Low rotation speed large torque engine

A high-torque, low-speed technology, applied in the field of low-speed and high-torque engines, can solve the problems of high speed at the maximum power and maximum torque point, poor low-speed performance, etc. Vibration reduction effect

Inactive Publication Date: 2008-08-06

吕清波

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the engines used in vehicles such as two-wheeled motorcycles, three-wheeled motorcycles, ATVs, and go-karts are all single-cylinder four-stroke gasoline engines, which have high maximum power and maximum torque point speed, and poor low-speed performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

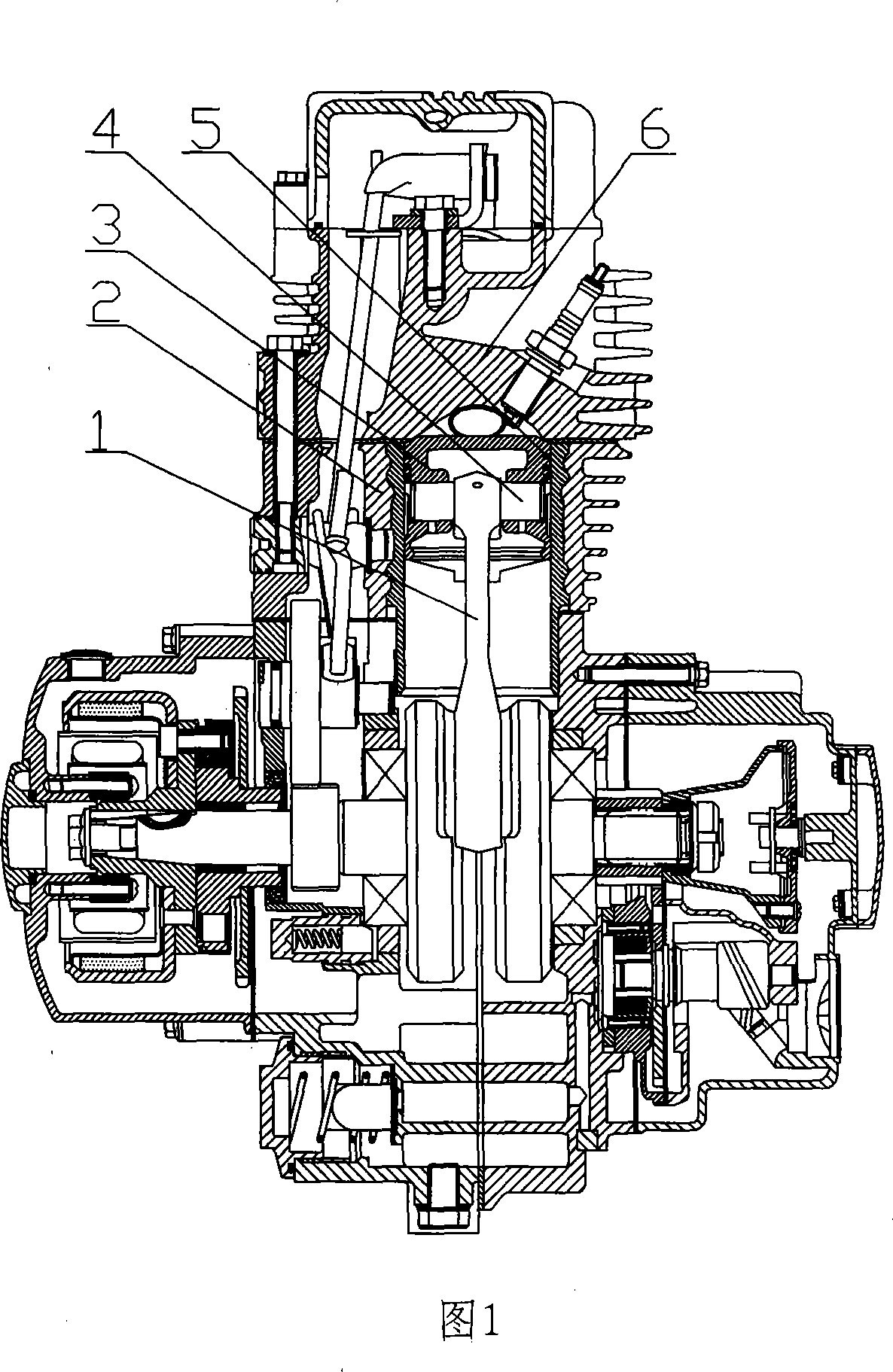

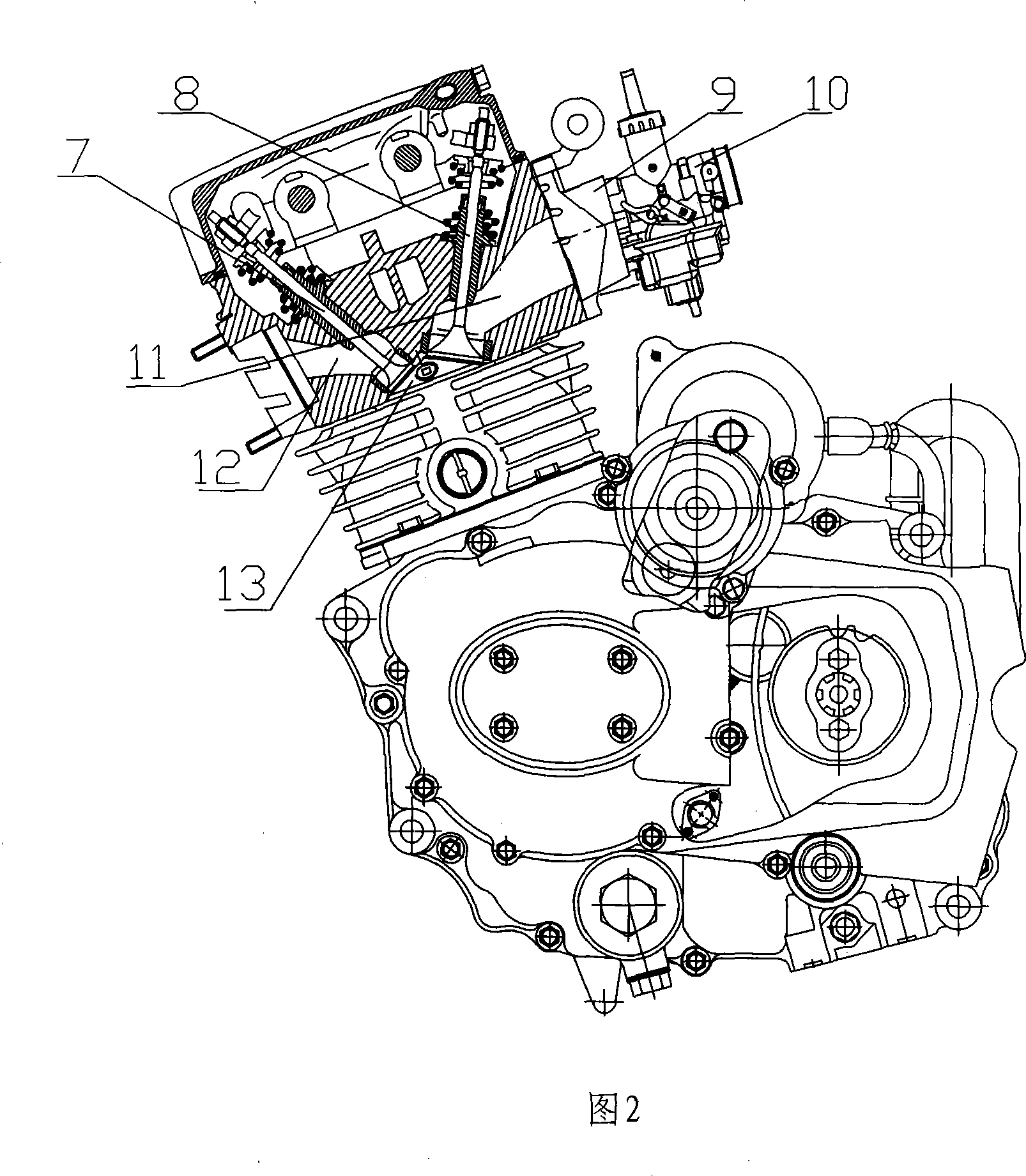

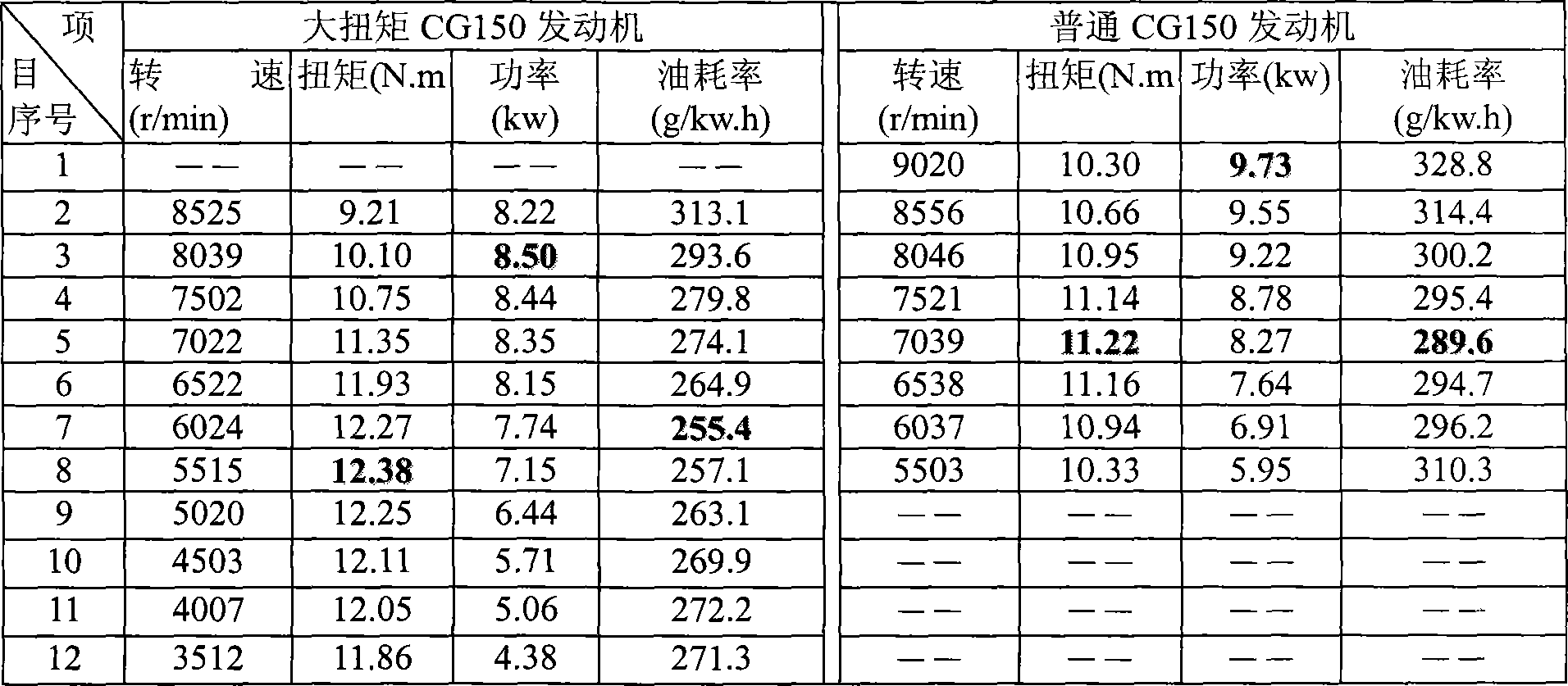

The invention discloses a motor with low rotary speed and large torque, which comprises a crank connecting rod assembly, a cylinder block, a piston, a piston pin, a piston ring assemblage, a cylinder head, an exhaust valve, an inlet valve, an air inlet pipe and a carburetor, wherein the piston is fixed on the crank connecting rod assembly via the piston pin, the piston is arranged in the cylinder block, the exhaust value and the inlet valve are arranged in the duct of the exhaust value and the inlet valve of the cylinder head, the cylinder head is arranged on the cylinder block, the air inlet pipe is arranged on one side of the intake of the cylinder head, the carburetor is arranged on the air inlet pipe, the eccentricity of the crank connecting rod assembly is from 28.90mm to 31.10mm, and the diameter of the piston is from 54.5mm to 57mm, and the diameter of the cylinder / the stroke ratio is from 0.88 to 0.98. The motor is suitable for motor bicycles, motor tricycles, sand bank cars and carting cars, which has the advantages of outputting larger torque at the low speed, reducing the rotary speed at the maximum torque point, improving the initial starting acceleration property and the transcending accelerating ability, reducing heat load, oil consumption and oscillation, and increasing the durability.

Description

technical field [0001] The invention relates to an engine, specifically a low-speed high-torque engine suitable for vehicles such as two-wheeled motorcycles, three-wheeled motorcycles, ATVs, karts and the like. Background technique [0002] The engines used in vehicles such as two-wheeled motorcycles, three-wheeled motorcycles, ATVs, go-karts, etc. are all single-cylinder four-stroke gasoline engines. Contents of the invention [0003] Aiming at the deficiencies in the prior art, the present invention aims to provide a low-speed high-torque engine whose output torque is significantly increased at medium and low speeds. [0004] The technical scheme adopted in the present invention is: [0005] A low-speed high-torque engine, including crank and connecting rod assembly, cylinder block, piston, piston pin, piston ring combination, cylinder head, exhaust valve, intake valve, intake pipe and carburetor, the piston is fixed by the piston pin On the crank connecting rod assemb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02B75/32F02F3/00F02F1/00F02F1/42

Inventor 吴高利周凤民彭冲

Owner 吕清波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com