Host of pulley block ejector

A technology of pulley blocks and catapults, applied in the direction of launching/dragging transmissions, etc., which can solve the problems of fresh water consumption and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

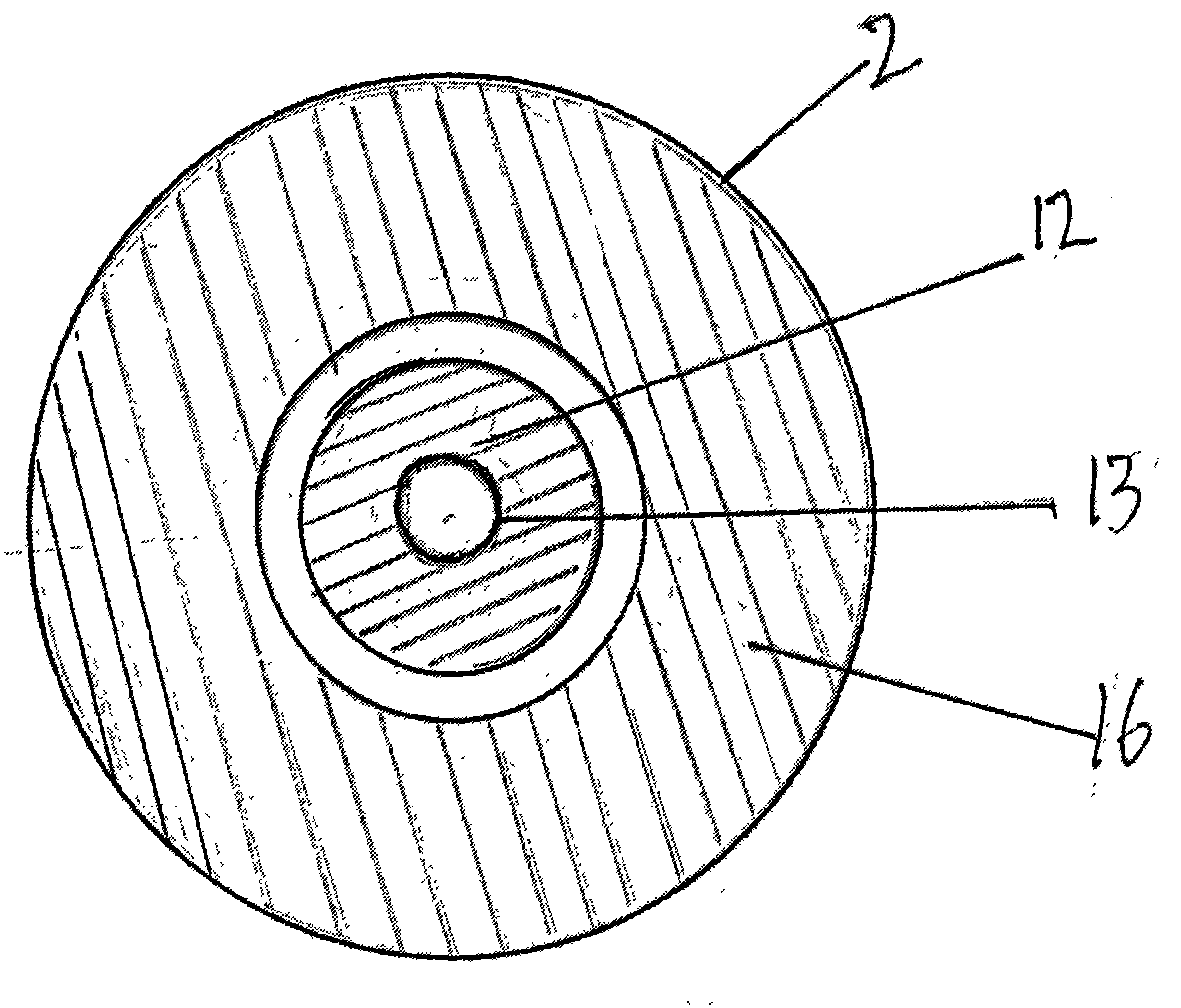

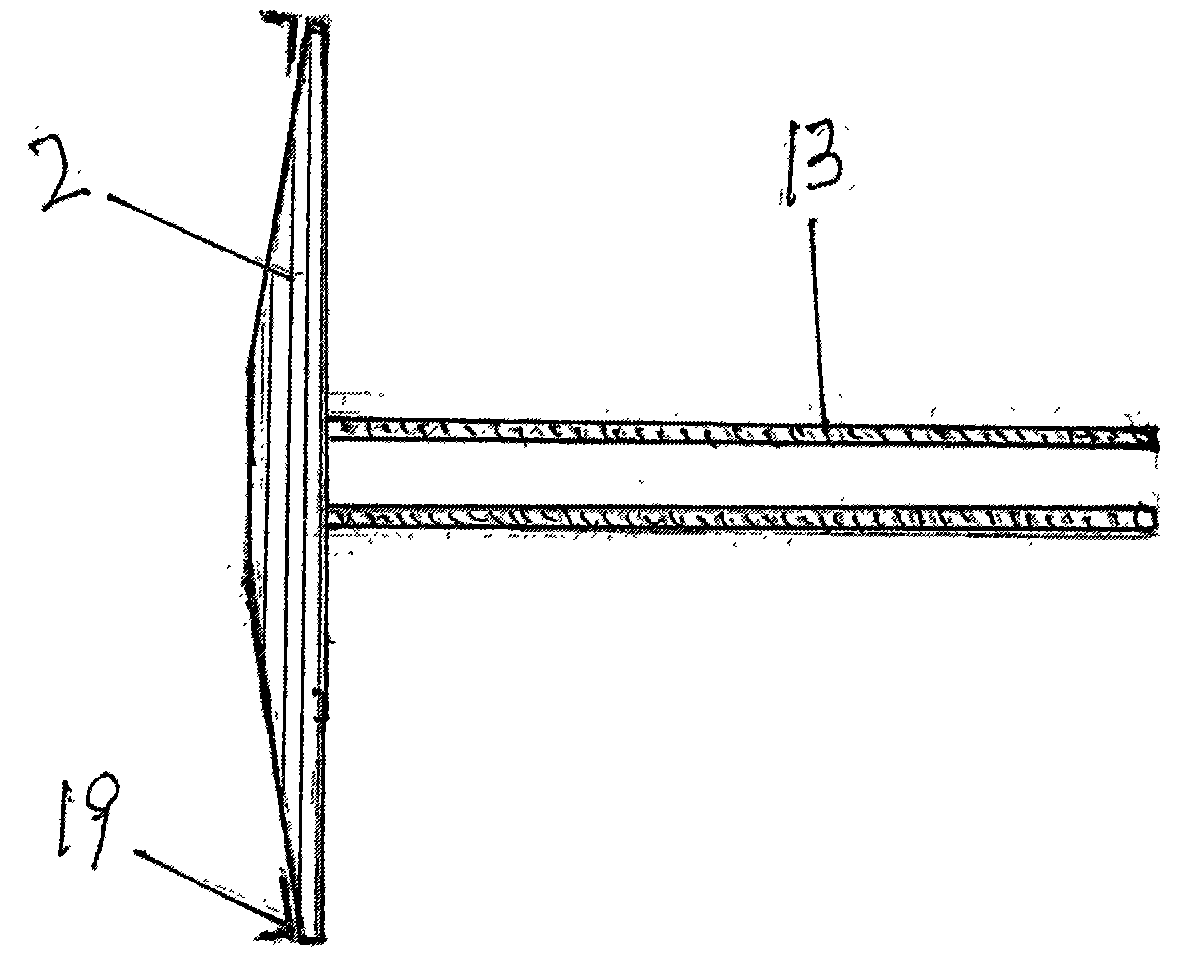

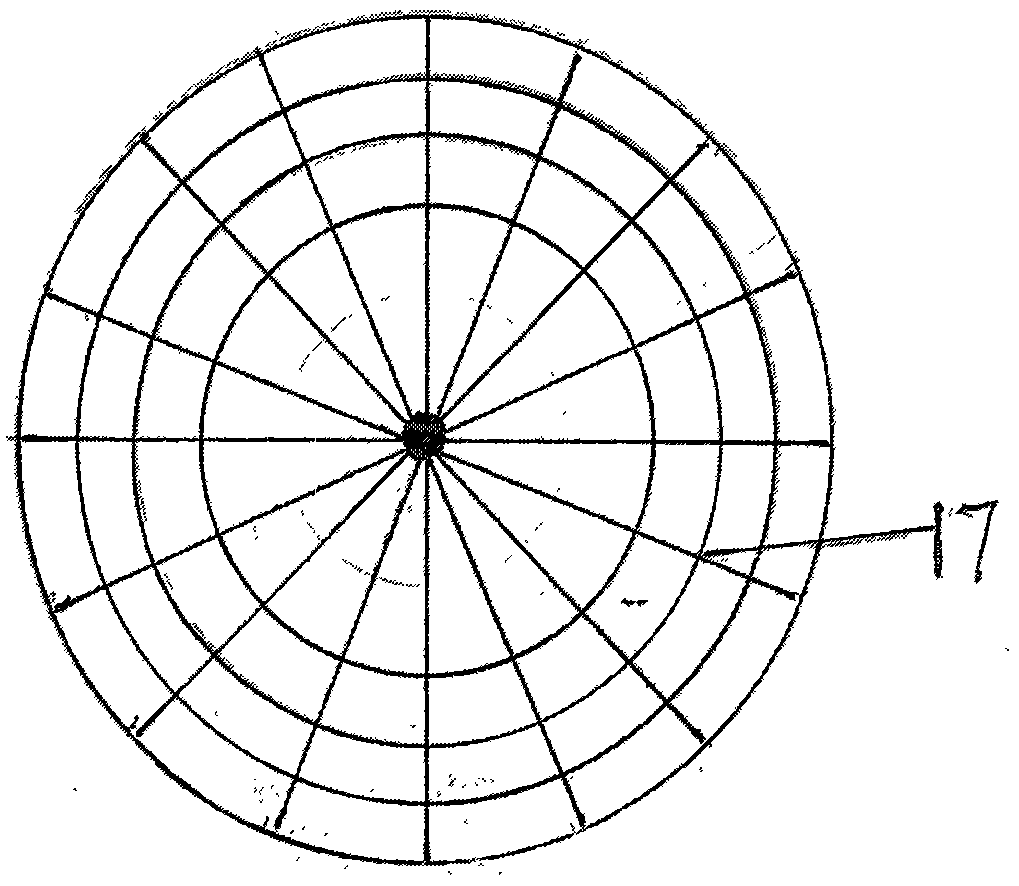

[0035] Dimensions and parameters of main components of pulley block catapult: ejection force design: cylinder (1) length 1500cm, inner diameter 115cm, cross-sectional area 10387cm^2, gas pressure 60kg / cm^2, cylinder (1) inner piston (2) thrust for 623T. The ejection force of 4 strands of pulley blocks pulling ejection shuttle (39) is 623T / 4=155.7T, deducts 10% frictional force (estimated value), net ejection force 140T. Add the carrier-based aircraft's own thrust to 25T. The total thrust is 165T. Piston (2) working stroke 1450cm*4=ejection shuttle (39) ejection stroke 58 meters.

[0036] The total acceleration mass of the ejection carrier-based aircraft (also the mass of high acceleration energy consumption) includes: the take-off mass of the carrier-based aircraft with full load is 32.5T, the mass of the ejection system's own acceleration running parts (estimated): the ejection shuttle (39) 0.5T mass of high acceleration energy consumption . The dynamic running parts of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com