Patents

Literature

81results about "Free piston pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

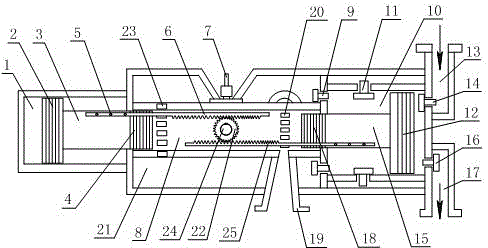

High-Pressure Gas Compressor And Method Of Operating A High-Pressure Gas Compressor

ActiveUS20080213115A1Reduce in quantitySimple manufacturing processPositive displacement pump componentsFlexible member pumpsFriction reductionInlet valve

A high-pressure gas compressor comprises a single-acting cam driven piston with a pressure compensation chamber disposed between the piston and the cam. A roller tappet assembly transmits reciprocating motion from the cam to the piston. A pressurized gas directed to the pressure compensation chamber offsets forces acting on the piston from the compression chamber gas pressure, thereby reducing Hertzian pressure between the tappet roller and the cam. Overall efficiency and durability can be improved by reducing friction between compressor components, for example by employing thin film coatings to reduce friction, pressurized oil lubrication systems and higher cylinder bore diameter to piston stroke ratios. The service life of gas seals and compression efficiency can be improved by thermal management strategies, including liquid-cooled compressor cylinder liners and intercoolers between compression stages. Employing a poppet-style intake valve and reducing parasitic volume in the compression chamber can improve compressor volumetric efficiency.

Owner:WESTPORT FUEL SYST CANADA INC

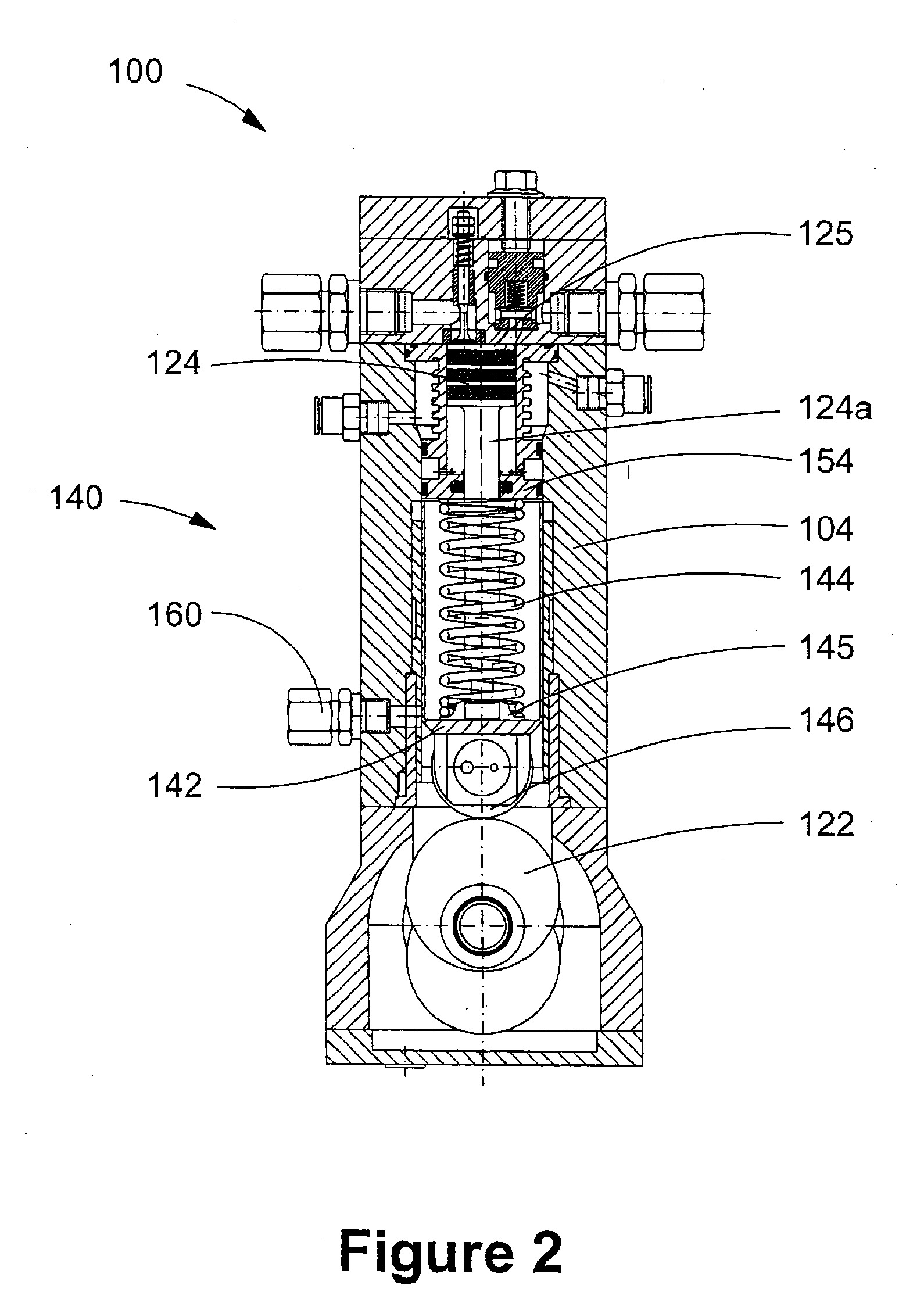

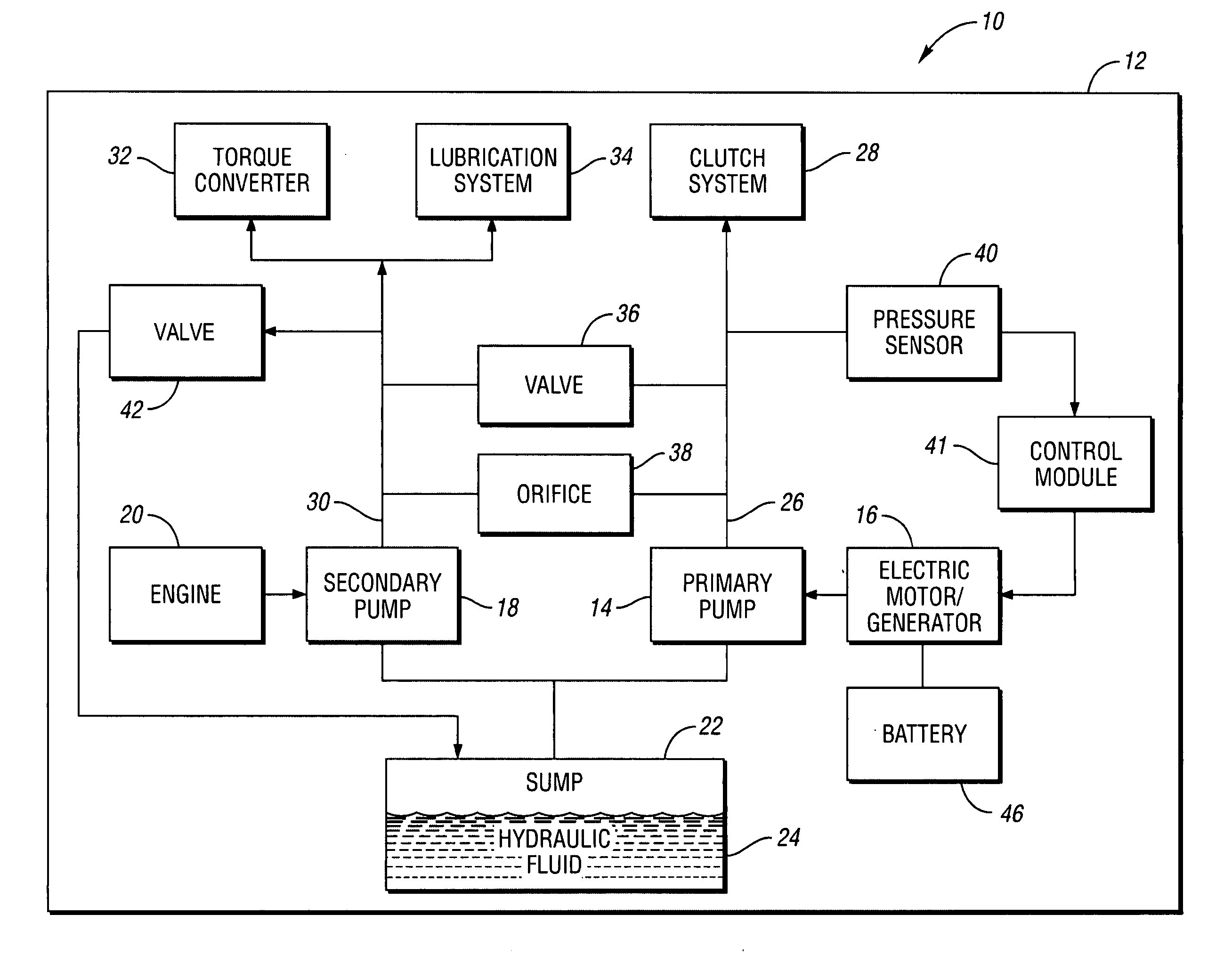

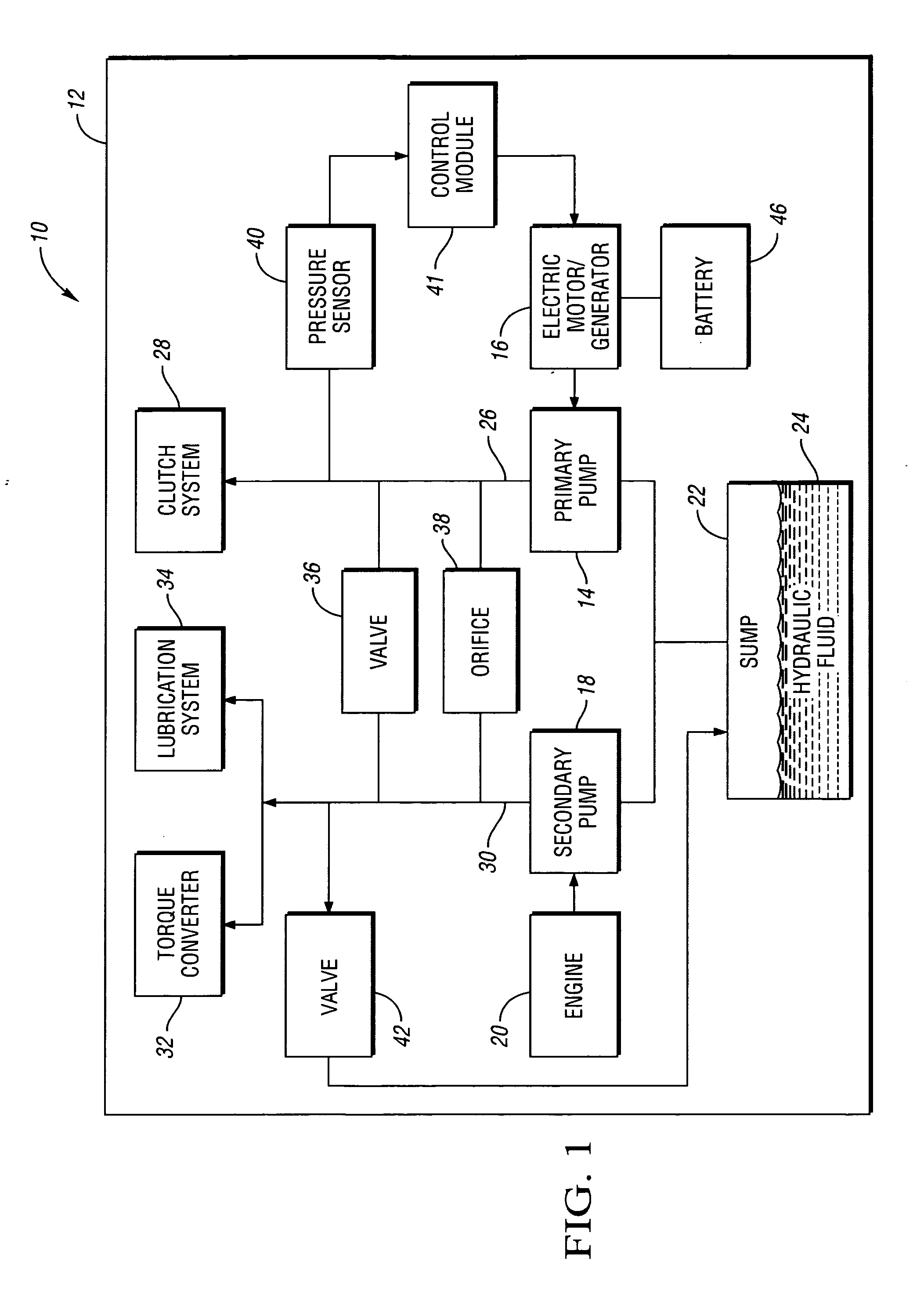

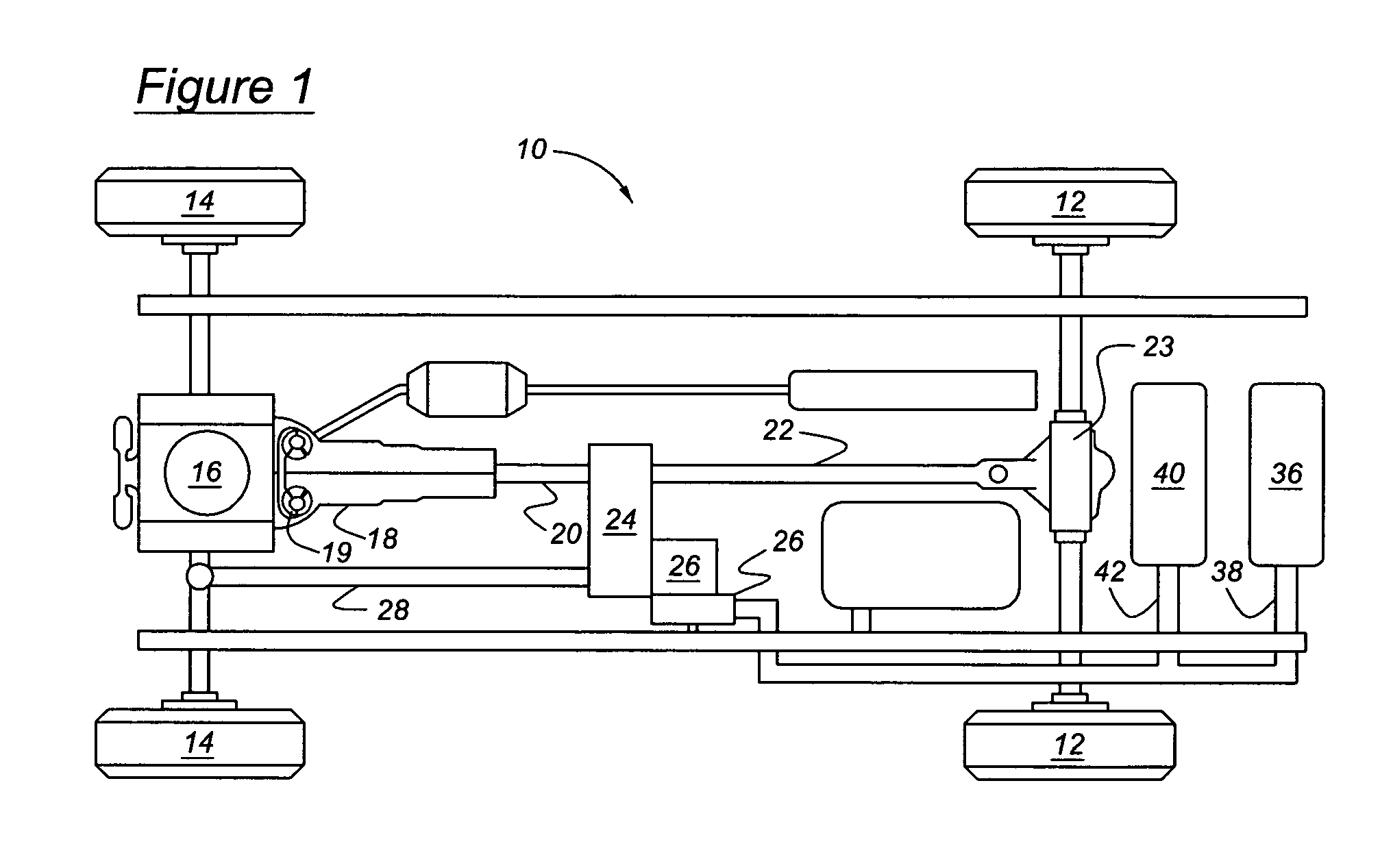

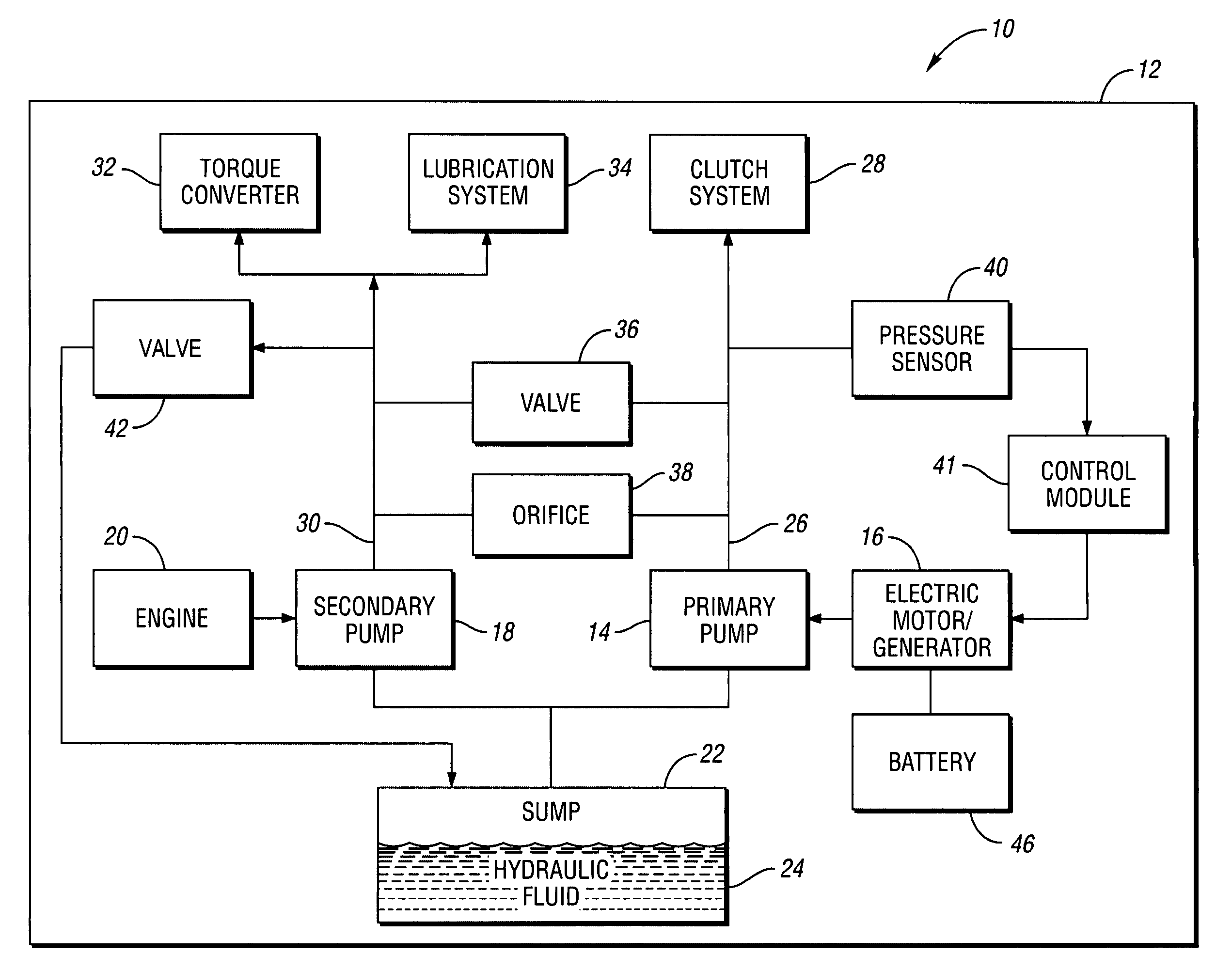

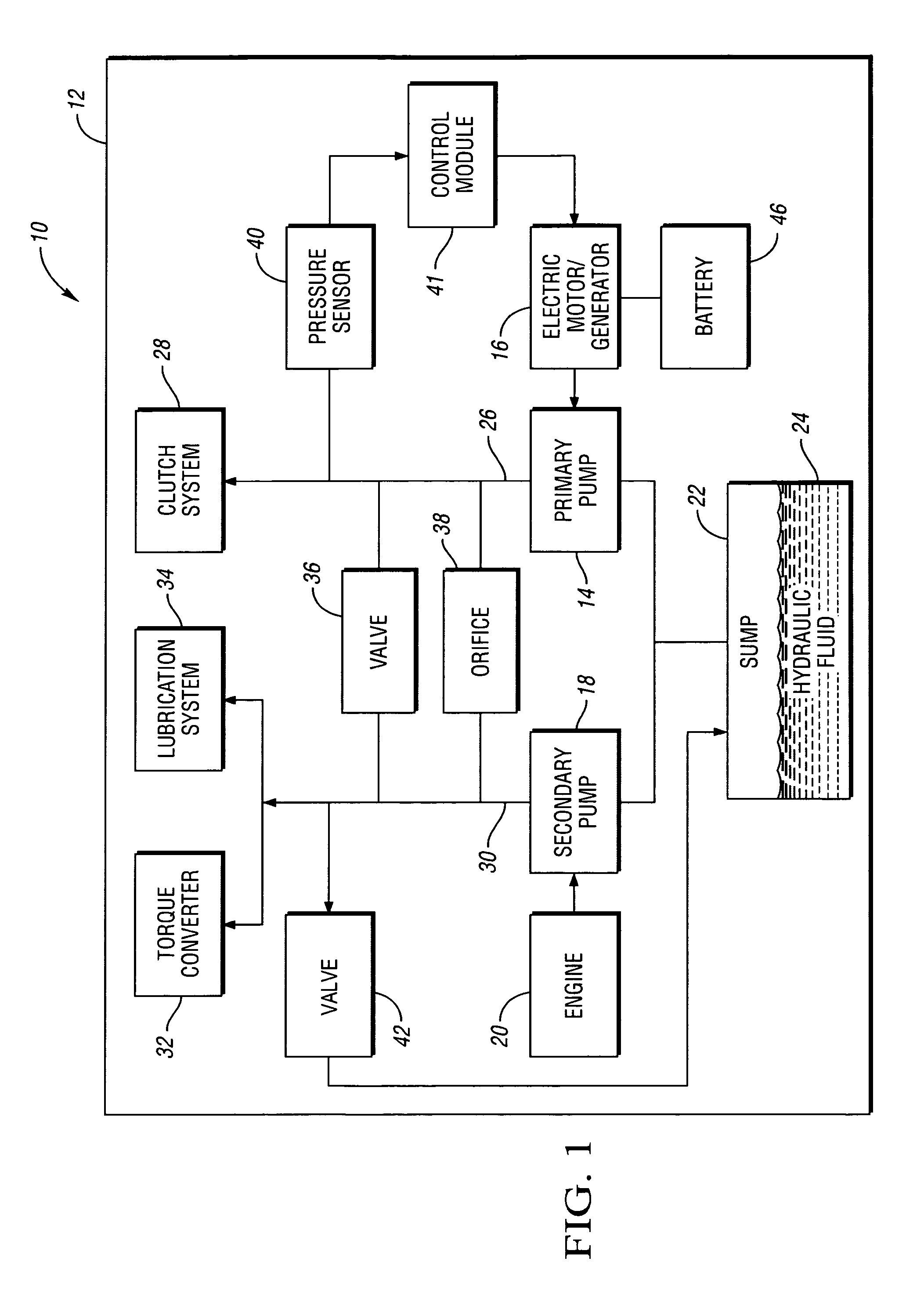

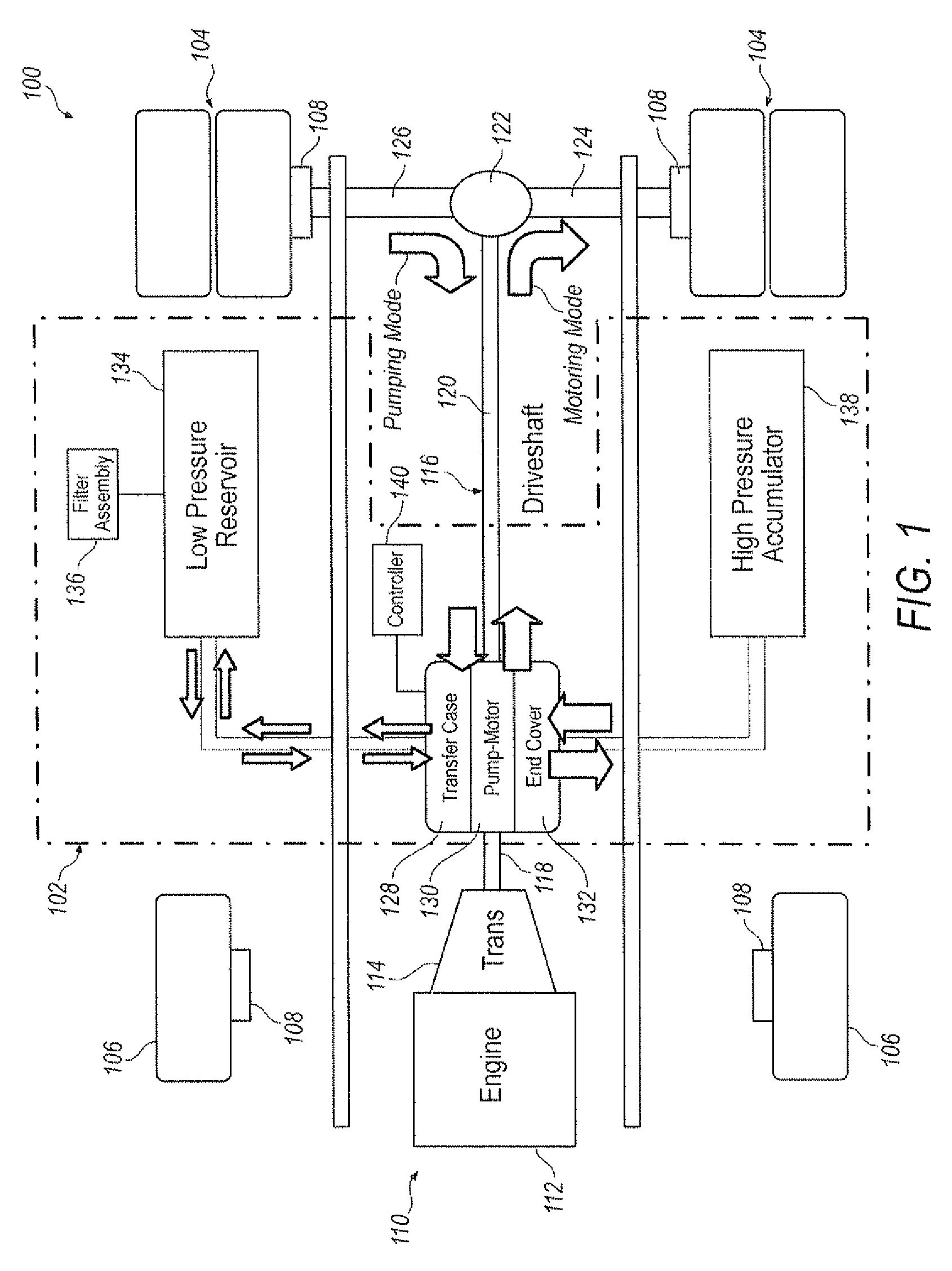

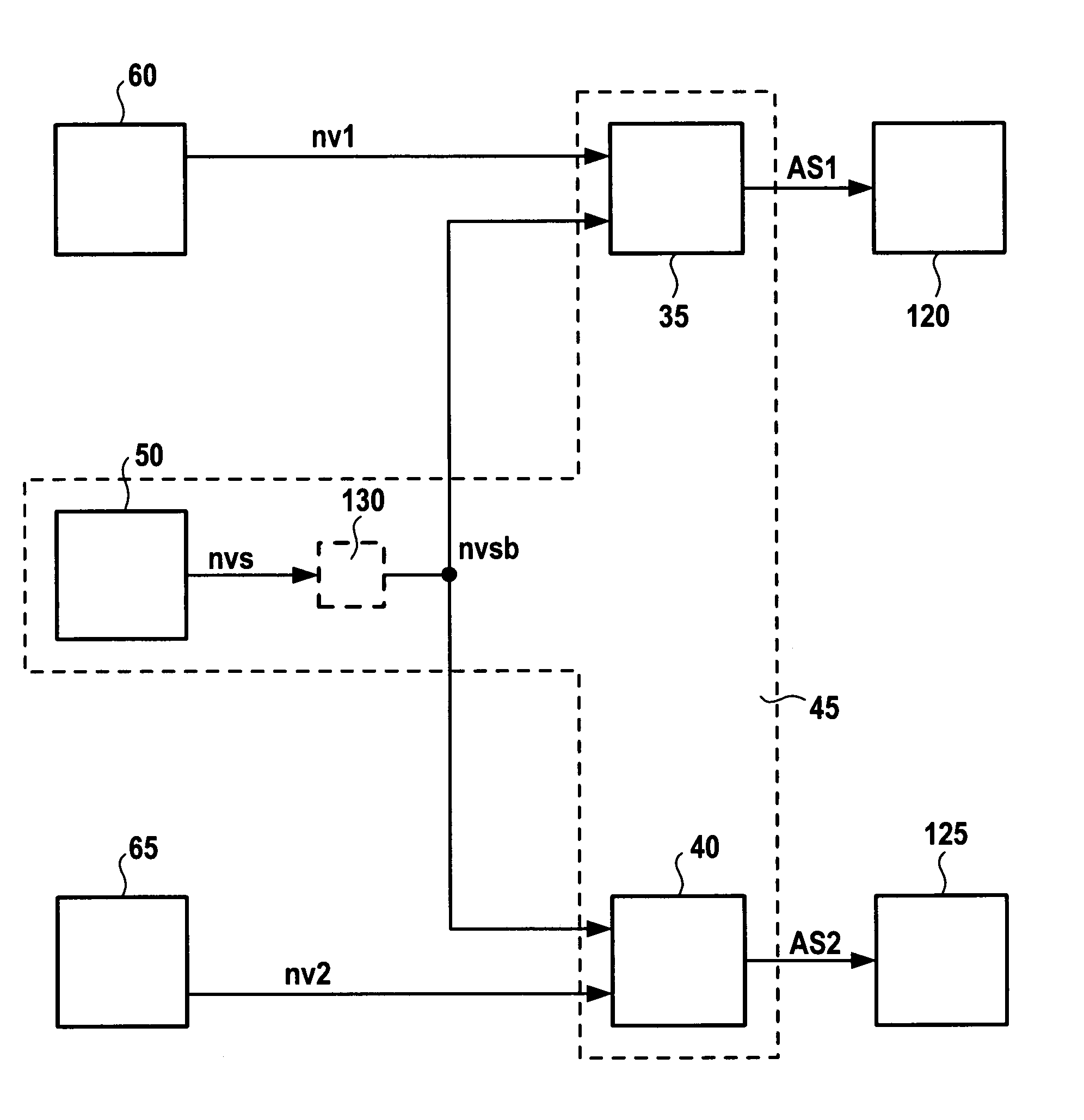

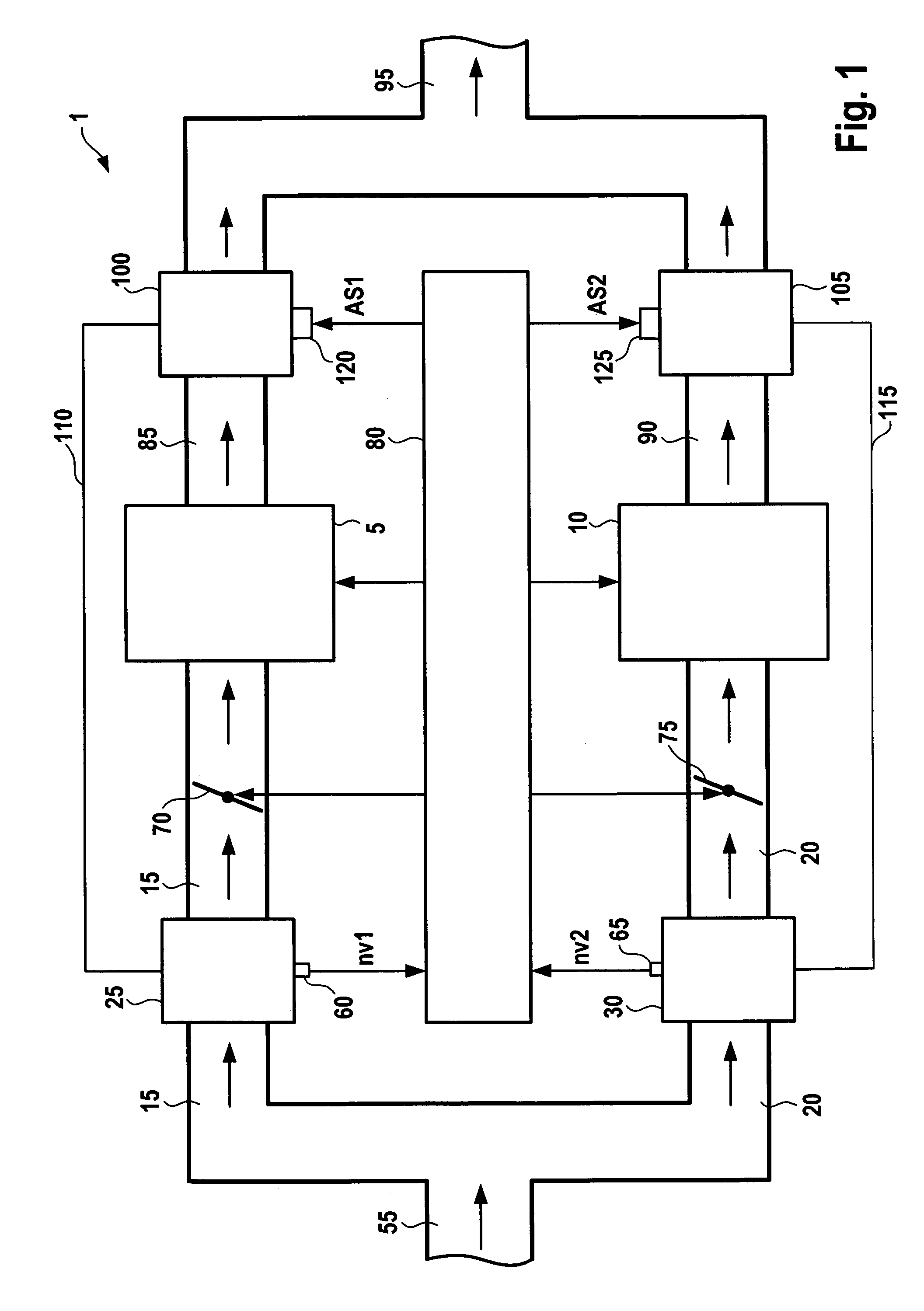

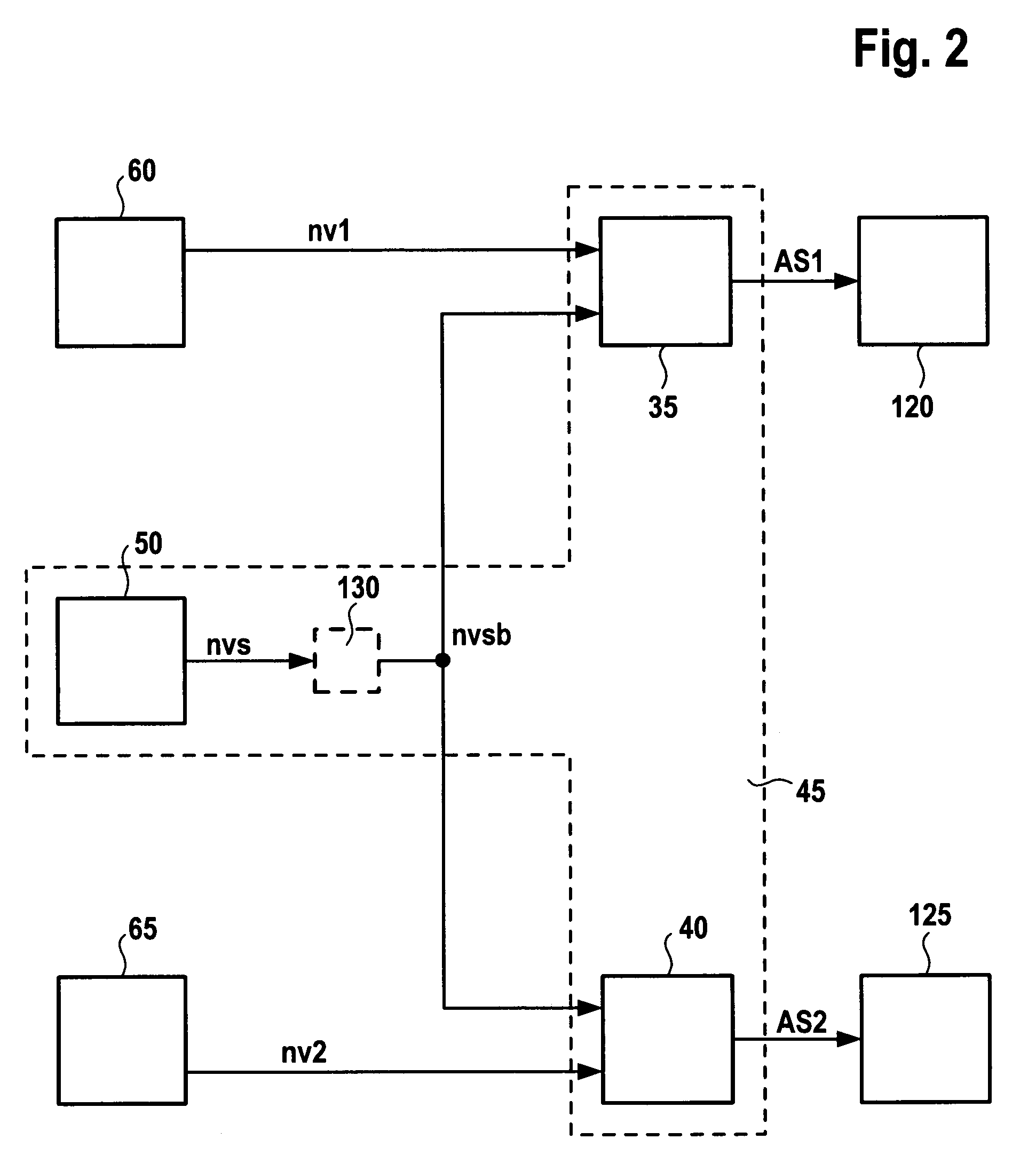

Dual-pump fluid distribution system for a hybrid electric vehicle

The dual-pump fluid distribution system of the present invention preferably includes a sump having hydraulic fluid disposed therein. A first pump driven by an electric motor and a second pump driven by an engine are disposed in fluid communication with the sump. A plurality of vehicle systems are disposed in fluid communication with the first and second pumps. The first pump is configured to transfer hydraulic fluid to the vehicle systems when the engine is off. The first and second pumps are both configured to transfer hydraulic fluid to the vehicle systems when the engine speed is at or below a predetermined value. The second pump is configured to transfer hydraulic fluid to the vehicle systems when the engine speed exceeds the predetermined value. Accordingly, the hydraulic pressure needs of the vehicle systems are met for any given engine speed. A corresponding method in accordance with the present invention is similarly provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

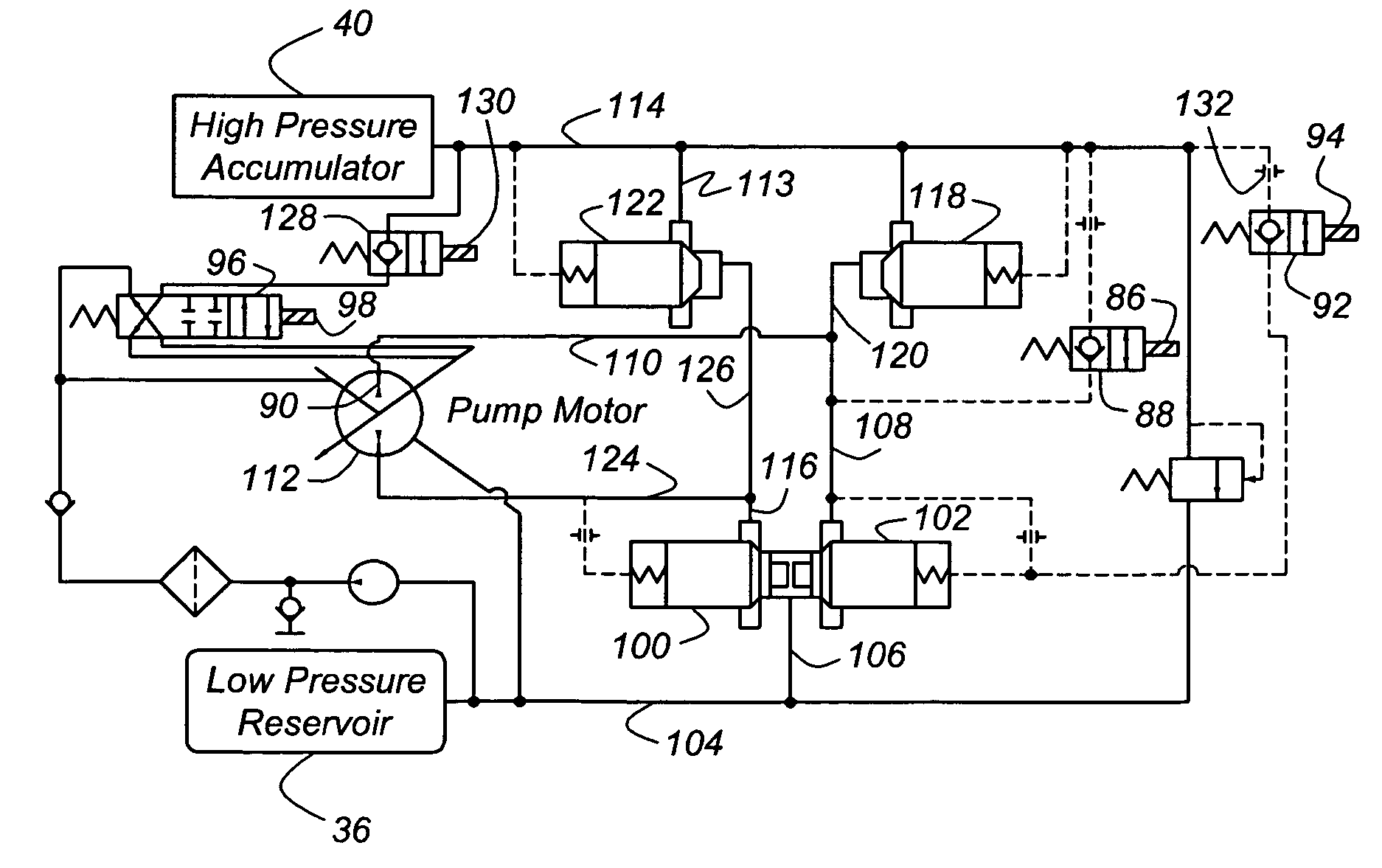

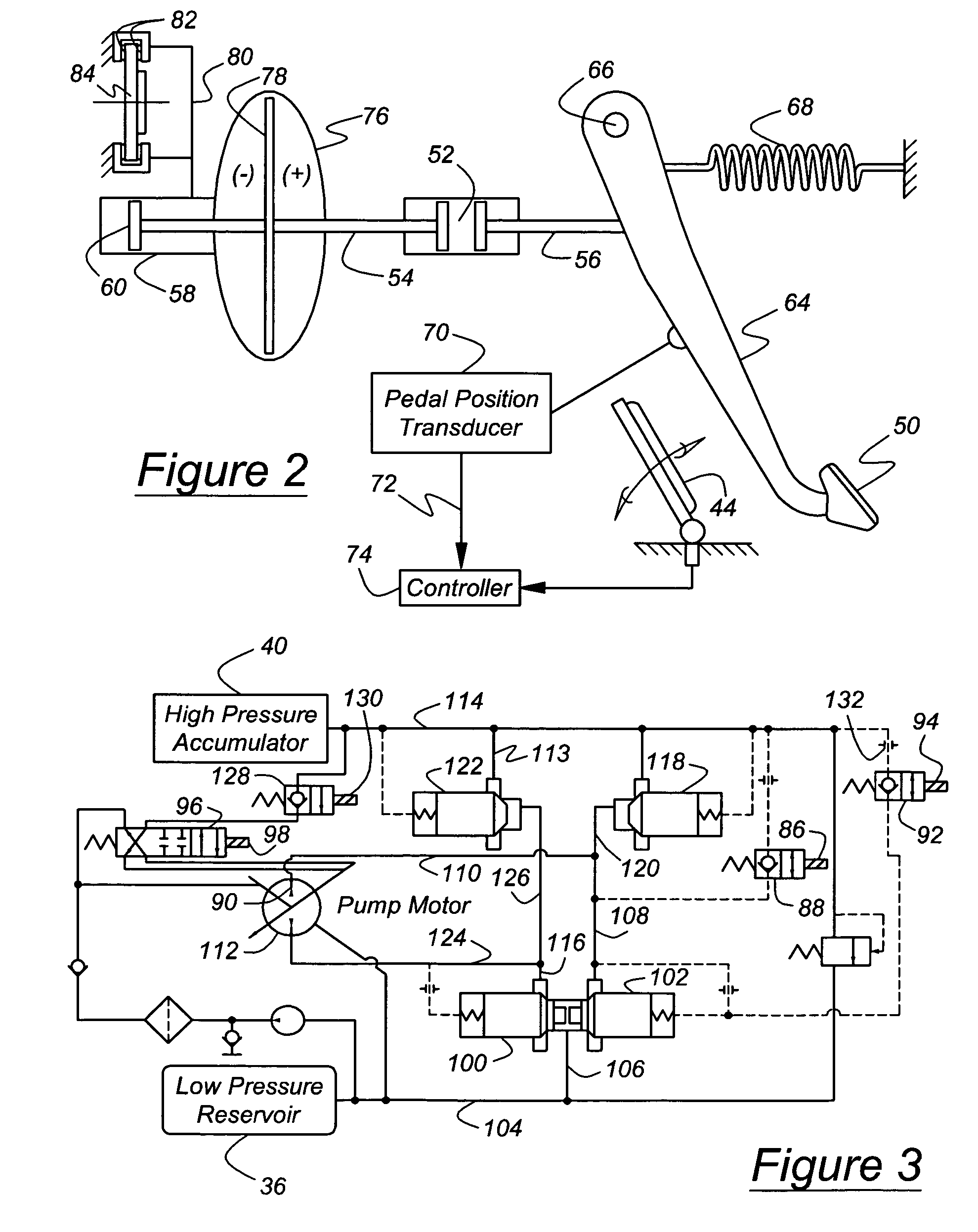

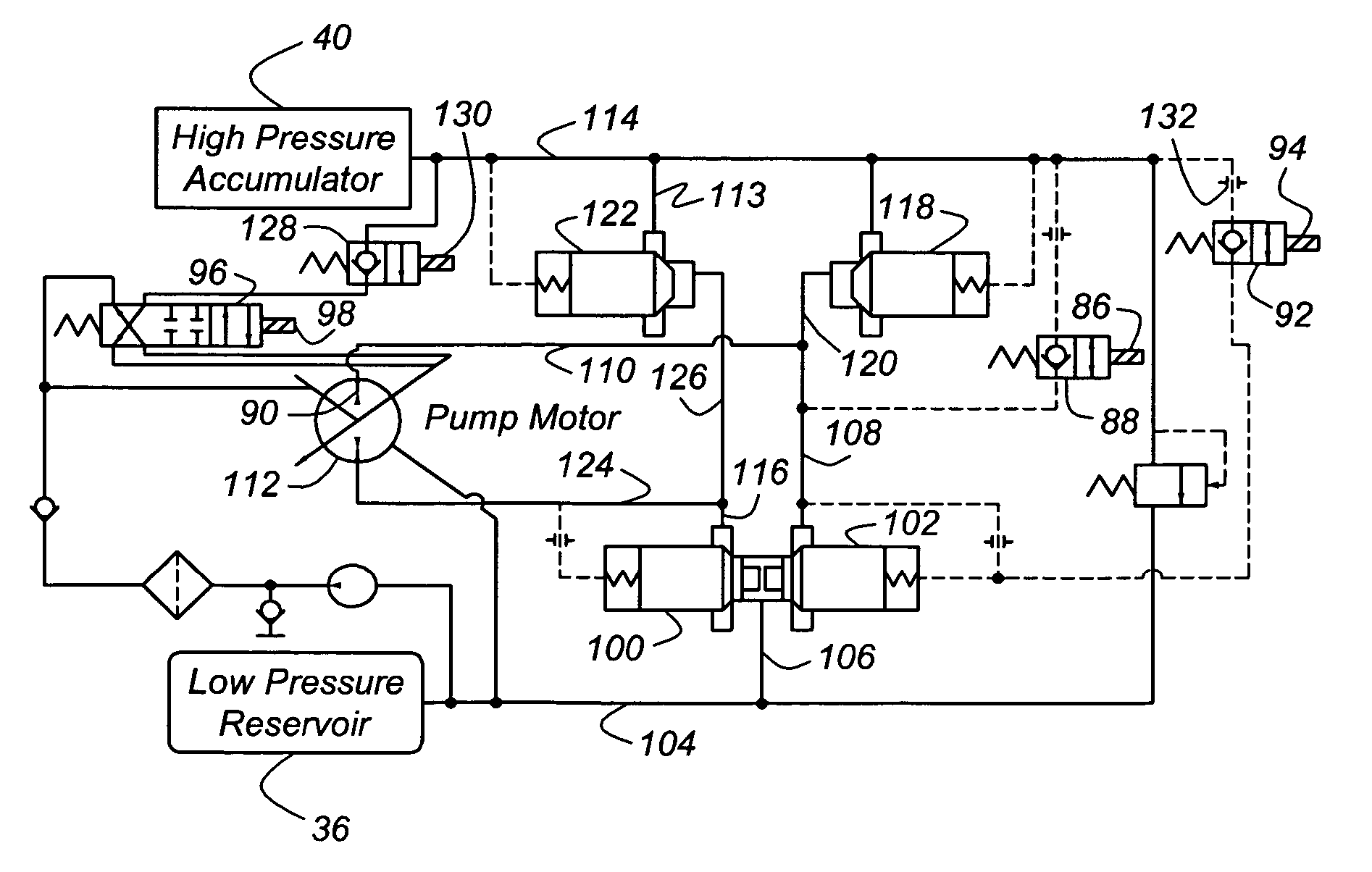

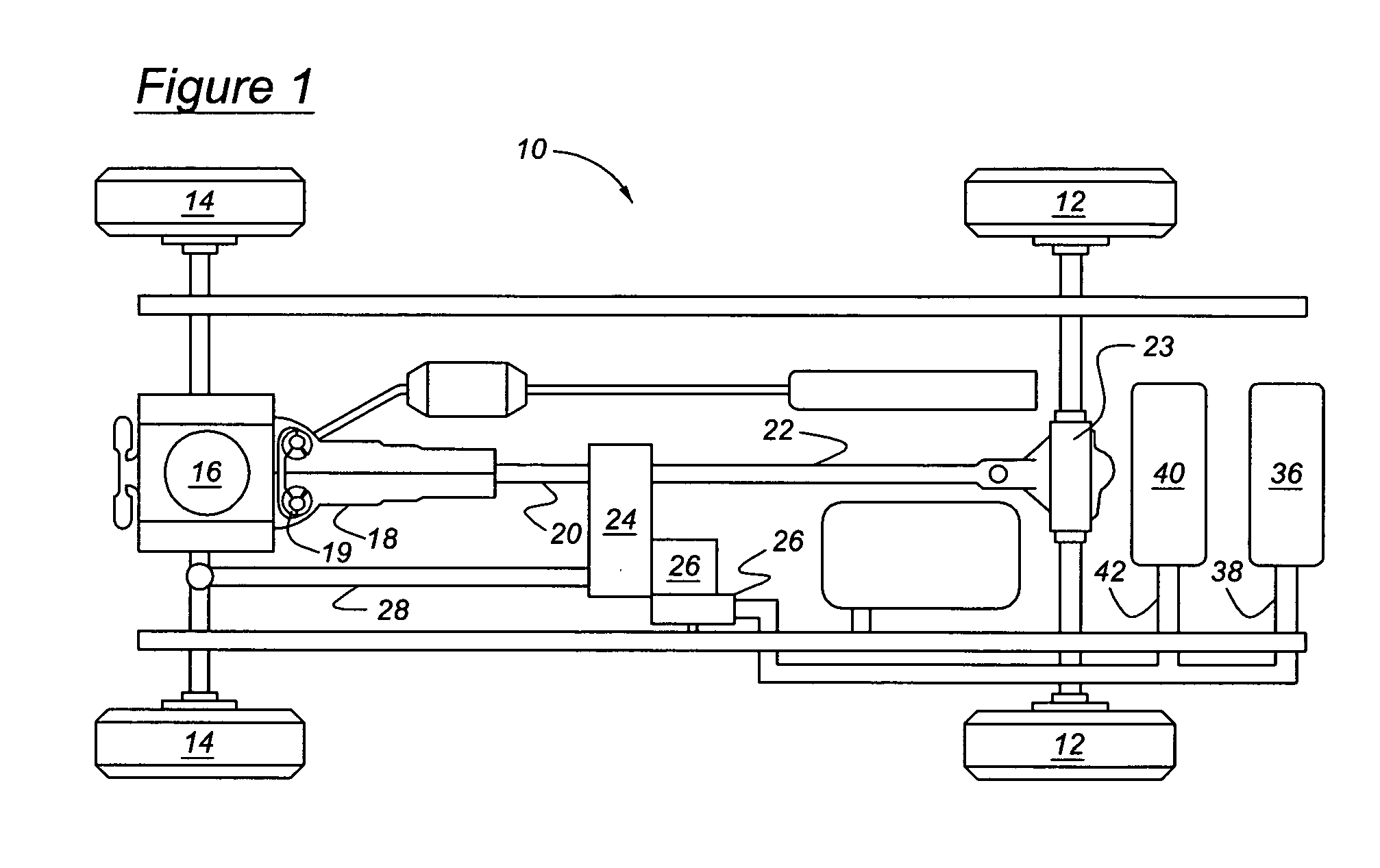

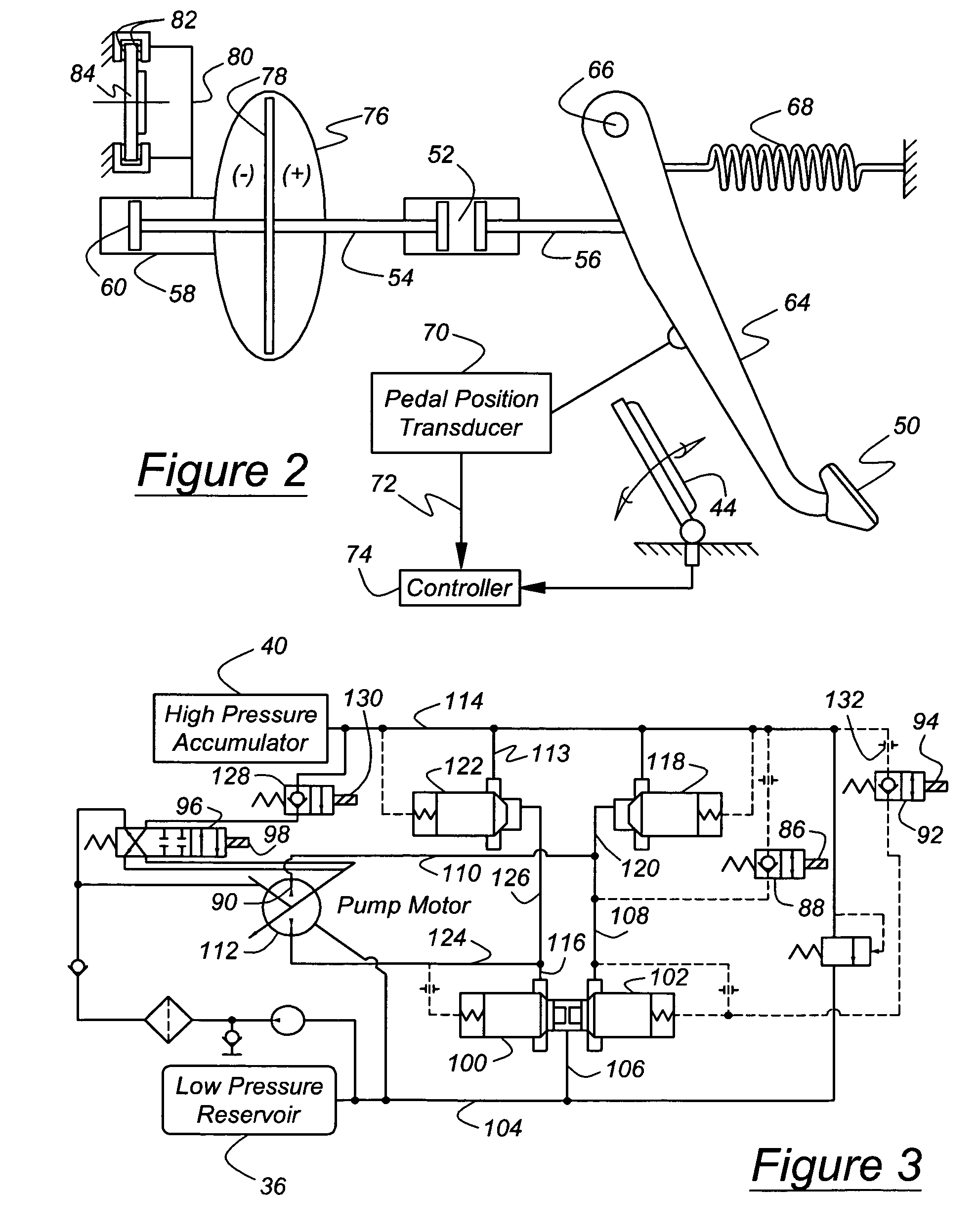

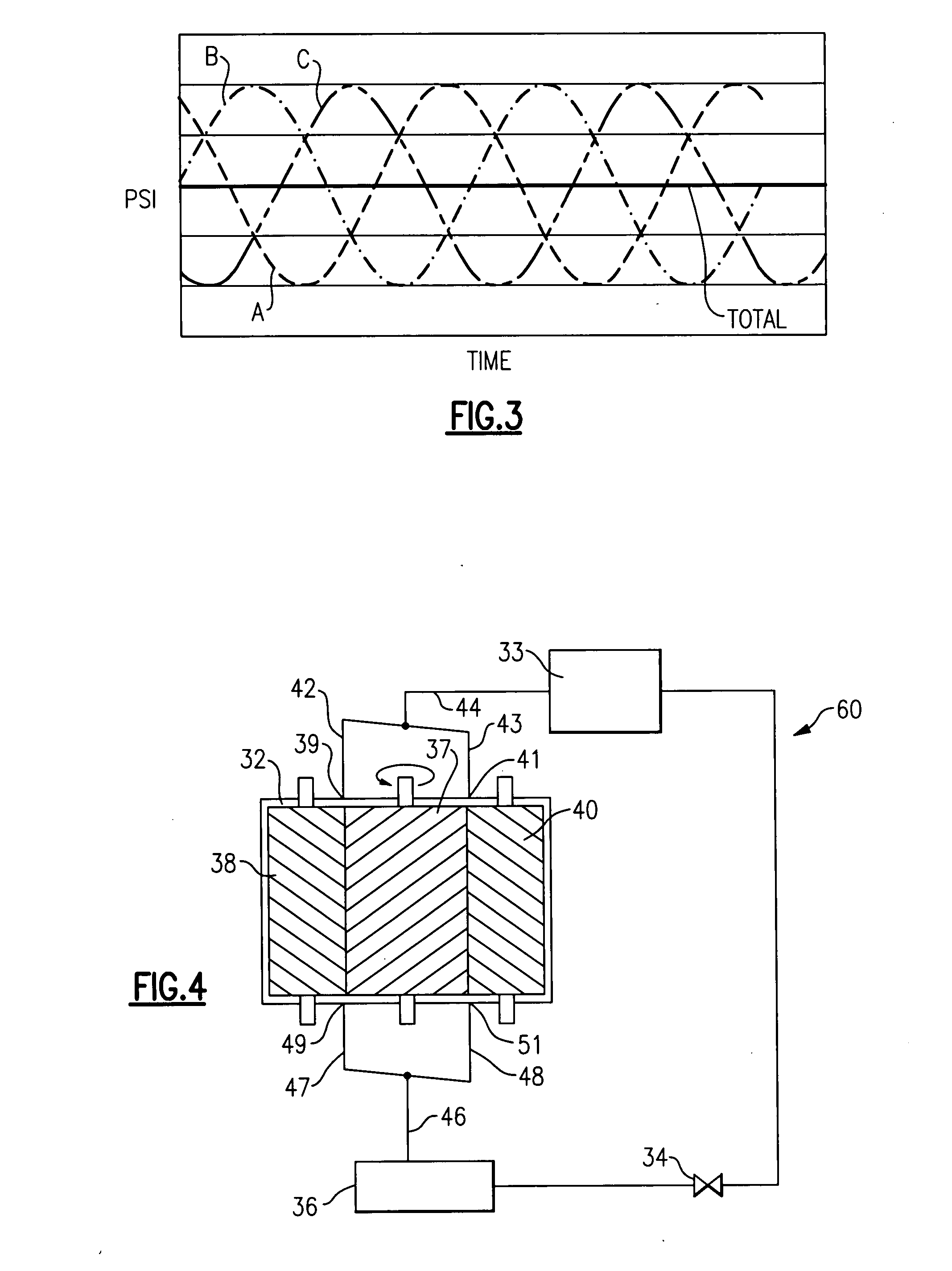

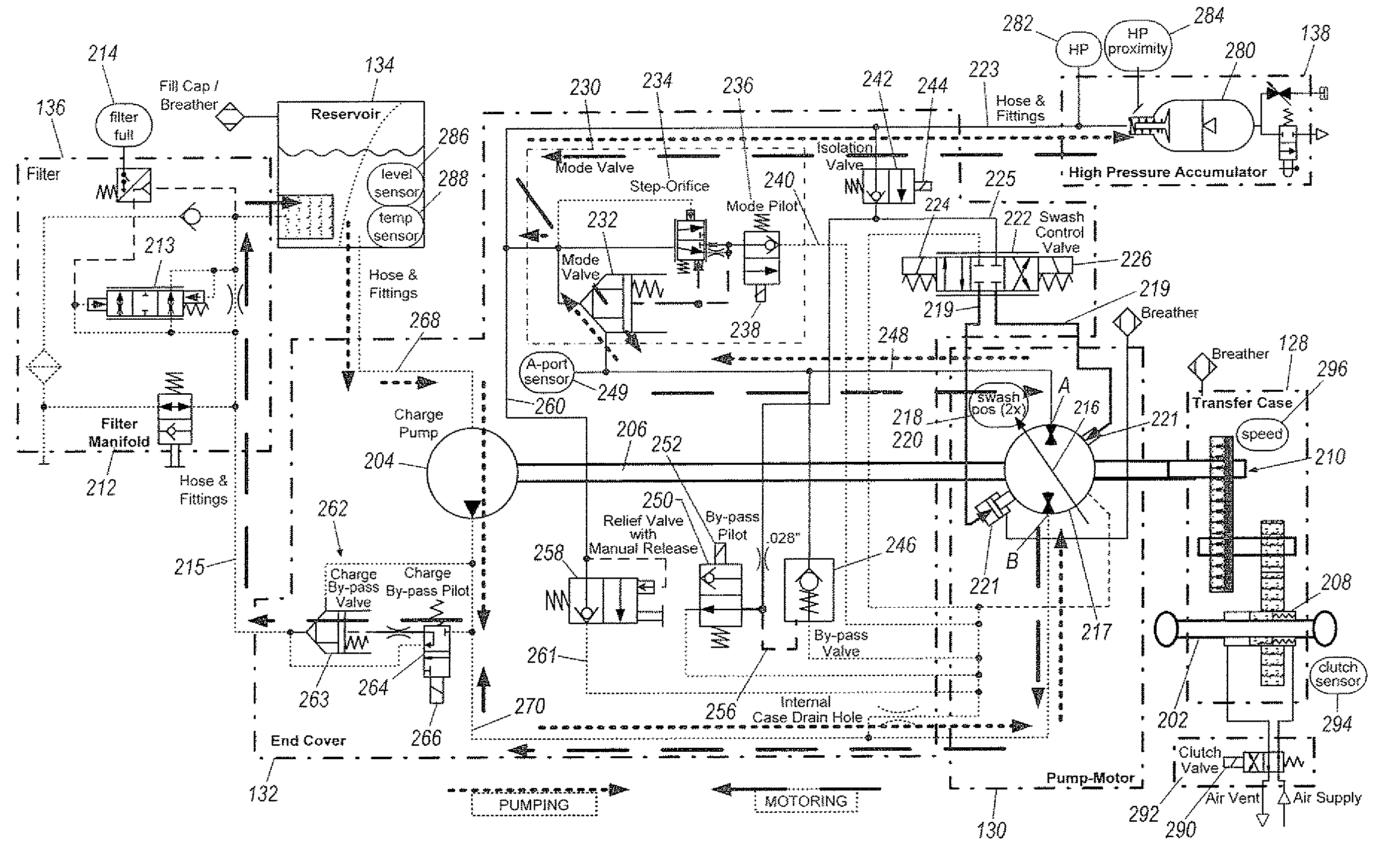

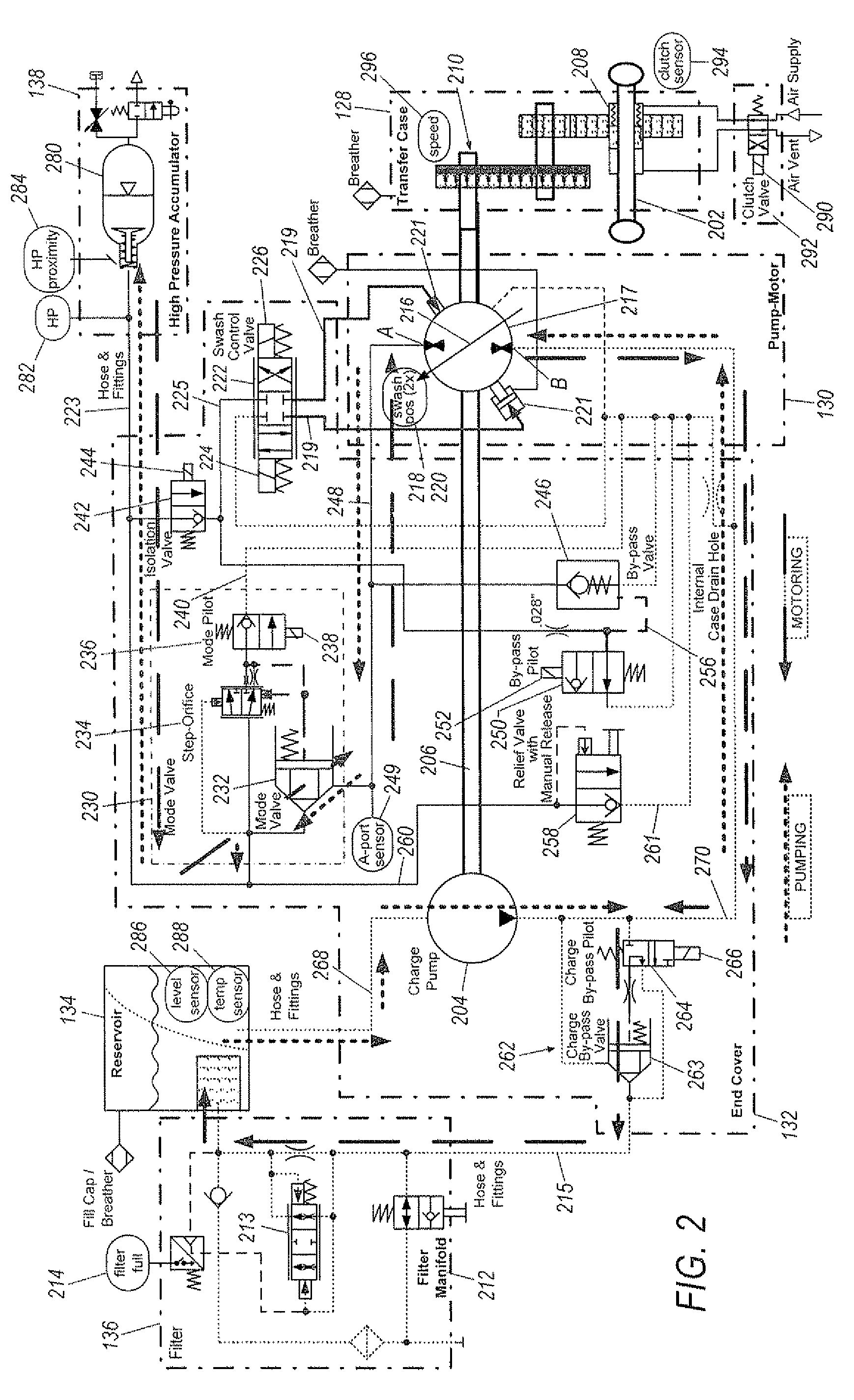

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS7082757B2Avoid vibration and noiseSlow pressureAuxillary drivesBraking element arrangementsMobile vehicleTransmitted power

A system for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation.

Owner:FORD GLOBAL TECH LLC

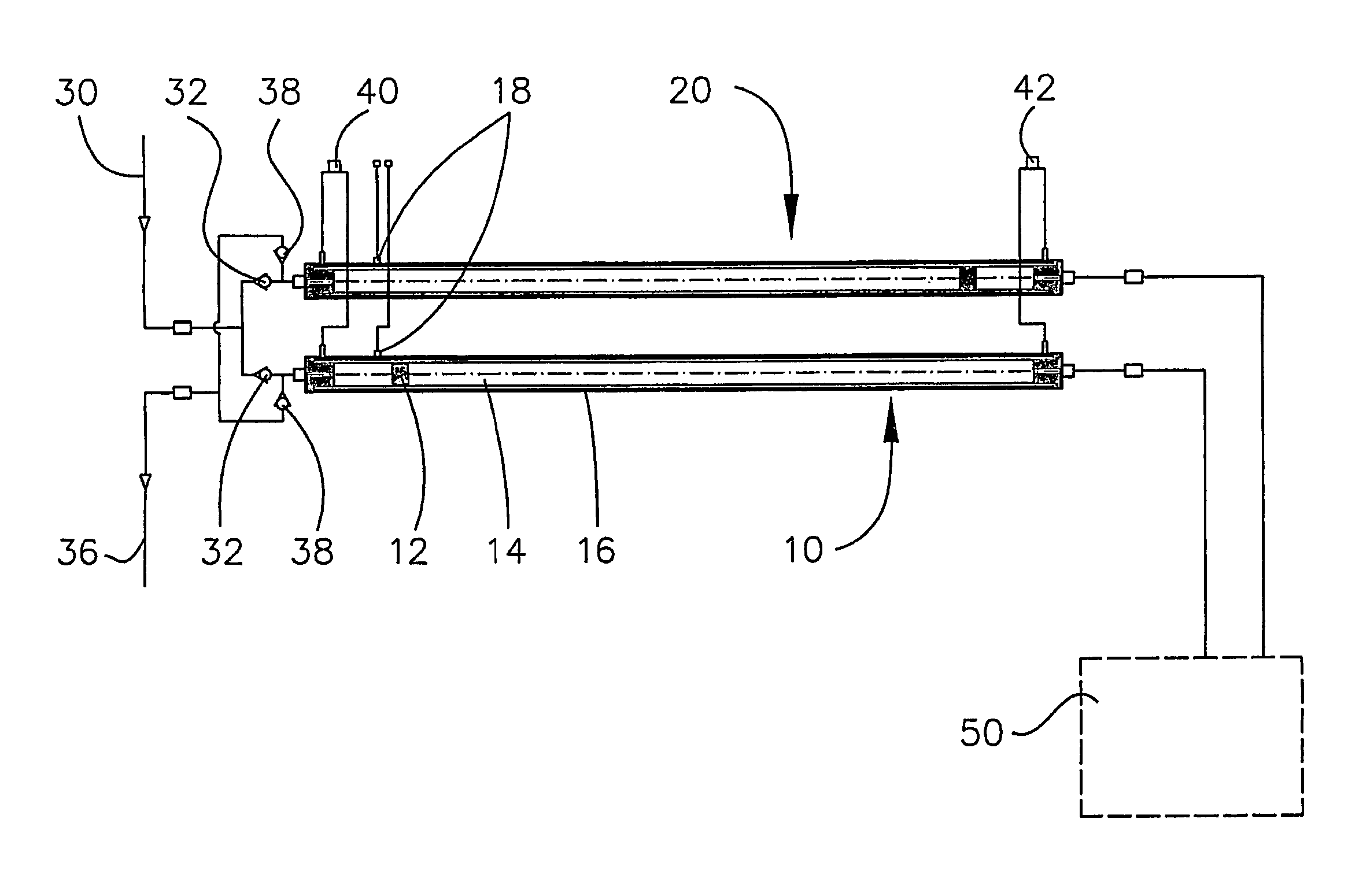

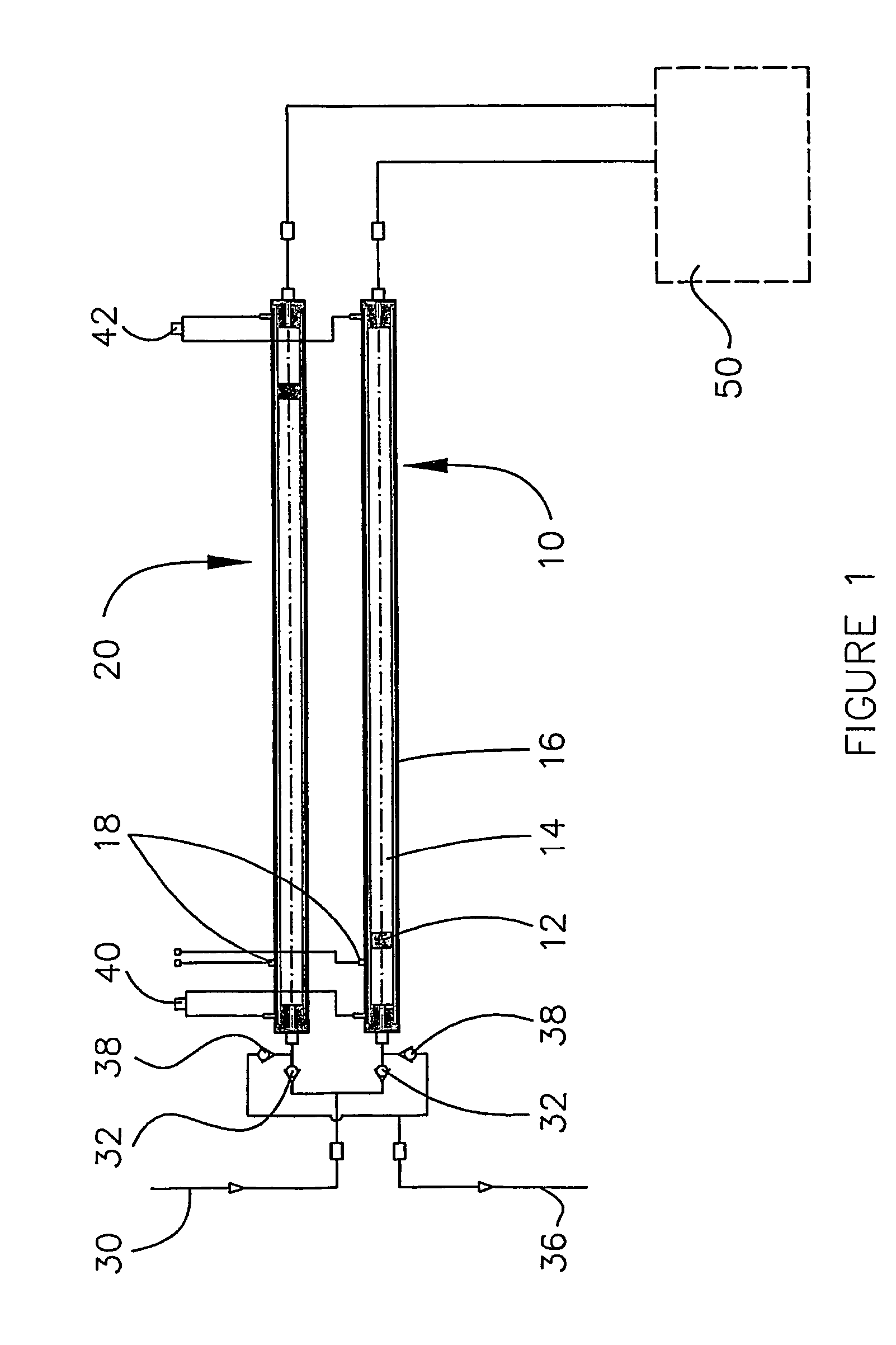

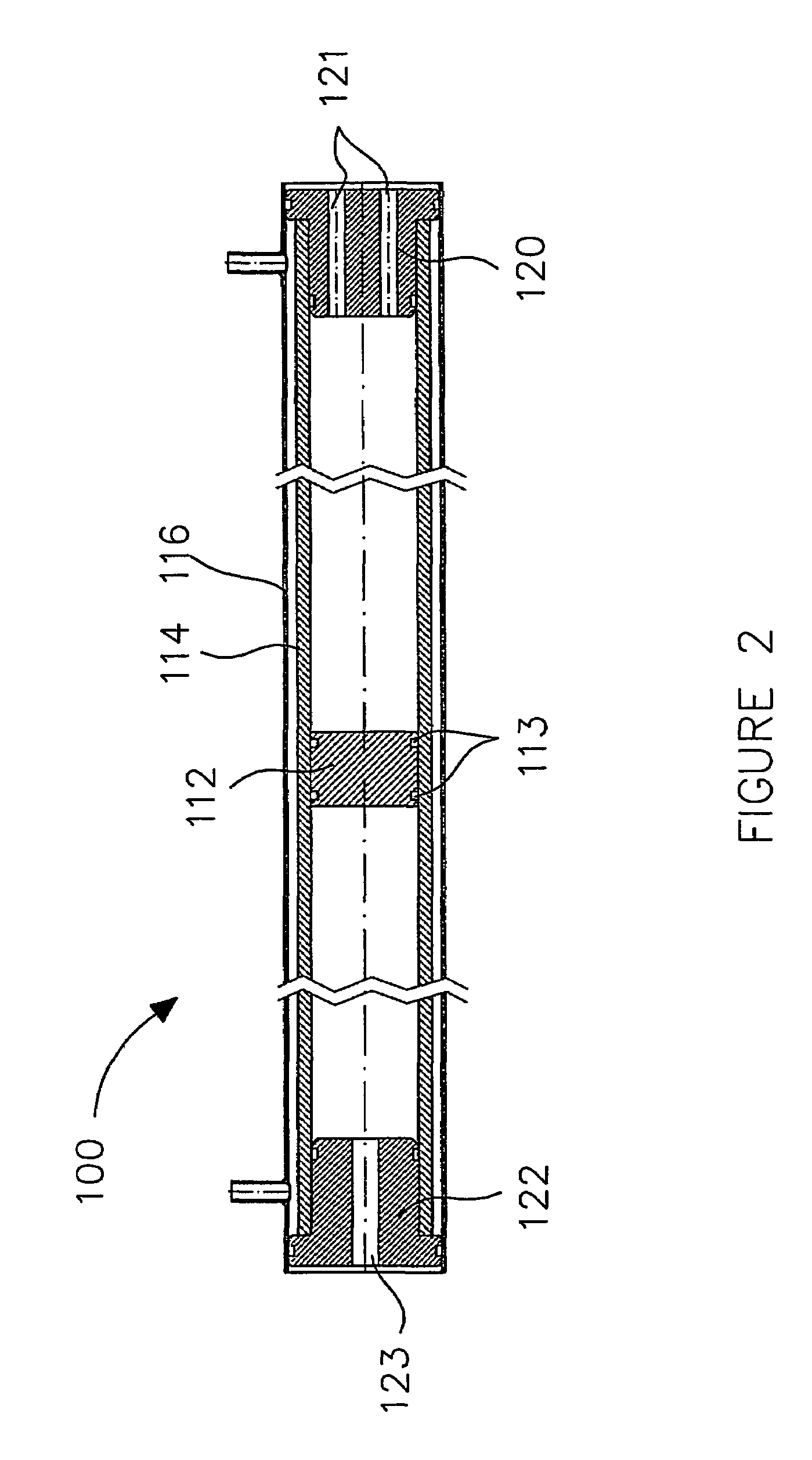

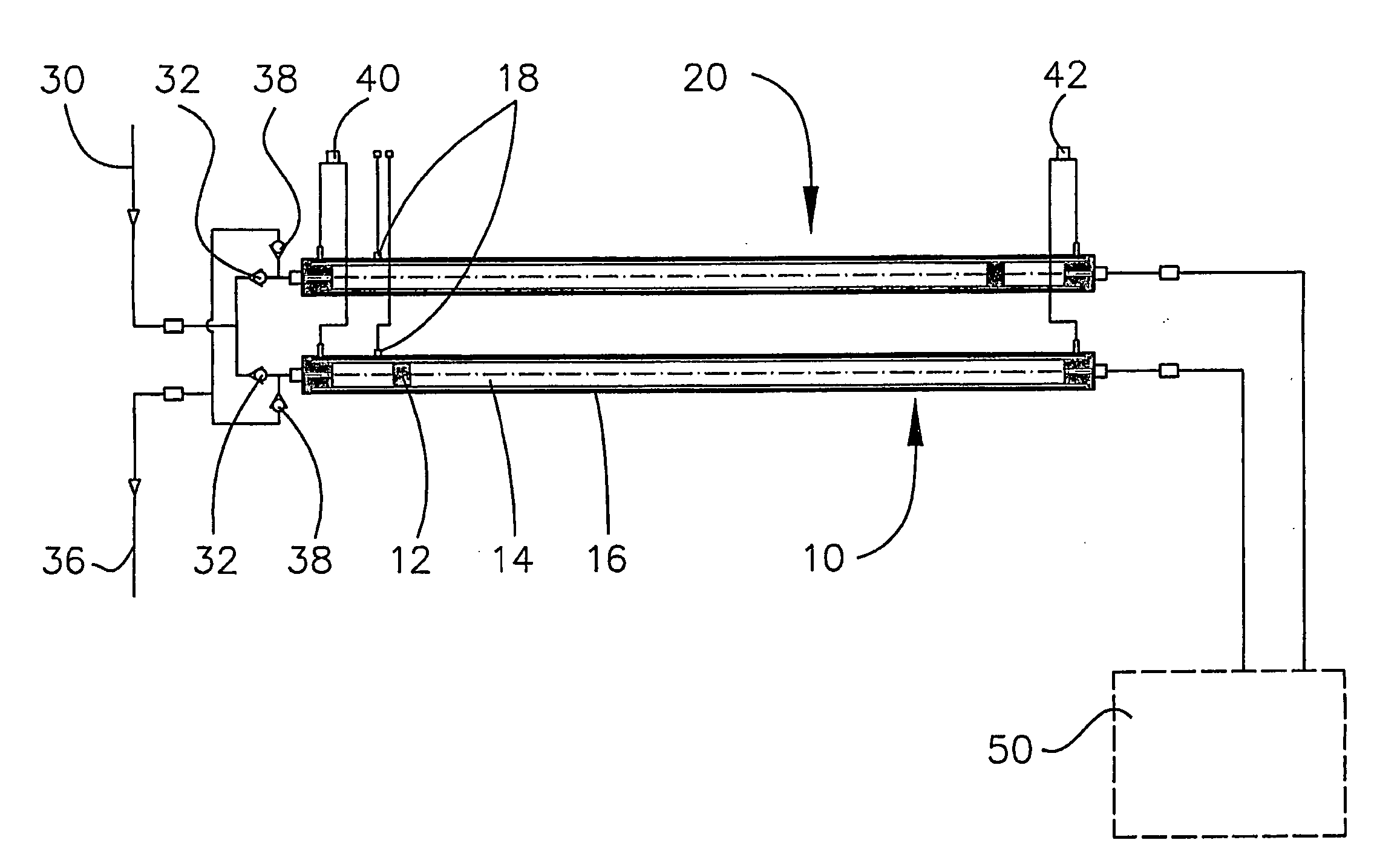

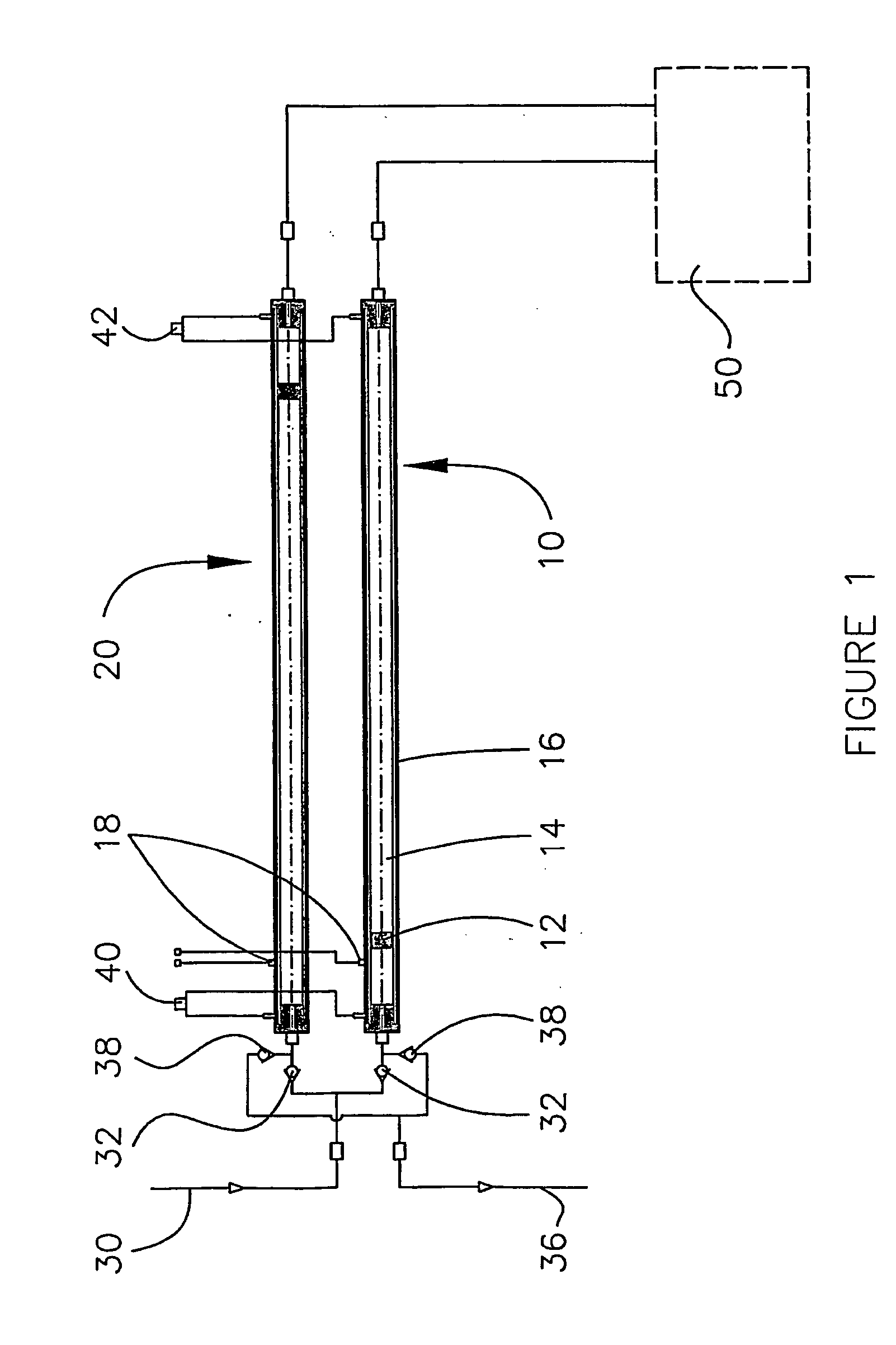

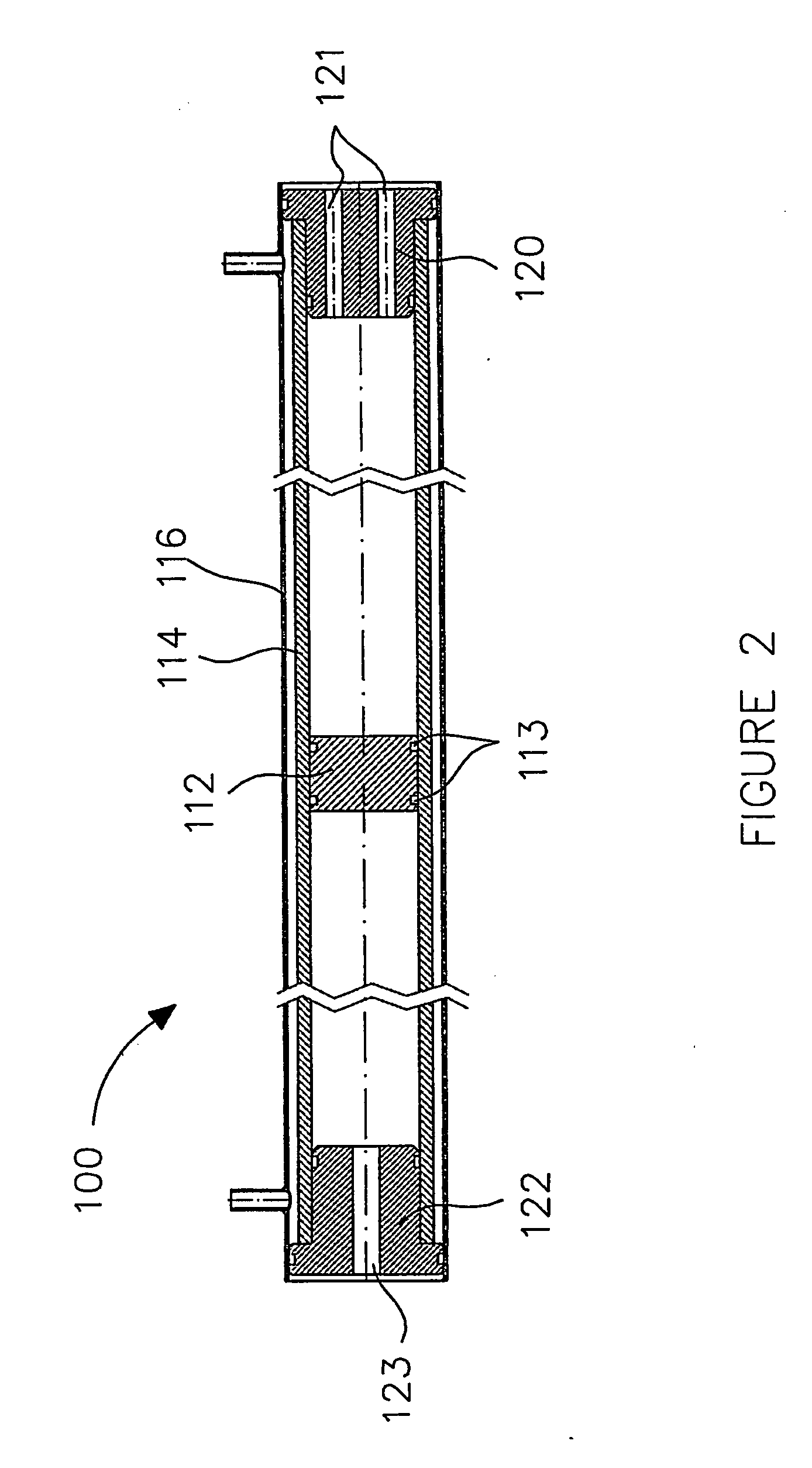

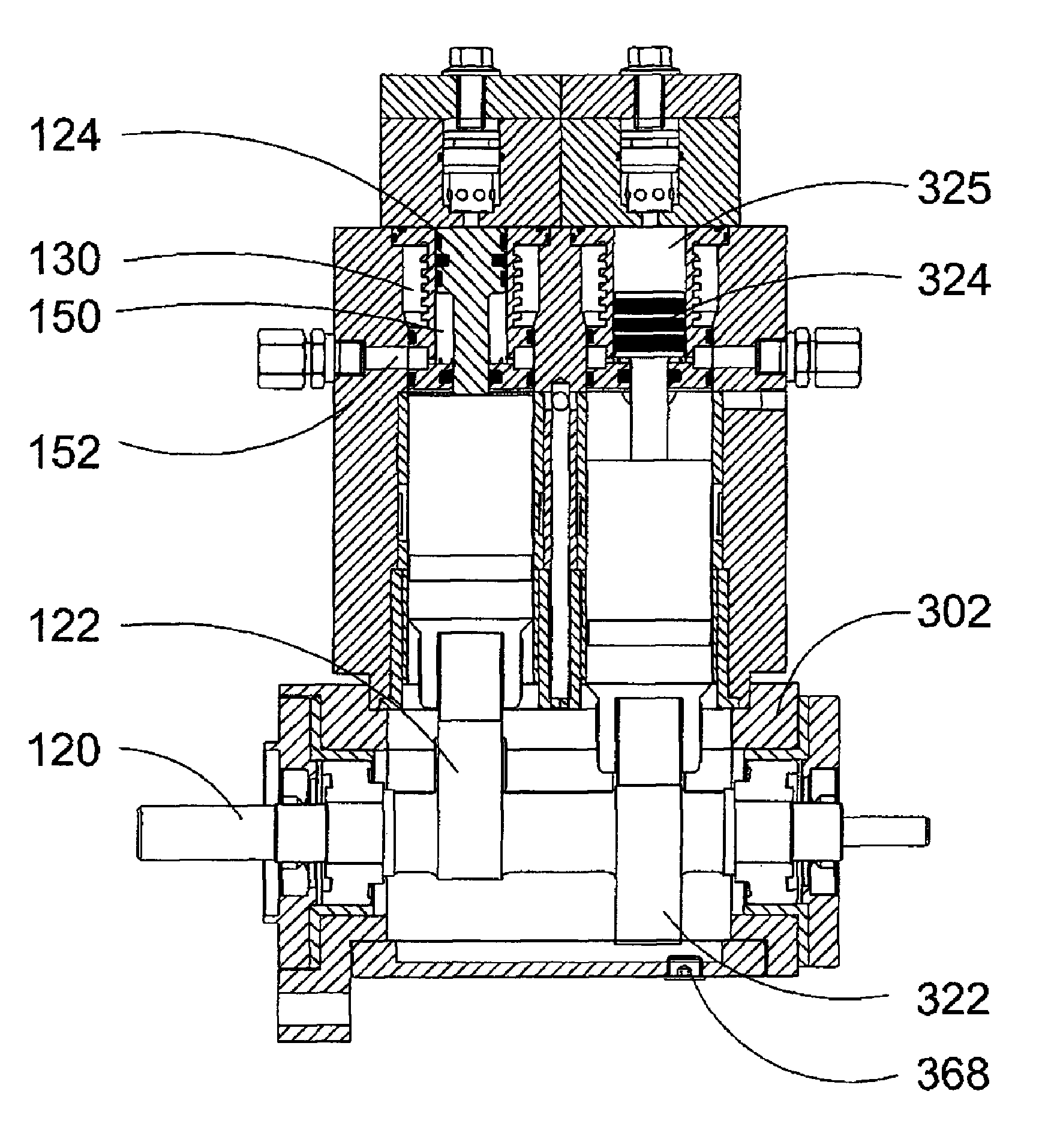

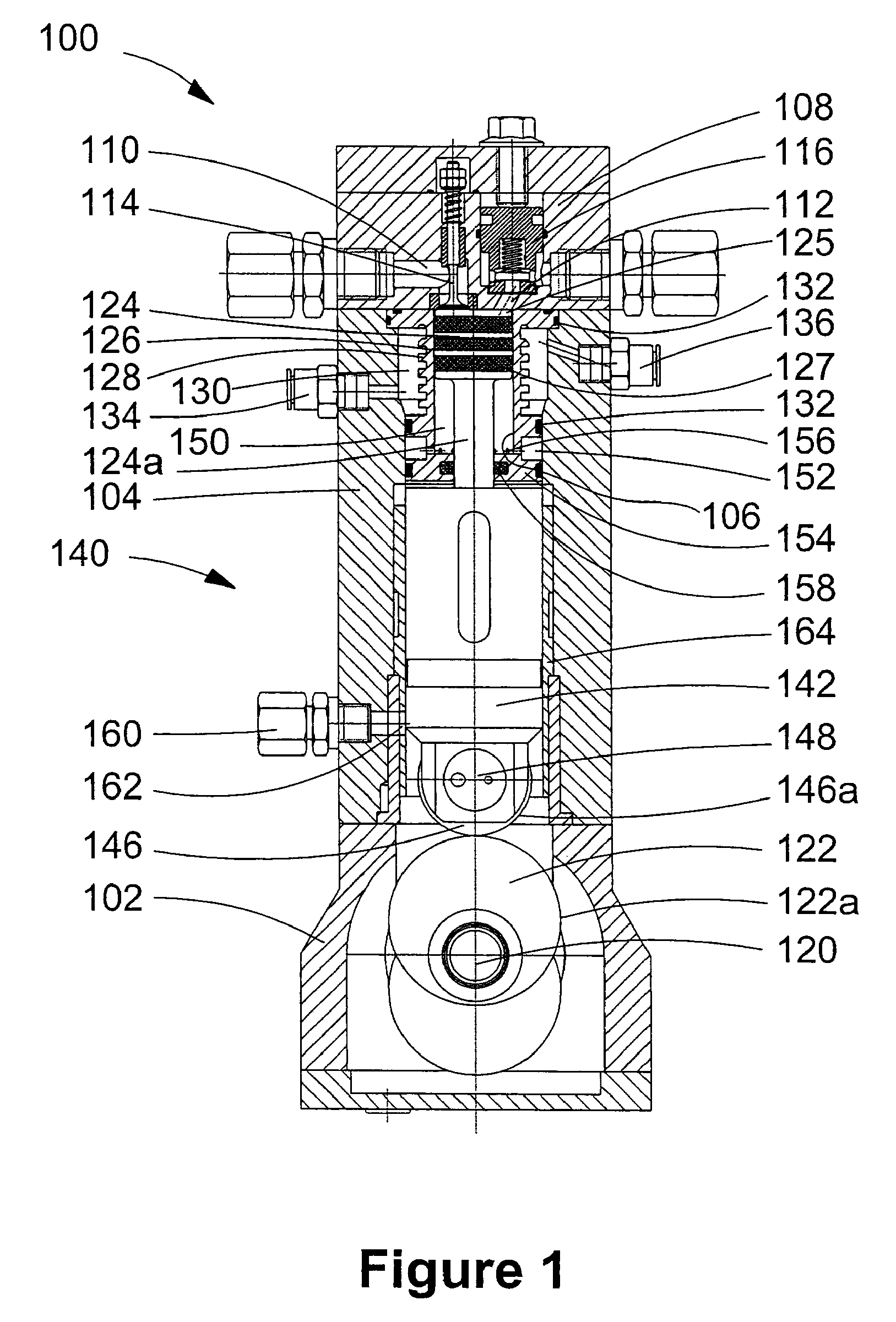

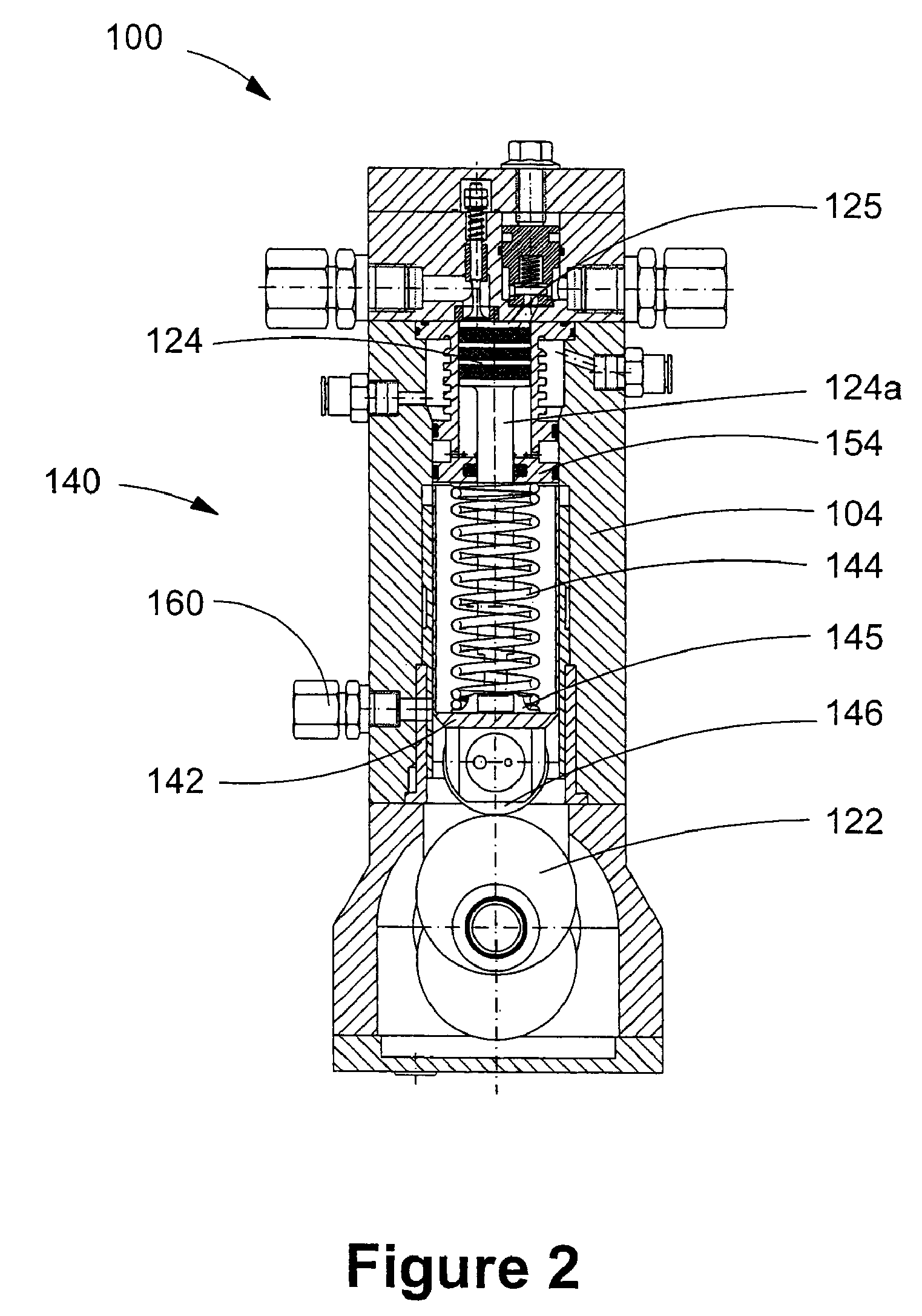

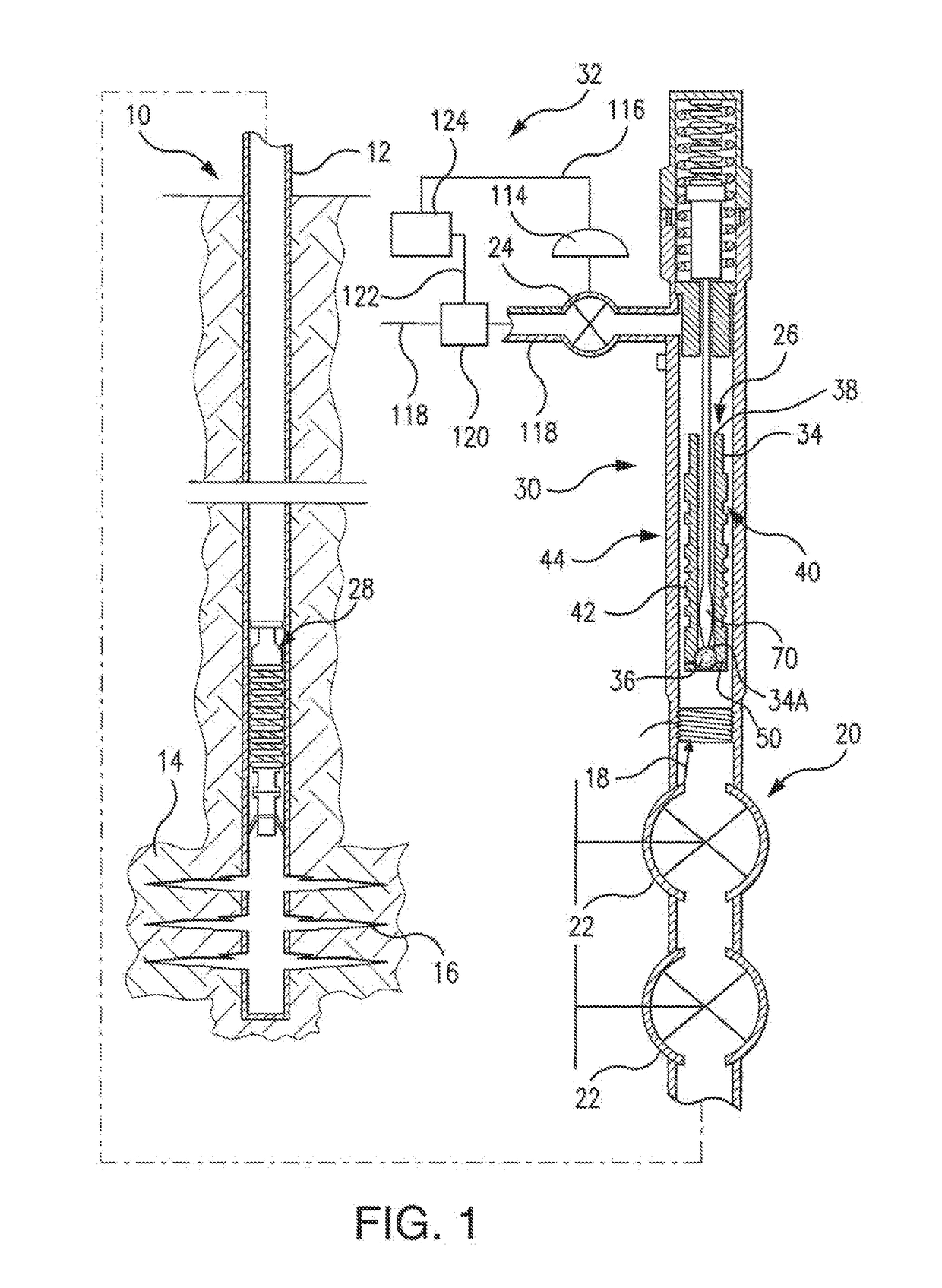

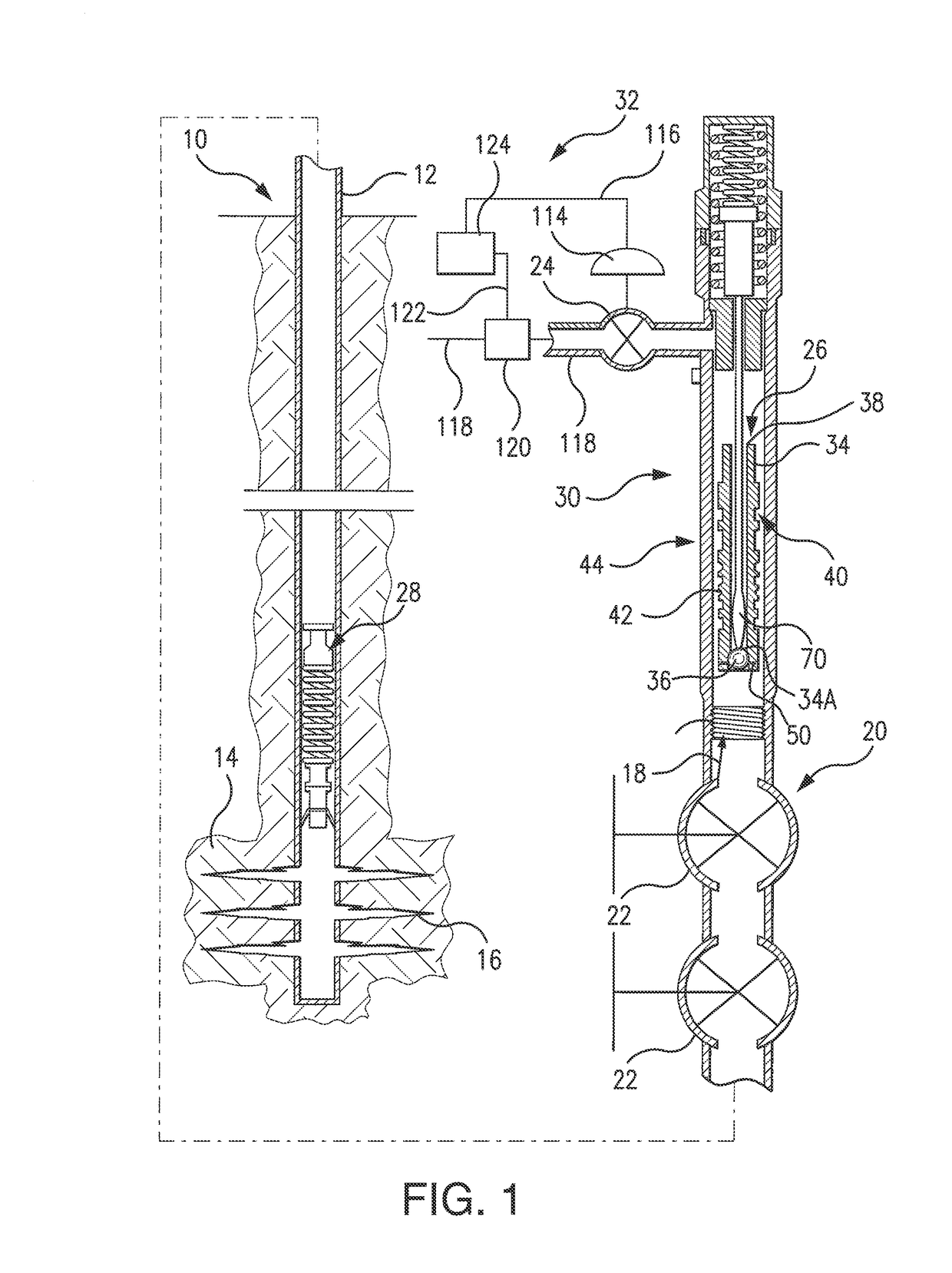

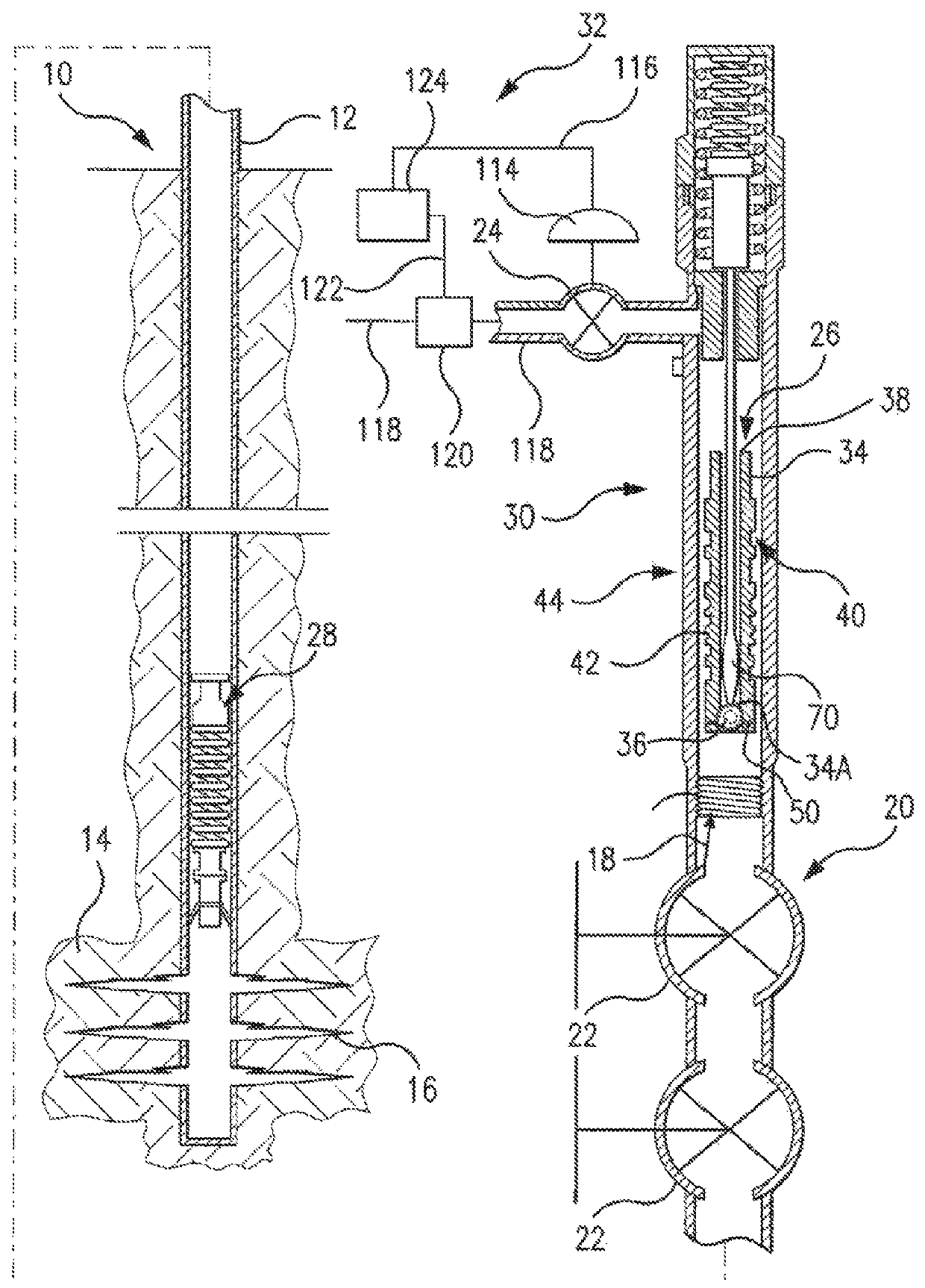

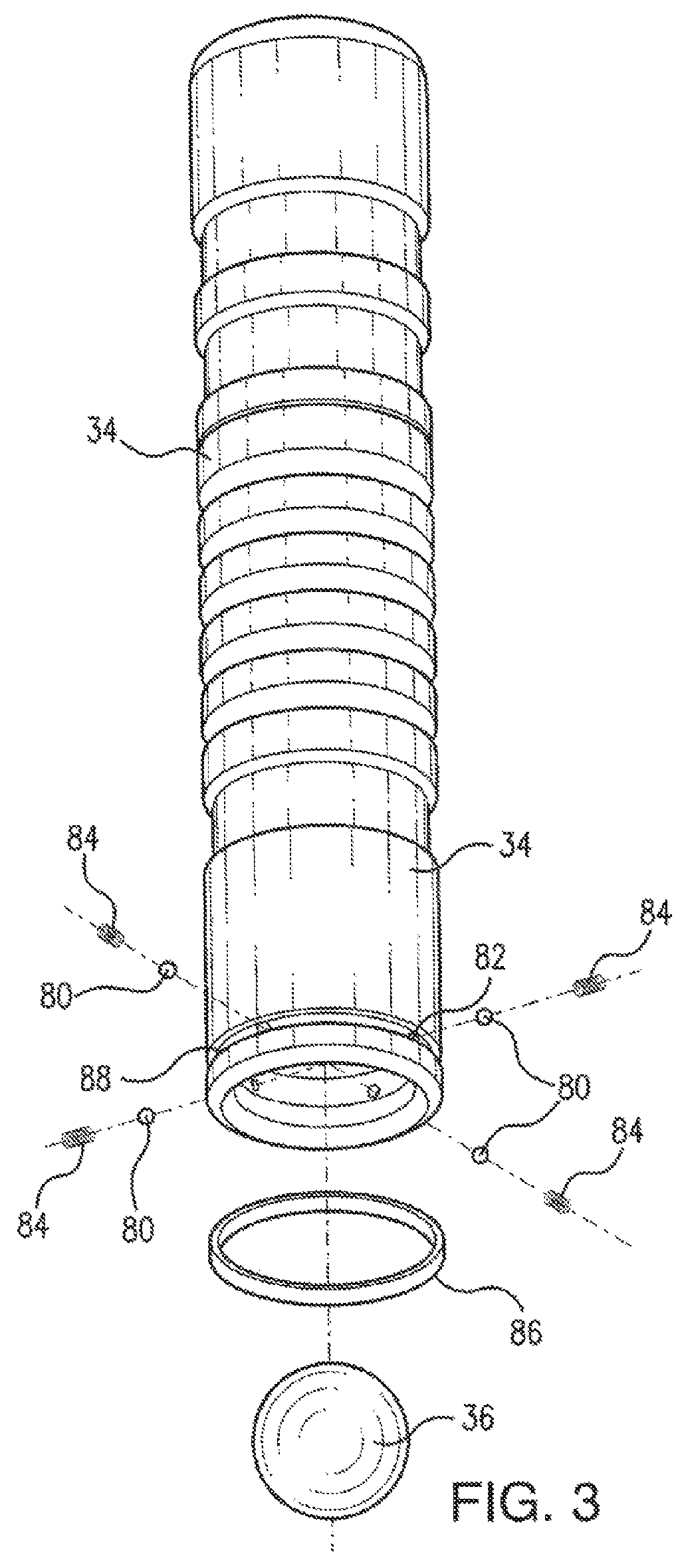

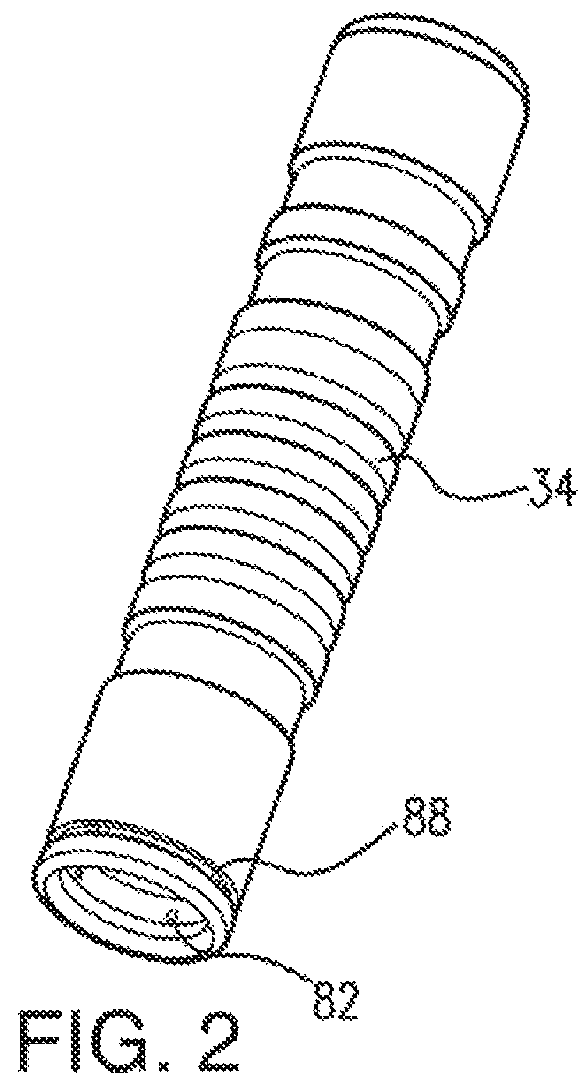

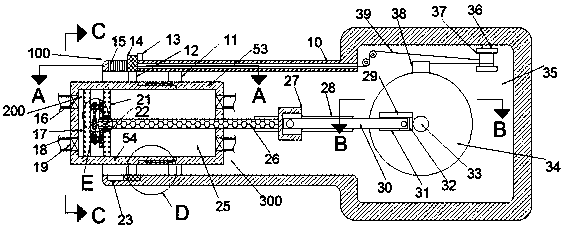

Method and apparatus for compressing a gas to a high pressure

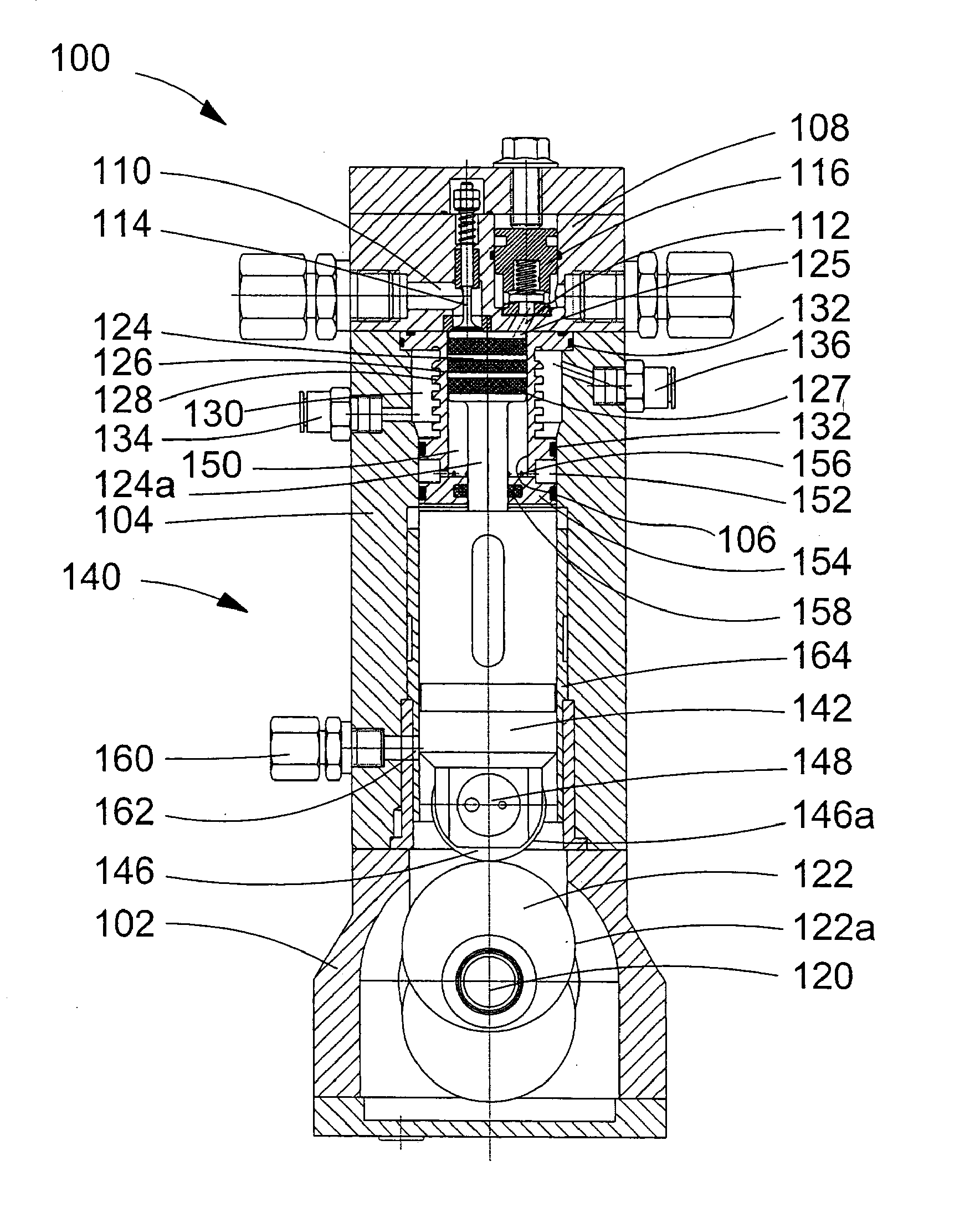

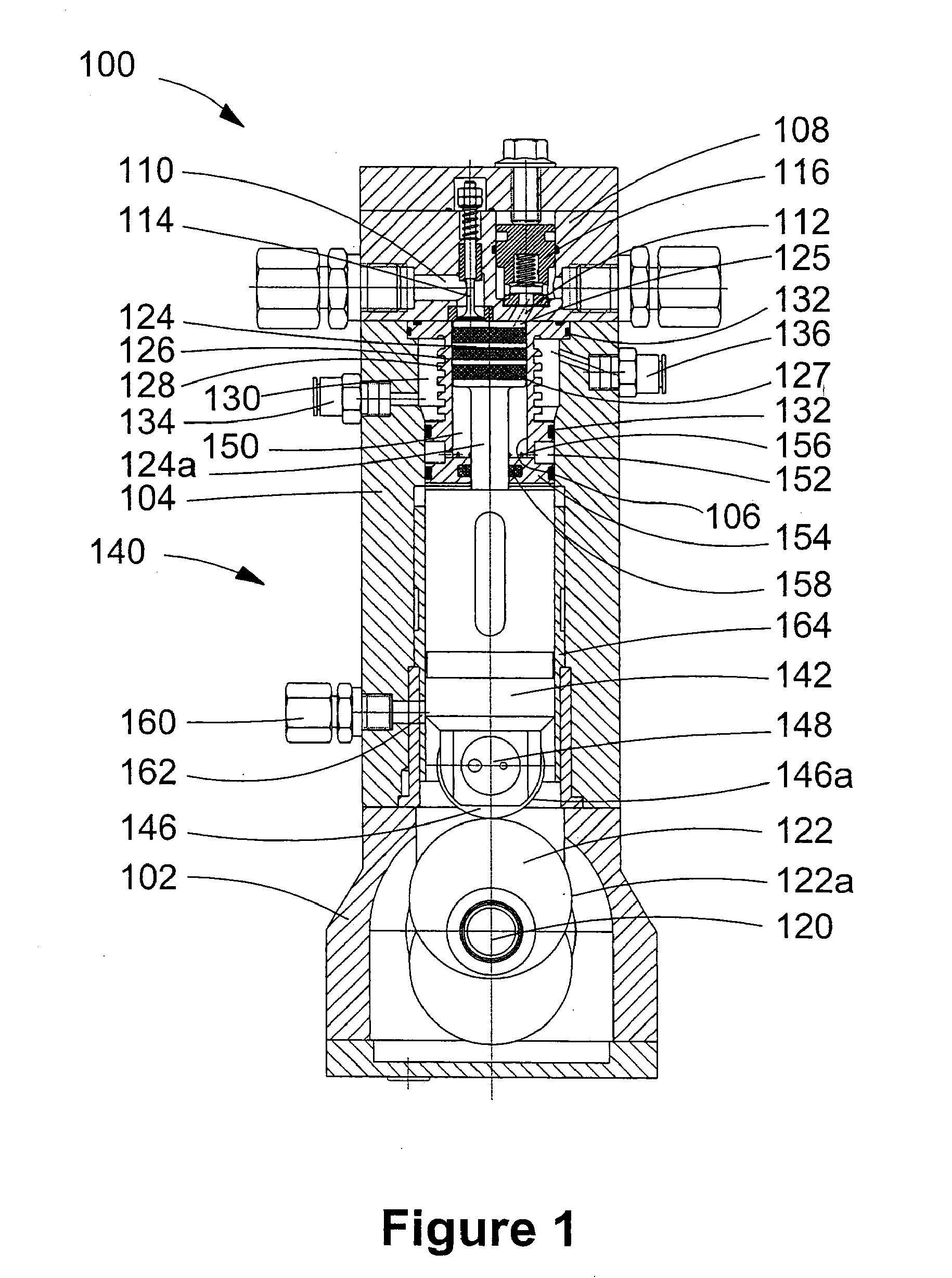

ActiveUS7527482B2Increase volumeReduce volumePositive displacement pump componentsFlexible member pumpsElectronic controllerFoot per second

A method is provided for compressing a gas in a single cycle and in a single cylinder to a pressure of at least 17.2 Mpa with a compression ratio of at least about five to one. The method further comprises dissipating heat from the cylinder during the compression stroke whereby the gas is discharged with a temperature significantly less than isentropic. The apparatus comprises a hollow cylinder and a reciprocable free-floating piston disposed therein. The piston divides the cylinder into: (a) a compression chamber within which a gas can be introduced, compressed, and discharged; and, (b) a drive chamber, into which a hydraulic fluid can be introduced and removed for actuating the piston. The apparatus further comprises a piston stroke length to piston diameter ratio of at least seven to one. For operating the apparatus with a compression ratio of at least five to one, an outlet pressure of at least 17.2 Mpa, and a gas discharge temperature significantly less than isentropic, the apparatus can further comprise a variable displacement hydraulic pump for controlling piston velocity, an electronic controller for maintaining an average piston velocity that is less than 0.5 feet per second, and a heat dissipator for dissipating heat from the cylinder.

Owner:WESTPORT FUEL SYST CANADA INC

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS20060000208A1Slow pressureAvoid cavitationAuxillary drivesBraking element arrangementsTransmitted powerEngineering

A system according to this invention for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having an inlet, an outlet, and a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit, which connects the inlet to the accumulator and the outlet to the reservoir, includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation. The first path includes a first valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a first orifice arranged in series with the first valve having a relatively low flow rate capacity. The second path, arranged in parallel with the first path between the accumulator and the inlet, includes a second valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a second orifice arranged in series with the second valve having a higher flow rate capacity than that of the first orifice.

Owner:FORD GLOBAL TECH LLC

Method and apparatus for compressing a gas to a high pressure

ActiveUS20050180864A1Improve compressor efficiencyHigh aspect ratioPositive displacement pump componentsFlexible member pumpsElectronic controllerHydraulic pump

A method is provided for compressing a gas in a single cycle and in a single cylinder to a pressure of at least 17.2 Mpa with a compression ratio of at least about five to one. The method further comprises dissipating heat from the cylinder during the compression stroke whereby the gas is discharged with a temperature significantly less than isentropic. The apparatus comprises a hollow cylinder and a reciprocable free-floating piston disposed therein. The piston divides the cylinder into: (a) a compression chamber within which a gas can be introduced, compressed, and discharged; and, (b) a drive chamber, into which a hydraulic fluid can be introduced and removed for actuating the piston. The apparatus further comprises a piston stroke length to piston diameter ratio of at least seven to one. For operating the apparatus with a compression ratio of at least five to one, an outlet pressure of at least 17.2 Mpa, and a gas discharge temperature significantly less than isentropic, the apparatus can further comprise a variable displacement hydraulic pump for controlling piston velocity, an electronic controller for maintaining an average piston velocity that is less than 0.5 feet per second, and a heat dissipator for dissipating heat from the cylinder.

Owner:WESTPORT FUEL SYST CANADA INC

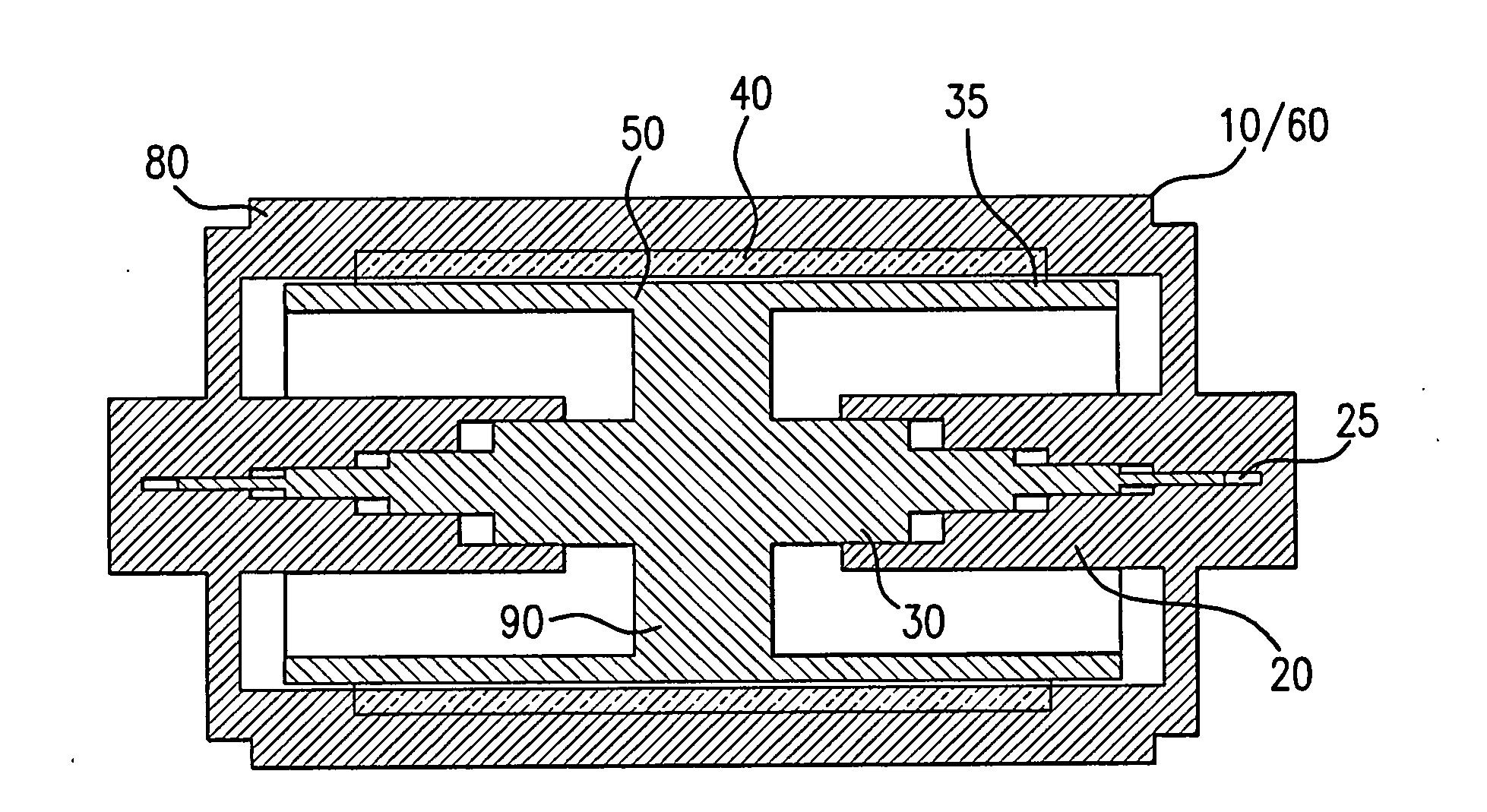

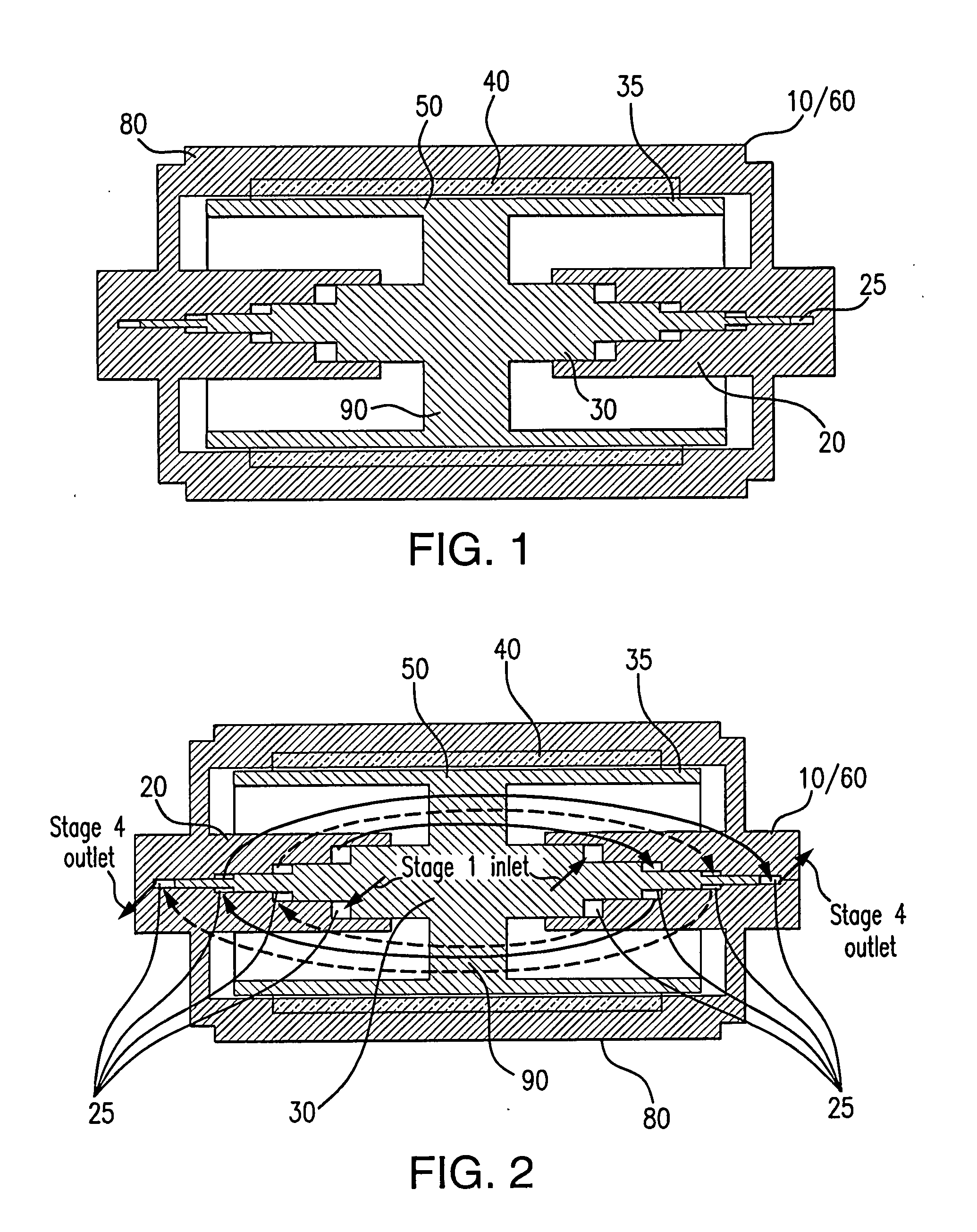

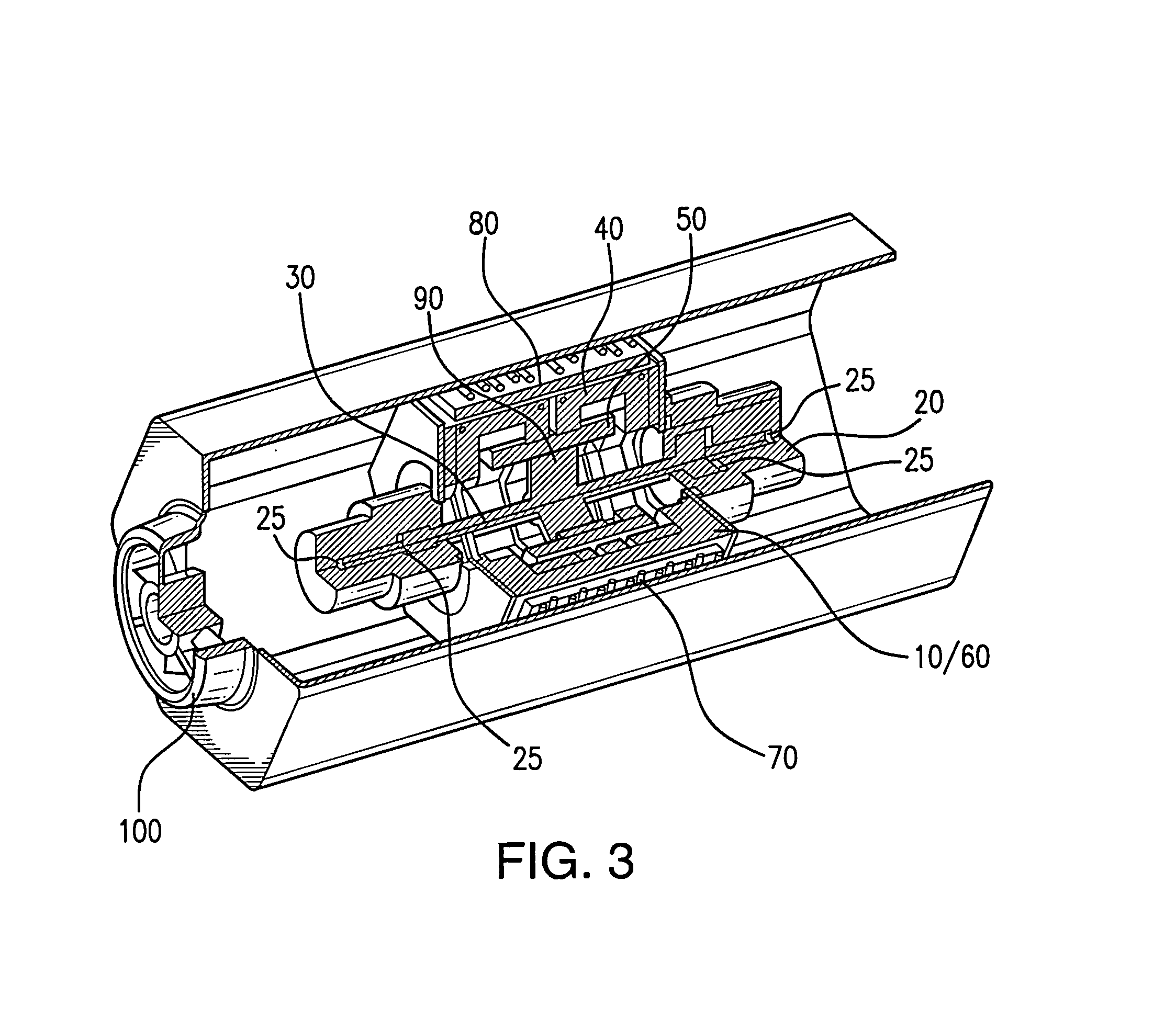

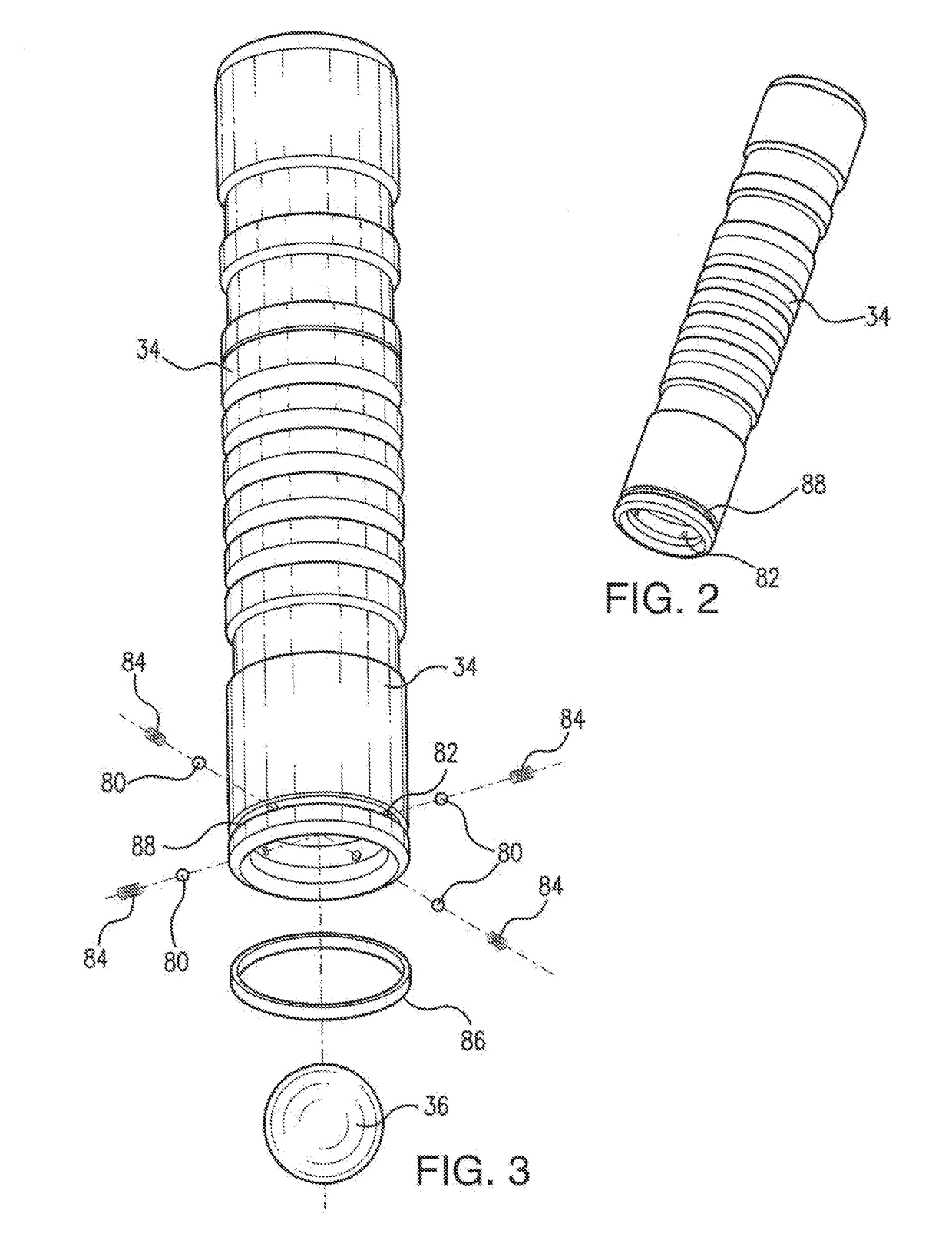

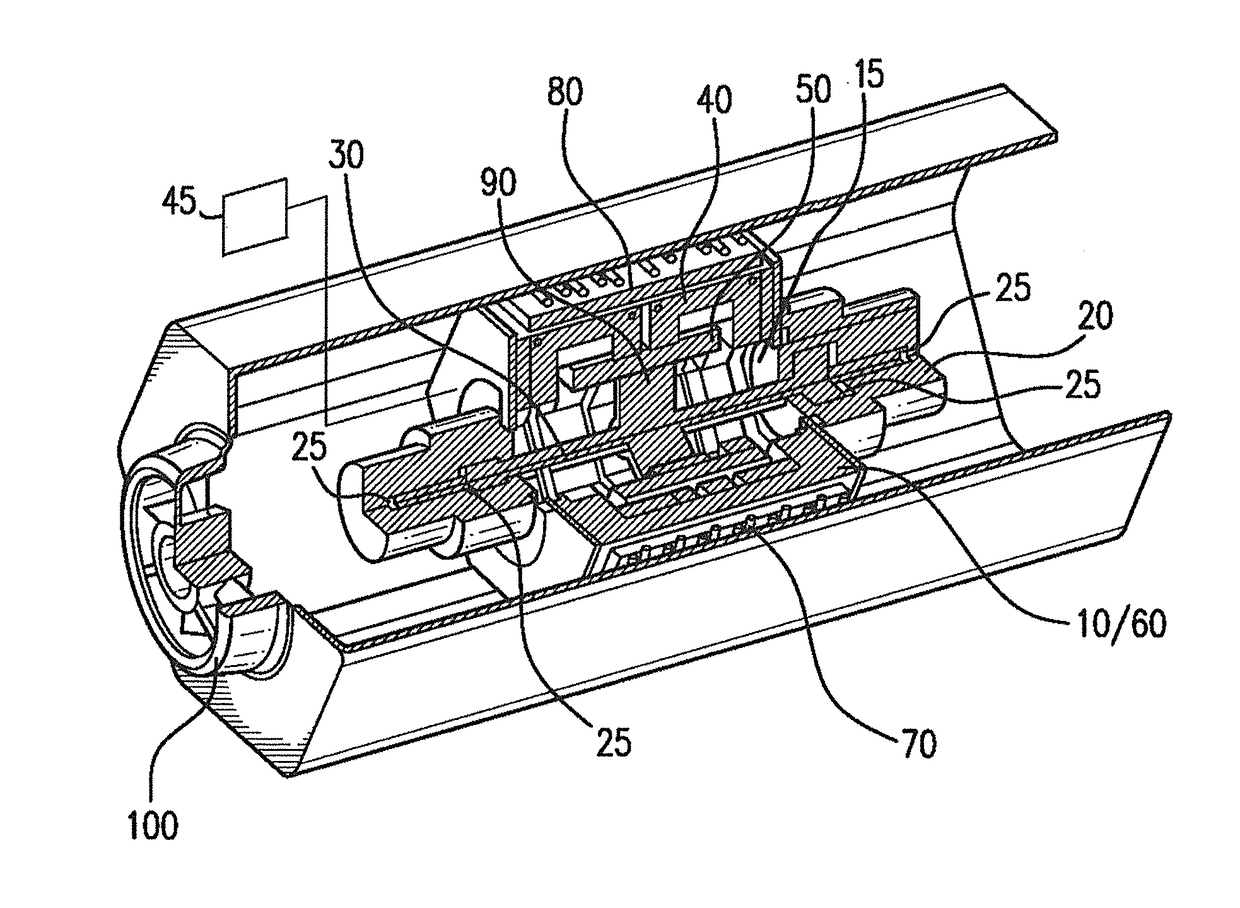

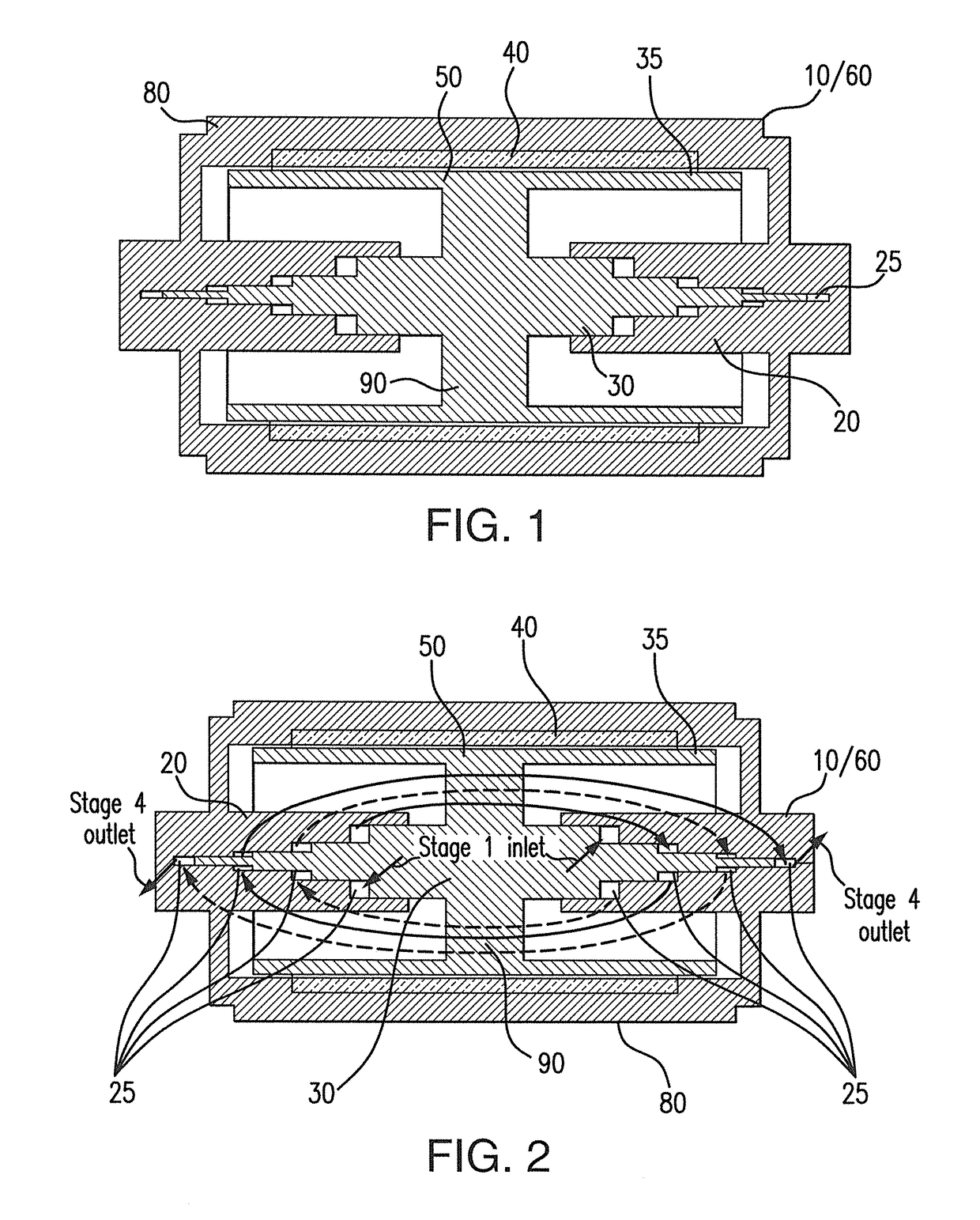

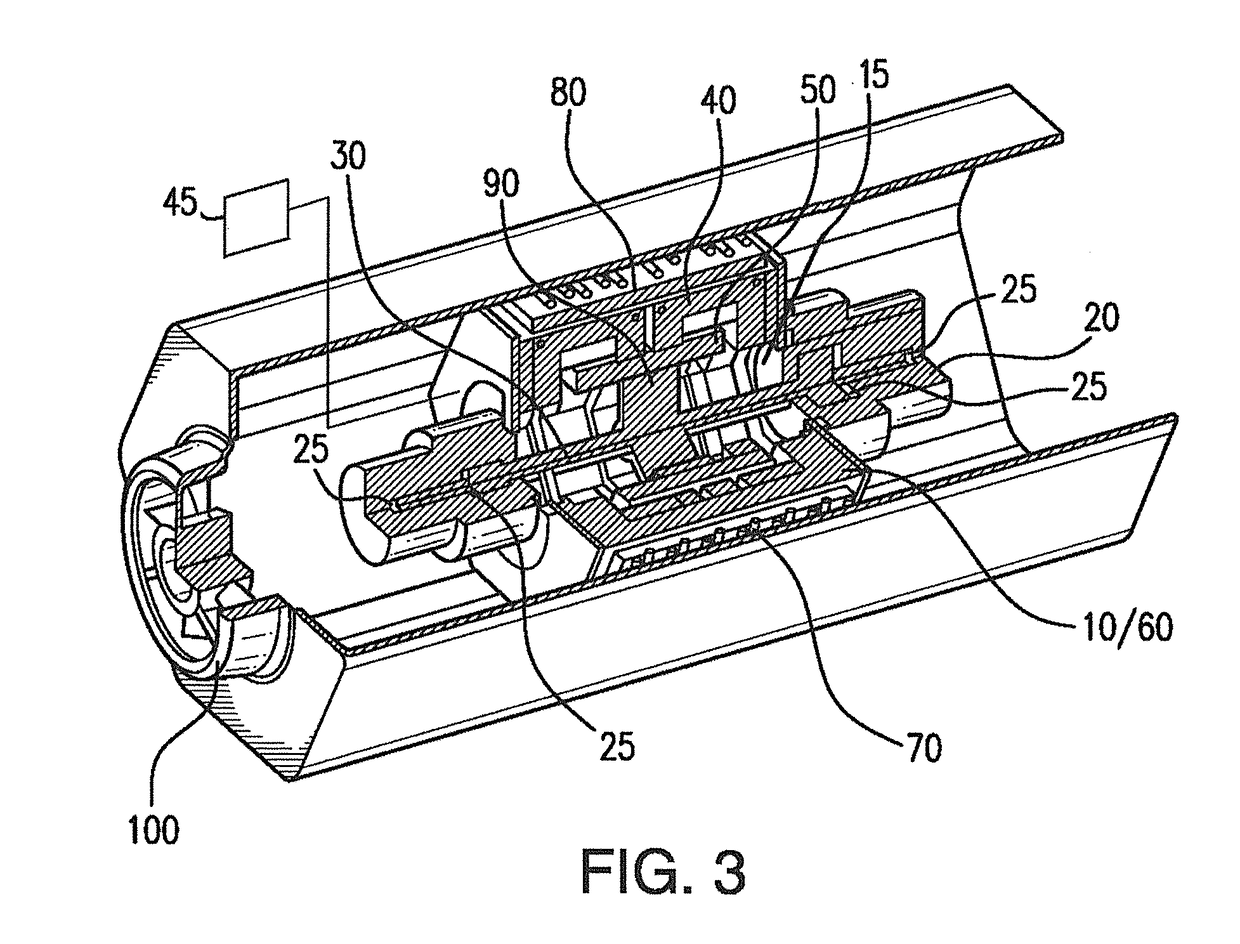

Free piston linear motor compressor and associated systems of operation

ActiveUS20150125323A1Increased durabilityImproves compressor system efficiencyFree piston pumpsPiston pumpsReciprocating motionEngineering

A linear motor compressor including a compressor housing and a cylinder housing having a plurality of opposing compression chambers. A piston freely reciprocates within the cylinder housing using a linear electric motor.

Owner:GAS TECH INST +1

High-pressure gas compressor and method of operating a high-pressure gas compressor

ActiveUS8172557B2Reduce in quantitySimple manufacturing processPositive displacement pump componentsFree piston pumpsFriction reductionInlet valve

Owner:WESTPORT FUEL SYST CANADA INC

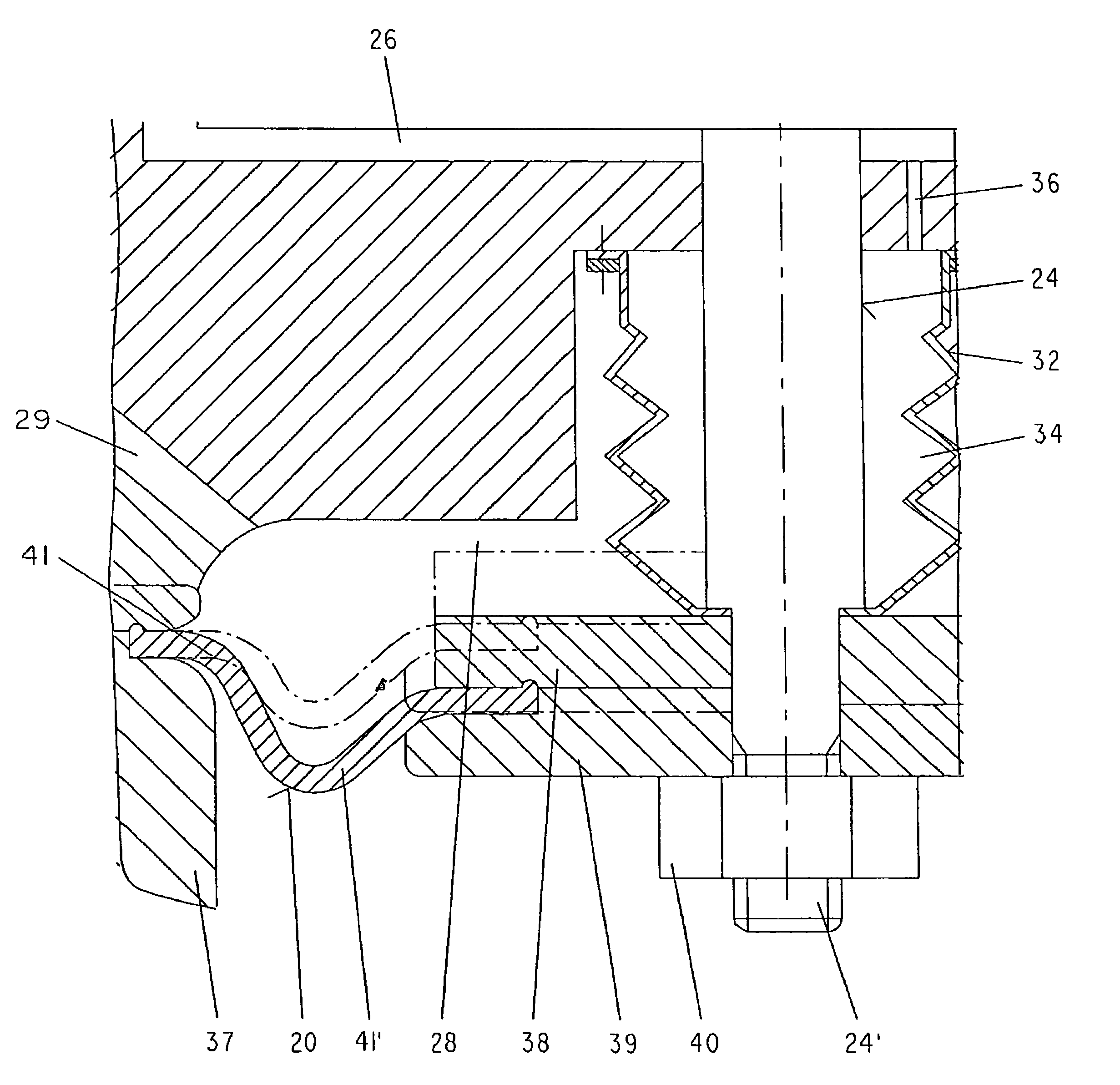

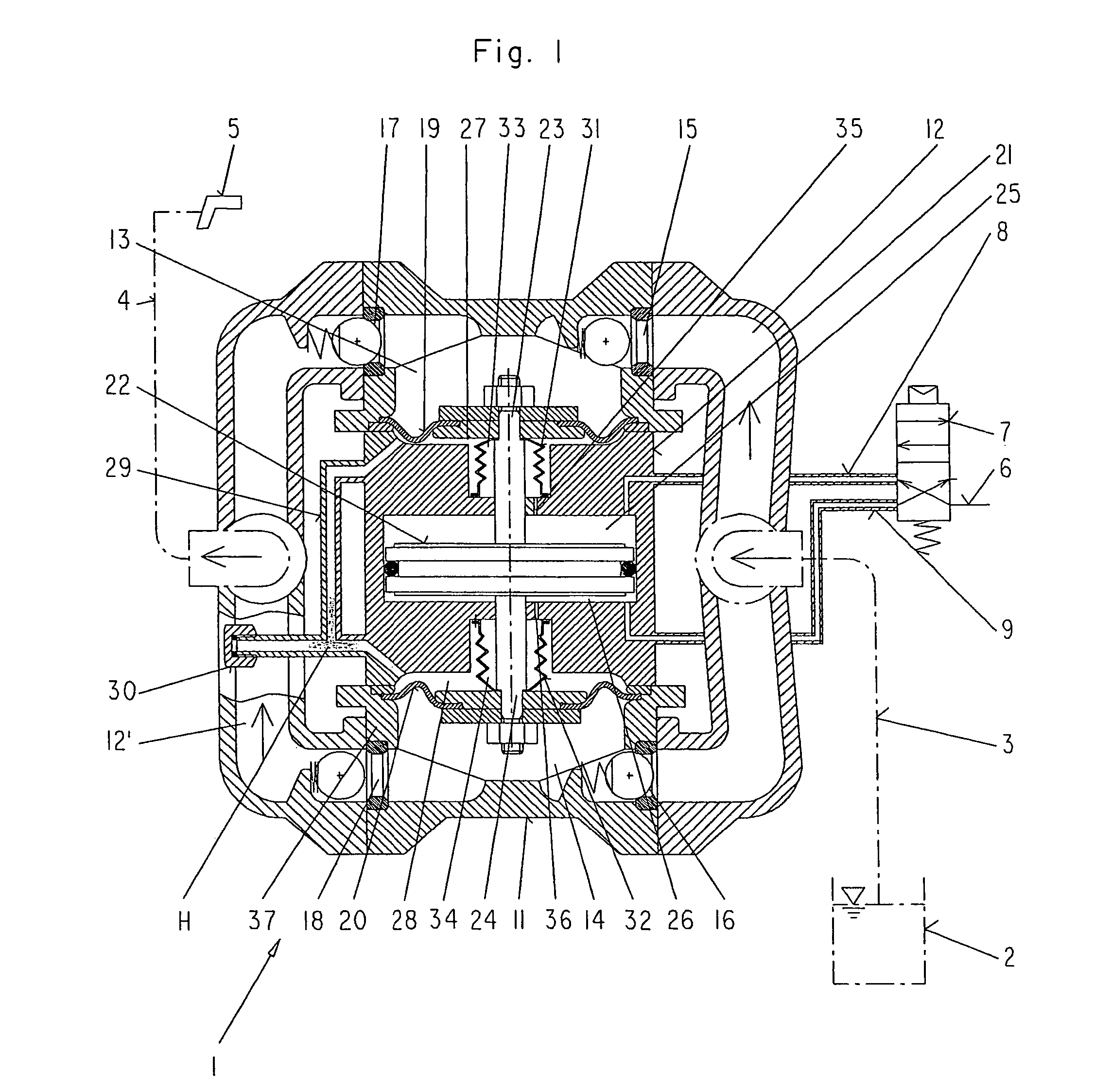

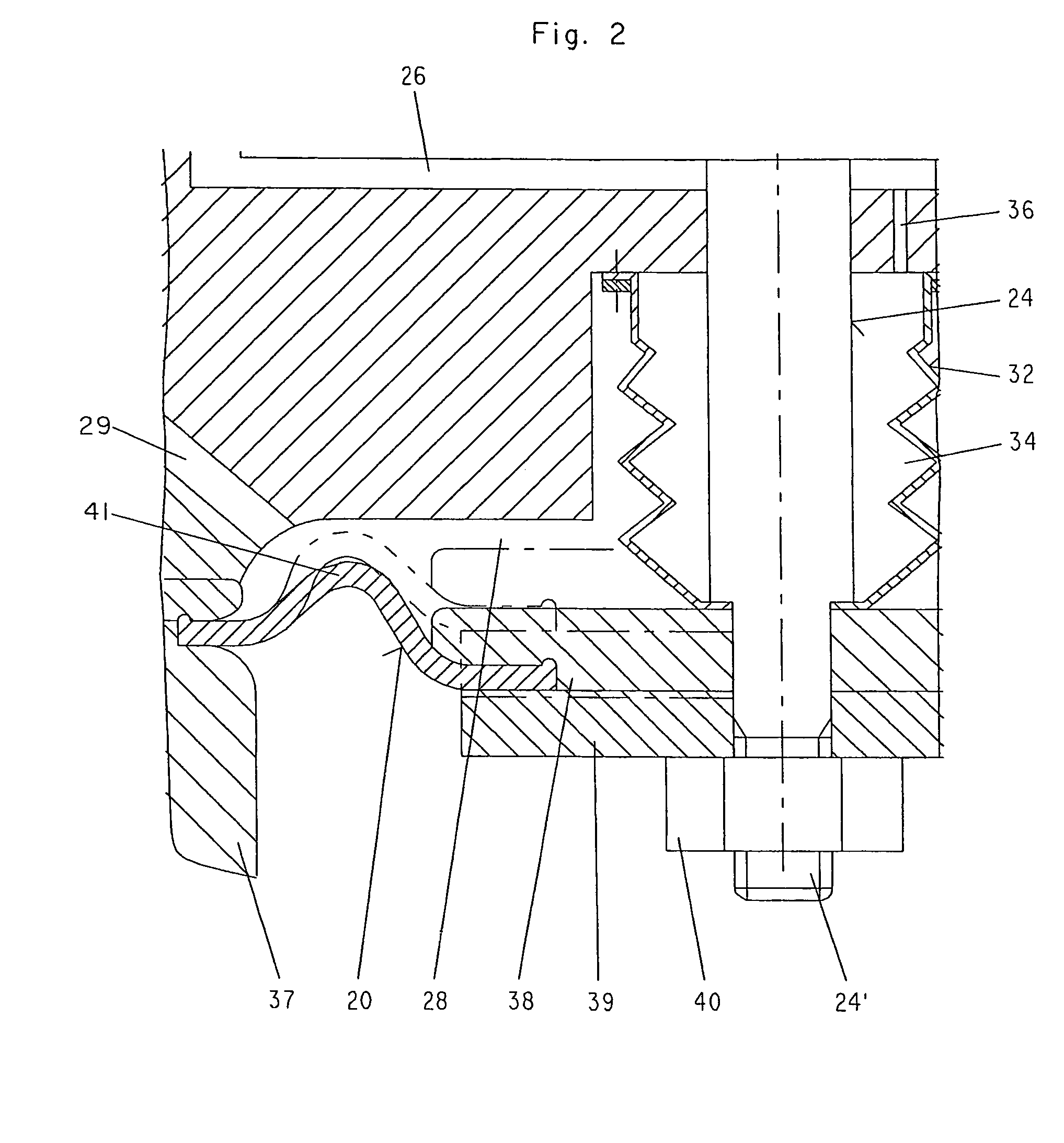

Diaphragm pump

InactiveUS8123500B2Extended service lifeReduce sensitivityPositive displacement pump componentsFlexible member pumpsDiaphragm pumpHydraulic pump

In a diaphragm pump with two diaphragms disposed in a pump housing and actuated by an adjusting piston which can be acted on alternately and which is arranged in between the diaphragms, the diaphragms are fixed with curvatures facing one another, or a curvature facing away from one another, and two reaction spaces are formed between the diaphragms and a cylinder, the reaction spaces accommodating the adjusting piston and being filled with a hydraulic medium and connected together in a constrained arrangement by means of hydraulic linkage lines. Both diaphragms remain in position and do not fold over during a transition from a suction stroke to a pressure stroke, because the diaphragms are continuously in contact with the hydraulic lines and are thereby fixed in place, so that the diaphragms are not subjected to alternating loadings.

Owner:J WAGNER GMBH

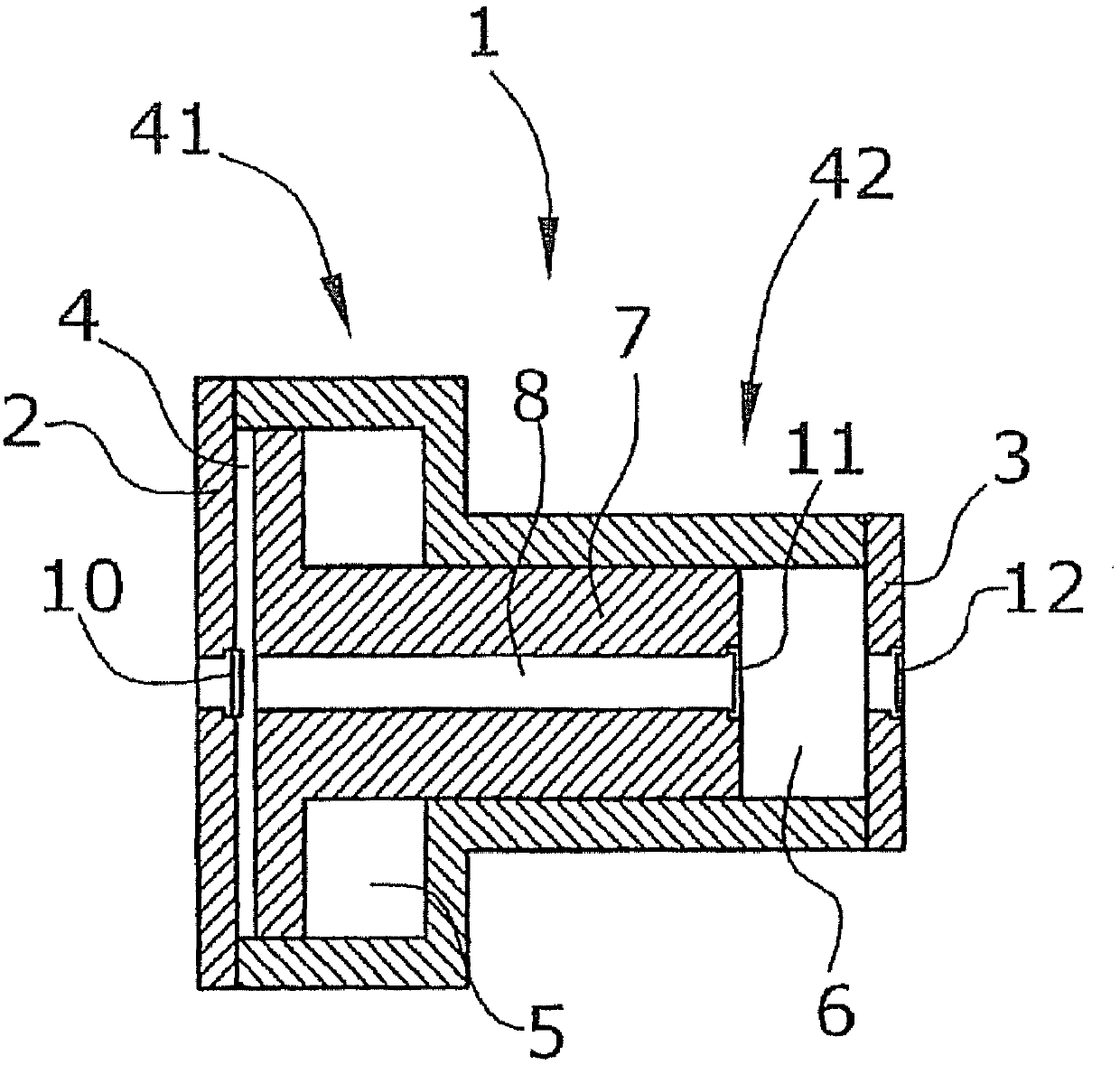

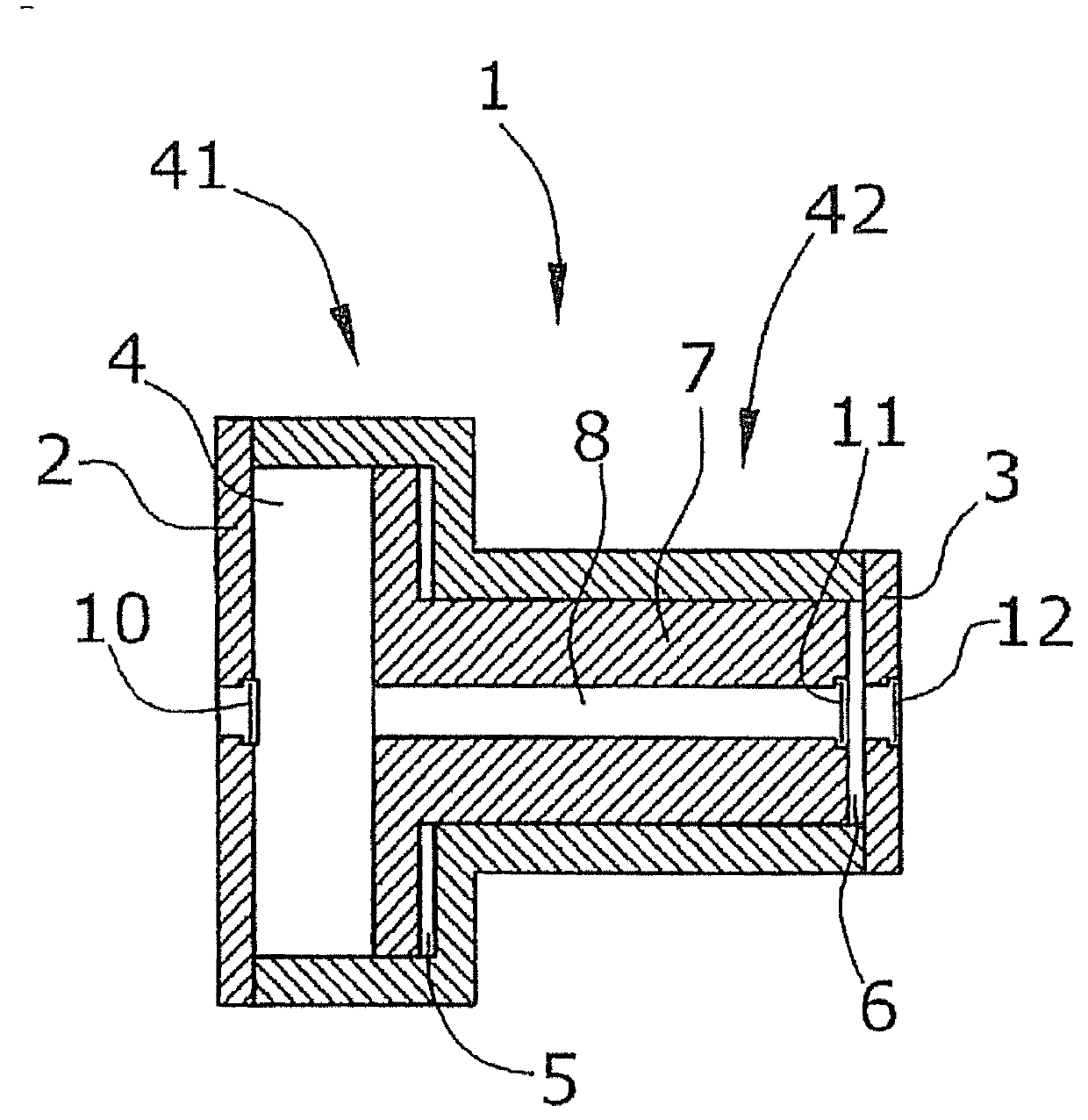

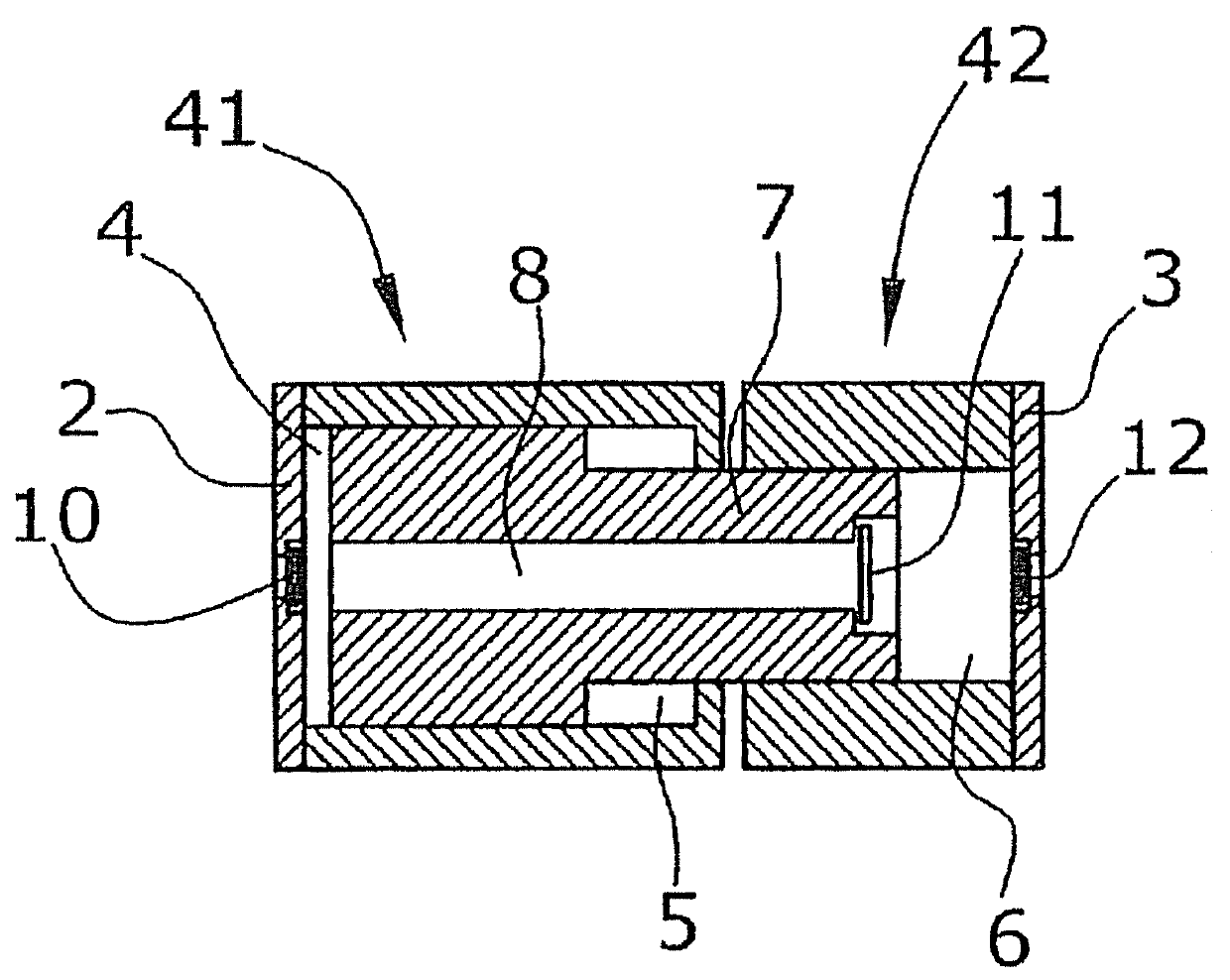

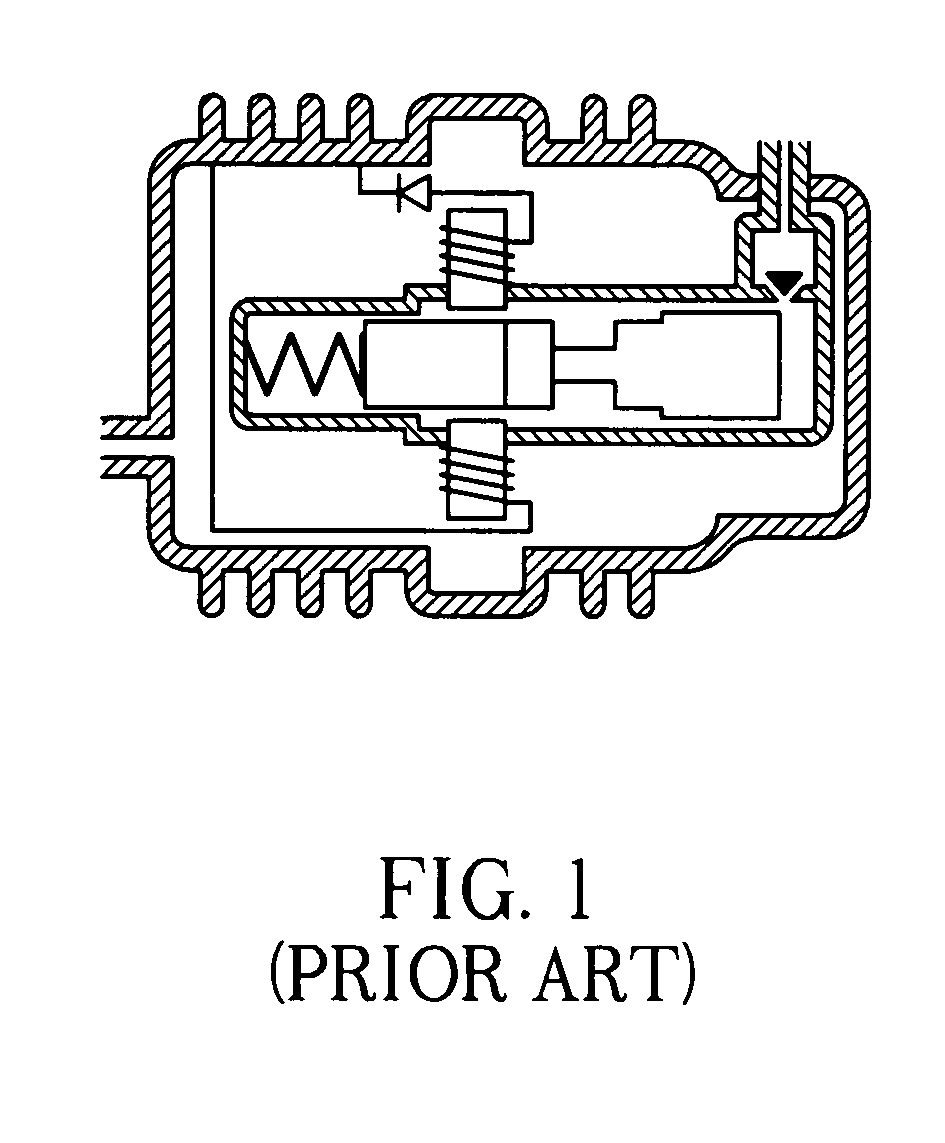

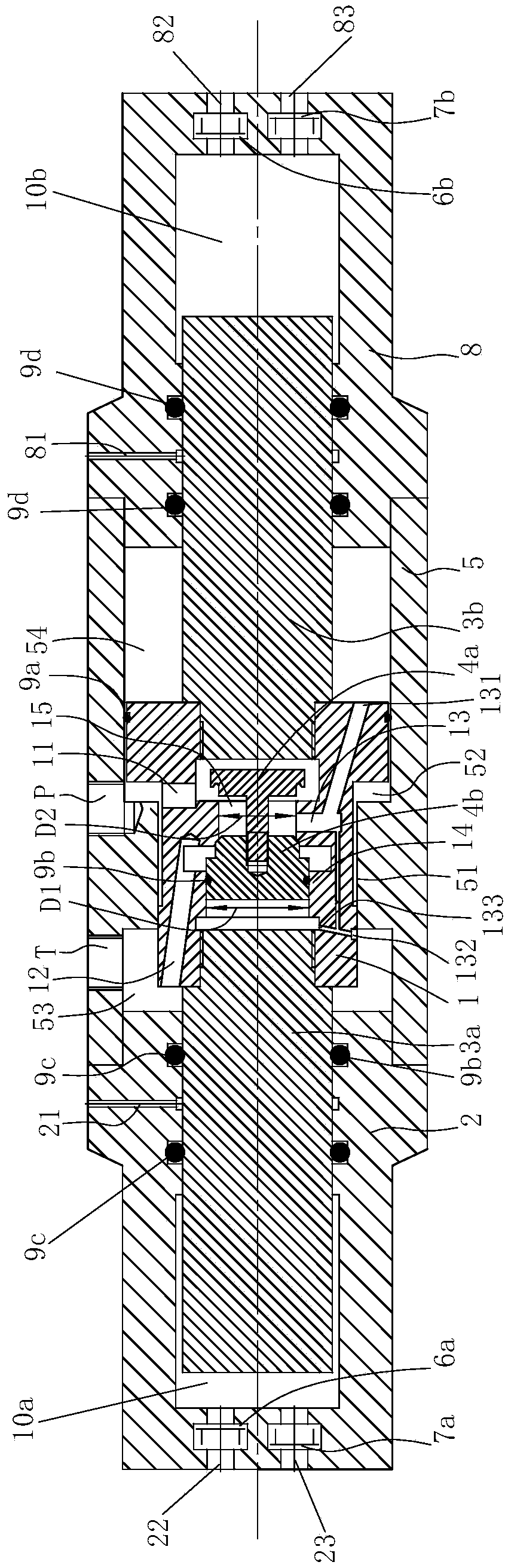

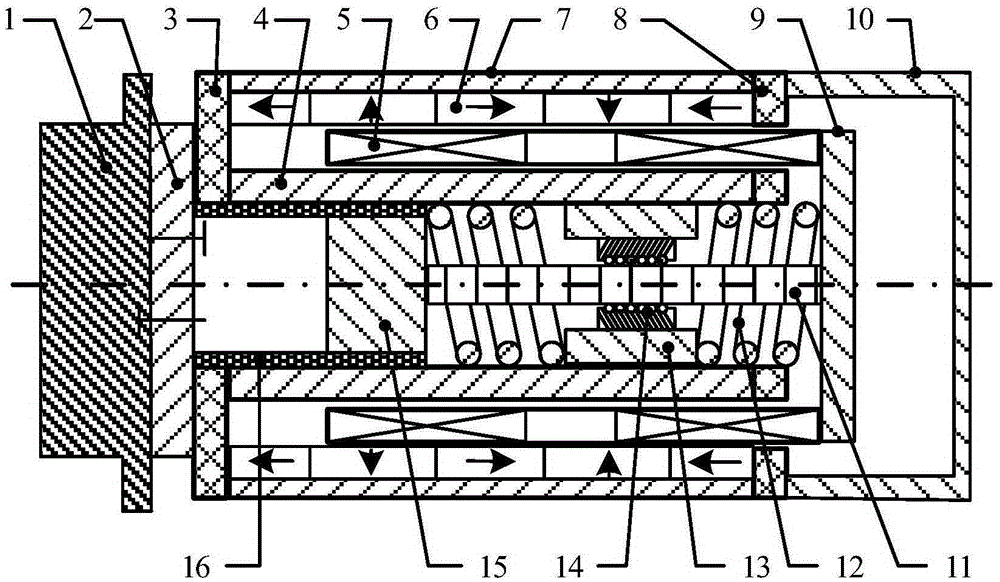

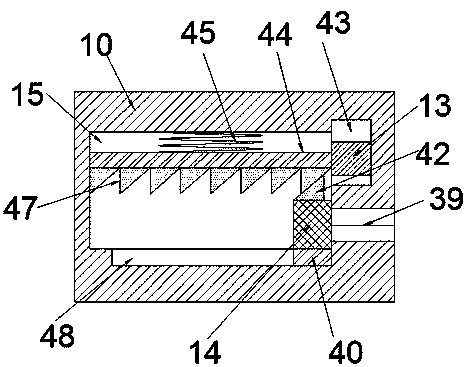

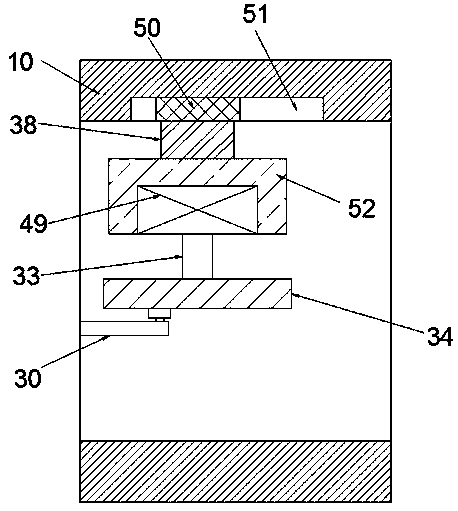

Double-acting refrigeration compressor

ActiveCN103282656AEasy to manufacturePositive displacement pump componentsFree piston pumpsRefrigeration compressorEngineering

The refrigeration compressor is a double-acting refrigeration compressor, comprising a piston (7), which is freely guided on two cylinder sections (41, 42) that are opposite each other and that cannot be moved relative to each other, and which has a flow channel (8) that extends internally through the piston (7), wherein each cylinder section (41, 42) and the piston (7) have at least one check valve (10, 11, 12) along the flow channel (8), wherein the check valves (10, 11, 12) are arranged in such a way that the flow directions thereof are oriented in the same direction.

Owner:INFICON INC

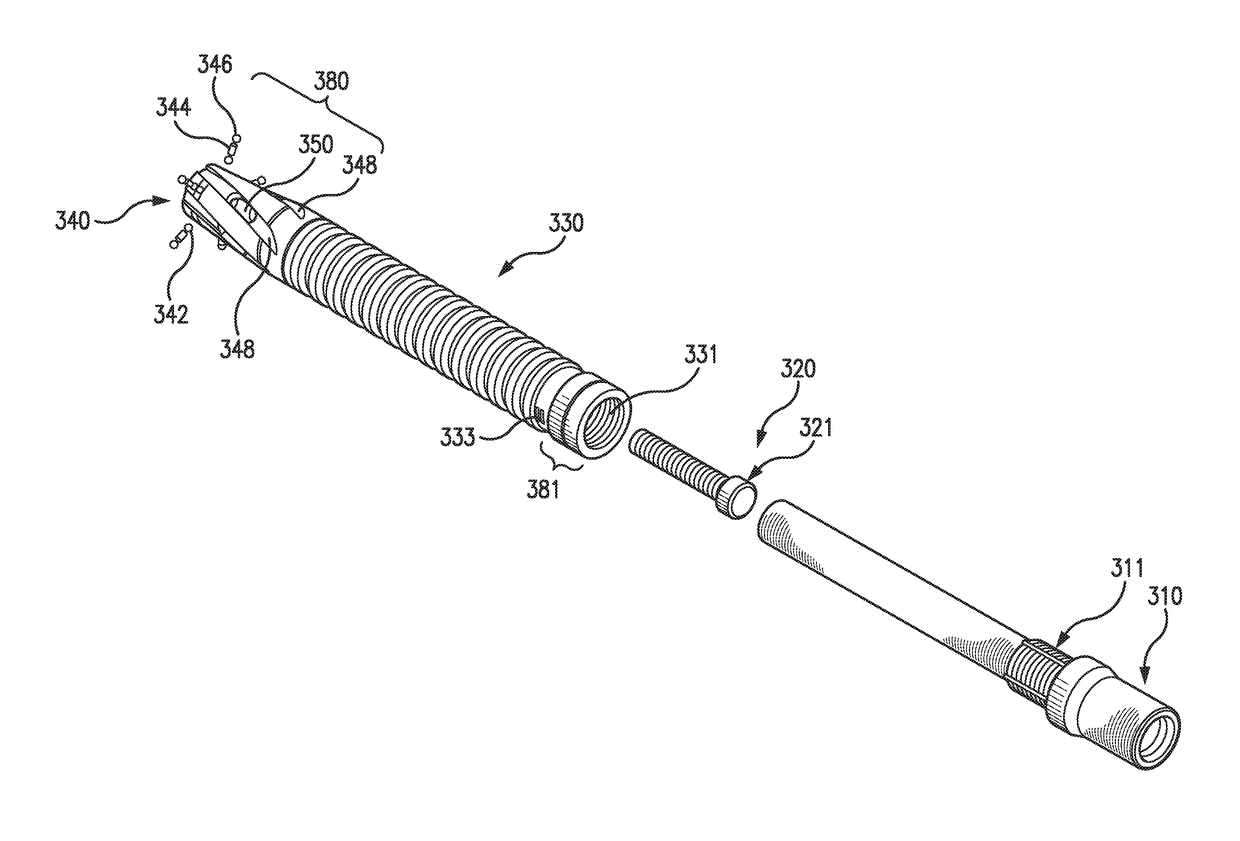

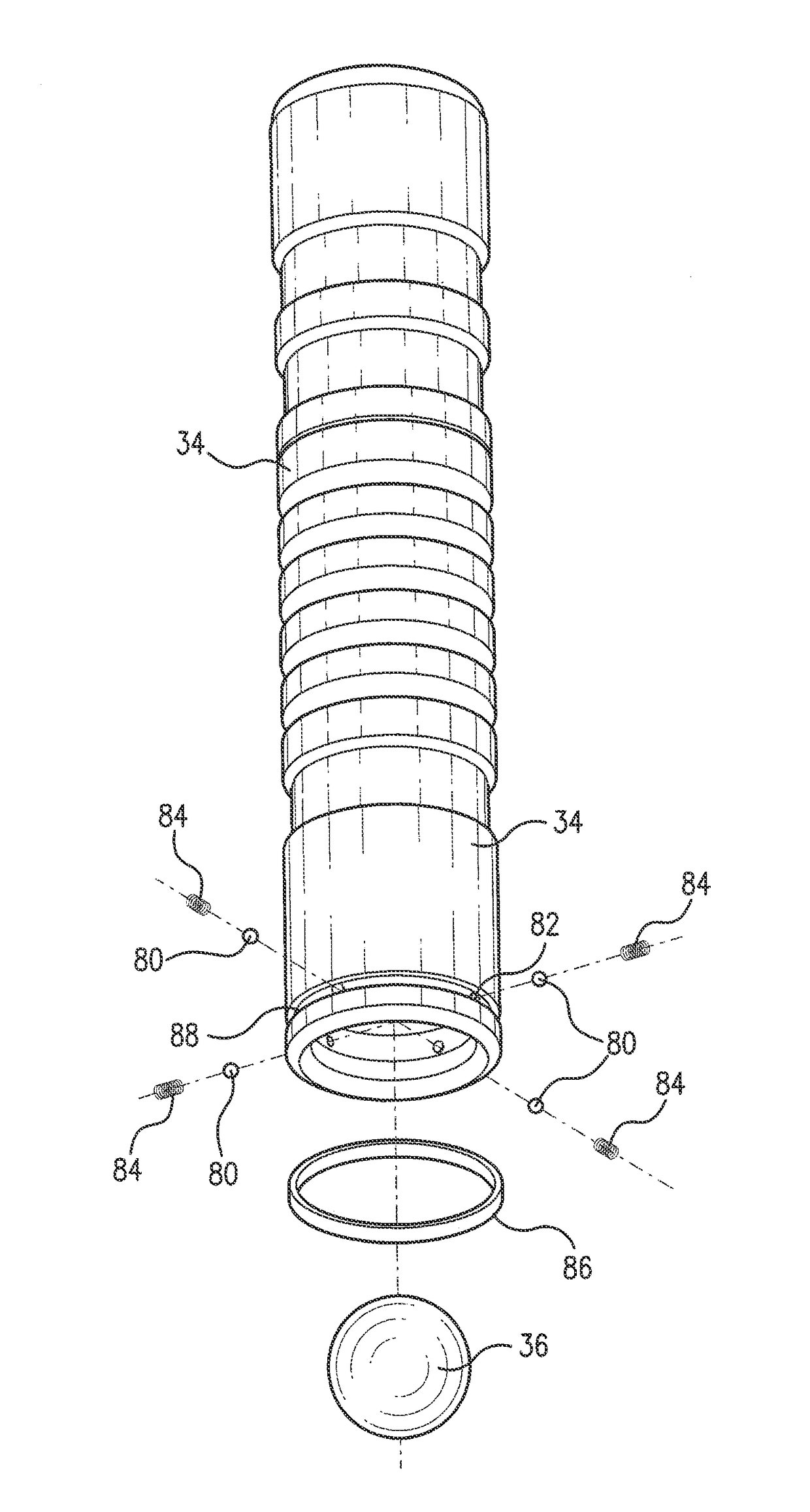

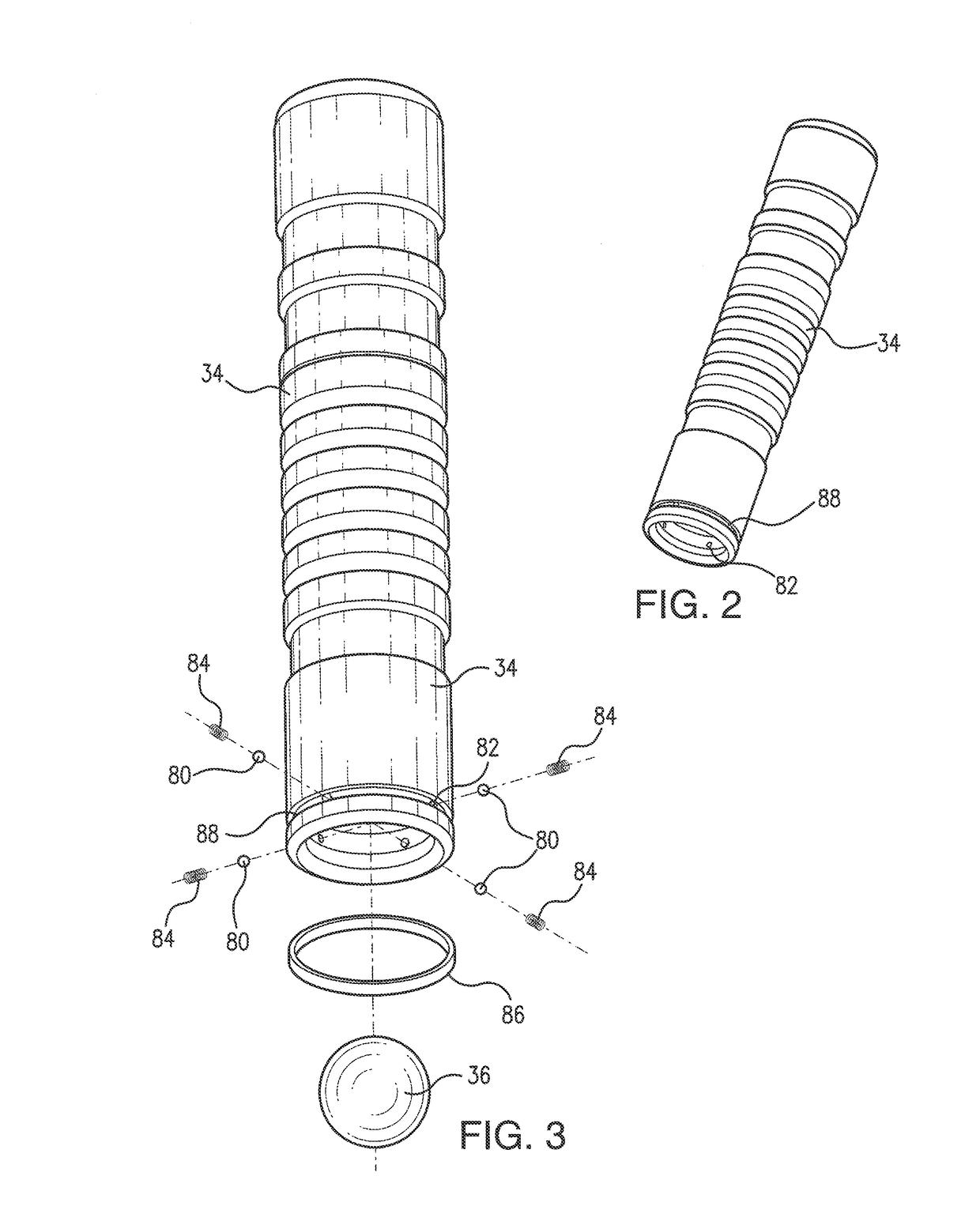

Durable dart plunger

ActiveUS20170107803A1Avoid flowPositive displacement pump componentsFlexible member pumpsEngineeringMechanical engineering

Provided is an improved bypass durable dart plunger that descends faster in a hydrocarbon well, is capable of lifting more fluids and has a durable and replaceable clutch assembly. The various components of the durable dart plunger includes a sleeve, a dart body with a one or more flow ports (chokes) cut at right angles through the dart body, a pin and a replaceable clutch assembly (also referred to a retention assembly). The chokes can be of varying sizes. In one embodiment, the clutch assembly includes a plurality of clutch mechanisms wherein each mechanism includes a ball, a socket screw and a resilient spacer.

Owner:ENDURANCE ELEVATOR SOLUTIONS LLC

Free piston linear motor compressor and associated systems of operation

ActiveUS20180051690A1Increased durabilityImproves compressor system efficiencyFree piston pumpsMotor parameterPower flowReciprocating motion

A linear motor compressor including a compressor housing and a cylinder housing having a plurality of opposing compression chambers. A piston freely reciprocates within the cylinder housing using a linear electric motor. A piston position feedback control system provides adaptive current output as a function of position feedback and / or velocity feedback from the piston and / or the electric motor, to directly power and control the electric motor, wherein the piston reciprocates without assistance from a mechanical spring or other equivalent centering force.

Owner:GAS TECH INST +1

Dual-pump fluid distribution system for a hybrid electric vehicle

The dual-pump fluid distribution system of the present invention preferably includes a sump having hydraulic fluid disposed therein. A first pump driven by an electric motor and a second pump driven by an engine are disposed in fluid communication with the sump. A plurality of vehicle systems are disposed in fluid communication with the first and second pumps. The first pump is configured to transfer hydraulic fluid to the vehicle systems when the engine is off. The first and second pumps are both configured to transfer hydraulic fluid to the vehicle systems when the engine speed is at or below a predetermined value. The second pump is configured to transfer hydraulic fluid to the vehicle systems when the engine speed exceeds the predetermined value. Accordingly, the hydraulic pressure needs of the vehicle systems are met for any given engine speed. A corresponding method in accordance with the present invention is similarly provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Plunger lift assembly with an improved free piston assembly

An improved free piston assembly for use in combination with a plunger lift assembly is provided. The improved free piston assembly includes a sleeve member, a flow restriction member, and retention means. In some embodiments of the invention the sleeve member has an inner surface that is contoured to provide a seat for the flow restriction member during lifting operations. The flow restriction member can be a ball held in the interior of the sleeve by retention means capable of overcoming the force of gravity but at the same time designed to release the flow restriction member when a rod of the plunger lift assembly contacts the flow restriction member. In one embodiment of the invention the retention means is a plurality of inwardly biased spring loaded held in place by a retention ring that is fittably received by a groove in the exterior surface of the sleeve. In other embodiments of the invention the retention means are in the form of a raised lip or a retention sleeve.

Owner:ENDURANCE ELEVATOR SOLUTIONS LLC

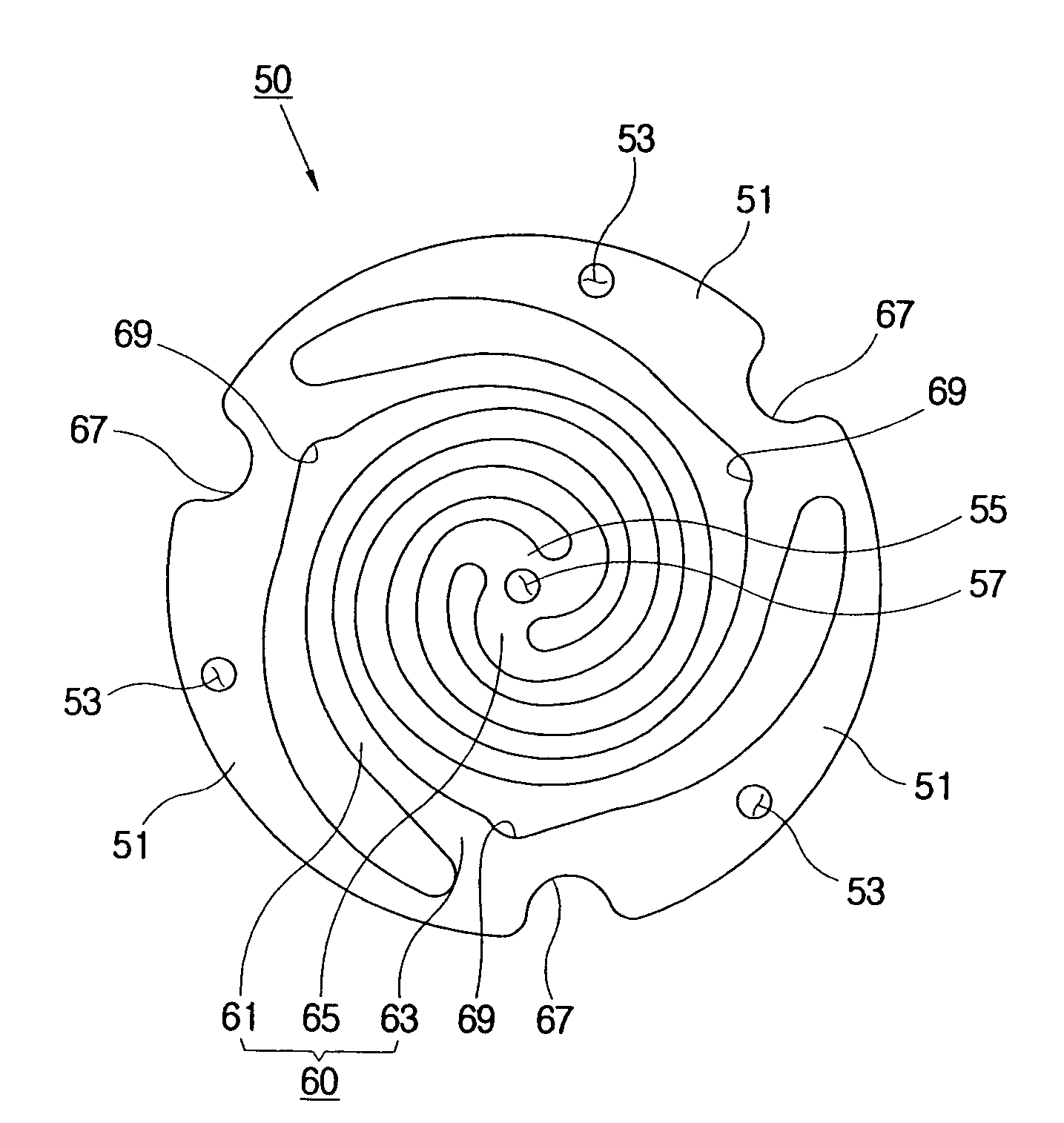

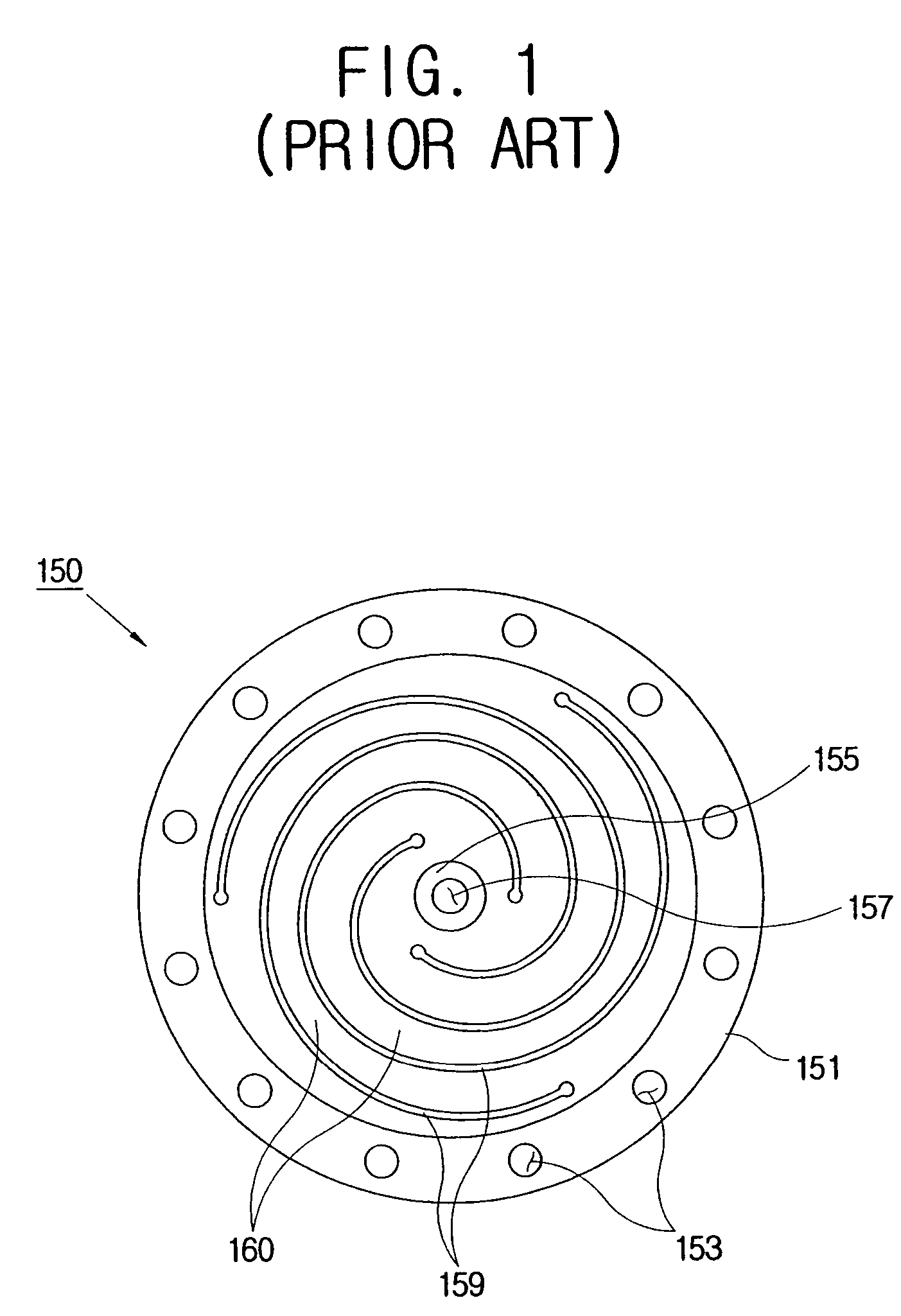

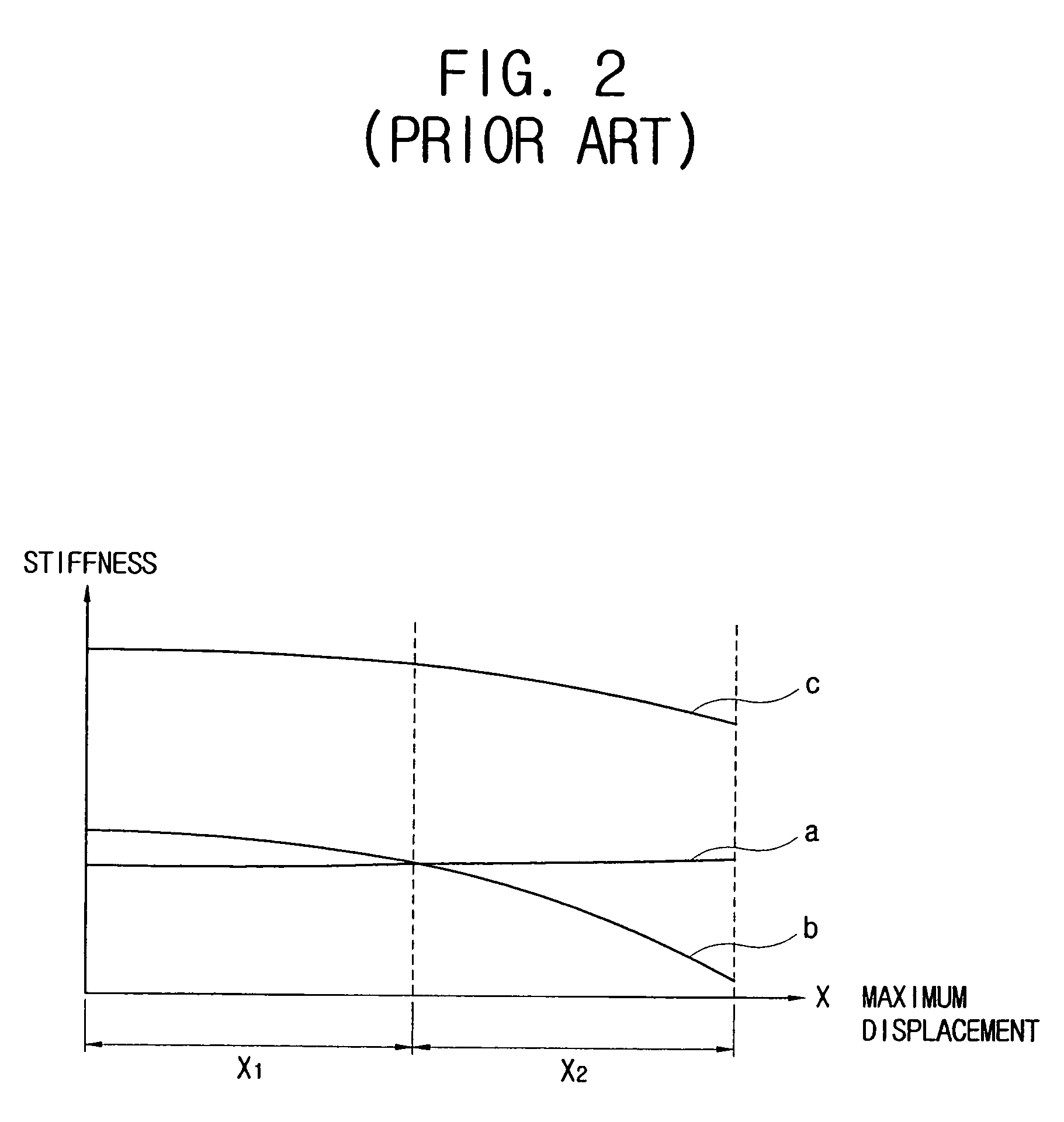

Linear compressor

A linear compressor includes: a cylinder block forming a compressing chamber; a piston reciprocatably provided in the compressing chamber; a reciprocating member connected to the piston to reciprocate with the piston as a single body; a driver driving the reciprocating member to reciprocate; and a resonance spring including a first connecting part formed with a plurality of first connecting holes to permit connection to the cylinder block, and a second connecting part that is provided inside of the first connecting part and formed with a second connecting hole to permit connection to the reciprocating member to reciprocate with the reciprocating member. A plurality of arms spaced apart from one another are disposed between the first connecting part and the second connecting part, each of the arms including a first end connected to the first connecting part to be positioned between the plurality of first connecting holes.

Owner:SAMSUNG ELECTRONICS CO LTD

Piston type thermodynamic gas compressor

InactiveCN1952391ASave energyImprove efficiencyFree piston pumpsPump controlSteam pressureGas compressor

The invention relates to a thermal compressor for recycling low pressure steam in heating system, especially the thermal compressor for improving heating supply steam pressure in steam power plant, comprising two cylinders with inlet and outlet port of high and low pressure steam (1), coaxial piston (2) in each cylinder and control system for it. Compared with prior technology, in the invention according to the principle that low pressure steam is not contacted with high pressure steam, the pressure of low pressure steam rises by low pressure steam in compressed way of piston and two cylinders work in turn so that the press of low pressure steam rises to destined value, outlet one-way valve of low pressure steam is opened and the steam is transported into steam supply pipe by the control system. It is energy saving and efficiency improving with two to four times by experiment testifying. It is no constrained by the parameter of high and low pressure steam and wide application while it is provided with simple structure and low cost.

Owner:王汝武

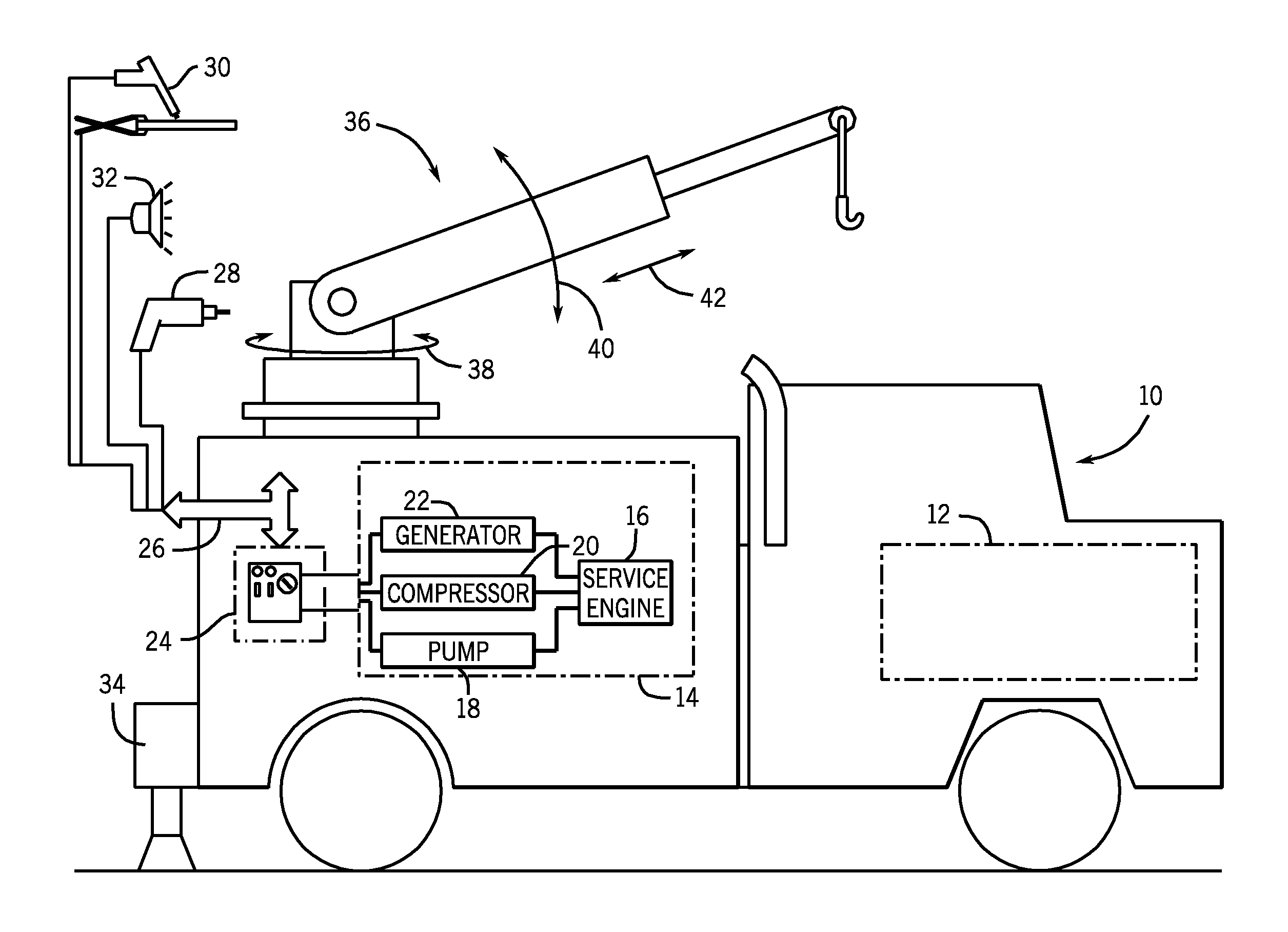

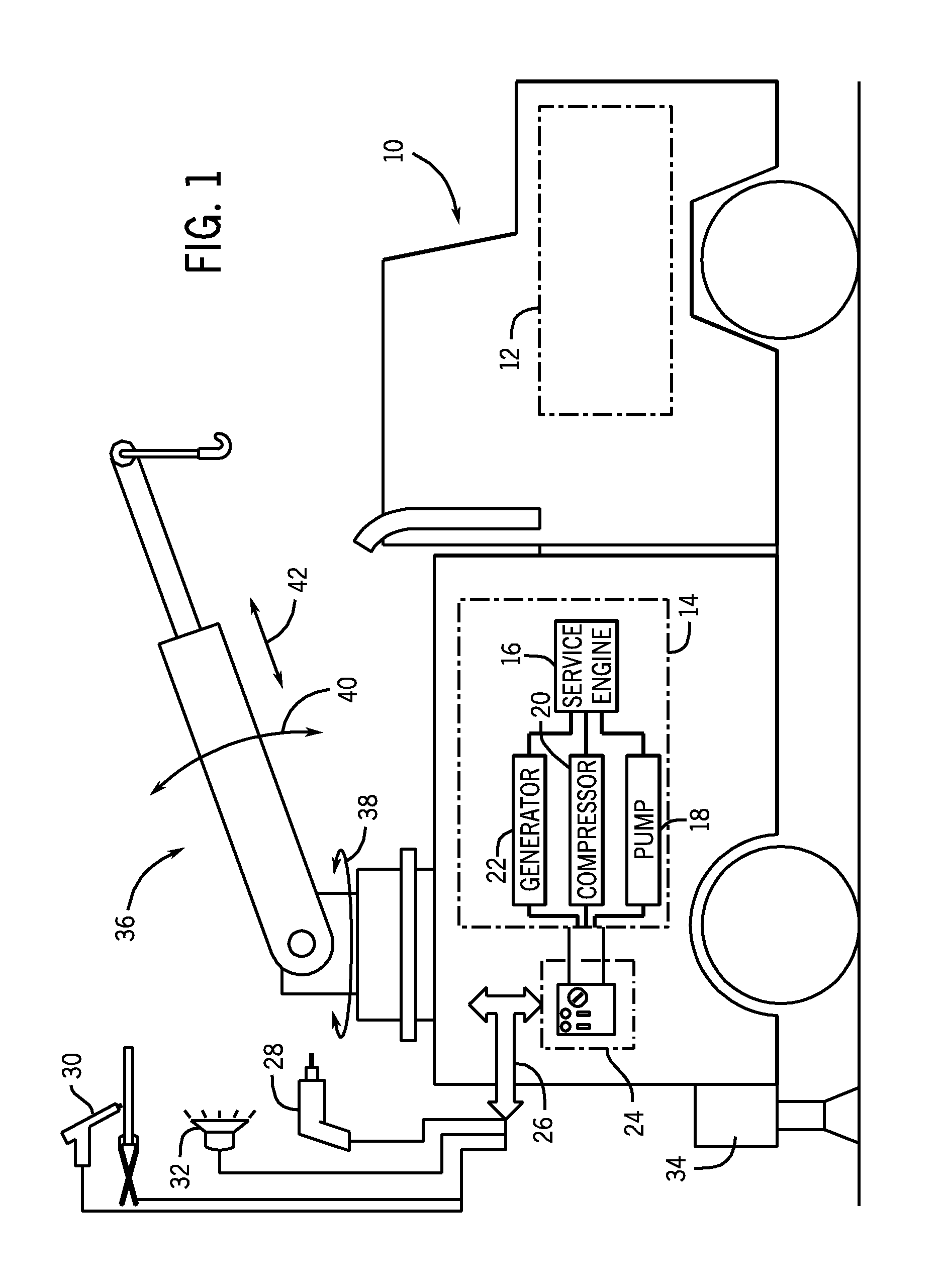

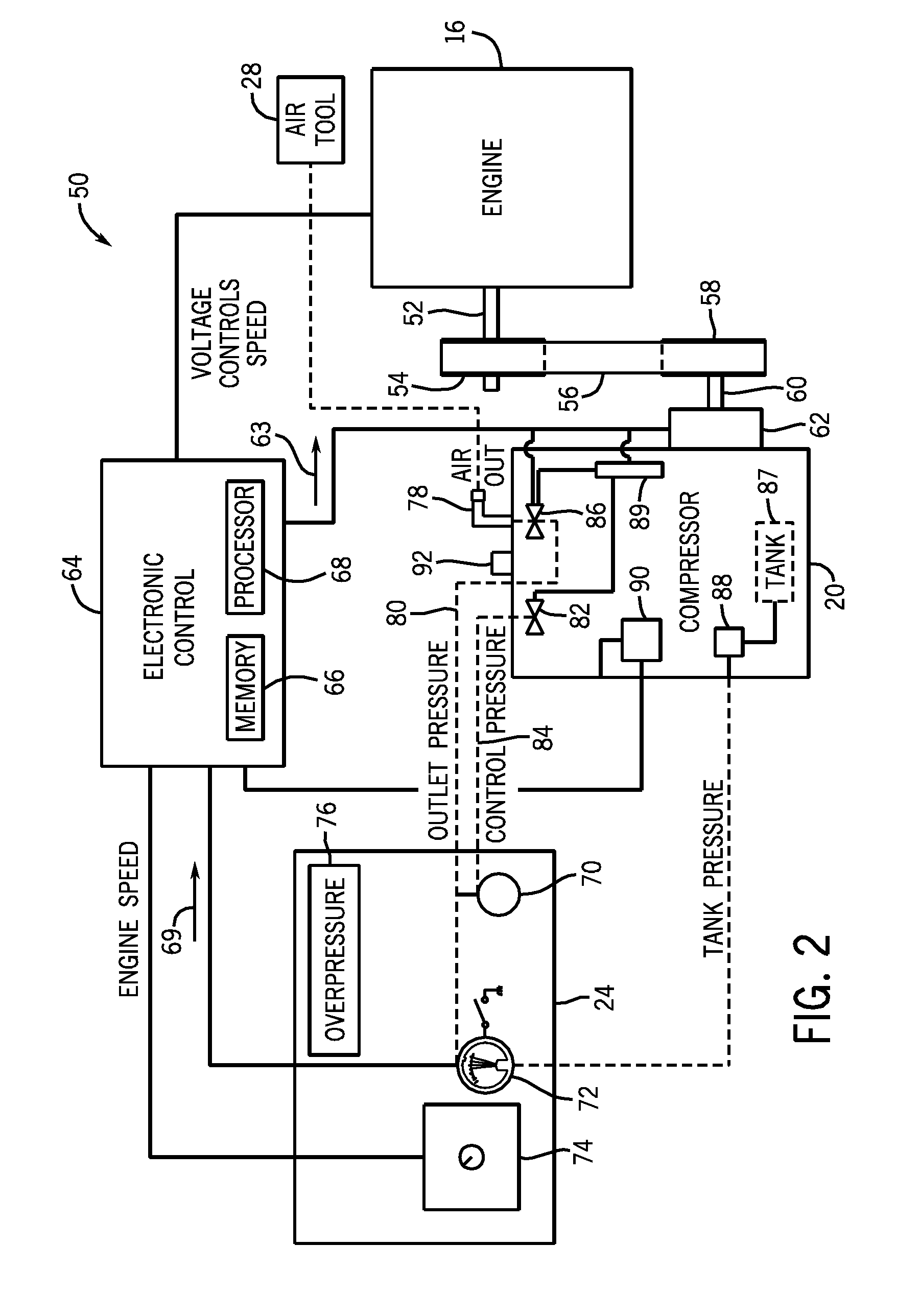

Automatic compressor overpressure control

The present embodiments provide a system having a motor, a compressor having a compression device configured to increase a pressure of a gas, a clutch configured to selectively transfer torque from the motor to the compressor to drive the compression device, and a controller configured to disengage the clutch if the pressure of the gas in the compressor meets or exceeds a first threshold pressure.

Owner:ILLINOIS TOOL WORKS INC

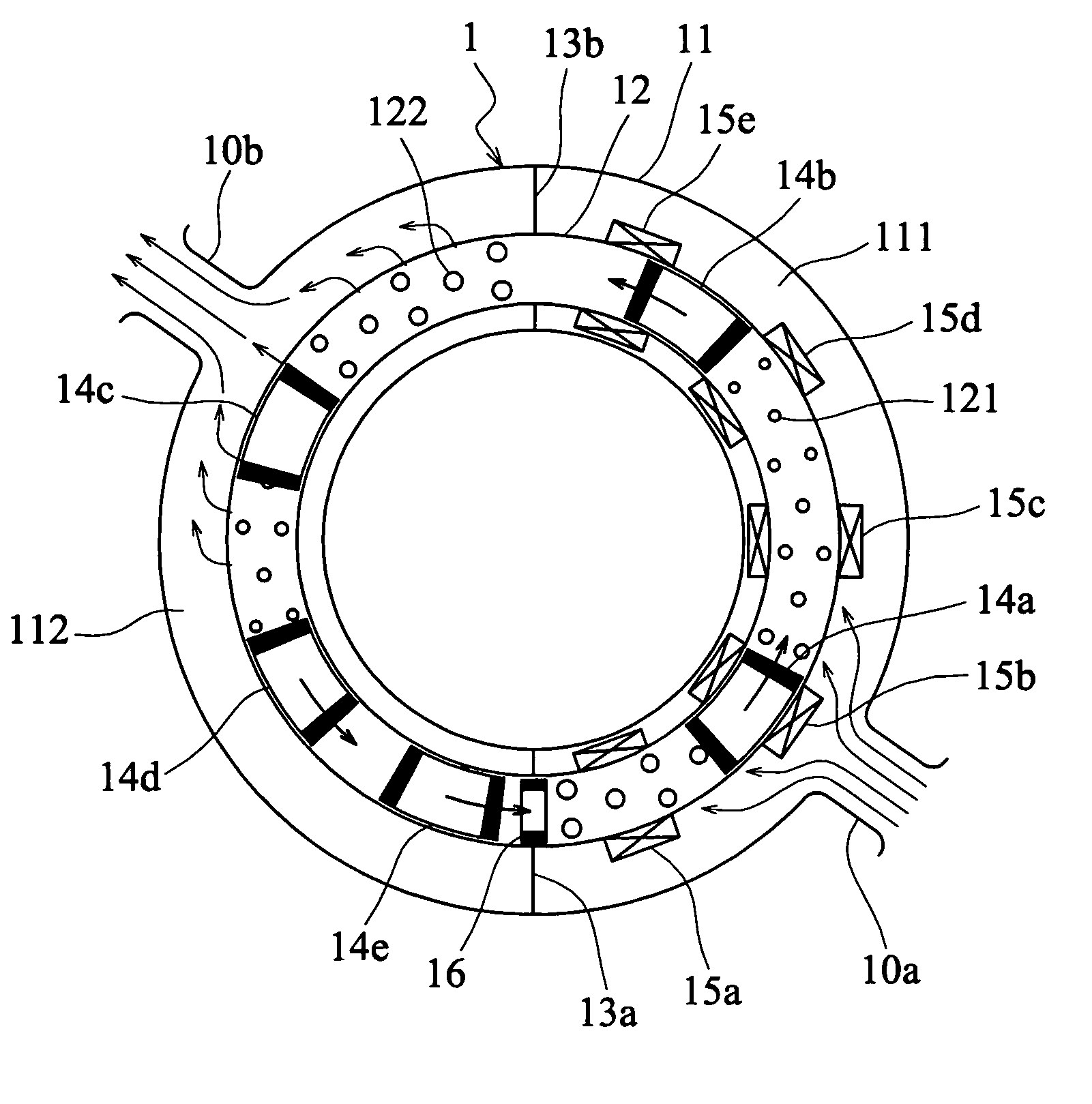

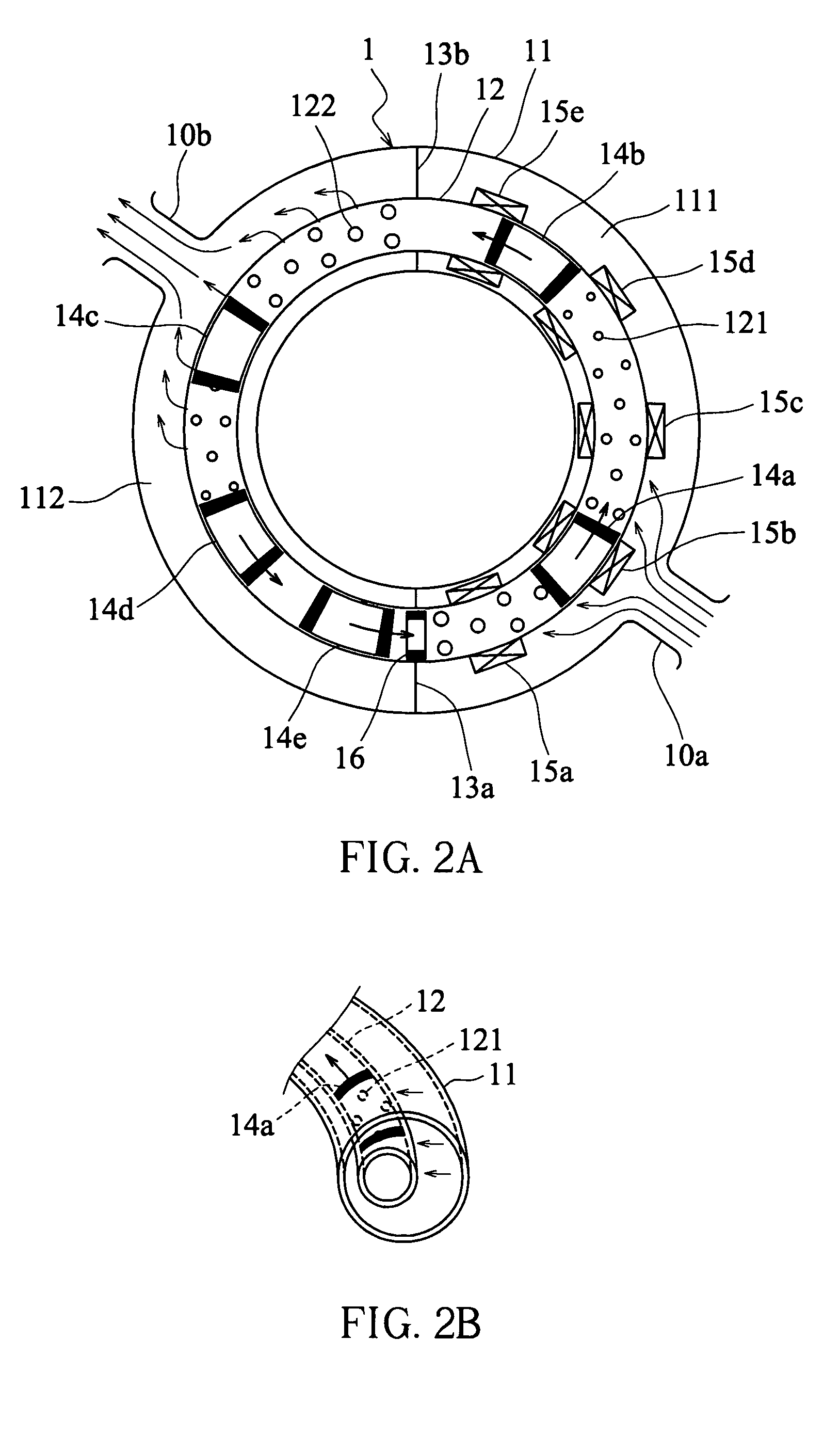

Singlestage and multistage electromagnetic revolutionary piston pump

InactiveUS20050169777A1Increase pressureImprove pumping efficiencyFree piston pumpsPiston pumpsInterior spaceEngineering

An electromagnetic revolutionary piston pump is disclosed. The electromagnetic revolutionary piston pump includes an inner tube, an outer tube, two annular separation plates, a plurality of pistons, and an electromagnetic coil. The inner tube has a plurality of first and second through holes, and it accommodates the abovementioned pistons to revolve inside. The outer tube has an intake opening and an exhaust opening, and it wraps the inner tube inside. In addition, the annular separation plates are disposed inside the outer tube for dividing the inner space of the outer tube into a first airproof space and a second airproof space. The first airproof space connects the intake opening and communicates the inner space of the first tube via the first through holes; the second airproof space connects the exhaust opening and communicates the inner space of the first tube via the second through holes. Moreover, the electromagnetic coil is mounted on the wall outside of the inner tube in the first airproof space for exerting magnetic force onto the pistons.

Owner:DELTA ELECTRONICS INC

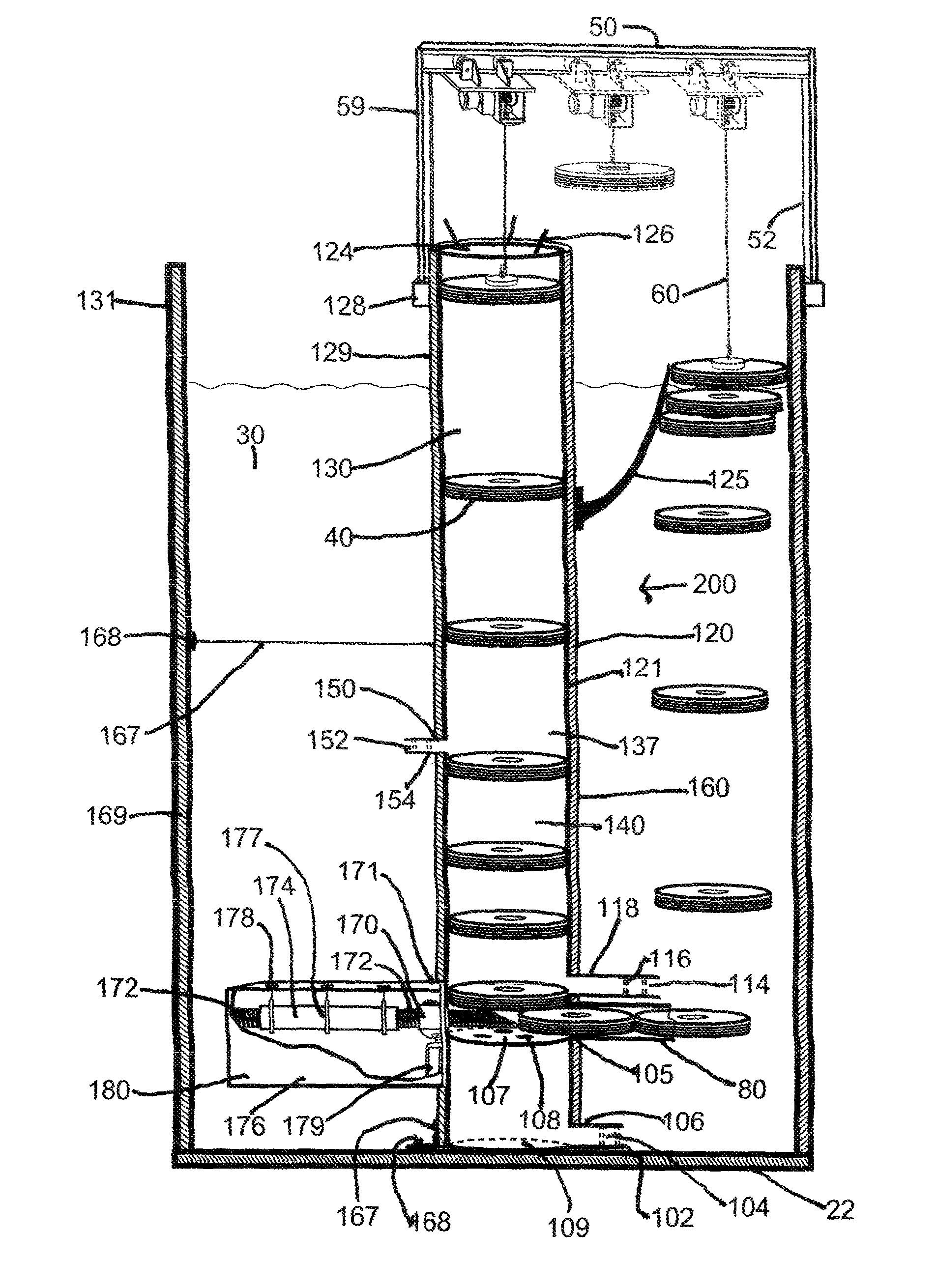

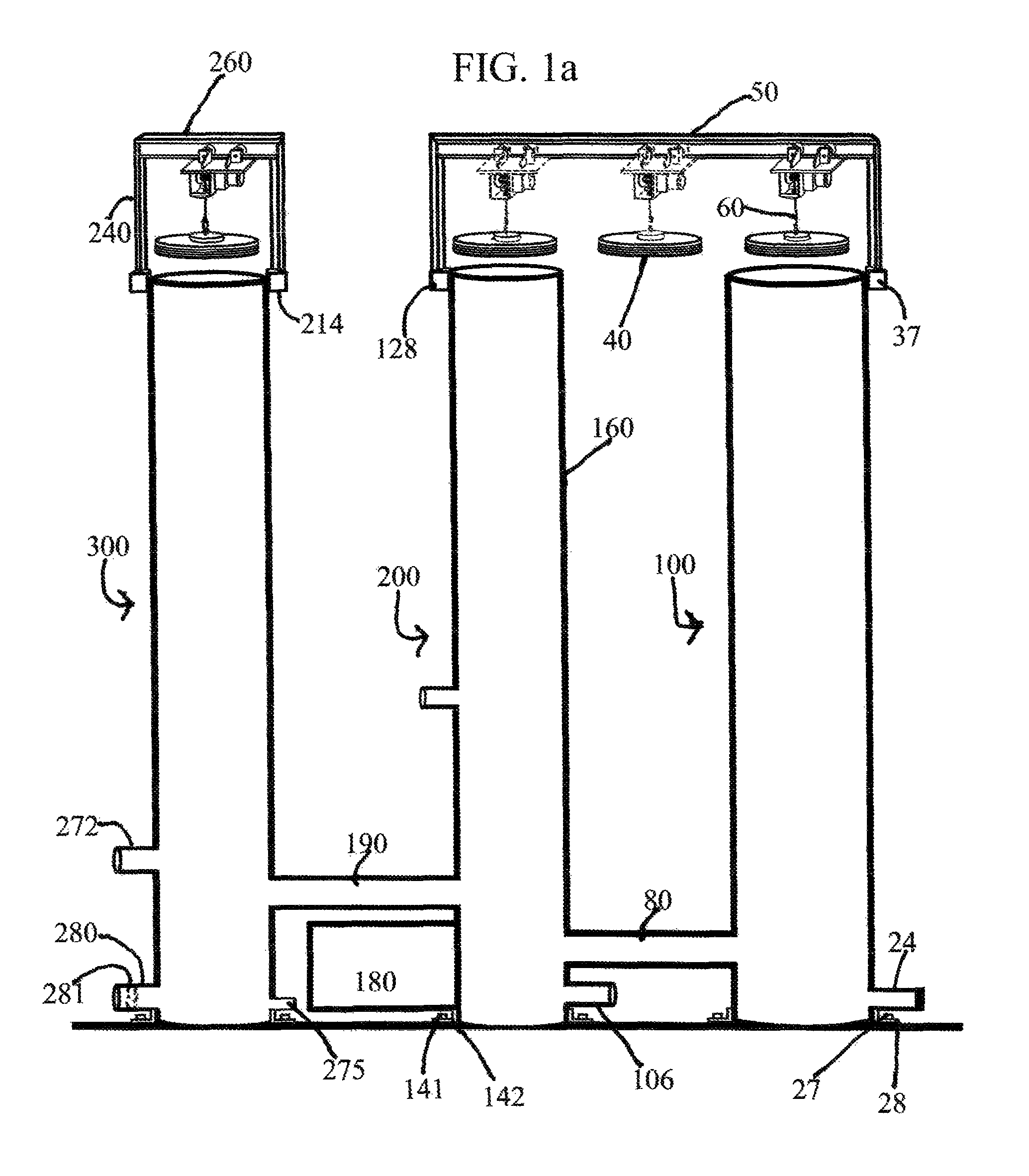

Multipurpose gravity air compressor

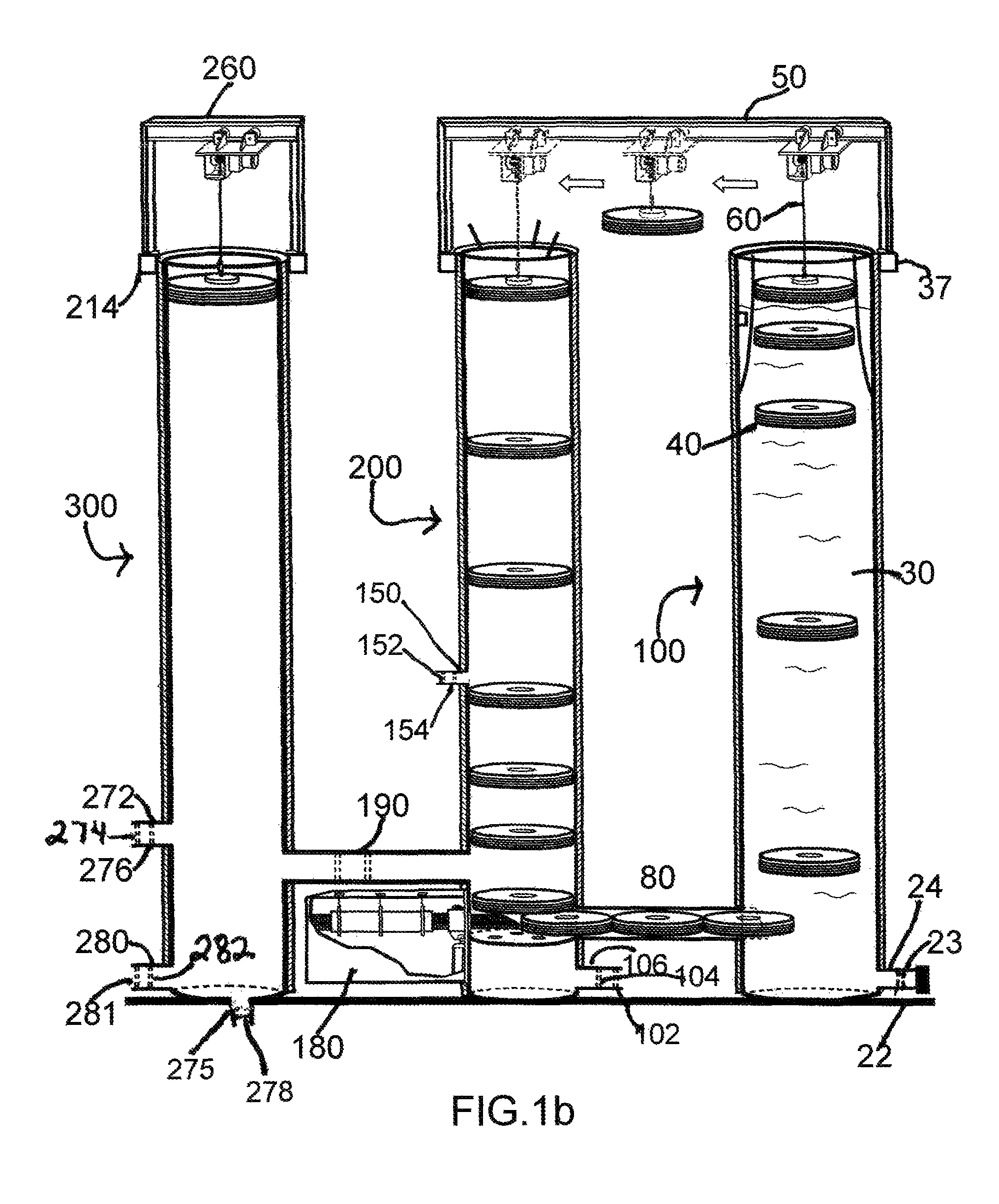

InactiveUS8920135B2Readily availablePositive displacement pump componentsFree piston pumpsElectricityCompressed fluid

A multipurpose gravity air compressor employs a piston (40) traveling down a cylinder (129) by the force of gravity compressing compressible fluid (140) in one or more compressible fluid chambers (137). Compressed fluid is emptied out of compressible fluid chambers (137) through compressible fluid exit (118) for use locally or downstream. A transporter such as transporter assembly 50 grabs piston (40) and recovers it back to opening (124) at predetermined intervals and deposits piston (40) into cylinder (129) to start another cycle. Multipurpose gravity air compressor through the generation of heat through compressing compressible fluid (140) also enjoys being a heat source. Air compressor 200 can provide a means for producing energy through compressing compressible fluid (140) and a source of heat for generating steam to produce electricity on-site or downstream. Water (condensation), possibly thousands of gallons a year, could be another rainfall-independent water source advantage enjoyed.

Owner:DAILY DENNIS EUGENE

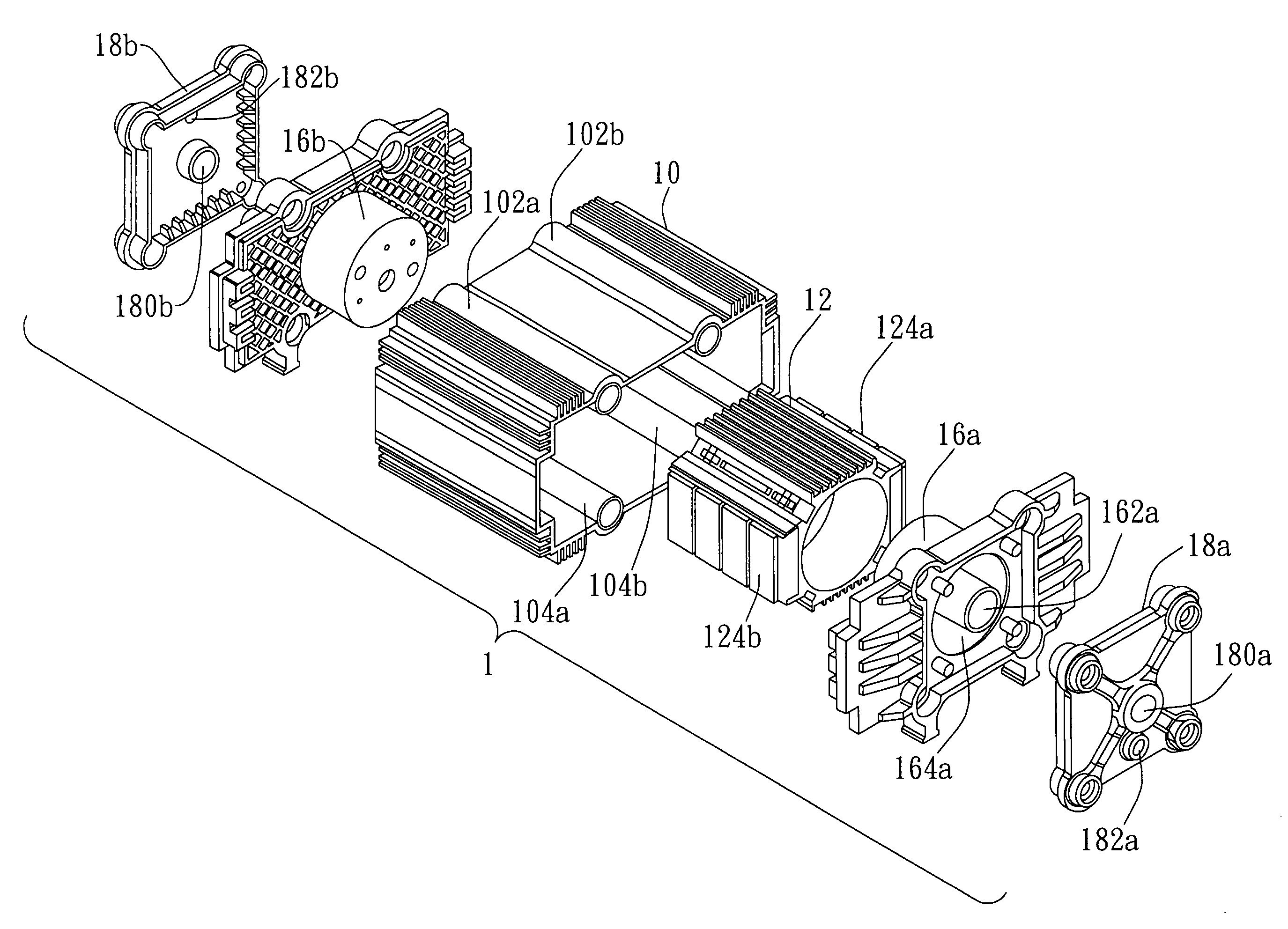

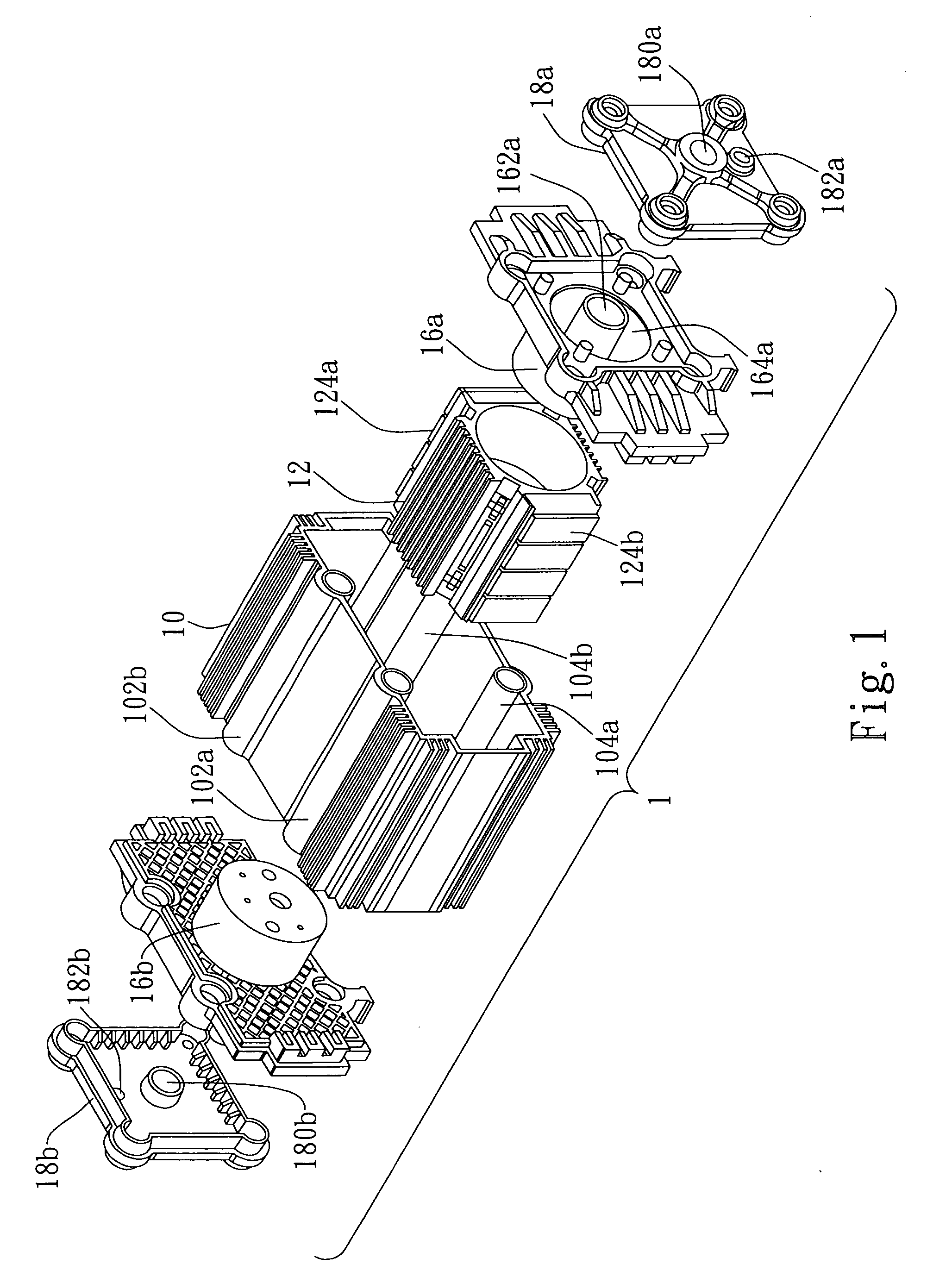

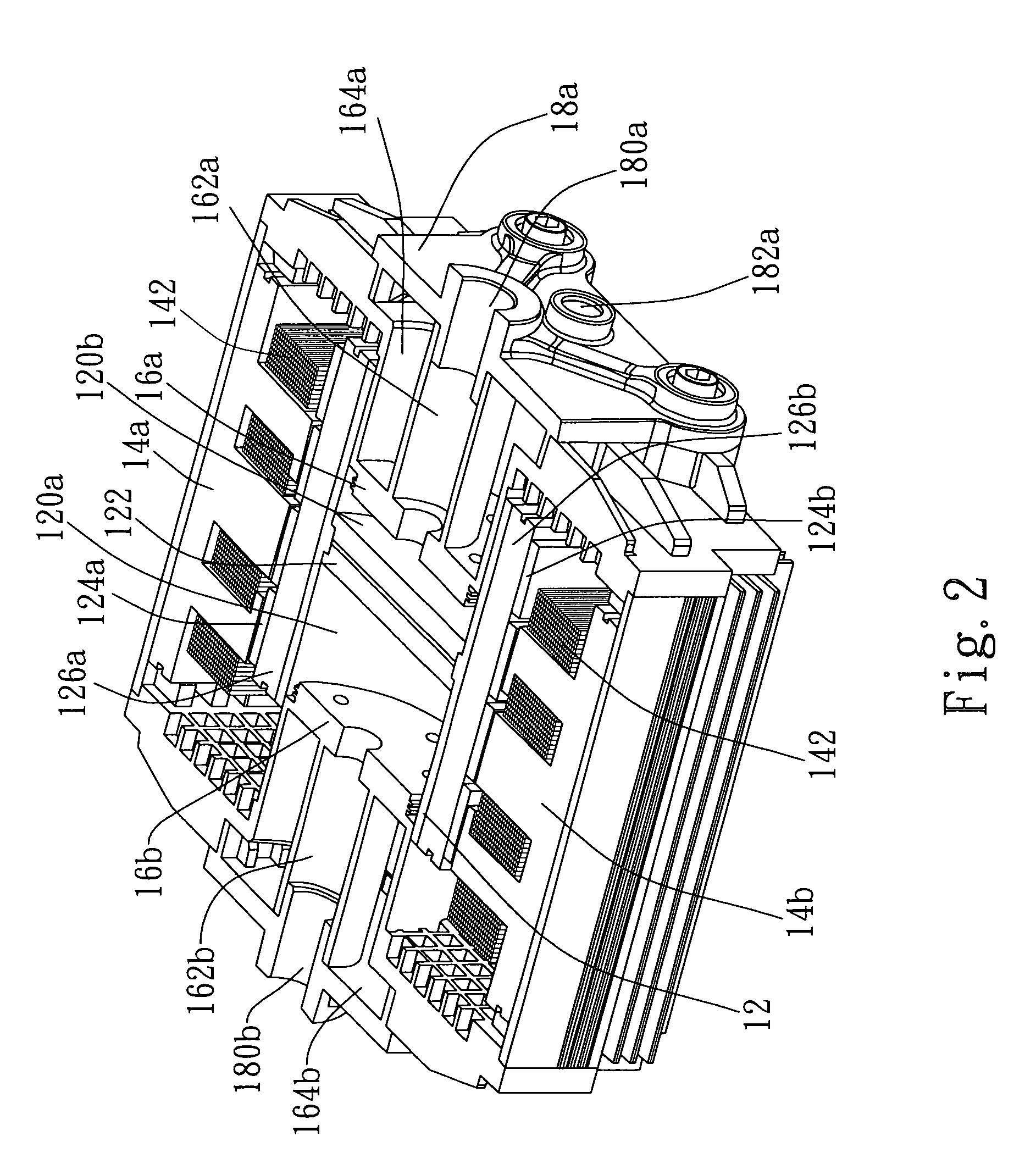

Linear compressor with permanent magnets

InactiveUS20090148319A1Guaranteed uptimeSaves extended lengthFree piston pumpsPiston pumpsLinear compressorAlternating current

This invention provides a compressor with brushless single-phase linear motor, which includes a movable cylinder associated with a permanent magnet array, at least a stationary electromagnetic winding set and a pair of stationary pistons. A partition plate is disposed in the movable cylinder to form a first sub-cylinder and a second sub-cylinder. The front ends of the pair of the stationary pistons are respectively placed in either of two openings of the movable cylinder at its two ends. An alternate current applied to the stationary electromagnetic winding set to generate alternately attracting / repelling forces to the permanent magnet array. The movable cylinder is hence alternately pushed forward and backward. The volumes of the first and second sub-cylinders are changed to compress air in the first sub-cylinder or the second sub-cylinder.

Owner:IND TECH RES INST

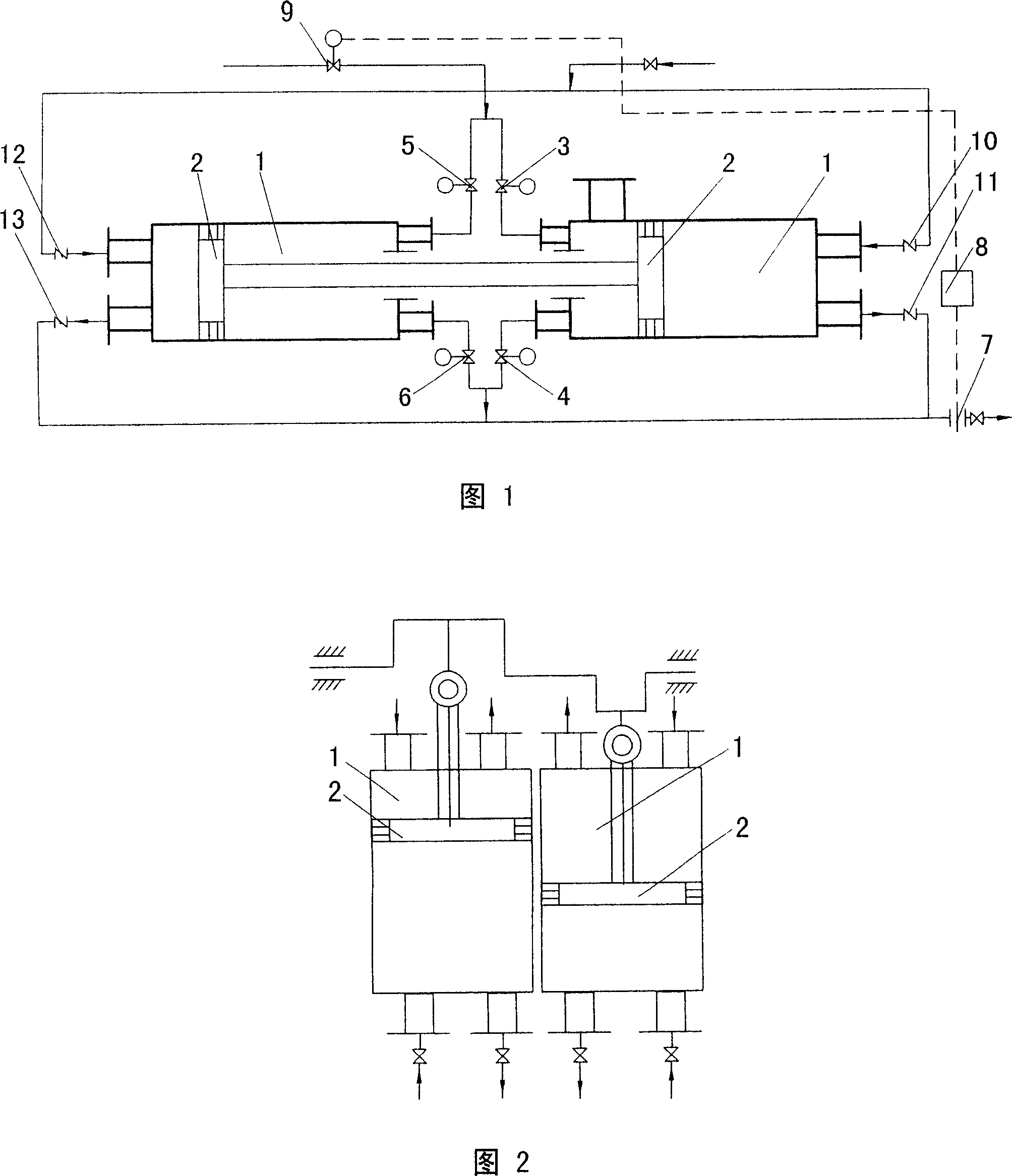

Synchronous movement realization based free-piston compressor

ActiveCN104912770AImprove bearing capacityFree piston pumpsPositive-displacement liquid enginesExhaust valveEngineering

The invention discloses a synchronous movement realization based free-piston compressor. A gas storage tank is connected with a cushion cylinder and a compressor cylinder, a power cylinder is arranged in the gas storage tank and arranged in the cushion cylinder and the compression cylinder, power pistons are arranged in the power cylinder and connected with piston rods, the piston rods are connected with a cushioning piston and a compressor piston, the cushioning piston is arranged in the cushion cylinder, and the compressor piston is arranged in the compressor cylinder. The compressor cylinder is provided with a first suction valve and a first exhaust valve, the power is provided with a gear, a gear shaft is arranged in the gear and fixed to the power cylinder, and racks are arranged on the gear, meshed with the gear and fixed to the piston rods correspondingly. The power cylinder is provided with suction holes and exhaust holes. The free-piston compressor can make moving piston sets completely equal in mass, inertia force during operation of a machine is fully balanced, bearing capacity is large, and accurate control in stroke is realized.

Owner:MIANYANG POWER SUPPLY COMPANY STATE GRID SICHUANELECTRIC POWER +1

Hydraulic driving air compressor

ActiveCN108644093AHighly integratedOverall small sizePositive displacement pump componentsFree piston pumpsGas compressorEngineering

The invention relates to a hydraulic driving air compressor. The hydraulic driving air compressor is characterized by comprising a valve shell, a left cylinder body provided with a left air chamber, aright cylinder body provided with a right air chamber, a piston which is provided with an axial channel and in a T shape, a large valve core, a small valve core, a left plunger and a right plunger, wherein the diameter of the large valve core is greater than the diameter of a valve opening; and the left plunger is arranged in the left cylinder body and can slide left to right, the inner end of the left plunger is connected with the left end of the axial channel of the piston and can slide left to right along with the piston, and the inner end of the right plunger is connected with the right end of the axial channel of the piston and can slide left to right along with the piston. The air compressor has high integration degree and compact volume; and because the second outlet end of a firstthrough-flow hole communicates with an oil returning cavity and a left piston cavity, a certain distance is arranged from each of the left and right ends of the piston to the bottom surface of the corresponding cylinder body, and in this way, the fact that reversing of a liquid-controlled reversing valve assembly can be completed before the piston collides with two end covers is ensured, therefore, non-impact vibration and less noise are achieved.

Owner:深圳市凯福机电设备有限公司

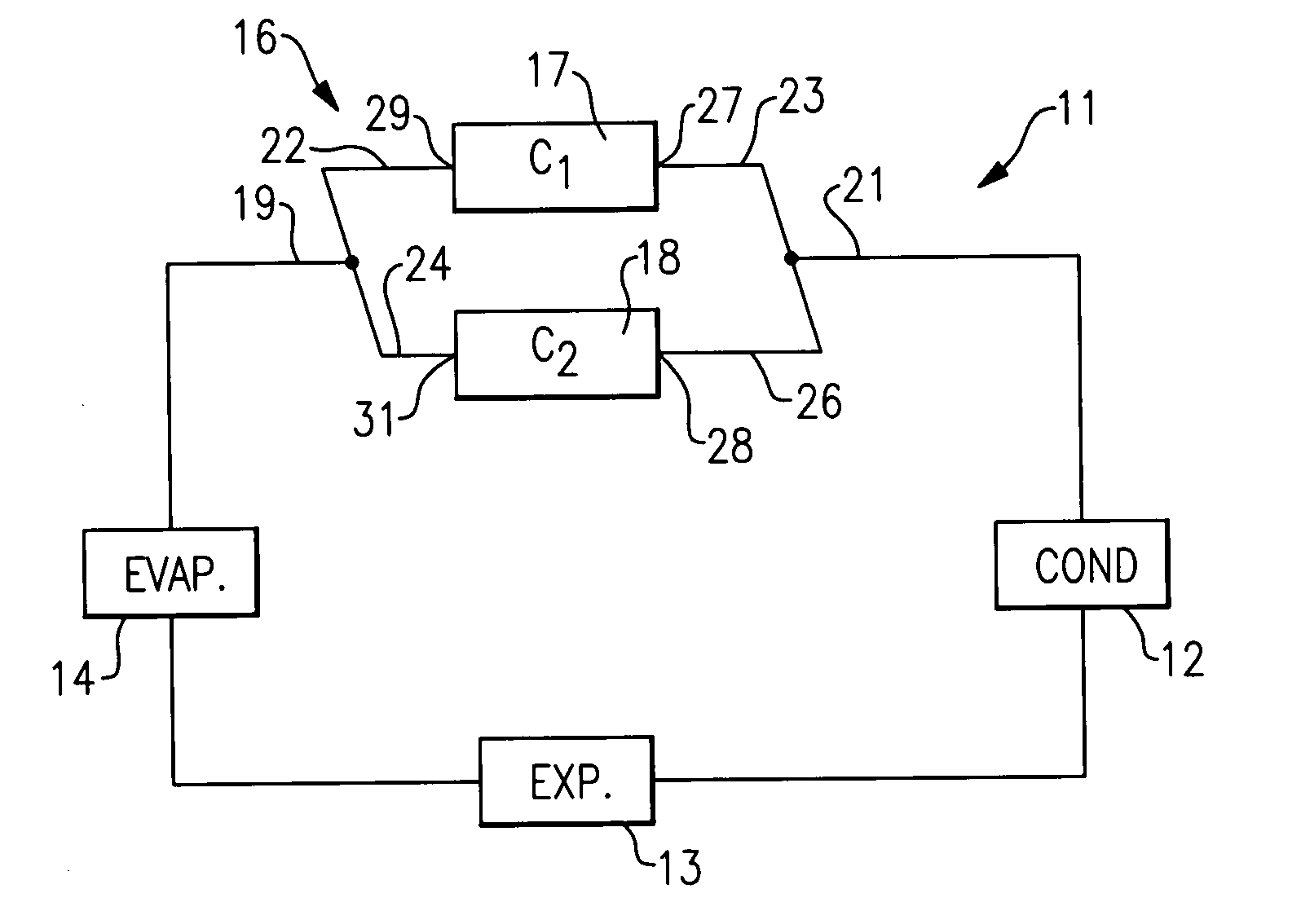

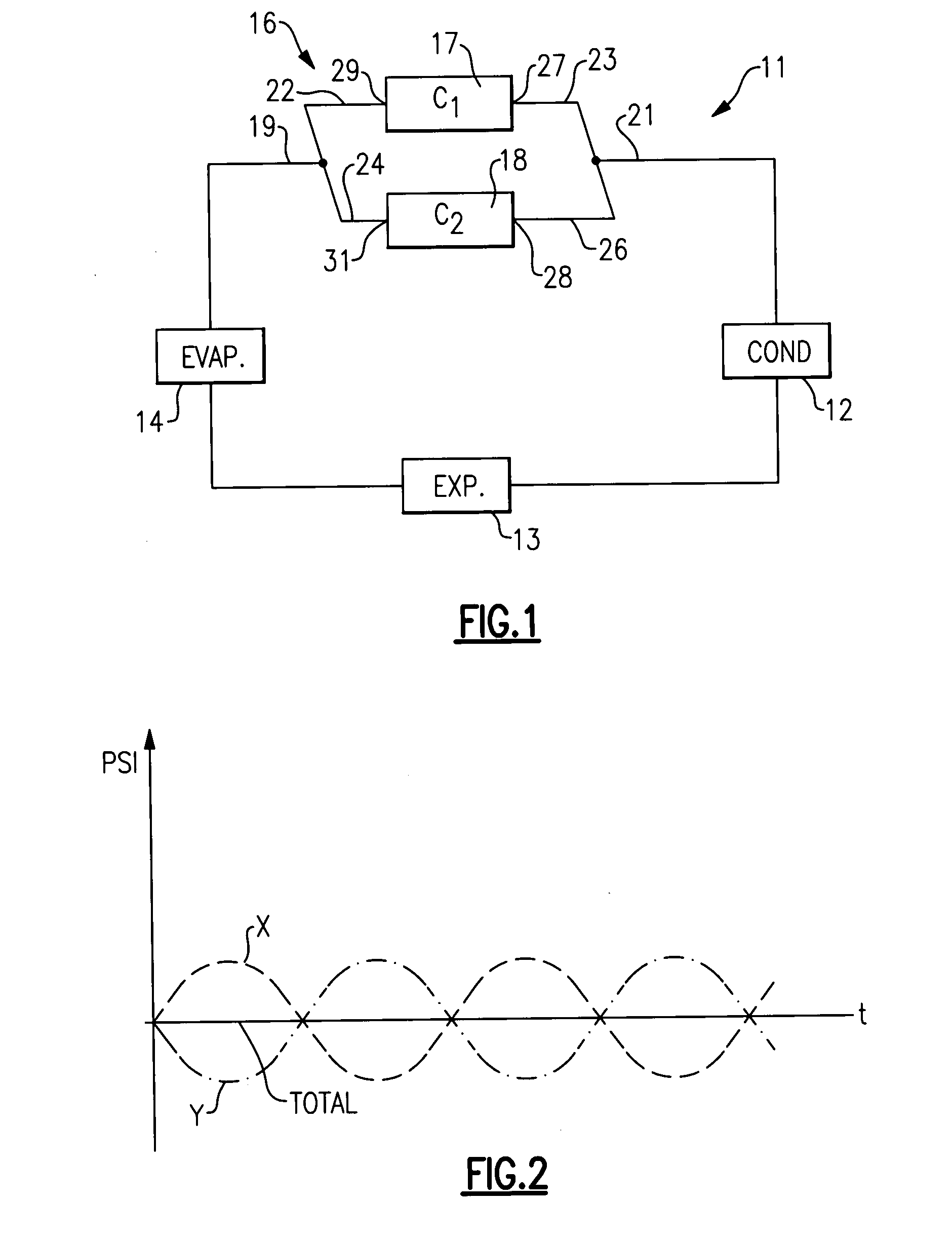

Pulsation attenuation in systems with multiple compression elements

InactiveUS20100215516A1Positive displacement pump componentsFree piston pumpsUltrasound attenuationEngineering

In compression systems having multiple sources of pulsation induced noise, provisions are made to reduce the noise by selectively varying the length of adjacent refrigerant lines leading to a common refrigerant manifold. Each of the refrigerant lines is associated with a particular noise source. The feature can be incorporated into compressors operating in parallel or in a single multi-rotor compressor having multiple suction or / and discharge ports. It is equally applicable to both discharge and suction ports.

Owner:CARRIER CORP

Electric linear compressor

ActiveCN105298792AIncrease specific thrustImprove controllabilityFree piston pumpsPiston pumpsPower factorNew energy

The invention provides an electric linear compressor which can be applied to new energy automobiles and has the characteristics of being efficient and compact. A stator of the electric linear compressor is composed of coaxial inner and outer magnetic yokes with annular structures and a permanent magnet array. Halbach arrays formed in the radial and axial magnetization directions are adopted as the permanent magnet array. A free piston assembly is connected with a rotor coil through a connection assembly, and the movement direction of the free piston assembly and the movement direction of the rotor coil are consistent with the direction of the axis of the stator. The rotor coil can make reciprocating linear movement in a work air gap; and the free piston assembly is driven by the rotor coil and a resonant spring jointly to make simple harmonic vibration at the static balance position, the amplitude is adjustable, and therefore the air inflow, compression, exhaust and expanding process can be completed. The electric linear compressor has the characteristics of being high in specific thrust, controllability and resonant frequency, the power factor of the linear compressor can be remarkably improved, and the volume specific energy is reduced.

Owner:NANJING UNIV OF SCI & TECH

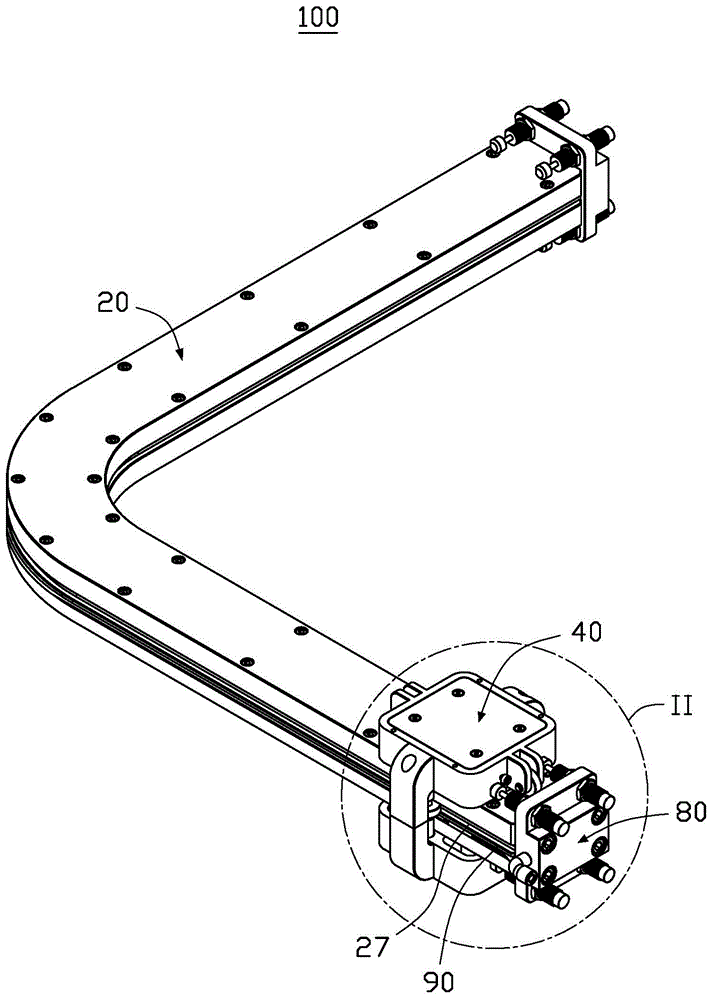

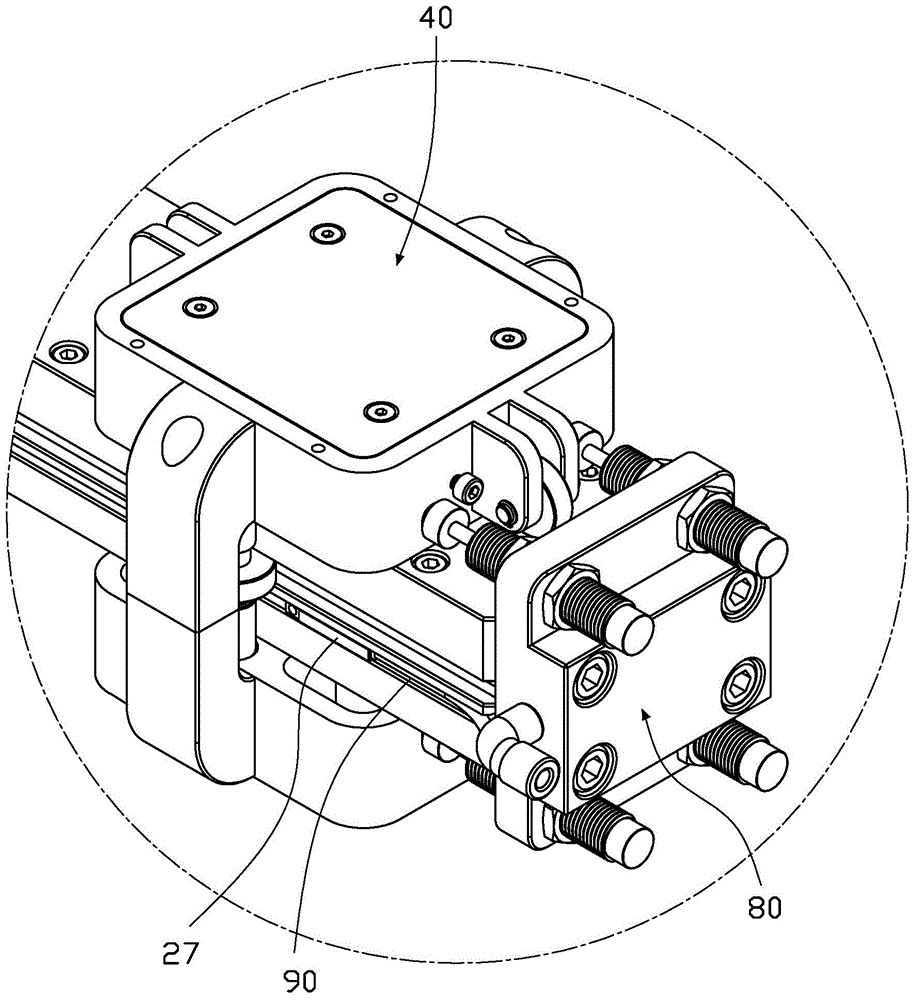

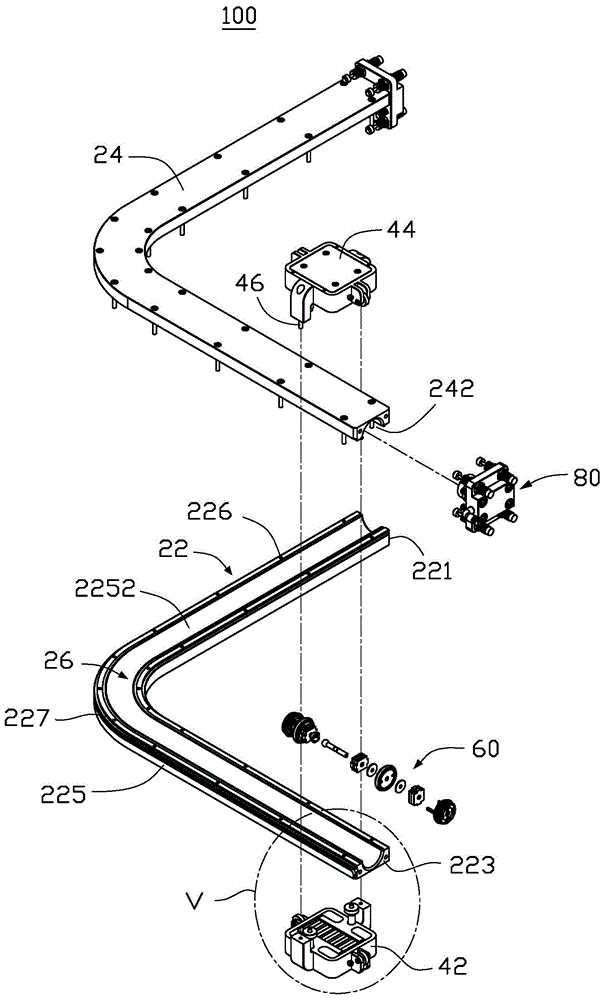

Air cylinder

ActiveCN106286461ANovel structurePositive displacement pump componentsPlungersCylinder blockAir cavity

The invention discloses an air cylinder which comprises an arc-shaped cylinder body and a piston assembly, wherein an air cavity is formed in the arc-shaped cylinder body; the piston assembly is movably accommodated in the air cavity. The air cylinder further comprises a first bearing part; the first bearing part comprises a shell and a first magnet fixedly accommodated in the shell; the shell is mounted on the outer side surface of the arc-shaped cylinder body in a sliding manner; the piston assembly comprises a first piston and a second piston rotatably connected with each other; the first piston comprises a first connecting rod as well as a second magnet and a piston body sequentially fixedly arranged on the first connecting rod in a sleeving manner; the second piston comprises a second connecting rod as well as another second magnet and another piston body sequentially fixedly arranged on the second connecting rod in a sleeving manner; the second connecting rod is rotatably connected onto the first connecting rod; magnetism of each second magnet is opposite to that of the first magnet; and when external gas pushes the piston assembly to move from one end of the arc-shaped cylinder body to the other end of the arc-shaped cylinder body along the air cavity, the first bearing part can slide to the other end of the arc-shaped cylinder body from one end of the arc-shaped cylinder body on the outer side surface of the arc-shaped cylinder body along with the piston assembly.

Owner:FU TAI HUA IND SHENZHEN +1

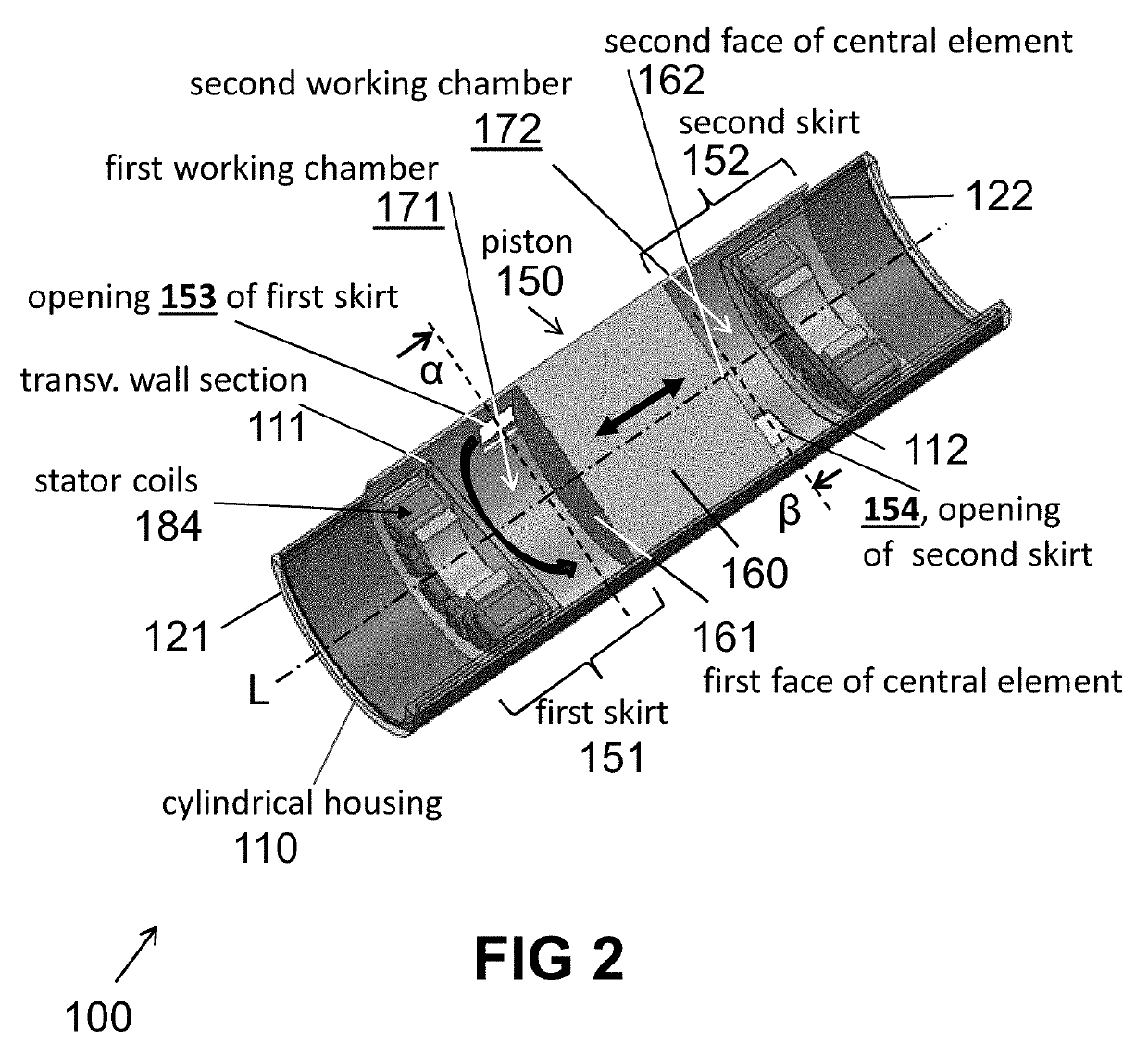

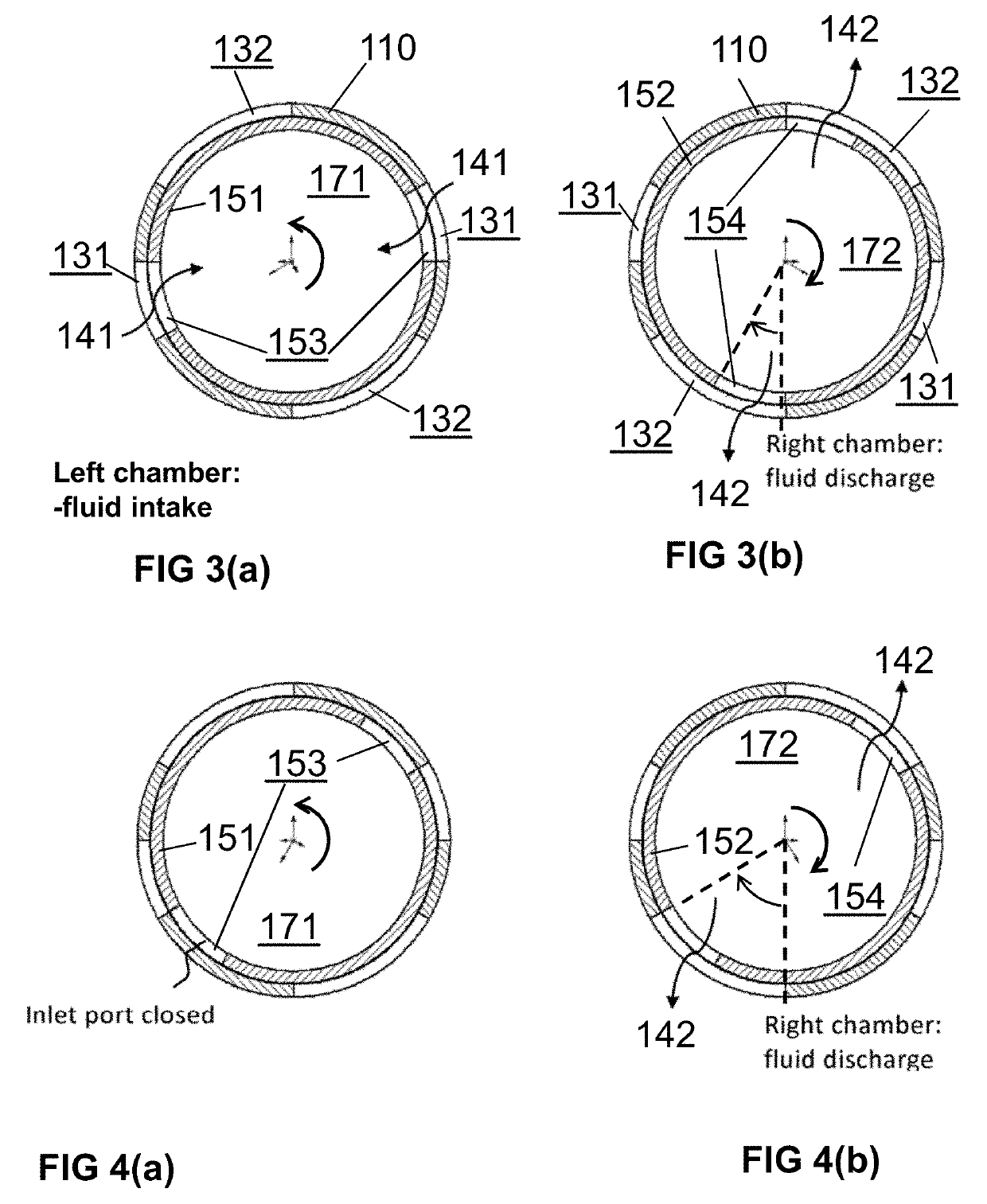

Free piston device

ActiveUS10472995B2Good free pistonGood free piston expanderMagnetic circuitFree piston pumpsDigital controlMechanical engineering

A free piston device, comprises a housing with a cylindrical inner wall having a first wall opening and a second wall opening; a cylindrical piston movable in axial direction and rotatable around its longitudinal axis; the piston comprising a first skirt forming a first chamber, said first skirt having at least a first opening in the form of a hole through the wall of the skirt for allowing passage of a fluid directly into or out of said chamber; control means for controlling axial and angular movement of said piston; sensing means for providing signals related to the axial position and / or the angular position of the piston; a digital control unit for rotating the piston around its longitudinal axis in synchronism with its axial movement.

Owner:UNIV GENT

Durable dart plunger

Owner:ENDURANCE ELEVATOR SOLUTIONS LLC

Method and device for operating an internal combustion engine having at least two cylinder banks

InactiveUS7165538B2Simple and precise mannerGood synchronizationElectrical controlInternal combustion piston enginesInternal combustion engineControl theory

A method and a device for operating an internal combustion engine having at least two cylinder banks are provided, each of the at least two cylinder banks having an air supply with an individual compressor, and a coordination of the compressors is possible in a simple and precise manner. In this context, a shared setpoint value is predefined for a characteristic variable for the rotational speed of a first compressor in a first air supply of a first cylinder bank, and a characteristic variable for the rotational speed of a second compressor in a second air supply of a second cylinder bank. An actual value of the characteristic variable for the rotational speed of the first compressor and an actual value for the characteristic variable for the rotational speed of the second compressor are corrected to the shared setpoint value.

Owner:ROBERT BOSCH GMBH

Extensible positive displacement pump

ActiveCN109989902AEasy to adjustReduce adjustment stepsPositive displacement pump componentsFree piston pumpsImpellerEngineering

The invention discloses an extensible displacement pump. The extensible displacement pump includes a pump body and a work cavity, an air cylinder mechanism is arranged in the work cavity and includesa right shell body fixedly connected with the inner wall of the work cavity through a first fixing ring, a lower sliding groove is formed in the wall of the work cavity, a lower sliding block is slidably arranged in the lower sliding groove, a ring-shaped sliding groove is formed in the wall of the right shell body, a ring-shaped sliding block is slidably arranged in the ring-shaped sliding groove, and a left shell body is fixedly connected with the ring-shaped sliding block. According to the extensible positive displacement pump, when the pumping speed needs to be adjusted, power supply poweror the impeller speed does not need to be adjusted, the thickness of a piston can be adjusted and extension of an air cavity is adjusted, the adjusting process is simple and fast, steps required foradjusting are reduced, the adjusting difficulty is reduced, and practicability is improved greatly.

Owner:江苏博利源机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com