Stroke proportional transmission hydraulic circuit

A hydraulic circuit and stroke technology, applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve the problems of large internal impact force, difficult process, huge structure, etc., to reduce internal impact and reduce operating speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

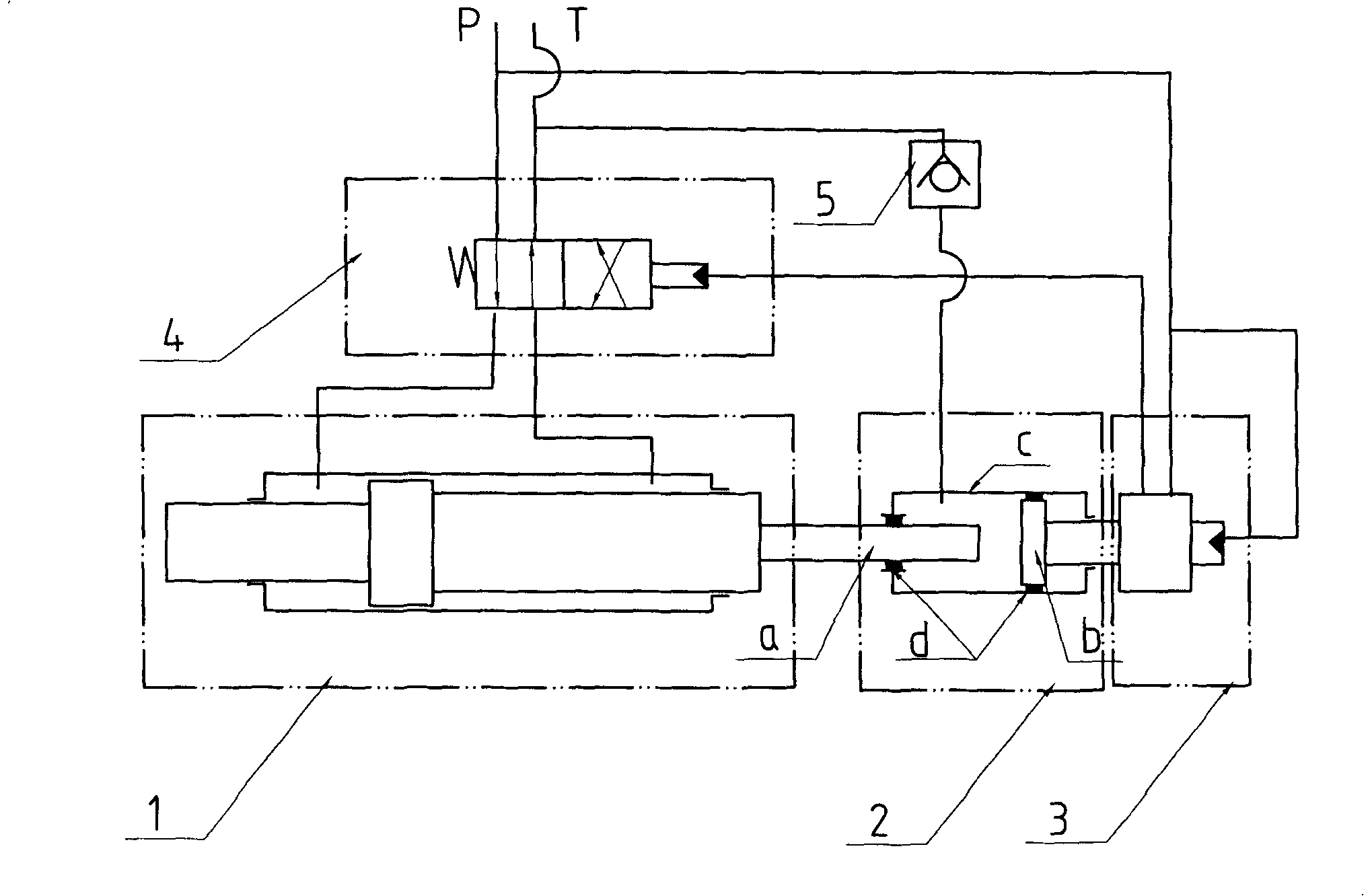

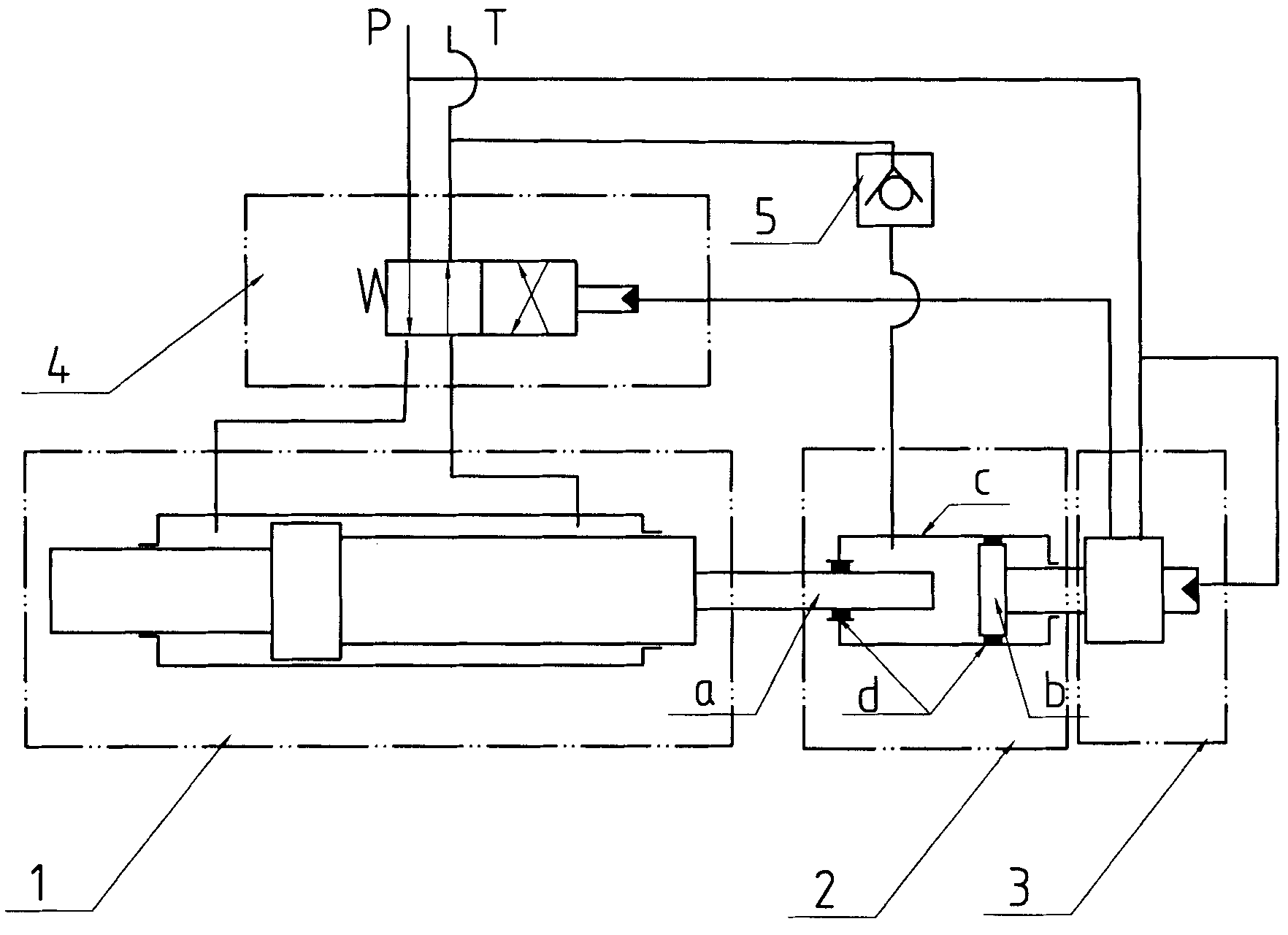

[0009] In the present invention:

[0010] Power Piston 1: It is a power output mechanism that reciprocates when the front and rear chambers are alternately supplied with oil to convert hydraulic energy into kinetic energy for output. The extension rod at the non-power output end of the power piston 1 serves as the piston a of the piston group 2 for the stroke ratio control.

[0011] Stroke proportional control piston group 2: Stroke proportional control piston group 2 consists of the non-power output end extension rod a of the power piston 1, the large piston b coaxially connected with the stroke signal feedback control valve 3, the cavity c and the oil seal group d composition. The cavity c is filled with hydraulic oil. The incompressibility of hydraulic oil is used to make the changes in the stroke positions of piston a and piston b equal to the reciprocal of their cross-sectional ratio. The position signal of the power piston 1 is transmitted to the stroke signal feedback con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com