Curved variable torque shift disc, shift mechanism and agricultural machinery

A shifting mechanism and shifting disc technology, applied in the direction of mechanical equipment, components with teeth, transmission device control, etc., can solve the problems of difficult to shift to the required gear, inconvenient shifting, and difficulty in shifting, etc. Achieve the effects of avoiding jumping gears, high gear shifting precision, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

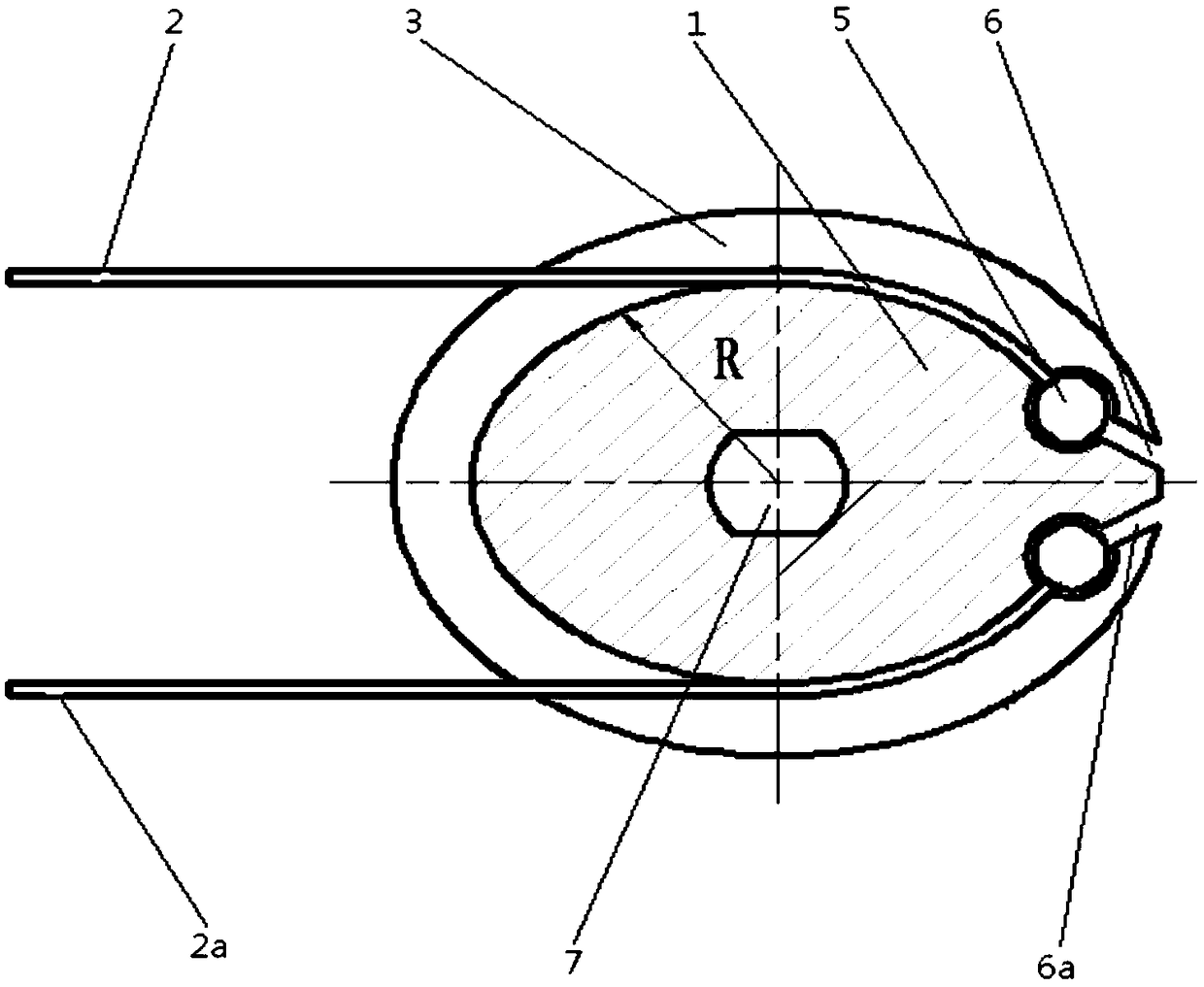

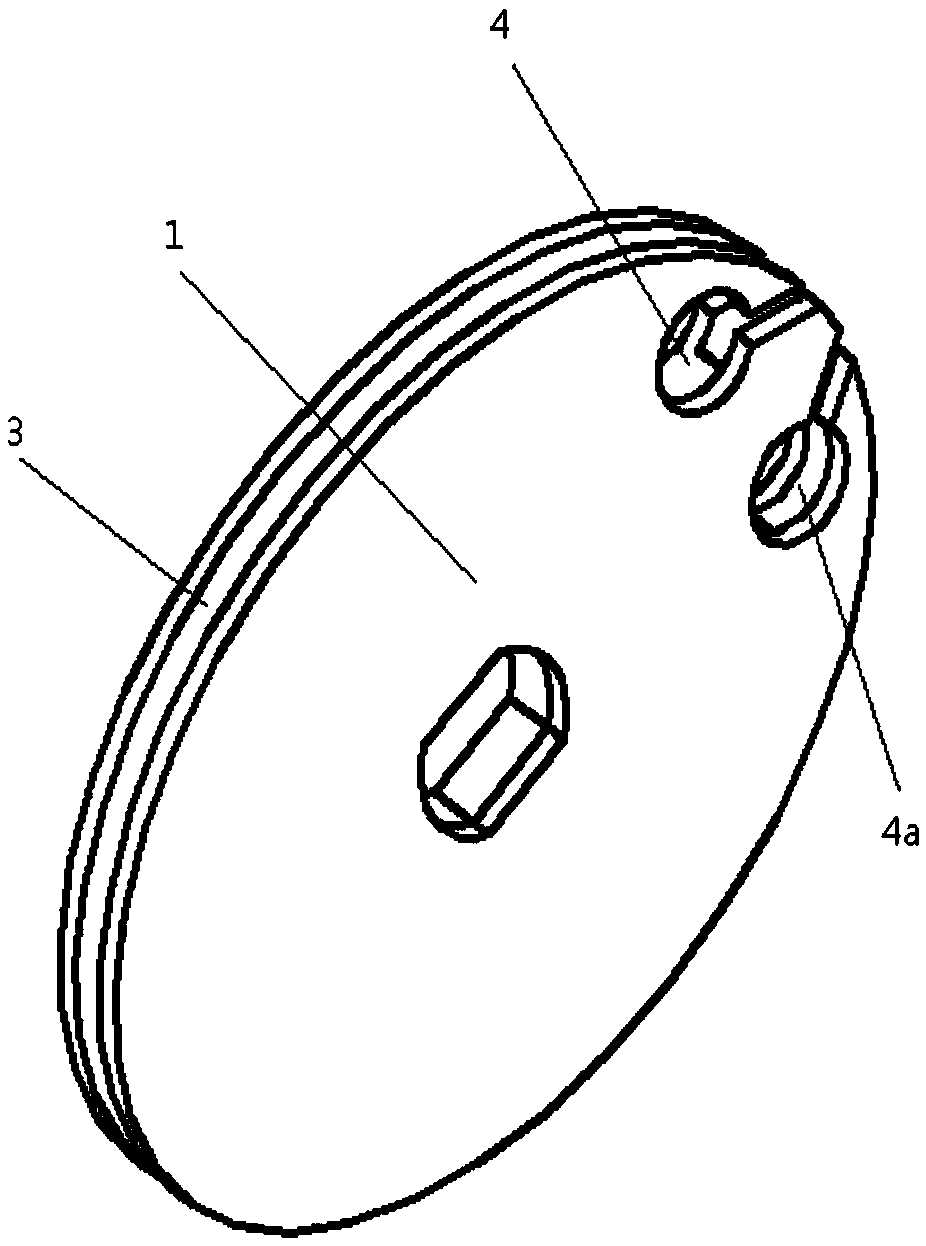

[0019] figure 1 It is a structural schematic diagram after the dragline is installed in the present invention, figure 2 It is a schematic diagram of the structure of the present invention without the installation of the cable. As shown in the figure, this embodiment discloses a curve-variable torque shift disc. The shift disc 1 and the shift shaft are fixed along the circumferential direction and are used to drive the shift The shaft rotates, the end of the cable 2 is fixed on the edge of the shifting disc 1 and the cable 2 wraps around a part of the edge of the shifting disc 1. The shifting disc 1 is a non-circular disc; The side wall of the gear plate body along the circumferential direction, the edge line of the shifting plate 1 is a non-circular line, of course, the edge line of the shifting plate can be set as a curve according to actual needs, and the curve is conducive to effective control of the driving force arm And adjust, so that the moment arm of the shifting dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com