Wire tightening tool for power transmission line lead and wire tightening method

A technology of transmission lines and tools, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of insufficient bending resistance of line fixtures, limited tonnage of pulling force, and difficulty in displaying, etc., to achieve reduced effective strokes, short effective strokes, and high operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

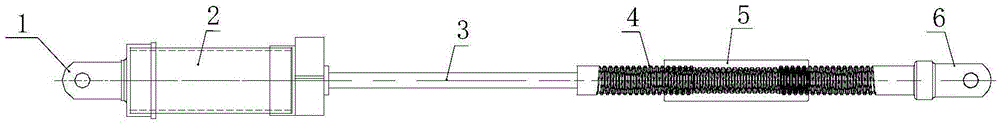

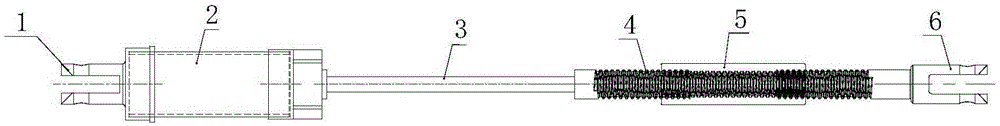

[0016] see figure 1 and figure 2 , one end of the manual screw rod is connected to the pull plate connector 6, the other end of the manual screw rod is connected to one end of the guide rod 3, the other end of the guide rod 3 is connected to the piston rod of the oil cylinder 2, and the cylinder body of the oil cylinder 2 is connected to a fixture connector 1.

[0017] Specifically, the manual screw rod is composed of a manual screw rod cover 5 and screw rods 4 located at both ends of the manual screw rod cover 5. The screw rod 4 at one end of the manual screw rod cover 5 is connected to the tie plate connector 6, and the manual screw rod cover The screw mandrel 4 of the other end of 5 connects one end of guide rod 3.

[0018] see figure 1 and figure 2 , use manual screw sleeve 5 and screw 4 to realize the load transfer of the first 300mm, and use the oil cylinder 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com