Design method of synchronous counterweight cover type explosion-proof door

A design method and technology for explosion-proof doors, which are applied in computing, mining equipment, earth-moving drilling, etc., to achieve the effect of reducing the amount of calculation, avoiding blindness, and simplifying the calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

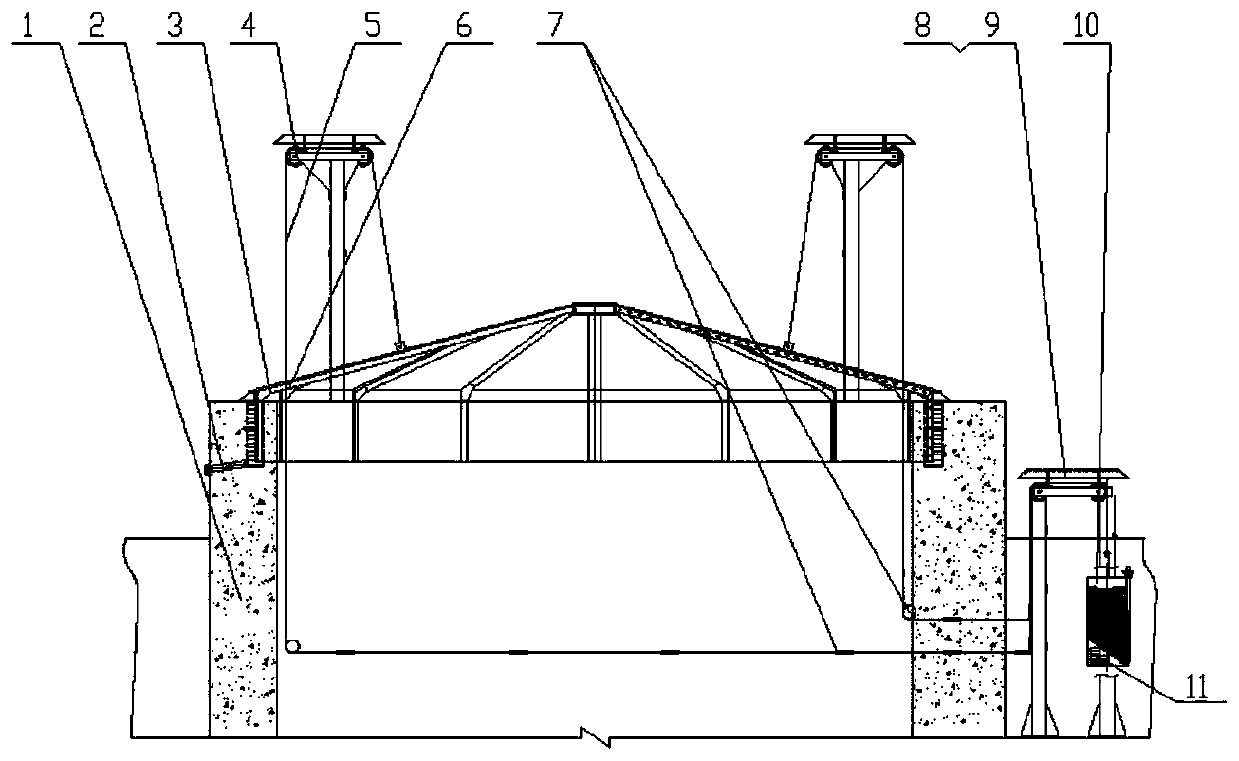

[0103] This embodiment is a synchronous counterweight cover type explosion-proof door, and its specific parameters are: the large end diameter of the explosion-proof door D=7500mm, the total negative pressure of the return air shaft P=5200Pa, and the half cone angle of the explosion-proof cover cone α=75°, Explosion-proof cover surface area S=44.18m 2 , The equivalent number of friction surfaces i=2, and the friction coefficient between the steel wire rope and the steering pulley f=0.1.

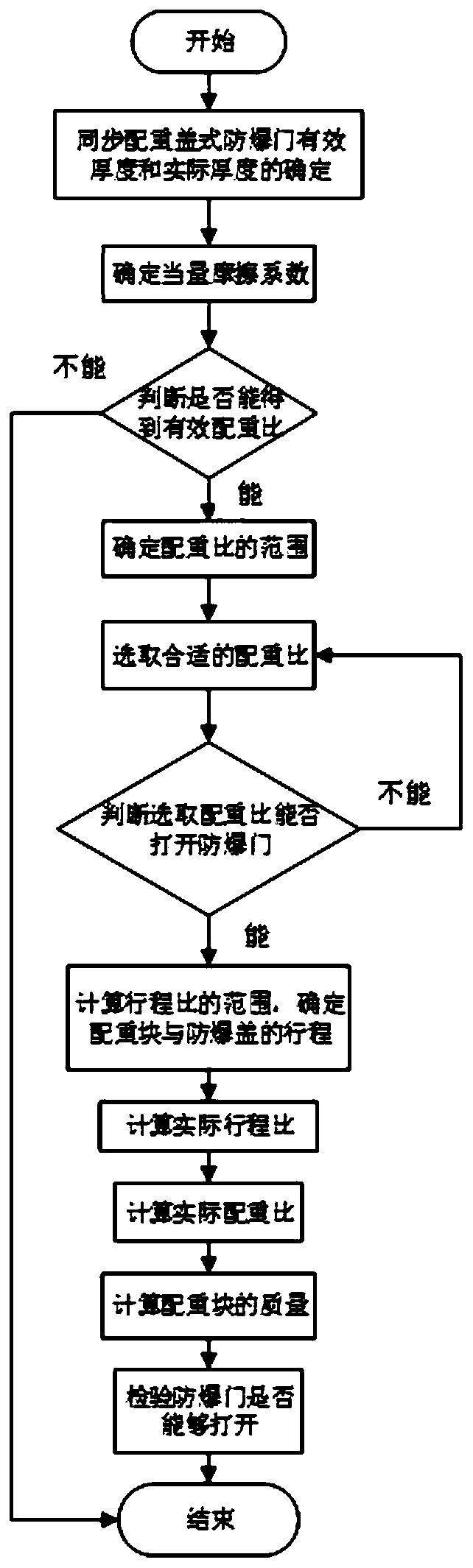

[0104] Combine figure 1 , The main steps include:

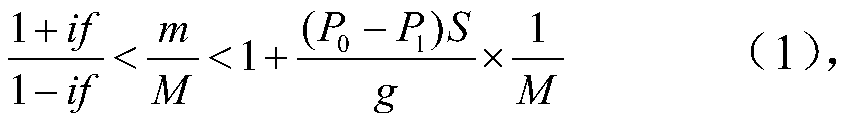

[0105] Step 1: Simplify the synchronous counterweight cover explosion-proof door to a pressure vessel model, determine the effective thickness of the synchronous counterweight cover explosion-proof door according to the pressure vessel strength theory, and determine the synchronous counterweight cover according to the negative deviation of the thickness of the material and the corrosion allowance The additional thickness of the explosion-proof do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com