Electric riveting tool

A technology of electric tools and rivets, applied in the field of machinery, can solve the problems of small gear design, limited space usage, and inability to pull off, and achieve the effects of slowing down the riveting speed, enhancing the discharge effect, and accelerating the riveting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing;

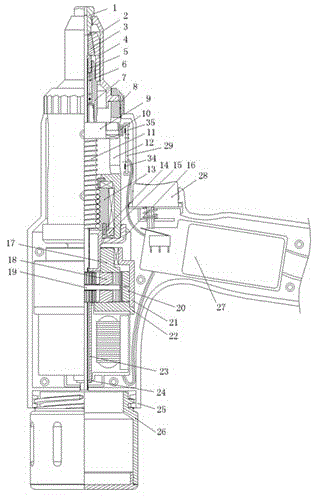

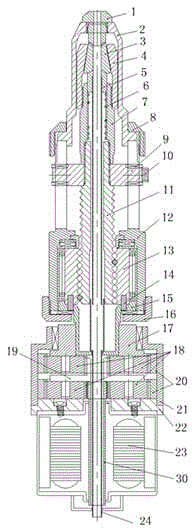

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the rivet power tool includes an outer cover 25, a trigger 28, a circuit board 27, a nail collection tube 26, a riveting system, a screw drive system, a planetary gear reduction system and a power motor assembly;

[0039] Such as figure 1 and figure 2 As shown, the screw drive system includes a roller positioning block 9, a ball screw 11, a screw nut 13, a front bearing seat 12, a rear bearing seat 16, and a connecting shaft 15, and the ball screw 11 is a hollow structure. It passes through the core pipe 32 and is used for the ejector rod. The front end is fixed by the roller positioning block 9, and the rear end is connected with the screw nut 13. The screw nut 13 is arranged in the front bearing seat 12; the rear bearing seat 16 and The front bearing block 12 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com