Porous series double-toggle inside and outside turning composite clamping mechanism and method

A technology of inside-out and double-toggle, which is applied in the field of multi-hole series double-toggle-inside-out composite clamping mechanism, which can solve the problem of unreasonable matching of force amplification ratio and stroke ratio, uneven mold moving speed, and large template deformation. and other problems, to achieve the effect of fast mold transfer, saving space and time, and small template deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

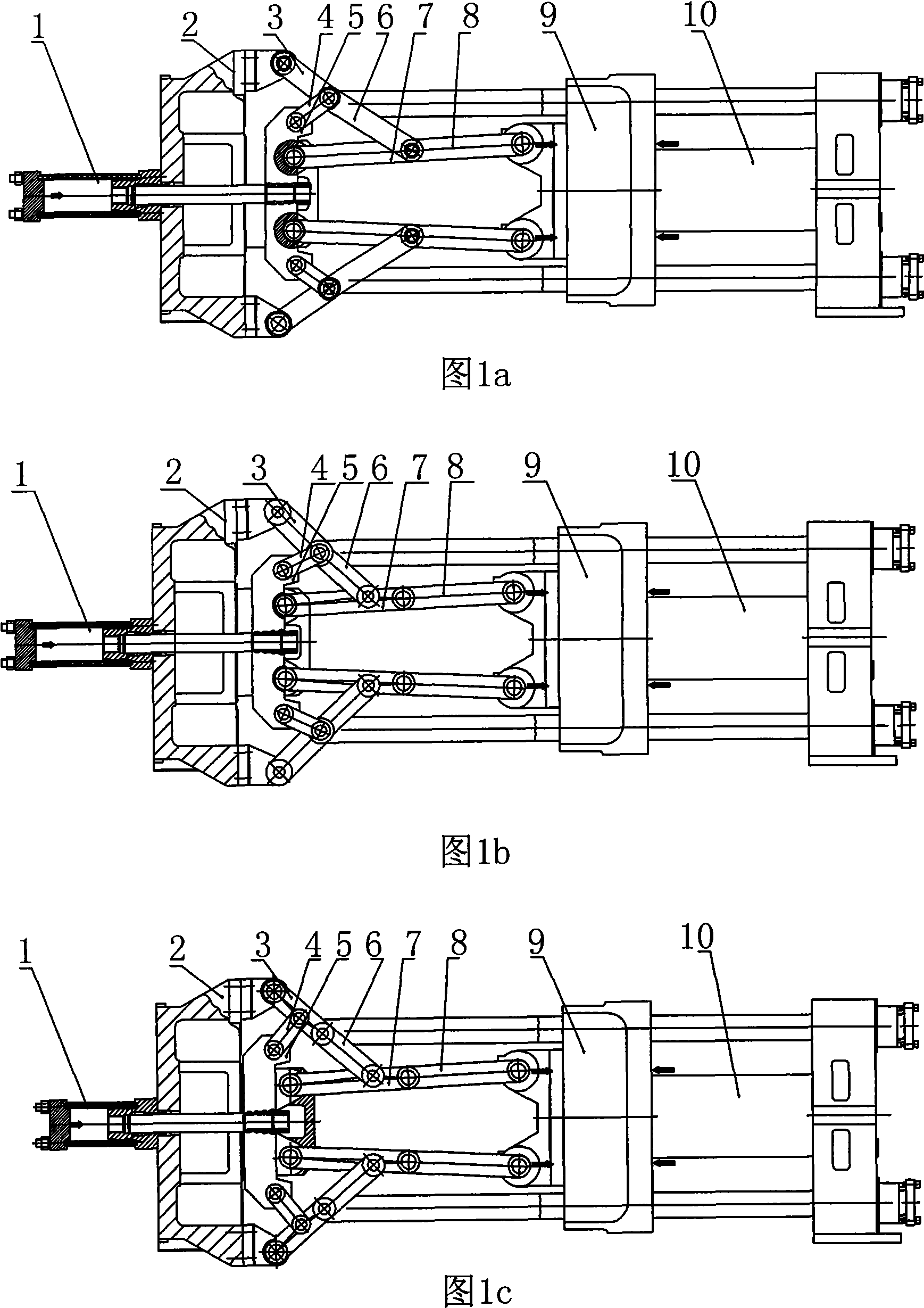

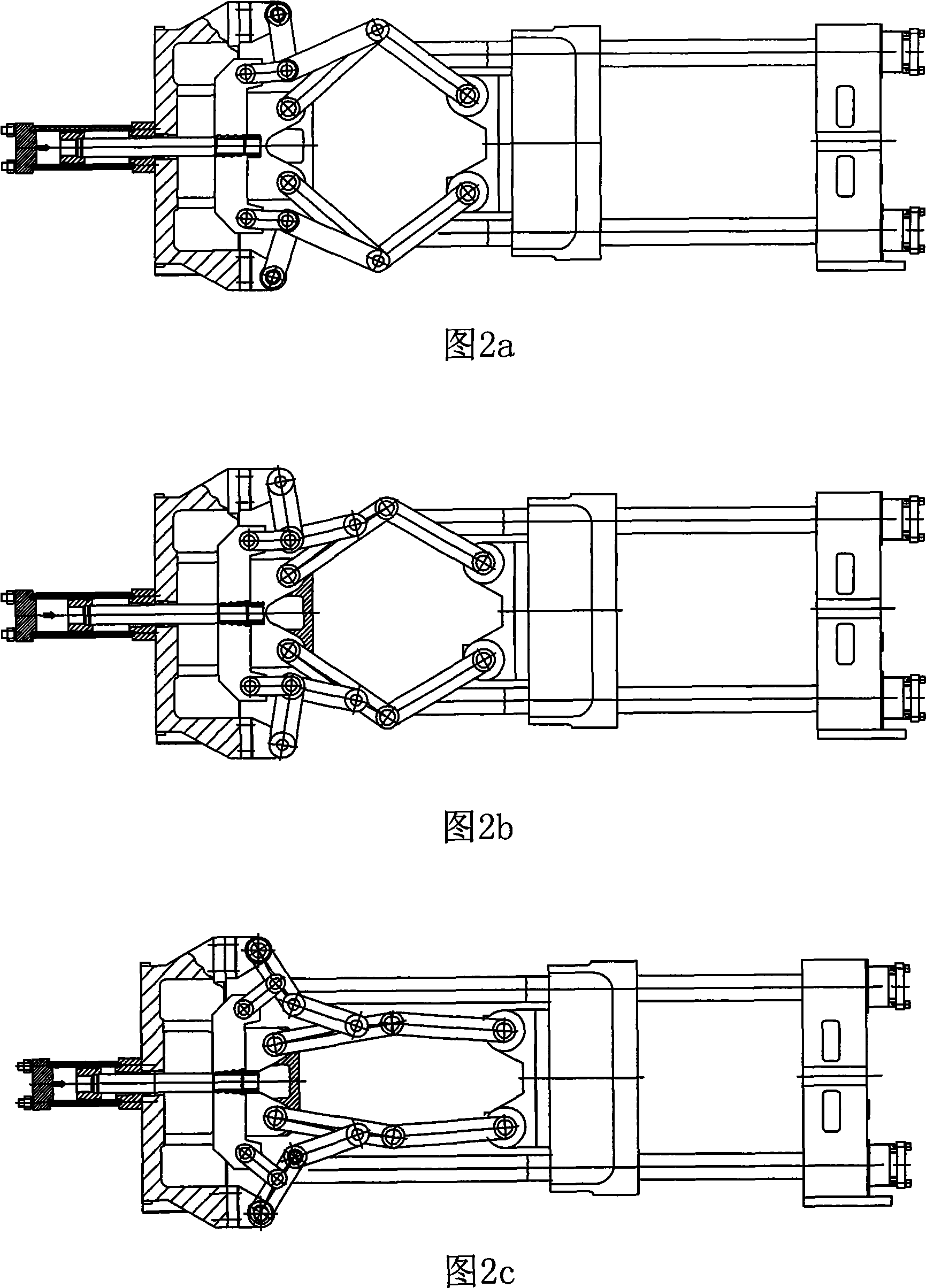

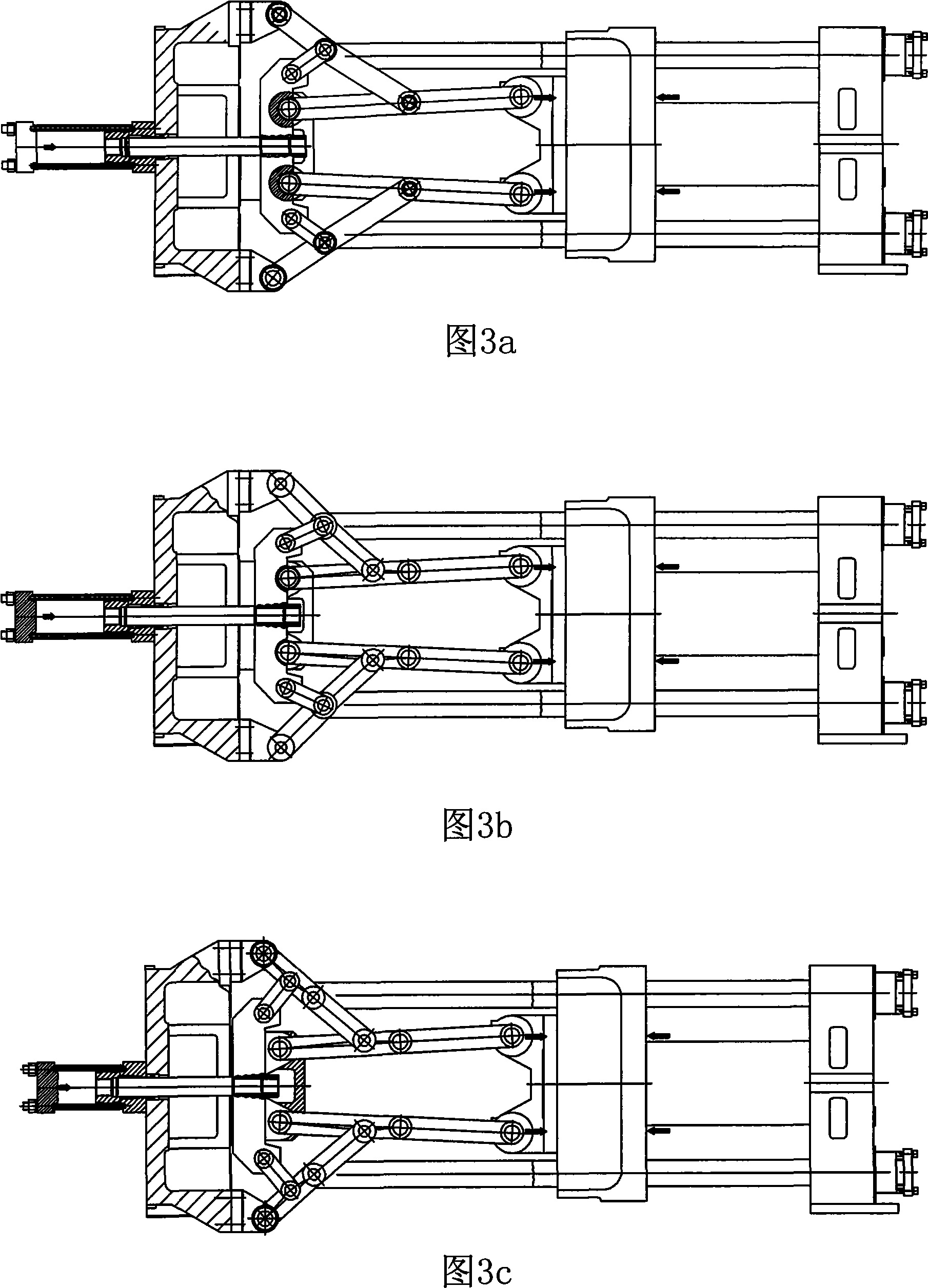

[0037] The specific implementation mode is now combined with the attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Describe the action of opening and locking the mold of the injection molding machine.

[0038] When model locking is performed (see figure 2 Middle), when the clamping cylinder 1 enters the mold clamping action, the crosshead 5 is pushed forward, and the short toggle 4 pushes the auxiliary toggle 3 and the middle toggle 6 to straighten the rear toggle 7 downwards, pushing the front toggle Rod 8, so as to push the movable template 9 to move forward to realize the action of linear high-pressure mold clamping, see the attached image 3 The schematic diagram of the completion of the action.

[0039] When performing mold opening, oil is fed from the other end of the clamping cylinder 1 to pull the crosshead 5 to move backward, the short toggle 4 causes the auxiliary toggle 3 to pull down, and the middle toggle 6 pulls up the rear tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com