Patents

Literature

35 results about "Stroke ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a reciprocating piston engine, the stroke ratio, defined by either bore/stroke ratio or stroke/bore ratio, is a term to describe the ratio between cylinder bore diameter and piston stroke. This can be used for either an internal combustion engine, where the fuel is burned within the cylinders of the engine, or external combustion engine, such as a steam engine, where the combustion of the fuel takes place outside the working cylinders of the engine.

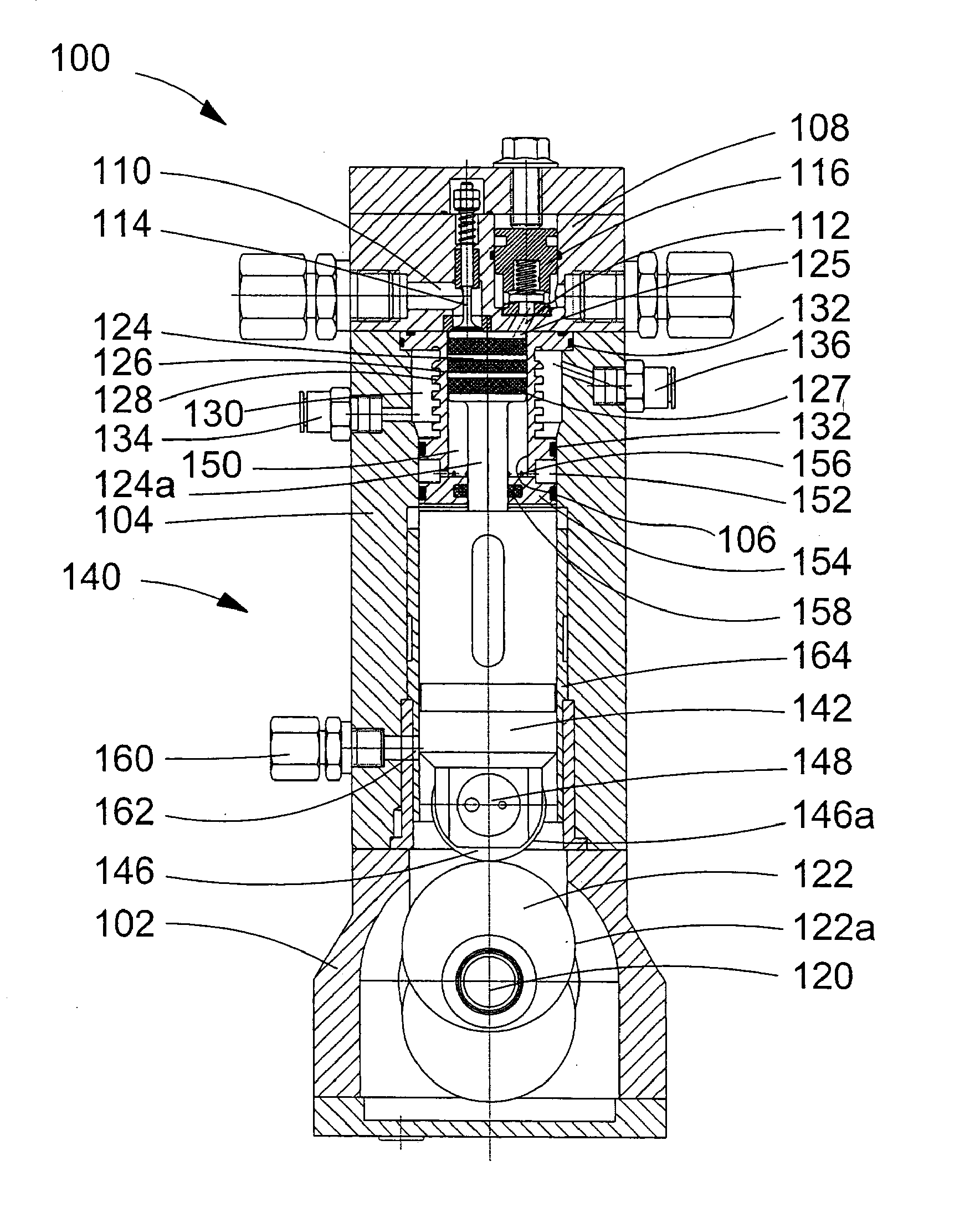

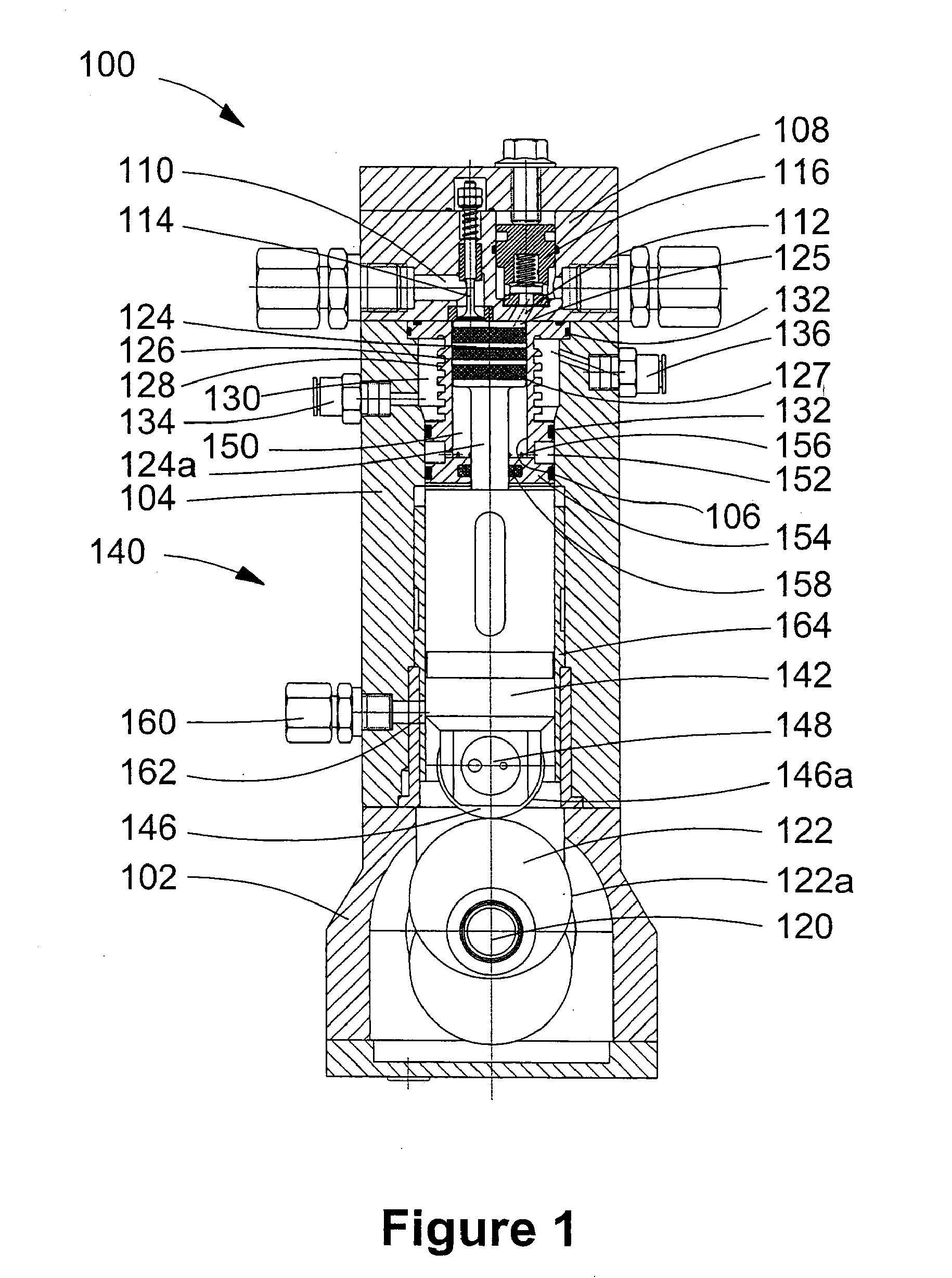

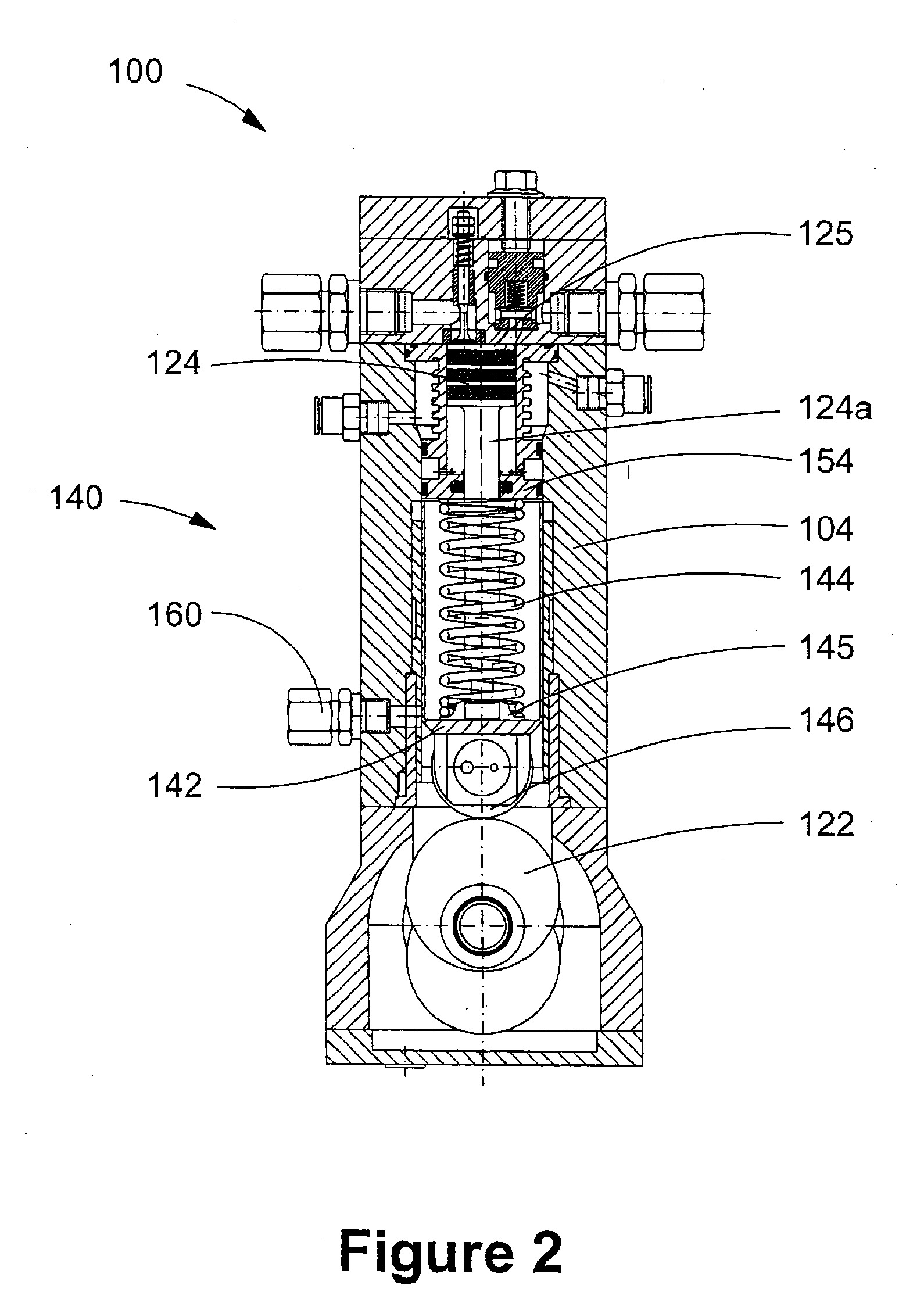

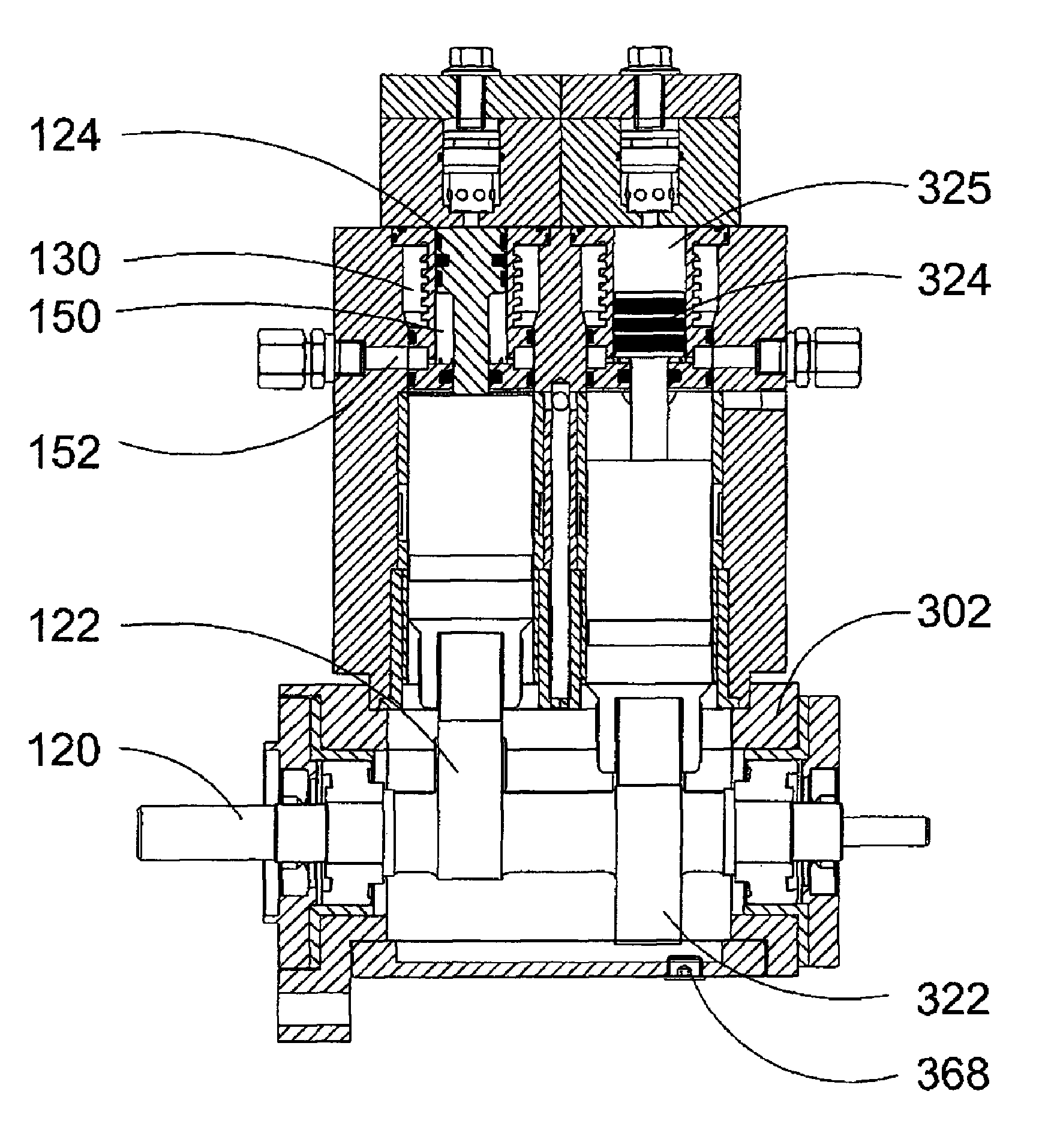

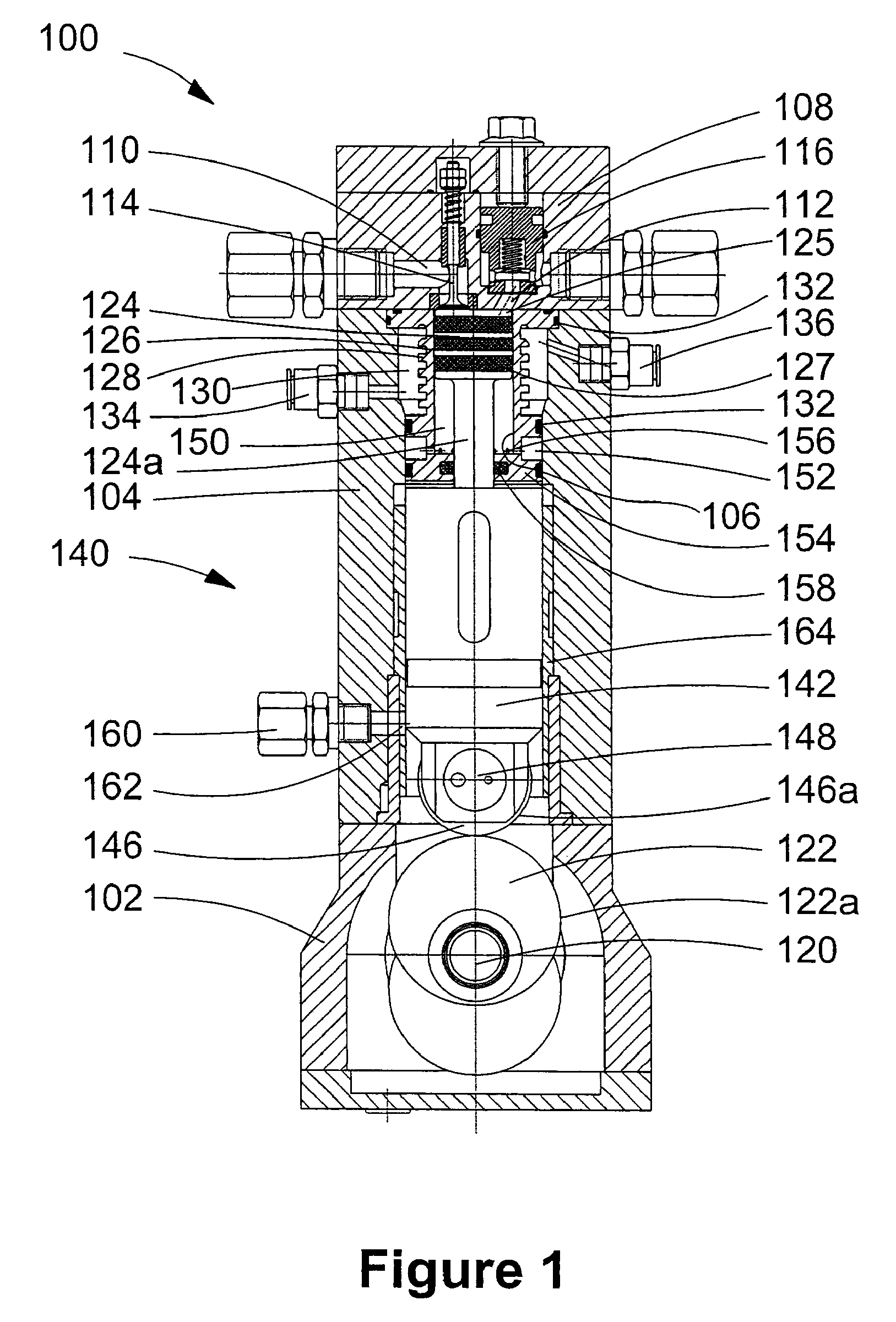

High-Pressure Gas Compressor And Method Of Operating A High-Pressure Gas Compressor

ActiveUS20080213115A1Reduce in quantitySimple manufacturing processPositive displacement pump componentsFlexible member pumpsFriction reductionInlet valve

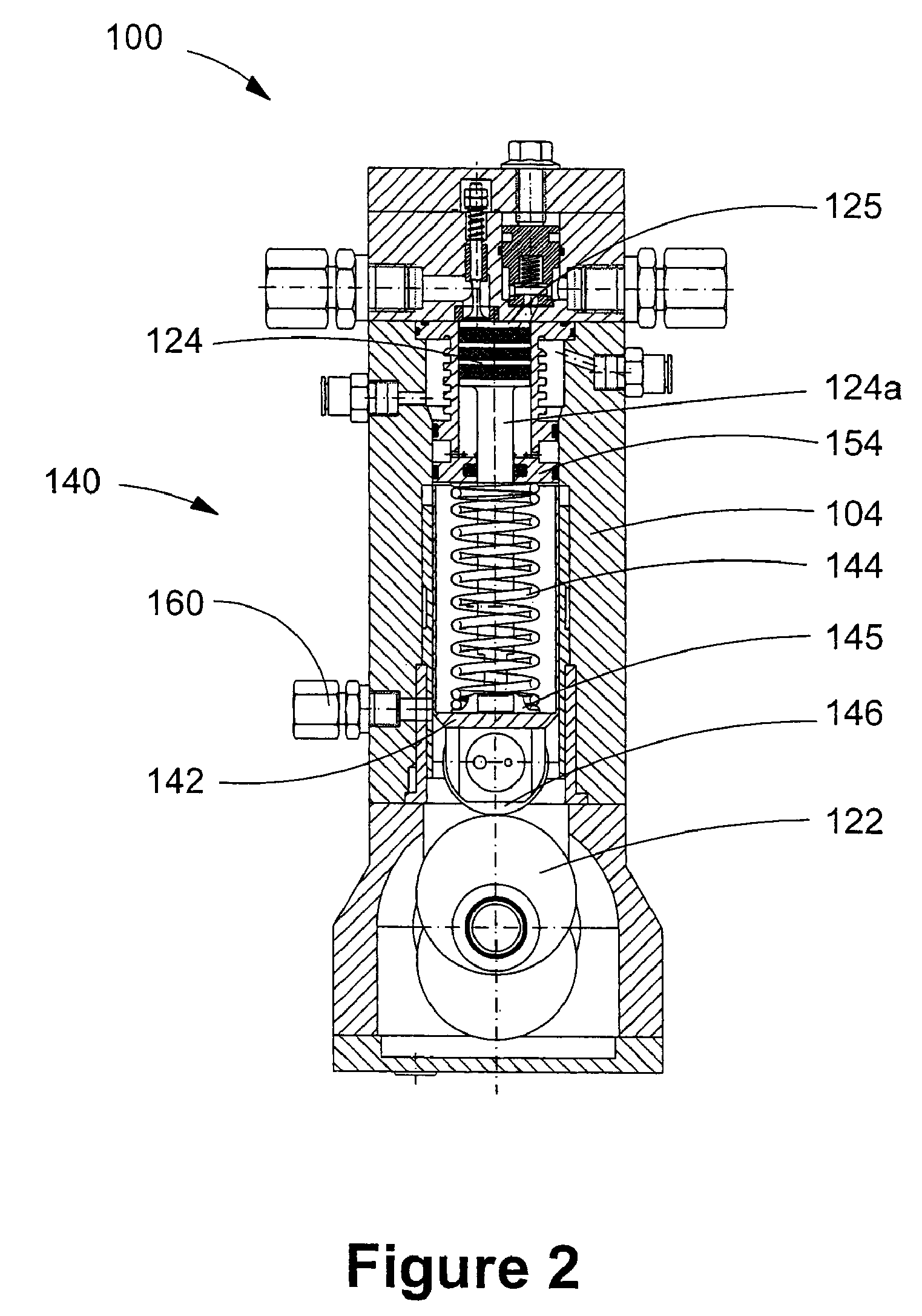

A high-pressure gas compressor comprises a single-acting cam driven piston with a pressure compensation chamber disposed between the piston and the cam. A roller tappet assembly transmits reciprocating motion from the cam to the piston. A pressurized gas directed to the pressure compensation chamber offsets forces acting on the piston from the compression chamber gas pressure, thereby reducing Hertzian pressure between the tappet roller and the cam. Overall efficiency and durability can be improved by reducing friction between compressor components, for example by employing thin film coatings to reduce friction, pressurized oil lubrication systems and higher cylinder bore diameter to piston stroke ratios. The service life of gas seals and compression efficiency can be improved by thermal management strategies, including liquid-cooled compressor cylinder liners and intercoolers between compression stages. Employing a poppet-style intake valve and reducing parasitic volume in the compression chamber can improve compressor volumetric efficiency.

Owner:WESTPORT FUEL SYST CANADA INC

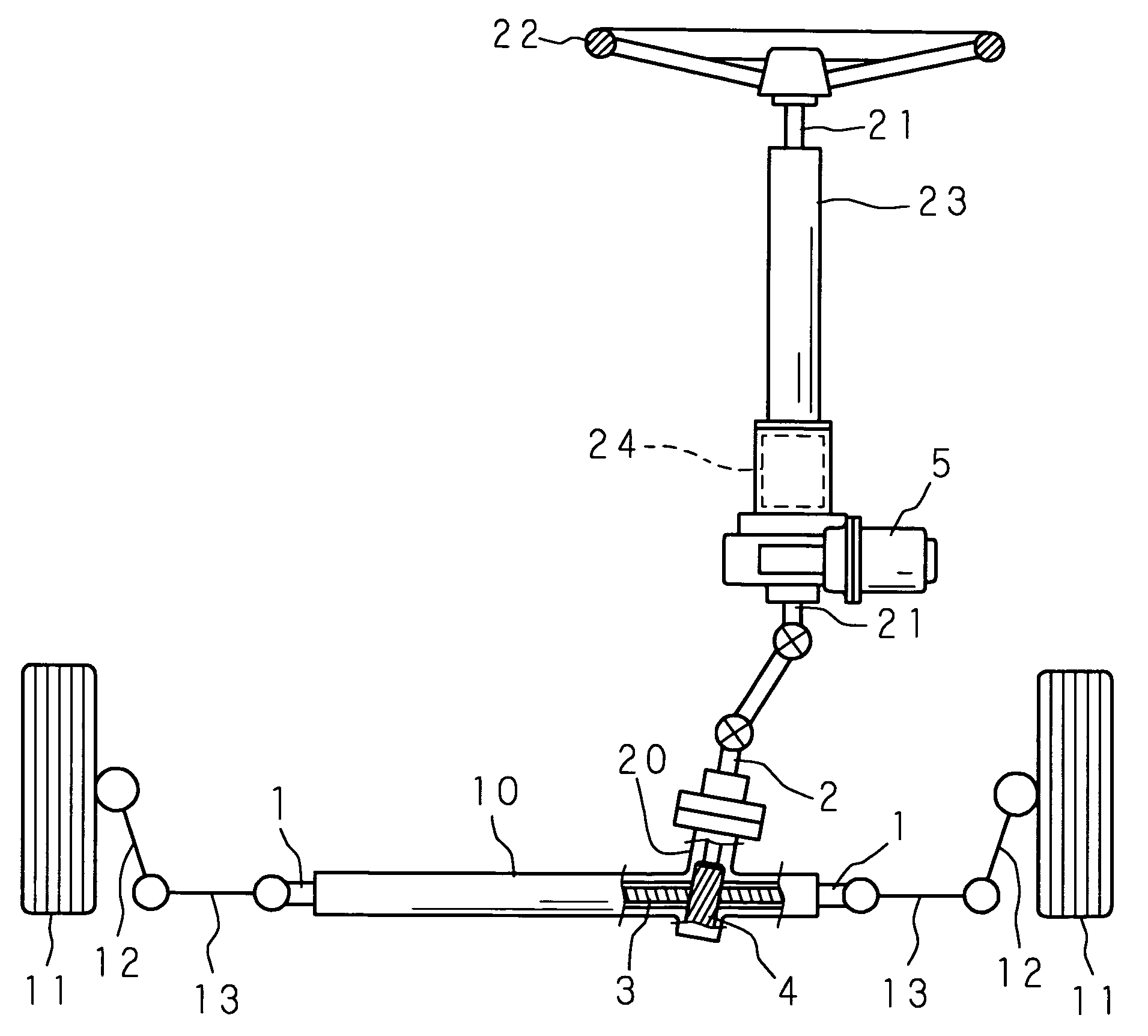

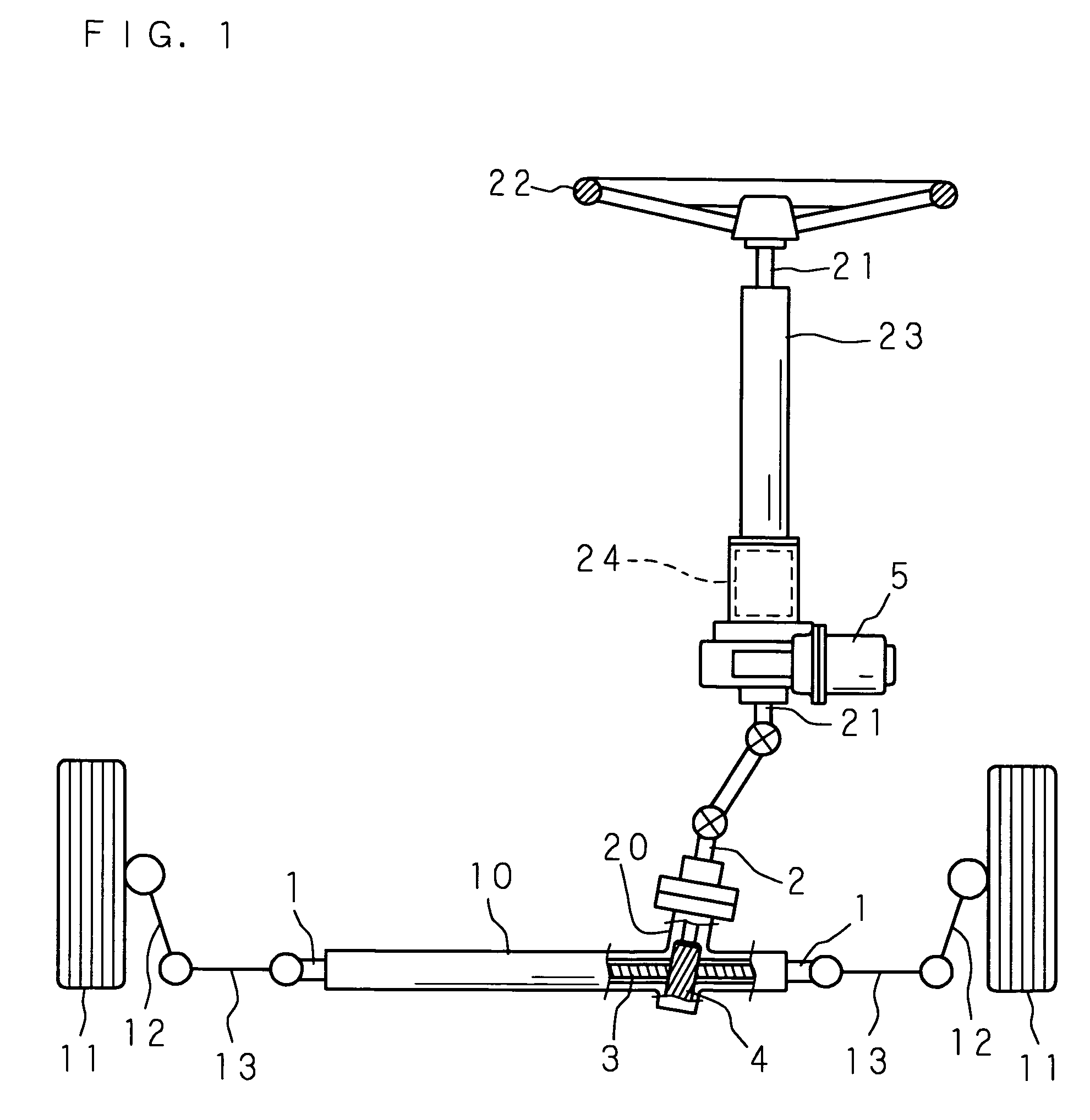

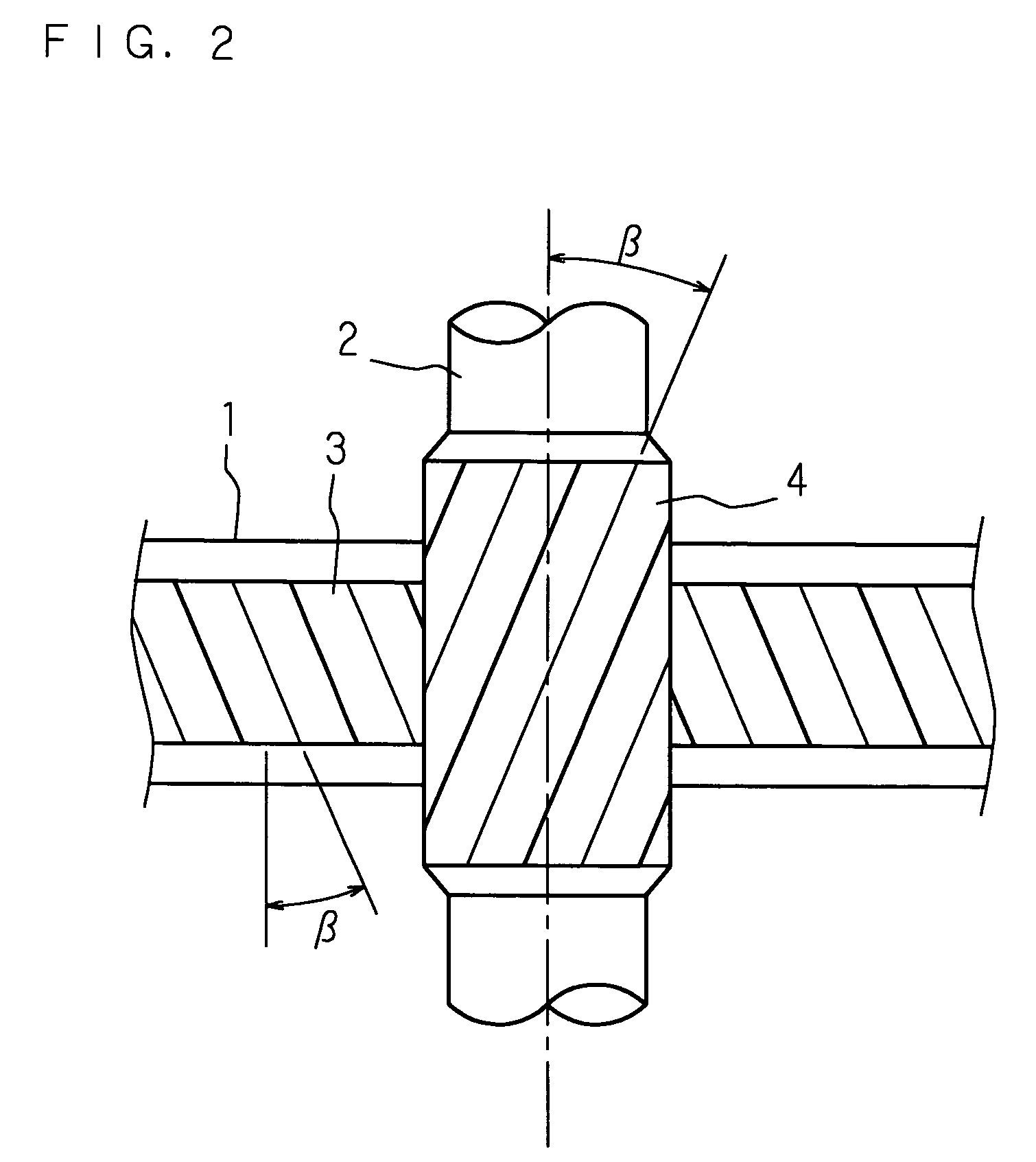

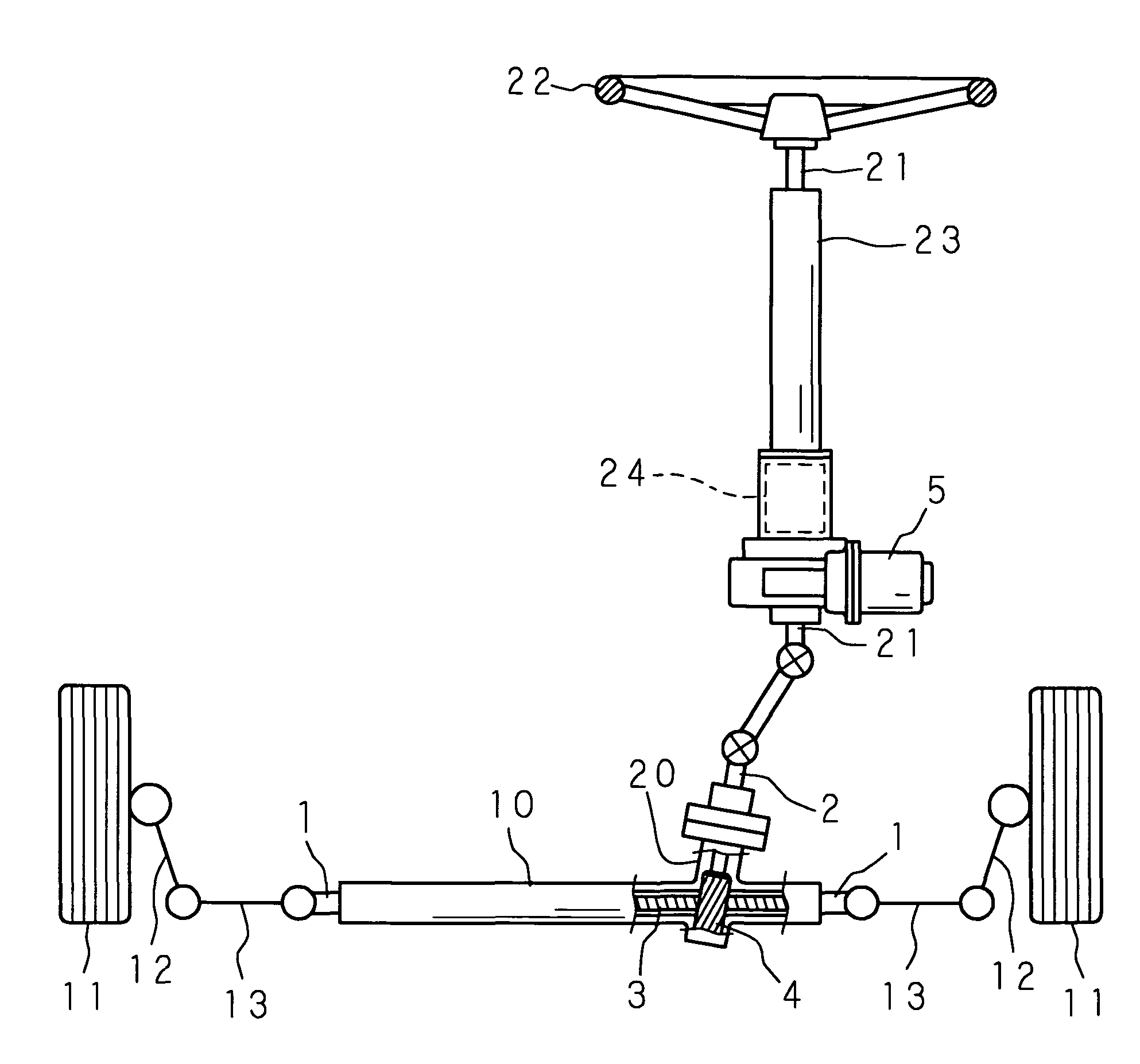

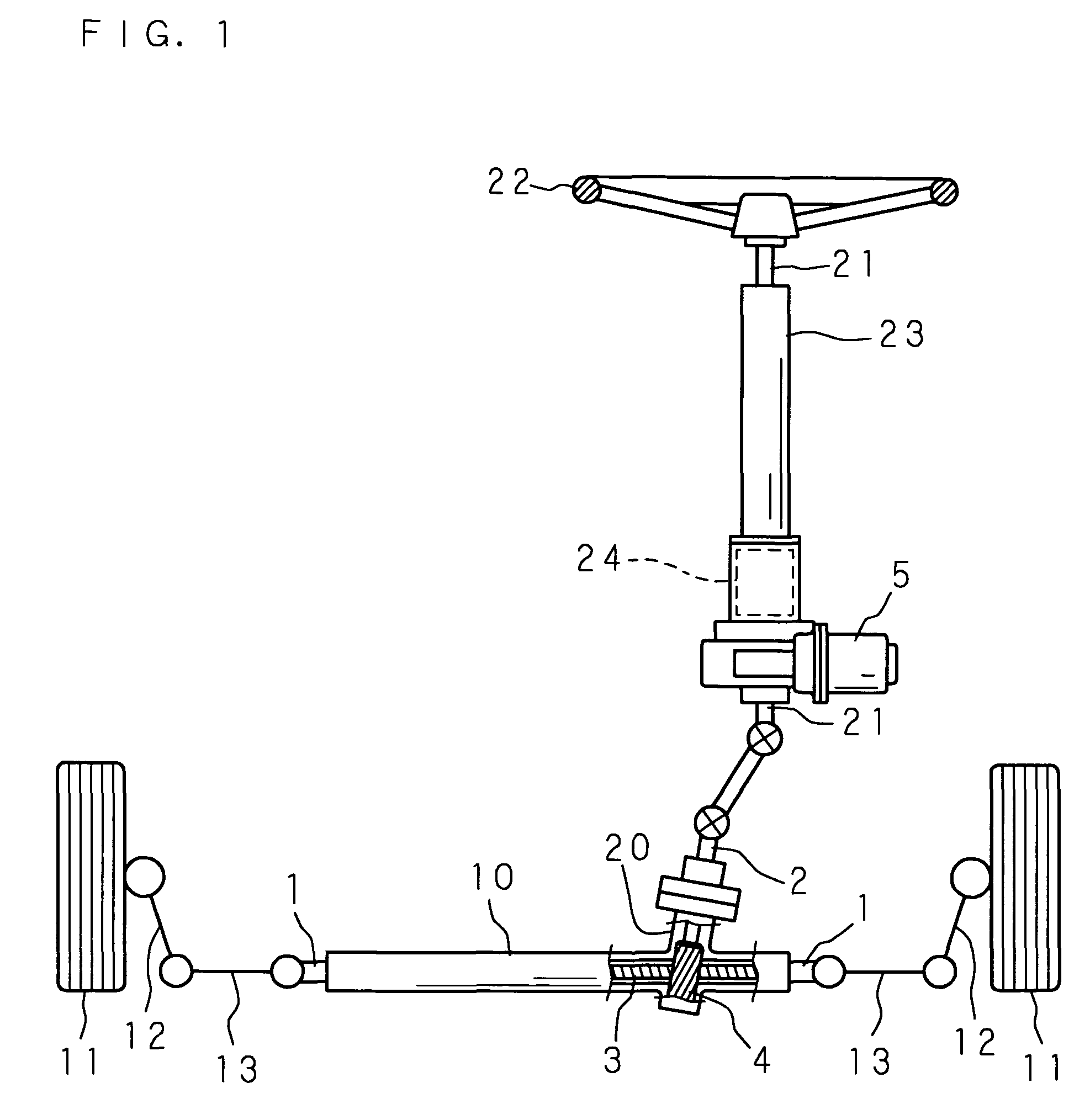

Rack-and-Pinion Steering Apparatus

InactiveUS20080223163A1Reducing meshing frictionStably offering smooth and comfortable steering feeling over a long timePortable liftingToothed gearingsEngineeringHelix angle

A rack-and-pinion steering apparatus comprises pinion teeth formed according to proper tooth specifications in other aspects under a larger pressure angle, thereby stably offering smooth and comfortable steering feeling over a long time. The module (m), number of teeth (z), tooth depth(h) and helix angle (β) of the pinion teeth (4) are set within the following ranges, under a pressure angle (α) set within a range of 24° to 30° and a given stroke ratio.module (m): 1.8 to 2.0number of teeth (z): 7 to 13tooth depth (h): 2 m to 2.5 mhelix angle (β): 350 or smaller

Owner:JTEKT CORP

High-pressure gas compressor and method of operating a high-pressure gas compressor

ActiveUS8172557B2Reduce in quantitySimple manufacturing processPositive displacement pump componentsFree piston pumpsFriction reductionInlet valve

Owner:WESTPORT FUEL SYST CANADA INC

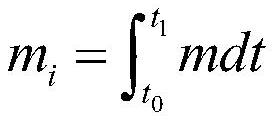

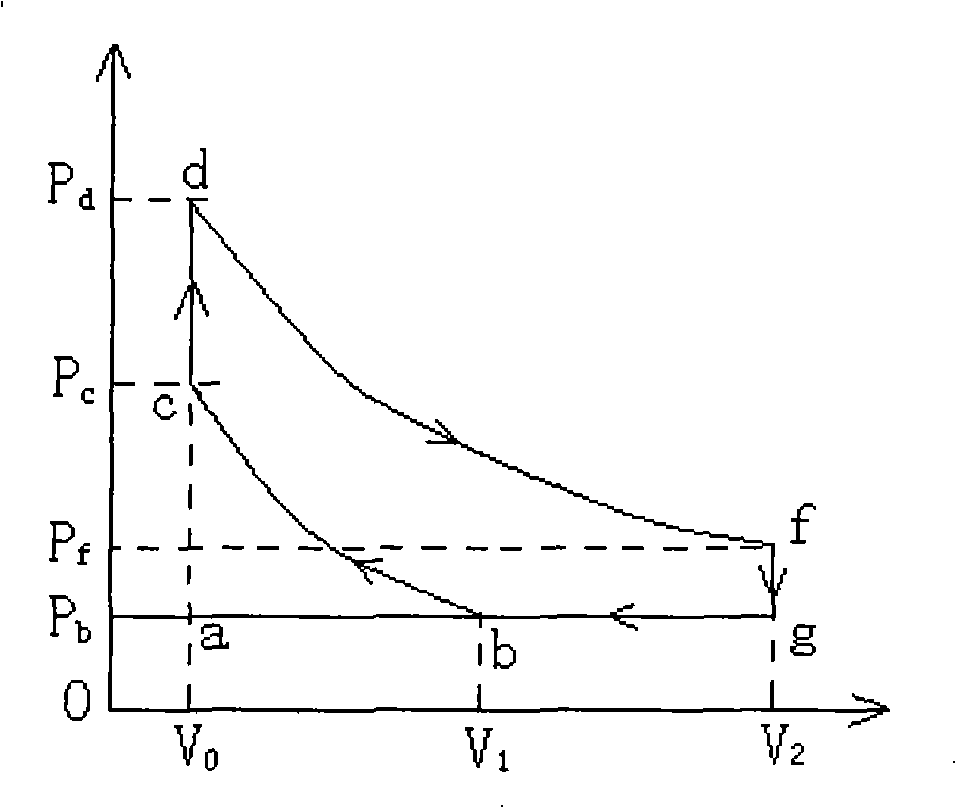

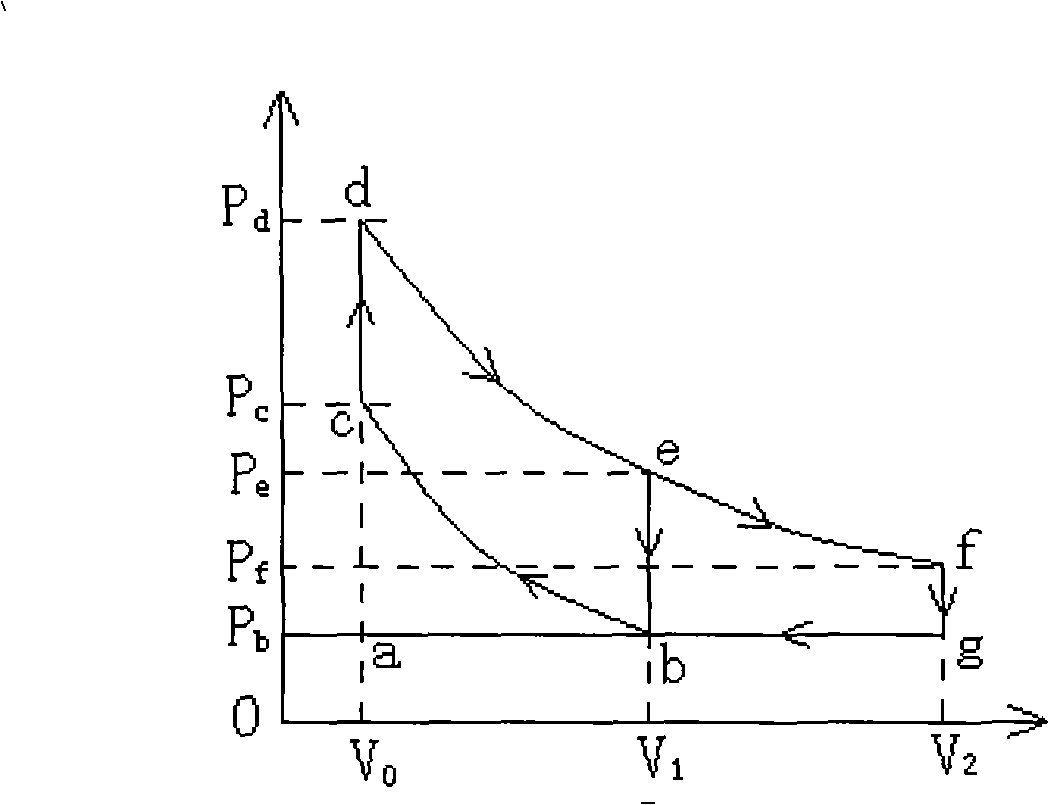

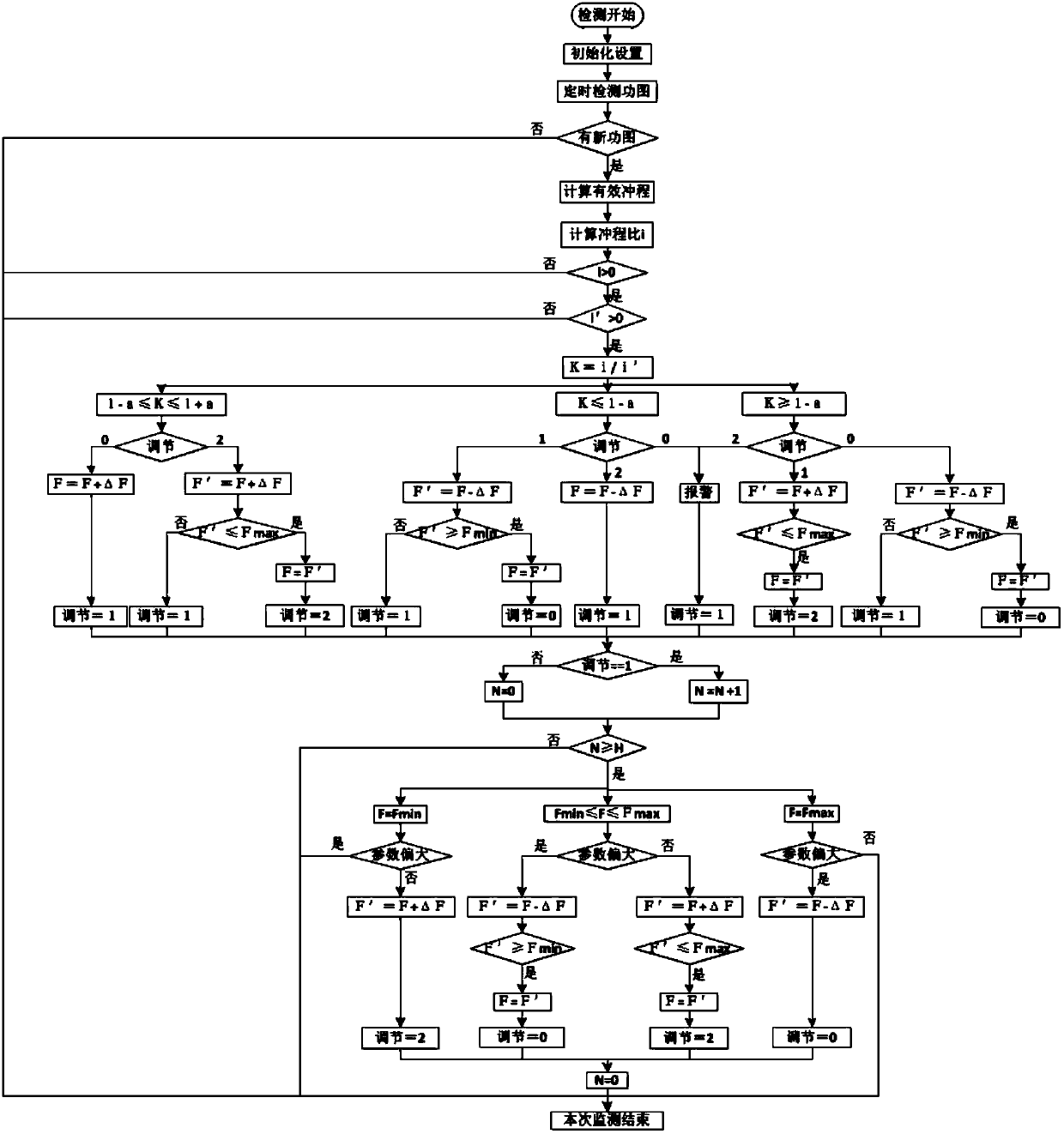

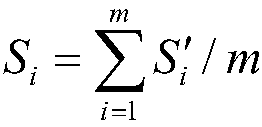

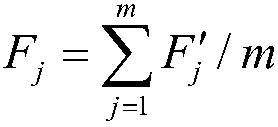

Pumping well frequency converting control method based on dynamic control chart and indicator diagram

InactiveCN108223343ARealize real-time frequency conversion optimizationOptimal YieldPump controlPositive-displacement liquid enginesFrequency conversionIndicator diagram

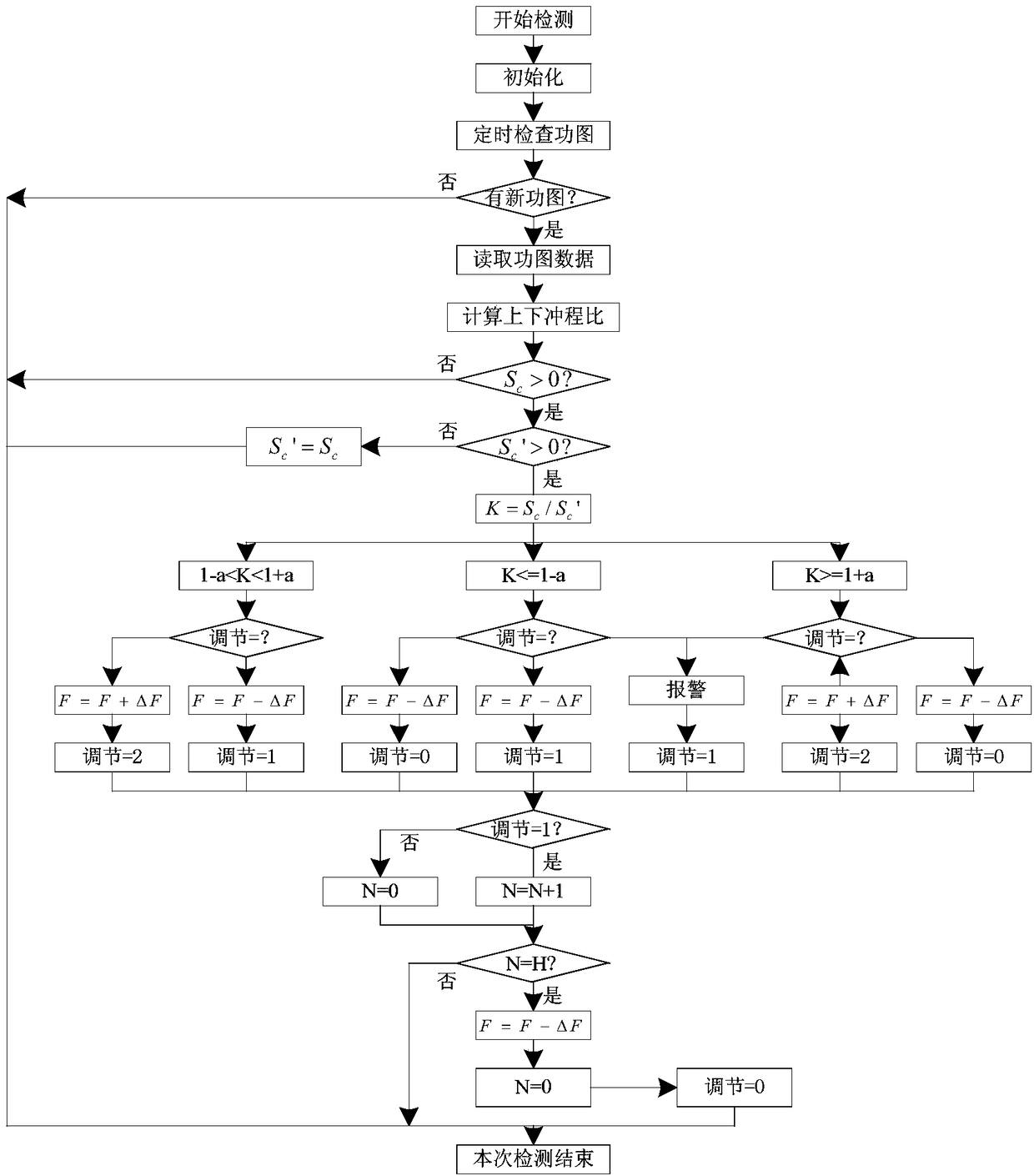

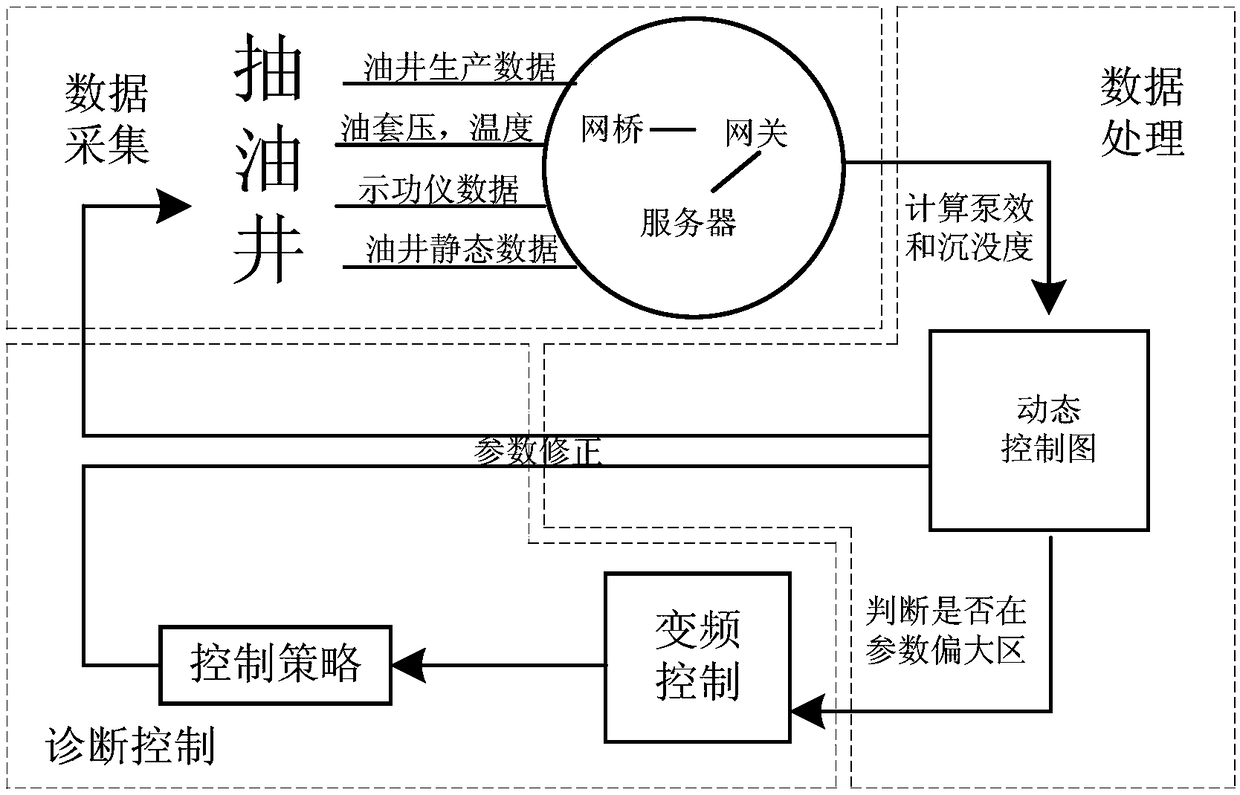

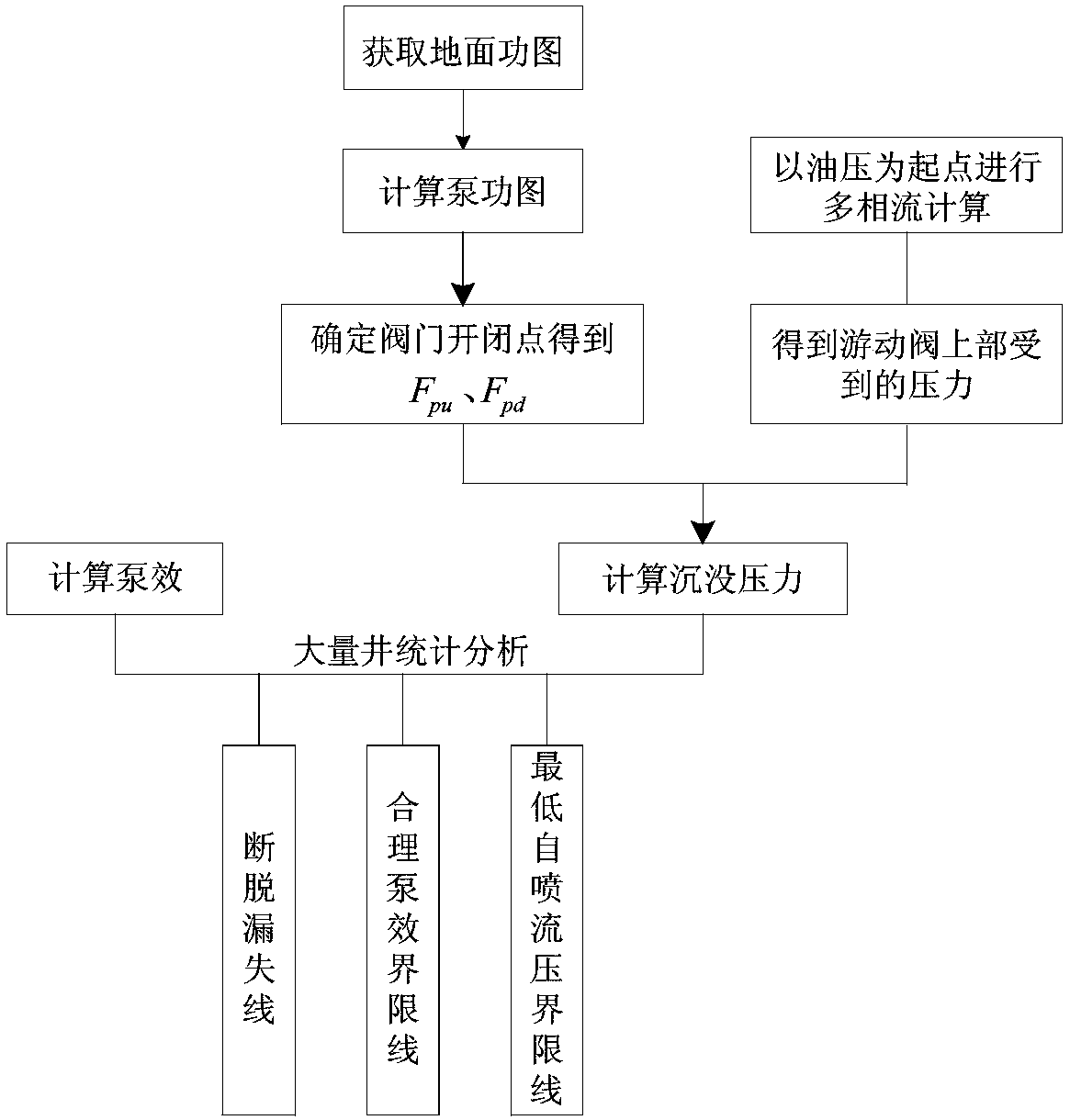

The invention relates to a pumping well frequency converting control method based on a dynamic control chart and an indicator diagram. By analyzing the indicator diagram of the ground of a pumping well and combining the actual production data and static parameters of an oil field, the stroke ratio of an up stroke to a down stroke of the pumping well is calculated and compared with previous data, the variation tendency of an effective stroke of the pumping well is analyzed, intelligent frequency conversion is carried out on the pumping well, and meanwhile, by combining the result of the dynamiccontrol chart of the pumping well, the frequency conversion effect of the pumping well is corrected. According to the pumping well frequency converting control method based on the dynamic control chart and the indicator diagram, the limitation that under an original traditional pattern, continuous optimization cannot be achieved due to the fact that the improvement of the pumping well pump efficiency depends on the maintaining operation, stimulation means, parameter adjusting optimization and other measures, and the defect that frequency converting control excessively depends on artificial participation, real-time adjusting on jig frequency cannot be achieved are changed. On the basis that the reservoir potentiality is brought into full play to the maximum extent, frequency conversion optimizing is achieved, the energy consumption of pumping well extraction is reduced, the efficiency of a rod pumped well is improved, and the yield of the pumping well and the continual optimization ofthe system efficiency are achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

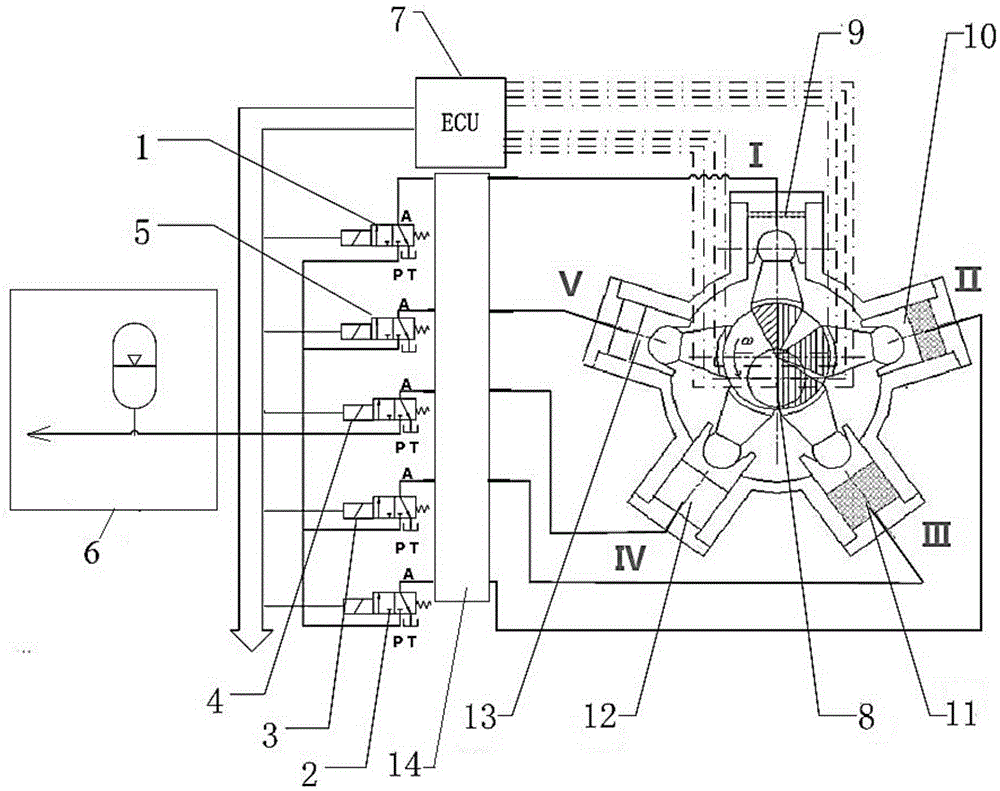

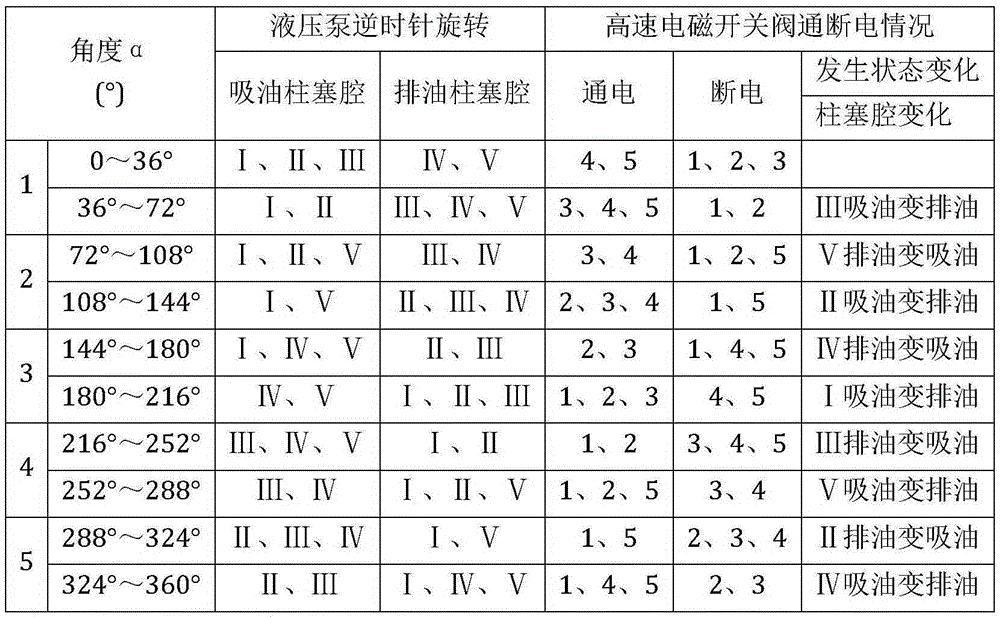

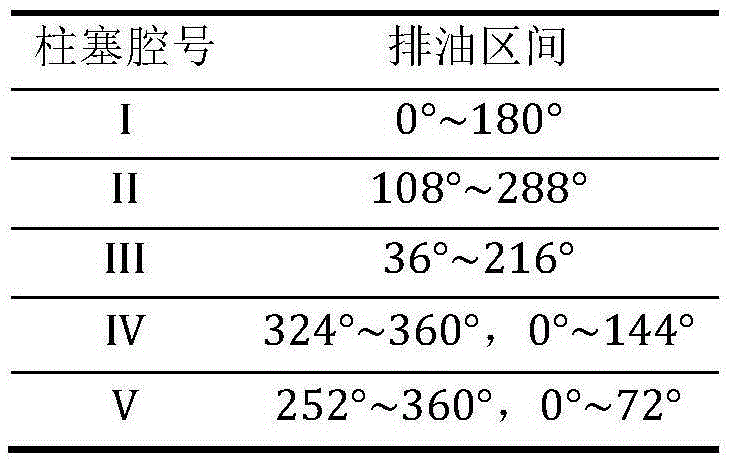

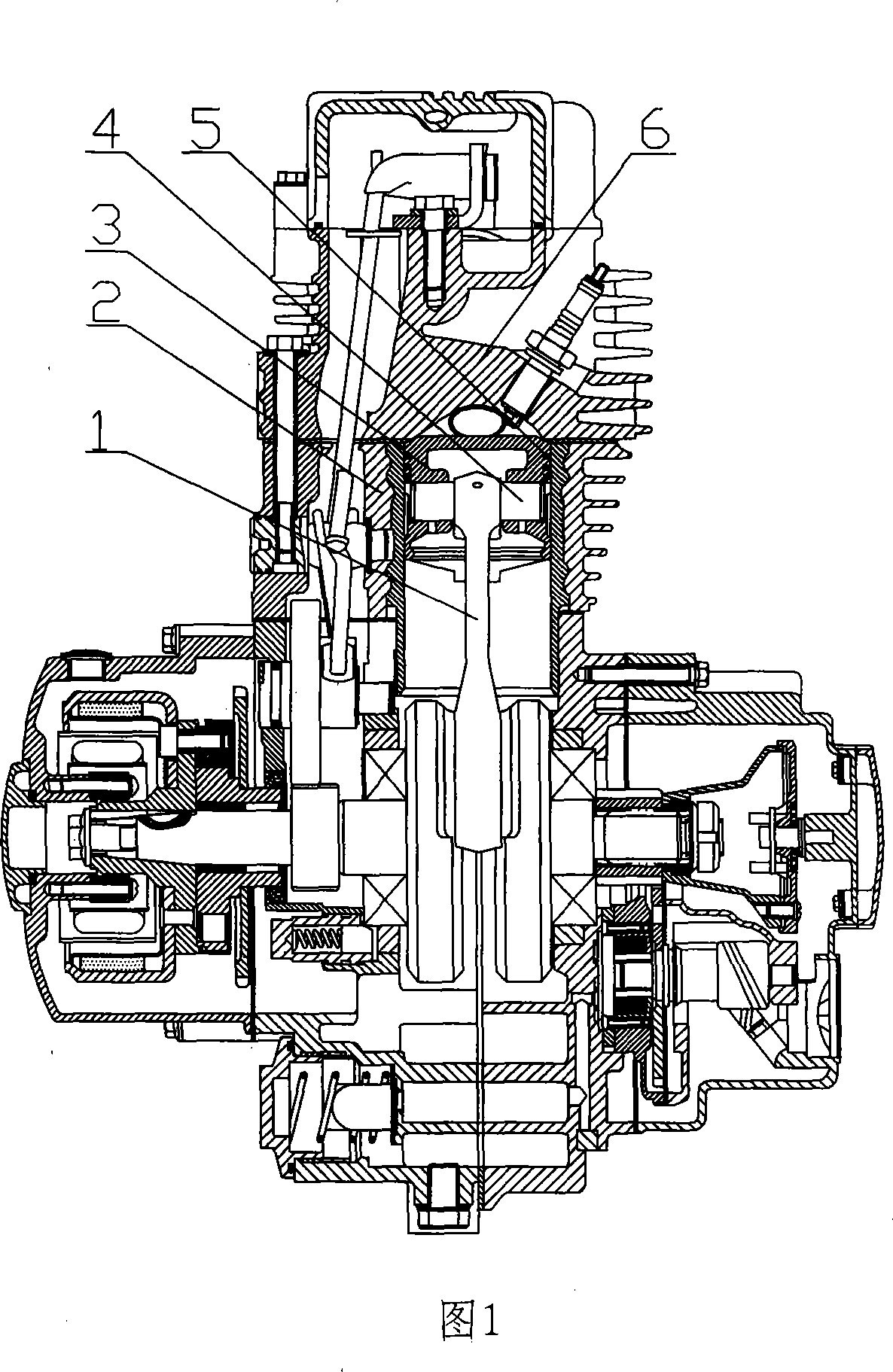

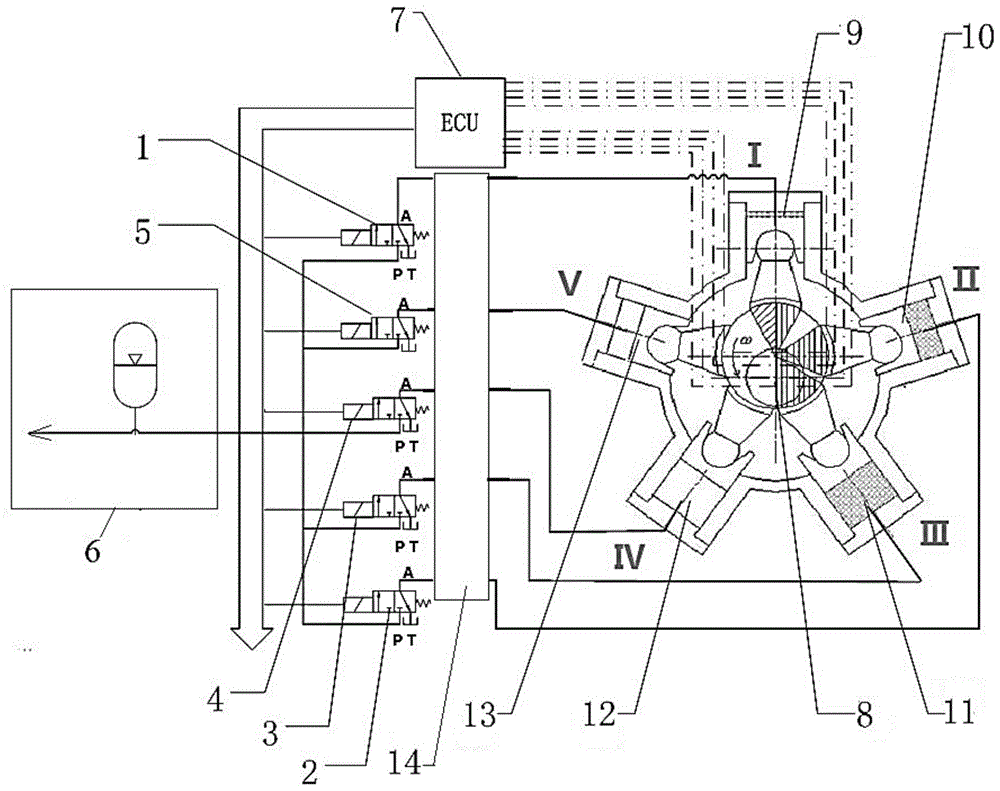

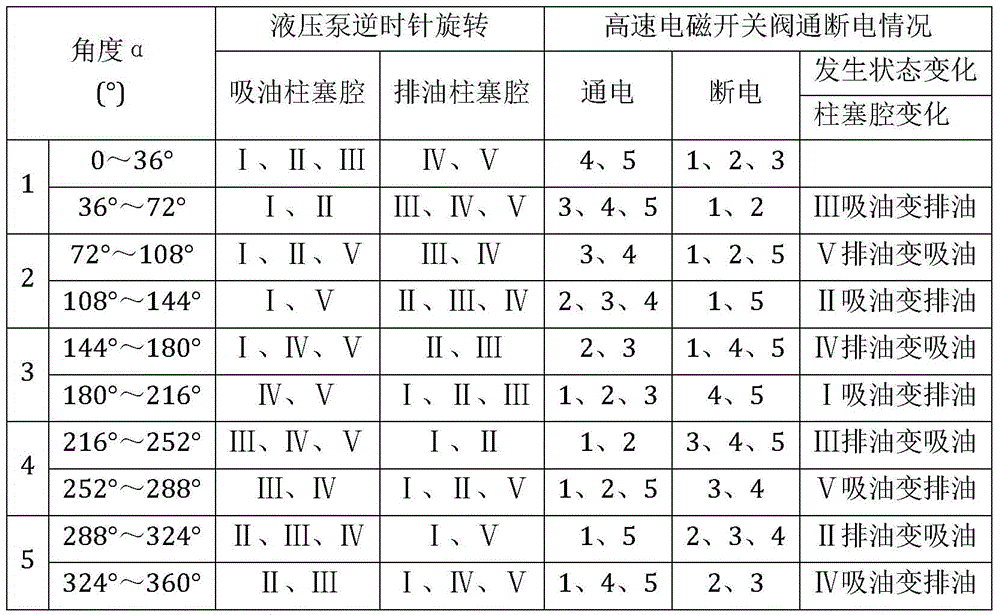

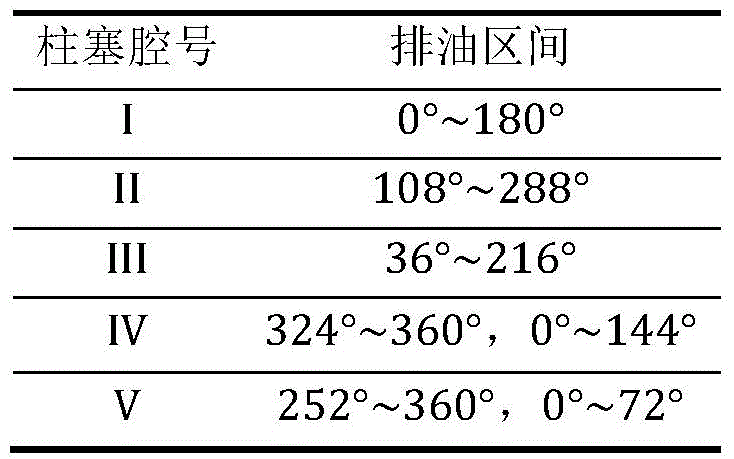

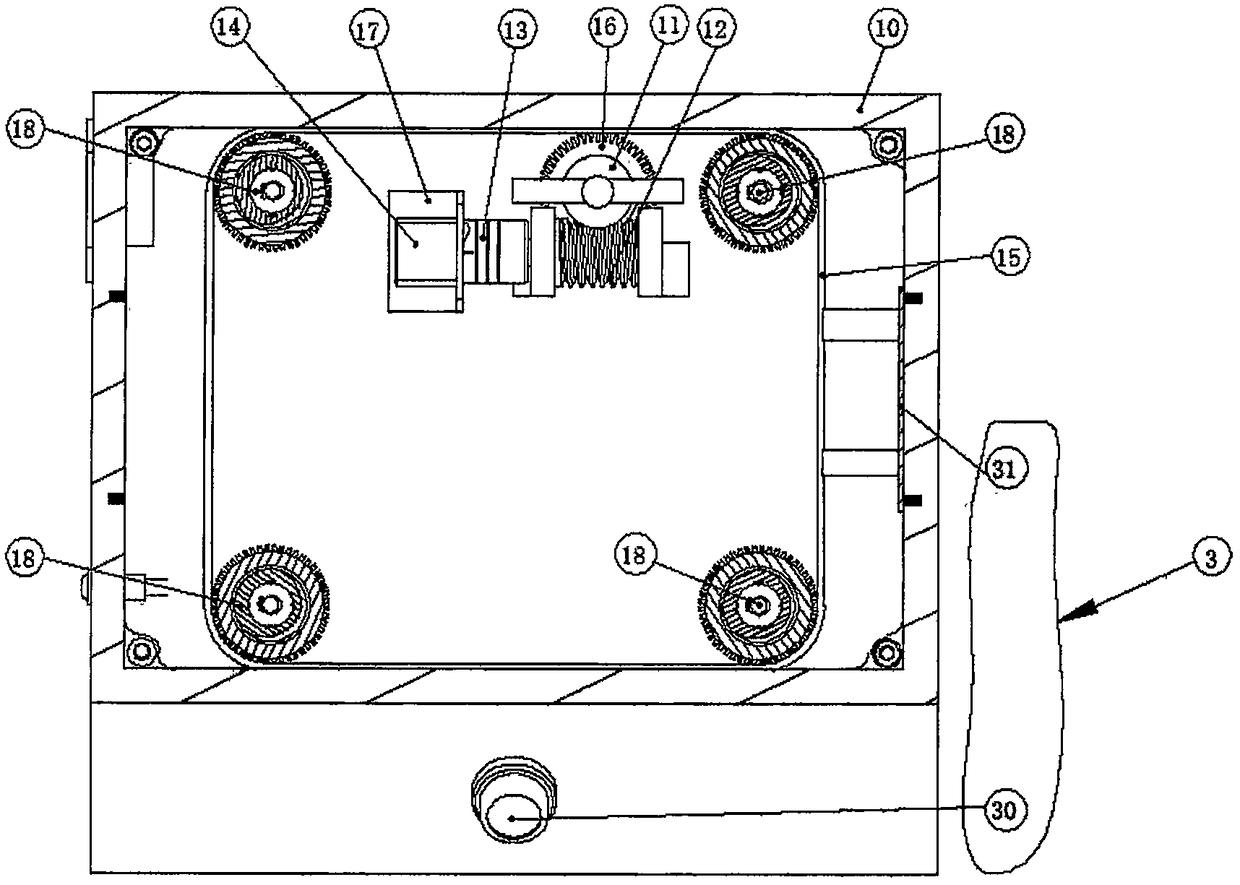

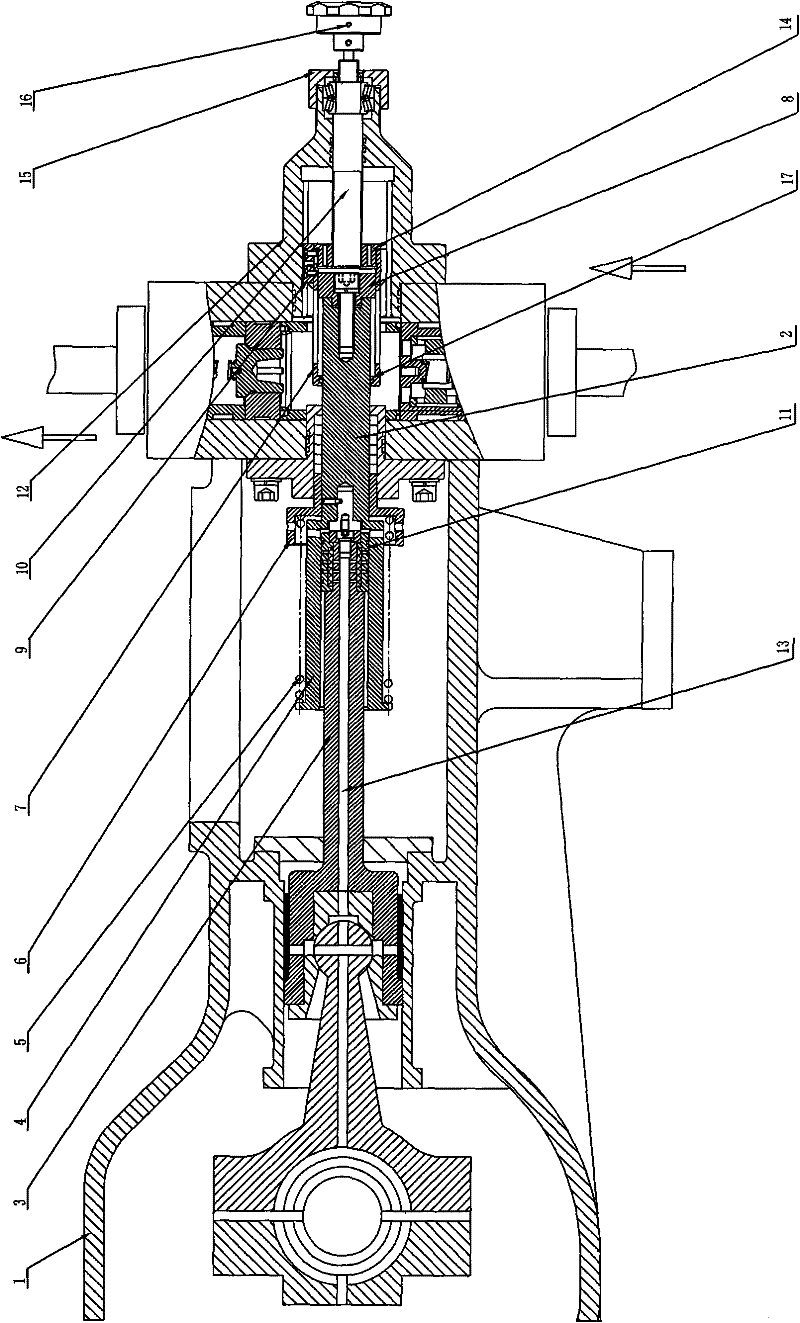

Digital flow-distribution constant-flow radial plunger pump

InactiveCN105386953ASmall pulsationGood for long time operationPositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpControl signal

Provided is a digital flow-distribution constant-flow radial plunger pump. The digital flow-distribution constant-flow radial plunger pump comprises plunger chambers arranged in a pump body, two-position three-way high-speed switching valves connected with an oil tank and a load, an absolute value angle encoder connected with crank shafts of the plunger chambers, a flow-distribution body and a controller, wherein the two-position three-way high-speed switching valves are connected with the plunger chambers through the flow-distribution body, the controller is connected with the absolute value angle encoder and the two-position three-way high-speed switching valves, the controller receives a corner signal measured through the absolute value angle encoder, a PWM signal and a stroke control signal are output to the two-position three-way high-speed switching valves through a duty ratio control algorithm and a stroke ratio control algorithm, and therefore constant flow of the pump is achieved. According to the digital flow-distribution constant-flow radial plunger pump, the valves are controlled through the duty ratio and the stroke ratio, pulsation of the output flow of a hydraulic pump is reduced, pump vibration is relieved, long-time running of the pump is facilitated, random rotating speed working condition can be adapted, and constant-flow output is achieved.

Owner:SHANGHAI JIAO TONG UNIV

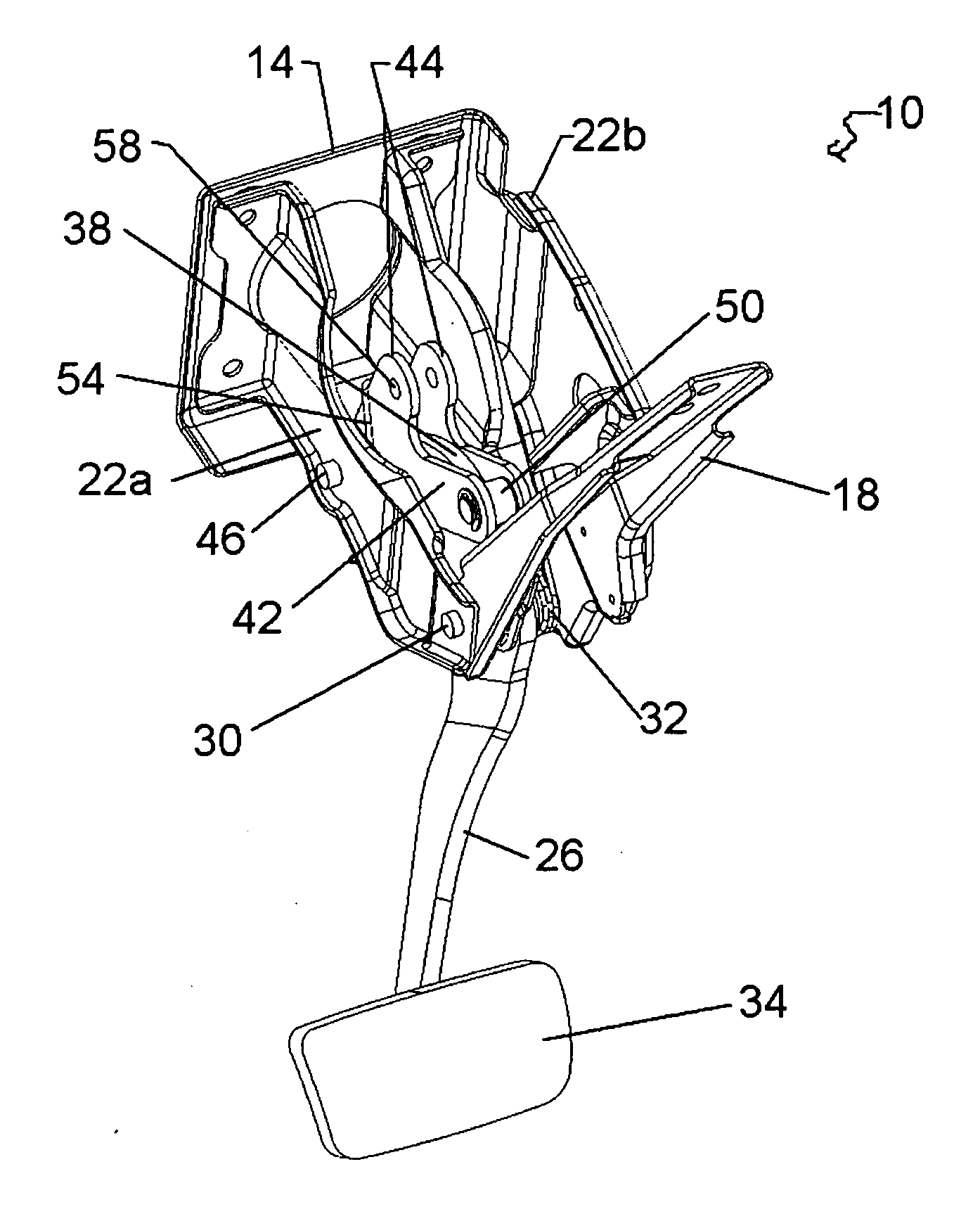

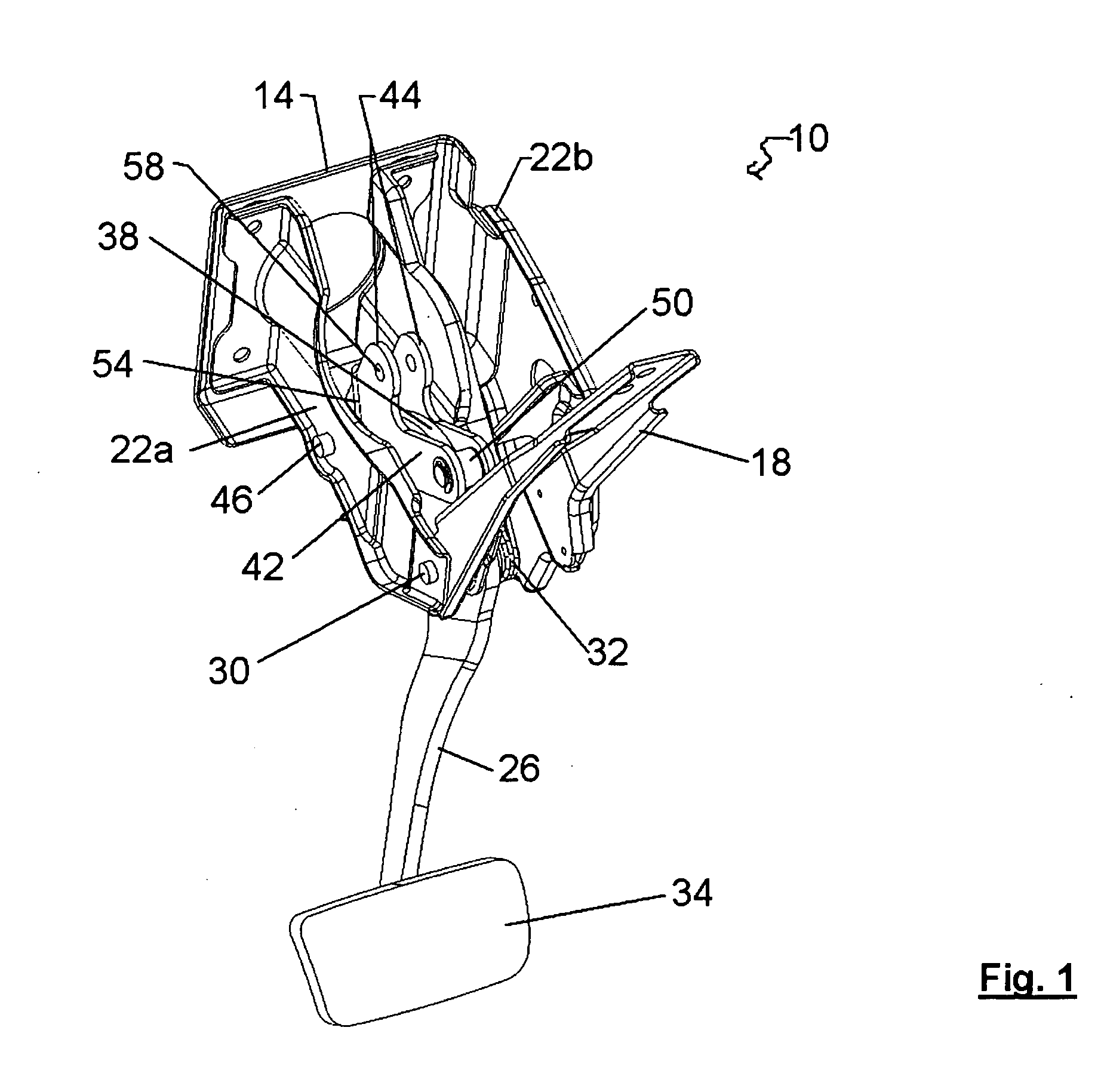

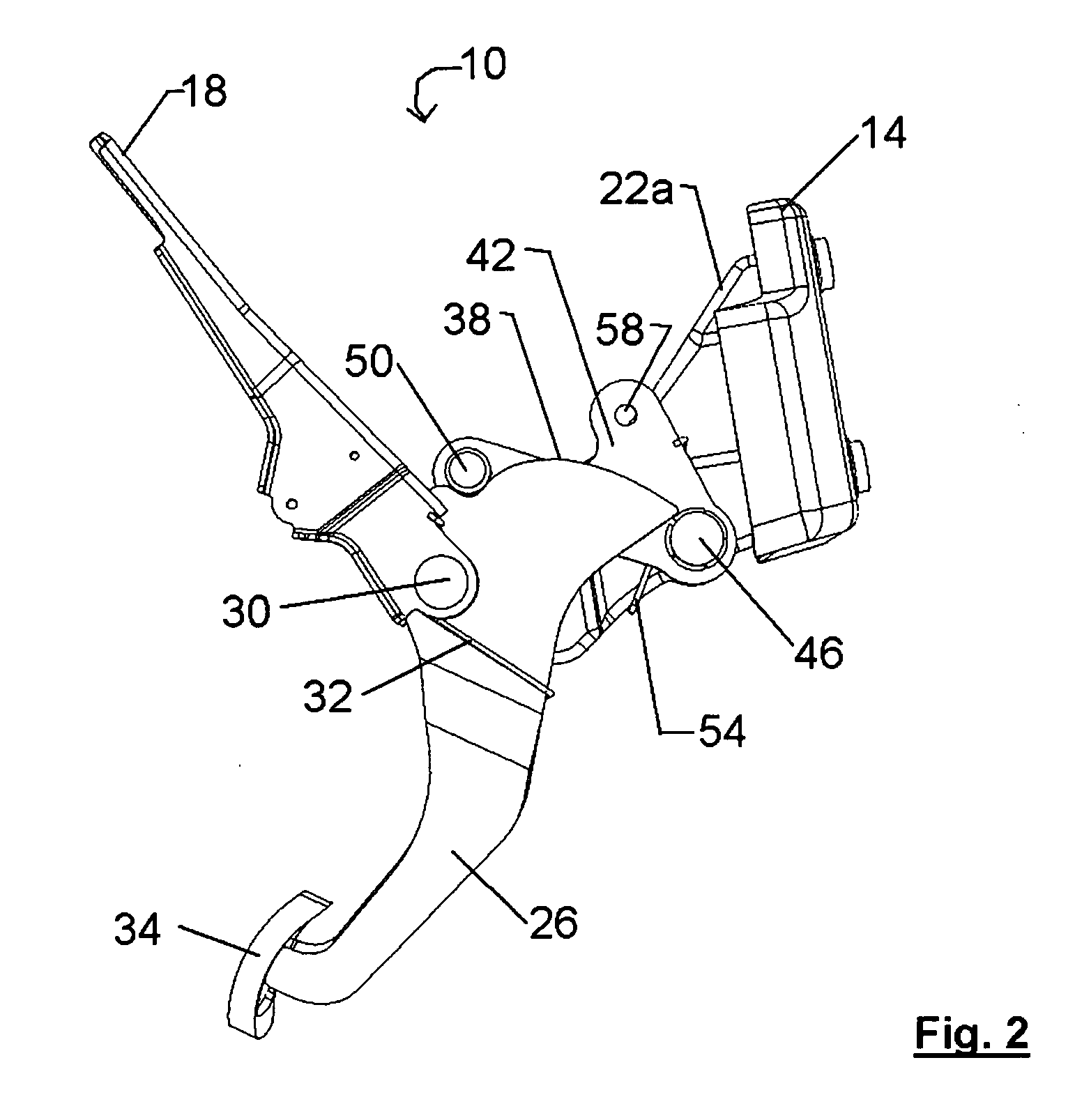

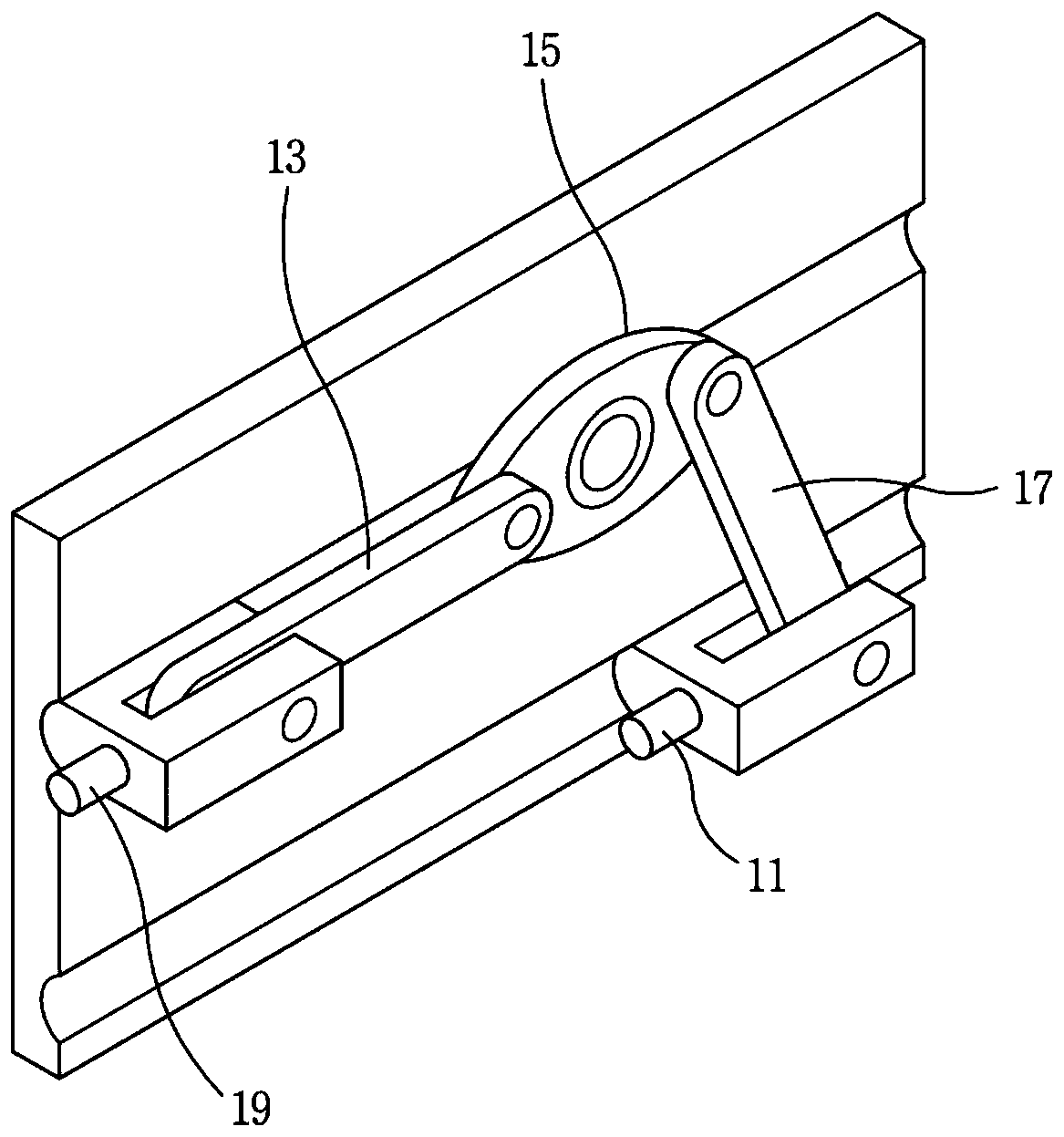

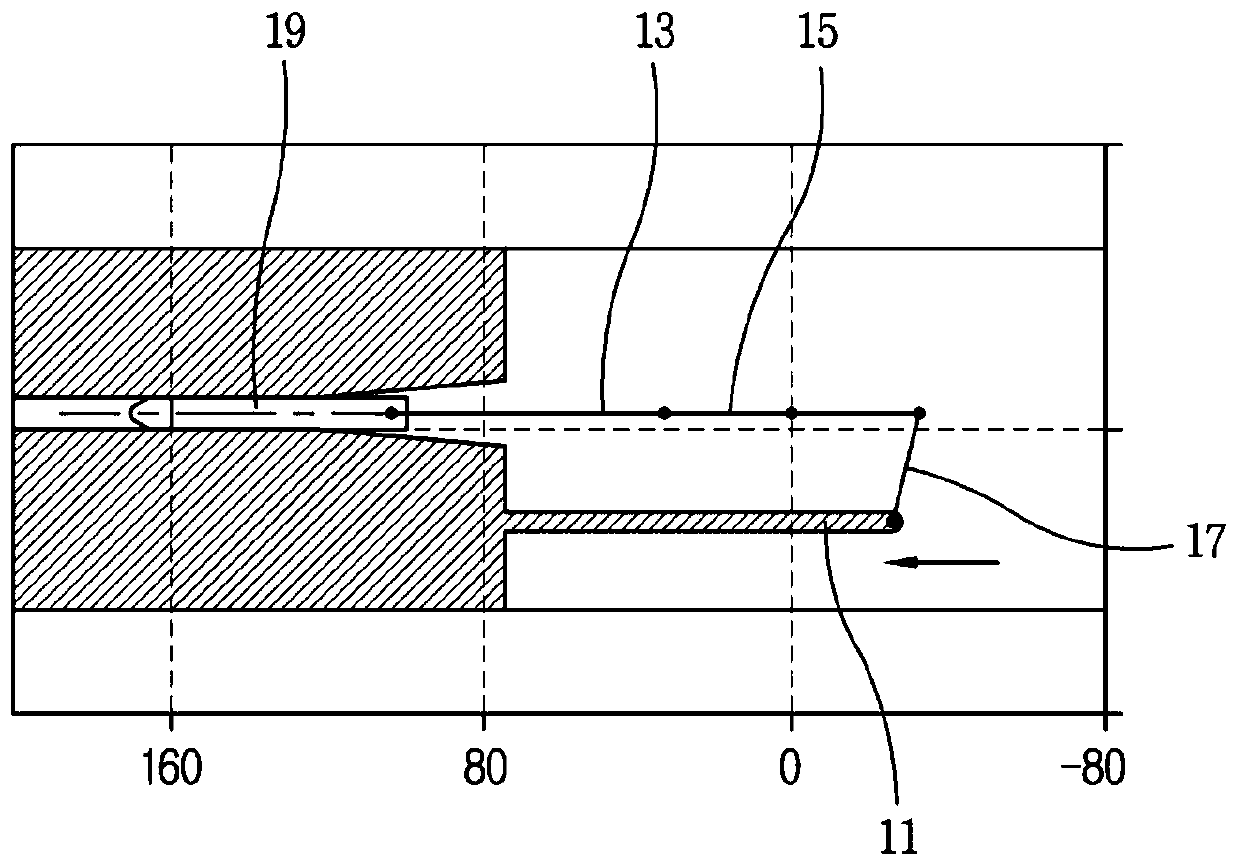

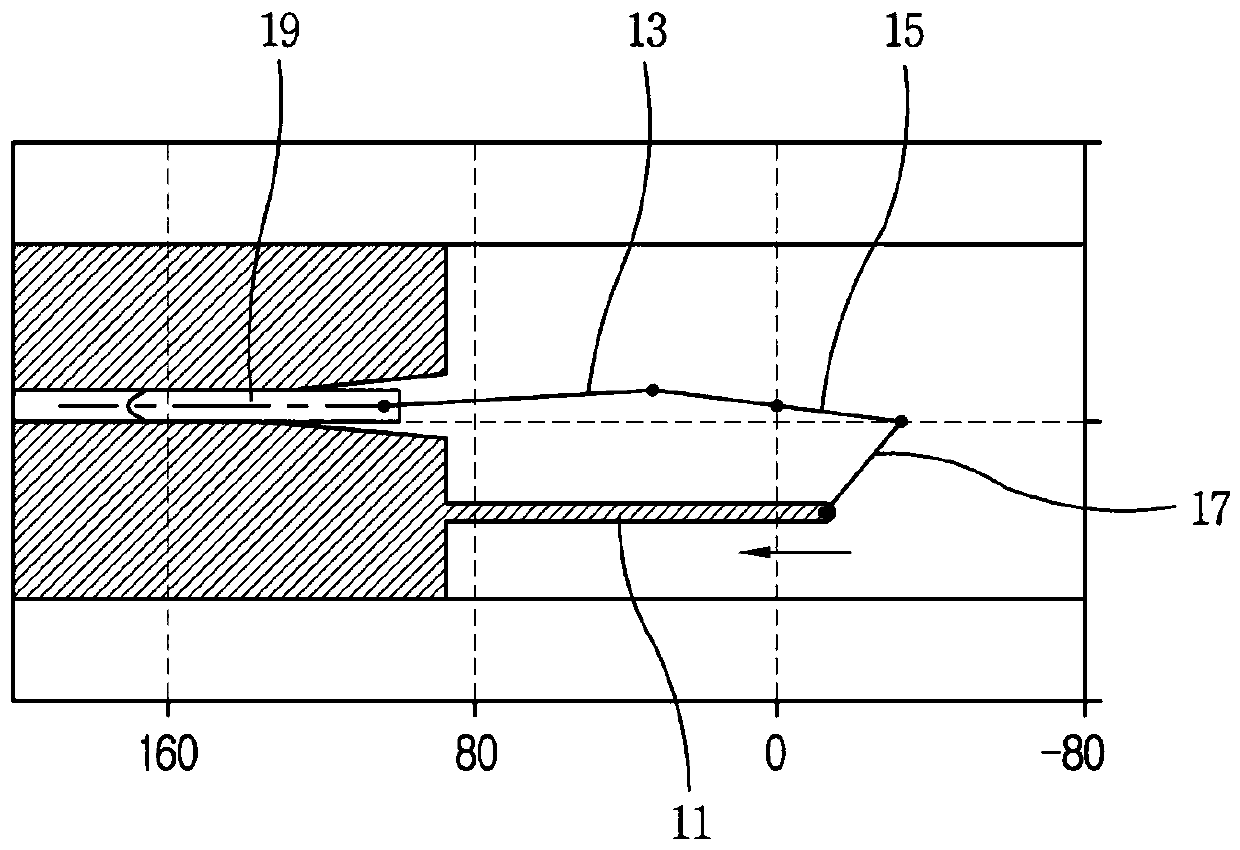

Variable rate control pedal

A control pedal assembly includes an eccentric curve as an actuator surface at one end of a pedal arm and a control member includes a first lobe with a roller that rides on the actuator surface and a second lobe that receives a connector rod to a control device to be controlled by the pedal. The eccentric curve changes the stroke ration between the pedal stroke and the connector rod stroke as the pedal is depressed. Designers can simply and efficiently vary the stroke ratio as desired by selecting an appropriate curve for the actuator surface.

Owner:INTIER AUTOMATIVE CLOSURES INC

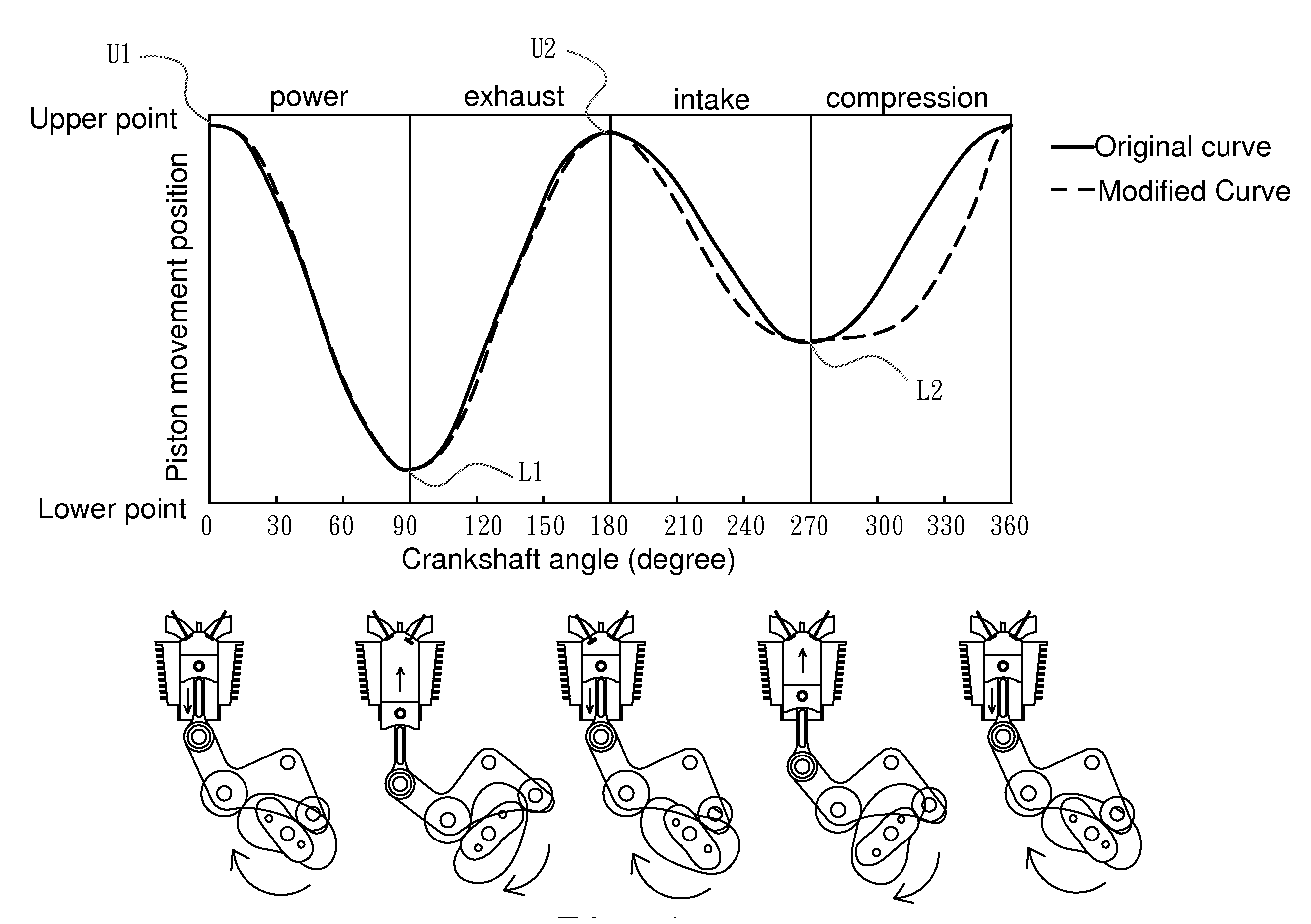

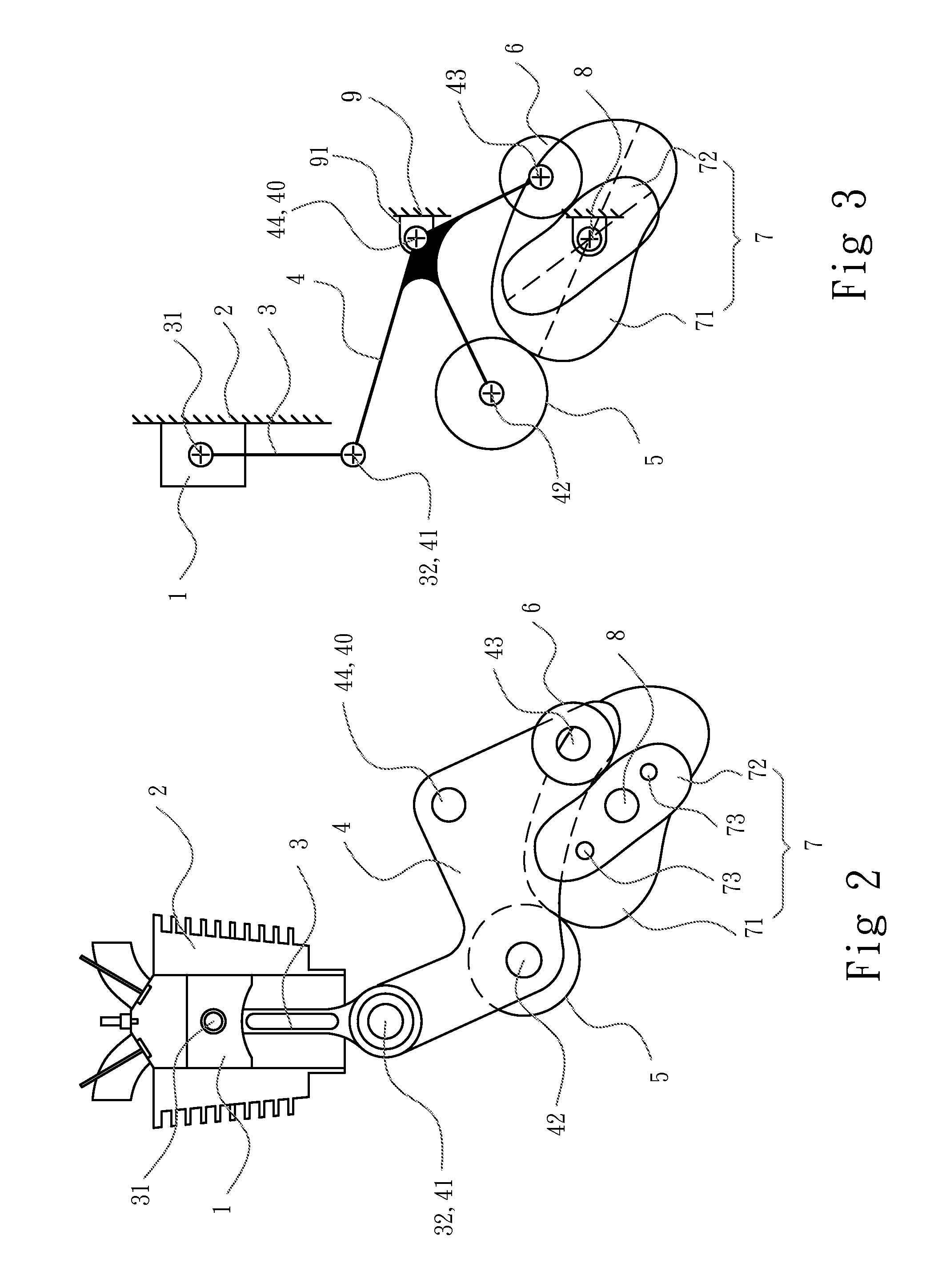

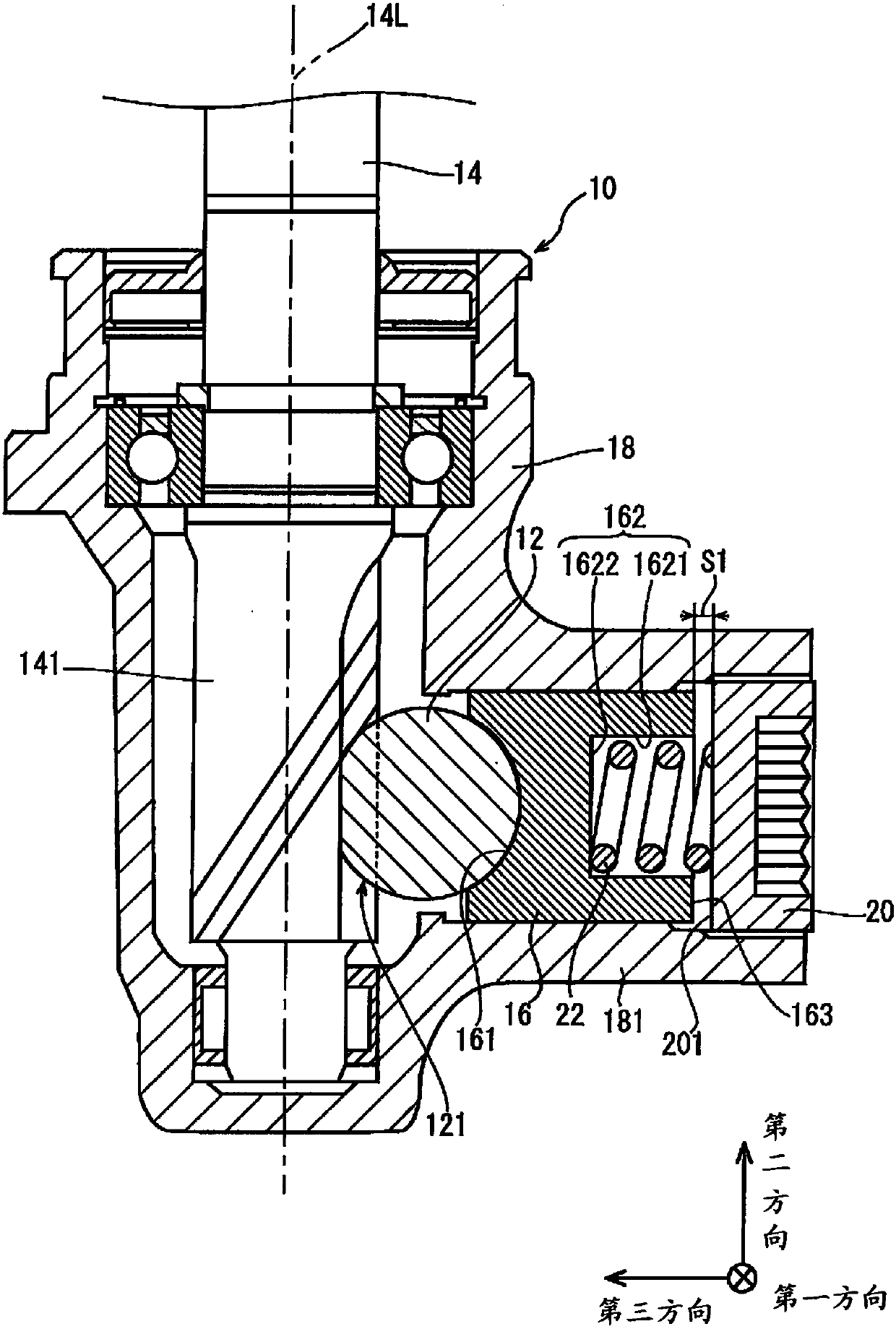

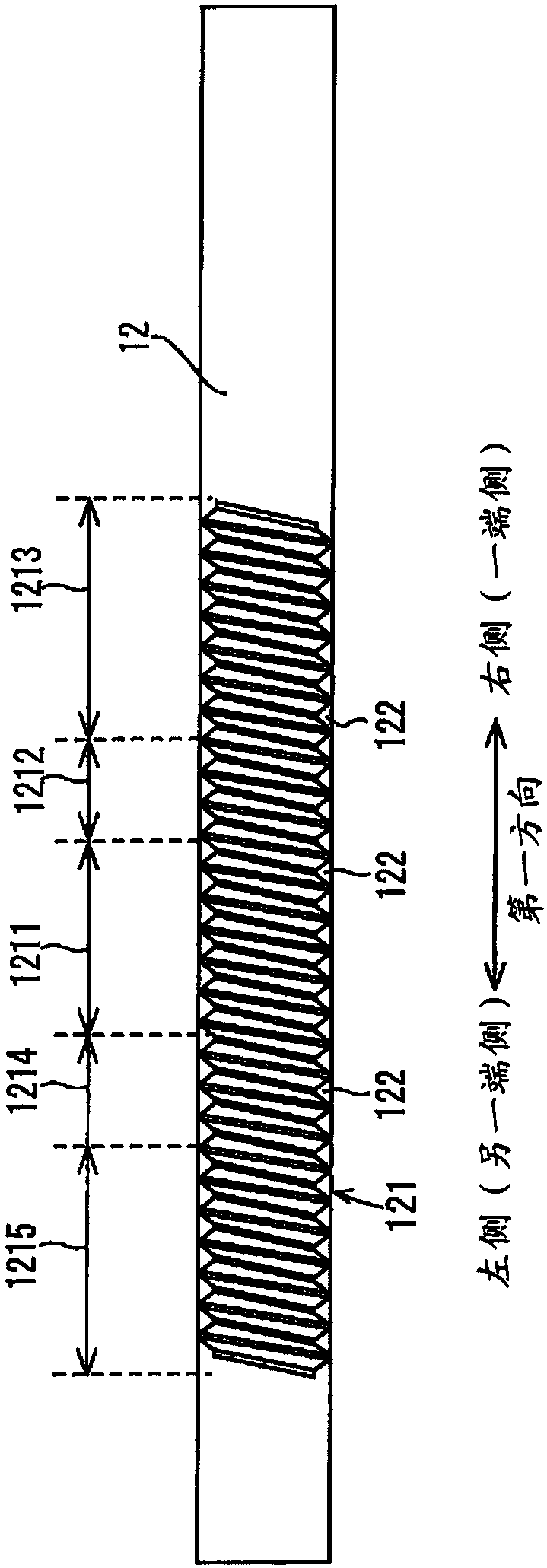

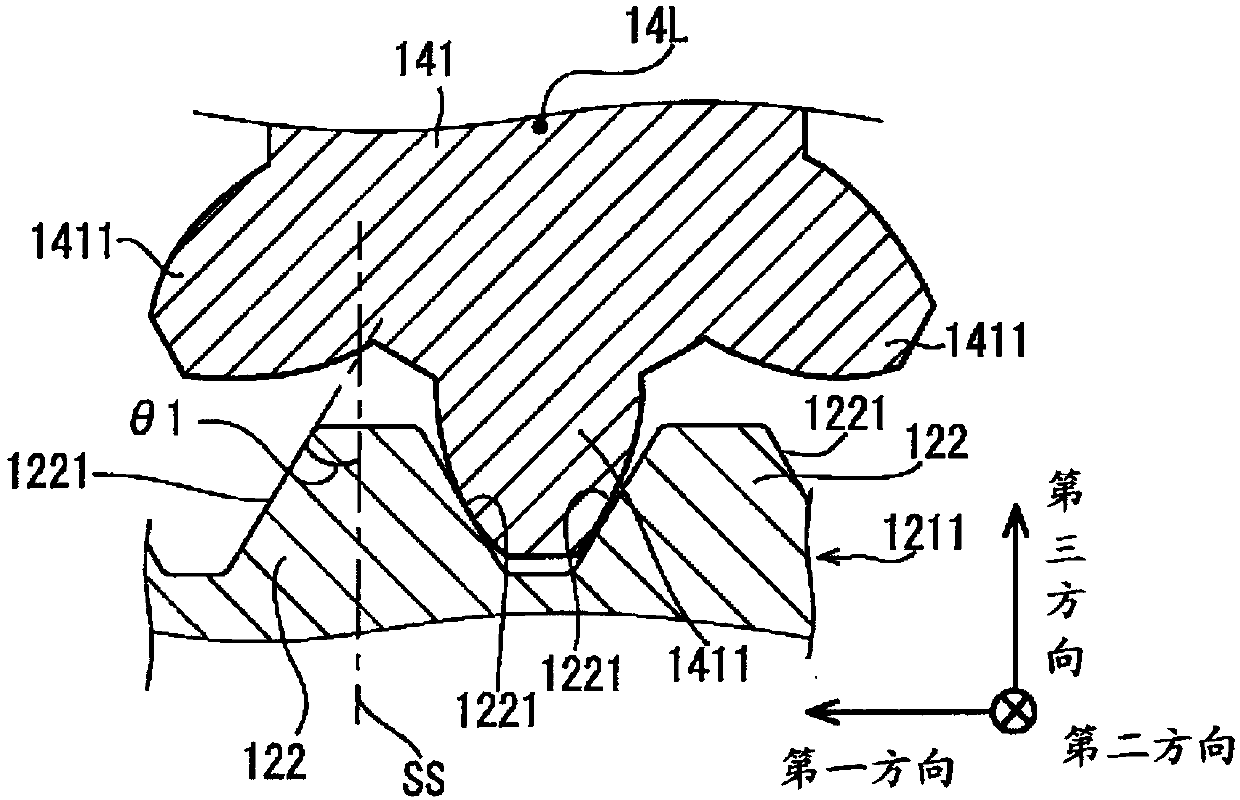

Engine structure having conjugate cam assembly

InactiveUS20110277732A1High power outputImprove efficiencyConnecting rodsCombustion enginesCamControl theory

An engine structure having a conjugate cam assembly is provided and includes a piston which can be used to push or pulled by the conjugate cam assembly mounted on a camshaft through a connection rod, a roller rocker and two rollers. The conjugate cam assembly has two cams with cam profiles and relative arrangement angle which can be varied according to actual operational desire, so as to vary the ratio of intake / exhaust strokes and the ratio of compression / power strokes. Thus, the combustion efficiency and the exhaustion efficiency can be enhanced. When the camshaft finishes four strokes of an operational cycle, the camshaft only rotates one circle (i.e. 360 degree), so that the rotation speed of the camshaft can be lowered.

Owner:NAT SUN YAT SEN UNIV

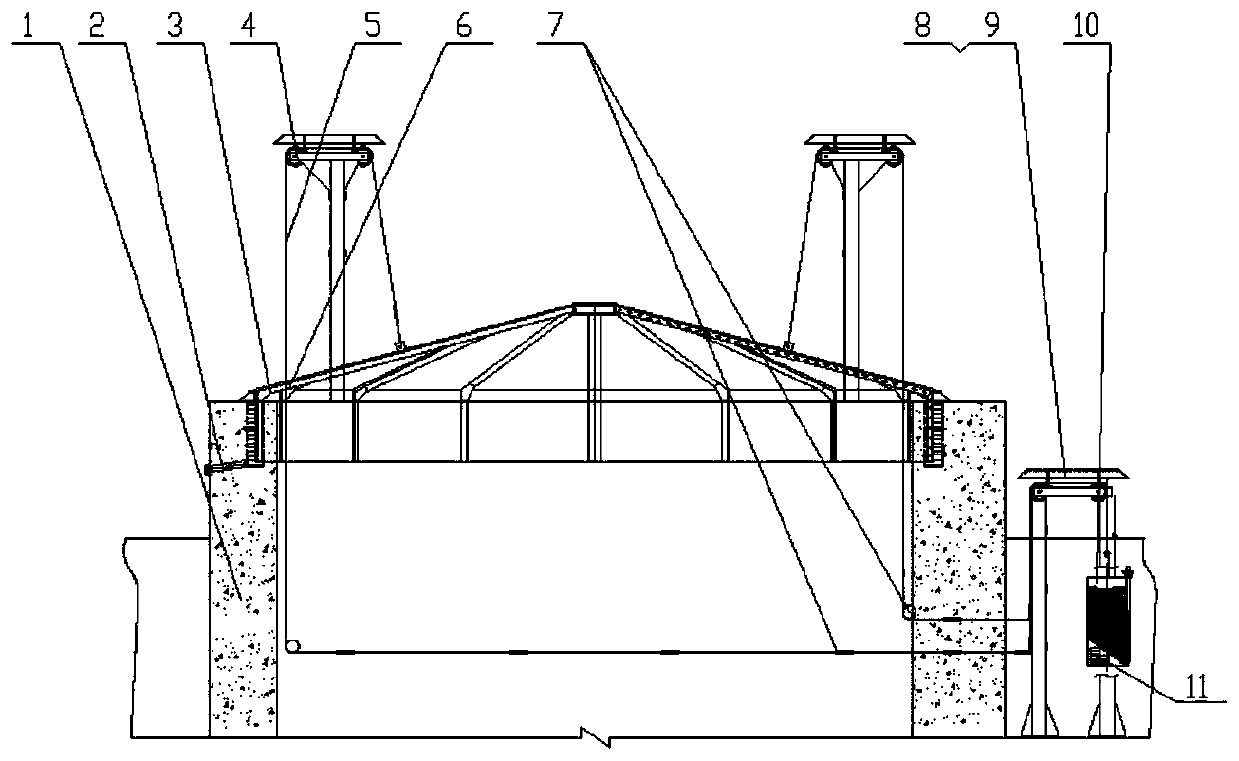

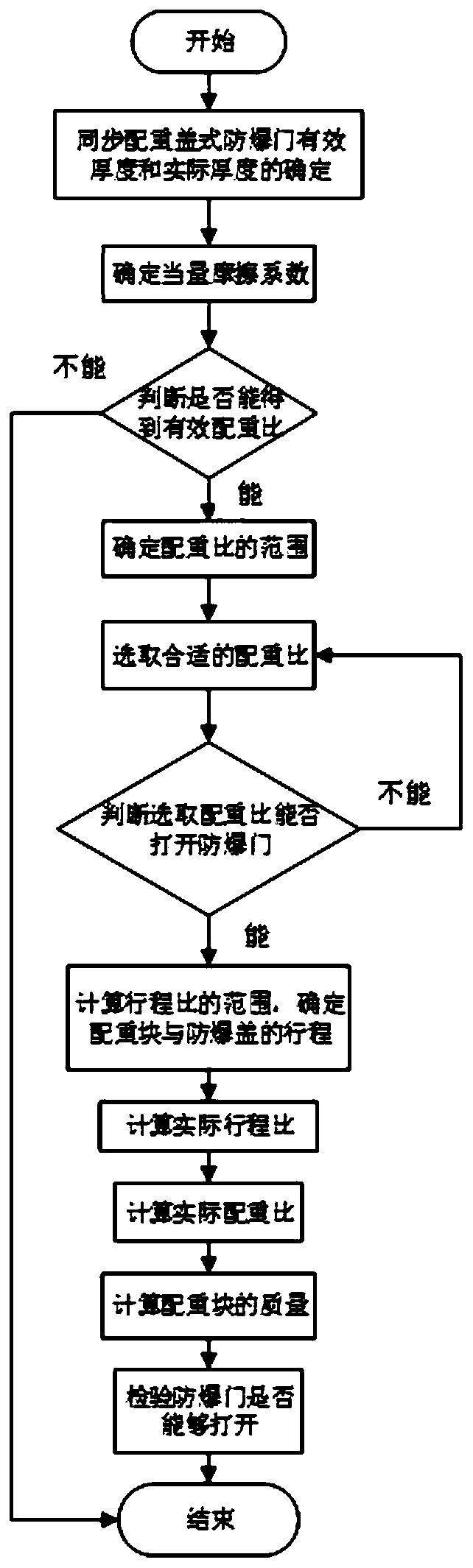

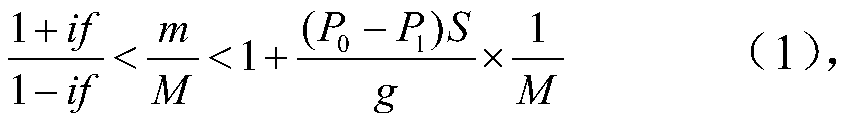

Design method of synchronous counterweight cover type explosion-proof door

ActiveCN110287635ASimple calculationSmall amount of calculationTunnel/mines ventillationDesign optimisation/simulationSystems designEngineering

The invention discloses a design method of a synchronous counterweight cover type explosion-proof door, and belongs to the field of mine ventilation system design. The method for calculating the thickness of the steel plate for the explosion-proof cover plate is given according to the strength theory in the design of the pressure container. The concept of the weight ratio and the stroke ratio is introduced for the first time, a method for calculating the weight ratio and the stroke ratio range is given to reasonably determine the weight, the stroke of the explosion-proof cover and the stroke of the balancing weight of the balancing weight system, and the height of the redirection wheel frame and the height of the balancing weight frame can be further determined through the stroke of the explosion-proof cover and the stroke of the balancing weight. The design and calculation method for the synchronous counterweight cover type explosion-proof door is simple in calculation, the calculation amount during design is reduced, concepts of the counterweight ratio and the stroke ratio are creatively provided, blindness of design of the synchronous counterweight cover type explosion-proof door can be avoided, and the design and calculation method has high engineering practice feasibility and effectiveness.

Owner:HEFEI UNIV OF TECH

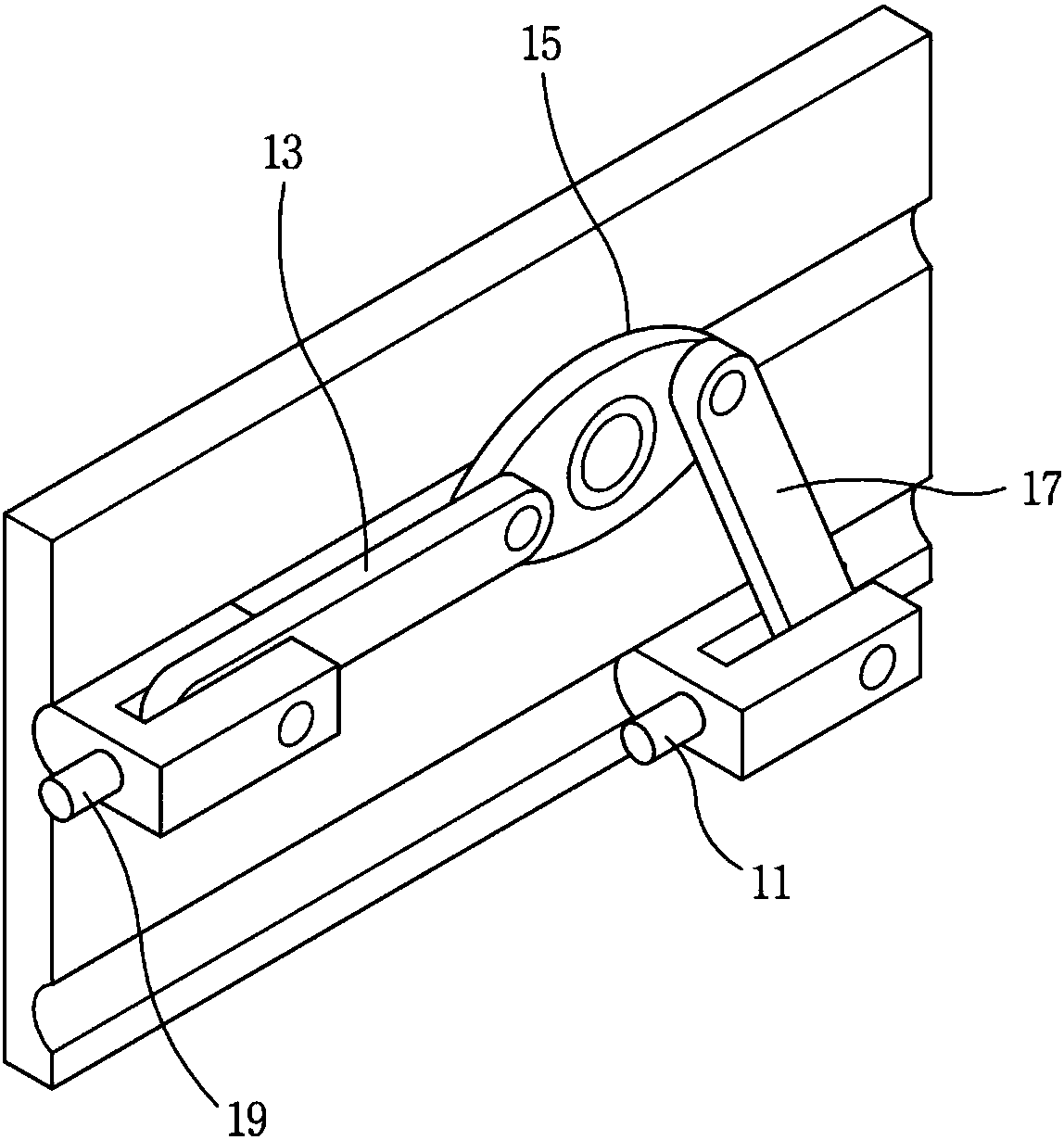

Rack-and-pinion steering apparatus

InactiveUS8683887B2Reducing meshing frictionStably offering smooth and comfortable steering feeling over a long timePortable liftingToothed gearingsEngineeringHelix angle

A rack-and-pinion steering apparatus comprises pinion teeth formed according to proper tooth specifications in other aspects under a larger pressure angle, thereby stably offering smooth and comfortable steering feeling over a long time. The module (m), number of teeth (z), tooth depth (h) and helix angle (β) of the pinion teeth (4) are set within the following ranges, under a pressure angle (α) set within a range of 24° to 30° and a given stroke ratio.module (m): 1.8 to 2.0number of teeth (z): 7 to 13tooth depth (h): 2 m to 2.5 mhelix angle (β): 35° or smaller

Owner:JTEKT CORP

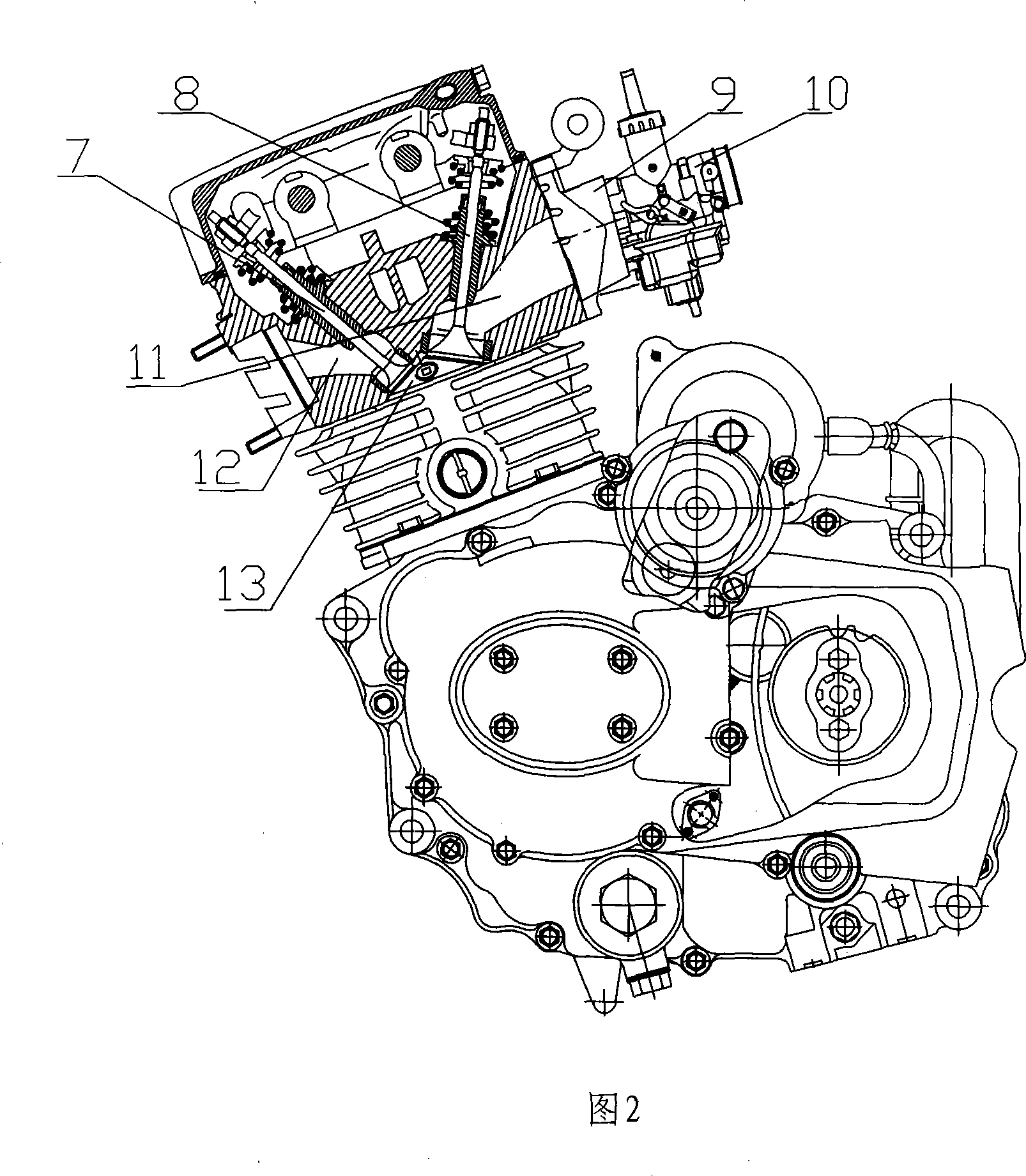

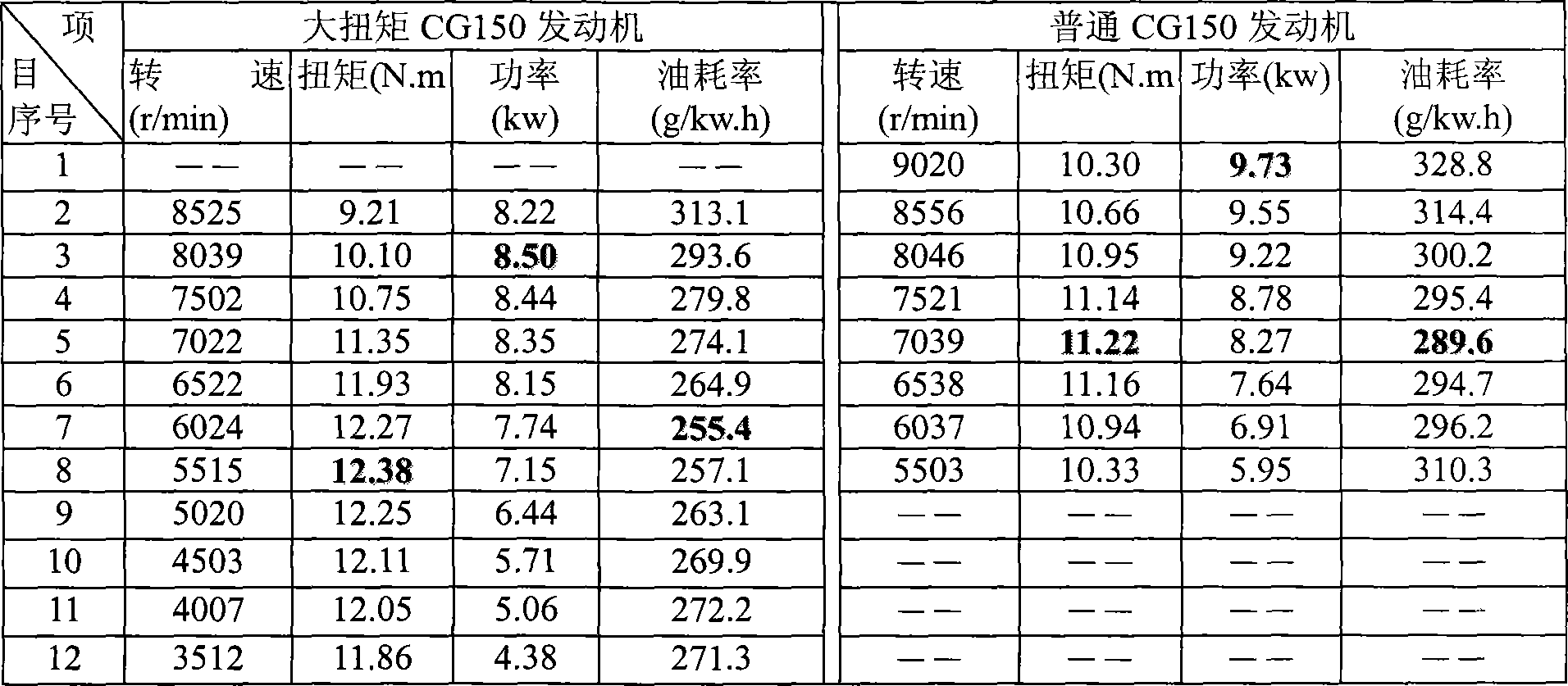

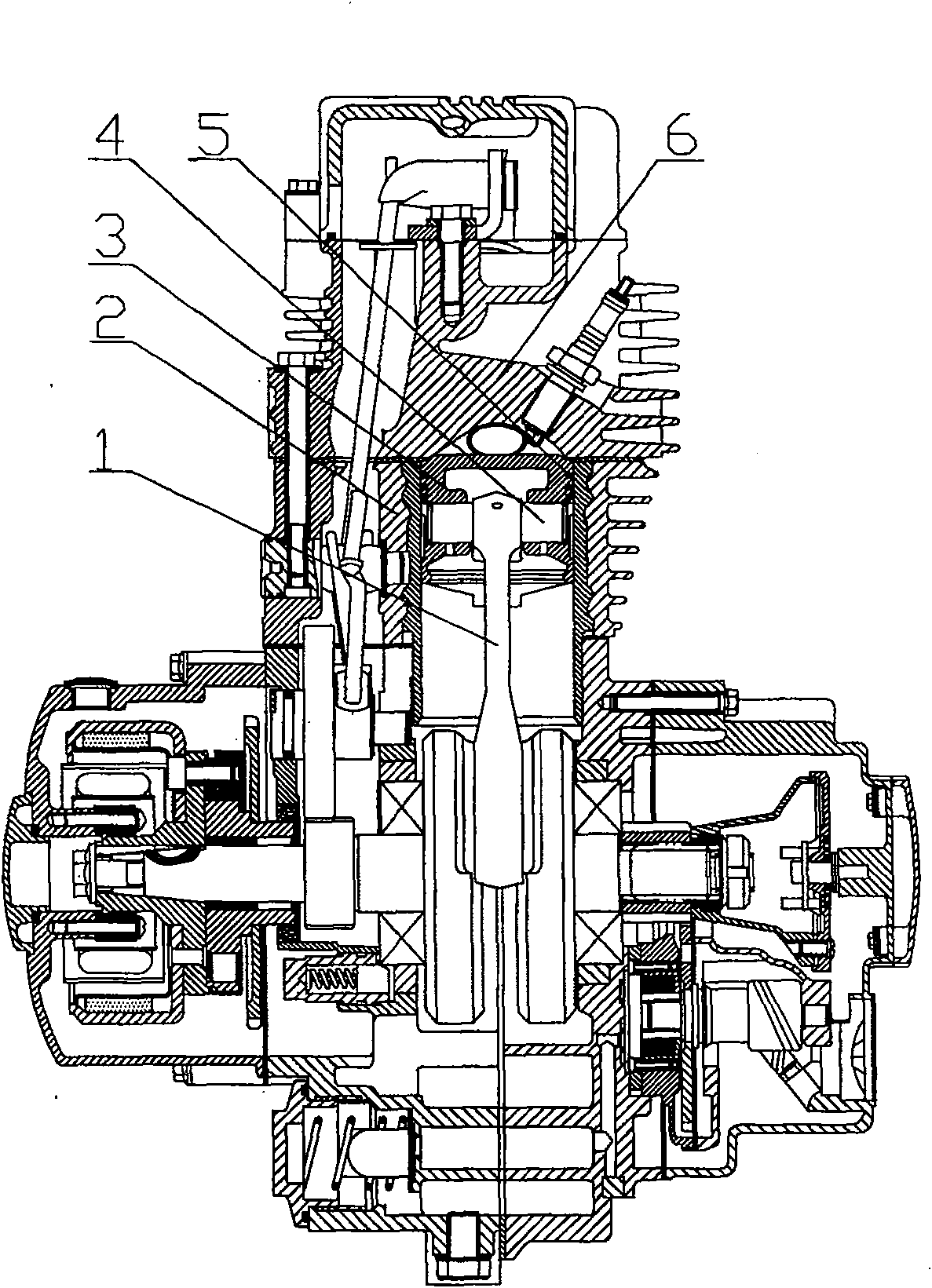

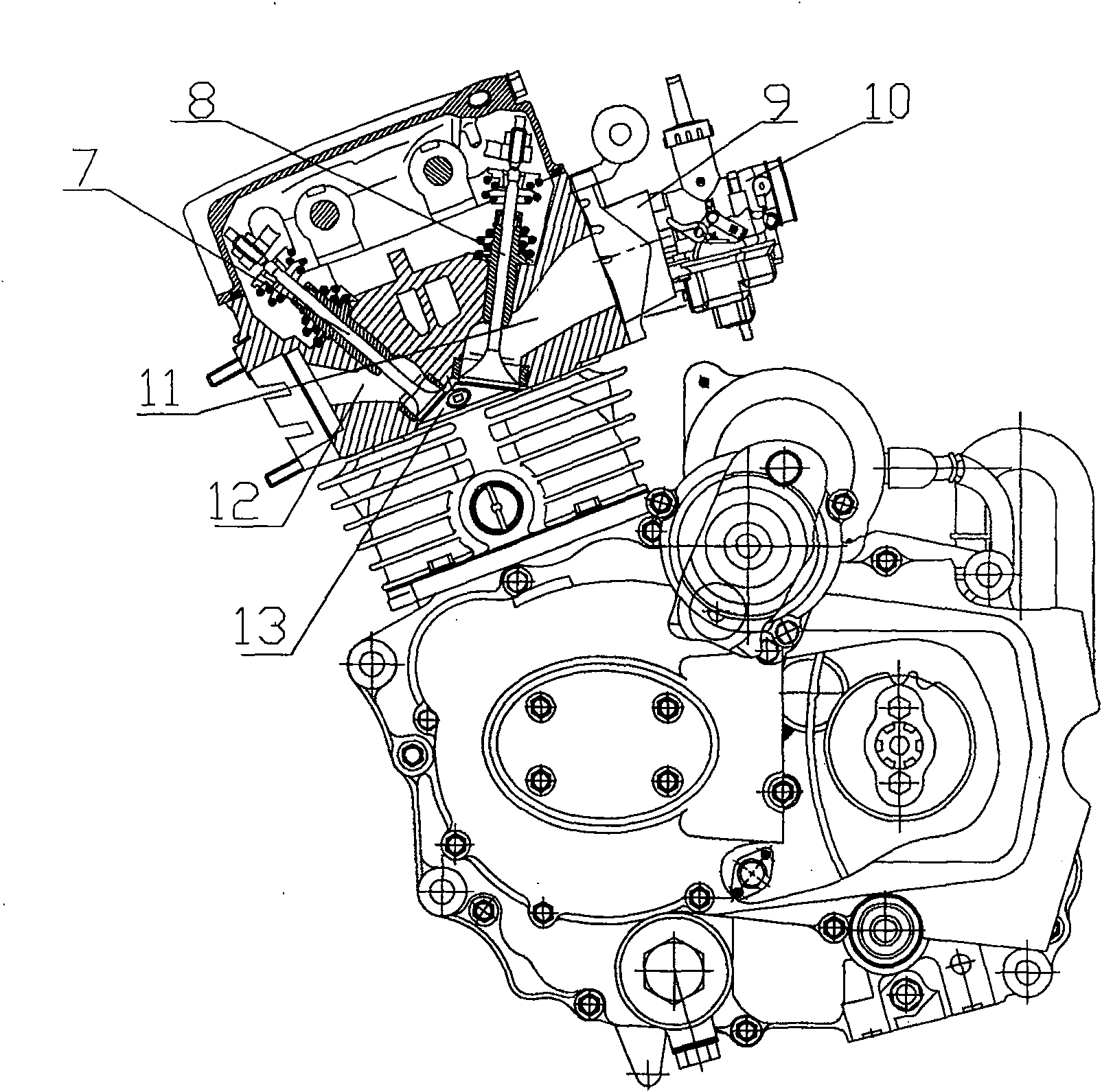

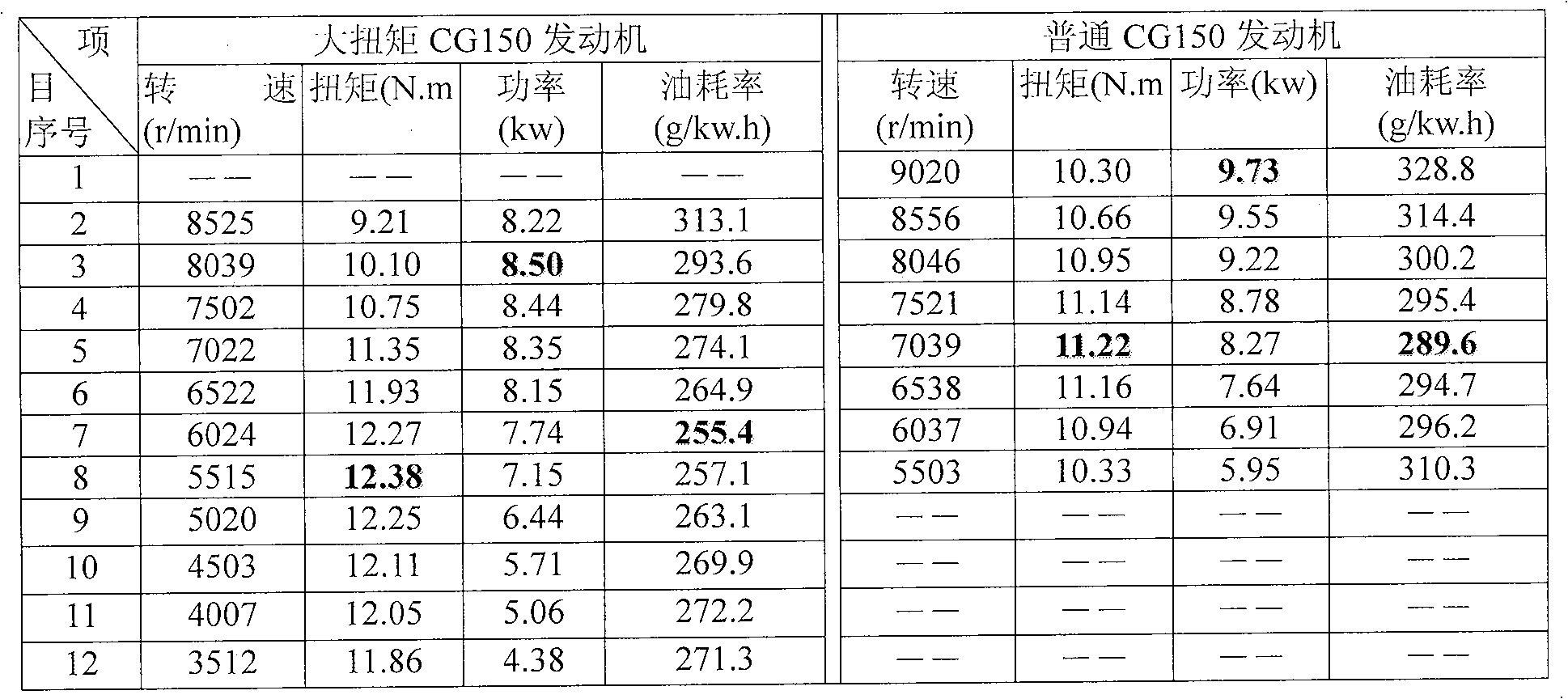

Low rotation speed large torque engine

InactiveCN101235749AHigh output torqueMaximum torque point speed dropCylinder headsCylindersLow speedExhaust valve

The invention discloses a motor with low rotary speed and large torque, which comprises a crank connecting rod assembly, a cylinder block, a piston, a piston pin, a piston ring assemblage, a cylinder head, an exhaust valve, an inlet valve, an air inlet pipe and a carburetor, wherein the piston is fixed on the crank connecting rod assembly via the piston pin, the piston is arranged in the cylinder block, the exhaust value and the inlet valve are arranged in the duct of the exhaust value and the inlet valve of the cylinder head, the cylinder head is arranged on the cylinder block, the air inlet pipe is arranged on one side of the intake of the cylinder head, the carburetor is arranged on the air inlet pipe, the eccentricity of the crank connecting rod assembly is from 28.90mm to 31.10mm, and the diameter of the piston is from 54.5mm to 57mm, and the diameter of the cylinder / the stroke ratio is from 0.88 to 0.98. The motor is suitable for motor bicycles, motor tricycles, sand bank cars and carting cars, which has the advantages of outputting larger torque at the low speed, reducing the rotary speed at the maximum torque point, improving the initial starting acceleration property and the transcending accelerating ability, reducing heat load, oil consumption and oscillation, and increasing the durability.

Owner:吕清波

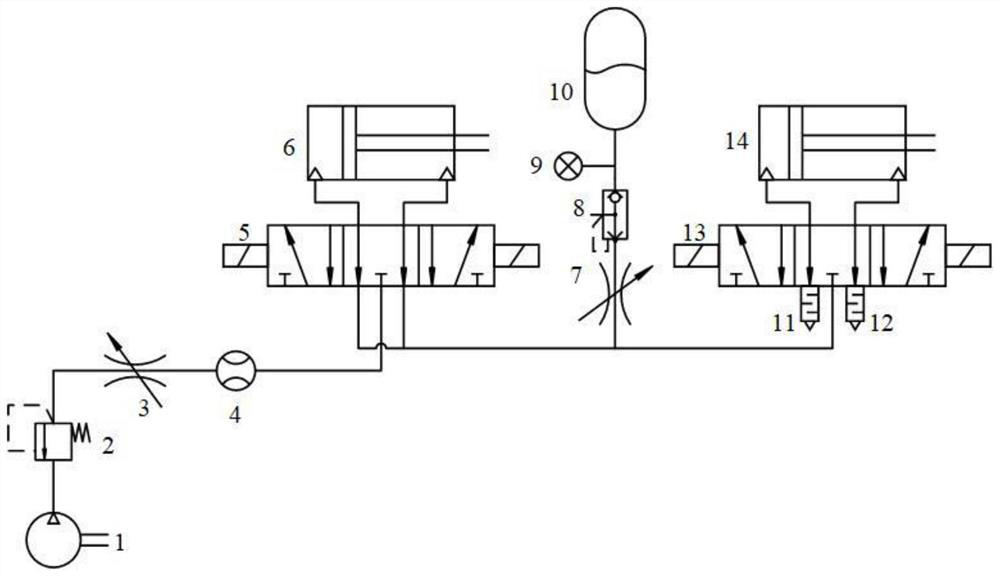

Air cylinder exhaust energy-saving system and method based on strain energy accumulator

PendingCN113565838AImprove efficiencyRealize energy storageServometer circuitsActuator accumulatorsEngineeringAir compressor

Owner:DALIAN MARITIME UNIVERSITY

Digital distribution constant flow radial piston pump

InactiveCN105386953BSmall pulsationGood for long time operationPositive-displacement liquid enginesMulti-cylinder pumpsRadial piston pumpControl signal

Provided is a digital flow-distribution constant-flow radial plunger pump. The digital flow-distribution constant-flow radial plunger pump comprises plunger chambers arranged in a pump body, two-position three-way high-speed switching valves connected with an oil tank and a load, an absolute value angle encoder connected with crank shafts of the plunger chambers, a flow-distribution body and a controller, wherein the two-position three-way high-speed switching valves are connected with the plunger chambers through the flow-distribution body, the controller is connected with the absolute value angle encoder and the two-position three-way high-speed switching valves, the controller receives a corner signal measured through the absolute value angle encoder, a PWM signal and a stroke control signal are output to the two-position three-way high-speed switching valves through a duty ratio control algorithm and a stroke ratio control algorithm, and therefore constant flow of the pump is achieved. According to the digital flow-distribution constant-flow radial plunger pump, the valves are controlled through the duty ratio and the stroke ratio, pulsation of the output flow of a hydraulic pump is reduced, pump vibration is relieved, long-time running of the pump is facilitated, random rotating speed working condition can be adapted, and constant-flow output is achieved.

Owner:SHANGHAI JIAOTONG UNIV

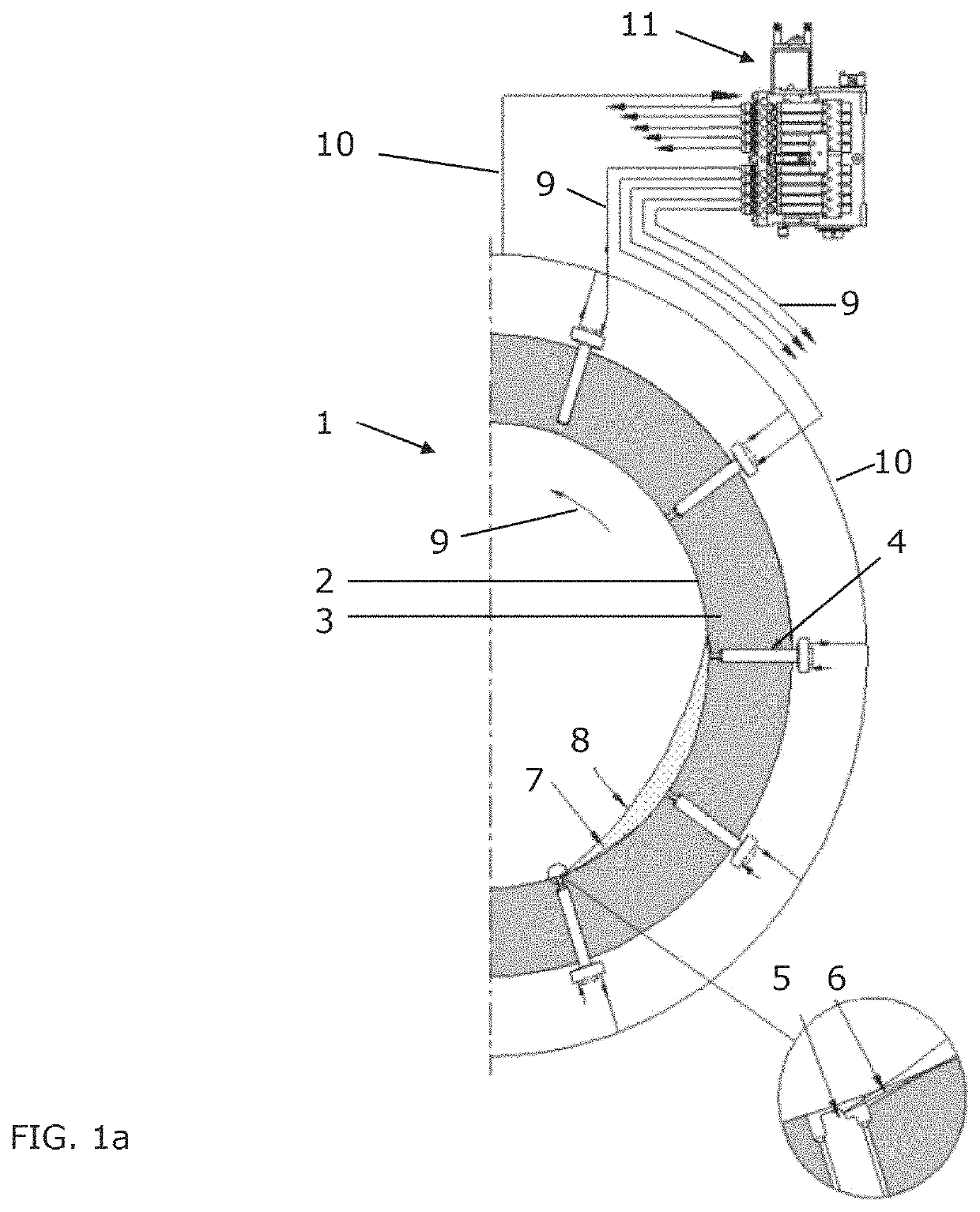

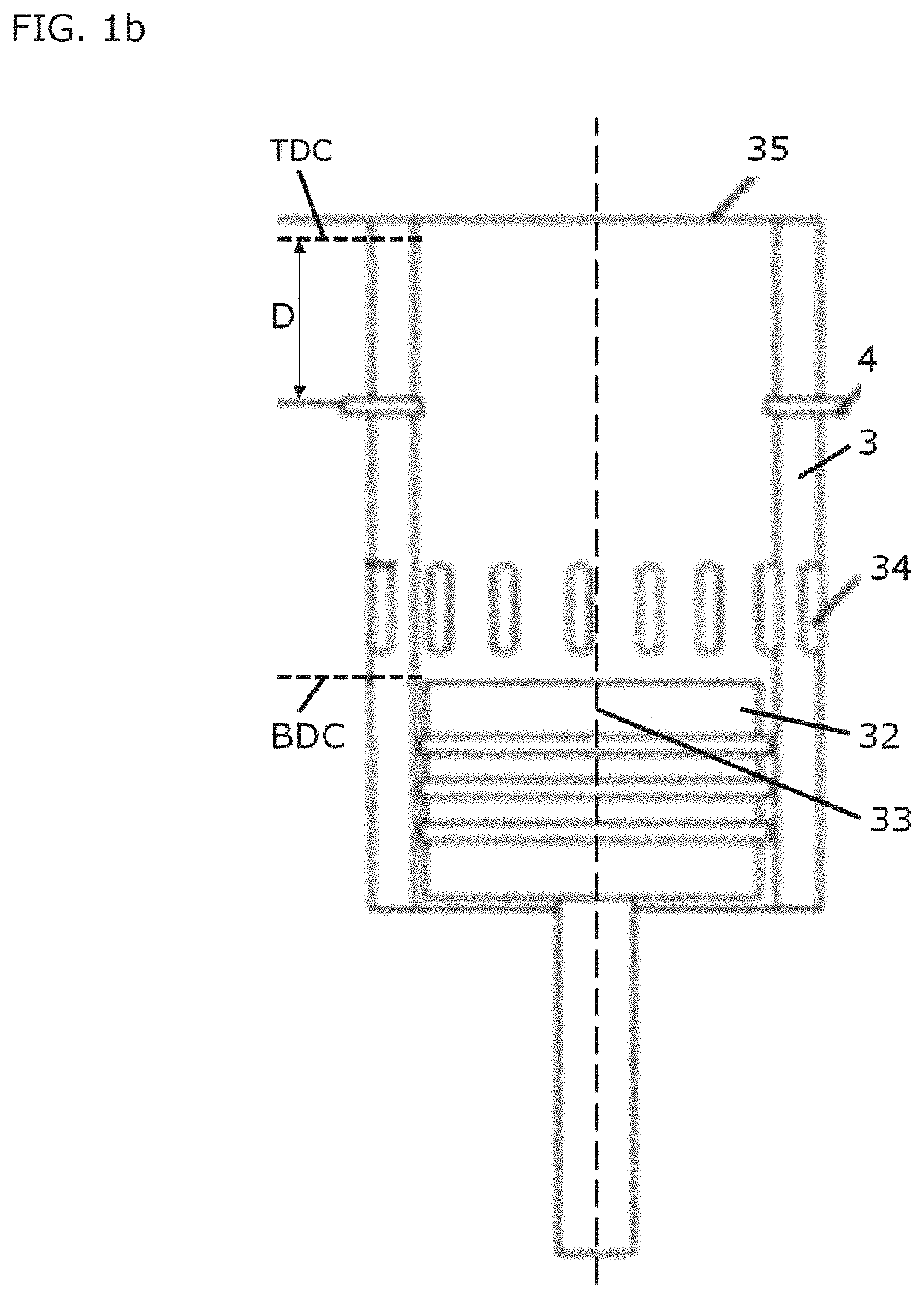

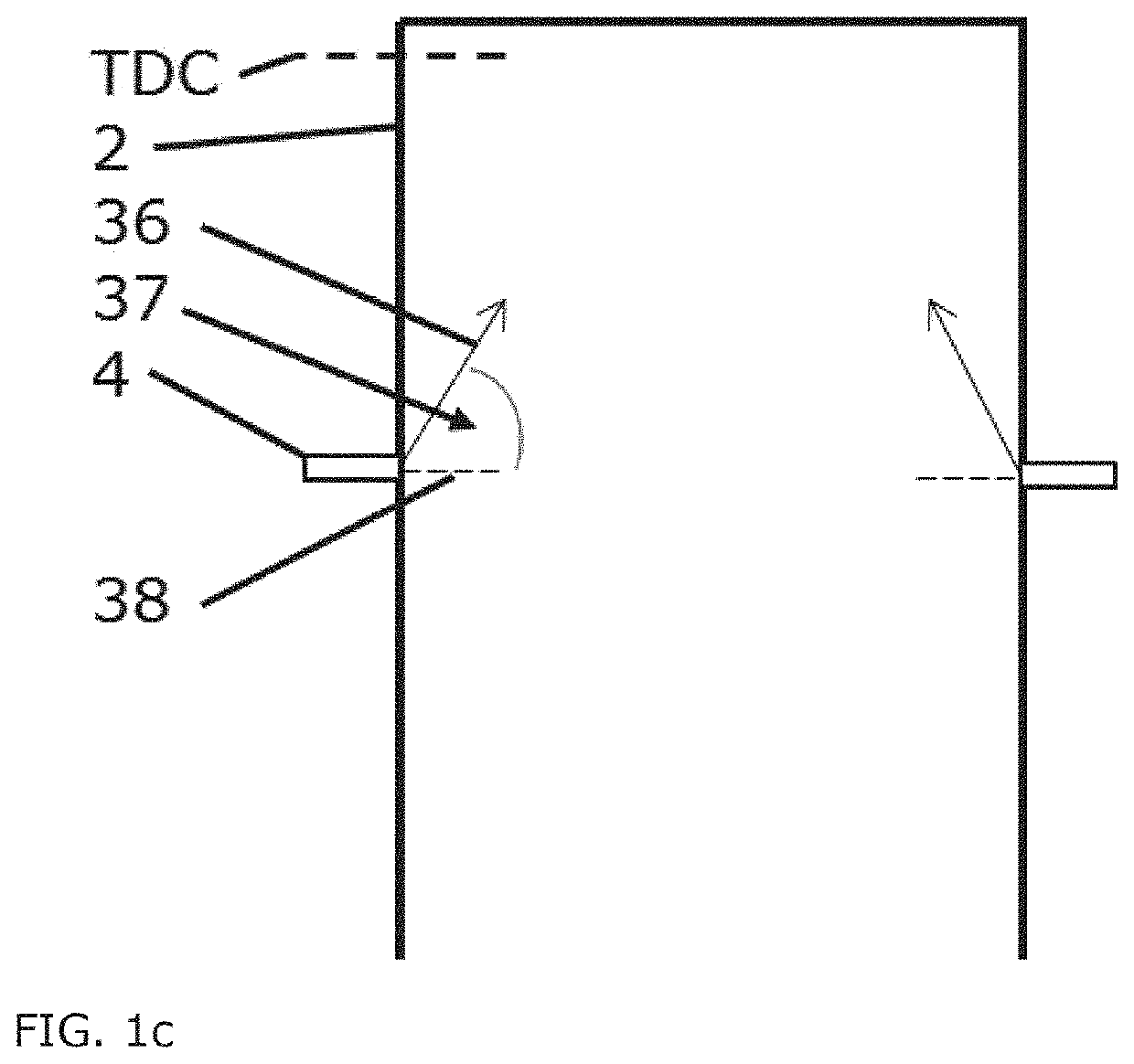

Large slow-running two-stroke engine with sip lubricant injector

ActiveUS10731527B2Improve the lubrication effectReduce wearCylinder headsCylindersDieselingControl theory

Disclosed is lubrication for a slow-running two-stroke engine, especially marine diesel engines. The lubrication uses Swirl Injection Principle by locating the lubricant injectors closer to the TDC than ⅕ of the full stroke of the piston, which is closer than in typical marine diesel engines. This can be achieved by reconstructing cylinder liners or by adding new mounting holes to the cylinder. In case that such reconstruction is not possible, an improvement of SIP principles can also be achieved by directing the spray towards the TDC or to a location on the cylinder liner closer to the TDC as compared to the location of the SIP valves, for example under an angle of more than 30 degrees or even more than 60 degrees when measured from a plane normal to the cylinder axis.

Owner:HANS JENSEN LUBRICATORS

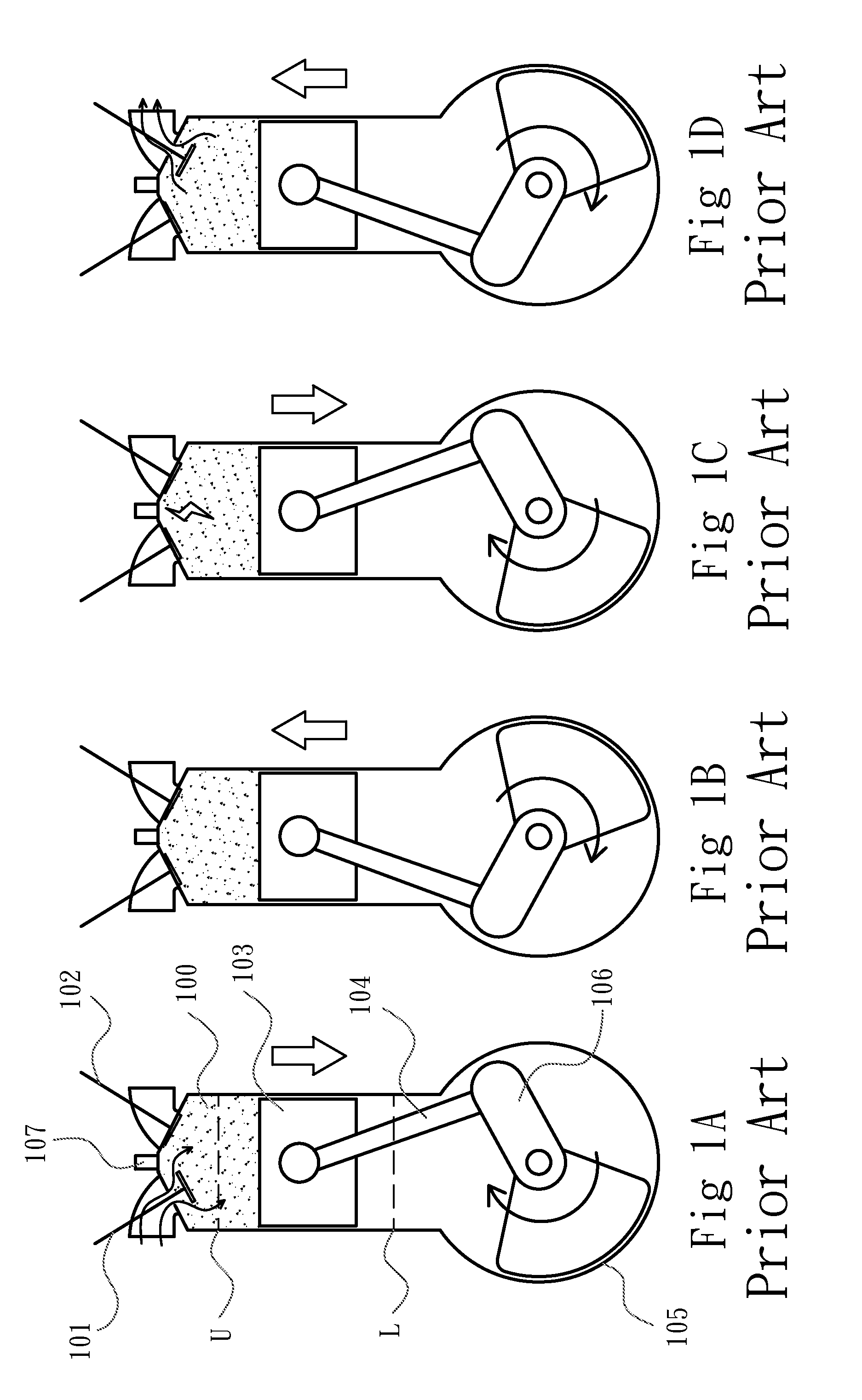

Work-increasing piston type four-stroke internal combustion engine

InactiveCN101353982AImprove work efficiencyIncrease output powerMachines/enginesCombustionInlet channel

The invention discloses a piston type four-stroke internal-combustion engine with high mechanical efficiency. Compared with the prior art, the four-stroke internal-combustion engine of the invention corresponds to that a cylinder block is lengthened if the same discharge amount is available. The next stroke at the end of an air suction stroke is not a compression stroke but a push-back stroke. At the moment, an air inlet valve is not closed and a piston is firstly pushed back to ensure a part of gas in the cylinder returns to an air inlet channel. The air inlet valve is closed to enter the compression stroke when the piston is pushed back to a designed position, therefore, the push-back stroke and the compression stroke are combined into a complete stroke. An expansion stroke has a longer piston stroke than the compression stroke while only the piston stroke of the complete stroke combined by the push-back stroke and the compression stroke is equal to that of the expansion stroke, and an output stroke and the air suction stroke have the same piston stroke as the explosion stroke so as to increase the comparative compression ratio, thereby improving the mechanical efficiency of the internal-combustion and greatly improving the output efficiency of the engine in the same discharge amount so as to save energy, reduce emission and consumption.

Owner:朱华标

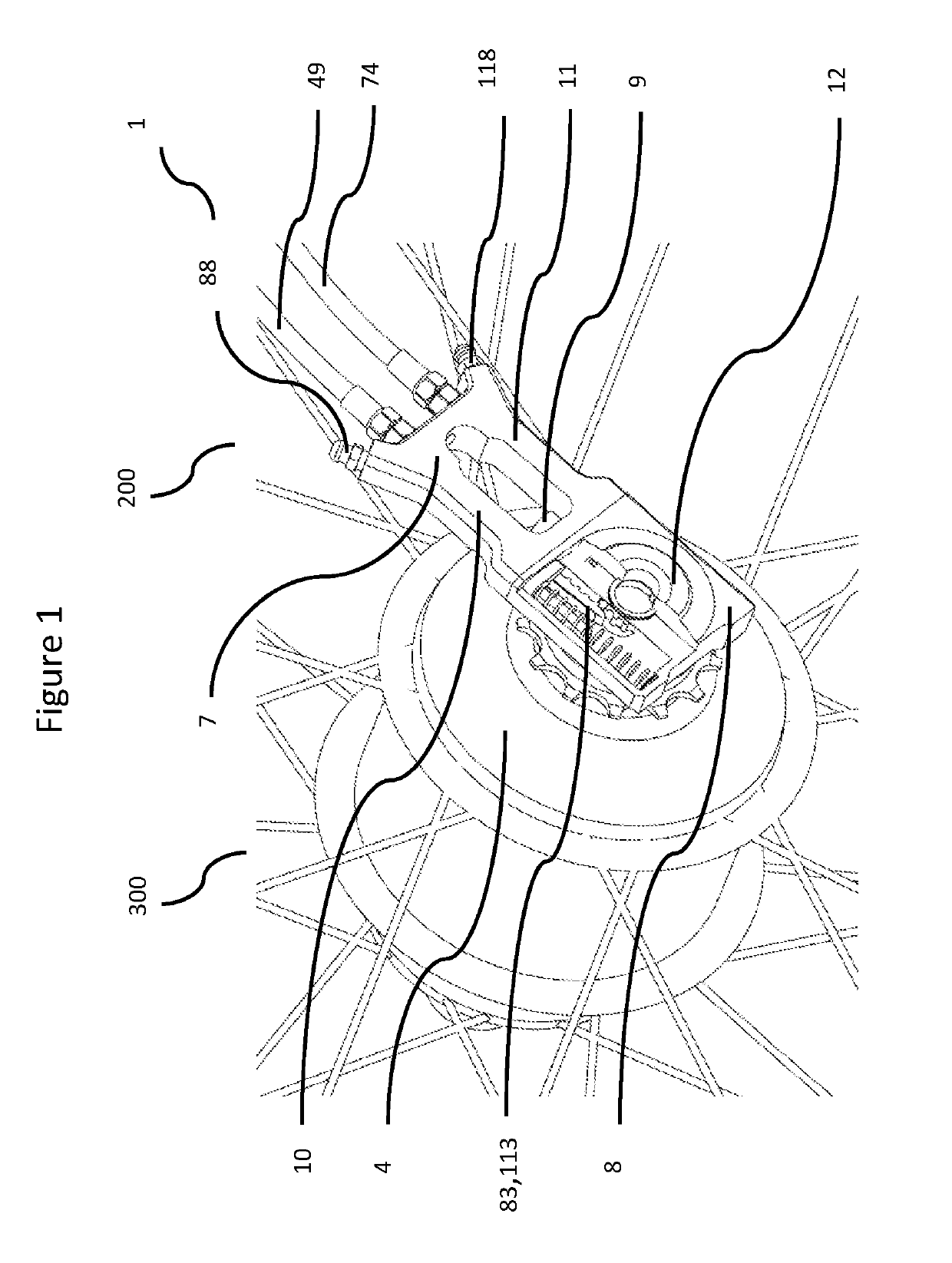

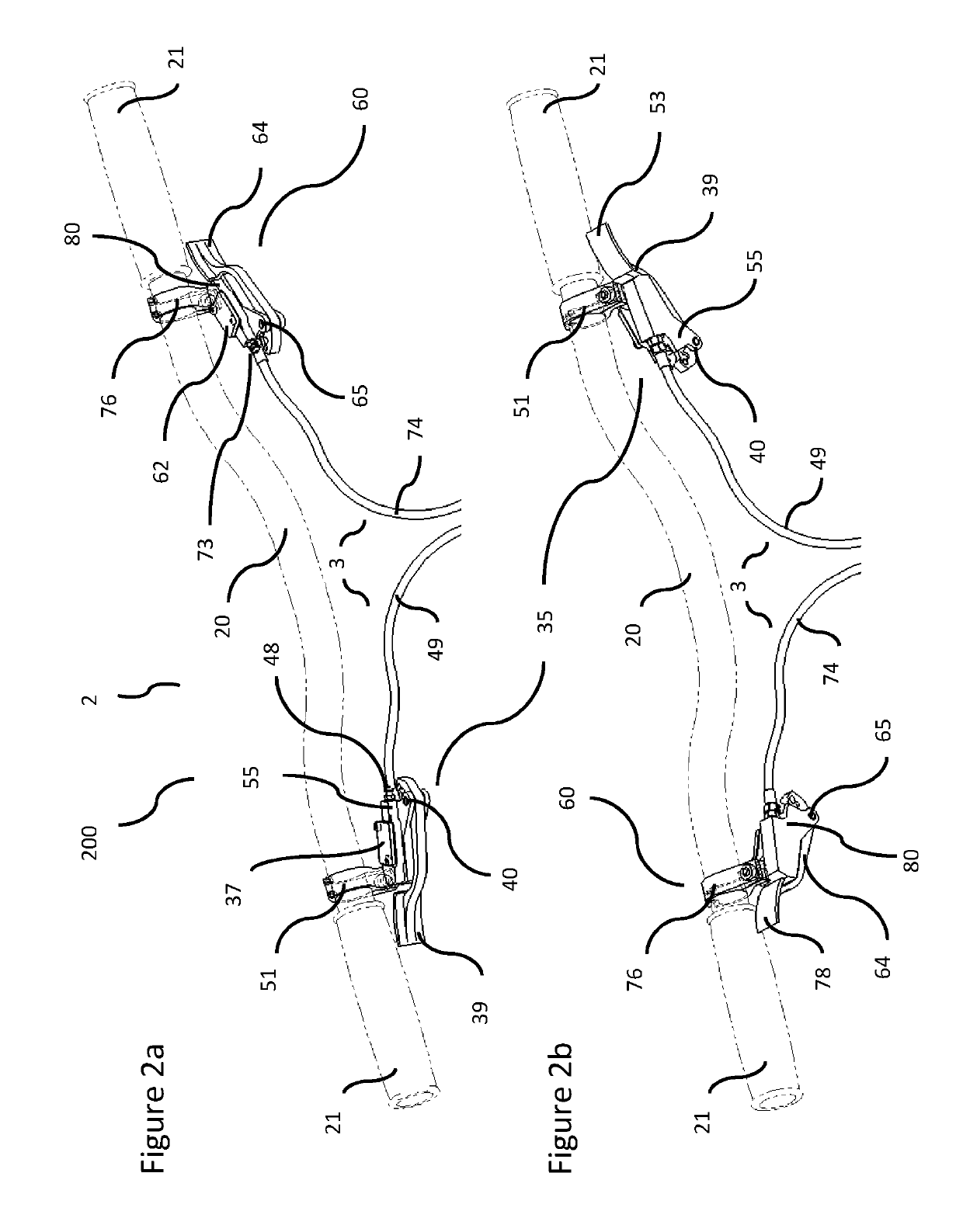

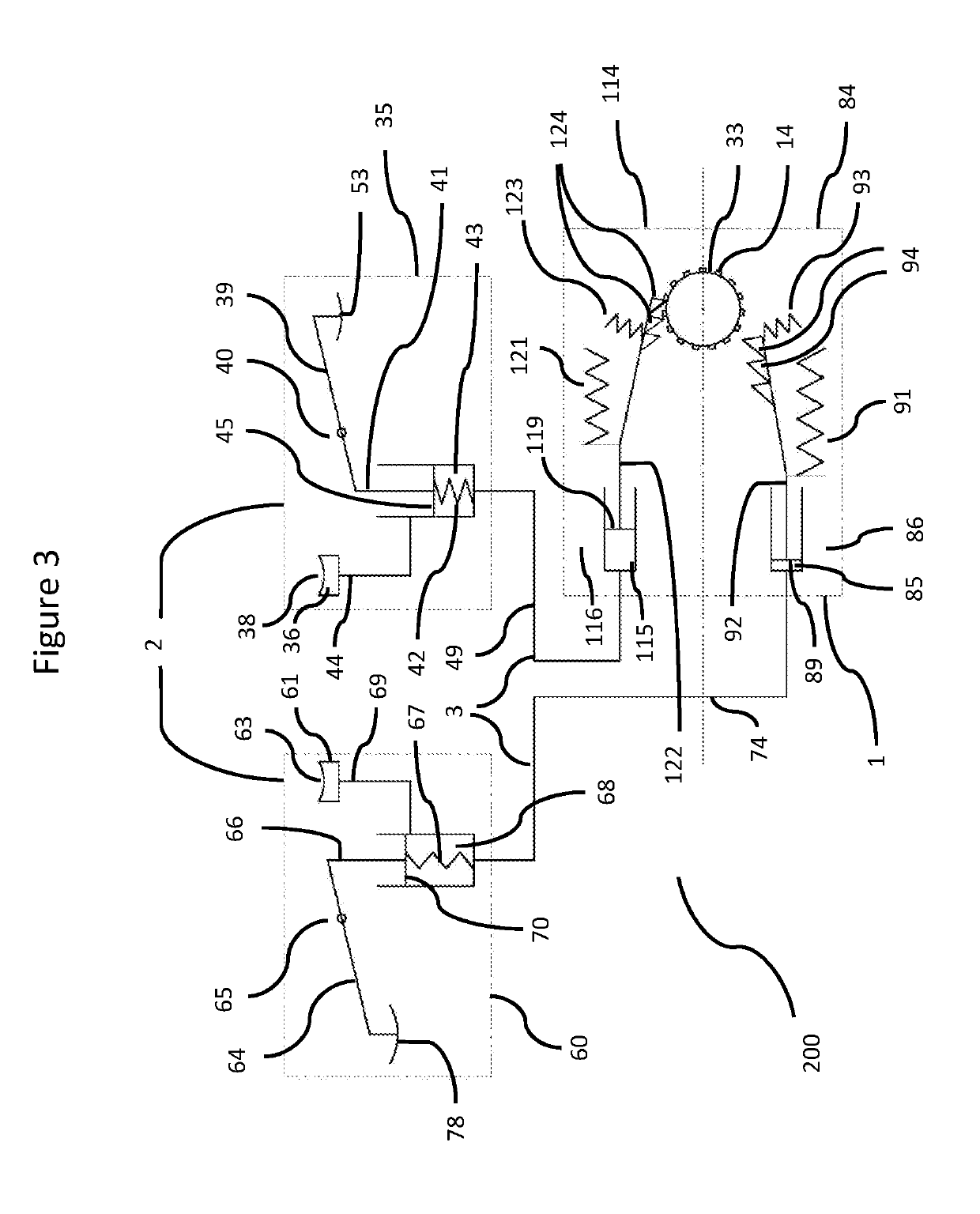

Host of pulley block ejector

The invention relates to a host of a pulley block ejector, which is suitable for ejecting aircraft carrier-borne aircraft. A piston (2) in a cylinder tube (1) is pushed by high-pressure gas, so as to drive a four-rope pulley block to pull an ejection sliding shuttle (39) to eject the carrier-borne aircraft. The working stroke ratio of a movable pulley block (25) to the ejection sliding shuttle (39) is 1:4, the acceleration ratio of the movable pulley block (25) to the ejection sliding shuttle (39) is 1:4, and the acceleration energy consumption ratio of the movable pulley block (25) to the ejection sliding shuttle (39) of equal mass is 1:16. Four times high-speed ejection to an ejected object by using a low-speed running component is realized, and the self mass acceleration energy consumption is low. An eccentric outer ring type pulley (5) is designed, and the piston (2) is separated from a connecting rod (3), so that the self energy consumption and the buffer braking force of the running component are greatly reduced; when the ejection sliding shuttle (39) is pulled back by an energy storage rope from a buffer end point (44) to an ejection starting point (42) to prepare for second-time ejection, the piston (2) is also driven to return to the tail of the cylinder tube, so as to push the high-pressure gas into an air storage cylinder (38) and finish storing energy. The high-pressure gas can be recycled, so as not to waste energy and fresh water like a steam ejector which uses non-expansion high-pressure hot gas once.

Owner:侯小红

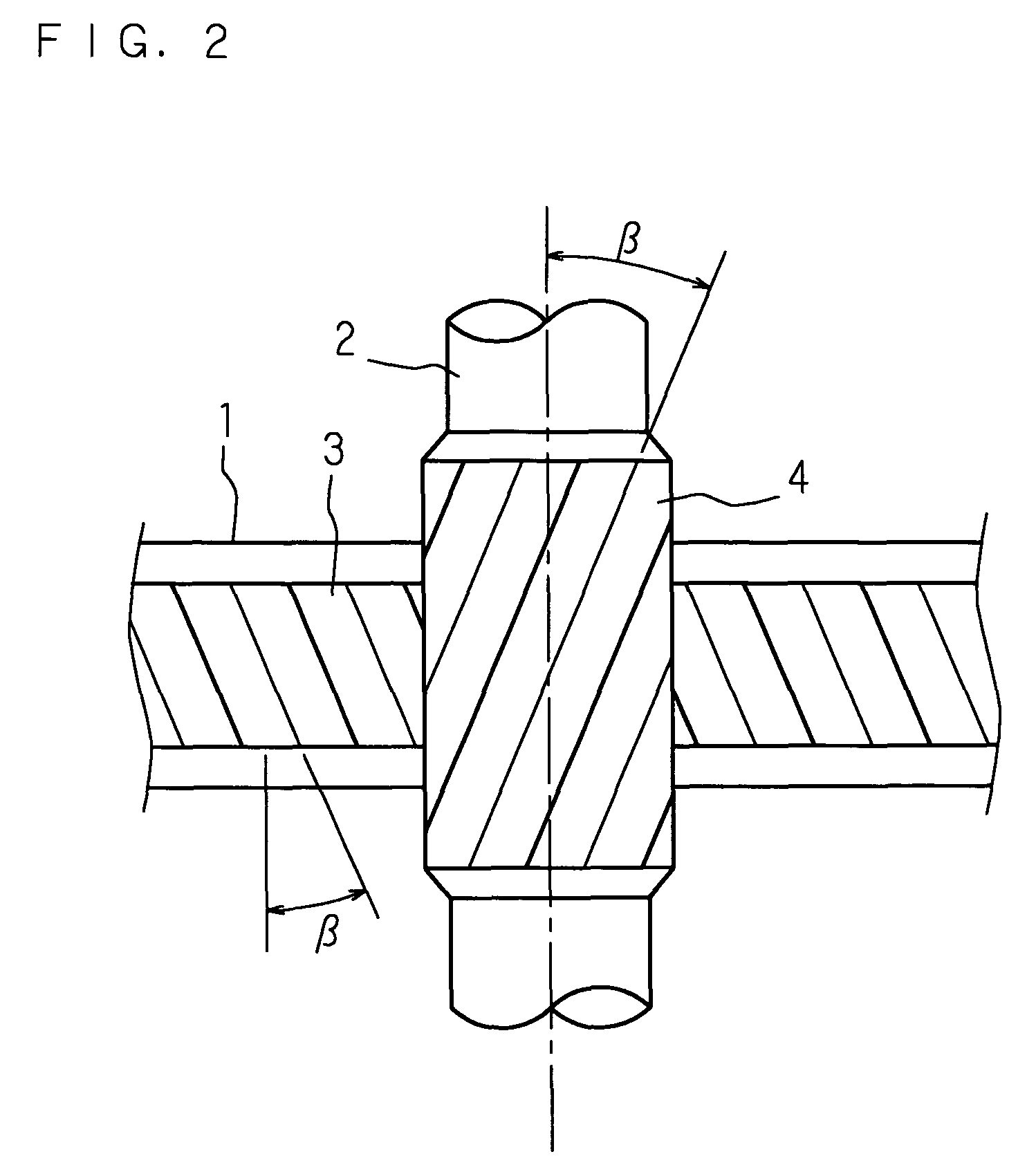

Steering System

InactiveCN107719462AIncrease forceMechanical steering gearsAutomatic steering controlPinionMechanical engineering

The present invention relates to a steering system. A ratio of the distance by which a rack shaft moves in a first direction relative to the angle by which a pinion shaft rotates in a circumferentialdirection is defined as a stroke ratio. The stroke ratio is larger when the pinion meshes with one of a third rack and a fifth rack than when the pinion meshes with a first rack. The stroke ratio changes while the pinion moves on one of a second rack and a fourth rack. A clearance defined between a rack guide and a guide plug is smaller when the pinion meshes with one of the third rack and the fifth rack than when the pinion meshes with the first rack. The clearance defined between the rack guide and the guide plug changes while the pinion moves on one of the second rack and the fourth rack.

Owner:JTEKT CORP

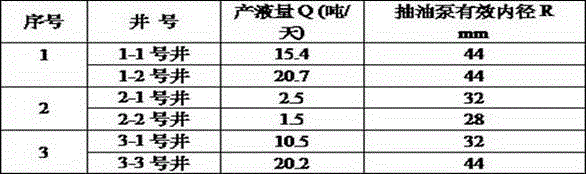

Method for changing stroke of double-well pumping unit

ActiveCN105909219AHigh strengthImprove wear resistanceFluid removalEngineeringUltimate tensile strength

The invention discloses a method for changing the stroke of a double-well pumping unit, and solves the problems of high cost, low efficiency and the like of the existing method for regulating the stroke of the double-well pumping unit. The method concretely comprises the following steps that the stroke ratio of two wells is calculated according to the liquid yield of the two wells and the effective inner diameter of an oil pump; then, a bushing needs to be additionally arranged on a rolling tube of which well is judged according to the ratio, wherein the length, the inner diameter, the spiral groove type and the rotation direction of the bushing are consistent with the rolling tube; the thickness of the bushing is obtained according to a formula of d=(i-1)*phi / 2; and the bushing is cut into two halves along the center line, and is then fixed on the corresponding rolling tube. The method provided by the invention has the advantages that the theory that the stroke is in direct proportion to the diameter of the driving rolling tube is used as the basis; after the additional arrangement of the bushing, the operation lengths of the steel wire ropes wound on the driving rolling tube are different; the stroke regulation is finally realized; the weight of the bushing is light, so that the mounting and the dismounting are convenient; and the stroke regulating cost and the work intensity of workers are greatly reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

The method of pushing the curved bridge by foot

A method of stepping on a curved bridge. Multiple sets of jacking units are arranged on the inner and outer sides of the pier, and the jacking units are located on the equidistant circular curves on both sides of the bridge centerline, namely the outer jacking trajectory line and the inner jacking trajectory line. It is arranged in the center along the tangential direction; an electro-hydraulic proportional speed control valve is set on the oil inlet oil circuit of the jack of the jacking unit. The cylinder can be extended at a speed with the same stroke ratio; during the jacking process, the photoelectric sensor detects the deviation of the main beam in real time. Whether correction is required; correction is performed when the correction jack exceeds the standard. The advantage is that it can automatically follow the curve trajectory without stopping the adjustment, and at the same time, it can rectify the deviation dynamically in real time.

Owner:GUANGDONG CONSTR CO LTD OF CHINA RAILWAY NO 3 ENG GRP CO LTD +2

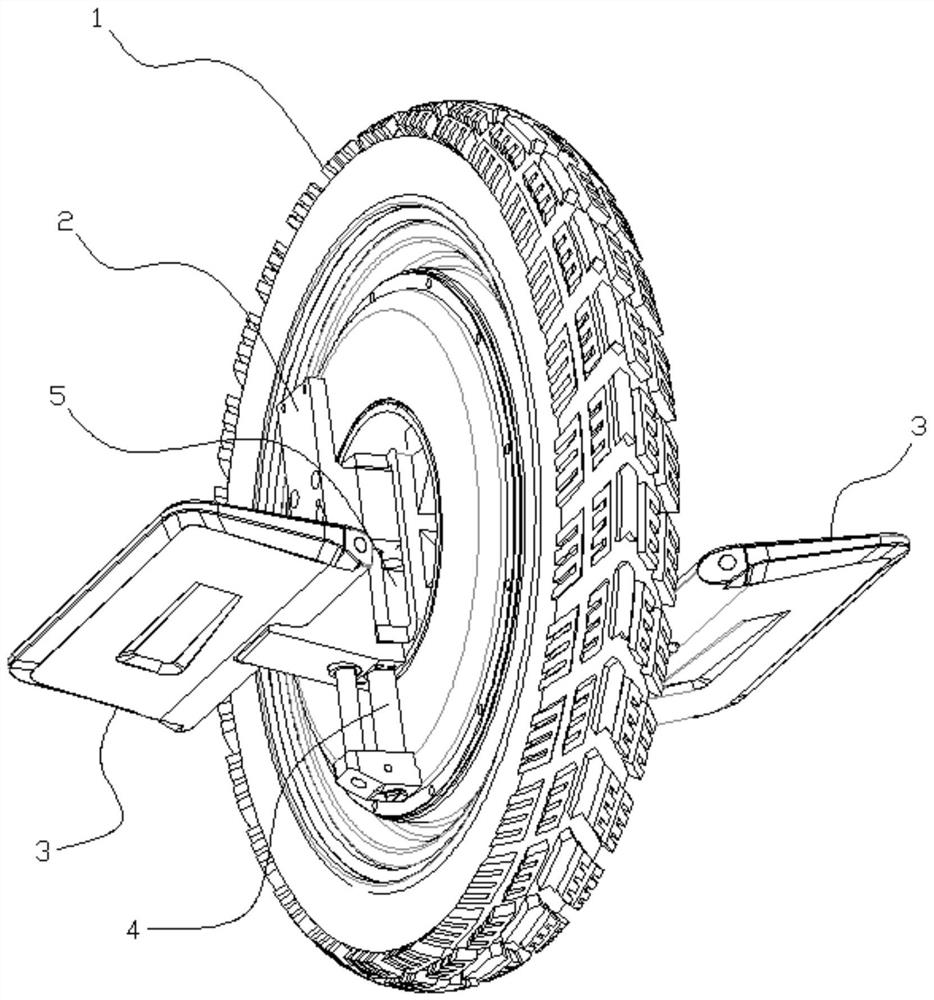

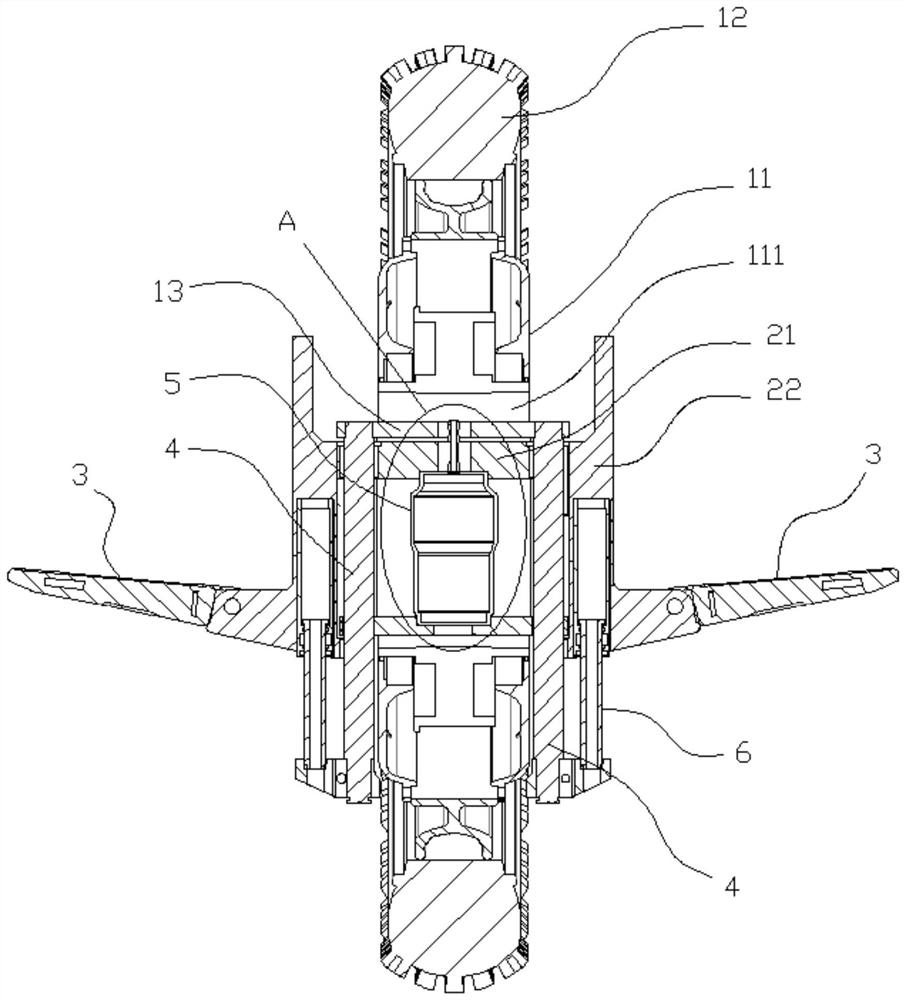

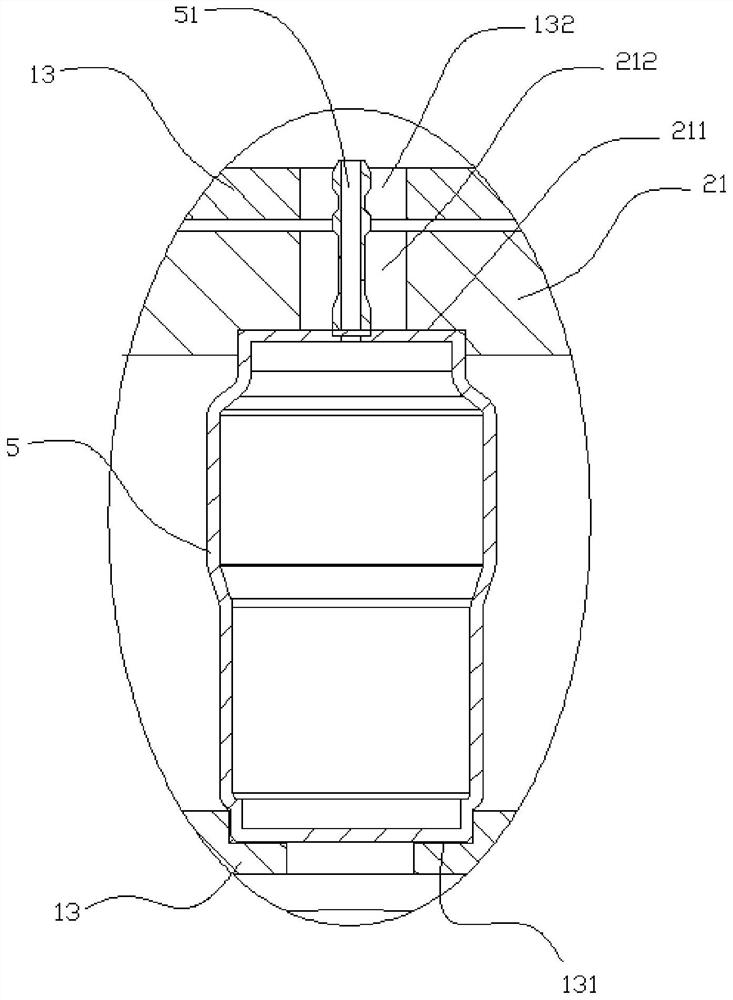

Air bag damping wheelbarrow

PendingCN112550542ALight in massExtended service lifeAxle suspensionsMotorcyclesElectric machineryRelative motion

The invention discloses an air bag damping wheelbarrow which comprises a motor wheel assembly, a wheel carrier provided with pedals are at the two sides respectively; a motor wheel assemblyin relativesliding connection with the wheel carrier through a guide device; and a damping air bag which is arranged between the wheel carrier and the motor wheel assembly ,and bears damping of relative movement between the wheel carrier and the motor wheel assembly. According to the wheelbarrow, the damping air bag is adopted for damping, the wheelbarrow has the advantages of being low in weight, high in comfortableness, resistant to fatigue, long in service life and the like, the stroke ratio is large, and a good damping effect can be achieved in a limited space; and meanwhile, the rigidity of the damping air bag is changed along with the vibration load capacity, so that elastic grounding can be avoided, and rigid collision between the wheel carrier and the motor wheel assembly is prevented.

Owner:东莞市比高德智能科技有限公司

Biaxial movement platform for preventing cervical spondylosis

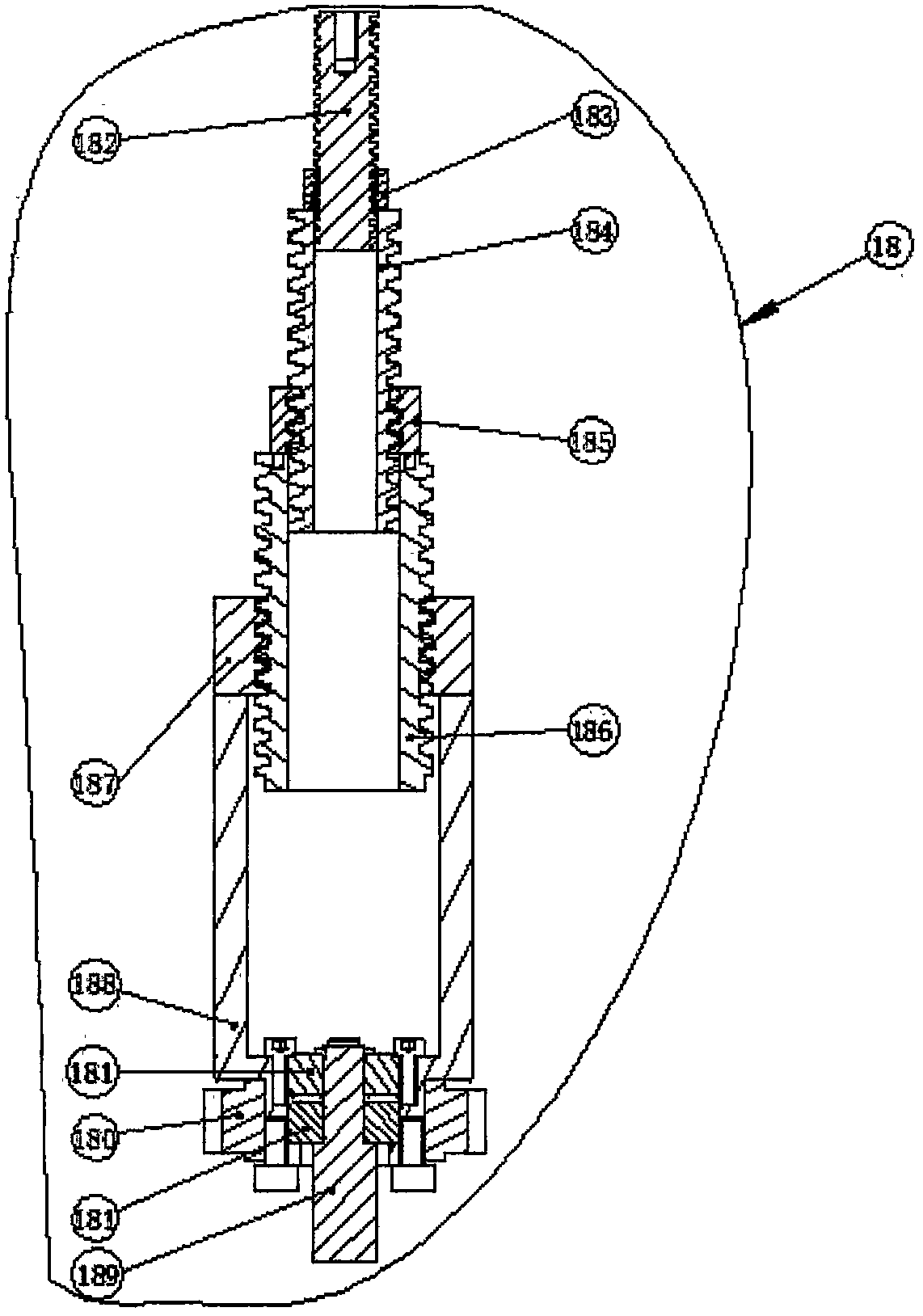

InactiveCN108938321AEffectively monitor exerciseAchieving a large stroke ratioChiropractic devicesHead movementsCervical spondylosis

The invention discloses a biaxial movement platform for preventing cervical spondylosis and belongs to the field of auxiliary medical instruments. The biaxial movement platform mainly solves the technical problems that equipment for preventing cervical spondylosis is monotonous in movement and low in stroke ratio, and autonomous adjustment cannot be achieved. The biaxial movement platform comprises a vertical movement platform, a horizontal movement platform and a machine vision system; a built-in motor of the vertical movement platform drives multi-stage lead screw transmission systems located at the four corners of a base to rotate through a worm gear, a synchronous belt pulley and a synchronous belt, so that a computer displayer moves up and down. The horizontal movement platform drivesthe synchronous belt pulley through the motor, and the synchronous belt drives a trapezoidal lead screw to move, so that the computer displayer moves left and right. The machine vision system includes an industrial camera and a calculation plate. The calculation plate controls a platform body to move up and down and move left and right according to calculated head movement posture, so that the cervical vertebra of a computer operator is relaxed to the maximize degree during work, and therefore the effect of preventing cervical spondylosis is achieved.

Owner:黄帅

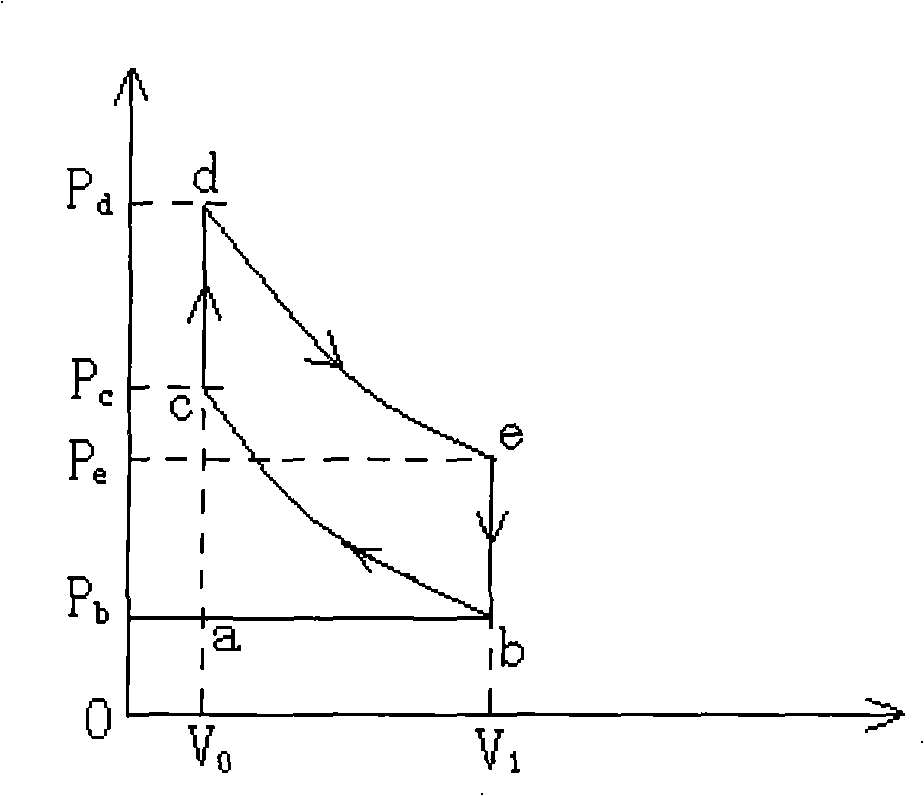

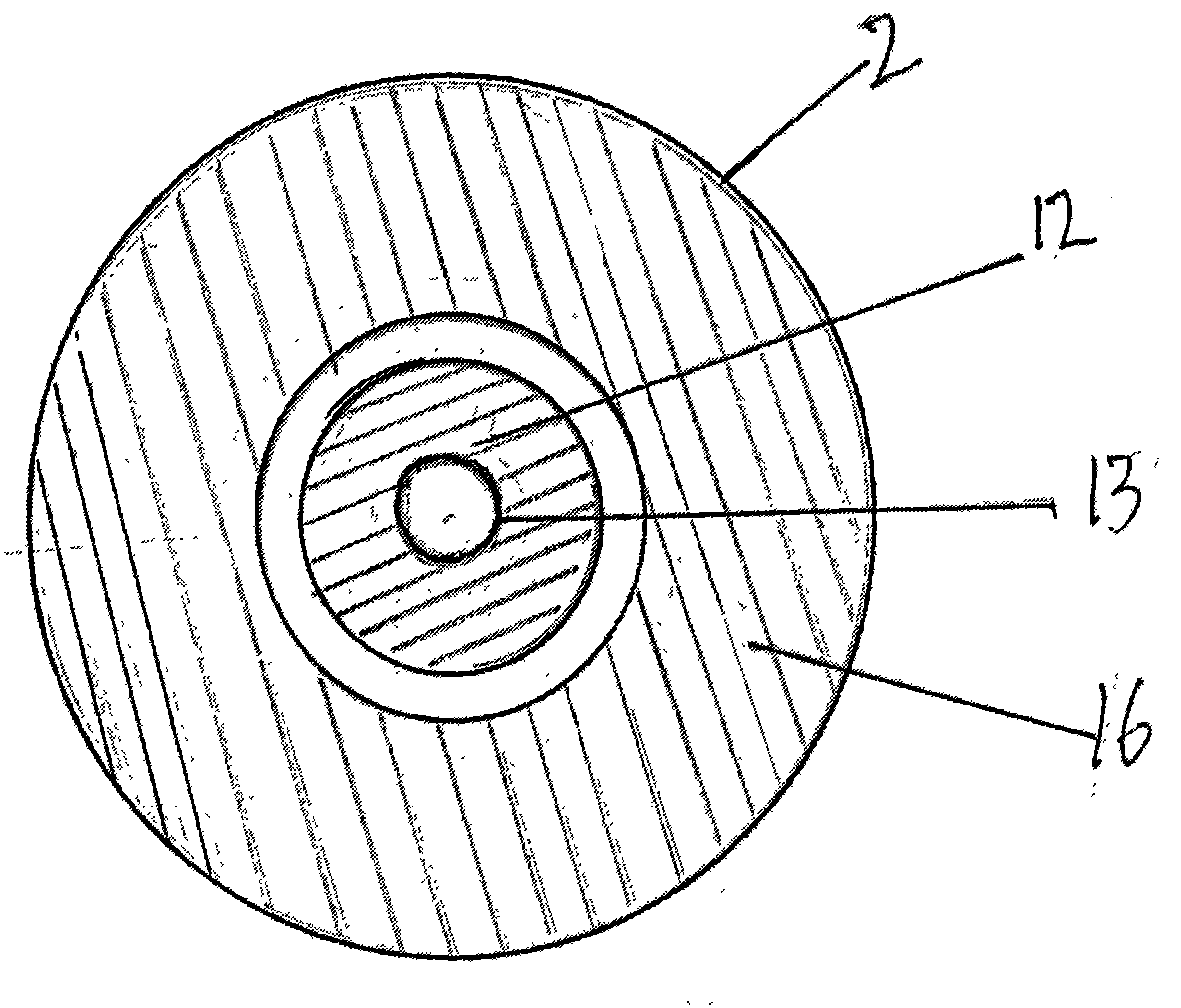

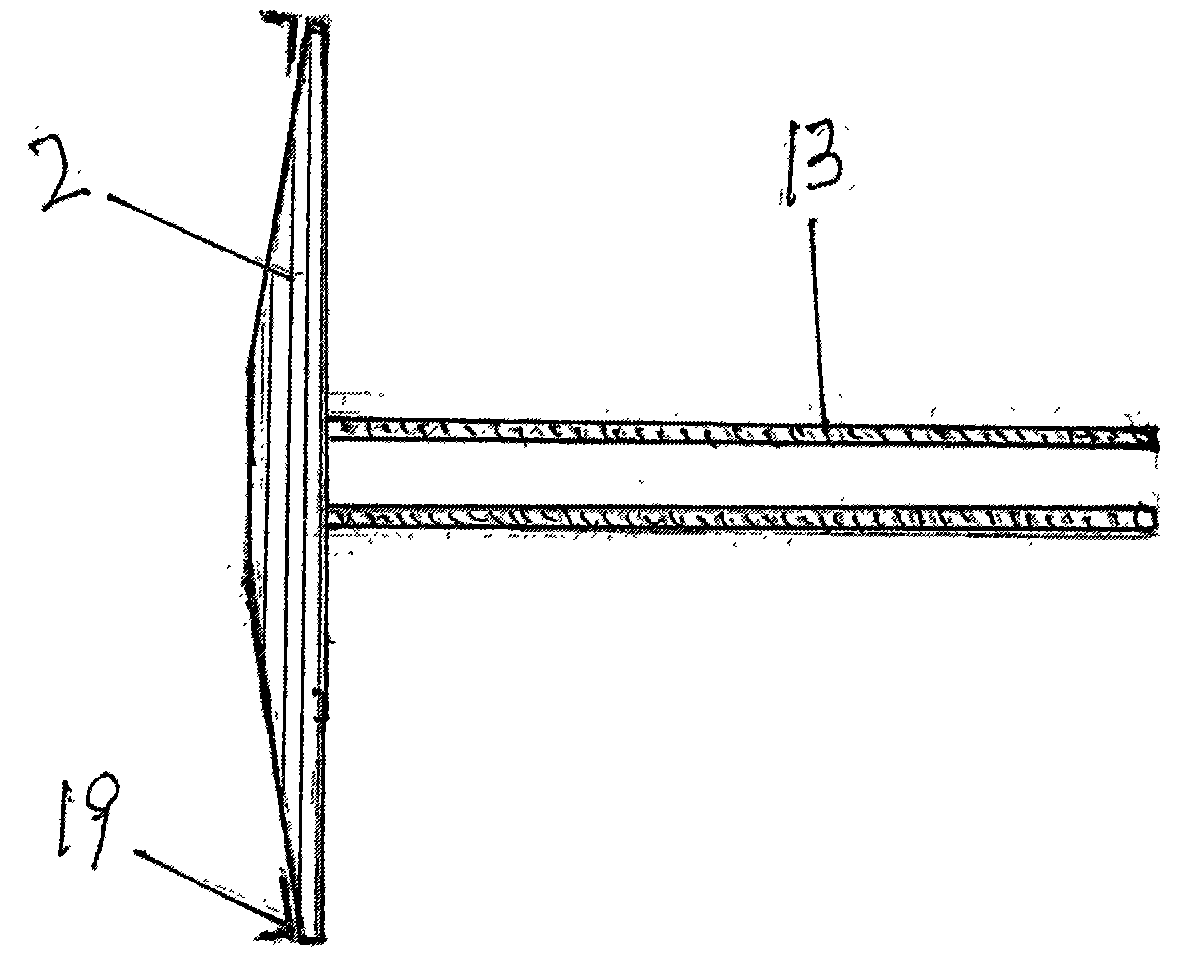

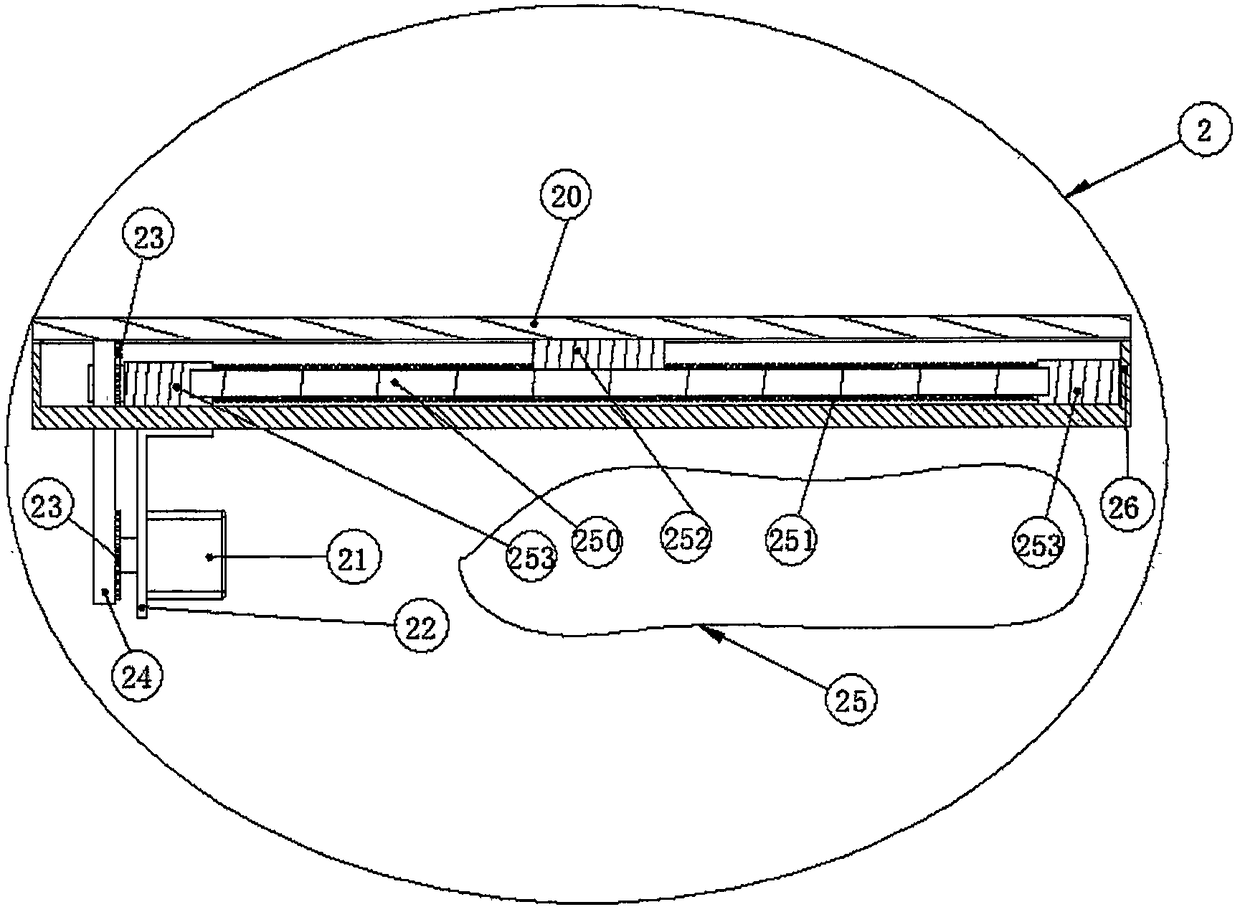

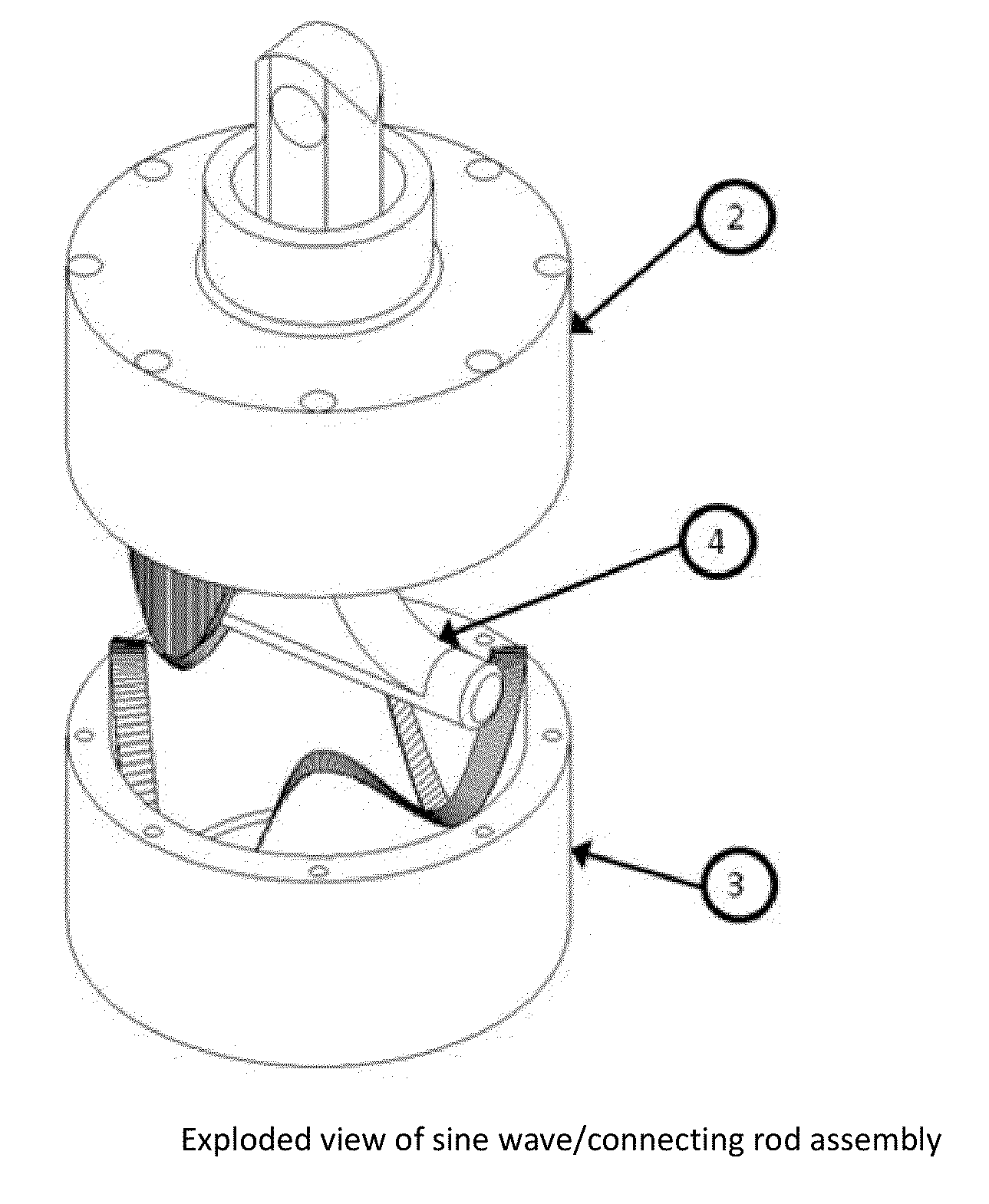

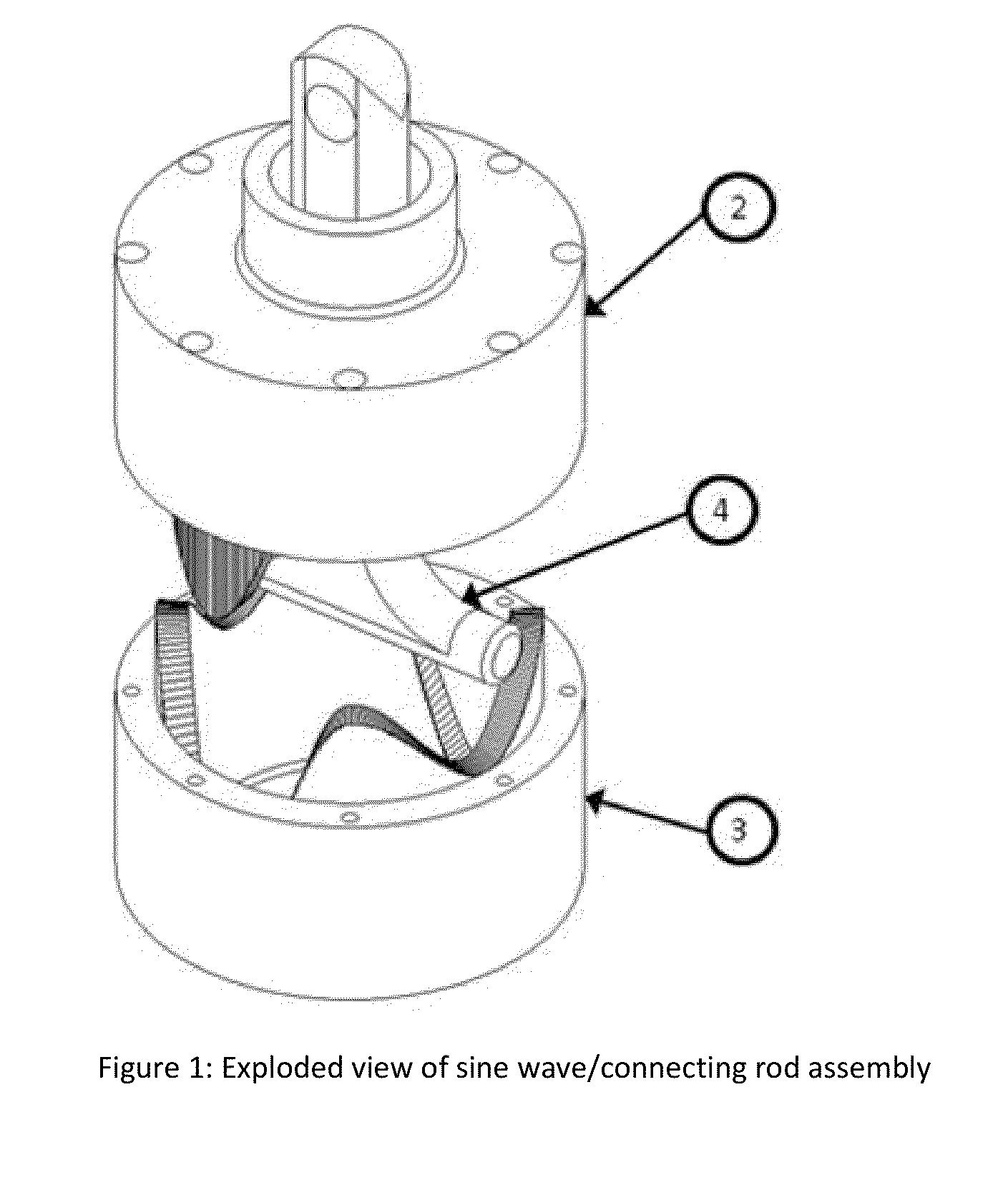

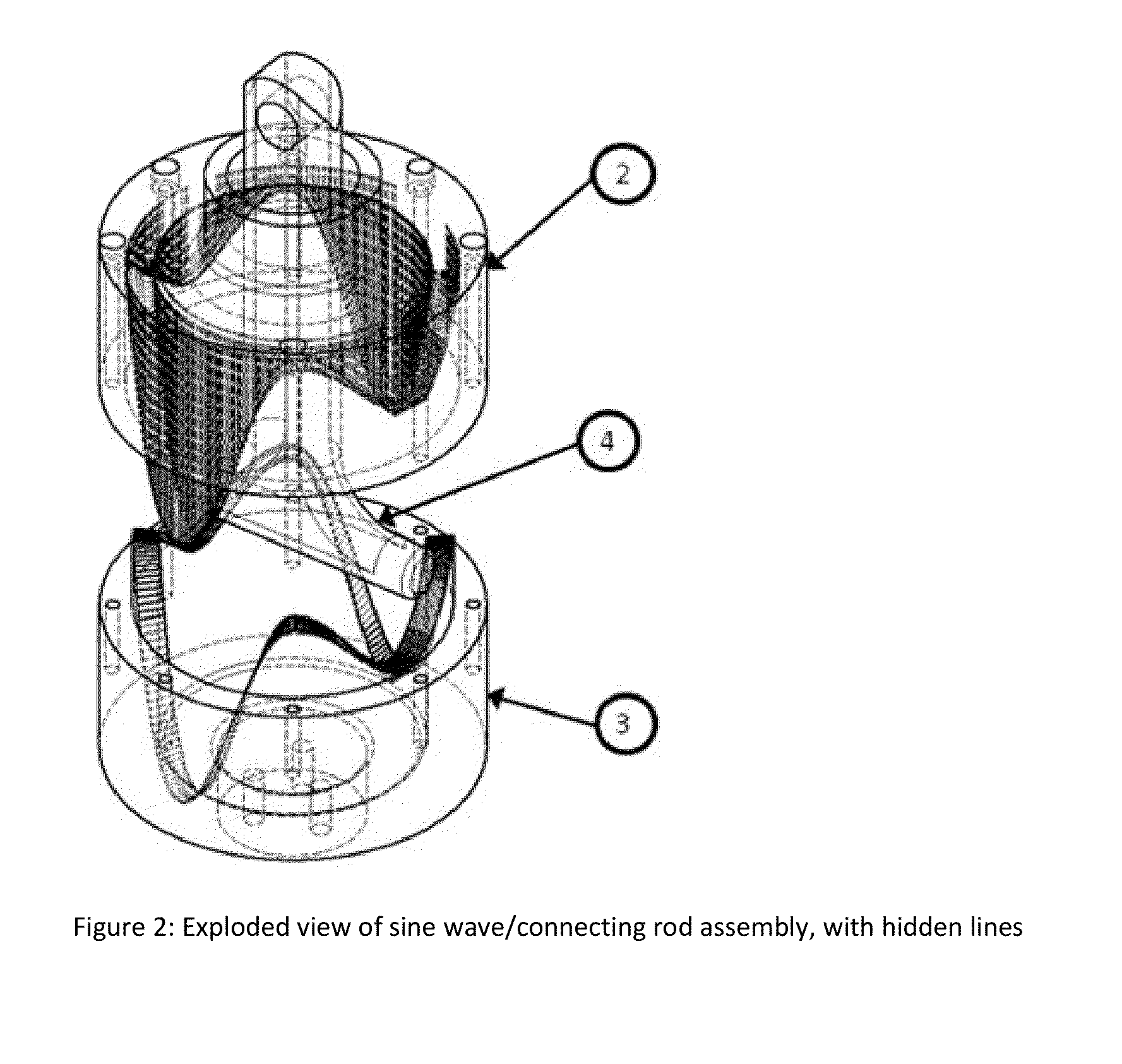

Axial Piston Internal Combustion Engine Using an Atkinson Cycle

InactiveUS20140182526A1Internal combustion piston enginesReciprocating piston enginesFriction reductionSpool valve

An axial piston internal combustion engine designed to improve the thermal efficiency of the engine by utilizing a sine wave / connecting rod assembly (5) to cause the piston (6) of the engine to travel vertically parallel to the engine's main shaft (13). The upper sine wave barrel (2) and lower sine wave barrel (3) have a channel in them that the cylindrical ends of the connecting rod (4) travel in, forcing the connecting rod (4) and piston (6) to travel vertically. The engine also utilizes slide valve (20) that has slots in it that when slid past the ports of the upper cylinder head (18) and lower cylinder head (19) controls the intake and exhaust timing events of the engine. The channel in the upper sine wave barrel (2) and lower sine wave barrel (3) is designed such that the vertical expansion / exhaust strokes of the engine are longer than the intake / compression strokes which allow the engine to make more efficient use of the energy produced by combusting the fuel, improving the thermal efficiency of the engine. The design also reduces the friction between the cylinder walls and piston (4) and the friction associated with typical engines valvetrain components, improving the overall efficiency of the engine. By reducing the frictional losses and improving the thermal efficiency the new engine should have decreased fuel consumption.

Owner:ROBARDS BRIAN

Oil wellmaximum yield mode control method based on stroke ratio and dynamic control diagram

InactiveCN109870902ARealize the purpose of reducing production costs and increasing efficiencyReduce oil recovery energy consumptionAdaptive controlMode controlEngineering

The invention relates to an oil well maximum yield mode control method based on the stroke ratio and a dynamic control diagram. A ground indicator diagram of an oil well is analyzed, the effective stroke of the oil well is calculated, the change condition of the stroke ratio is analyzed, under the premise that the pump efficiency is as high as possible, a pumping unit is maintained to run at the low frequency, that is, based on the principles of the high pump efficiency and low energy consumption, an intelligent optimization frequency conversion scheme of the oil well is designed, and a frequency conversion control strategy is corrected combined with evaluation results of the dynamic control diagram of the oil well, so that the oil well maintains a reasonable maximum yield model to produce. Under traditional frequency conversion control modes, frequency conversion control of a rod pumping well is still dominated by human decision-making, real-time adjustment of a pumping well is difficult to realize, according to a rod pumping well intelligent frequency conversion control method based on the indicator diagram stroke ratio and the oil well dynamic control diagram, the oil well is optimized and controlled in real time, the oil well is subjected to frequency conversion optimization control while the reservoir potentiality is exerted to the maximum limit, oil extraction energy consumption is lowered, the system efficiency is improved, and the purposes of cost lowering and efficiency improving of production of an oil field are achieved.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Low rotation speed large torque engine

InactiveCN100582457CHigh output torqueMaximum torque point speed dropCylinder headsCylindersLow speedExhaust valve

The invention discloses a motor with low rotary speed and large torque, which comprises a crank connecting rod assembly, a cylinder block, a piston, a piston pin, a piston ring assemblage, a cylinder head, an exhaust valve, an inlet valve, an air inlet pipe and a carburetor, wherein the piston is fixed on the crank connecting rod assembly via the piston pin, the piston is arranged in the cylinder block, the exhaust value and the inlet valve are arranged in the duct of the exhaust value and the inlet valve of the cylinder head, the cylinder head is arranged on the cylinder block, the air inlet pipe is arranged on one side of the intake of the cylinder head, the carburetor is arranged on the air inlet pipe, the eccentricity of the crank connecting rod assembly is from 28.90mm to 31.10mm, and the diameter of the piston is from 54.5mm to 57mm, and the diameter of the cylinder / the stroke ratio is from 0.88 to 0.98. The motor is suitable for motor bicycles, motor tricycles, sand bank cars and carting cars, which has the advantages of outputting larger torque at the low speed, reducing the rotary speed at the maximum torque point, improving the initial starting acceleration property and the transcending accelerating ability, reducing heat load, oil consumption and oscillation, and increasing the durability.

Owner:吕清波

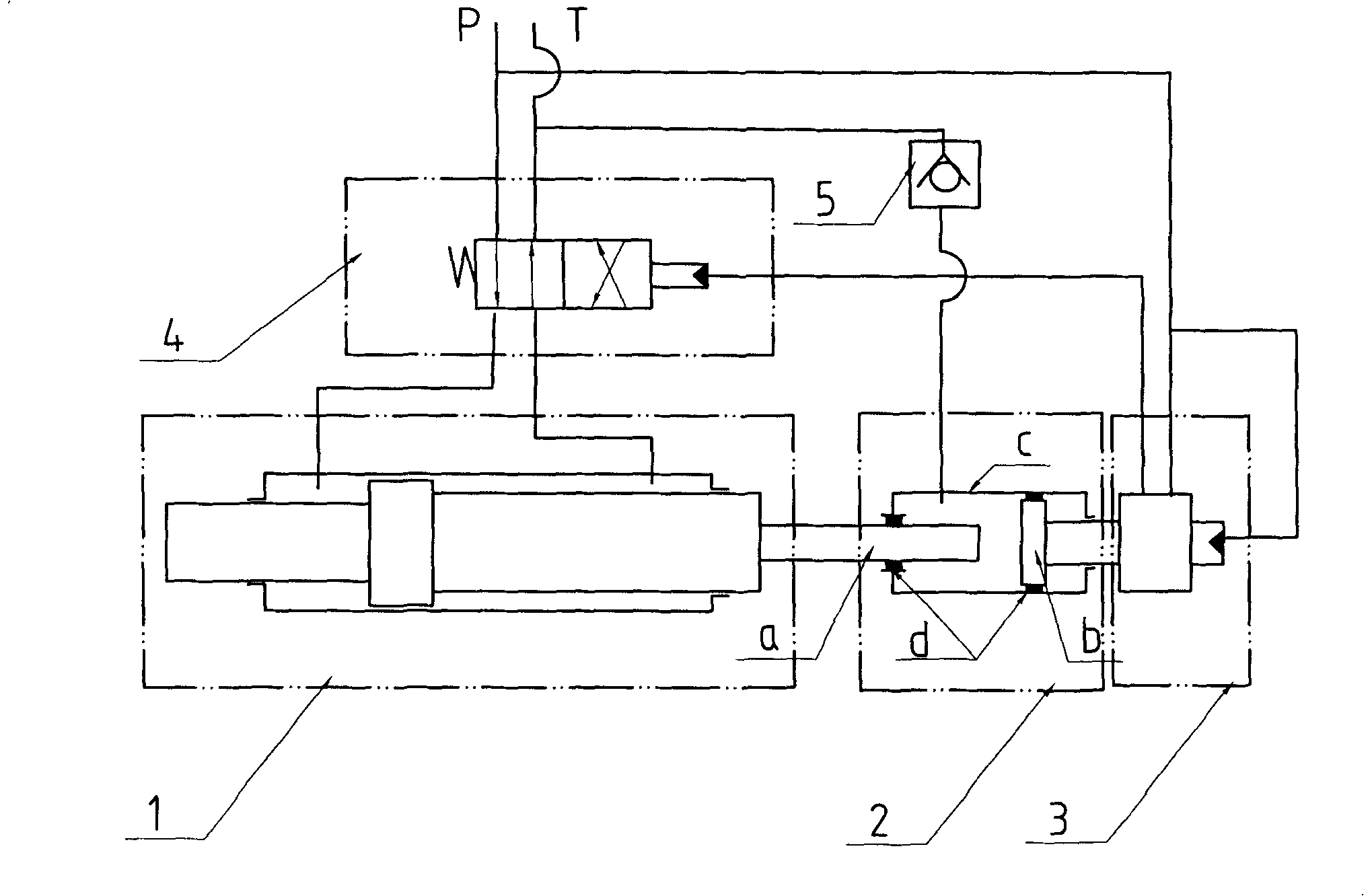

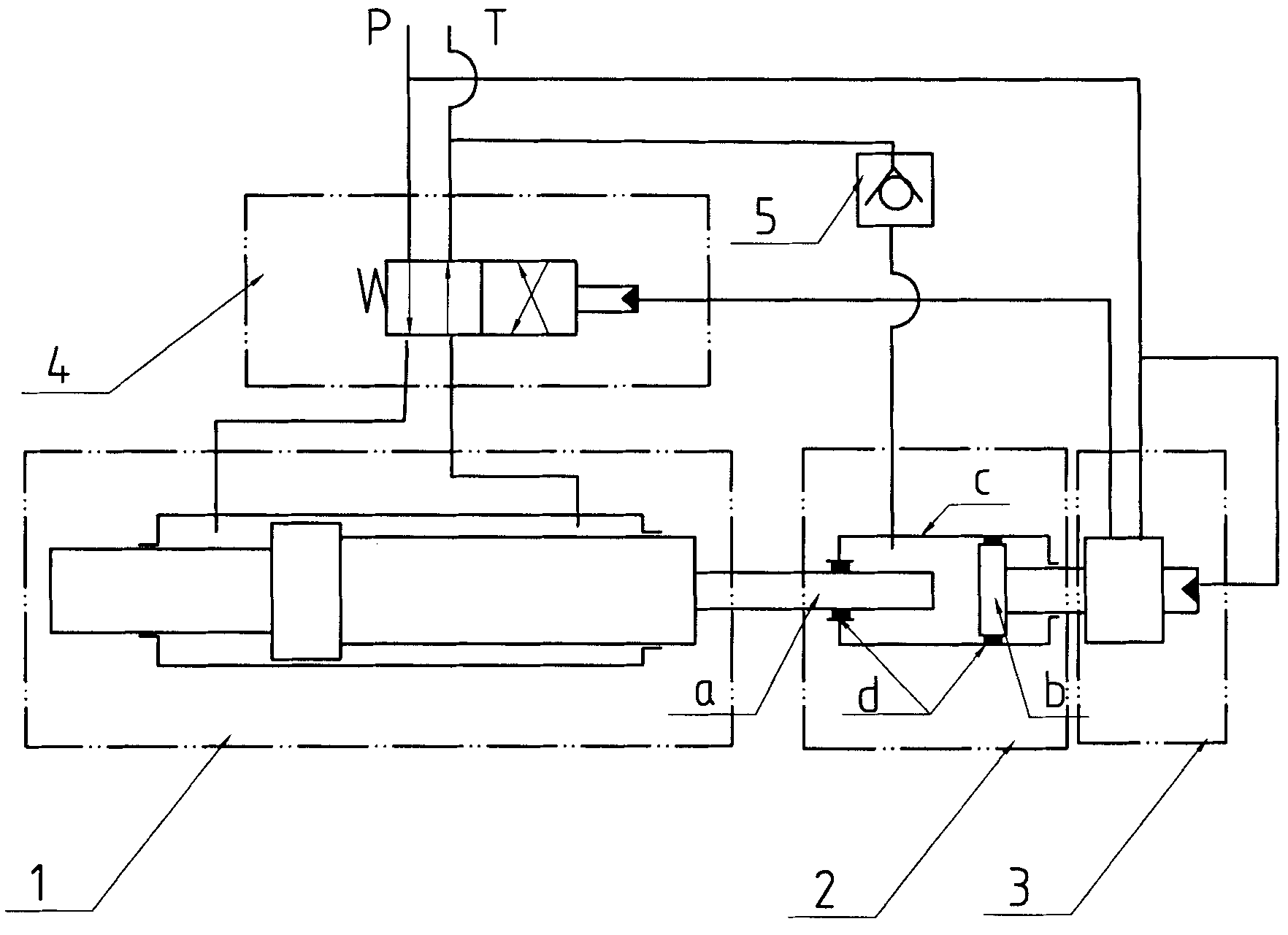

Stroke proportional transmission hydraulic circuit

The invention discloses a stroke equal-ratio transmission hydraulic circuit, which can be applied to hydraulic crushing equipment, hydraulic rock drilling and other equipment. It is mainly composed of a power piston, a stroke proportional control piston group, a stroke signal feedback control valve, a reversing valve, and an oil filling valve. The rod, the large piston, the cavity and the oil seal group of the stroke equal ratio control piston group form a closed cavity, and the cavity is filled with hydraulic oil. The reciprocating motion of the power piston controls the piston group through the proportional stroke, and transmits the stroke position signal proportionally to the stroke signal feedback control valve; the reversing valve is controlled by the stroke signal feedback control valve to control the reciprocating motion of the power piston. The invention can make the power piston and the stroke signal feedback control valve unnecessary to be arranged on the same axis, and can effectively reduce the operating speed of the spool of the stroke signal feedback control valve and reduce the internal impact.

Owner:CHINA GEZHOUBA GROUP CO LTD

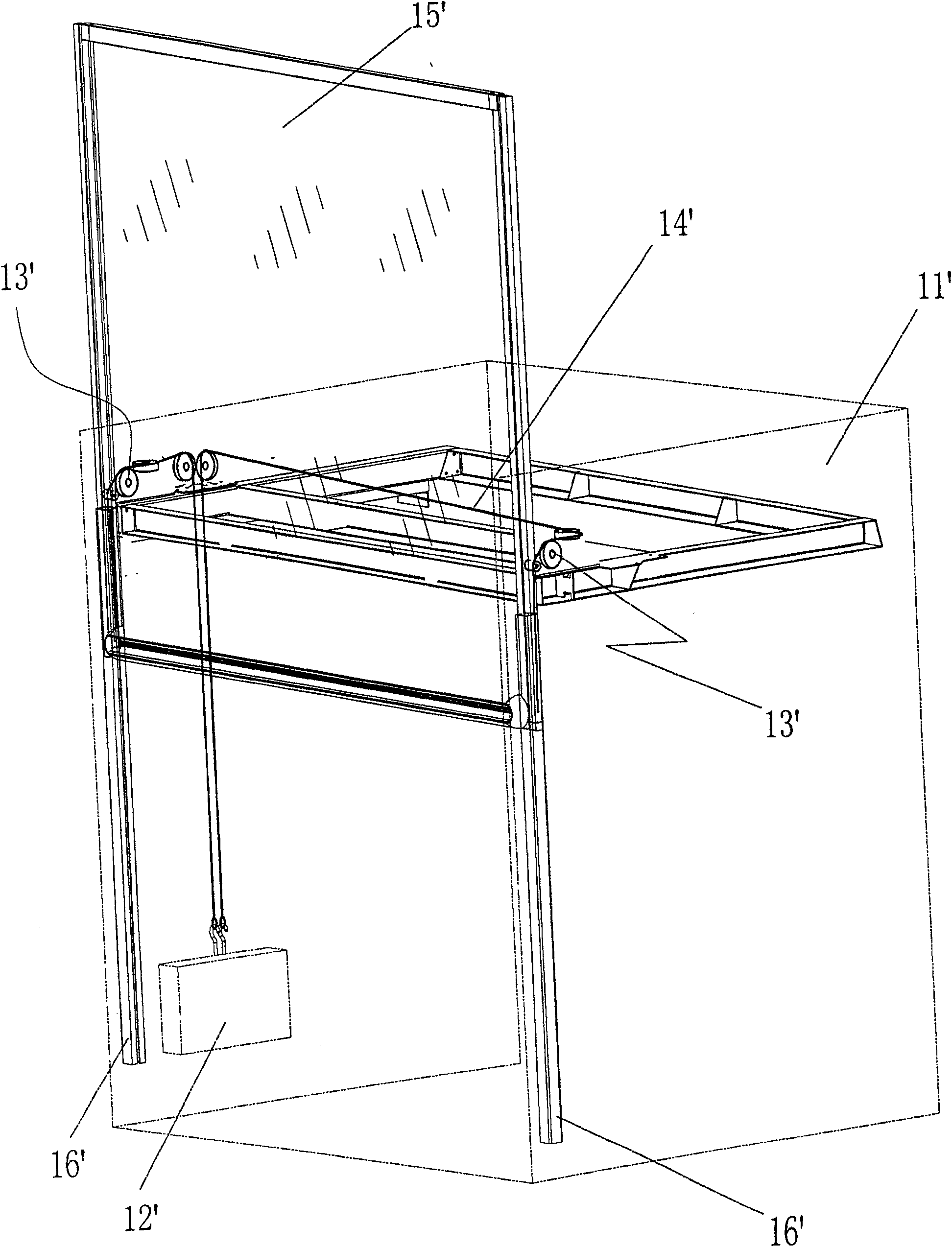

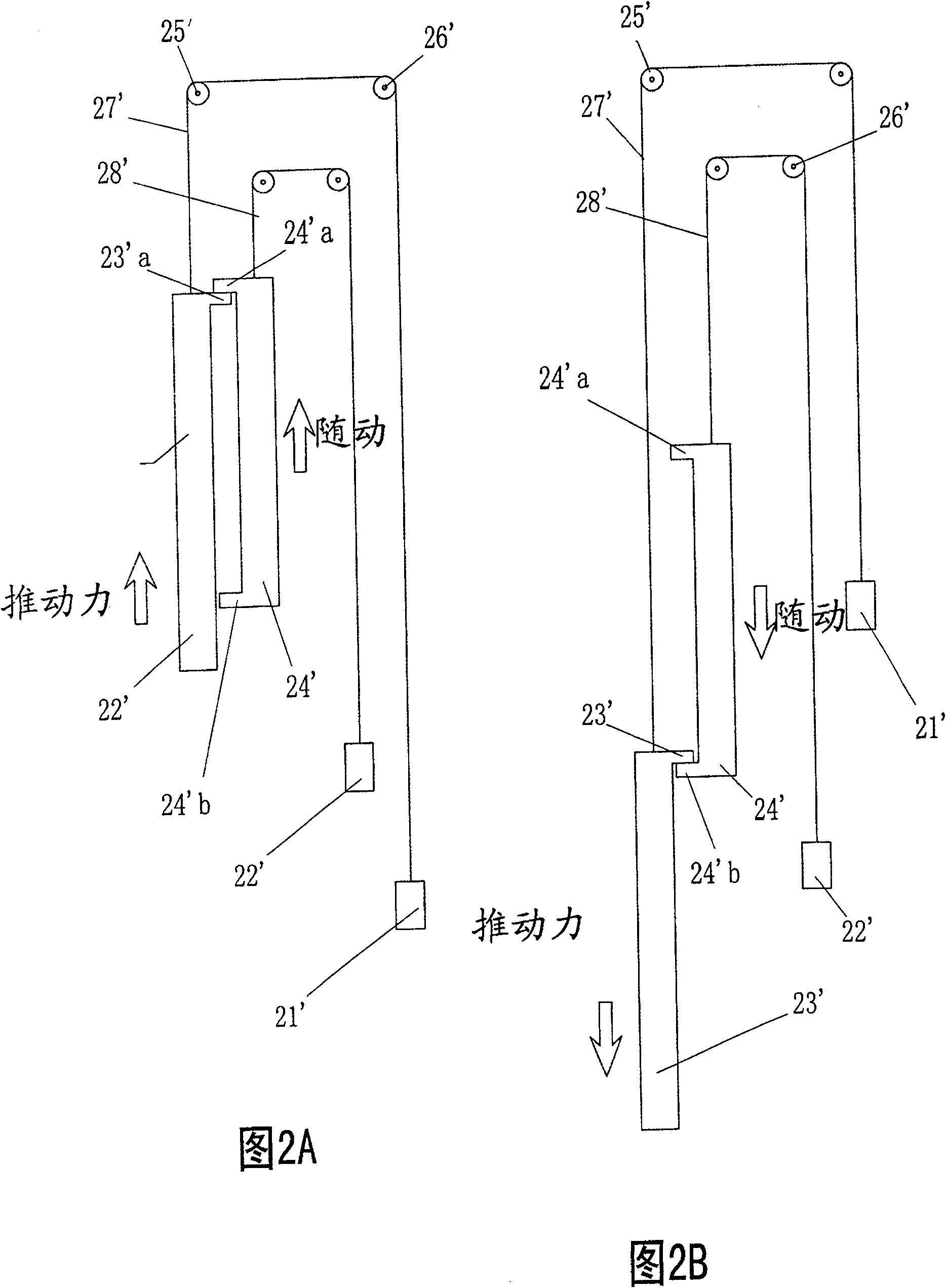

Interlock double-damper mechanism for smoke discharging cabinet

ActiveCN100551559CRealize two-door linkageNo damage caused by touching each otherDirt cleaningWing arrangementsAgricultural engineeringFume hood

The present invention aims to design a linkage type double-adjustment door mechanism for a smoke exhaust cabinet, including: a smoke exhaust cabinet, a pulley mechanism, several steel cables, a counterweight box, an up and down adjustment door and guide rails. The two sides of the upper and lower adjustment doors are connected to a counterweight box through their own steel cables through the pulley mechanism, so that the upper and lower adjustment doors can produce a double-door linkage movement effect with a stroke ratio of 1:2, and can achieve positioning at the same time.

Owner:奥卓莱流体科技(上海)有限公司

Sequential gear shifter

PendingUS20190283839A1Easy to adjustEasy to set upWheel based transmissionChain/belt transmissionGear systemEngineering

A sequential gear shift system for two-way operated speed change gear units of manually propelled vehicles. Mirrored, spaced-apart lever operators, are provided with increasing lever stroke ratio, and actuate sequentially with twin mirrored one-way multi-tooth rack-clutch mechanisms, that rapidly engage with a shift element and convert linear torque to rotate the shift element in diametrically opposite directions. The rack-clutch mechanisms may be disengaged from the shift element when returning to normal. The actuating may occur via independent hydraulic operation of an actuator. The actuator housing and load bearing axle of the speed change gear hub are selectively, releasably, and coaxially interconnected into a rigid gear system load bearing axle, and may be combined at any angle, and a shift direction is selectively reversible.

Owner:CA TECH SYST

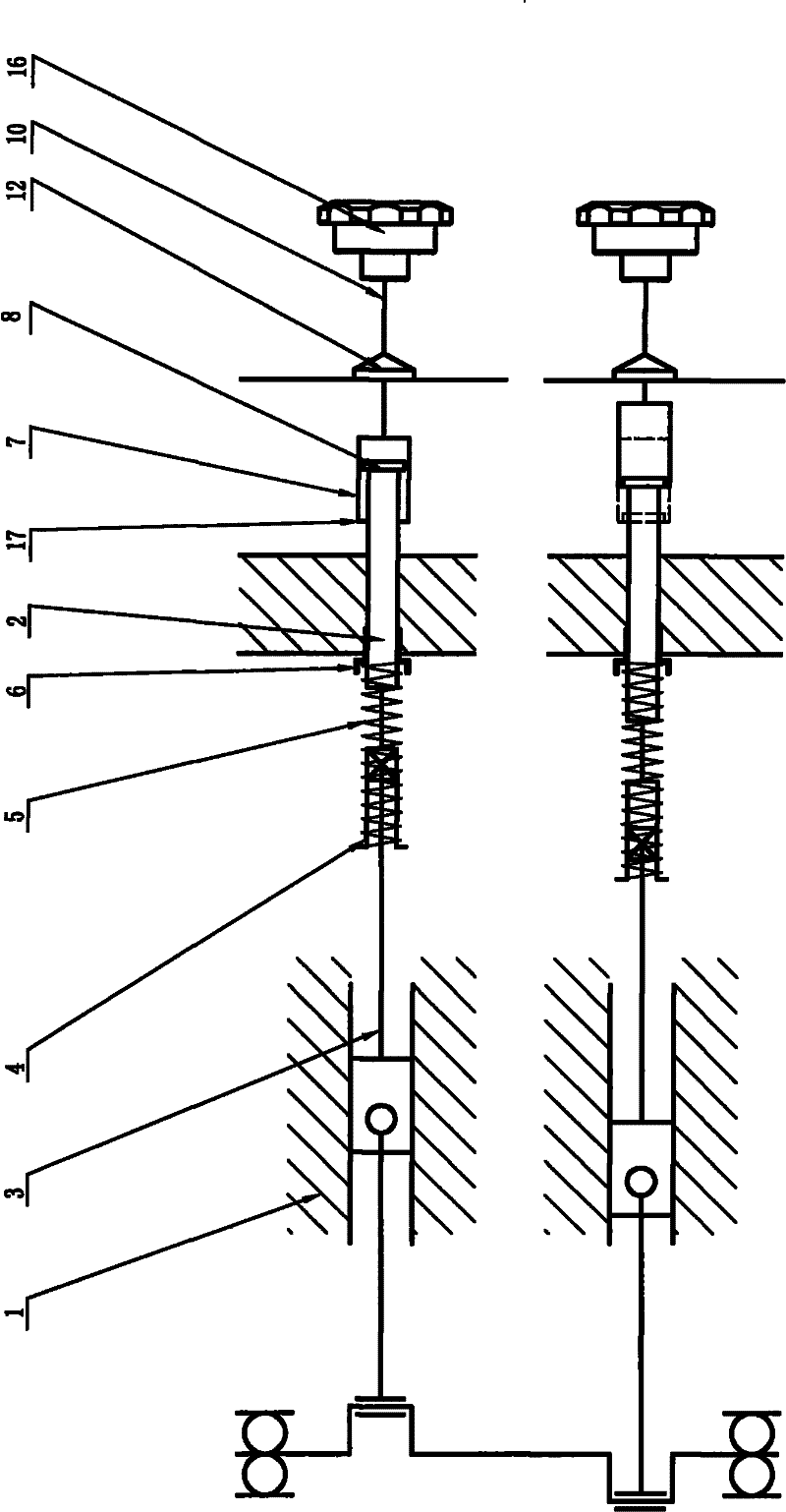

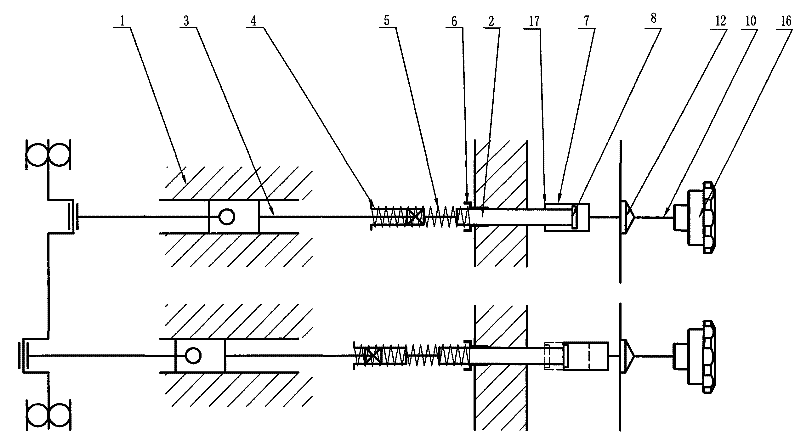

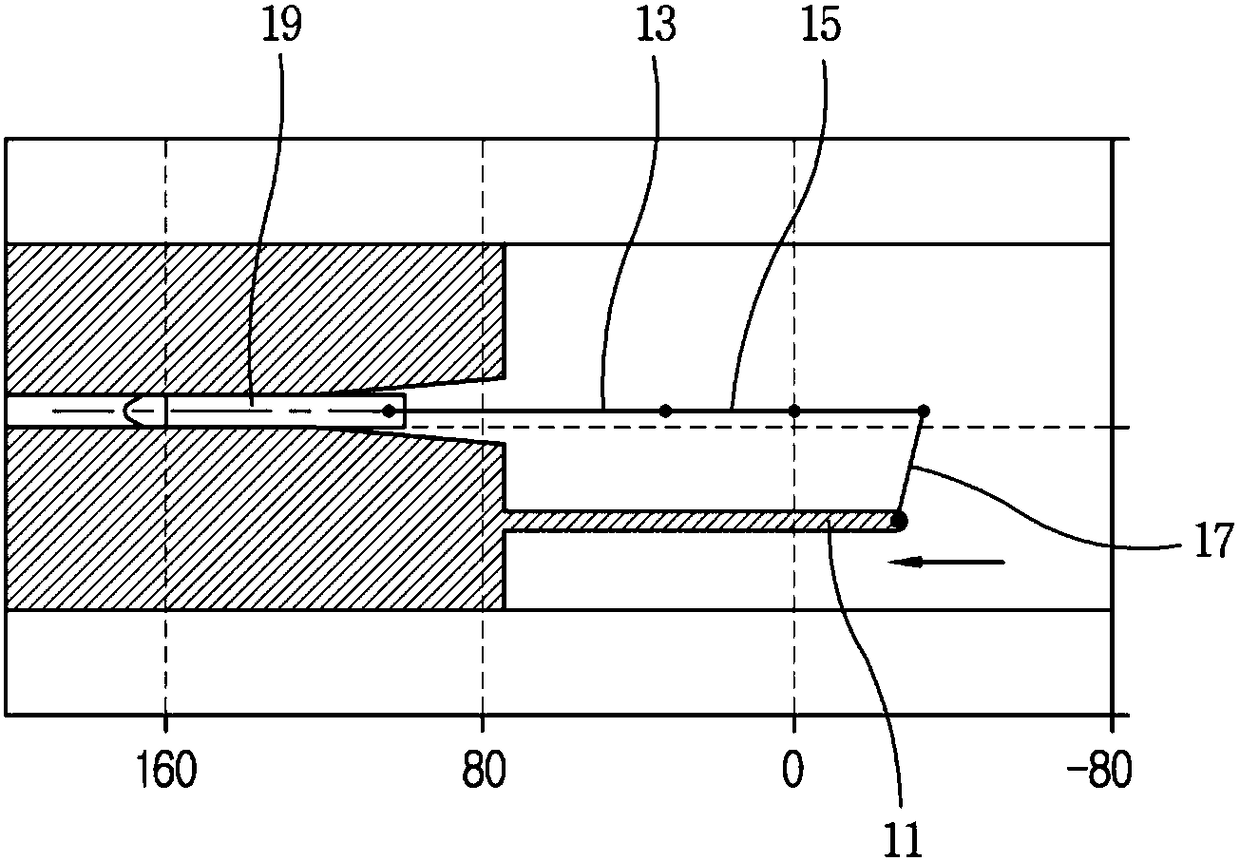

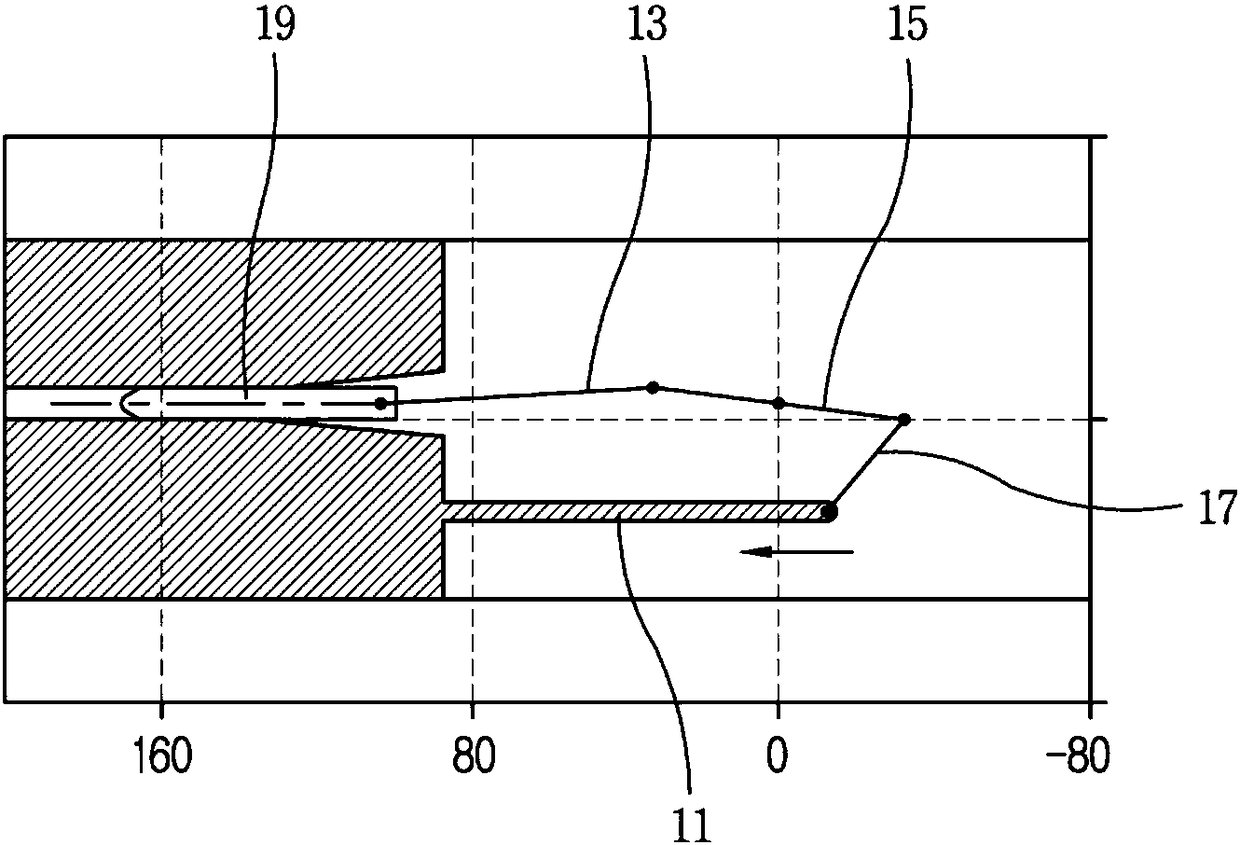

Variable-stroke ratio-regulated reciprocating pump

ActiveCN101696678BShorten the effective strokeReduce suctionPiston pumpsPositive-displacement liquid enginesEngineeringInjection pump

The invention relates to a variable-stroke ratio-regulated reciprocating pump and mainly solves the problem that the liquid flow of the traditional injection pump cannot be regulated. The ratio-regulated reciprocating pump is characterized in that a pump body (1) is provided with more than two plungers (2) which are in parallel and independent from each other, a plunger clutch mechanism for ensuring that a cross spider (3) is clutched with the plunger (2) when the plunger (2) absorbs the liquid is arranged at one end of the plunger (2), the cross spider (3) is connected with a crankshaft through a connected rod and a plunger travel limiting mechanism for limiting the liquid absorbing stroke is arranged at the other end of the plunger (2). The variable-stroke ratio-regulated reciprocating pump has the characteristic that the liquid flow can be adjusted.

Owner:大庆惠博普石油机械设备制造有限公司

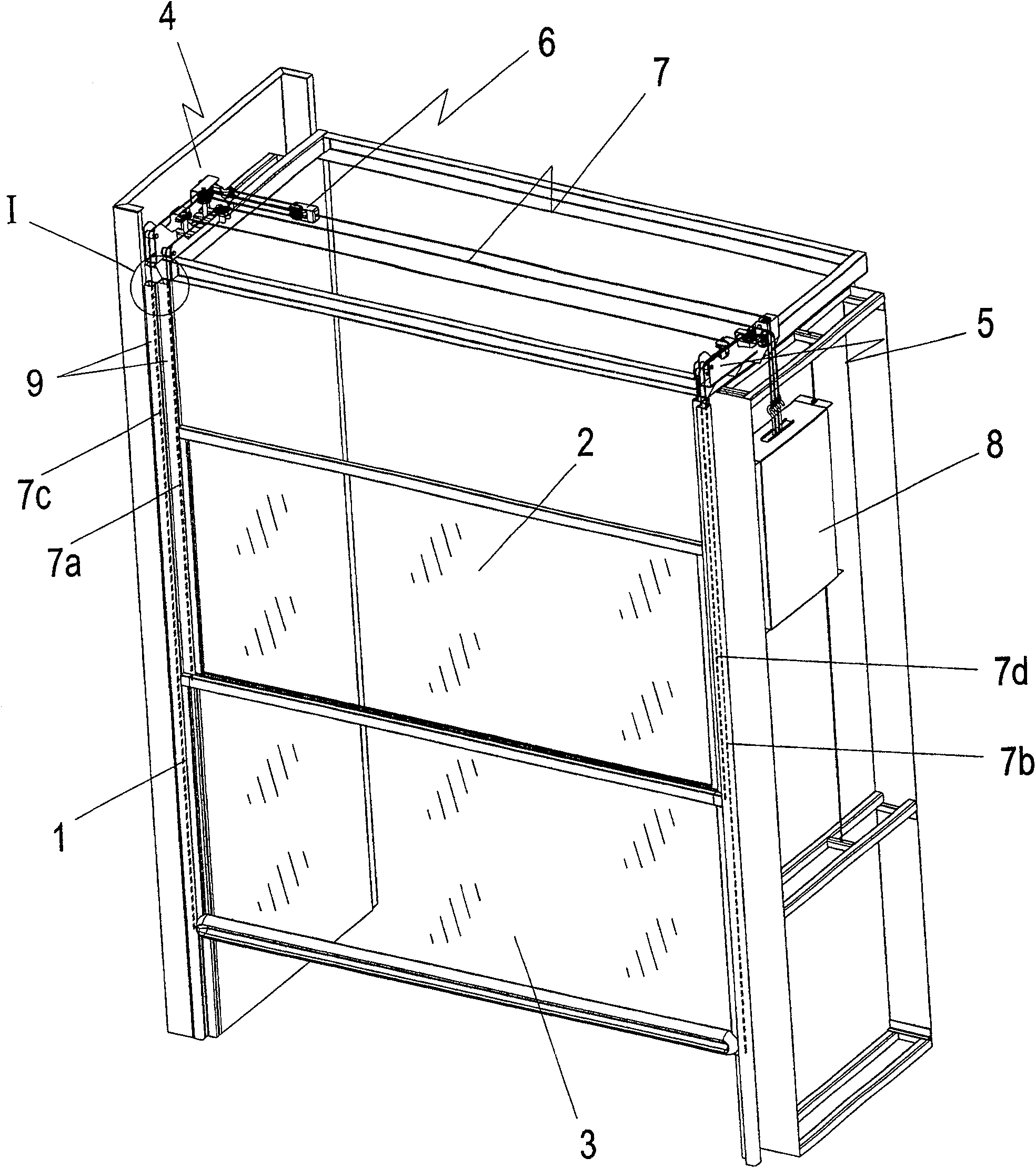

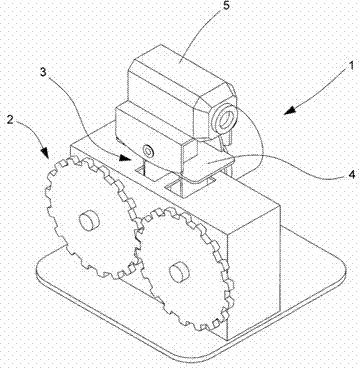

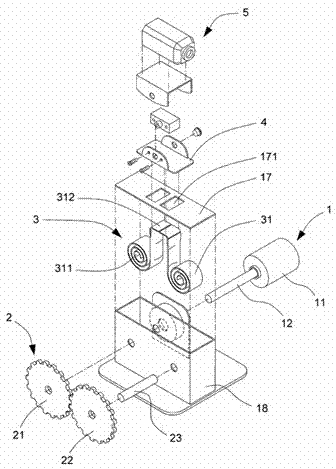

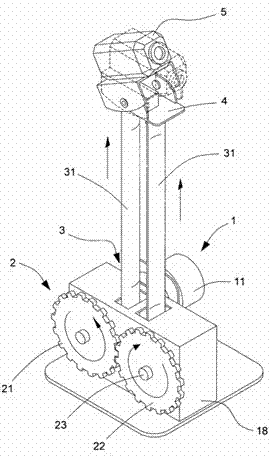

Conjoined multi-tape type power lifting device

The invention discloses a conjoined multi-tape type power lifting device. The conjoined multi-tape type power lifting device is characterized in that the conjoined multi-tape type power lifting device comprises a driving unit, a transmission unit, a lifting unit, a bearing platform and a monitoring unit. The driving unit can be a motor, and a first rotary shaft is arranged at the power output end of the driving unit. The transmission unit comprises a first gear, a second gear and a second rotary shaft, the first gear is connected with the first rotary shaft in a matched mode, the second gear is connected with the second rotary shaft in a matched mode, and the first gear is meshed with the second gear. The lifting unit comprises two pieces of tape and is of a rolling structure, a central end is formed in the lifting unit, the relative outer end of the lifting unit is an outer tail end, and the central end of the lifting unit is respectively connected with the first rotary shaft and the second rotary shaft. The bearing platform is arranged on the top of the lifting unit, and is combined with the outer tail ends of the tape, and the monitoring unit is arranged on the bearing platform. The conjoined multi-tape type power lifting device has the advantages that the structure is simple, control is easy, the lifting stroke ratio is large, the device can ascend to a large height with few materials, and deformation and shimmy are avoided.

Owner:宁波市鄞州科启动漫工业技术有限公司

Gas-insulated switch gear using dual motion with multi-lever

ActiveCN108346547AStroke ratio controlMiniaturizationSwitchgear arrangementsContact driving mechanismsEngineeringCircuit breaker

The present disclosure may allow the movable base and the second movable contact driven in a dual-motion manner to be connected by a plurality of levers, and a force transferred to the movable base while the plurality of levers are in close contact with one another or released from the close contact may be transferred to the second movable contact, and thus a size of the levers may not be requiredto increase even when a stroke ratio between the movable base and the second movable contact increases, thereby having an effect capable of minimizing a size of the gas circuit breaker as well as appropriately controlling a stroke ratio between the movable base and the second movable contact.

Owner:LSIS CO LTD

Use of double motion gas insulated switchgear with multiple rods

ActiveCN108346547BStroke ratio controlMiniaturizationSwitchgear arrangementsContact driving mechanismsEngineeringCircuit breaker

The present disclosure may allow a movable base driven in a dual-motion manner and a second movable contact to be connected together by a plurality of rods, and the force transmitted to the movable base may be when the plurality of rods are in close contact with each other or are released from close contact. to the second movable contact, and thus may not require an increase in the size of the rod even when the stroke ratio between the movable base and the second movable contact is increased, thereby having It is possible to minimize the size of the gas circuit breaker and to appropriately control the stroke ratio between the movable base and the second movable contact.

Owner:LSIS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com