTributyl citrate

The invention discloses a new type green environmental protection type plastic plasticizer, which belongs to the technical field of plastic plasticizers and has the chemical name of maleic acid tributyl citrate diester. The invention also discloses a preparation method of the compound. Tributyl citrate and trans-maleic acid chloride are synthesized into a whole by a converging method, thereby effectively preparing a final product of the maleic acid tributyl citrate diester. The Maleic acid tributyl citrate diester as the plastic plasticizer has the advantages of small volatility, high stability, good anti-migration, good anti-extraction performance, good low-temperature flexibility, safety and no toxicity.

Owner:XI AN JIAOTONG UNIV

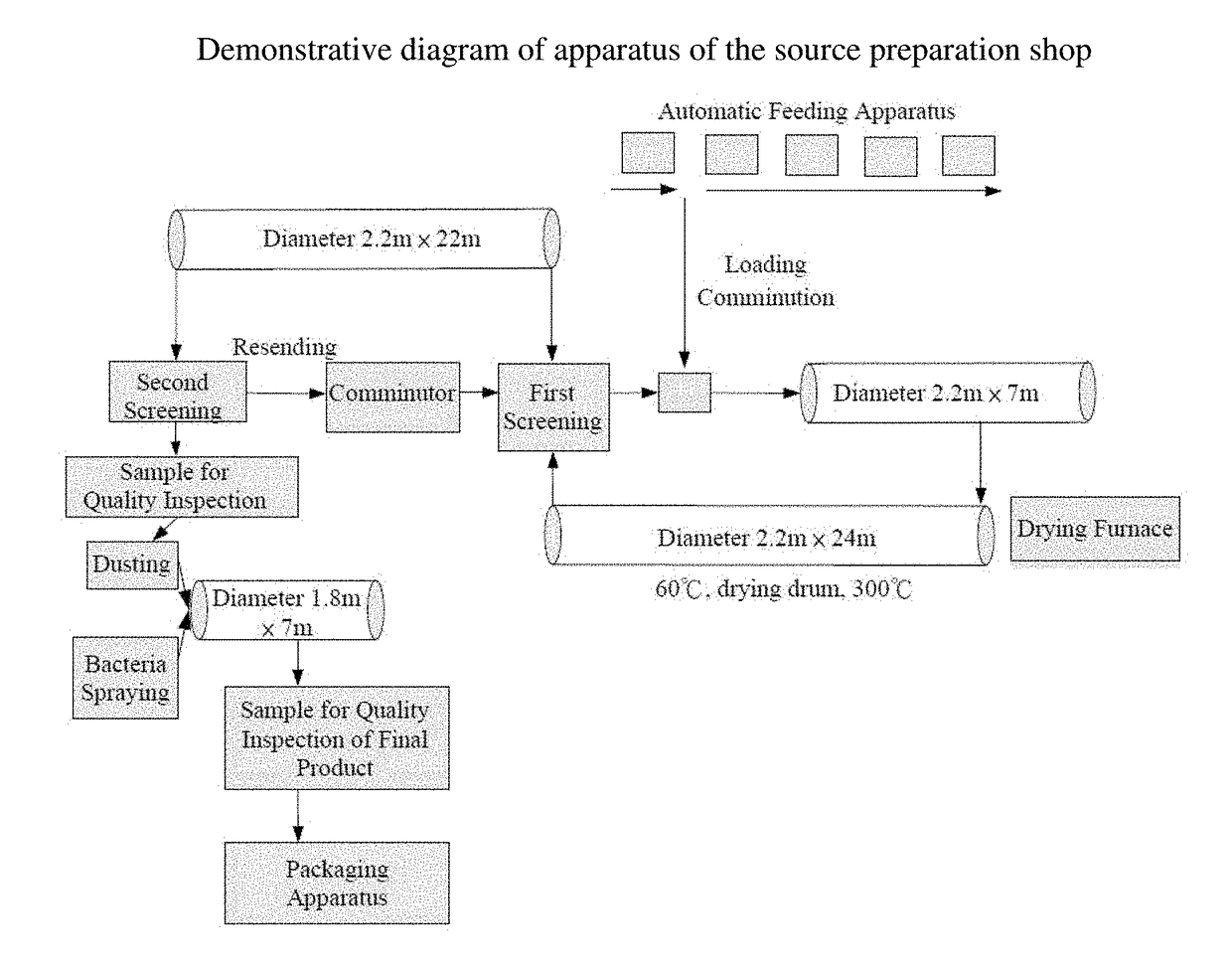

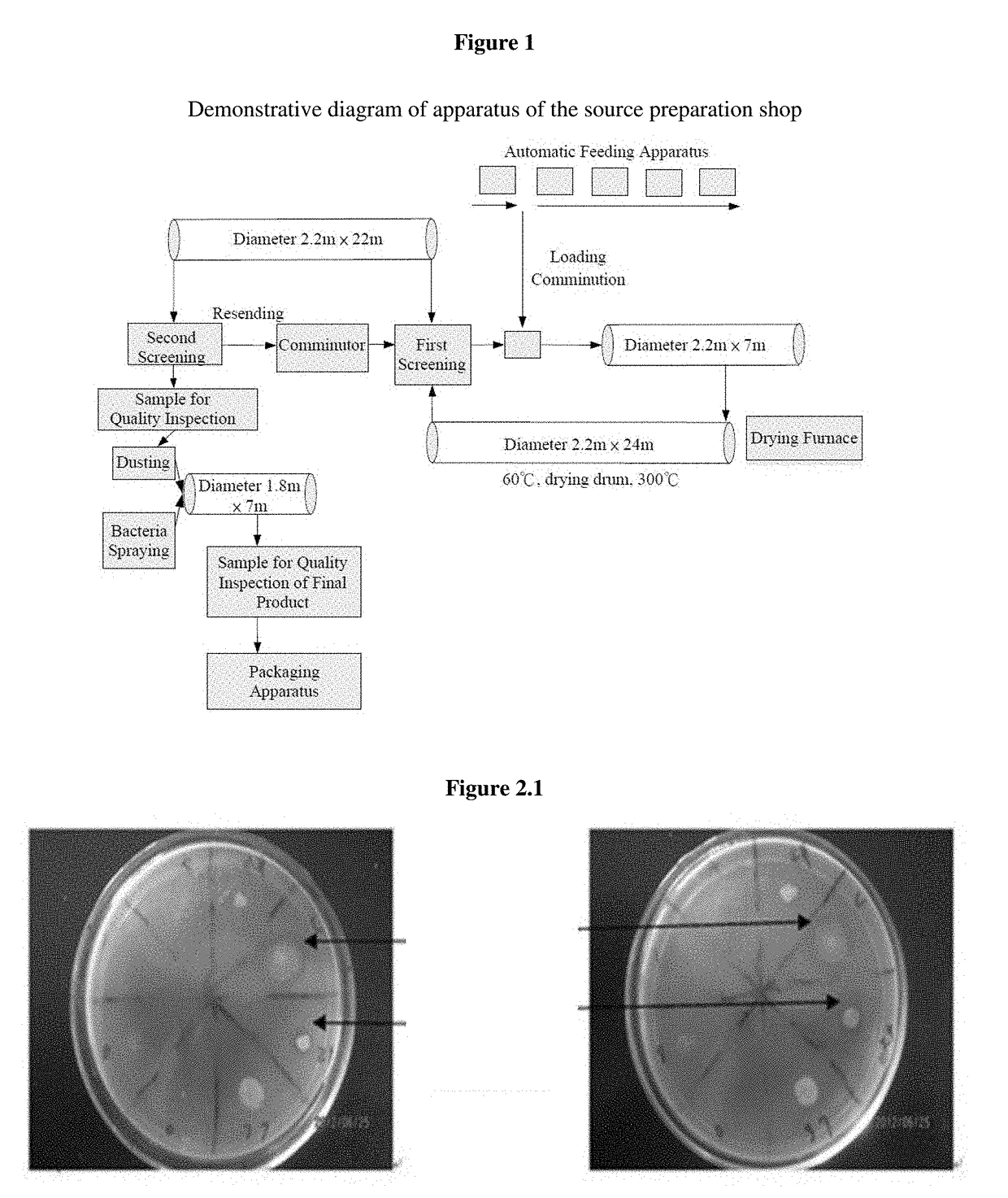

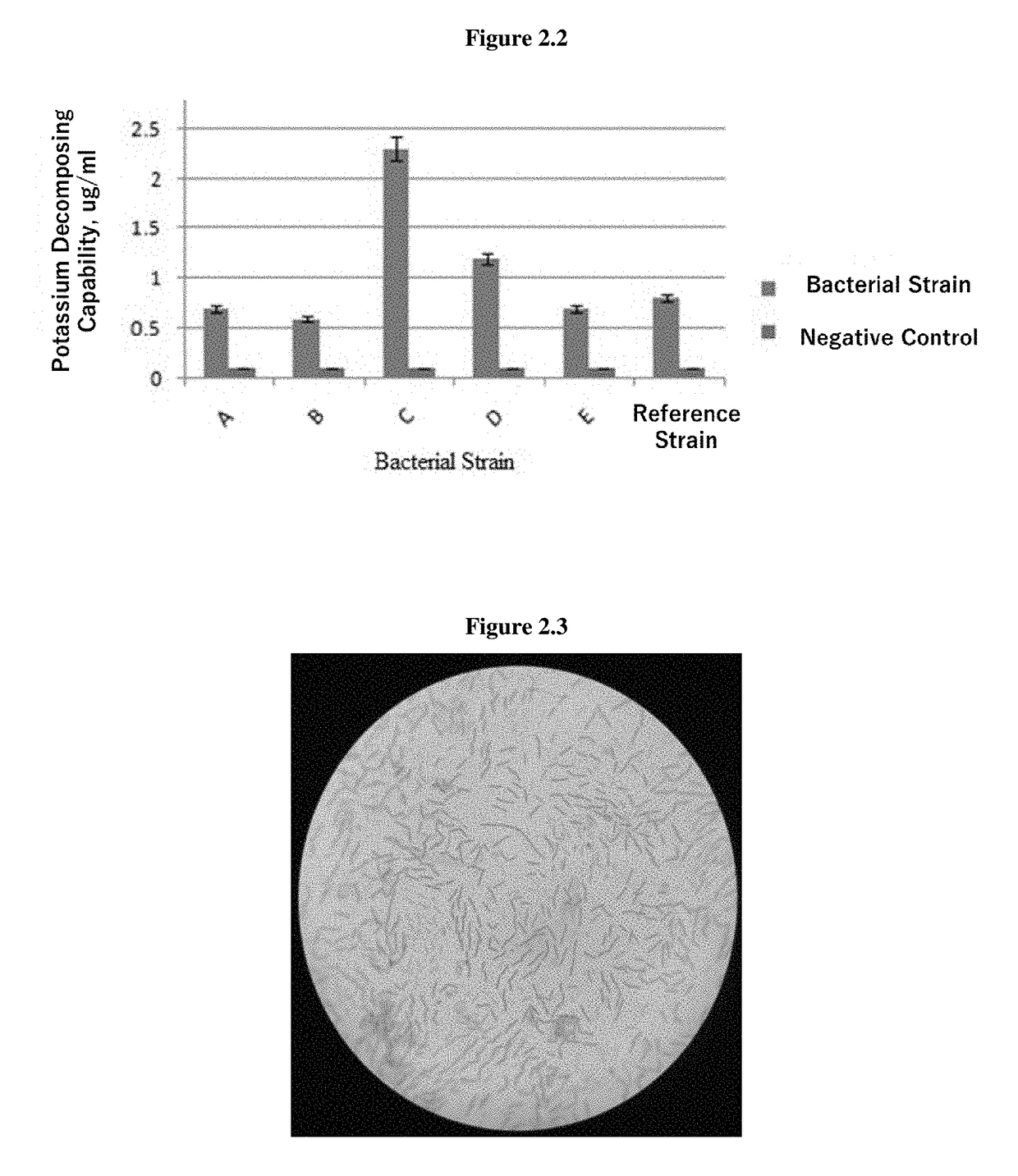

Bacillus mucilaginosus and high-density fermentation method and use thereof

This invention discloses a mutated strain of wild type Bacillus mucilaginosus HSCUP-76-8 and a high-density fermentation method thereof. The mutated strain HSCUP-76-8 was assigned an Accession No. CGMCC No. 8481. A two-stage and regulated high-density fermentation method has been established for the production of HSCUP-76-8. In the first stage, parameters are controlled to reduce the viscosity of the fermentation broth and promote the growth of bacteria, thereby allowing the bacteria to reach an amount in the range of 2.0×109 cfu / mL-2.3×109 cfu / ml. In the second stage, nutritional factors and fermentation conditions are controlled to promote sporulation, thereby producing endospores in the range of 1.5×109 cfu / mL-2.0×109 cfu / ml. The fermentation cycle of the two-stage high-density fermentation is 32-48 hours.

Owner:SHANXI LUTU BIOTECH CO LTD

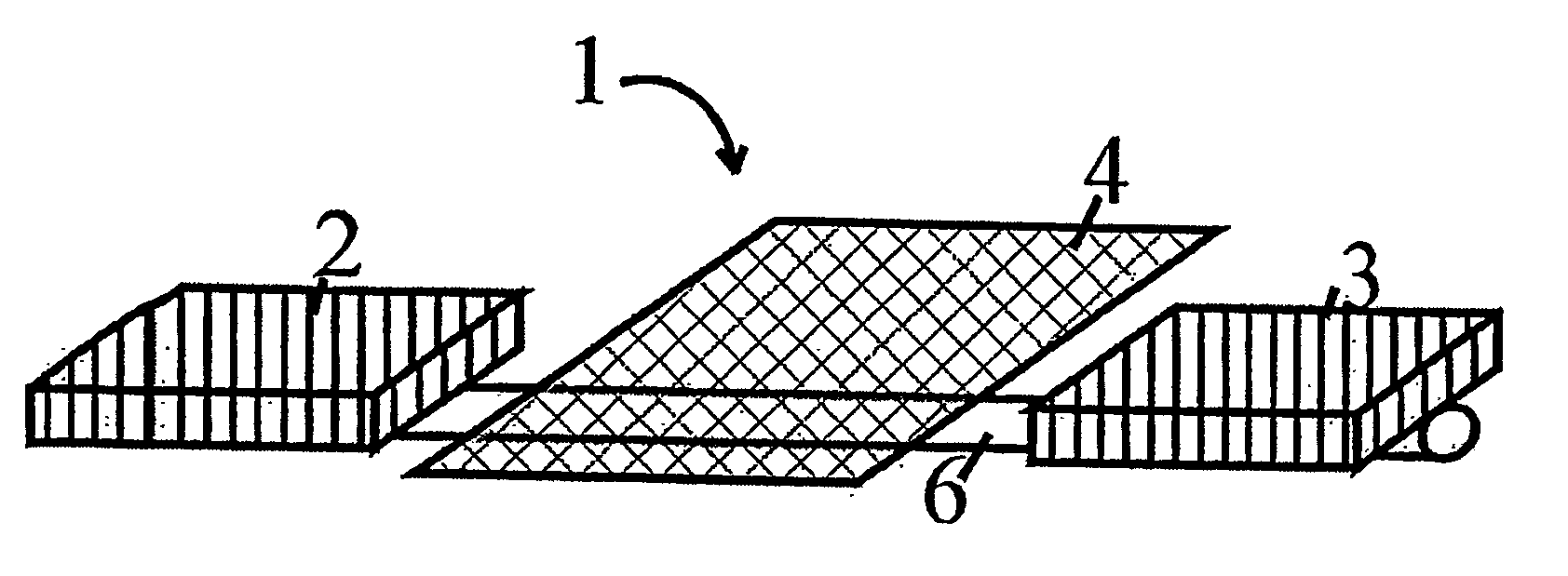

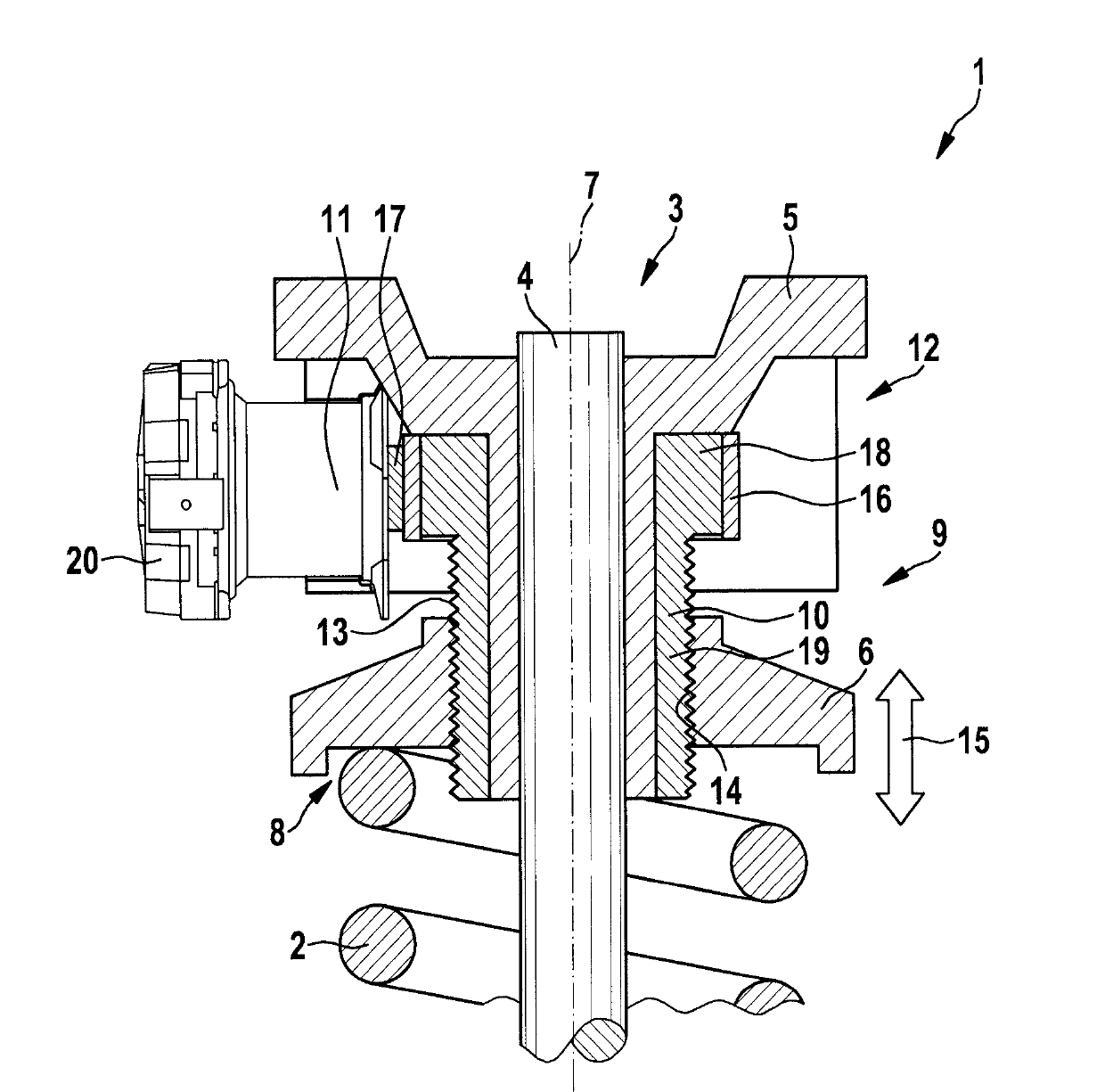

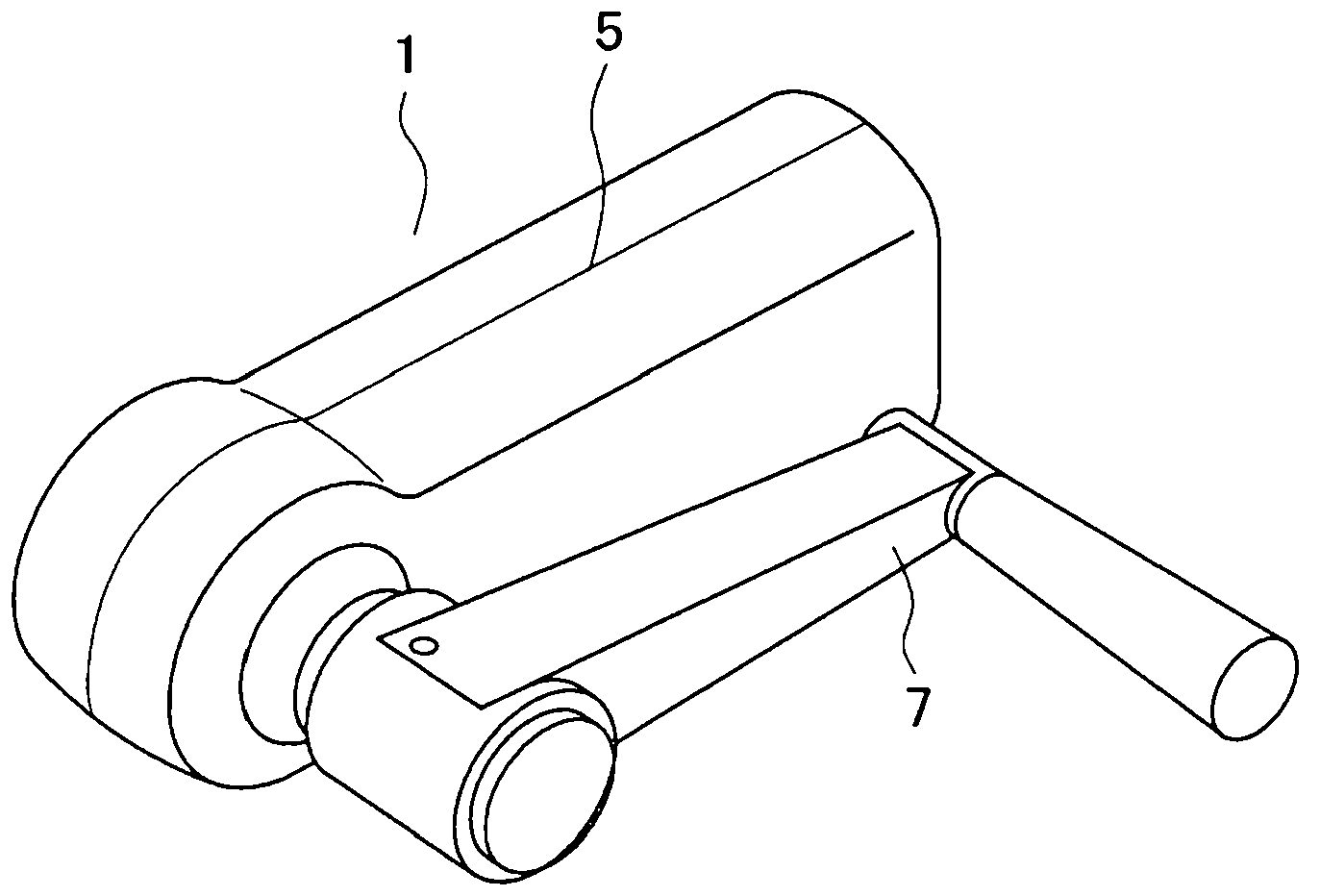

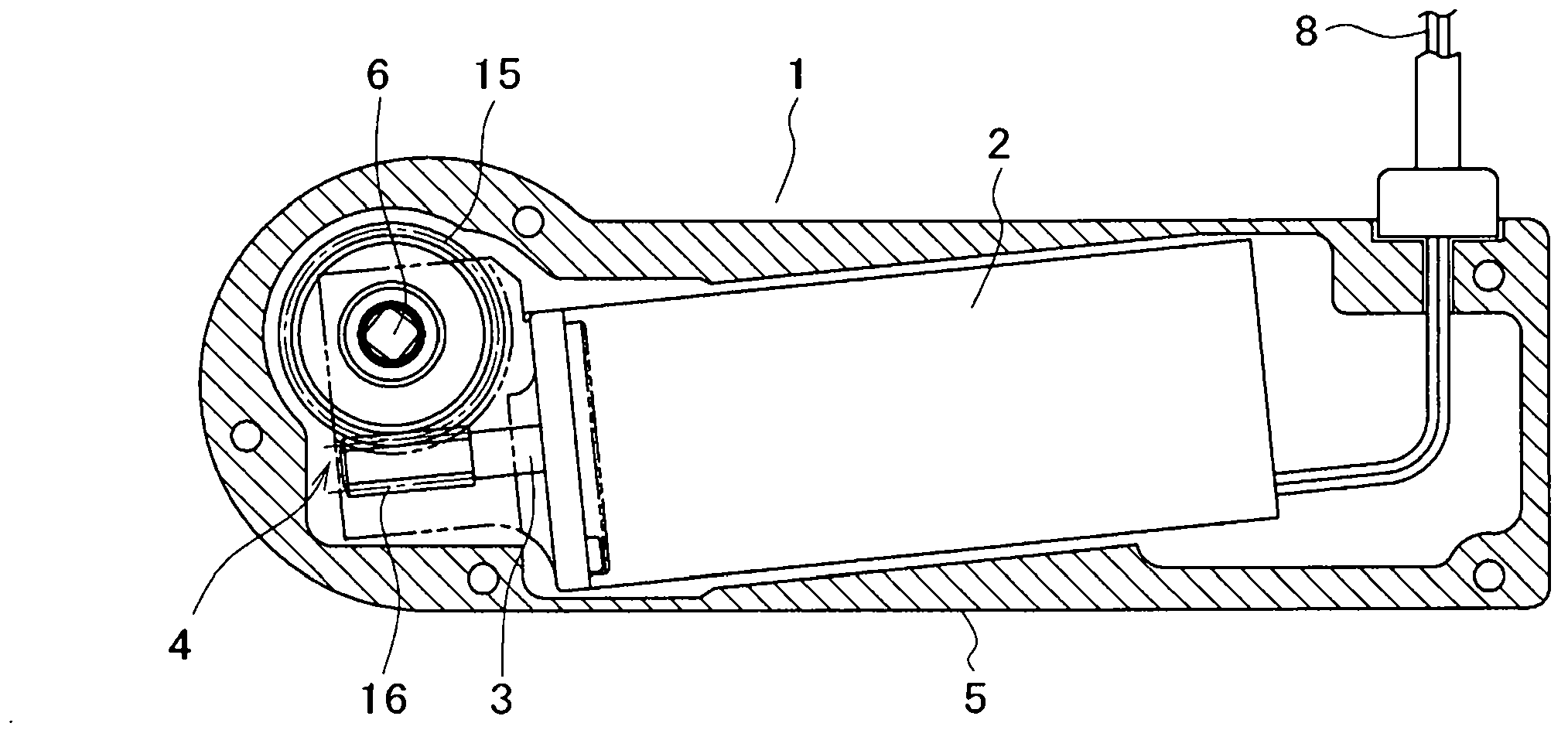

Suspension strut of a motor vehicle

InactiveCN103182917AGuaranteed runningReliable driving operationResilient suspensionsVehicle springsControl theoryPiston rod

The spring strut (1) has a spring element (2) and a damper (3), where the damper has a damper cylinder partially received over a damper piston. The spring element is coupled on one side at a coupling point (8) with a piston rod (4) and at another side at another coupling point with the damper cylinder. The piston rod is connected with damper piston. The former coupling point is present on a spring plate which is displaceable relative to the damper piston by an adjusting unit. The spring plate is fixed in the circumferential direction with respect to a longitudinal axis of the piston rod.

Owner:ROBERT BOSCH GMBH

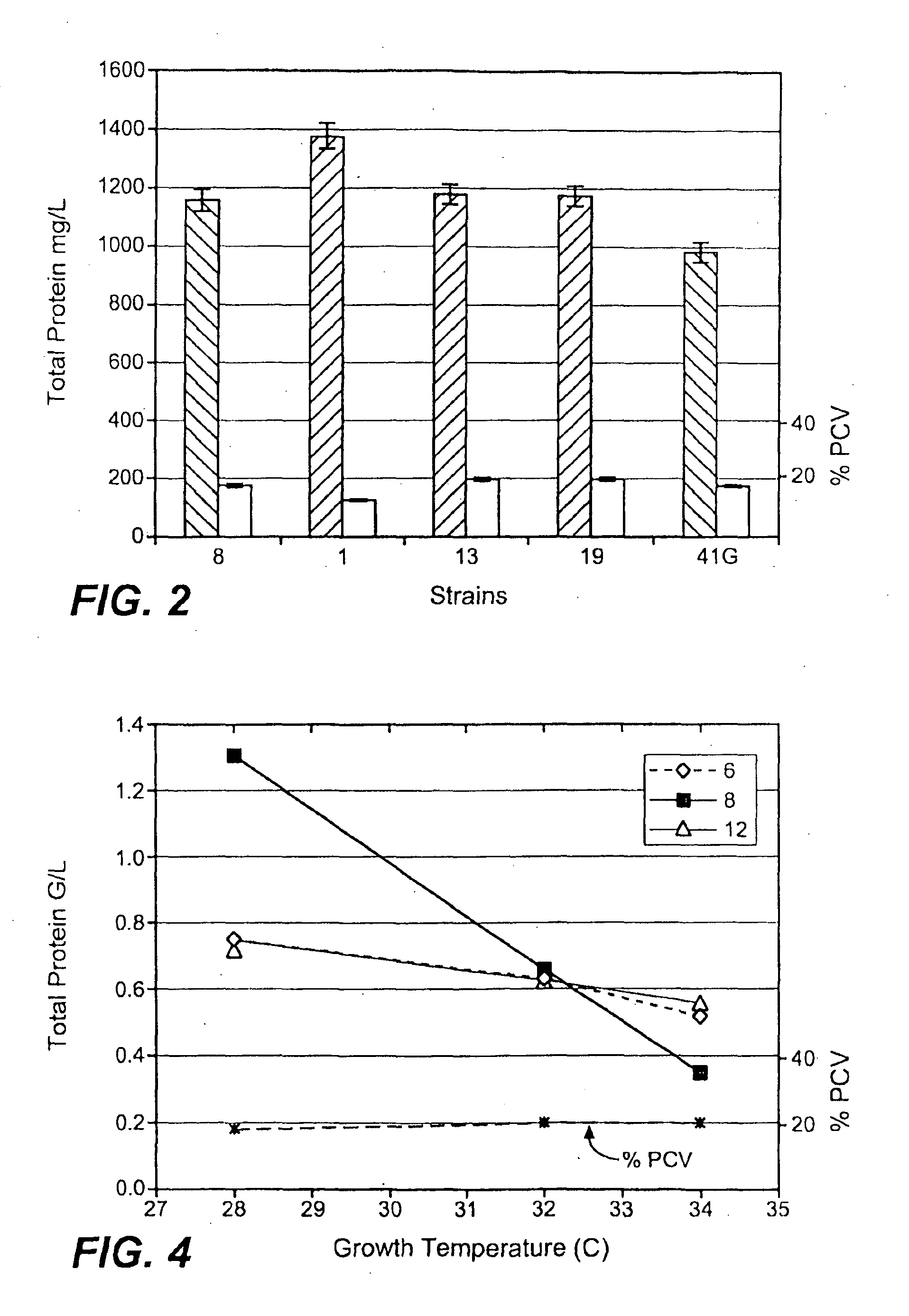

Methods for the production of hemagglutinating virus of Japan and adenovirus using cultured cells

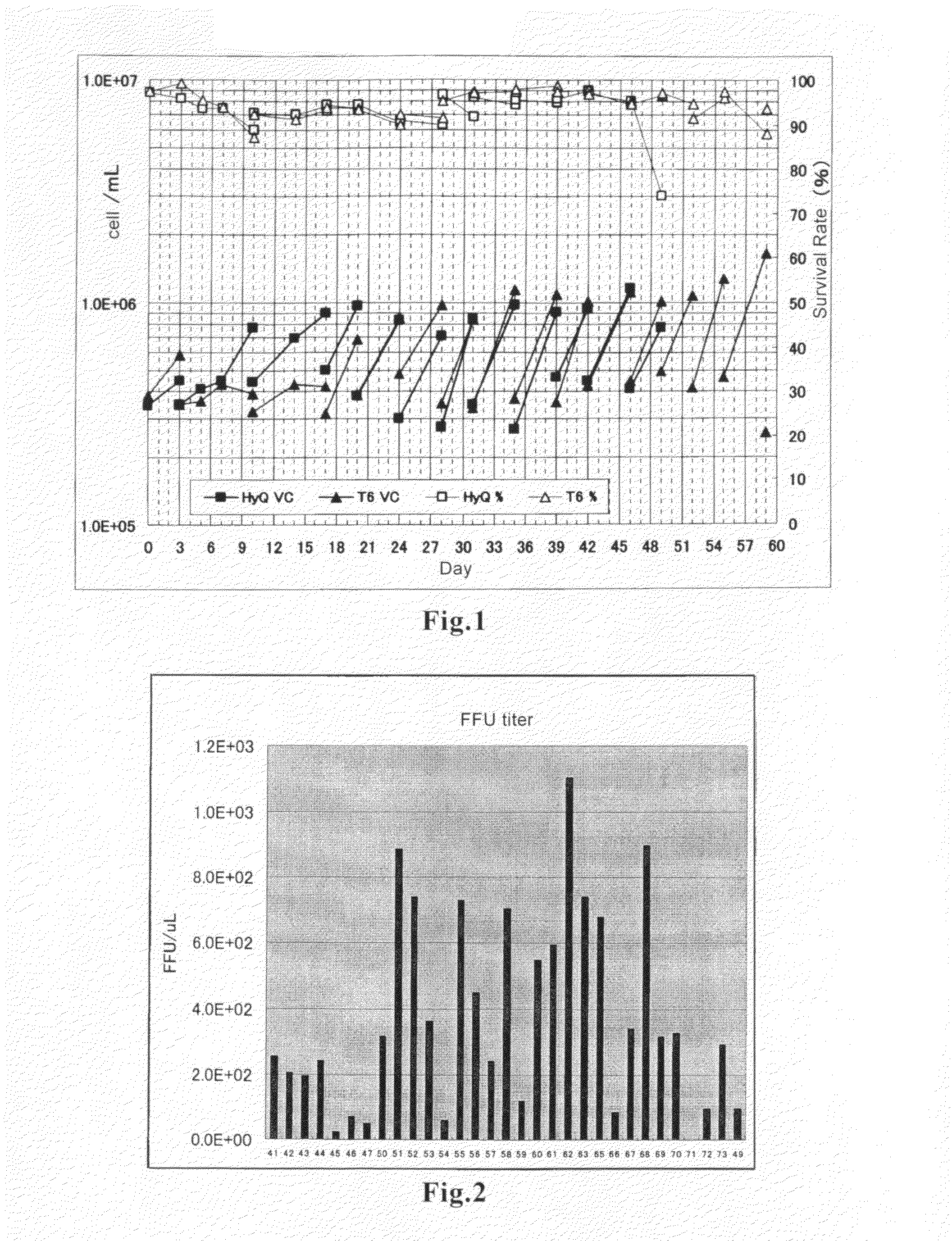

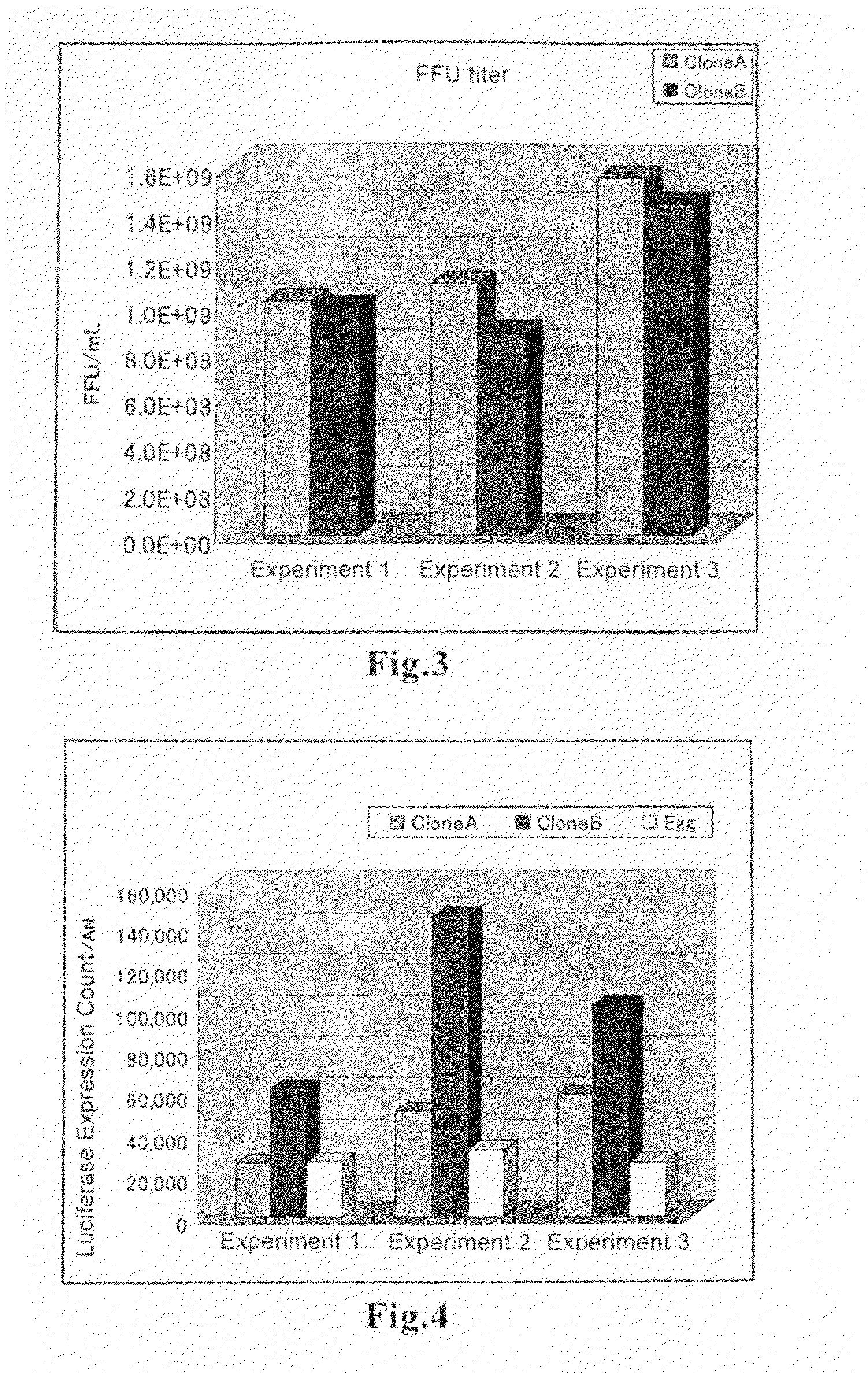

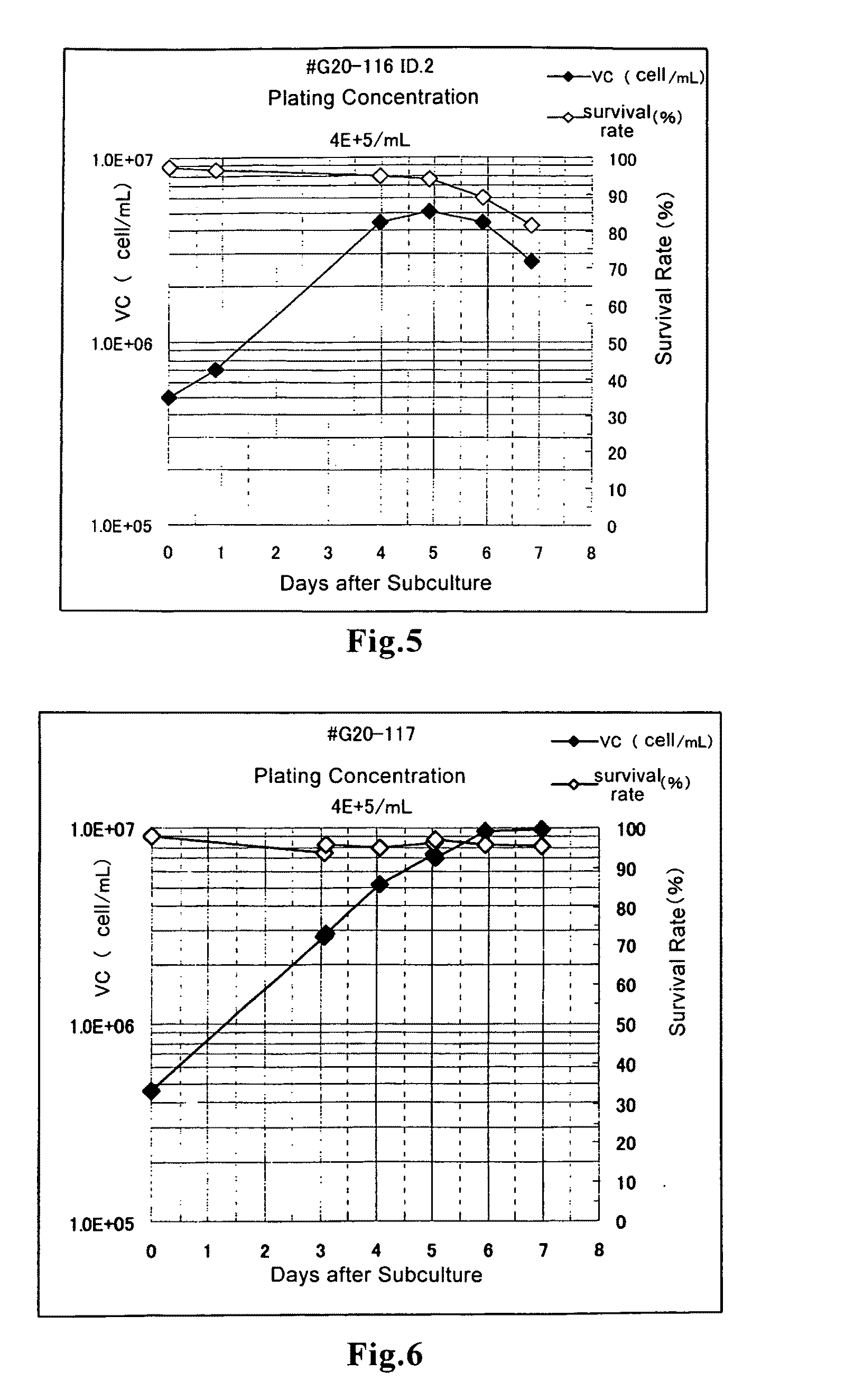

ActiveUS8012749B2Increase probabilityHigh densitySsRNA viruses negative-senseCulture processSerum free mediaDouble-time

A novel cell suited for mass production of Hemagglutinating Virus of Japan (HVJ), a method for obtaining the cell and use of the cell are disclosed. The human cell is originated from a transformed human kidney cell line, the doubling time thereof in logarithmic growth phase in suspension culture in a serum-free medium is not more than 40 hours, the cell has a freeze-recovery property, the maximum density of viable cells in suspension culture is not less than 106 cells / mL, and HVJ can grow in the cell. The method for obtaining the human cell comprises the steps of suspension-culturing a human transformed kidney cell line in a serum-free medium, and cloning the grown cells; and selecting, from the cloned cells, a cell whose doubling time in logarithmic growth phase in suspension culture in a serum-free medium is not more than 40 hours, which has a freeze-recovery property, whose maximum density of viable cells in suspension culture is not less than 106 cells / mL, in which HVJ can grow.

Owner:GENOMIDEA INC +1

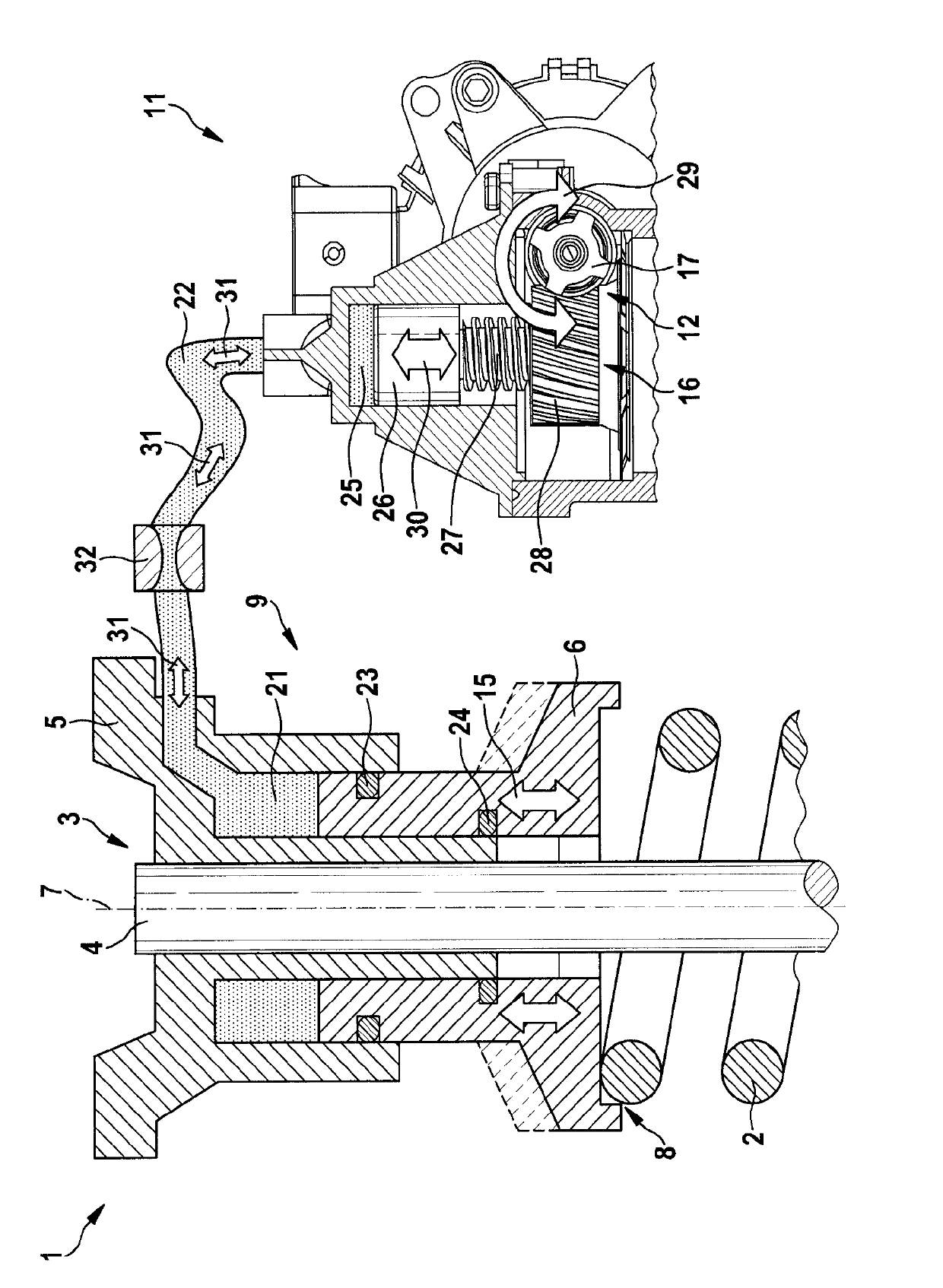

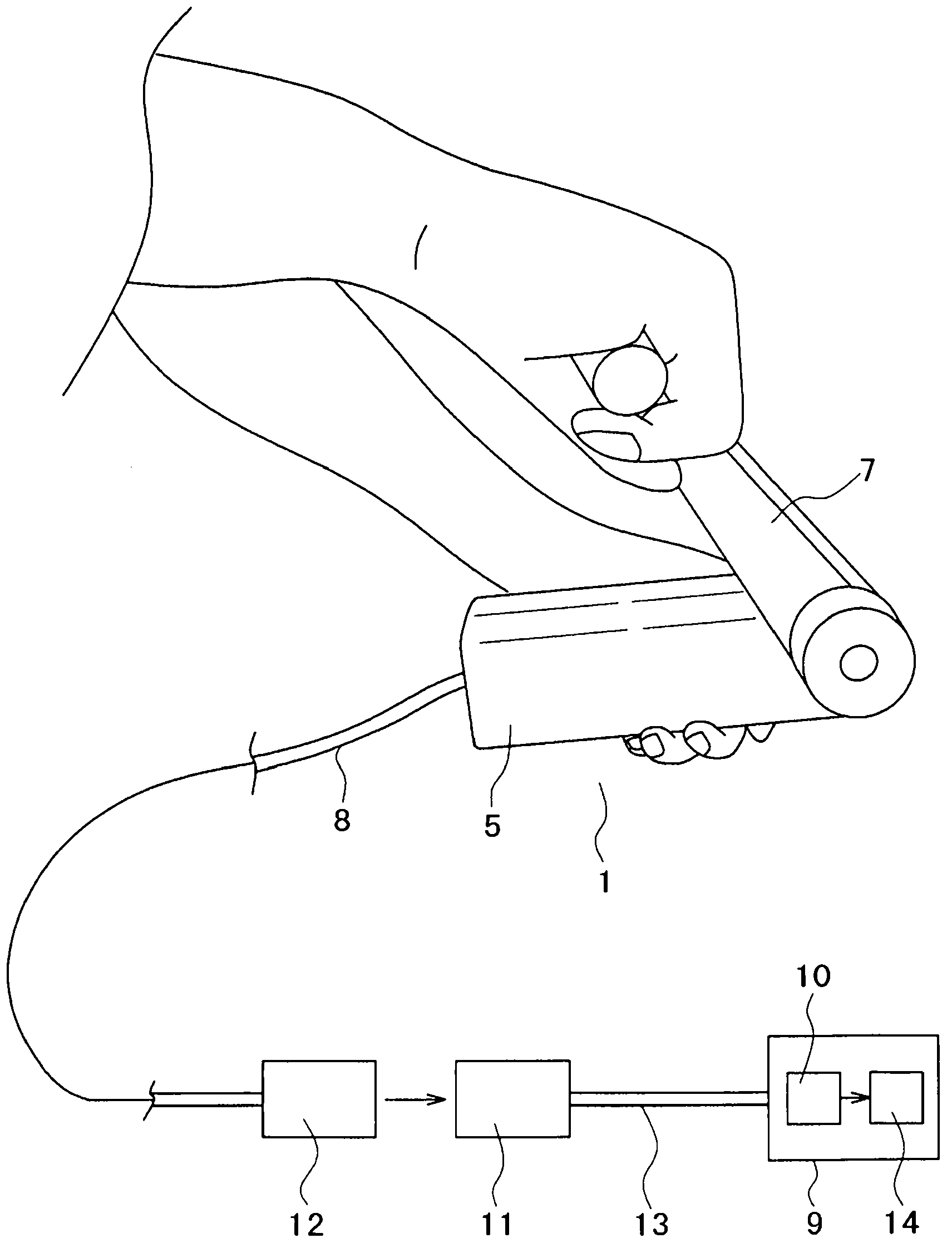

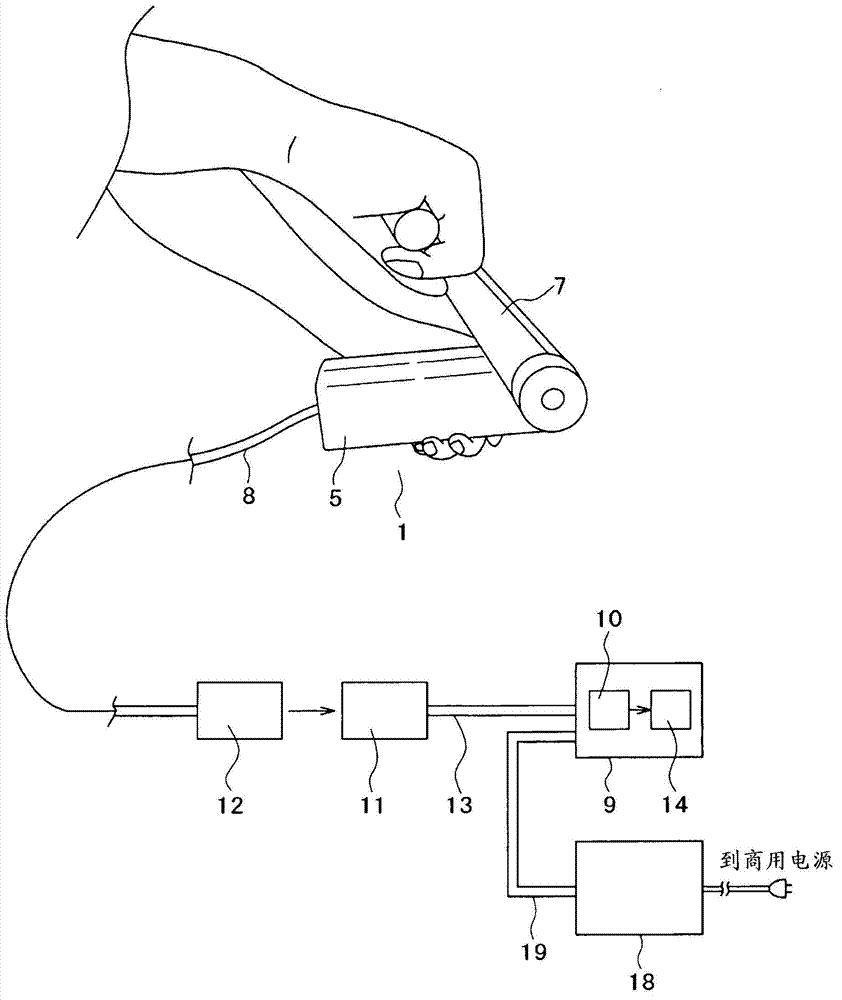

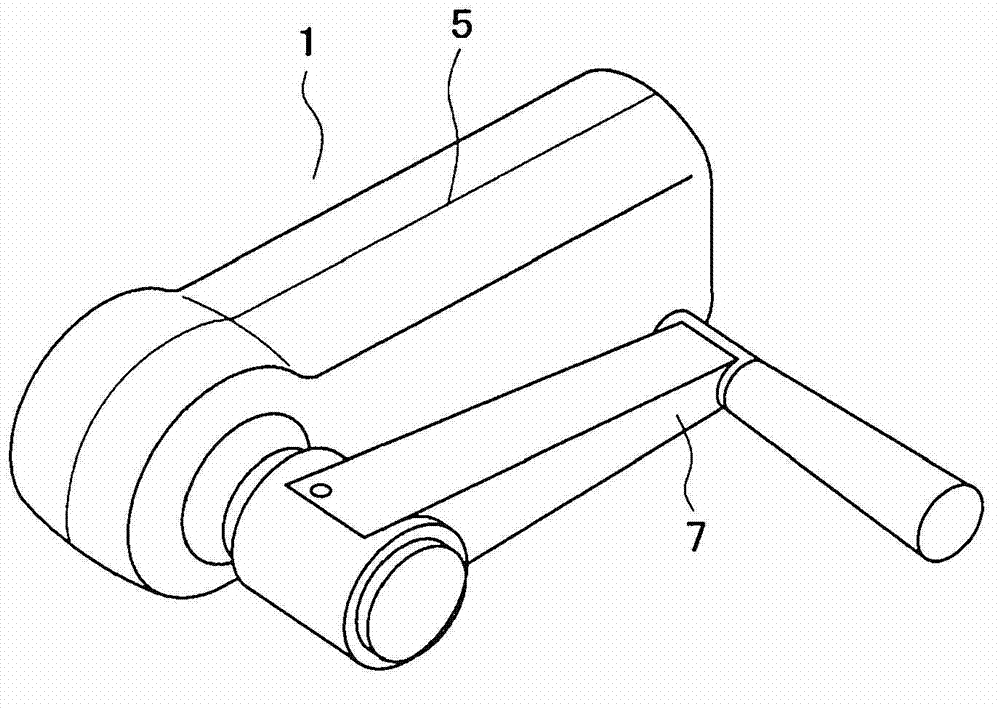

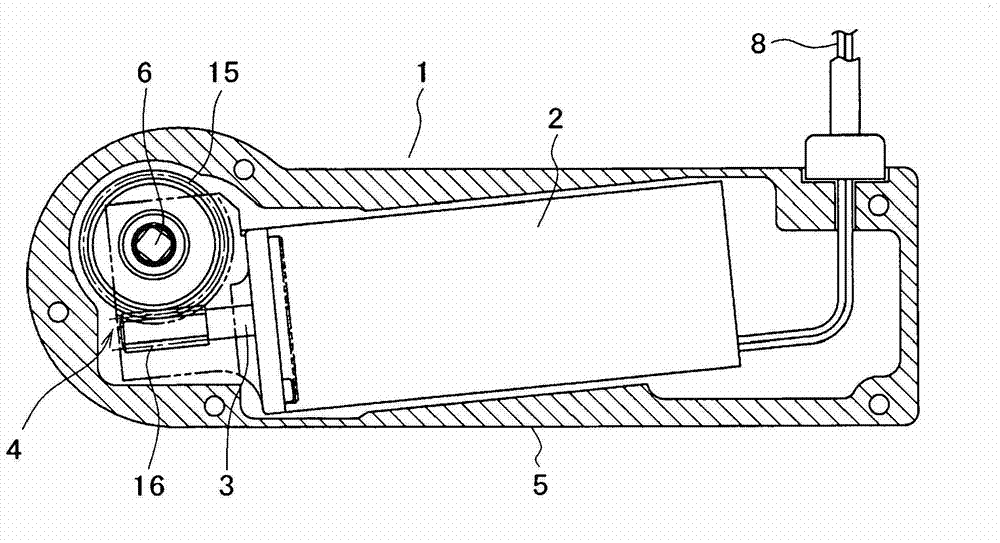

Manual power generation device for driving actuator, and actuator drive device

[Problem] To increase the applications for a manual power generation device for which applications were limited, and to make same more compact and lightweight. [Solution] In this manual power generation device: a direct-current motor (2) capable of reversible operation and an acceleration mechanism (4) connected to the rotation axis (3) thereof are housed in a container (5); a crank handle connected to an input shaft (6) for the acceleration mechanism (4) and a power supply cable (8) connected to the power-supply side of the direct-current motor (2) are provided on the outside of the container (5); and a connector connectable to a power supply-side connector in the direct-current motor configuring an actuator is provided on the tip side of this power supply cable (8). The acceleration mechanism (4) has greatly reduced size and weight, as a result of being configured by a worm gear mechanism having the crank handle (7) side as the worm wheel (15) and the direct-current motor (2) side as a multiple-thread screw worm (16).

Owner:PARAMOUNT BED CO LTD

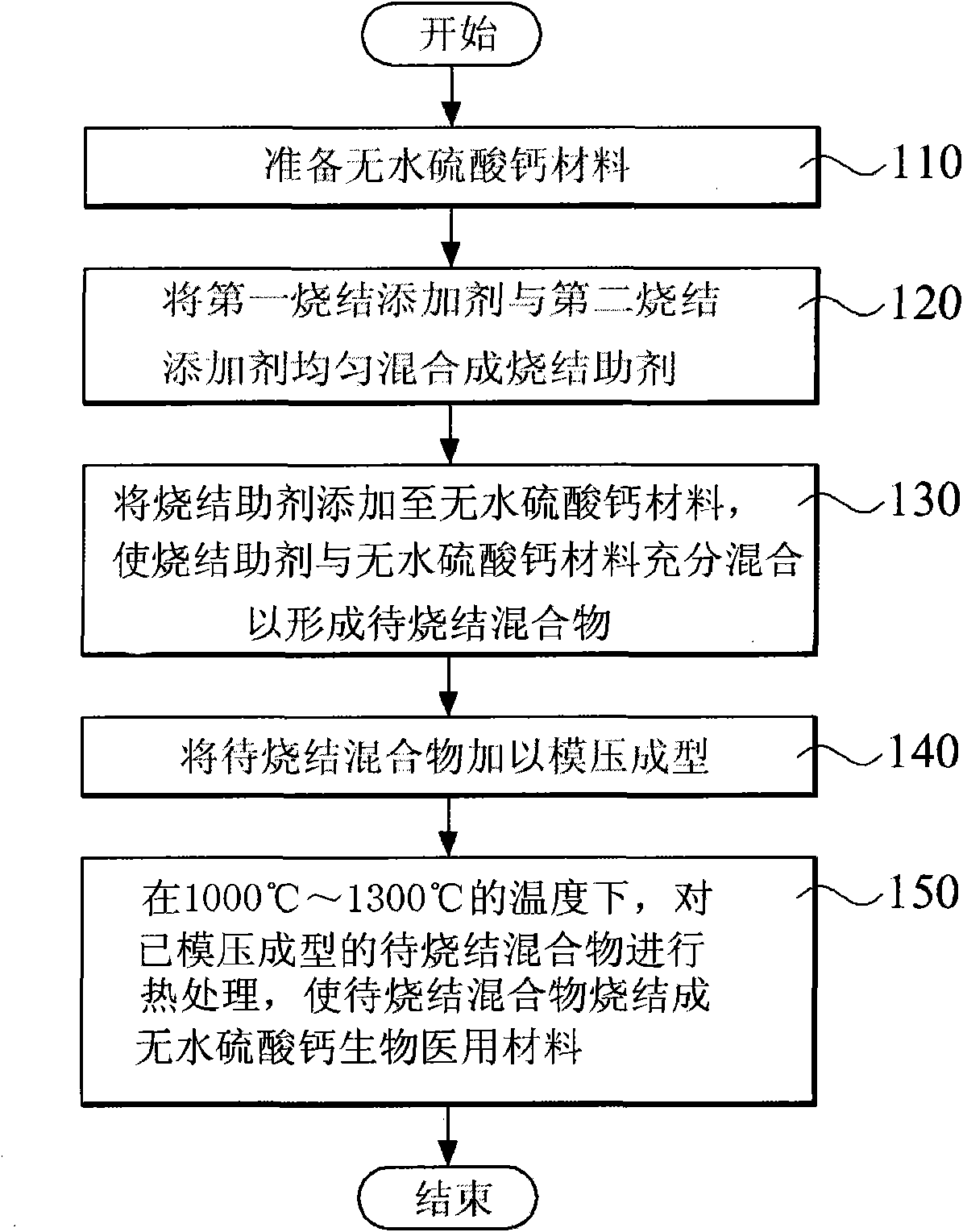

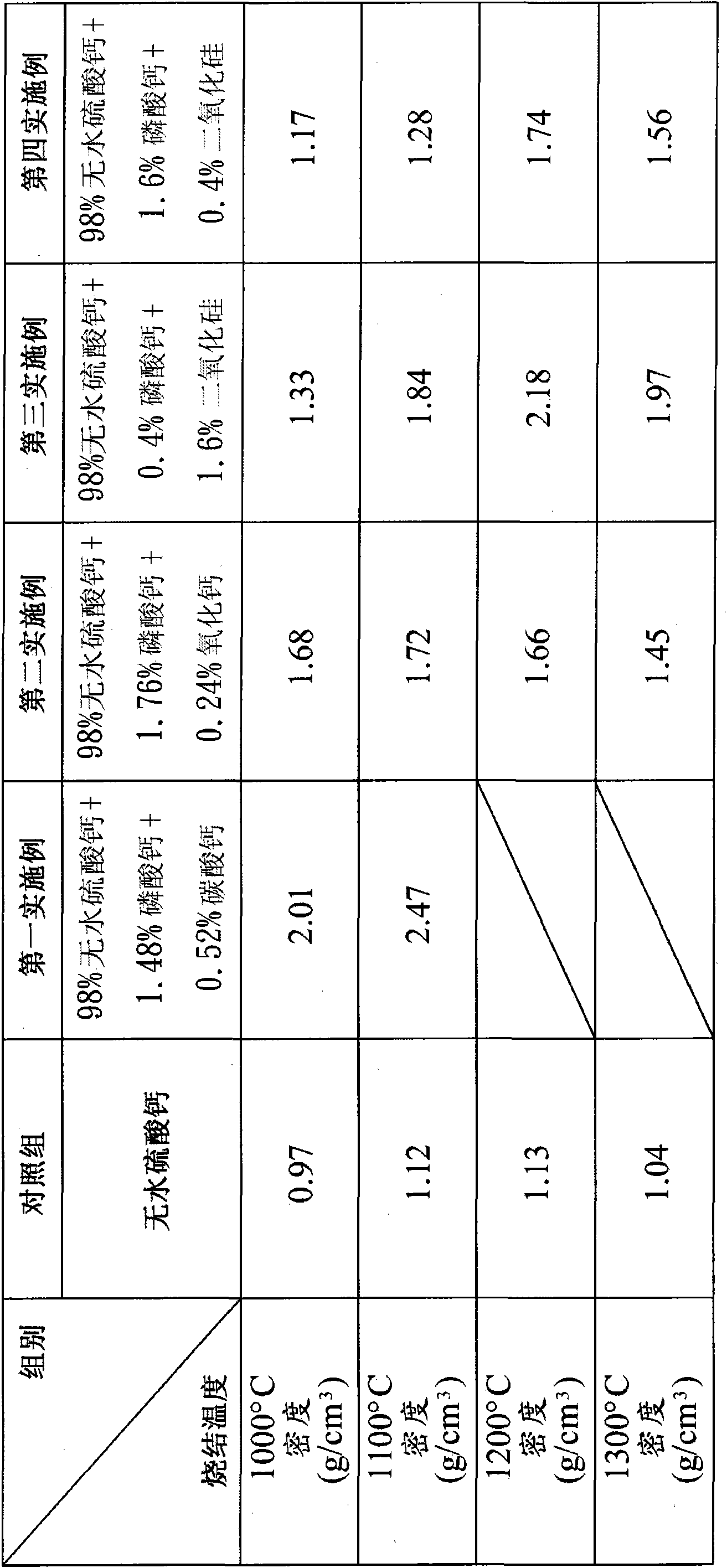

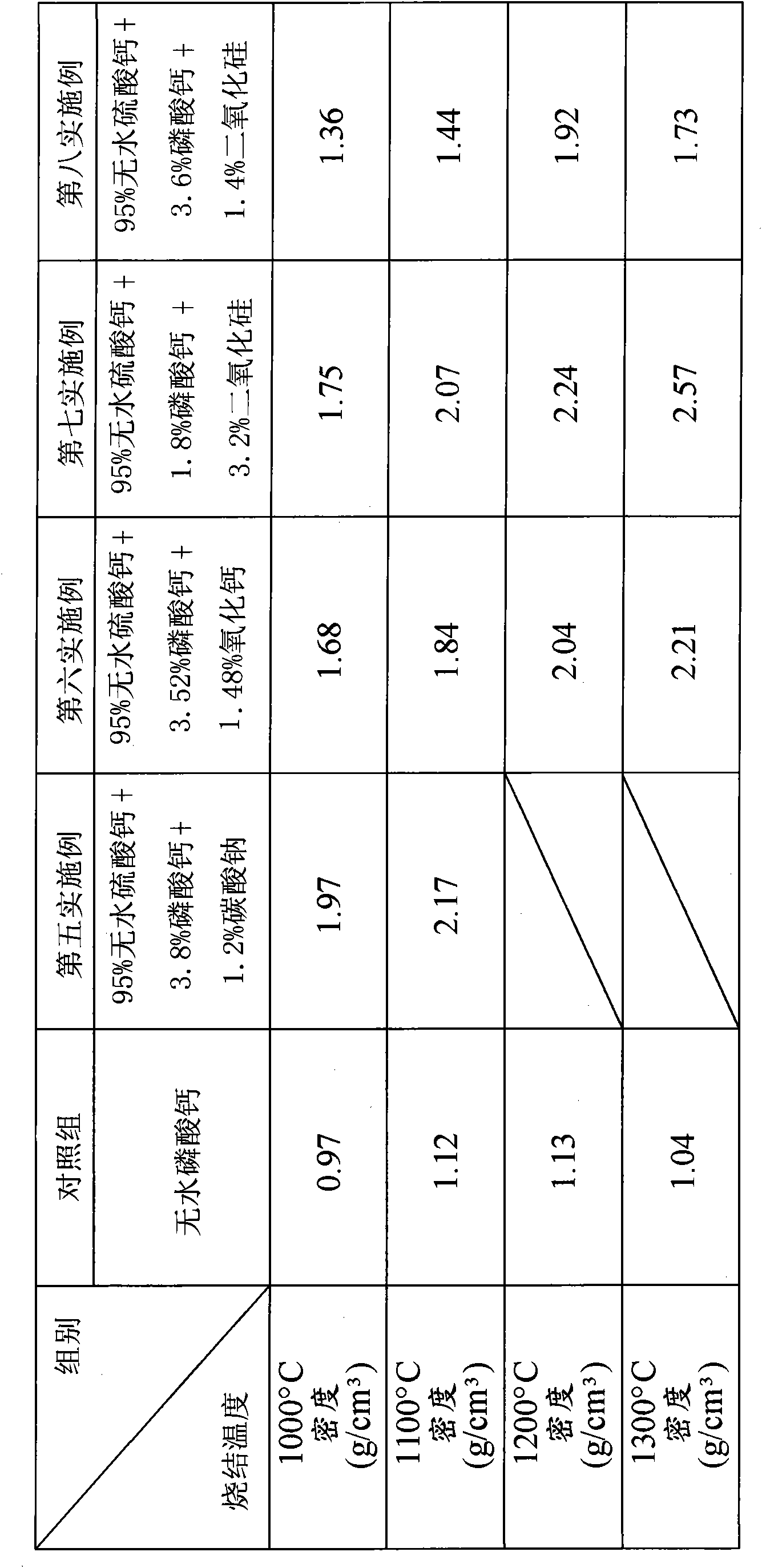

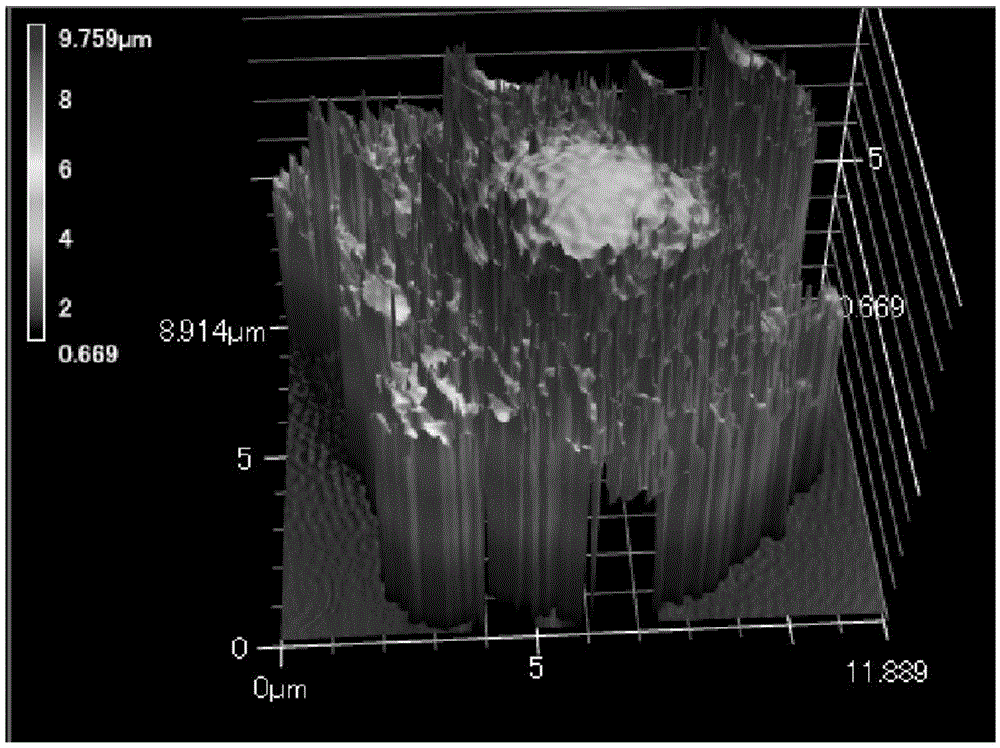

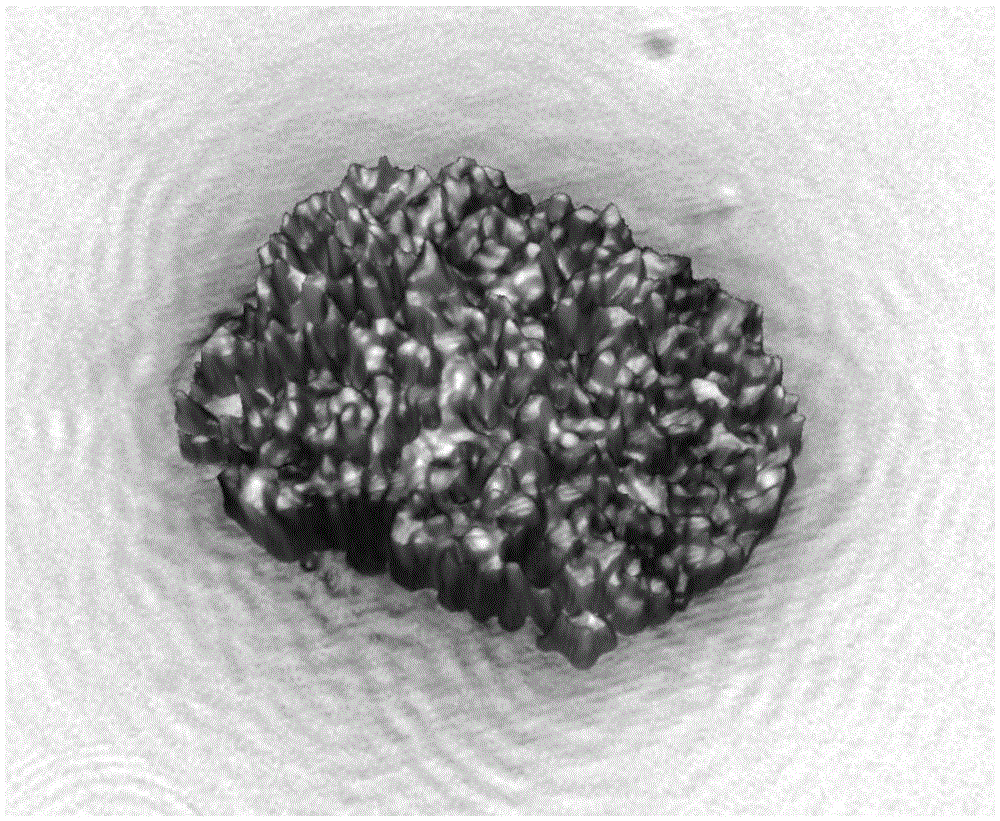

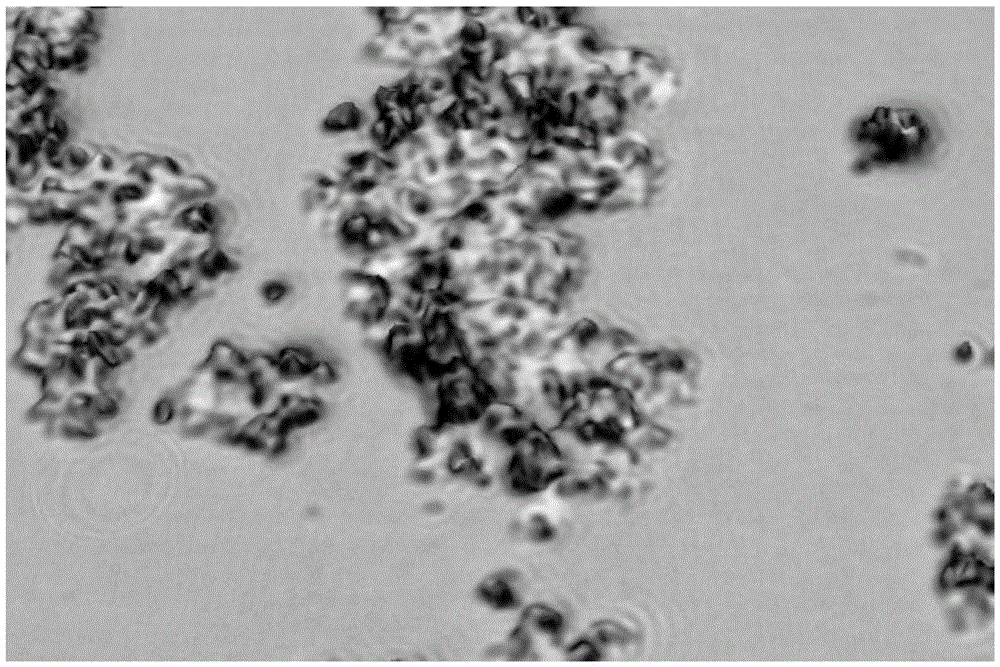

Method for sintering anhydrous calcium sulfate biomedical material

The invention relates to a method for sintering an anhydrous calcium sulfate biomedical material, which comprises the following steps of: preparing an anhydrous calcium sulfate material, and adding a sintering aid into the anhydrous calcium sulfate material, so that the sintering aid and the anhydrous calcium sulfate material are mixed fully to form a mixture to be sintered; performing compression molding on the mixture to be sintered; and performing heat treatment on the mixture which is subjected to the compression molding and is to be sintered, so that the mixture to be sintered is sintered to form the anhydrous calcium sulfate biomedical material. The sintering aid contains a first sintering additive and a second sintering additive, wherein the first sintering additive is formed by calcium phosphate, and the second sintering additive is formed by at least one of sodium carbonate, calcium oxide and silicon dioxide. The anhydrous calcium sulfate prepared by the method has excellent sintering capacity and high breaking strength and biologic compatibility, and the degradation rate of the anhydrous calcium sulfate biomedical material implanted into human bodies can be controlled.

Owner:林玉雪

Raw material for high-speed growth of silicon carbide crystals and silicon carbide crystal growing method

InactiveCN105603530AIncrease the amount of sublimationGood suspensionPolycrystalline material growthFrom condensed vaporsCrucibleSemiconductor

The invention relates to a raw material for high-speed growth of silicon carbide crystals and a silicon carbide crystal growing method, and belongs to the technical field of semiconductors. The raw material for high-speed growth of the silicon carbide crystals and the silicon carbide crystal high-speed growing method are provided for solving the problem that existing silicon carbide crystals are small in growing speed and low in efficiency. The raw material contains silicon carbide particles, the average particle size of the silicon carbide particles is smaller than 5 mum or at least two types of silicon carbide particles which are in different shapes and / or have different particle sizes are mixed to form a mixed raw material, and the raw material at last contains a type of silicon carbide particles with the average particle size smaller than 5 mum. The silicon carbide crystal growing method comprises the following steps: placing the raw material in a crucible; and heating the crucible and enabling the raw material in the crucible to be recrystallized after sublimating so as to obtain the silicon carbide crystals. The purpose of increasing sublimating speed and efficiency can be achieved.

Owner:TAIZHOU BEYOND TECH

Electric bed

The purpose of the present invention is to increase freedom of design because conventional electric beds had little freedom of design including the installation position of the crank handle. In this bed which uses an actuator having a rotational motion-to-linear motion conversion mechanism to raise a floor section and perform an undulating action, the rotating side of the rotational motion-to-linear motion conversion mechanism of the actuator is configured by a DC motor and a deceleration mechanism, and the bed has a configuration whereby power to the DC motor is selectively supplied by a controller (18) connected to a commercial power supply and a manual generator (1) driven by a crank handle (7). The manual generator houses the DC motor capable of reverse operation and an acceleration mechanism in a container (5), and has a configuration whereby a power supply cable (8) and the crank handle connected to the input shaft of the acceleration mechanism are provided on the outside of the container. The acceleration mechanism has greatly reduced size and weight, as a result of being configured from a worm gear mechanism using the crank handle side as a worm wheel and the DC motor side as a multiple-thread screw worm.

Owner:PARAMOUNT BED CO LTD

Hairy crab breeding method

InactiveCN105994074AHigh growth rateIncrease productionClimate change adaptationAnimal feeding stuffEcologyGrowth speed

The invention discloses a hairy crab breeding method. The hairy crab breeding method comprises steps as follows: selection of a pond, selection of juvenile crabs, management of the juvenile crabs and the like. According to the scheme, the hairy crab breeding method is scientific and reasonable, not only is growth speed of hairy crabs increased, but also the yield and the quality of the hairy crabs are improved.

Owner:SUZHOU CITY XIANGCHENG DISTRICT YANGCHENGHU TOWN JIANMEI AQUATIC PROD ECOLOGICAL CULTURE PROFESSIONAL COOP

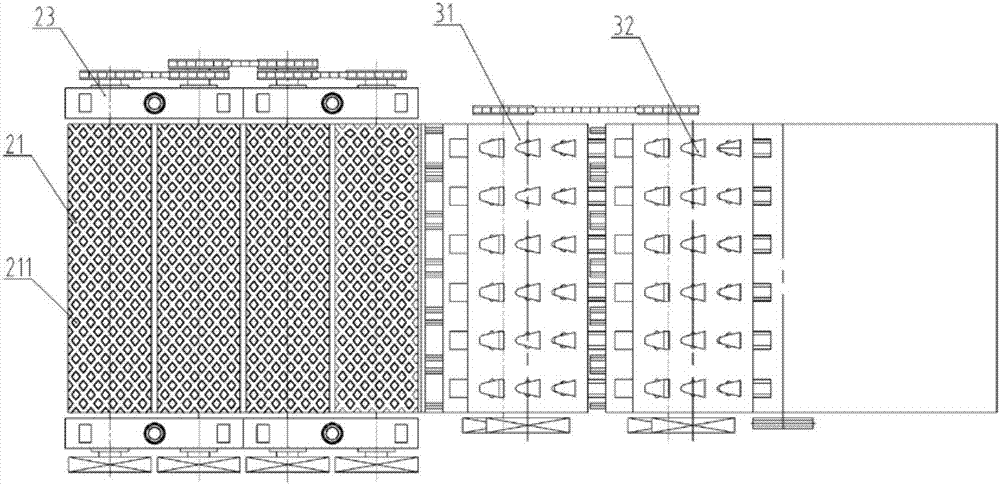

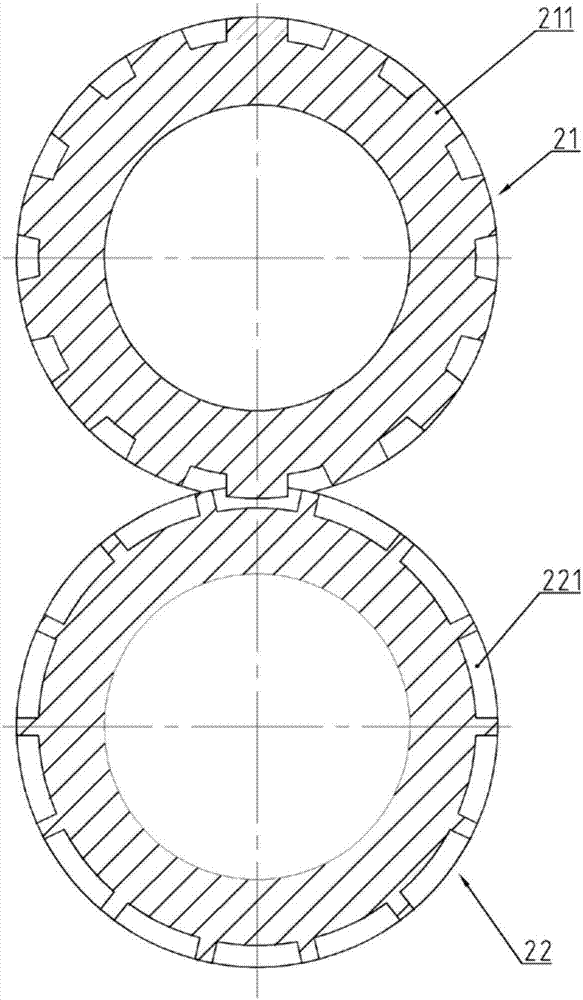

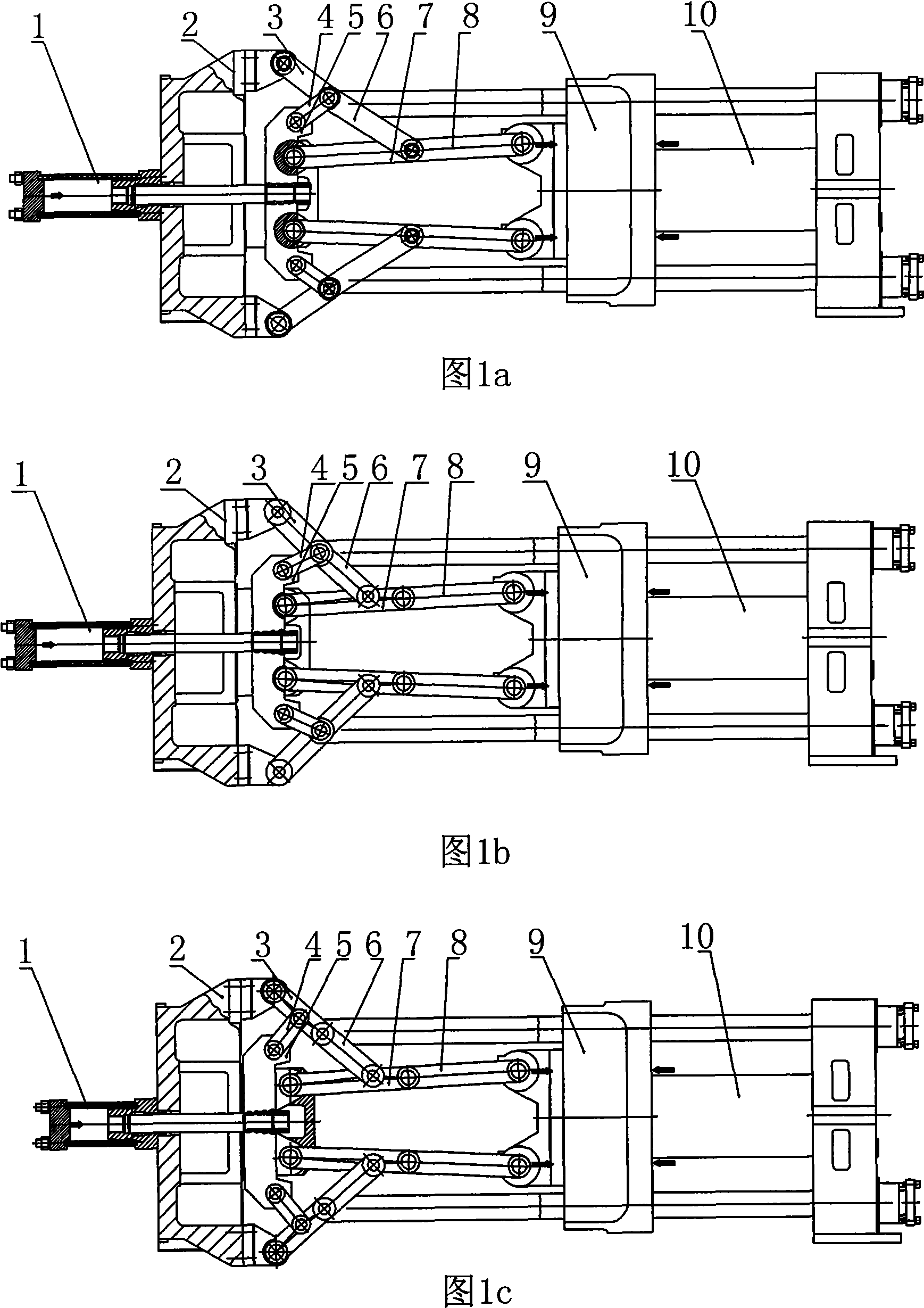

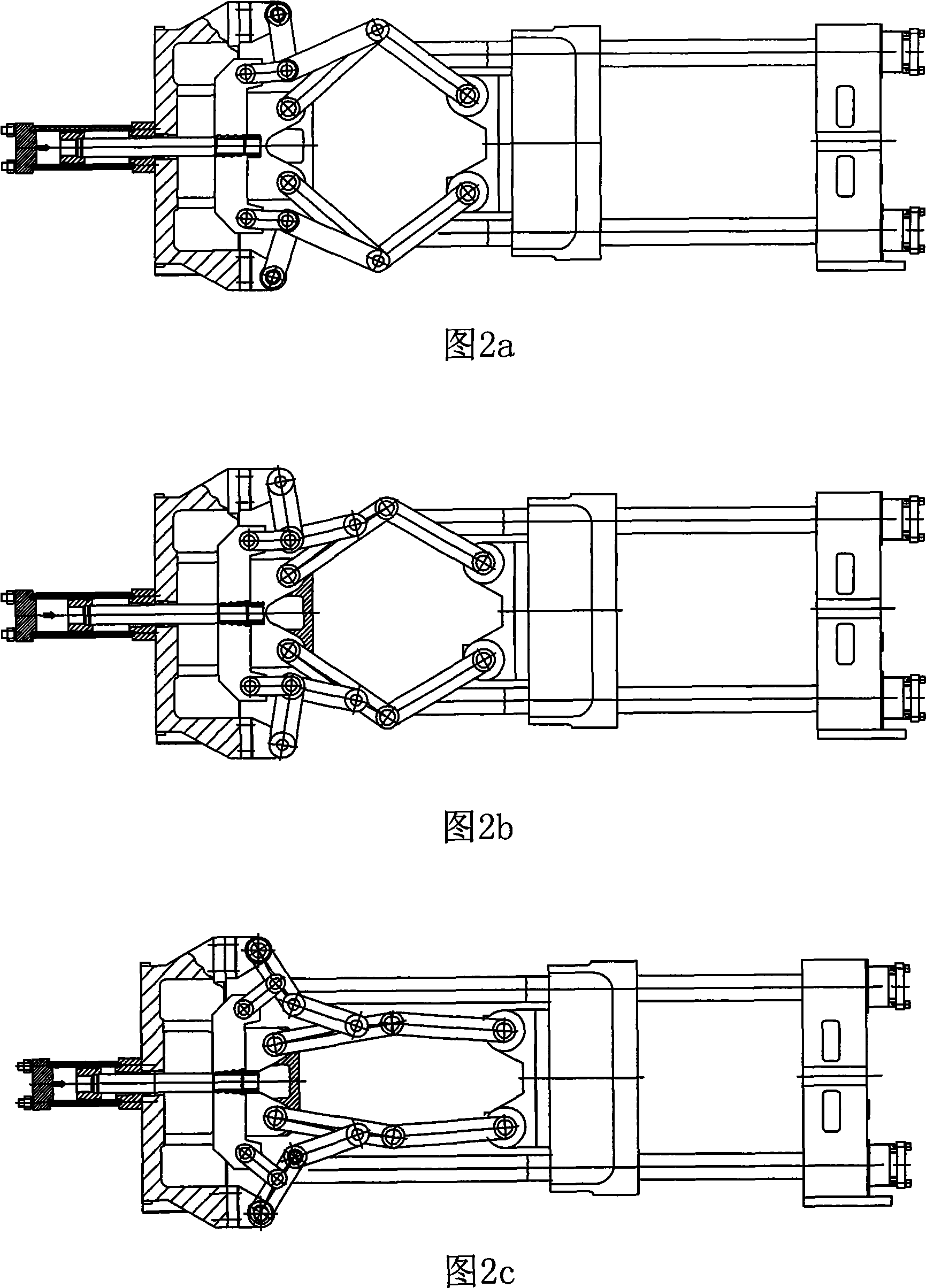

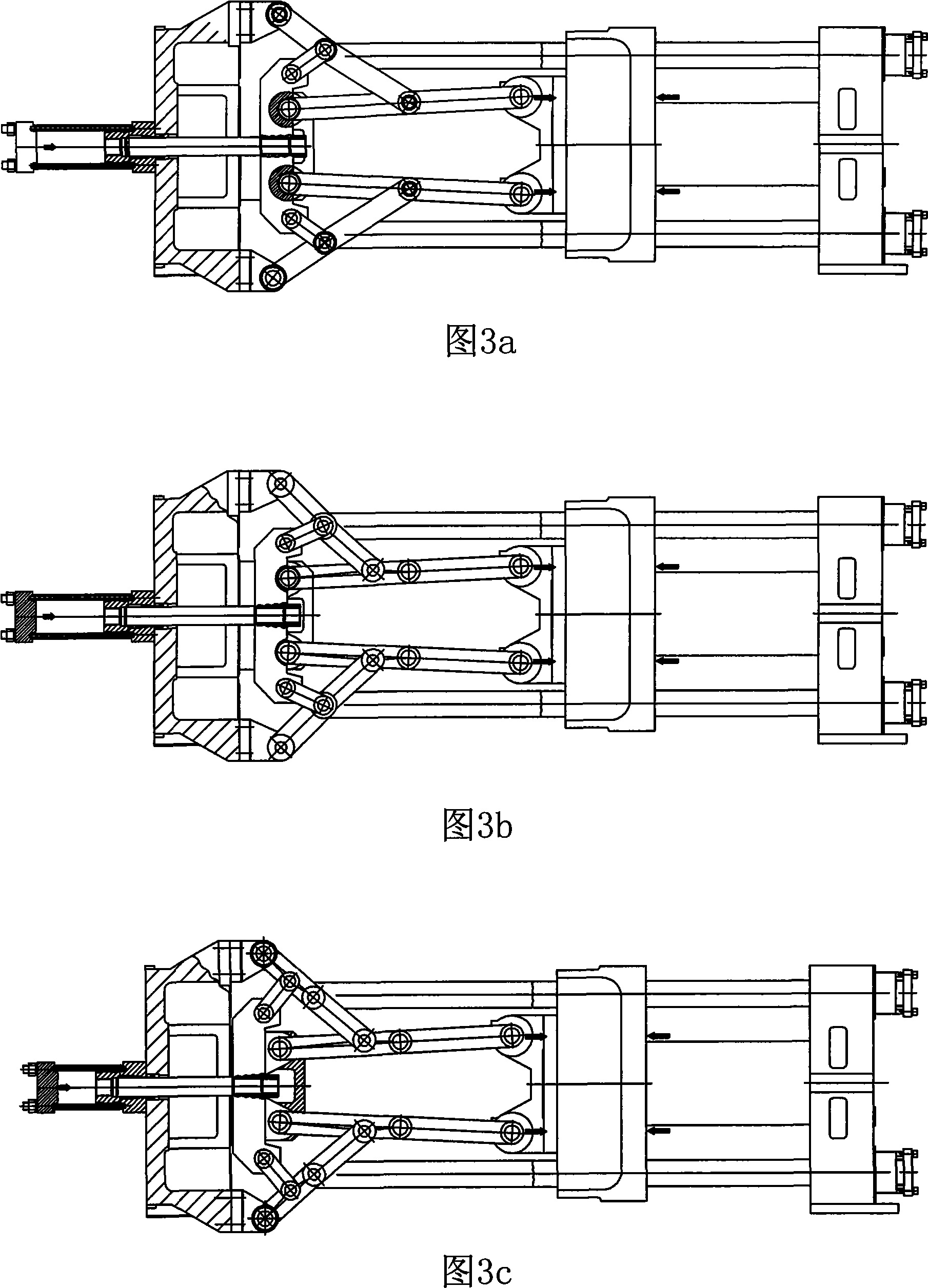

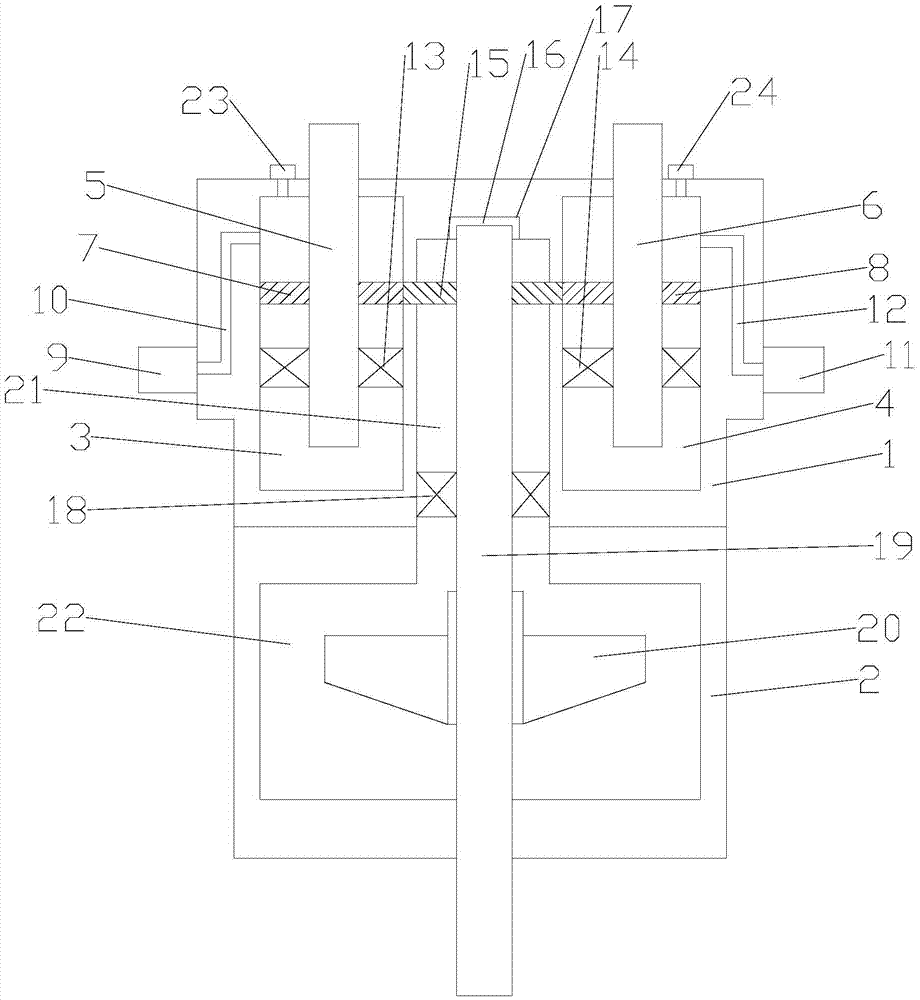

Porous series double-toggle inside and outside turning composite clamping mechanism and method

The invention relates to a clamping mechanism of an injection machine, in particular to a porous series double-toggle inside and outside turning composite clamping mechanism and a method. The clamping mechanism is designed aiming at the problems of nonuniform template stress and template moving speed and large impact force of the clamping mechanism of the prior injection machine field, and combines the advantages of a mechanical twisting locked mode and a hydraulic direct pressure locked mode. The design key point of the clamping mechanism is as follows: the clamping mechanism is provided with a plurality of rotating shaft hinge points respectively arranged at the intersections of an auxiliary toggle rod and an intermediate toggle rod as well as a rear toggle rod and a front toggle rod according to the number of hinge holes of the auxiliary toggle rod and the intermediate toggle rod, and is provided with 6, 7, 8 or more than 8 rotating shaft hinge points to lead the auxiliary toggle rod and the intermediate toggle rod as well as the rear toggle rod and the front toggle rod to from a straight line. The method is as follows: the intersections are formed into straight lines, and the high-pressure locked mode force is produced by inside and outside turning of toggles so as to achieve the purposes for quickly moving the modes, reasonably matching the mechanism rigidity, shortening the cylinder stroke and lowering the template weight. The invention is suitable for the development and the upgrading reconstruction of the precise injection machine.

Owner:NINGBO HAIDA PLASTIC MACHINERY

Soft PVC (Poly Vinyl Chloride) plasticizer

The invention discloses a soft PVC (Poly Vinyl Chloride) plasticizer prepared from the following components in parts by weight: 10-20 parts of fatty acid methyl ester, 20-30 parts of epoxy fatty acid methyl ester, 5-8 parts of benzoic acid, 5-10 parts of ethylene glycol, 3-5 parts of carbonyl diamine, 5-8 parts of soluble polyvinyl alcohol and 2-6 parts of epoxy soybean oil. The soft PVC plasticizer disclosed by the invention has the advantages of no toxicity, environment friendliness, good compatibility with PVC resin, high plasticizing efficiency and favorable durability.

Owner:QINGDAO HUARUI RUBBER IND EQUIP

Artificial snake raising feed and preparation method thereof

The present invention discloses an artificial snake raising feed and a preparation method thereof. The snake feed is prepared from the following raw materials in parts by weight: dry silkworm chrysalis, marine fish, duck skeleton, compound vitamins and Chinese herbal medicines. The Chinese herbal medicines consist of herba houttuyniae, eucalyptus robusta leaves, herba ecliptae, andrographis paniculata and ficus concinna. The preparation method provides a snake feed which is nutritionally comprehensive, also can prevent snake pneumonia, and enables the rapid growth of snakes.

Owner:韦有任

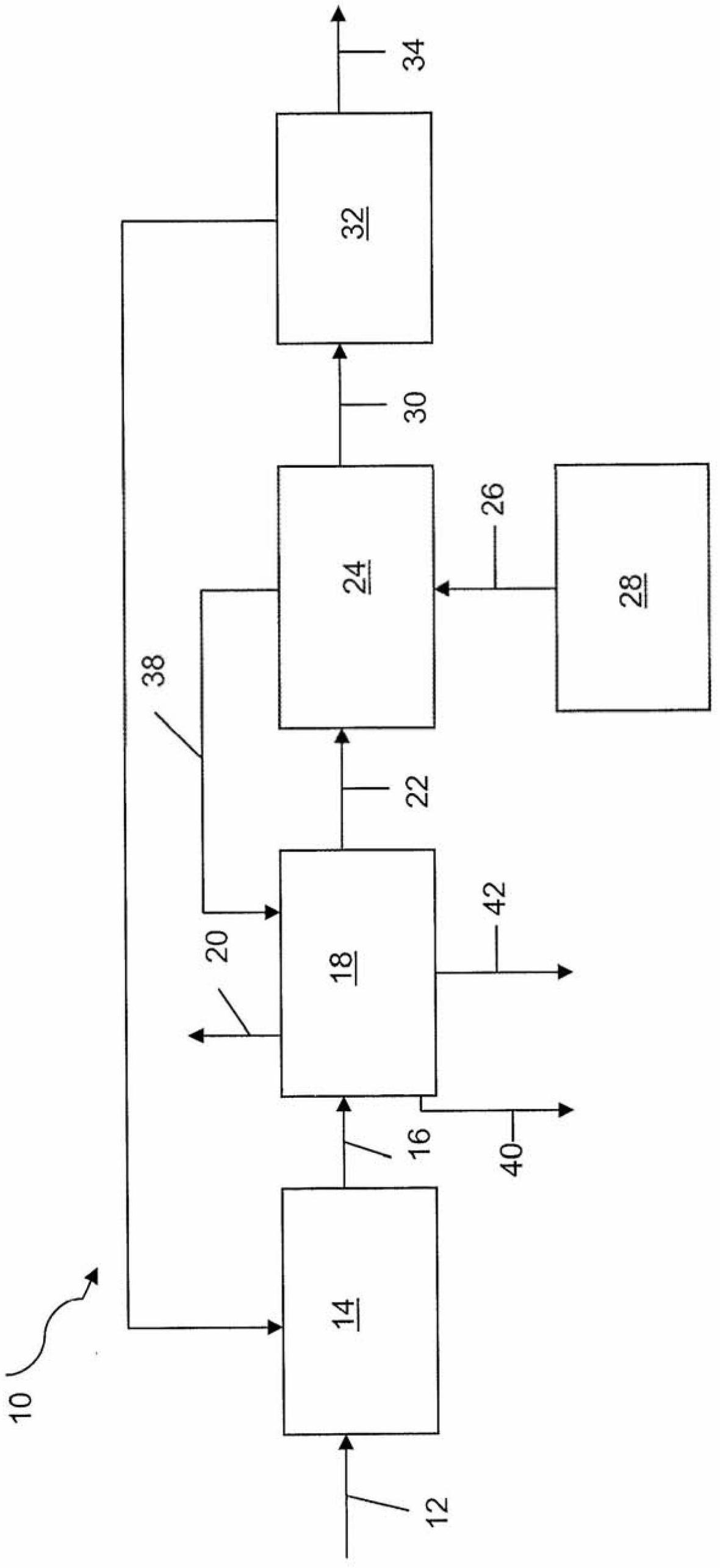

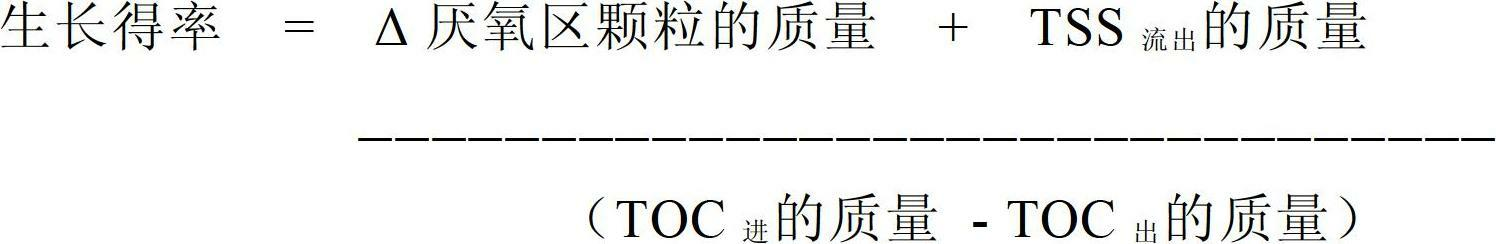

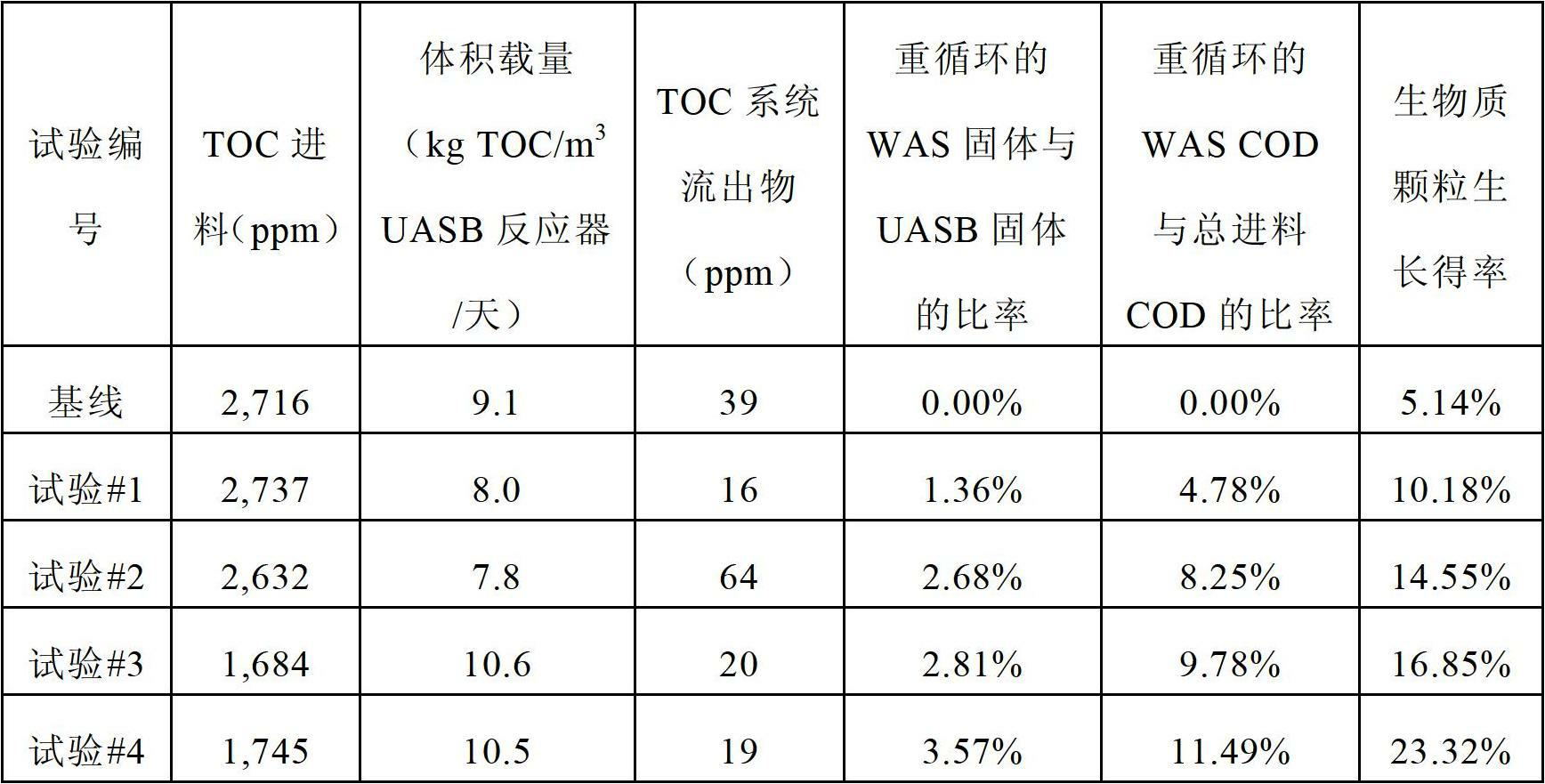

Methods and systems for producing granules of biomass in the treatment of wastewater

InactiveCN102695680AHigh growth rateSpecific water treatment objectivesWater contaminantsActivated sludgeOxygen

The method for treating wastewater, comprising treating wastewater in an anaerobic zone to remove organic matter from the wastewater in an anaerobic zone to remove organic matter from the wastewater and to form granules of a biomass; transferring wastewater effluent from the anaerobic zone to an aeration zone; treating the wastewater effluent with a source of oxygen and an activated sludge in the aeration zone to further remove organic matter from the wastewater effluent and to form additional activated sludge; and transferring a portion of the activated sludge from the aeration zone to the anaerobic zone.

Owner:BP CORP NORTH AMERICA INC

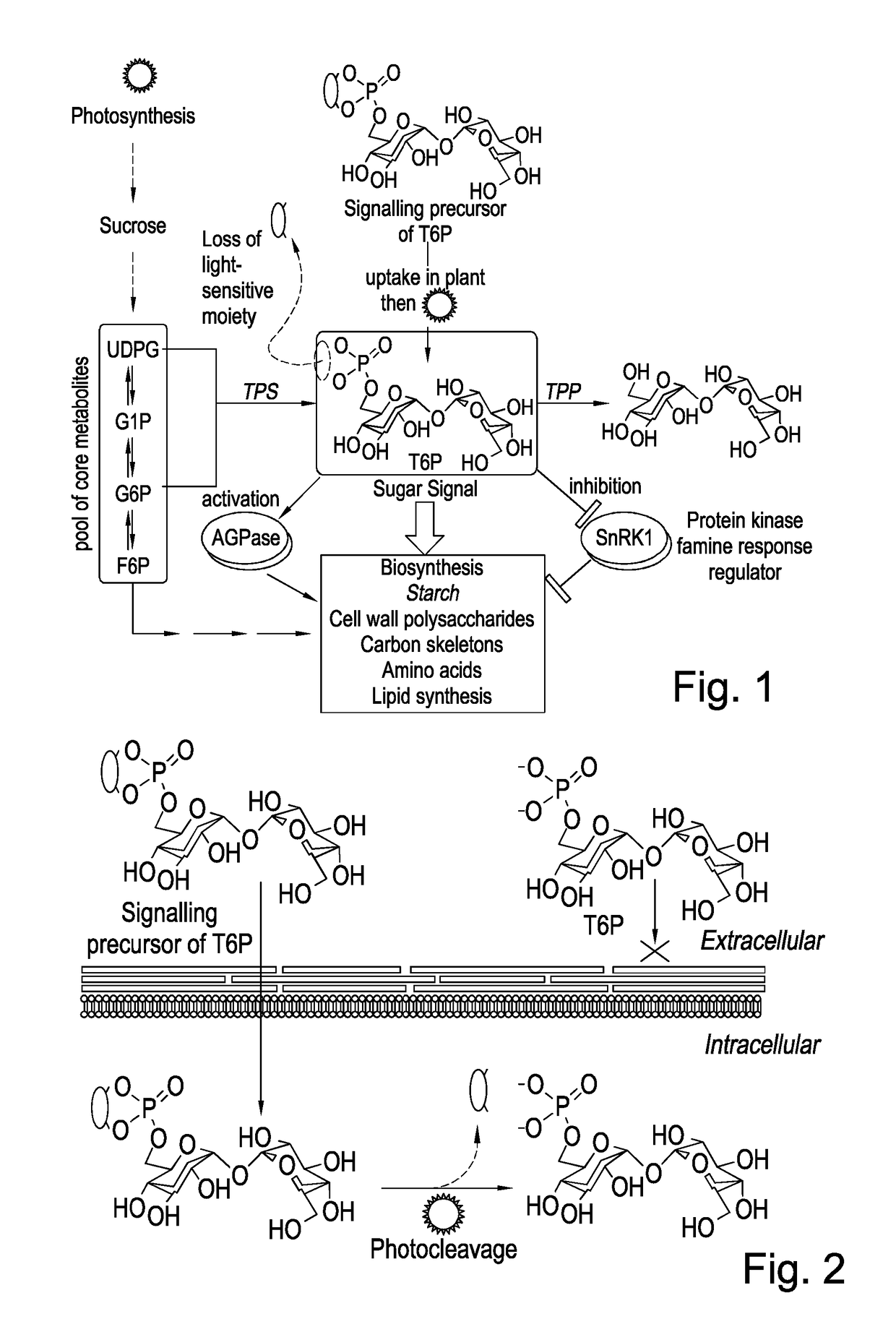

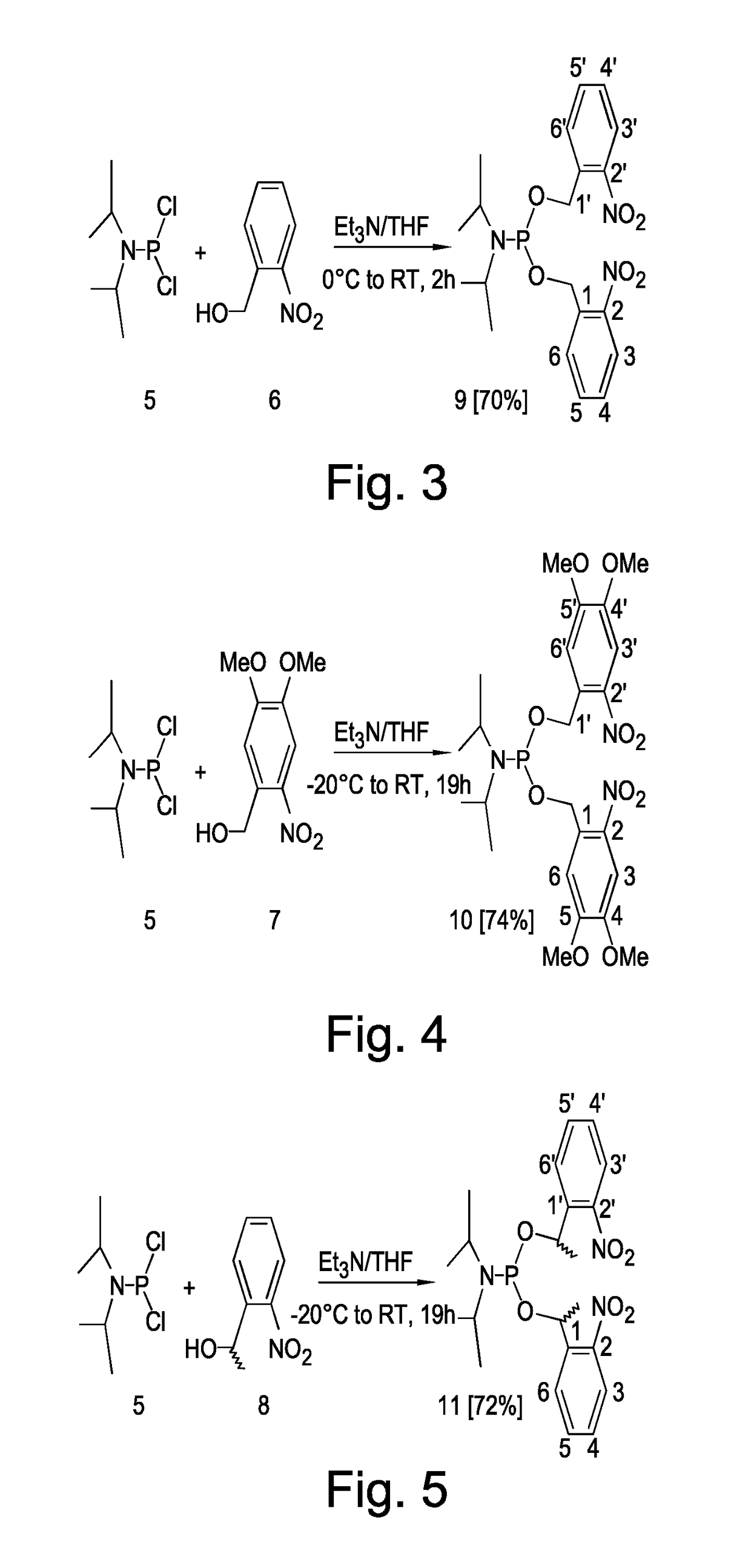

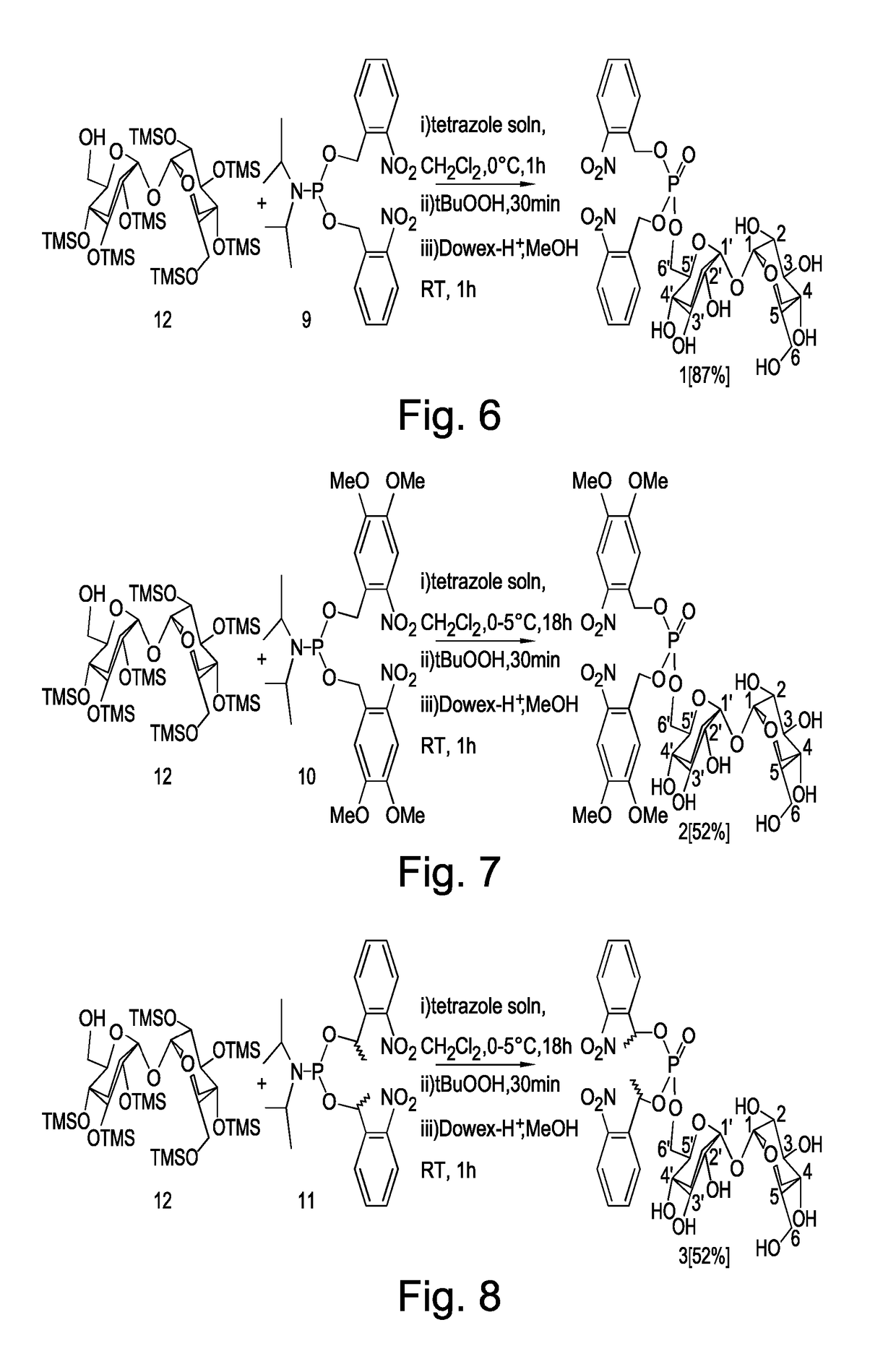

Treating water stress in plants

ActiveUS20180213793A1Increase productionRelieve pressureEsterified saccharide compoundsBiocidePhosphoric acidCrop

The present invention relates to methods and uses of photo-labile compounds which are trehalose-6-phosphate or trehalose-6-phosphonate or agriculturally acceptable salts thereof in the treatment of water stress in plants. The invention also concerns methods and the use of the compounds for resurrection of water stressed plants, and for improvement of yield of crop plants under water stressed conditions compared with untreated plants.

Owner:ROTHAMSTED RES LTD

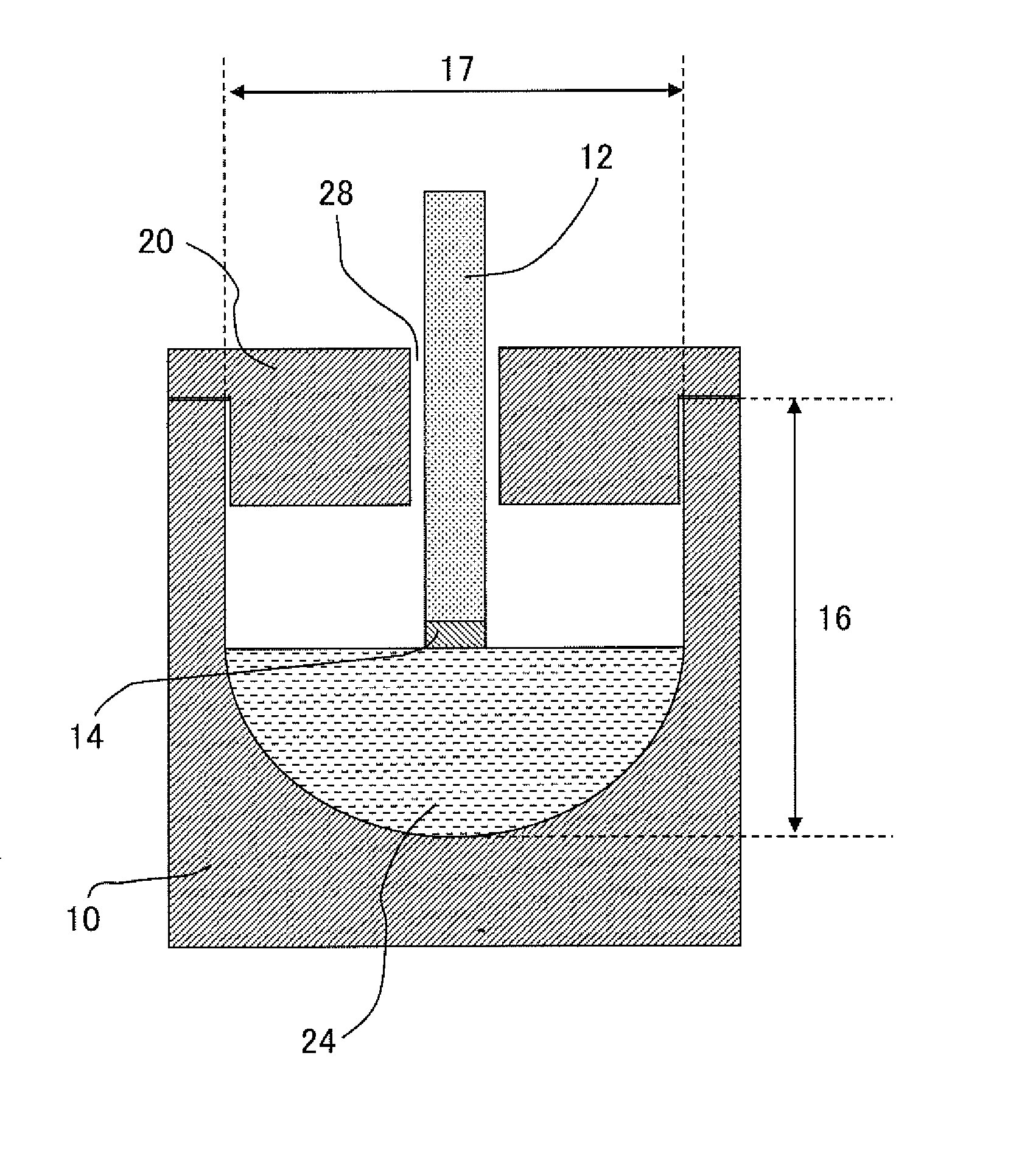

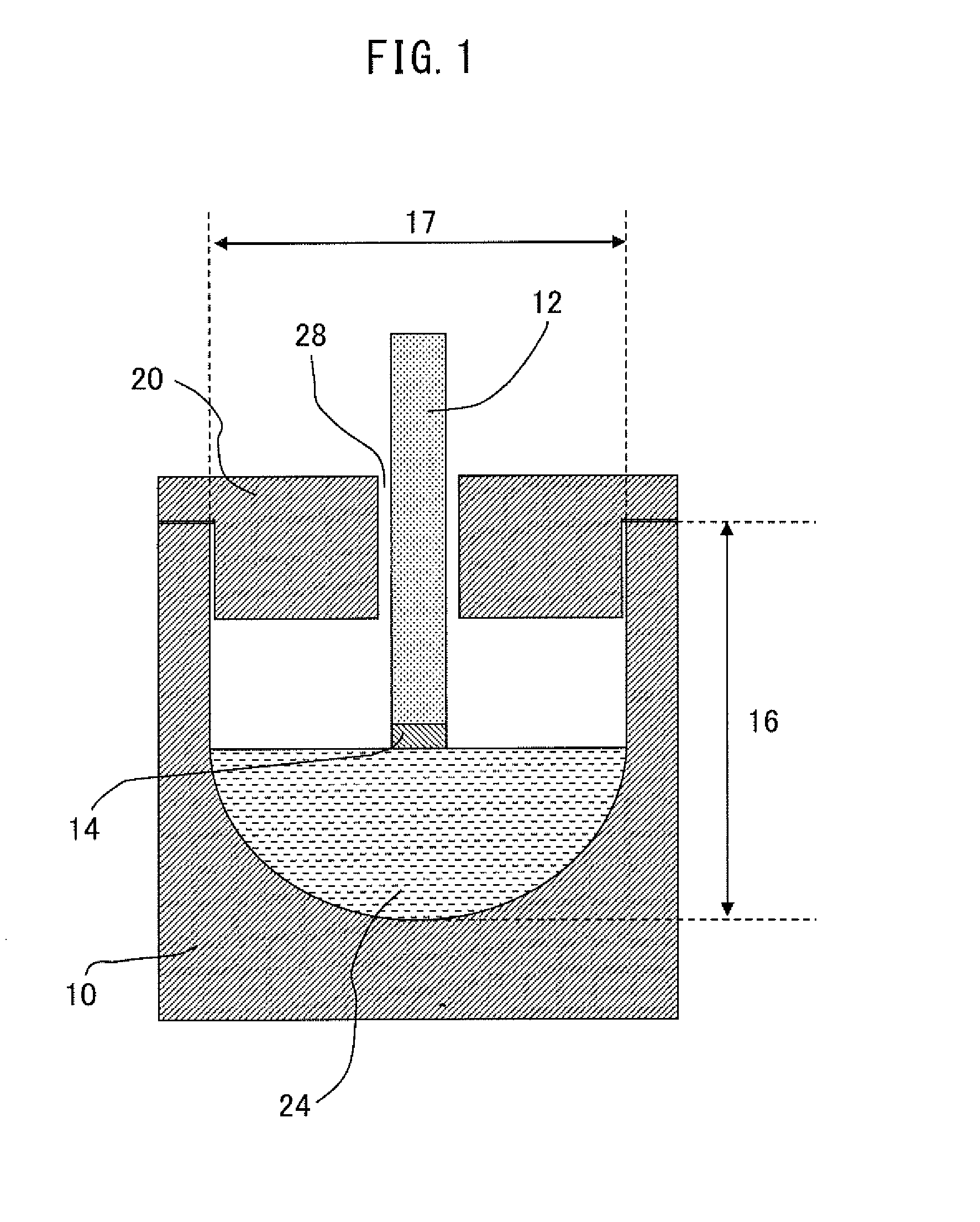

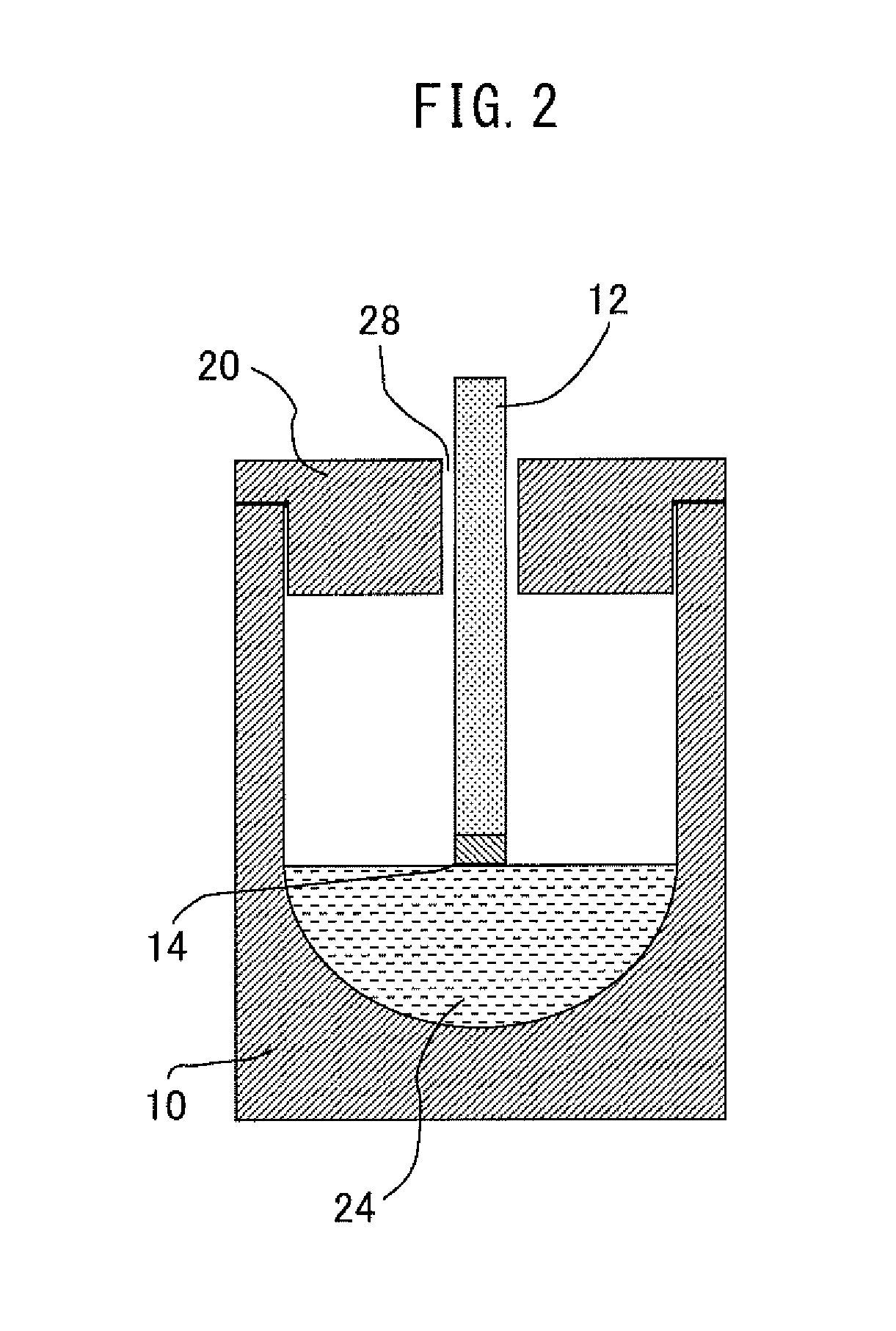

Method for producing sic single crystal

ActiveUS20150221511A1High growth rateIncrease probabilityPolycrystalline material growthLiquid-phase epitaxial-layer growthSeed crystalCrucible

Provided is a method for producing an SiC single crystal, which is capable of greatly increasing the growth rate in a solution technique in comparison to conventional methods. A method for producing an SiC single crystal, wherein an SiC single crystal is grown by bringing a seed crystal substrate into contact with an Si—C solution that is put in a crucible and has a temperature gradient decreasing from the inside to the liquid level, and wherein the value of depth / inner diameter of the crucible is less than 1.71 and the temperature gradient of the Si—C solution from the liquid level to 10 mm below the liquid level is larger than 42° C. / cm.

Owner:TOYOTA JIDOSHA KK

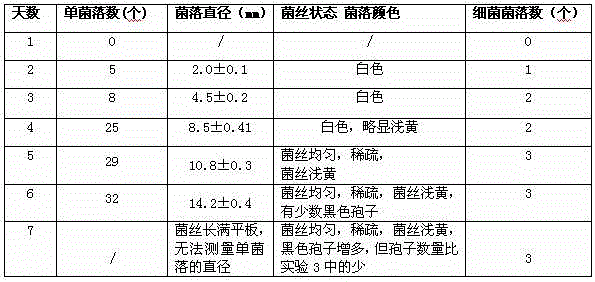

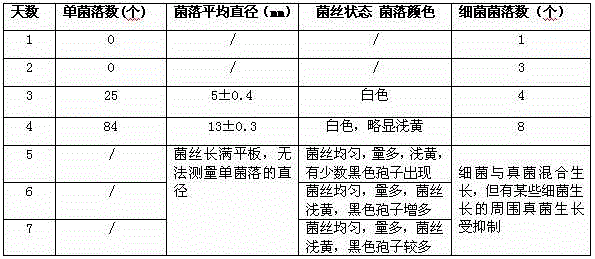

Culture medium for screening blakeslea trispora capable of producing high-yield lycopene

InactiveCN106282031AAvoid spreadingGrowth inhibitionFungiMicroorganism based processesBlakeslea trisporaHypha

The invention provides a culture medium for screening blakeslea trispora capable of producing high-yield lycopene. The culture medium is prepared from glucose, potatoes, agar and water. The culture medium is characterized in that deoxysodium cholate is added, and the culture medium is prepared from, by mass, 2.0%-2.5% of glucose, 20%-25% of potatoes, 0.05%-0.06% of deoxysodium cholate, 2.0%-2.5% of agar and the balance water. After deoxysodium cholate is added, the culture medium effectively prevents mould hypha spreading, inhibits growth of Gram-positive bacteria, helps to obtain an independent single colony in the process of culturing screened seeds and screens out blakeslea trispora capable of producing high-yield lycopene.

Owner:丽江映华生物药业有限公司

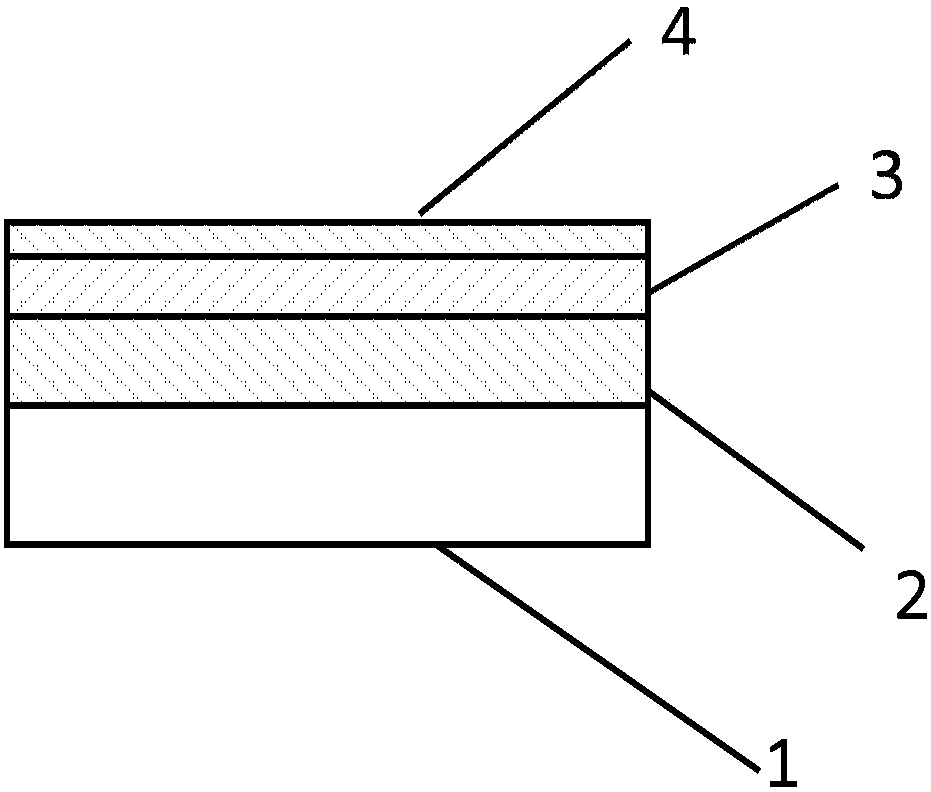

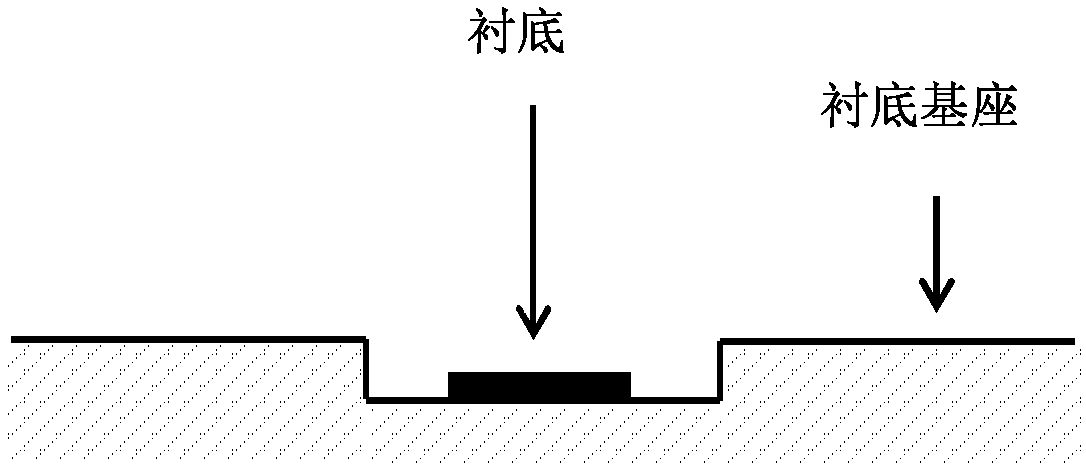

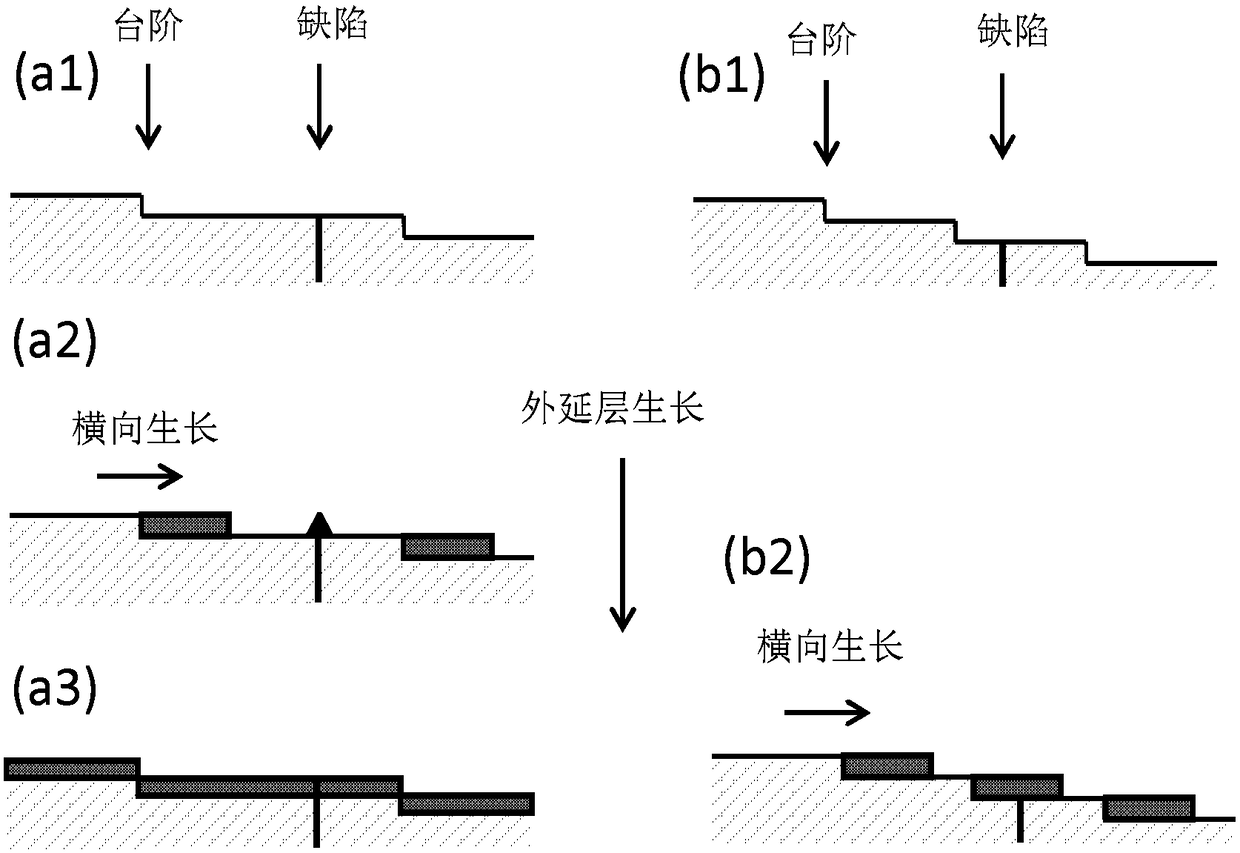

Growth method for high-speed and high-quality monocrystal diamond

ActiveCN108611680AQuality improvementGuaranteed high growthPolycrystalline material growthFrom chemically reactive gasesSurface layerSingle crystal

The invention discloses a growth method for a high-speed and high-quality monocrystal diamond. The method comprises the following steps: growing a diamond supporting layer on the surface of a substrate; growing an intermediate defect barrier layer on the surface of the diamond supporting layer; growing a diamond surface layer on the surface of the intermediate defect barrier layer. The method is characterized in that a layer of thick diamond supporting layer grows on the substrate at higher growth rate; the intermediate defect barrier layer grows on the diamond supporting layer and prevents defects in the diamond from extending towards the surface by adopting a step growth mode; the diamond surface layer grows on the intermediate defect barrier layer; the high-quality diamond surface layeris obtained at lower growth rate by adopting optimized growth conditions. According to the growth method, the high-quality monocrystal diamond grows by adopting a three-layer structure. According tothe growth method disclosed by the invention, the problem of contradiction between high growth rate and quality of an epitaxial layer in the traditional diamond growth process is solved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI +1

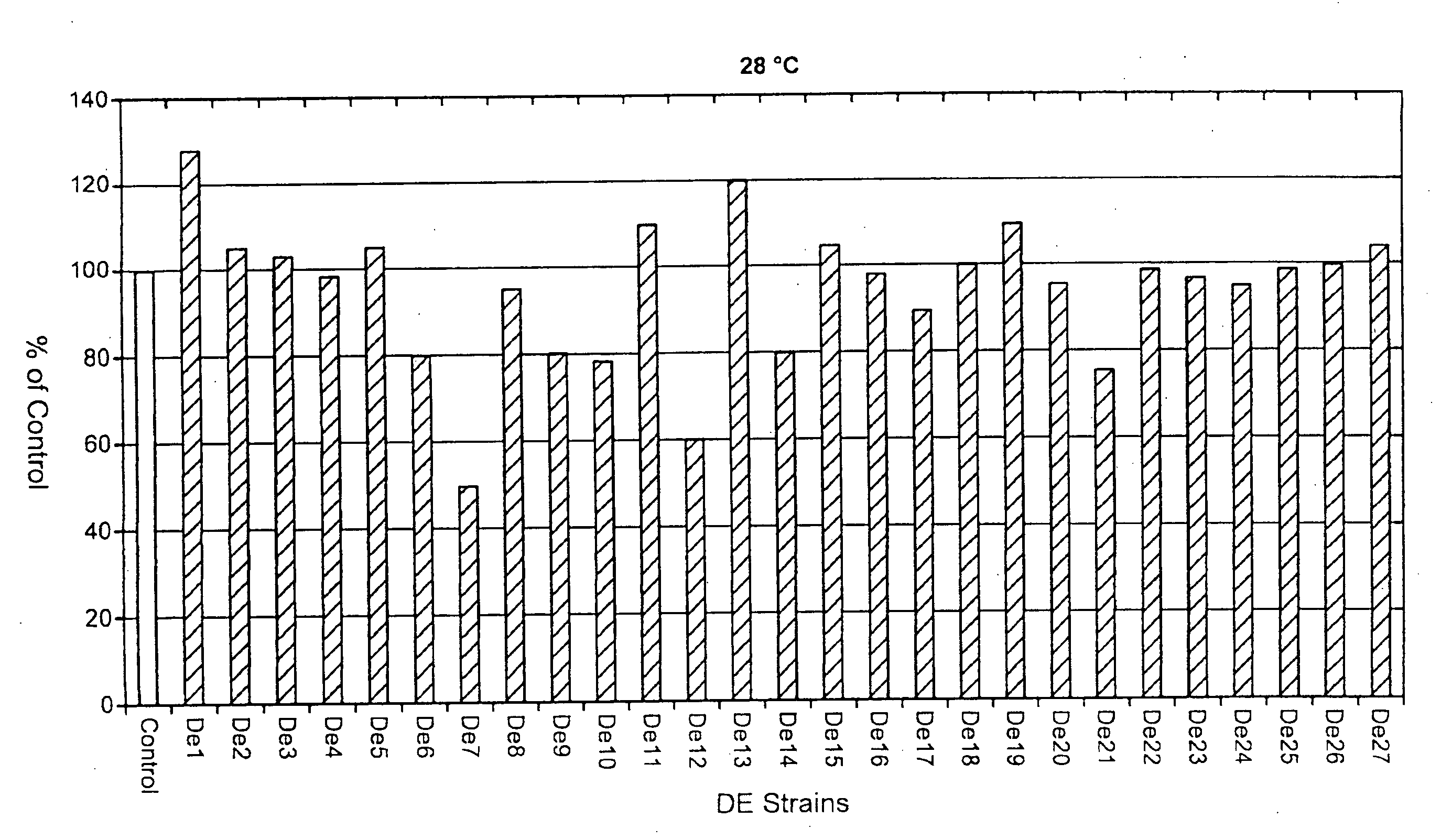

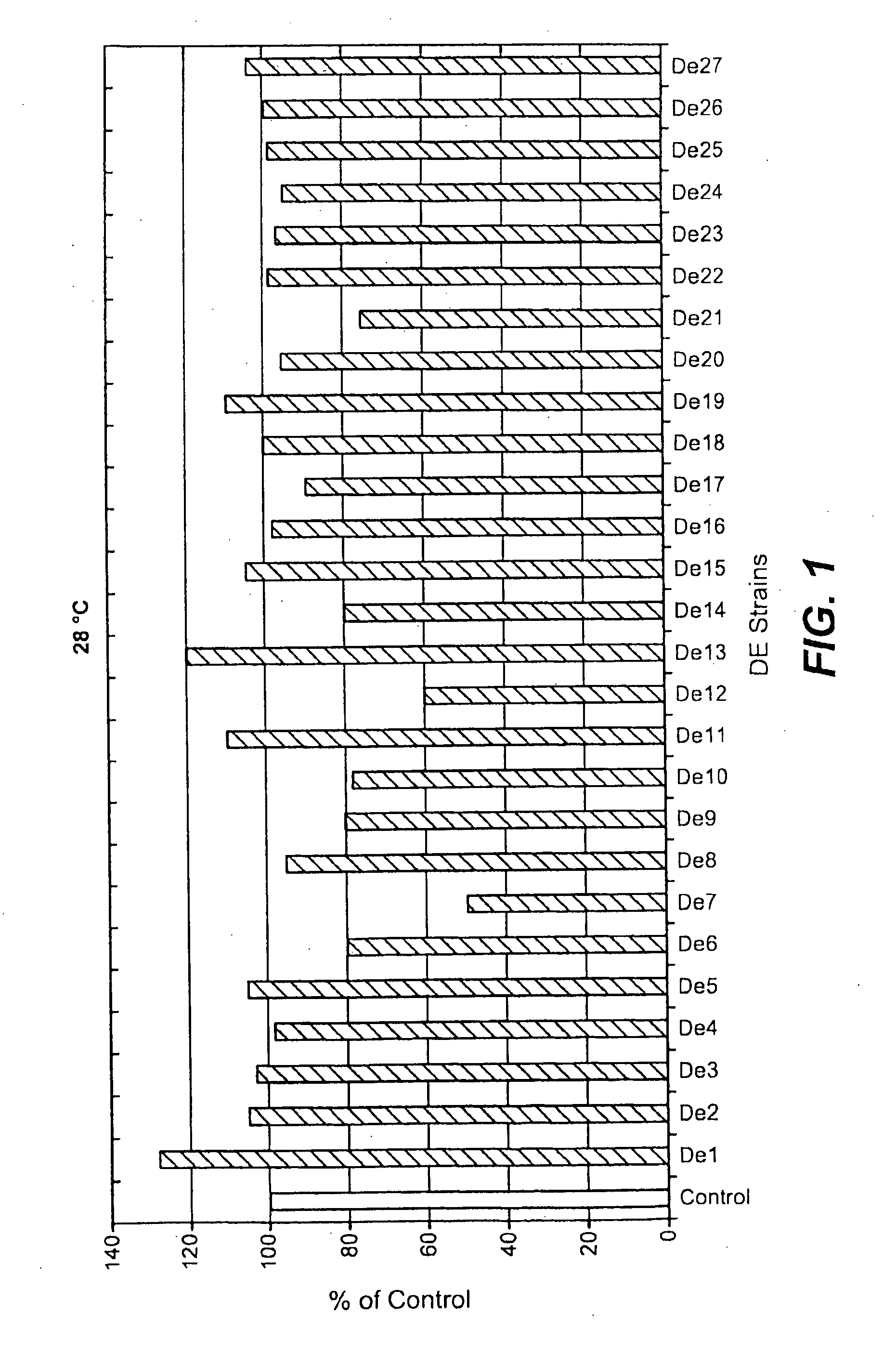

Methods for Selecting Improved Strains

InactiveUS20100129835A1Facilitate identification and isolationHigh growth rateMutant preparationBiological testingBiologyCulture cell

The present invention relates to a system for improving a strain of filamentous fungus that is useful in producing an enzyme of interest such as a cellulase. The invention involves generating genetic diversity in a strain of fungal cells, subjecting the population of cells to selection, and isolating the cells that overproduce the enzyme. The selection techniques involve culturing the population of cells in purified cellulose and / or at an elevated temperature that is adverse to production of the enzyme.

Owner:DANISCO US INC

Speed increaser of wind driven generator

InactiveCN106917725AHigh growth rateImprove inhalation functionGear lubrication/coolingToothed gearingsWind drivenDrive shaft

The invention belongs to the technical field of novel energy, and particularly relates to a speed increaser of a wind driven generator. The speed increaser comprises an upper shell and a lower shell. A first driven bearing cavity, a second driven bearing cavity and a main bearing cavity are formed in the upper shell; a first driven shaft is arranged in the first driven bearing cavity; a second driven shaft is arranged in the second driven bearing cavity; the first driven shaft is sleeved with a first driven gear and a first driven bearing; the first driven bearing is located below the first driven gear; the second driven shaft is sleeved with a second driven gear and a second driven bearing; the second driven bearing is located below the second driven gear; a first lubricating oil filter is arranged on one side of the upper shell, and a second lubricating oil filter is arranged on the other side of the upper shell; the first lubricating oil filter is connected with a first oil injection channel communicating with the first driven bearing cavity; and the second lubricating oil filter is connected with a second oil injection channel communicating with the second driven bearing cavity.

Owner:天津河西津企通商务服务有限公司

Rivier giantarum rhizome pit planting method

InactiveCN105493822AIncrease organic matterHigh yieldPlant cultivationCultivating equipmentsDiseaseSoil organic matter

The invention relates to a rivier giantarum rhizome pit planting method, and belongs to the technical field of crop cultivation. The method comprises the specific steps that 1, seeds are selected, wherein 100-250 g of rivier giantarum rhizomes with no scab or rot are selected as seed rivier giantarum rhizomes; 2, storage is carried out, wherein the seed rivier giantarum rhizomes are stored at the indoor temperature in a heat preservation mode after being dried in the sun; 3, grooves are dug, wherein land parcel outer edges are selected, and grooves are dug along the land edges; 4, backfilling is carried out, wherein the grooves are backfilled with straw and fine soil, and strip-shaped planting belts are formed through accumulation; 5, seeding is carried out, wherein seeding is carried out in mid-to-late April next year. By the adoption of the rivier giantarum rhizome pit planting method, the soil organic matter can be increased, the soil quality can be improved, the soil water permeability and breathability are improved, the development space is expanded, the problems that the rivier giantarum rhizomes have harsh requirements for land parcels and a few of appropriate planting areas exist are solved, and the purpose of controlling and relieving diseases and improving the yield of the rivier giantarum rhizomes is achieved. Chemical fertilizer and pesticide can be replaced, or the usage amount of chemical fertilizer and pesticide can be reduced, high yield and stable yield of the rivier giantarum rhizomes are achieved, and it is ensured that the product is environmentally friendly and safe in quality.

Owner:竹溪县雨润特色种养家庭农场

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com