Variable-stroke ratio-regulated reciprocating pump

A proportional adjustment, reciprocating pump technology, applied in pumps, piston pumps, liquid variable capacity machines, etc., can solve the problems of high equipment maintenance costs, high construction costs, and difficult equipment management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

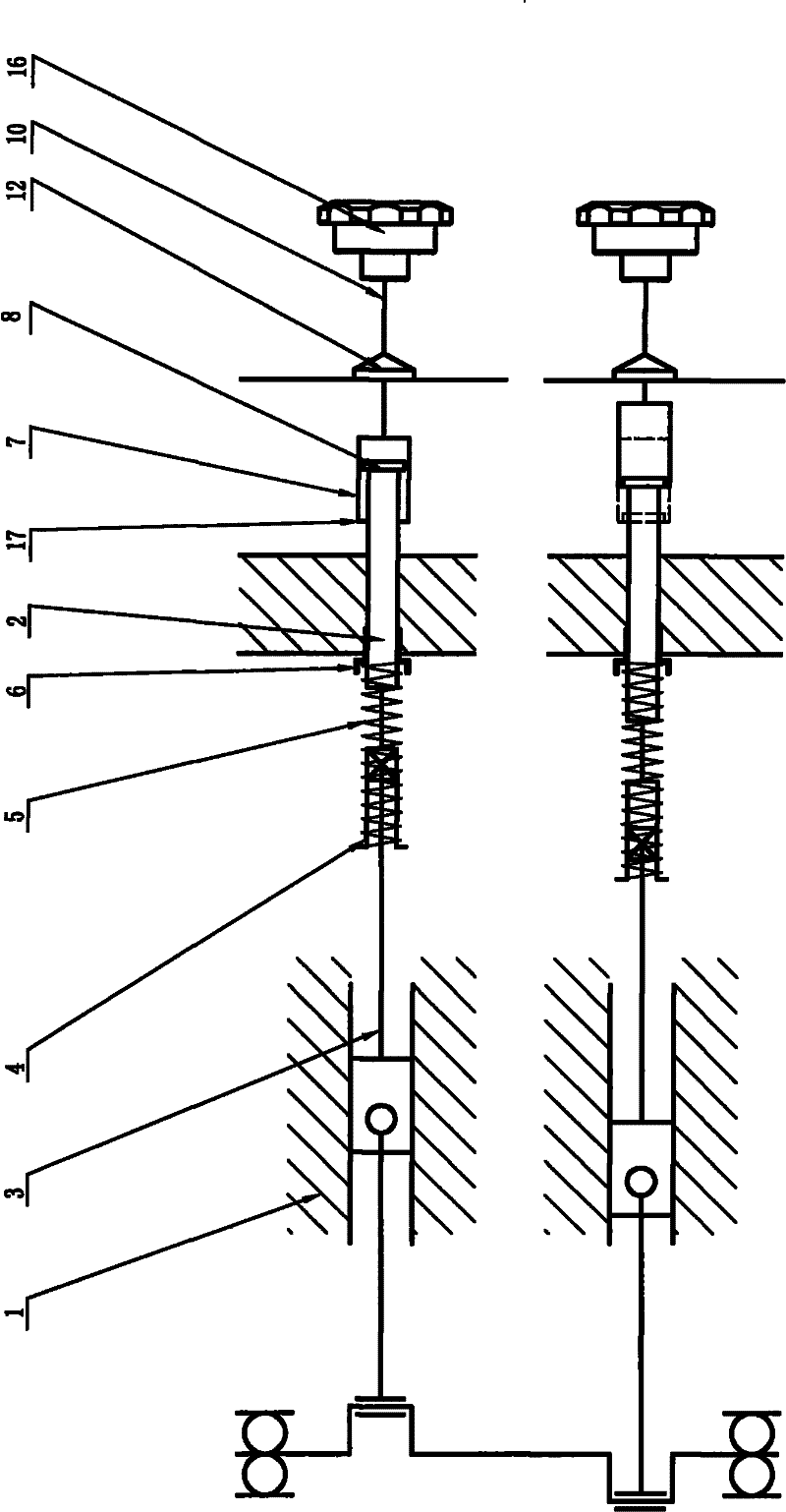

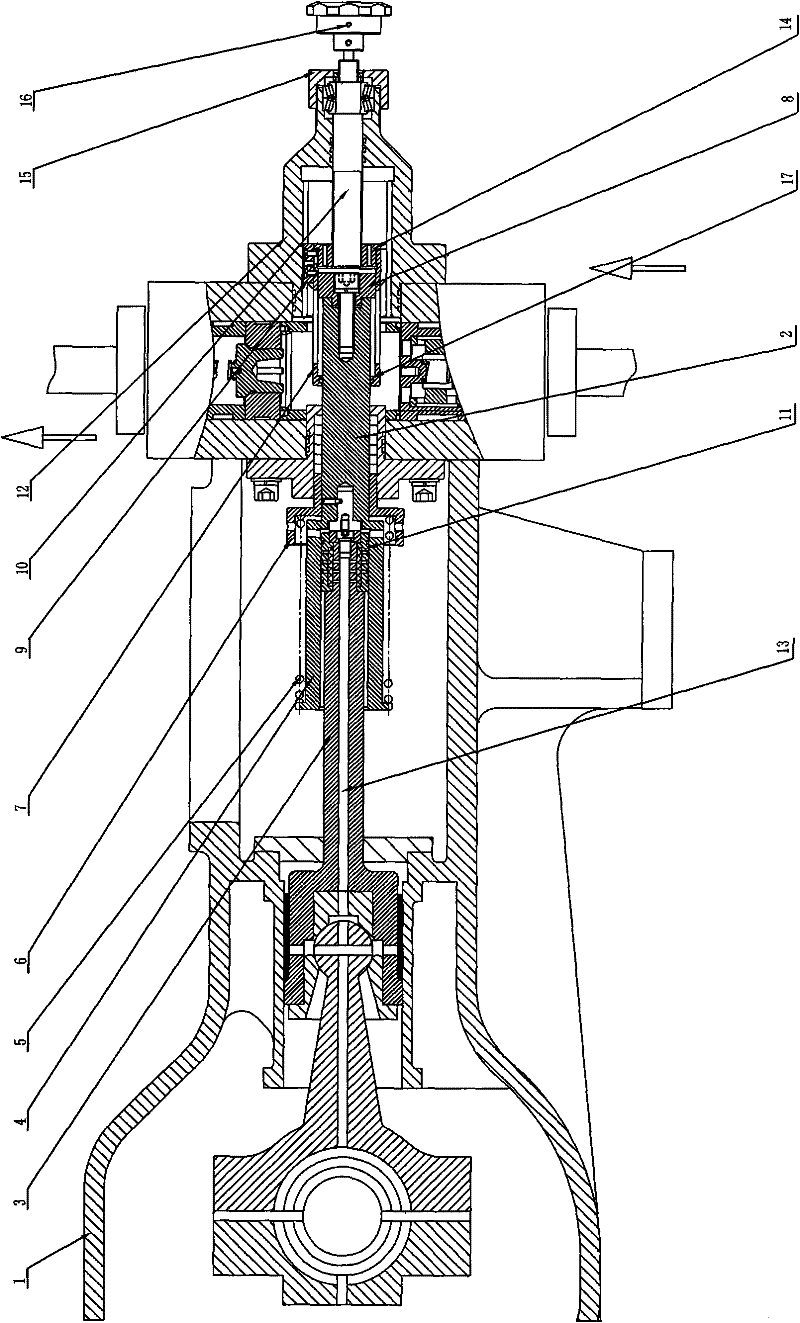

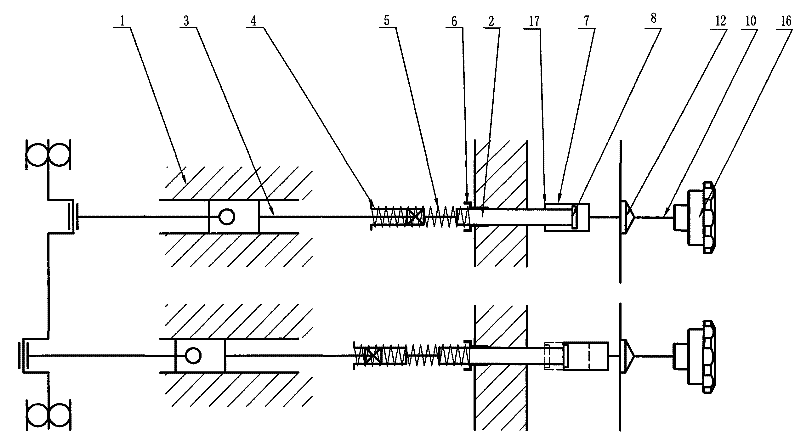

[0010] The present invention will be further described below in conjunction with accompanying drawing:

[0011] As shown in the accompanying drawings, the variable stroke proportional adjustment reciprocating pump includes a pump body 1, 3 connecting rods are connected to the crankshaft at one end of the pump body 1, and a cross shaft 3 is connected to the ball head of the connecting rod, and the cross shaft 3 has the characteristics of a piston. And lubricating function, the end of the cross shaft 3 is connected with a lubricating piston sleeve 11, the lubricating piston sleeve 11 is processed with an oil groove, the lubricating piston sleeve 11 and the cross shaft 3 are provided with oil-absorbing packing, and the outer ends of the lubricating piston sleeve 11 are provided with dust-proof supports Rubber ring, a lubricating cavity is formed between the two dust-proof supporting rubber rings. There is a lubricating channel 13 communicating with the oil-absorbing packing in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com