Method for changing stroke of double-well pumping unit

A pumping unit and stroke technology, which is applied in the direction of earthwork drilling, wellbore/well parts, production fluid, etc., can solve the problems of heavy drum weight, time-consuming and labor-intensive disassembly, etc., and achieve reduced labor intensity, low cost, and durability. good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

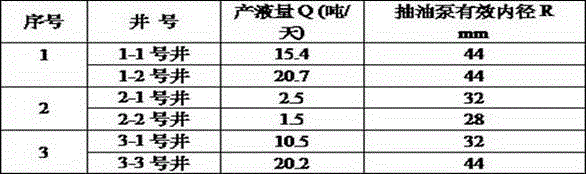

[0035] Example 1: The first double well pumping unit

[0036] 1. The stroke ratio of No. 1-1 well and No. 1-2 well

[0037] i = (Q 1 × R 2 2 ) / (Q 2 × R 1 2 )=15.4×(44 / 2) 2 / 20.7×(44 / 2) 2 =0.74

[0038] That is, A1 / A2=0.74 (A1 is the stroke of No. 1-1 oil well, A2 is the stroke of No. 1-2 oil well)

[0039] i < 0.95, indicating that the outer diameter of the drum corresponding to the No. 1 oil well is smaller than that of the No. 2 oil well, and a bushing should be added to the No. 2 drum.

[0040] 2. The thickness of the bushing

[0041] d=(1-i)×∮ / 2

[0042] d=(1-0.74)×600 / 2

[0043] =78(mm)

[0044] The outer diameter of the added bushing: 600+78×2=756 (mm)

Embodiment 2

[0045] Embodiment 2: The second double well pumping unit

[0046] 1. The stroke ratio of No. 2-1 well and No. 2-2 well

[0047] i = (Q 1 × R 2 2 ) / (Q 2 × R 1 2 )=2.5×(28 / 2) 2 / 1.5×(32 / 2) 2 =1.28

[0048] That is, A1 / A2=1.28

[0049] i>1.05, indicating that the outer diameter of the drum corresponding to the No. 1 oil well is larger than that of the No. 2 oil well, and a bushing should be added on the No. 1 drum.

[0050] 2. The thickness of the bushing

[0051] d=(i-1)×∮ / 2 =(1.28-1)×600 / 2=84(mm)

[0052] The outer diameter of the additional bushing: 600+84×2=768 (mm)

Embodiment 3

[0053] Embodiment 3: The third double well pumping unit

[0054] 1. The stroke ratio of No. 3-1 well and No. 3-2 well

[0055] i = (Q 1 × R 2 2 ) / (Q 2 × R 1 2 ) =10.5×(44 / 2) 2 / 20.2×(32 / 2)2 =0.98

[0056] 0.95≦i≦1.05, indicating that the drum corresponding to the No. 1 oil well and the drum corresponding to the No. 2 oil well do not need to add bushings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com