Design of host machine part of hot-pressing sintering machine in geological exploration

A hot-pressing sintering and geological exploration technology, applied in lighting and heating equipment, furnaces, muffle furnaces, etc., can solve the problems of poor sealing, insufficient bearing strength, unreasonable selection of hydraulic cylinders, etc. The effect of strong carrying capacity and small stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] By comparing the working principles of the two hydraulic cylinders, the single-acting buffer hydraulic cylinder is selected.

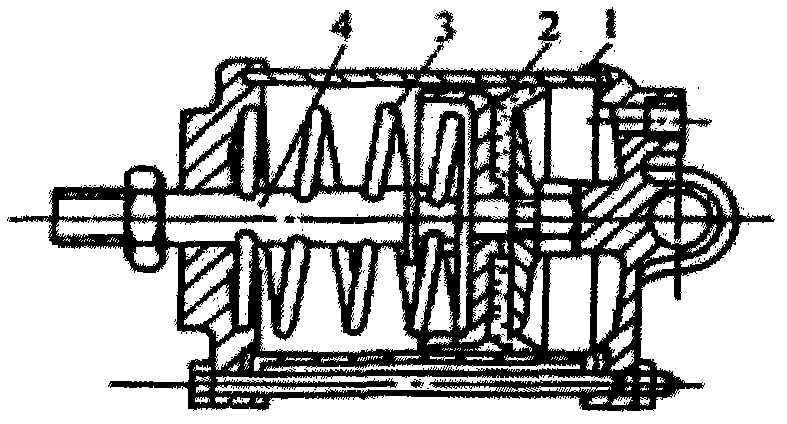

[0010] 1. The single-acting hydraulic cylinder has only one cavity that can input hydraulic oil to realize movement in one direction. Its piston rod can only be pushed back by external force; usually by spring force, diaphragm tension, gravity, etc. Such as figure 1 .

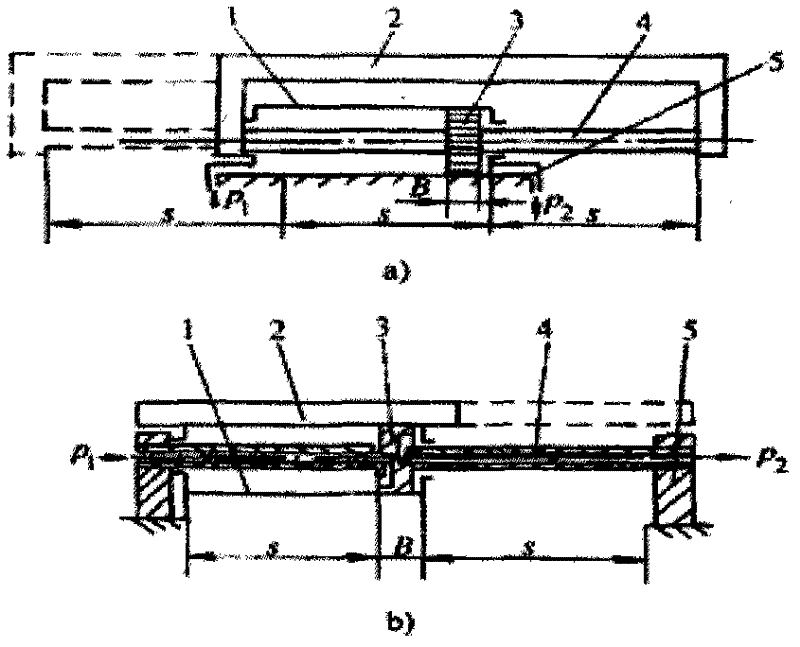

[0011] 2. Double-acting hydraulic cylinder such as figure 2 , its working principle is: when the cylinder body is fixed, the load it carries (such as a workbench) is integrated with the two piston rods of the hydraulic cylinder, and the hydraulic oil enters the two chambers of the hydraulic cylinder in turn (one chamber enters the other chamber and discharges oil), The piston rod drives the worktable to move left and right, and the movement range of the worktable is equal to three times of its effective stroke s. The installation takes up a lot of space and is generally used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com