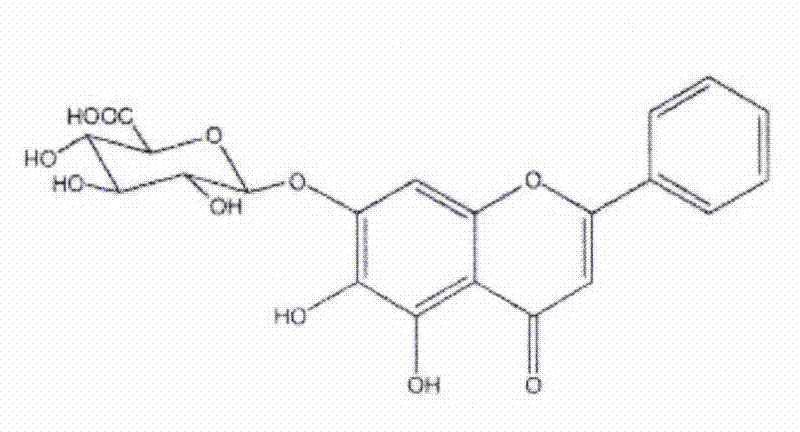

Nanometer composite gel dressing containing baicalin and soapstone and preparation method for nanometer composite gel dressing

A nano-composite, baicalin technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of easy rupture and exudation, and achieve the effects of good biocompatibility and antibacterial performance, mild conditions, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Dispersion of inorganic nano-saponite particles: at 22°C, add 0.2 g of hectorite to 10 mL of deionized water, and stir for 20 min until completely dispersed to form a transparent solution;

[0046] 2) Preparation of gel dressing: under nitrogen protection and magnetic stirring, first add 1.0 g of isopropylacrylamide to the above transparent solution, then cool down to 3°C with ice cubes, add 0.01 g of ammonium persulfate, and stir for 20 minutes. Inject 80 μL of tetramethylethylenediamine aqueous solution with a mass percentage concentration of 2%, and slowly pour the solution into a glass vessel with a thickness of 2 mm after 15 minutes, seal it and carry out in-situ free radical polymerization reaction, control the reaction temperature at 22°C for 36 hours Stop reaction after;

[0047] 3) Purification of the gel dressing: Cut the reacted product into thin slices with a diameter of about 10mm, soak them in deionized water and absolute ethanol for 1 week respectively...

Embodiment 2

[0051] 1) Dispersion of inorganic nano-saponite particles: at 20°C, add 0.1 g of hectorite to 10 mL of deionized water, and stir for 15 min until completely dispersed to form a transparent solution;

[0052] 2) Preparation of gel dressing: under nitrogen protection and magnetic stirring, first add 1.1g of isopropylmethacrylamide to the above transparent solution, then cool down to 2°C with ice cubes, add 0.01g of potassium persulfate, and stir for 15 minutes Finally, inject 100 μL of sodium sulfite aqueous solution with a mass percentage concentration of 1%, and slowly pour the solution into a glass vessel with a thickness of 2 mm after 20 minutes. After sealing, carry out in-situ free radical polymerization reaction, control the reaction temperature at 23 ° C, and stop the reaction after 40 hours ;

[0053] 3) Purification of the gel dressing: Cut the reacted product into thin slices with a diameter of about 10mm, soak them in deionized water and absolute ethanol for 1 week r...

Embodiment 3

[0057] 1) Dispersion of inorganic nano-saponite particles: at 25°C, add 0.3 g of stesterite to 15 mL of deionized water, and stir for 25 min until completely dispersed to form a transparent solution;

[0058] 2) Preparation of gel dressing: under nitrogen protection and magnetic stirring, first add 1.5g of isopropylacrylamide to the above transparent solution, then cool down to 1°C with ice cubes, add 0.015g of ammonium persulfate, and stir for 20 minutes. Inject 120 μL of an aqueous solution of tetramethylpropylenediamine with a concentration of 0.5% by mass, and pour the solution slowly into a glass vessel with a thickness of 2 mm after 15 minutes. After sealing, carry out in-situ free radical polymerization reaction, and control the reaction temperature at 24°C for 48 hours Stop reaction after;

[0059] 3) Purification of the gel dressing: Cut the reacted product into thin slices with a diameter of about 10mm, soak them in deionized water and absolute ethanol for 1 week res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com