Patents

Literature

39results about How to "Slow pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

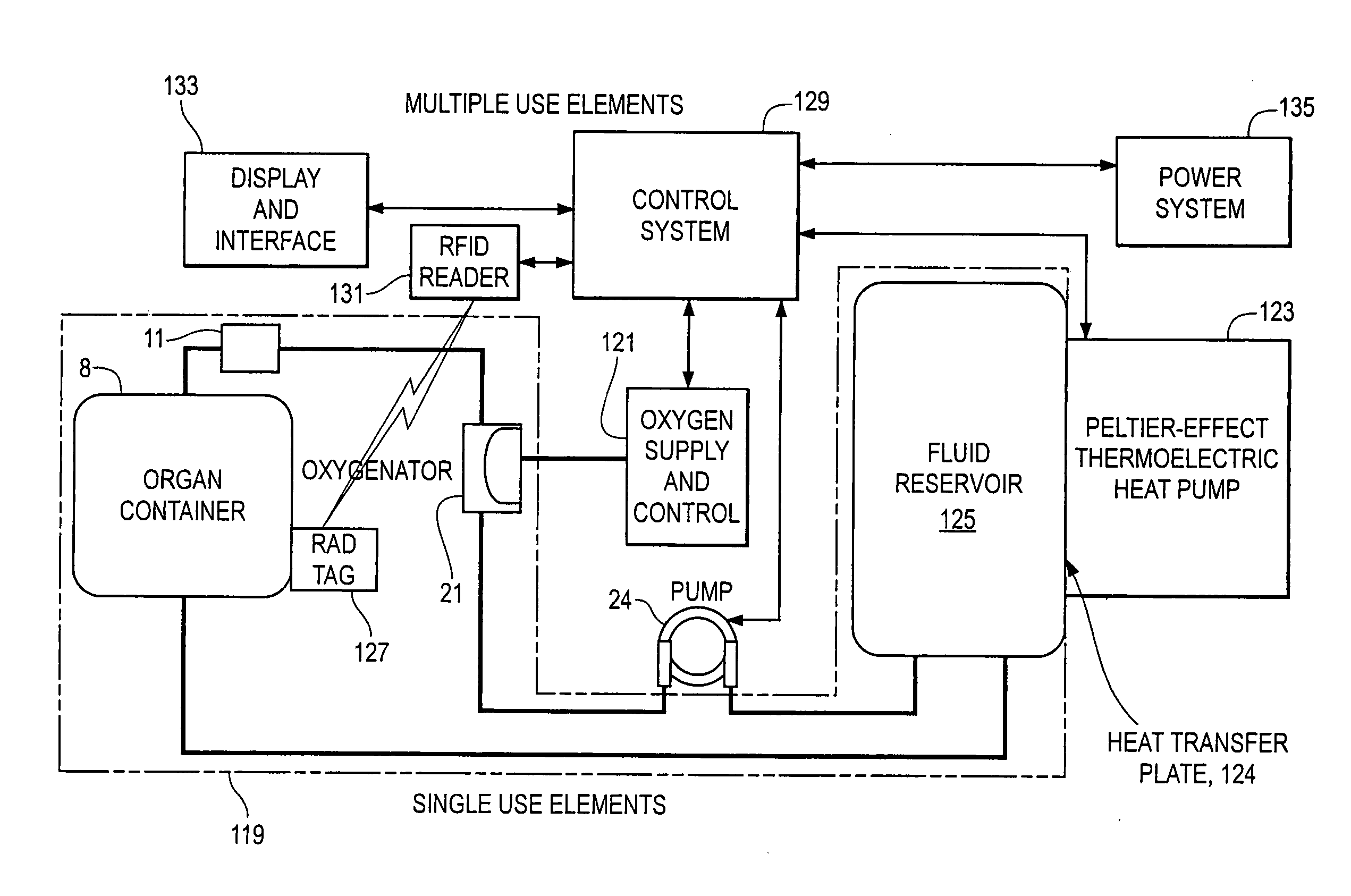

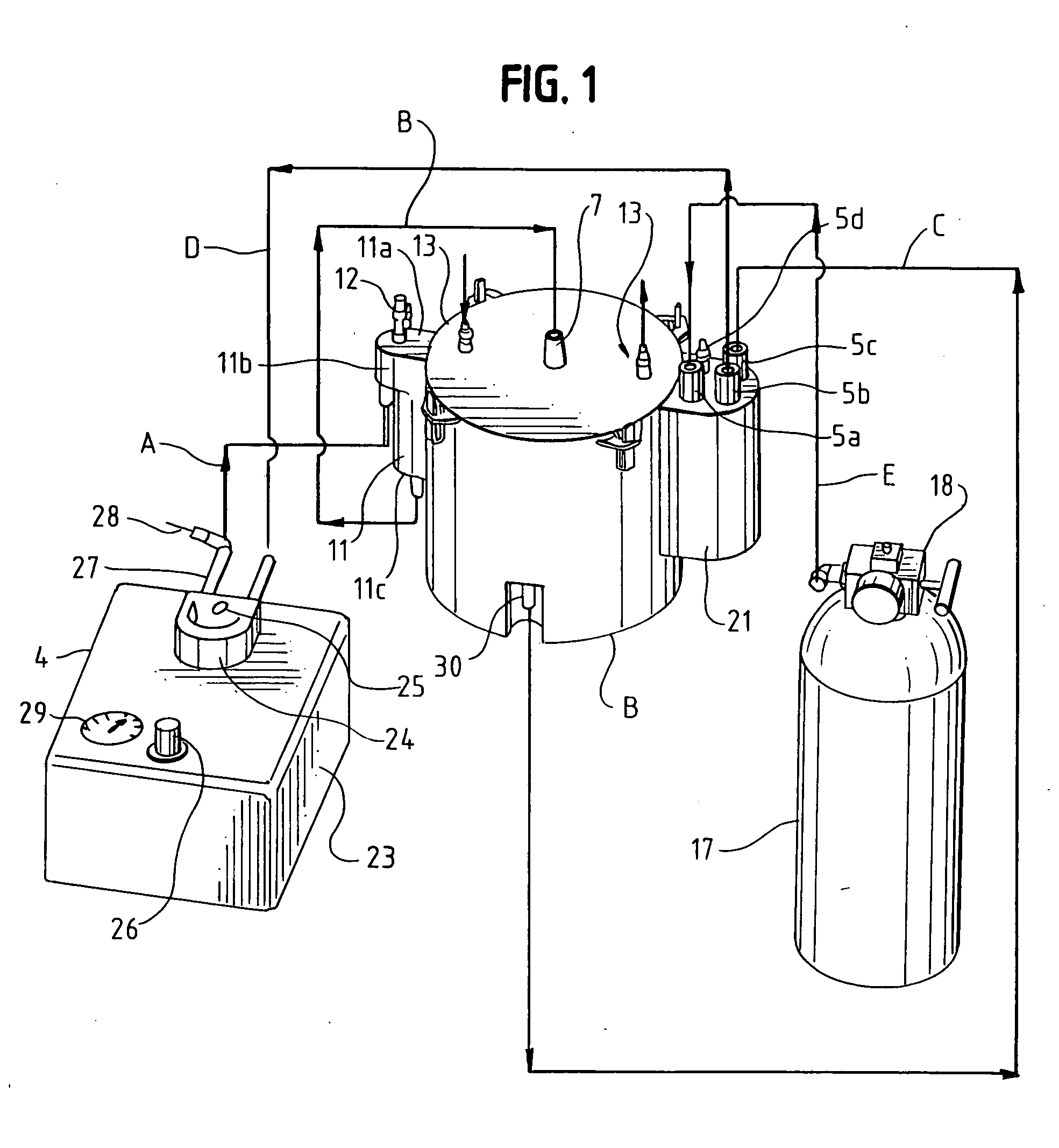

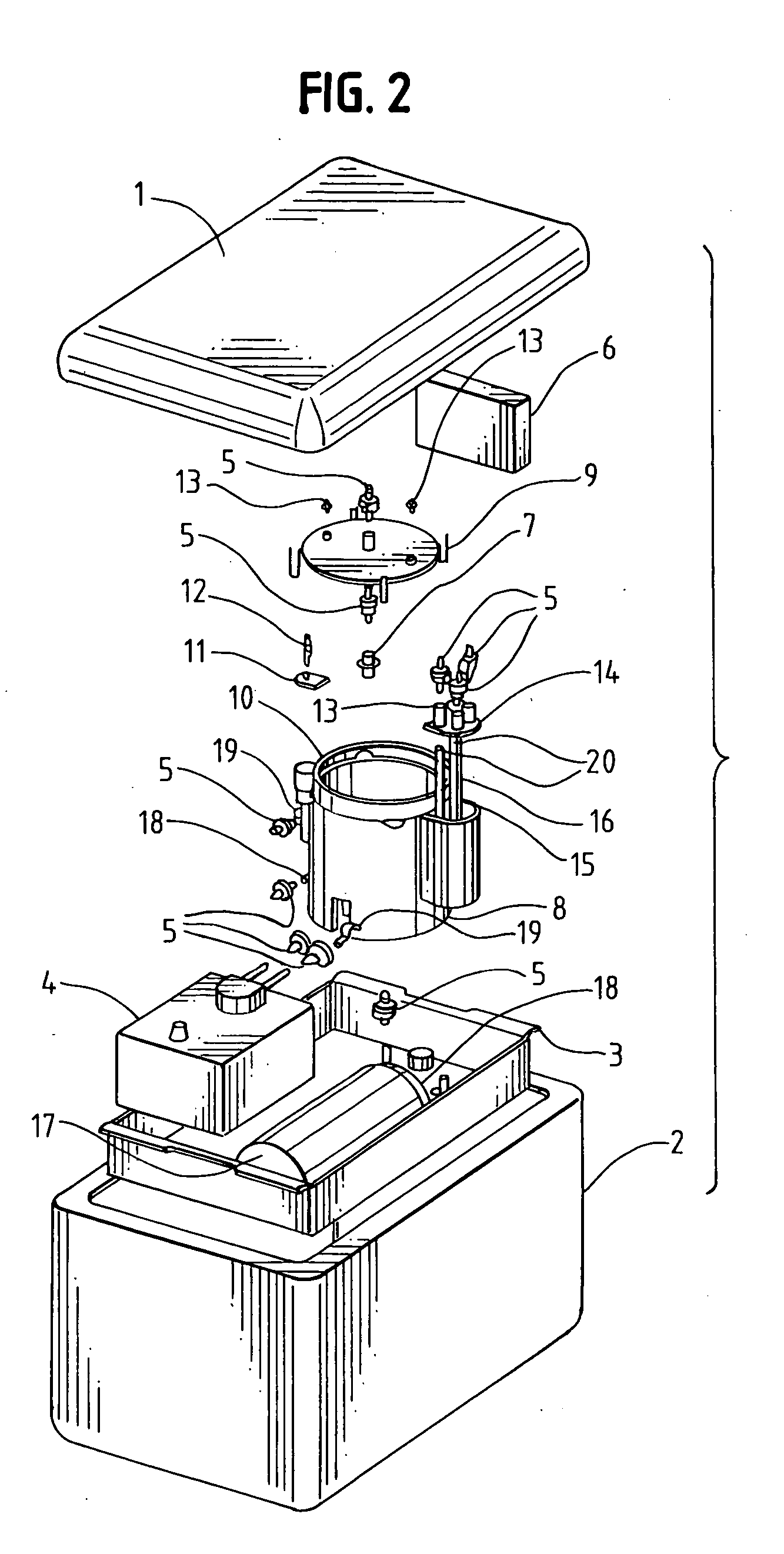

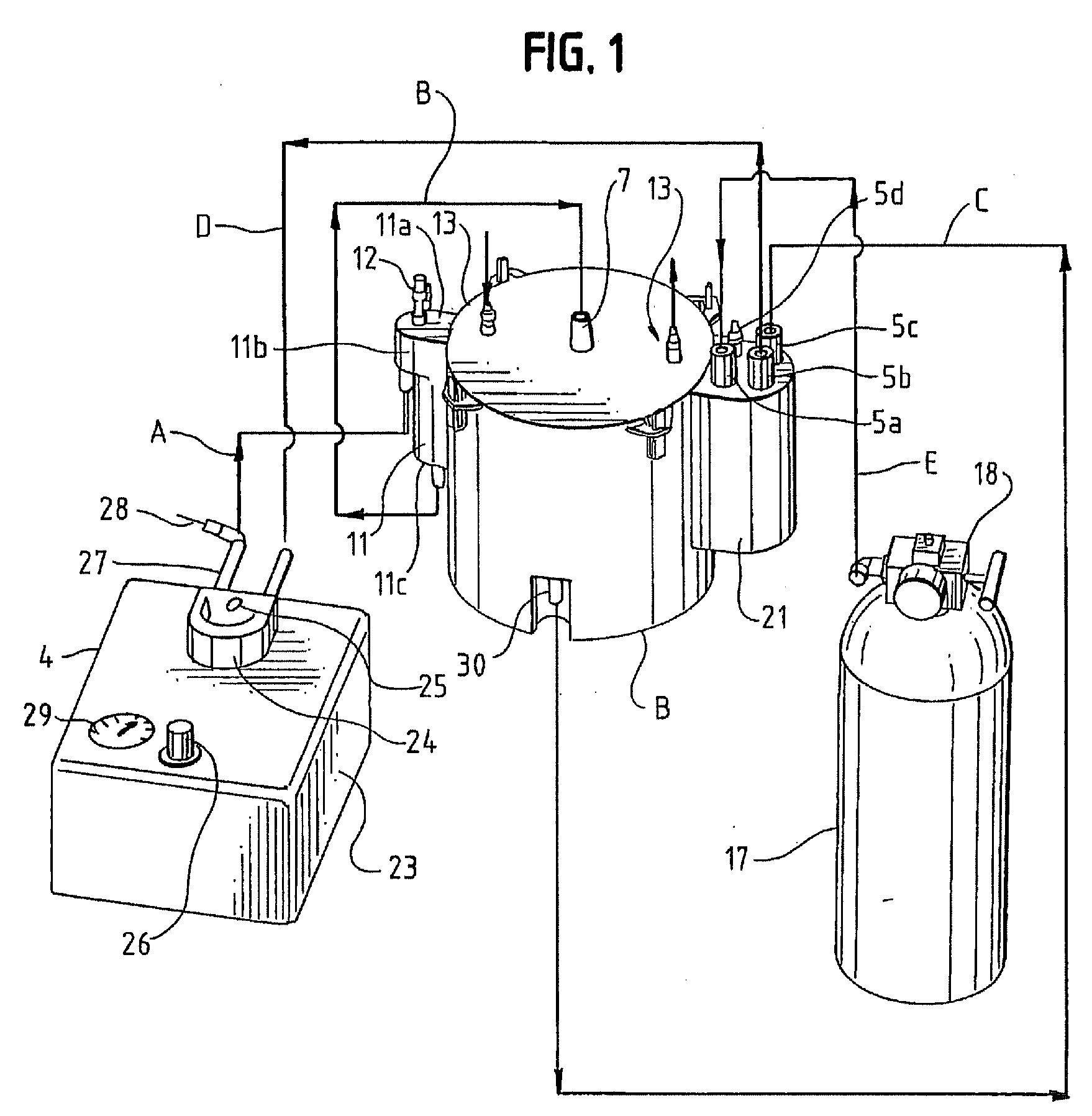

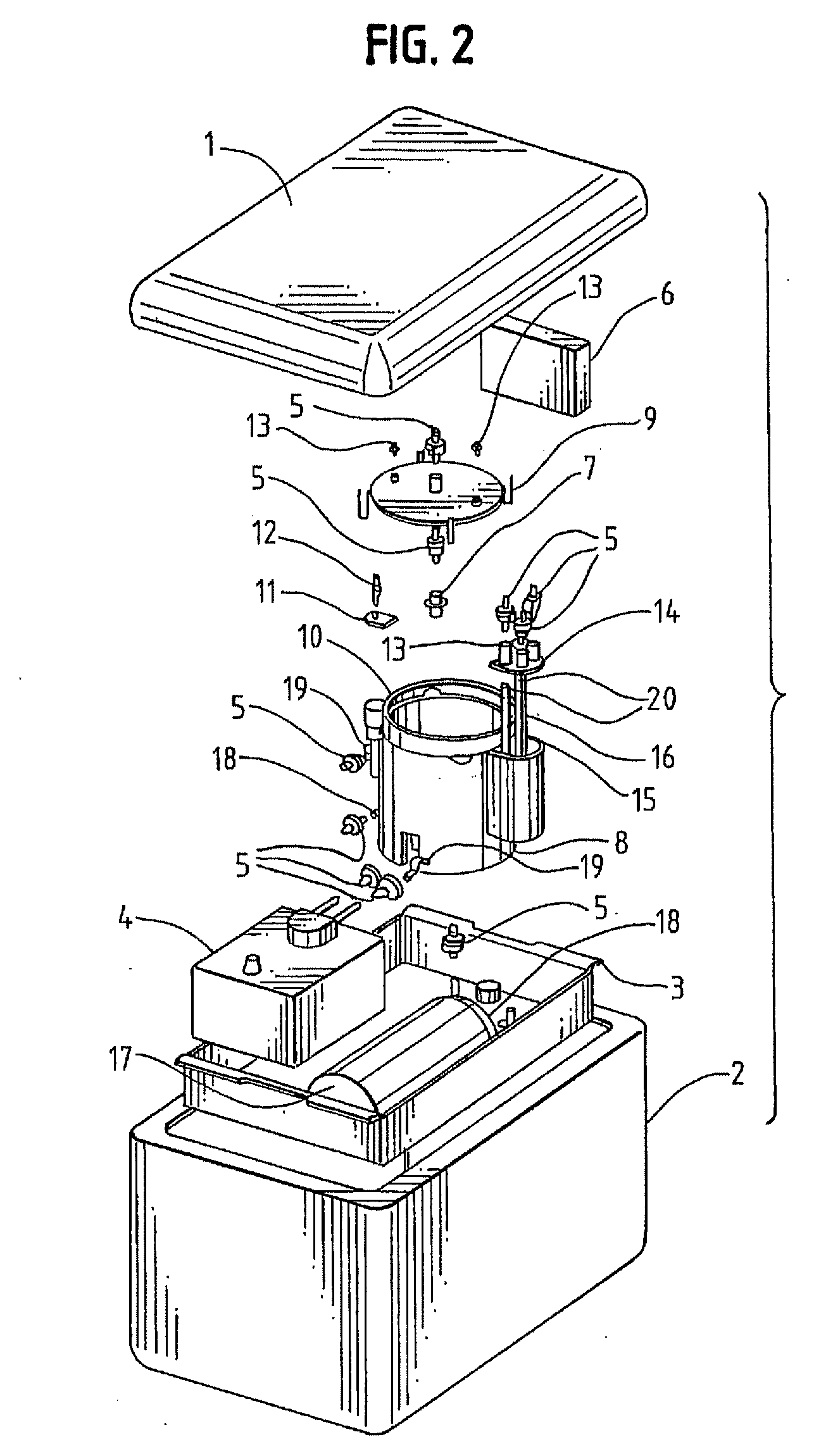

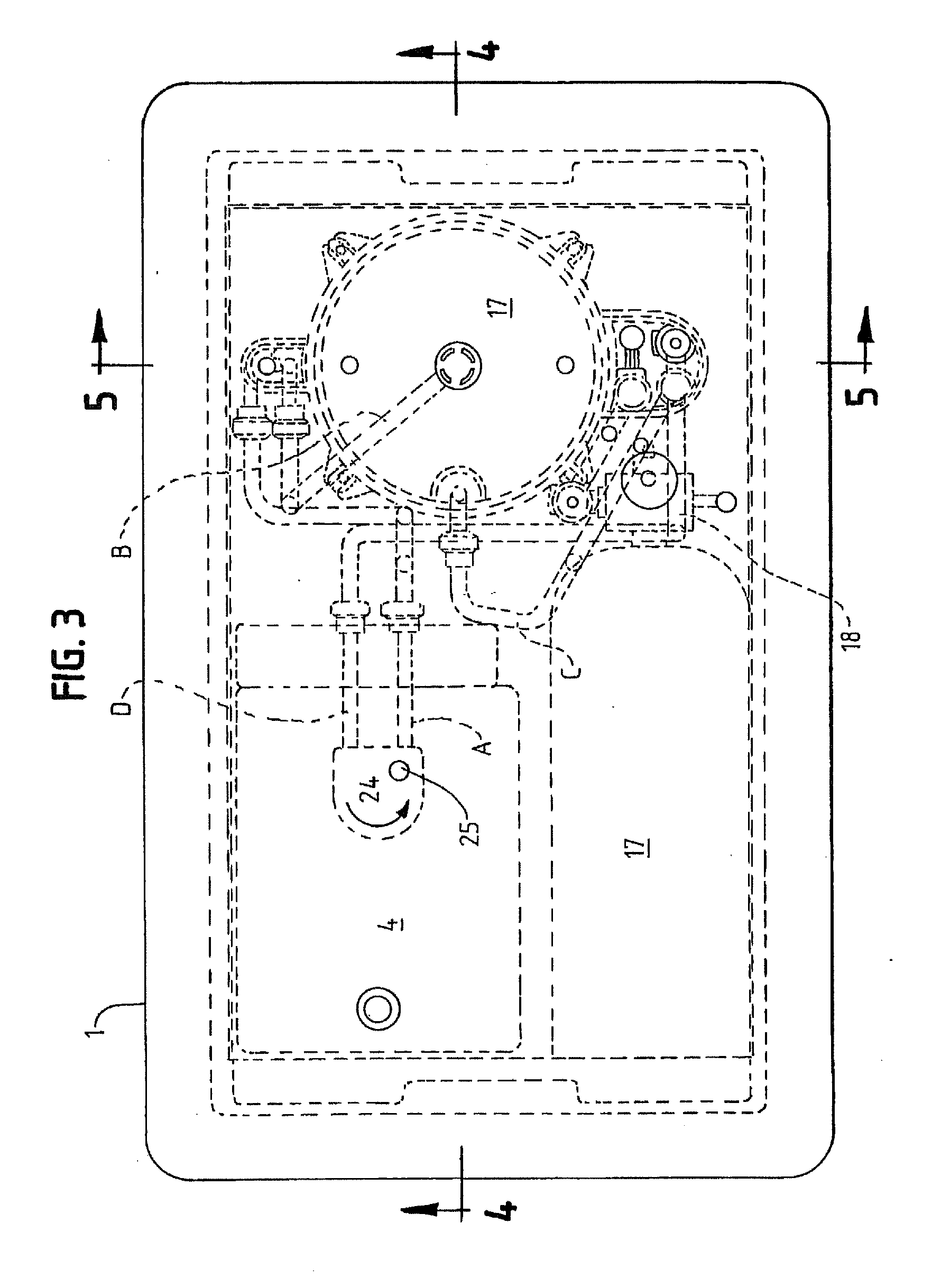

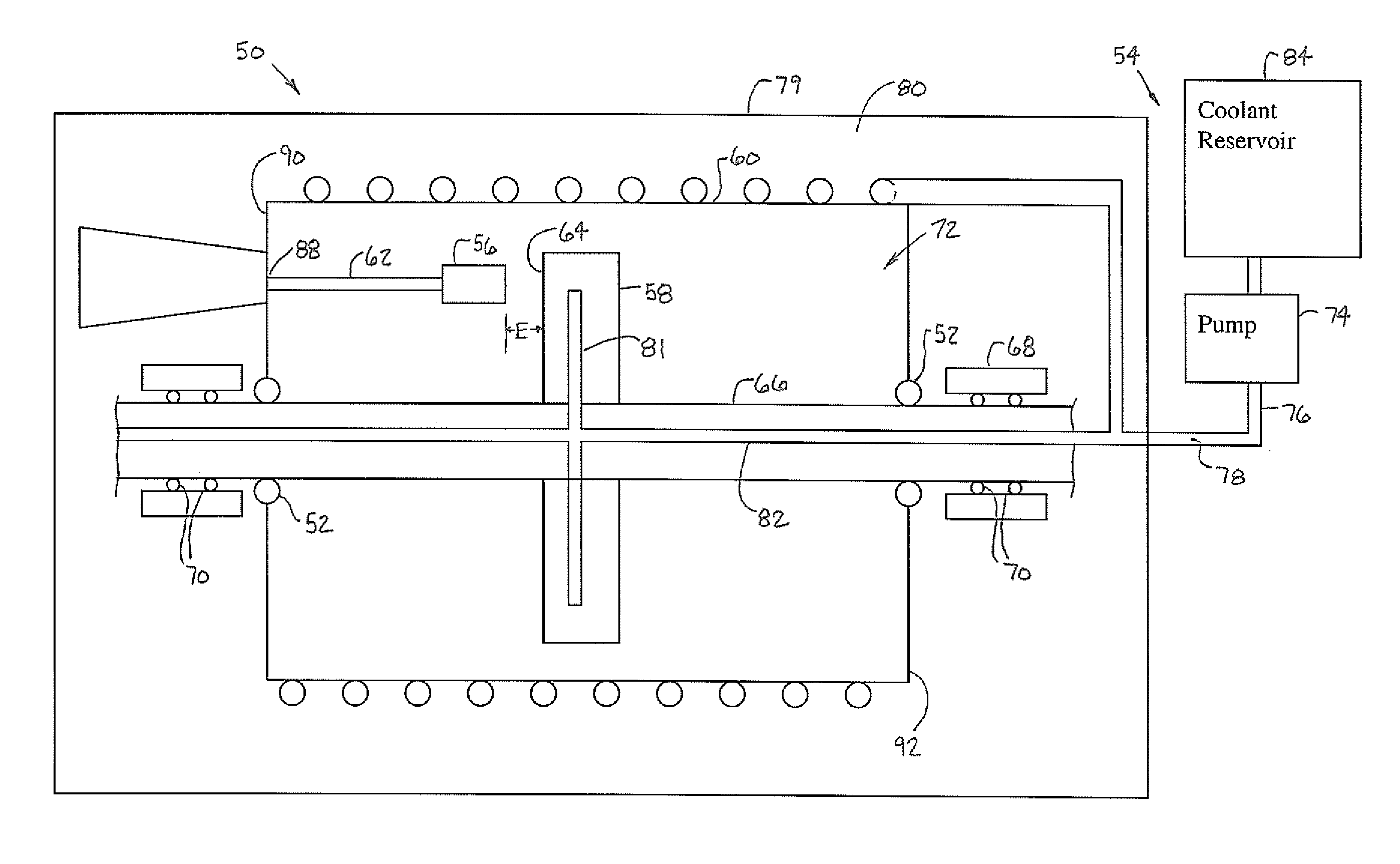

Organ preservation apparatus and methods

InactiveUS20050153271A1Increase the lengthReduce decreaseDead animal preservationMachines using electric/magnetic effectsNutrient solutionOxygen

This invention is a transportable organ preservation system that substantially increases the time during which the organ can be maintained viable for successful implantation into a recipient. A chilled oxygenated nutrient solution can be pumped through the vascular bed of the organ after excision of the organ from the donor and during transport. The device of the present invention uses flexible permeable tubing to oxygenate the perfusion fluid while the CO2 produced by the organ diffuses out of the perfusion fluid. One pressurized two-liter “C” cylinder can supply oxygen for up to 34 hours of perfusion time. The device can use a simple electric pump driven by a storage battery to circulate the perfusion fluid through the organ being transported. The vessel containing the organ to be transported can be held at a suitable temperature by a chiller.

Owner:ORGAN TRANSPORT SYST

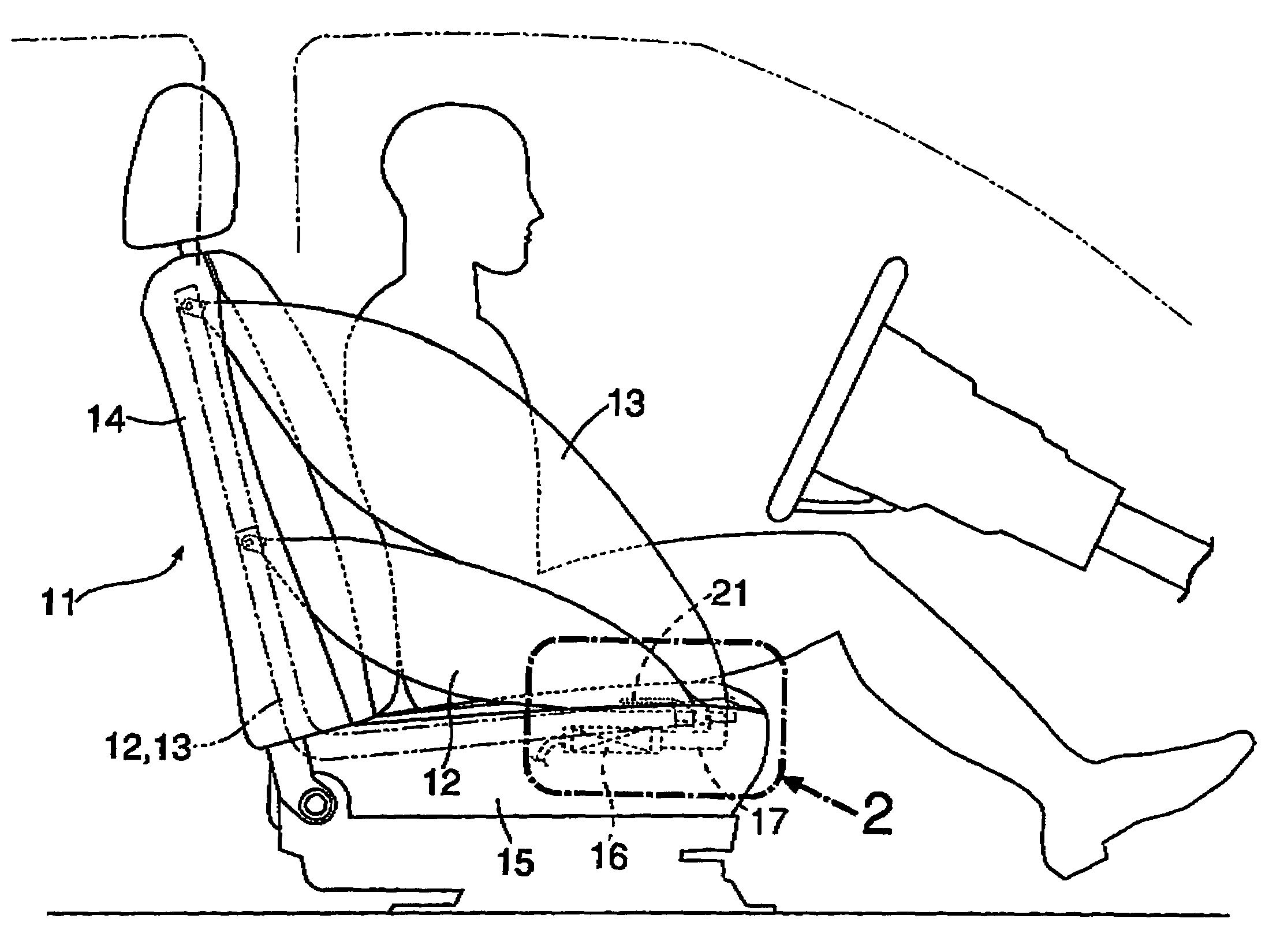

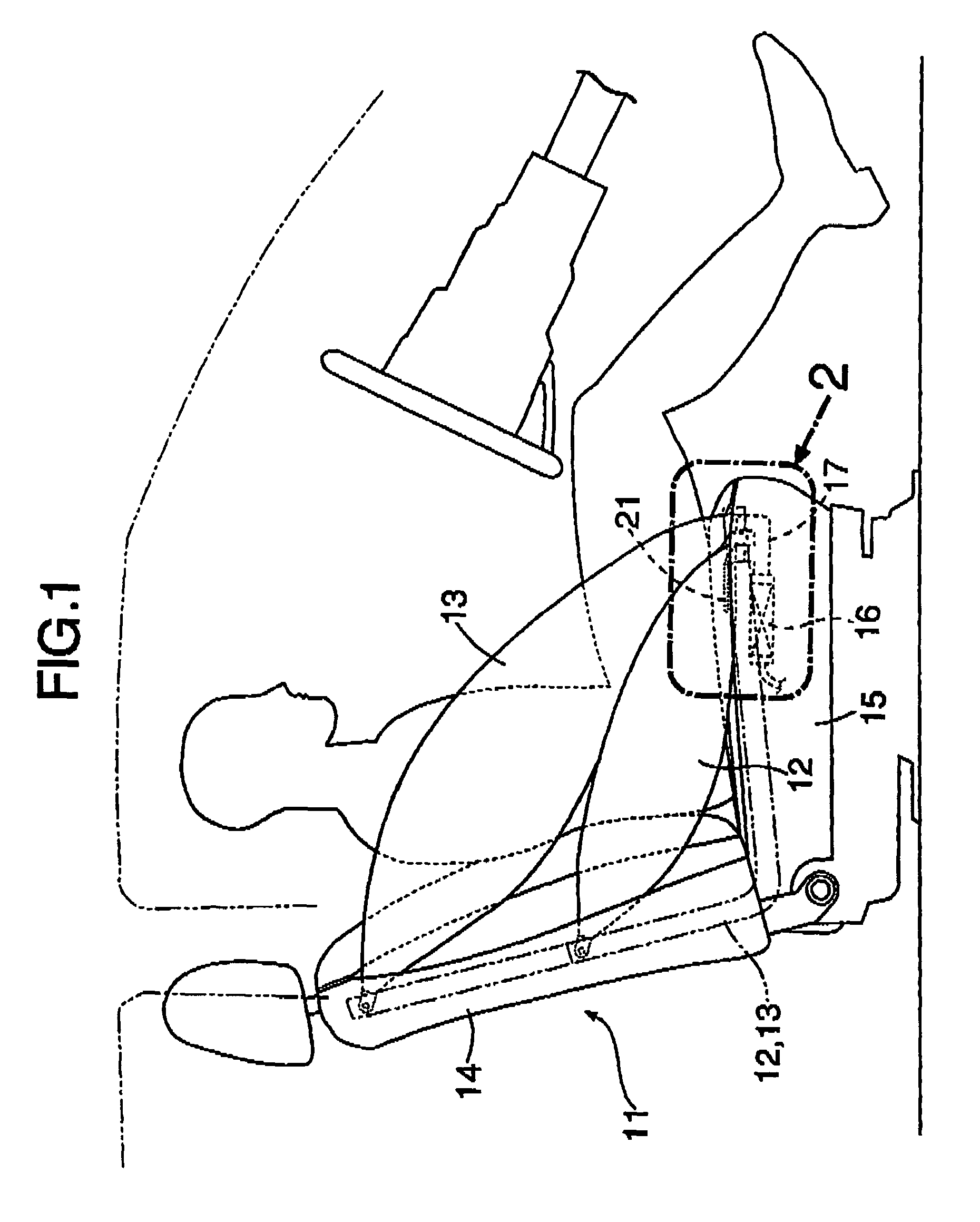

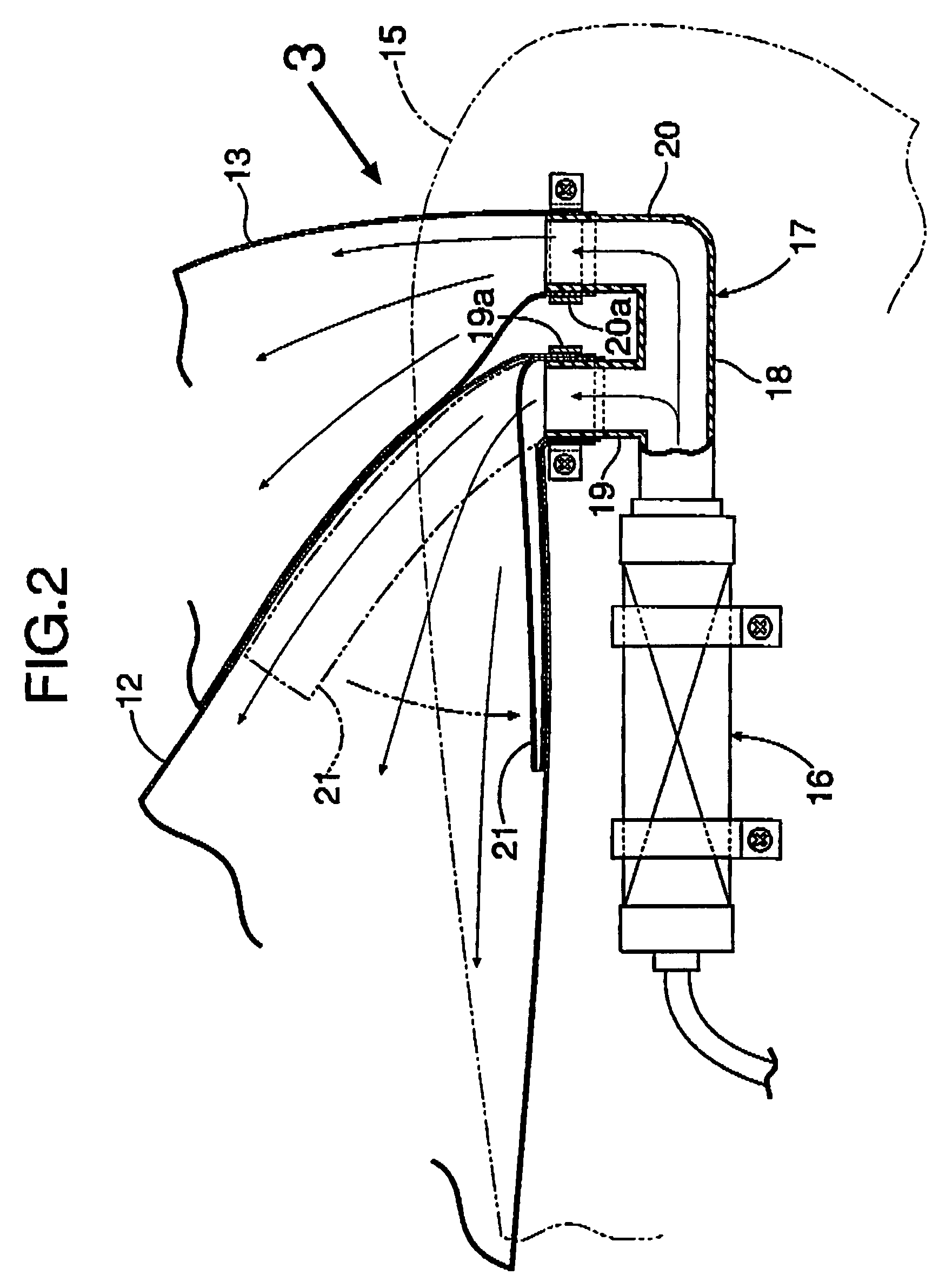

Side air bag device

InactiveUS7086663B2Minimize the numberInhibit gas flowPedestrian/occupant safety arrangementInternal pressureGas passing

A gas generated by an inflator is supplied through a branching pipe to first and second air bags, which are deployed from a side of a seat to a space between an inner surface of a side of a vehicle compartment and an occupant. A one-way valve mounted in the branching pipe permits the gas to move from the second air bag to the first air bag and inhibits a back flow of the gas, whereby the internal pressure in the first air bag can be maintained higher than that in the second air bag, to thereby restrain the occupant's waist more strongly than the occupant's breast. Moreover, the gas generated by the single inflator is diverted by the branching pipe and supplied to the two air bags. Therefore, the two air bags can be deployed while minimizing the number of the inflator.

Owner:HONDA MOTOR CO LTD

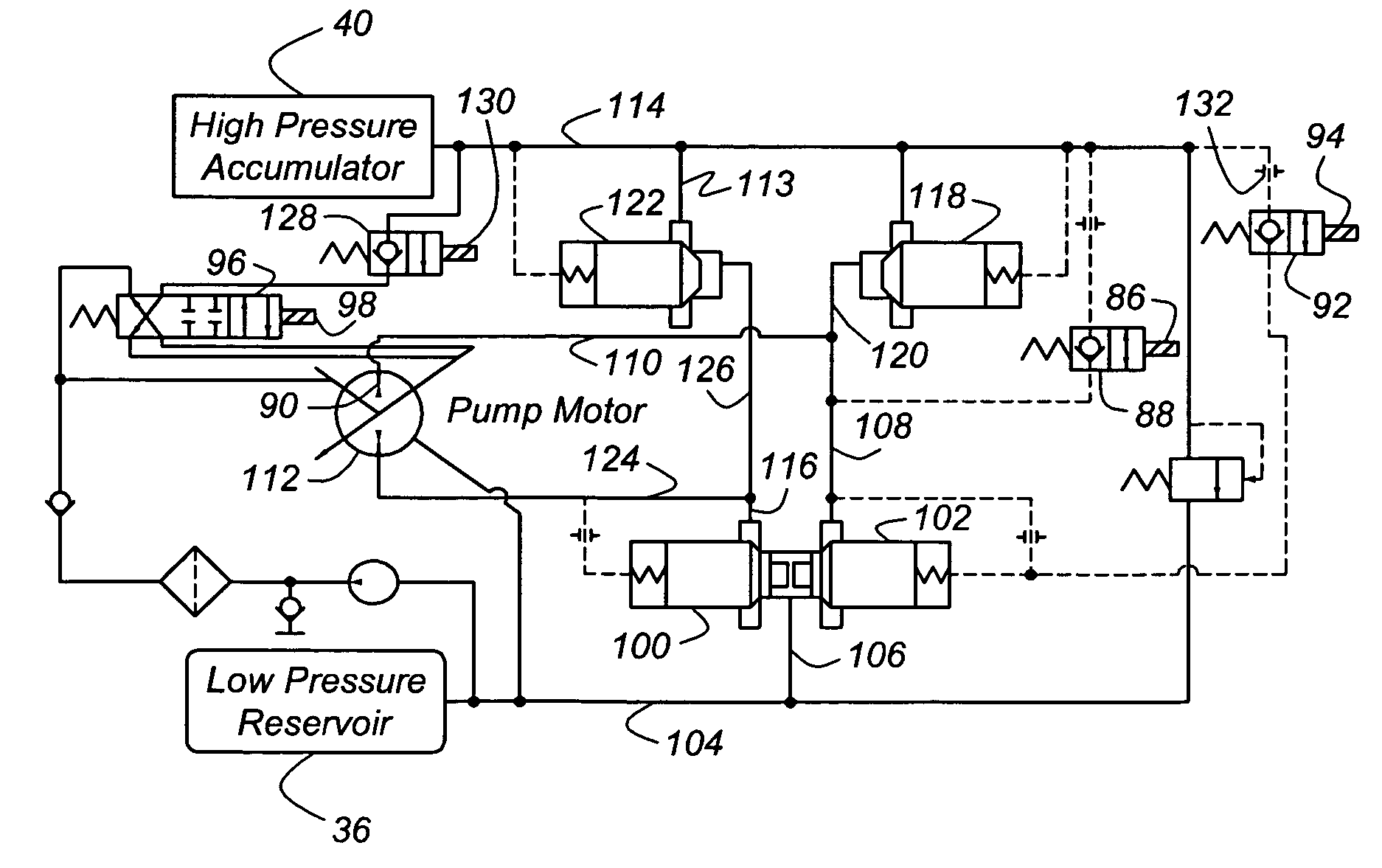

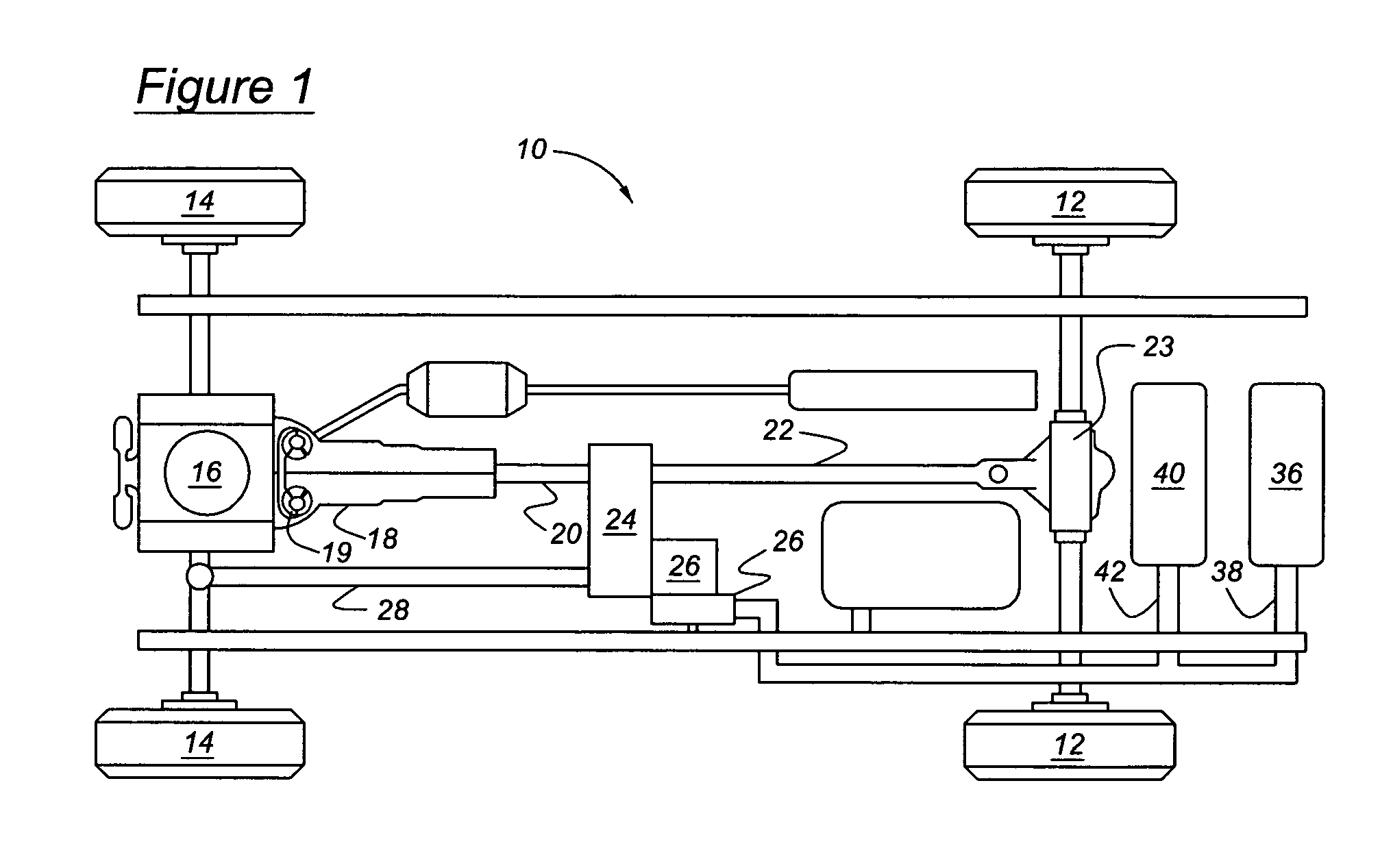

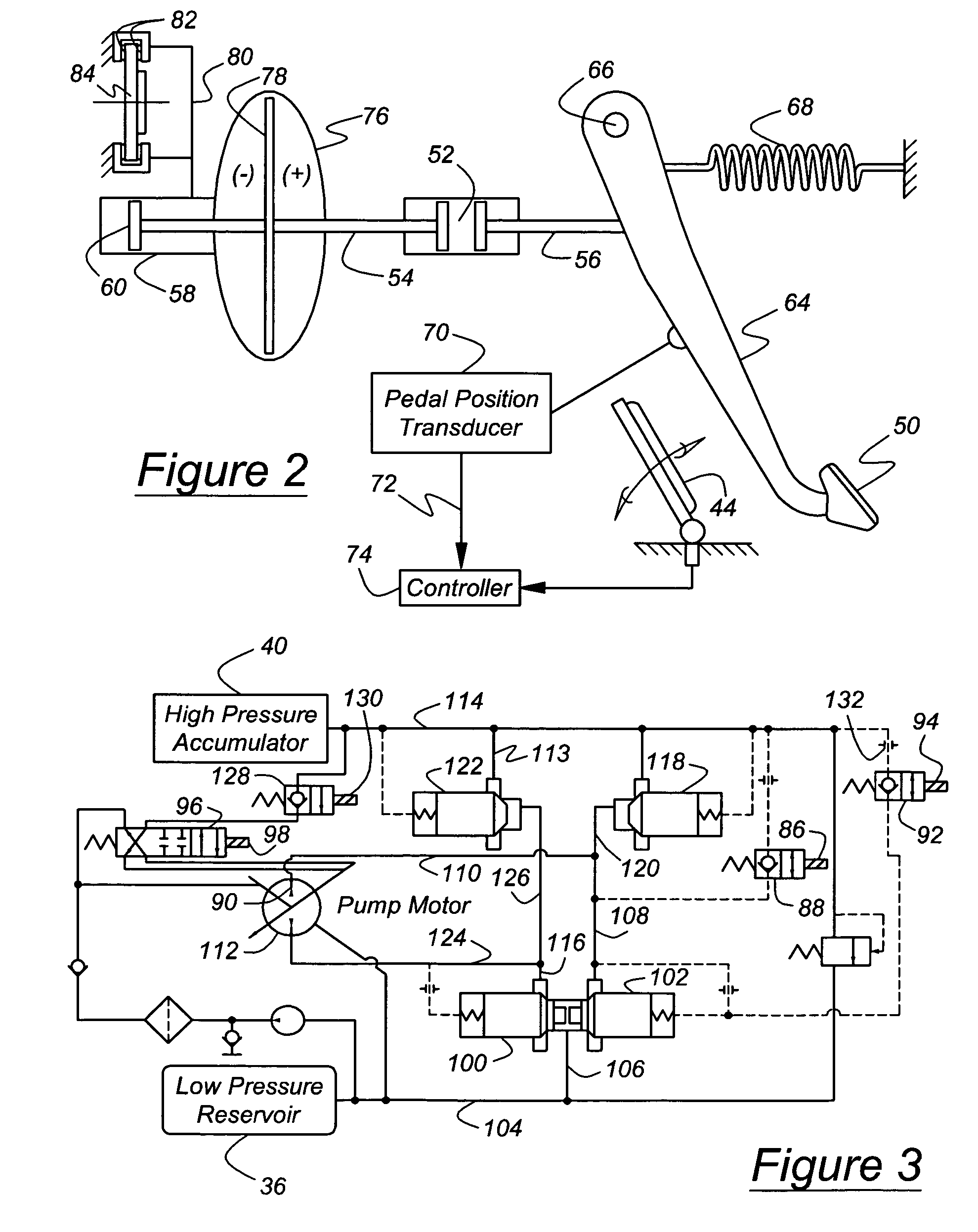

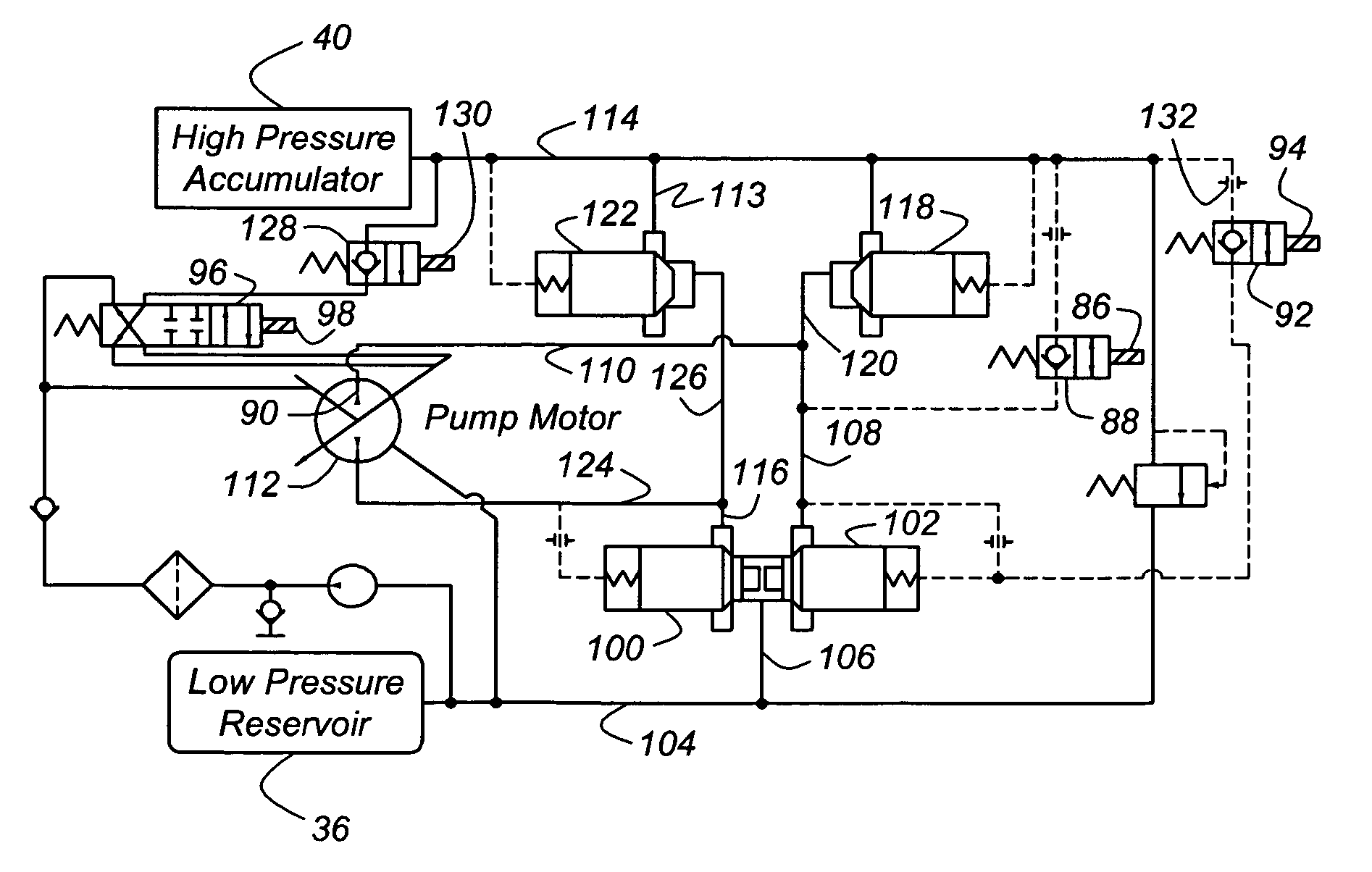

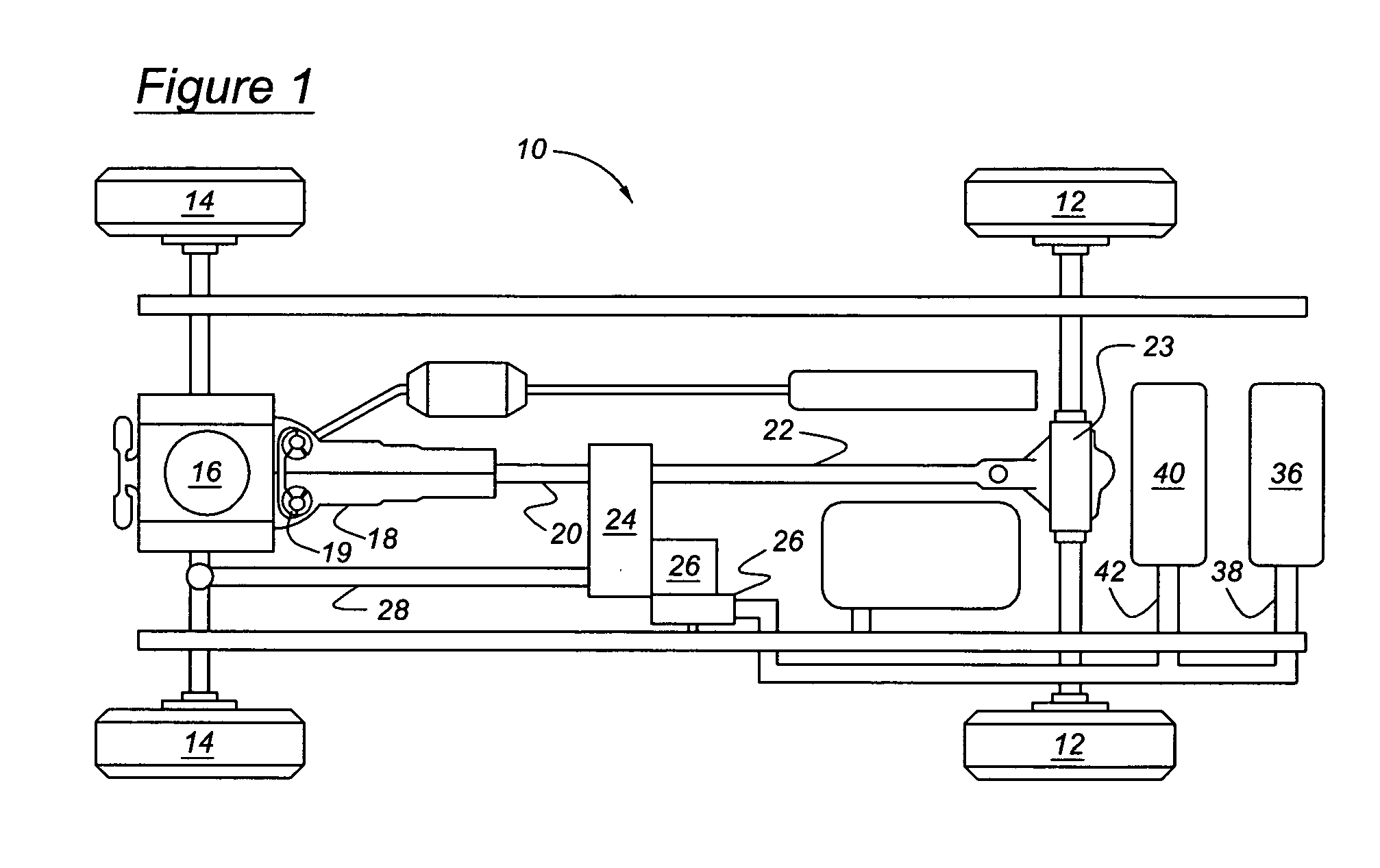

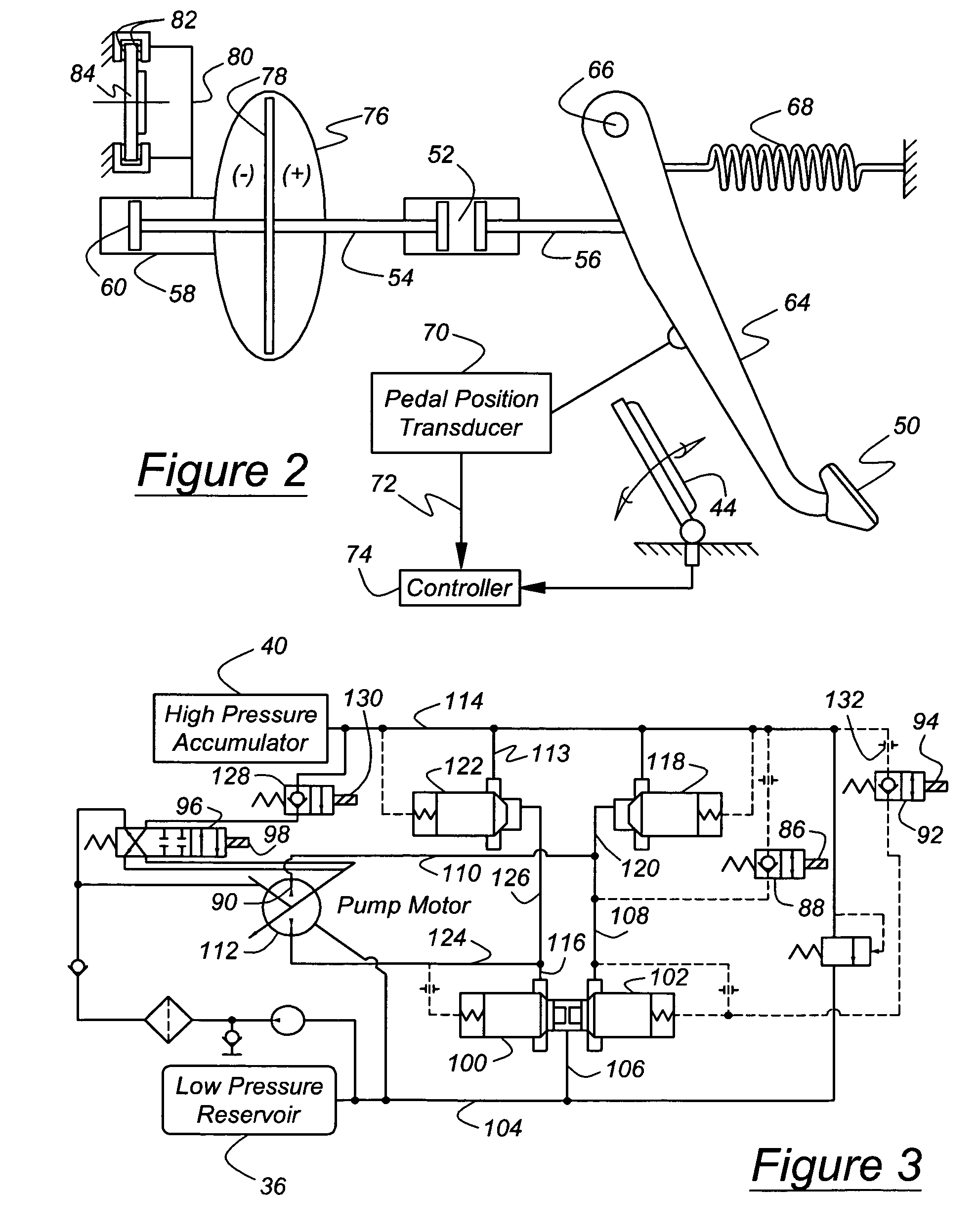

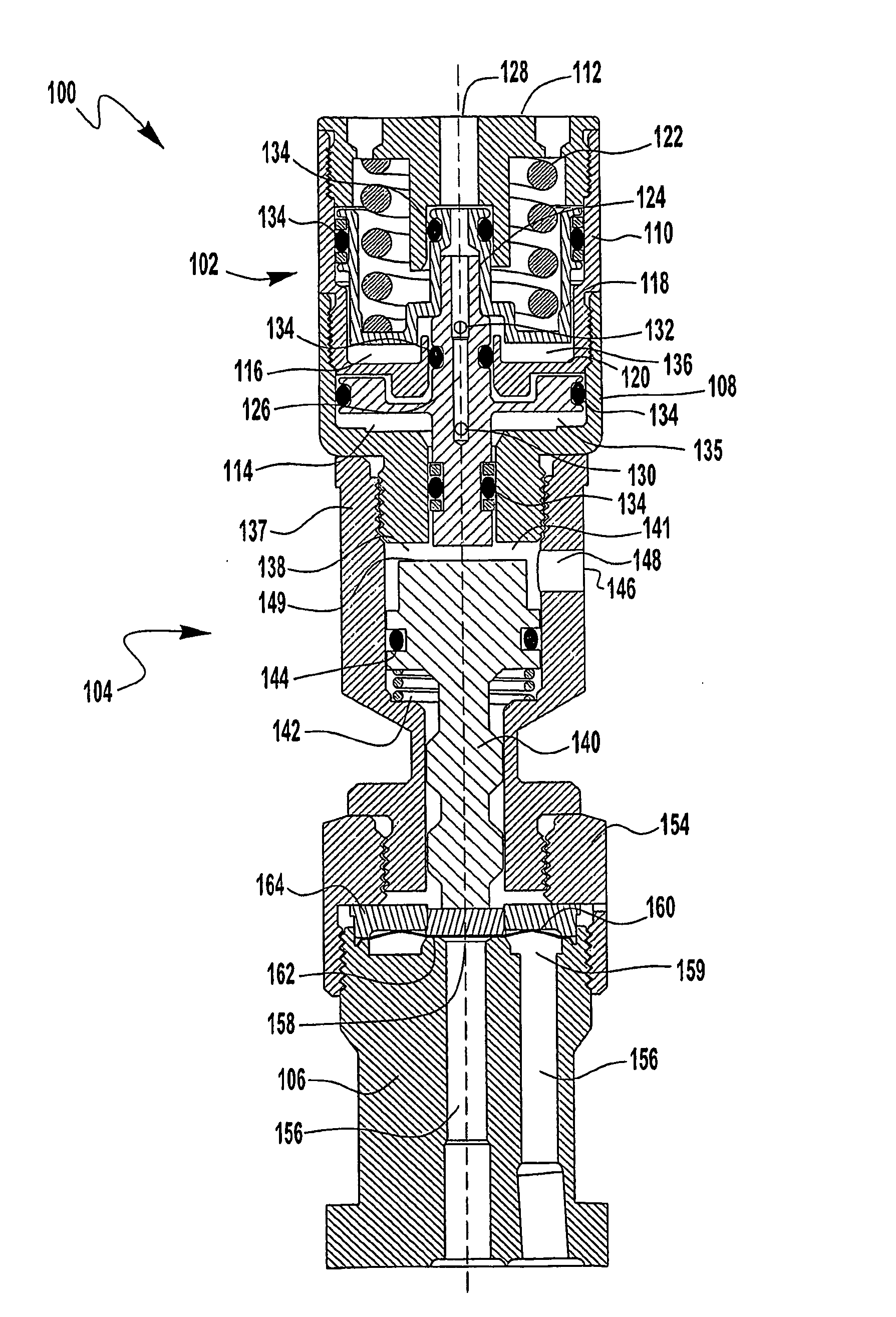

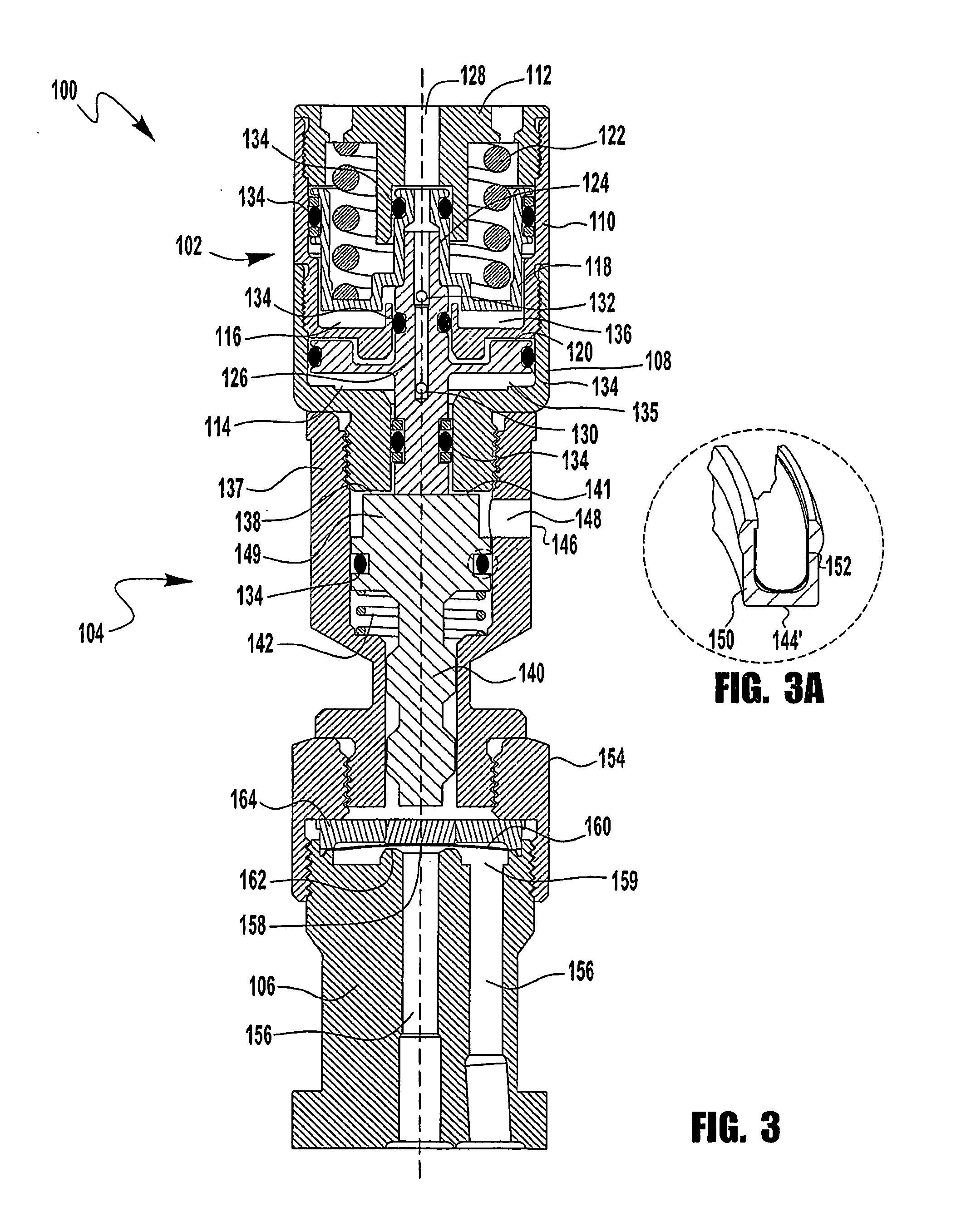

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS7082757B2Avoid vibration and noiseSlow pressureAuxillary drivesBraking element arrangementsMobile vehicleTransmitted power

A system for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation.

Owner:FORD GLOBAL TECH LLC

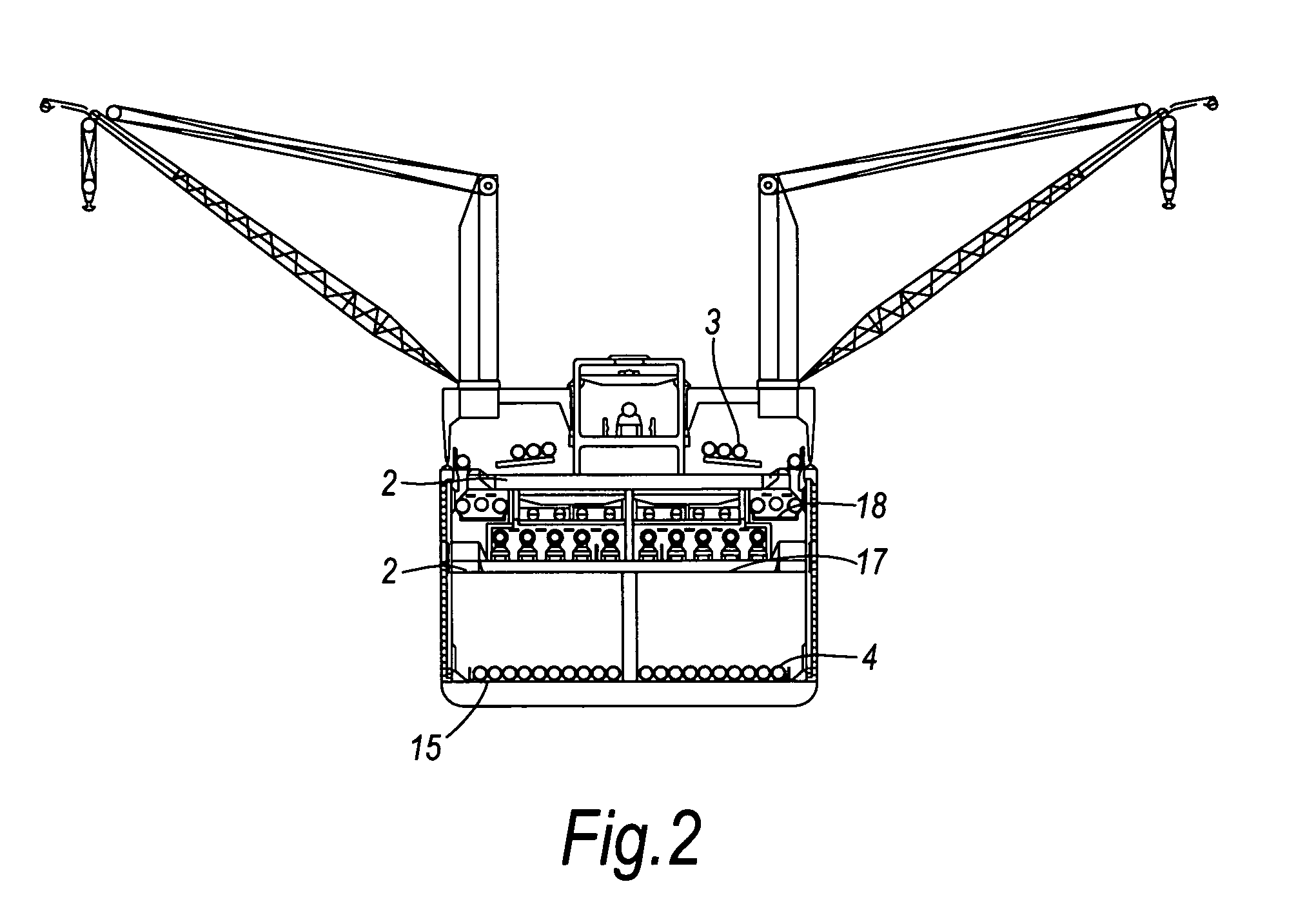

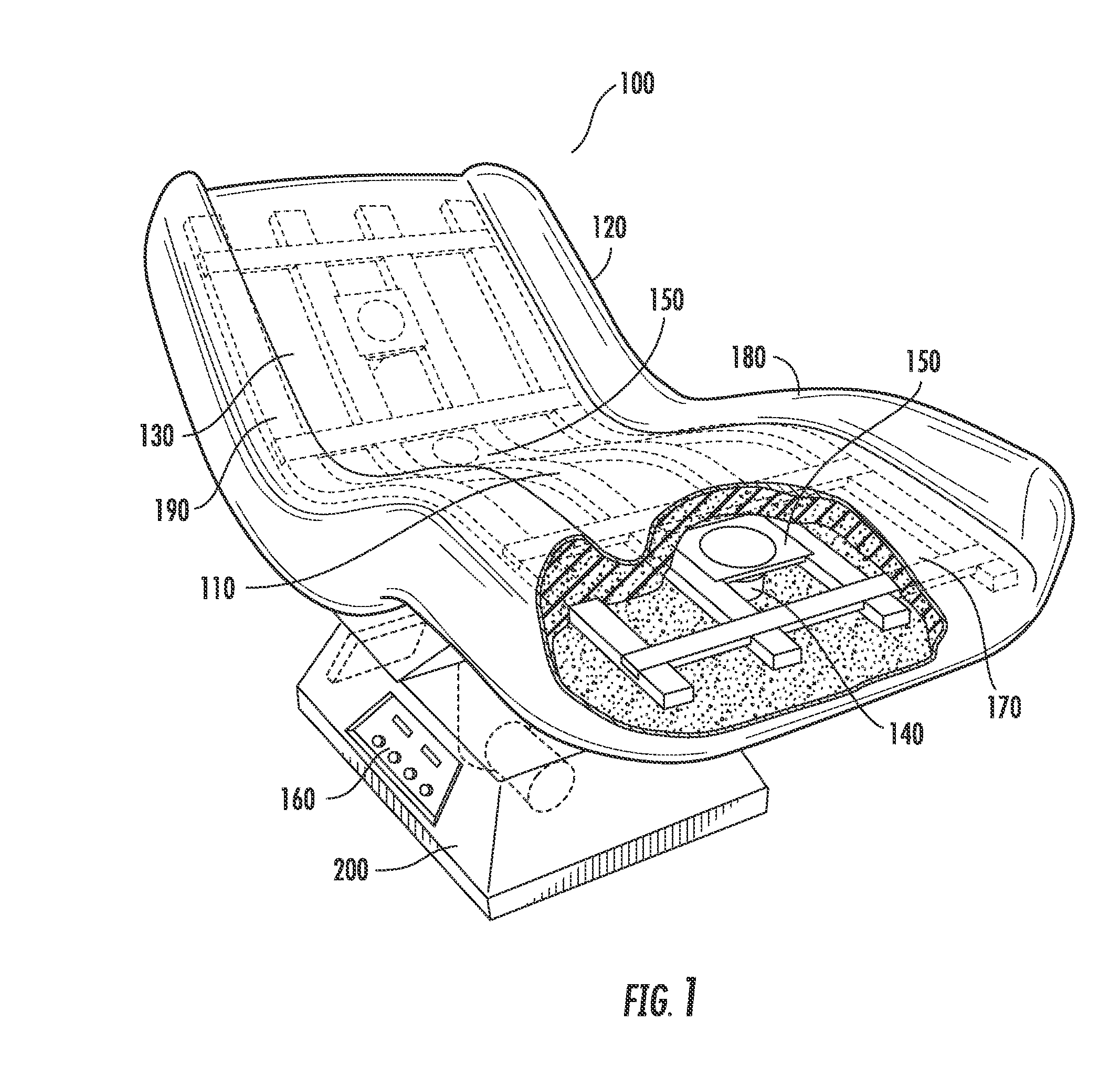

Induced Relaxation and Therapeutic Apparatus and Method

Owner:BENDER EDDIE L

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS20060000208A1Slow pressureAvoid cavitationAuxillary drivesBraking element arrangementsTransmitted powerEngineering

A system according to this invention for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having an inlet, an outlet, and a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit, which connects the inlet to the accumulator and the outlet to the reservoir, includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation. The first path includes a first valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a first orifice arranged in series with the first valve having a relatively low flow rate capacity. The second path, arranged in parallel with the first path between the accumulator and the inlet, includes a second valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a second orifice arranged in series with the second valve having a higher flow rate capacity than that of the first orifice.

Owner:FORD GLOBAL TECH LLC

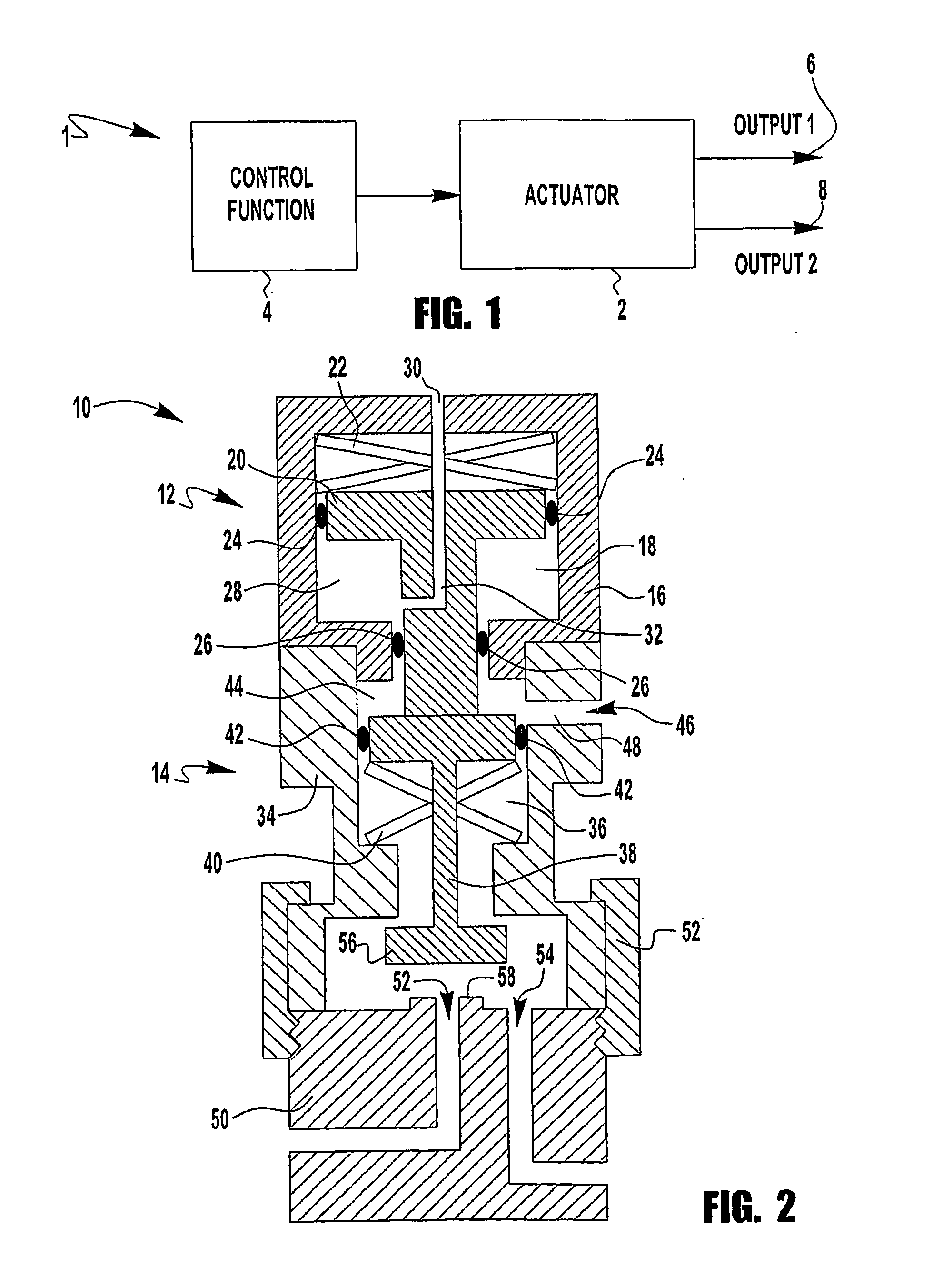

Method and arrangement for actuation

InactiveUS20100138051A1Slow pressureOperating means/releasing devices for valvesServomotorsPistonEngineering

The present application relates to an arrangement for selectively providing a plurality of output forces, such as for example, a higher and a lower output force or a predetermined, time dependent output force. In one embodiment, a first piston assembly is moveable between a first and a second position and a second piston assembly moveable between a third and a fourth position. When the first piston assembly is in the first position, the second piston assembly is selectively movable between the third position and the fourth position. When the first piston assembly moves the second position, it moves the second piston assembly to the fourth position.

Owner:SWAGELOK CO

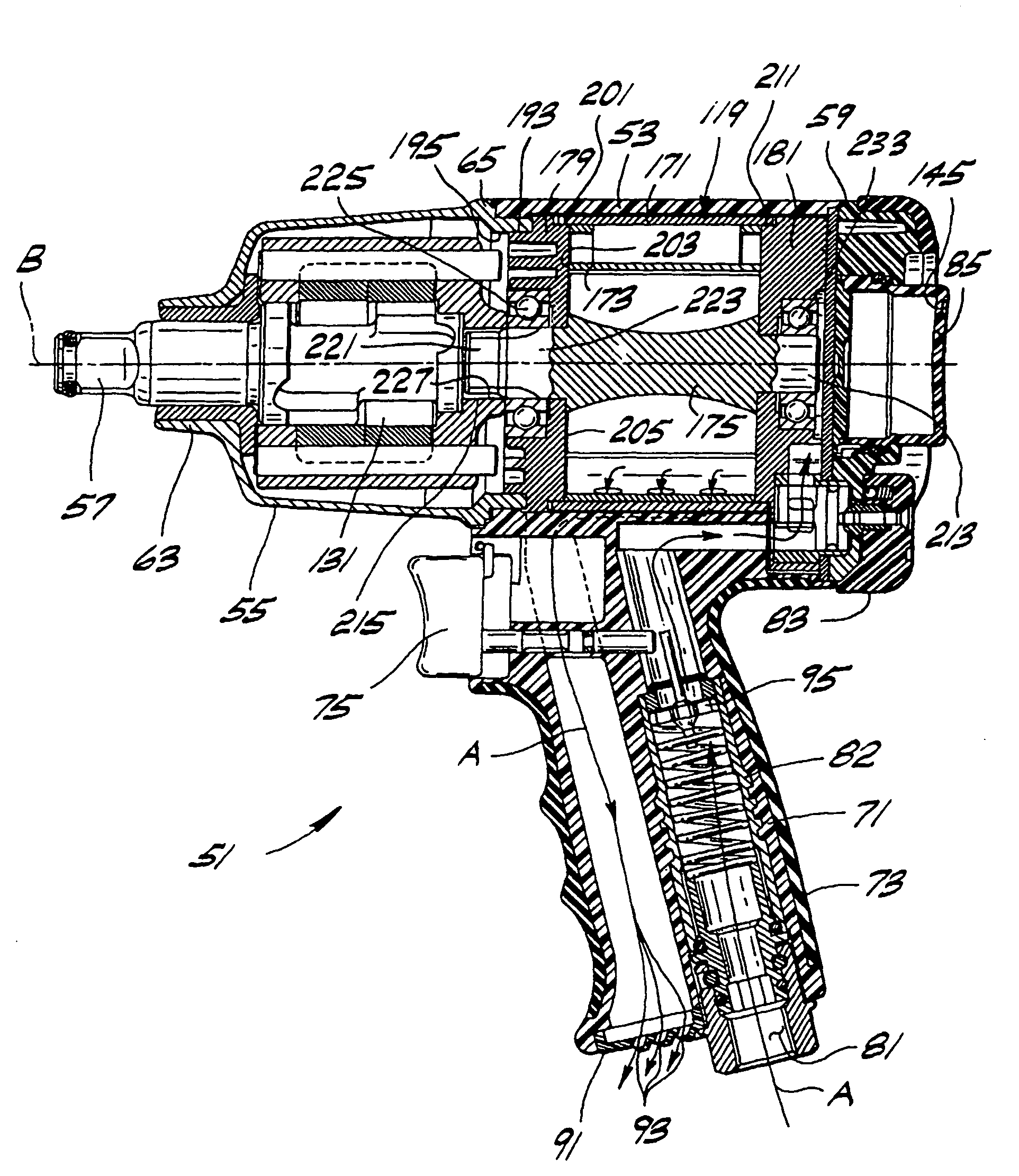

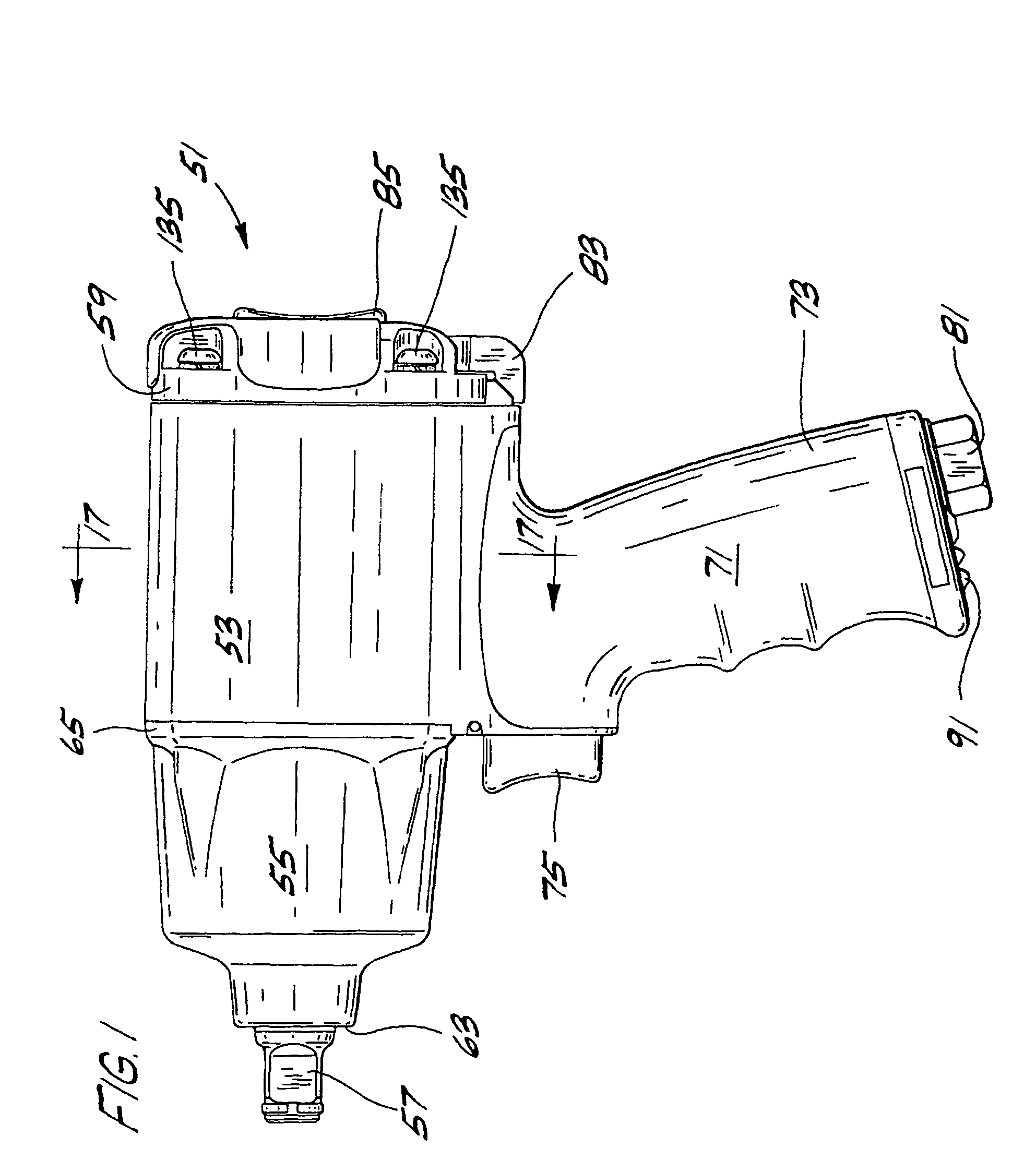

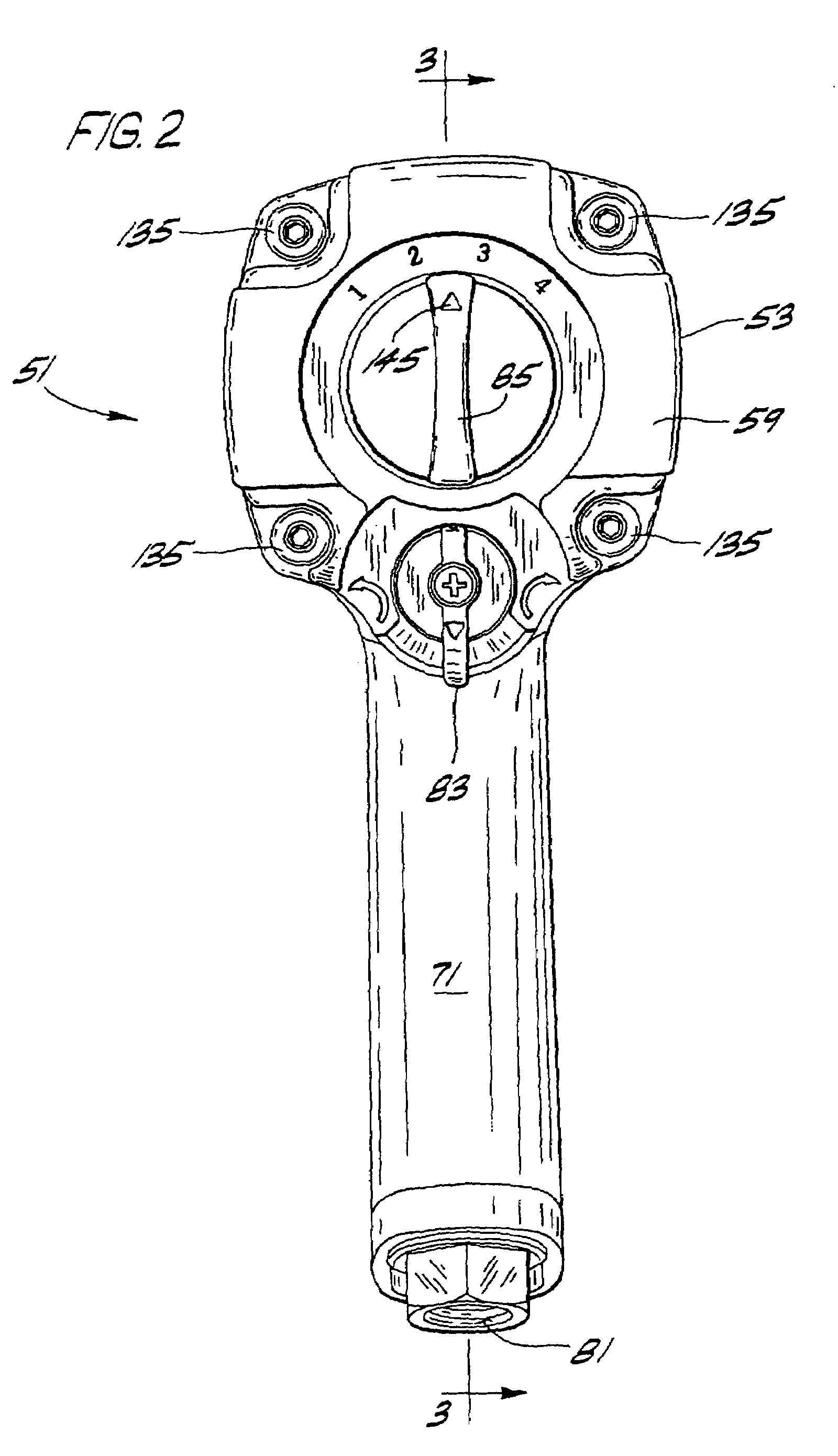

Pneumatic rotary tool

InactiveUS7404450B2Reduce back pressureLow costConstructionsReciprocating drilling machinesPneumatic toolLate stage

A pneumatic rotary tool has a housing formed primarily from plastic so that the weight and price of the tool are substantially reduced. The air motor is formed for economic assembly while permitting greater structural stability should the housing deflect under an impact. The tool includes a torque selector which controls the amount of pressurized air allowed to enter the air motor, thereby controlling the torque output of the motor. The user may adjust the torque selector to a number of set positions which correspond to discrete torque values. The tool additionally incorporates early and late stage exhaust ports, so that backpressure within the air motor does not slow motor rotation or decrease tool power.

Owner:S P AIR

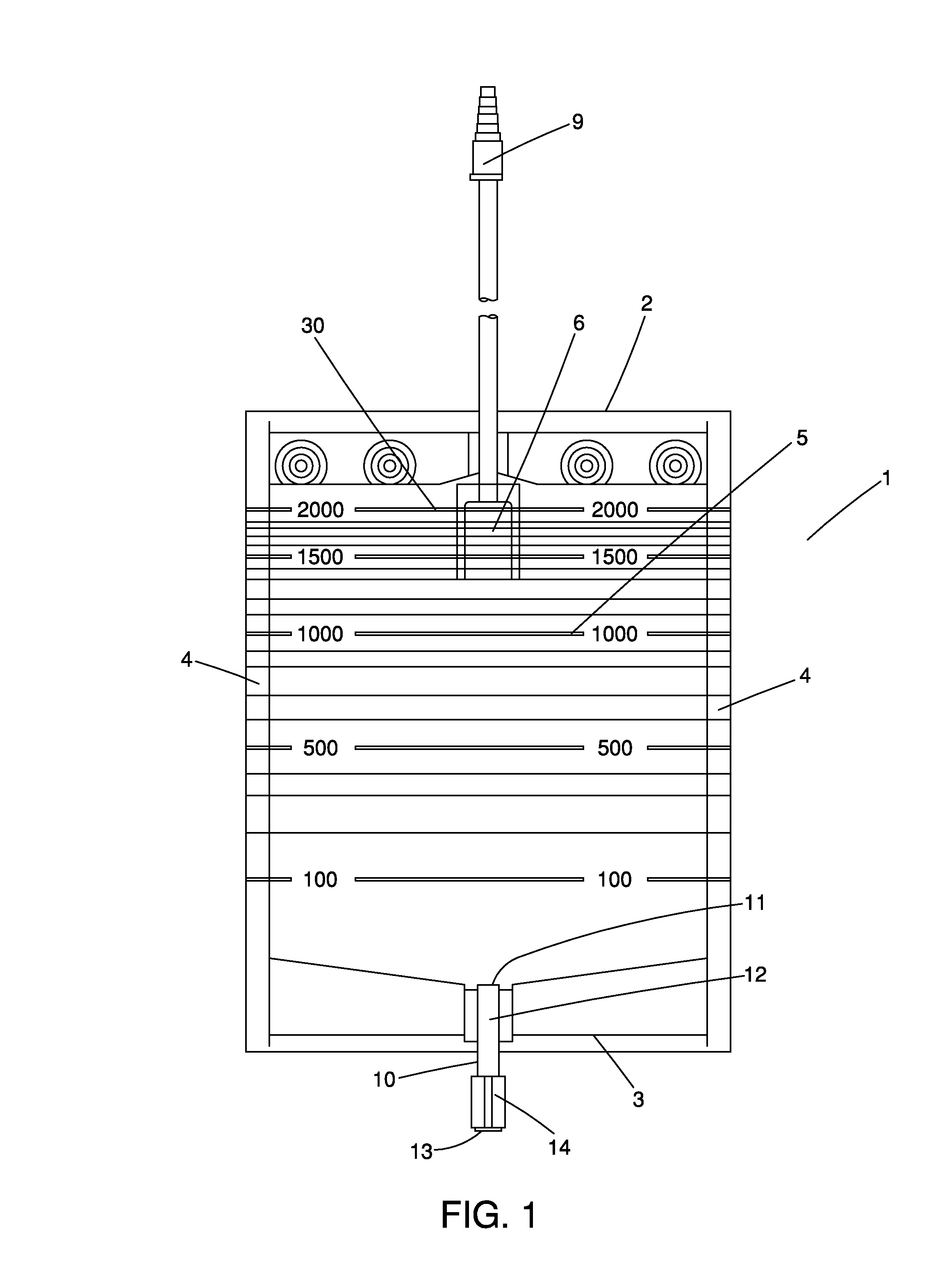

Organ preservation apparatus and methods

InactiveUS20090291486A1Increase the lengthReduce decreaseDead animal preservationMachines using electric/magnetic effectsNutrient solutionOxygen

A transportable organ preservation system that substantially increases the time during which the organ can be maintained viable for successful implantation into a recipient is disclosed. A chilled oxygenated nutrient solution can be pumped through the vascular bed of the organ after excision of the organ from the donor and during transport. The device of the present invention uses flexible permeable tubing to oxygenate the perfusion fluid while the CO2 produced by the organ diffuses out of the perfusion fluid. One pressurized two-liter “C” cylinder can supply oxygen for up to 34 hours of perfusion time. The device can use a simple electric pump driven by a storage battery to circulate the perfusion fluid through the organ being transported. The vessel containing the organ to be transported can be held at a suitable temperature by a chiller.

Owner:ORGAN TRANSPORT SYST

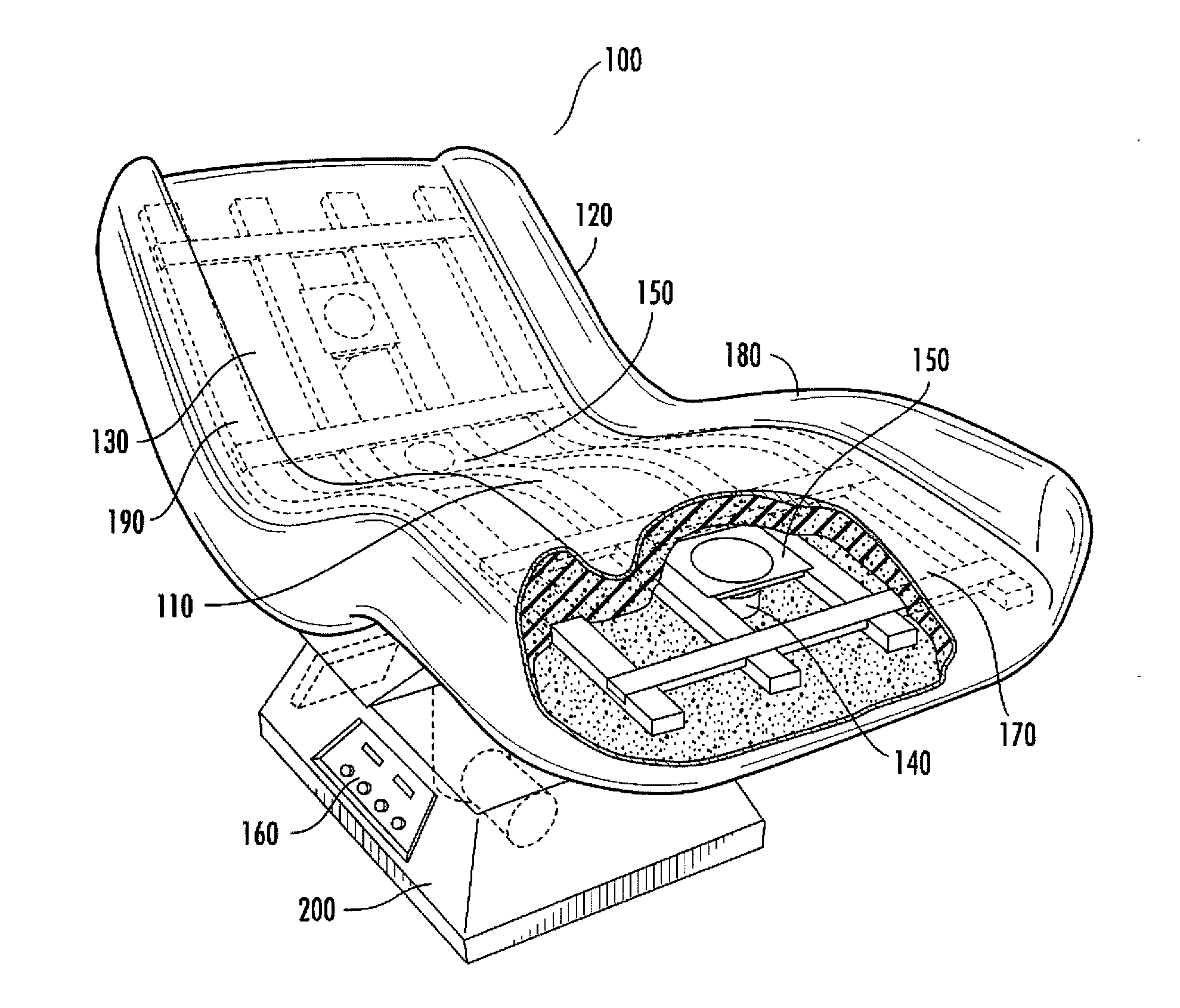

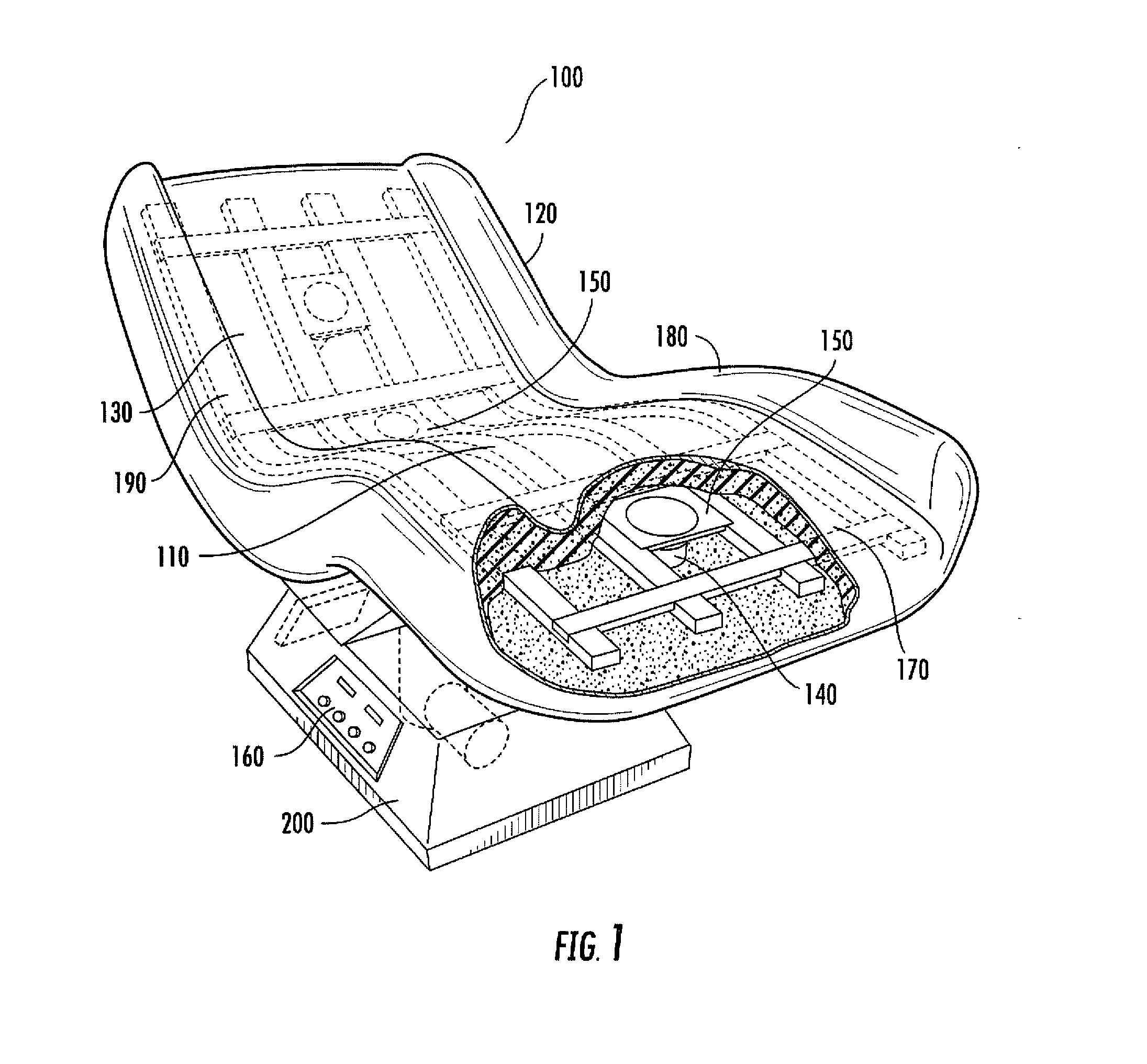

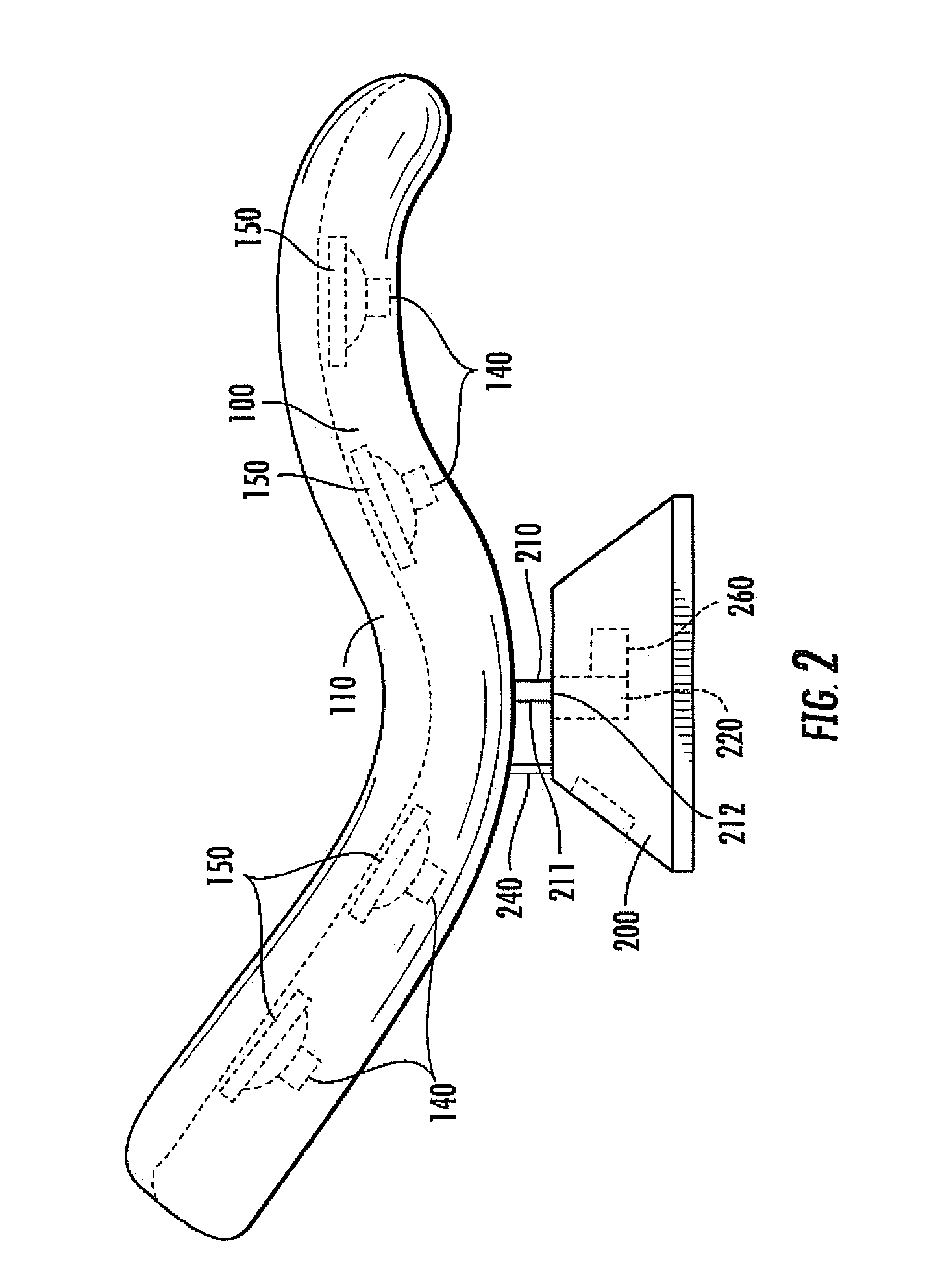

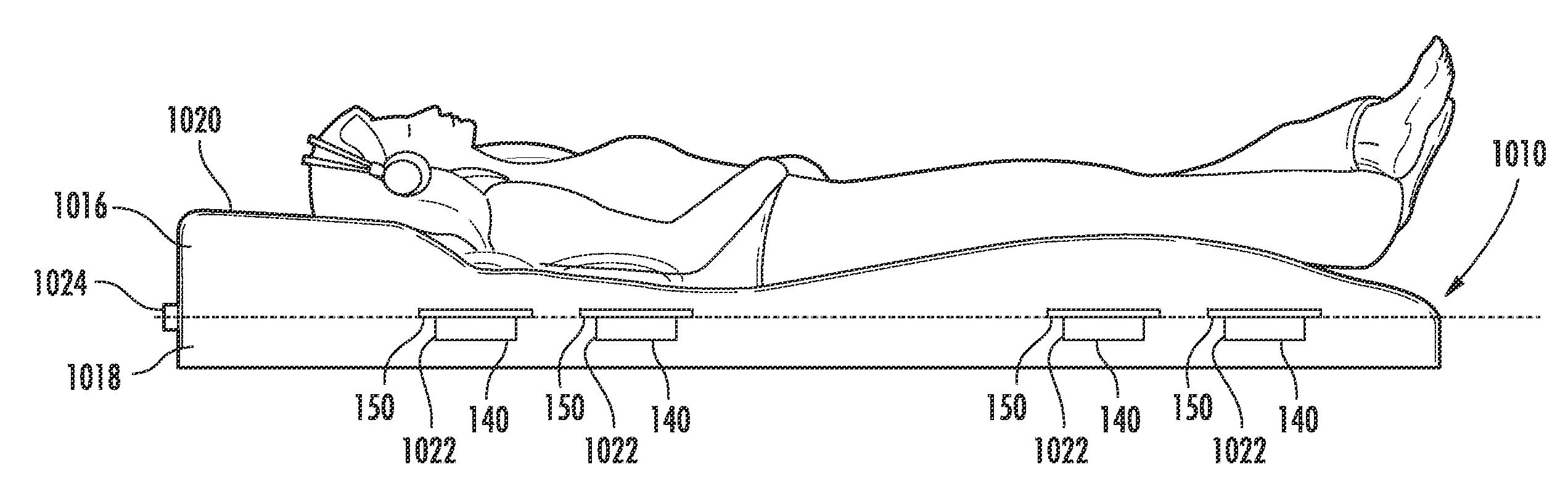

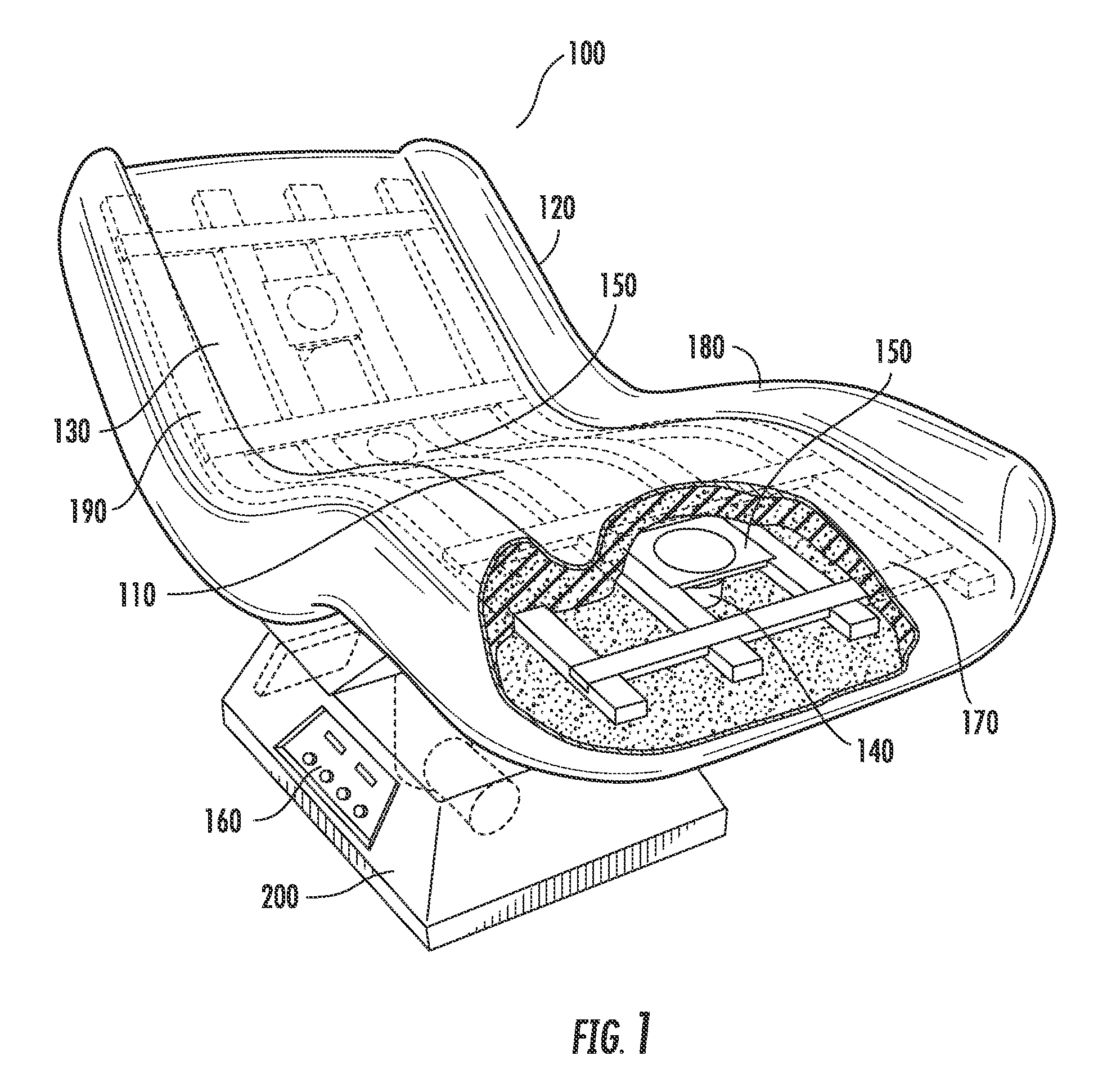

Induced Relaxation And Therapeutic Apparatus And Method

InactiveUS20110054242A1Good responseFacilitate responseMedical devicesSleep inducing/ending devicesEngineering

Owner:BENDER EDDIE L

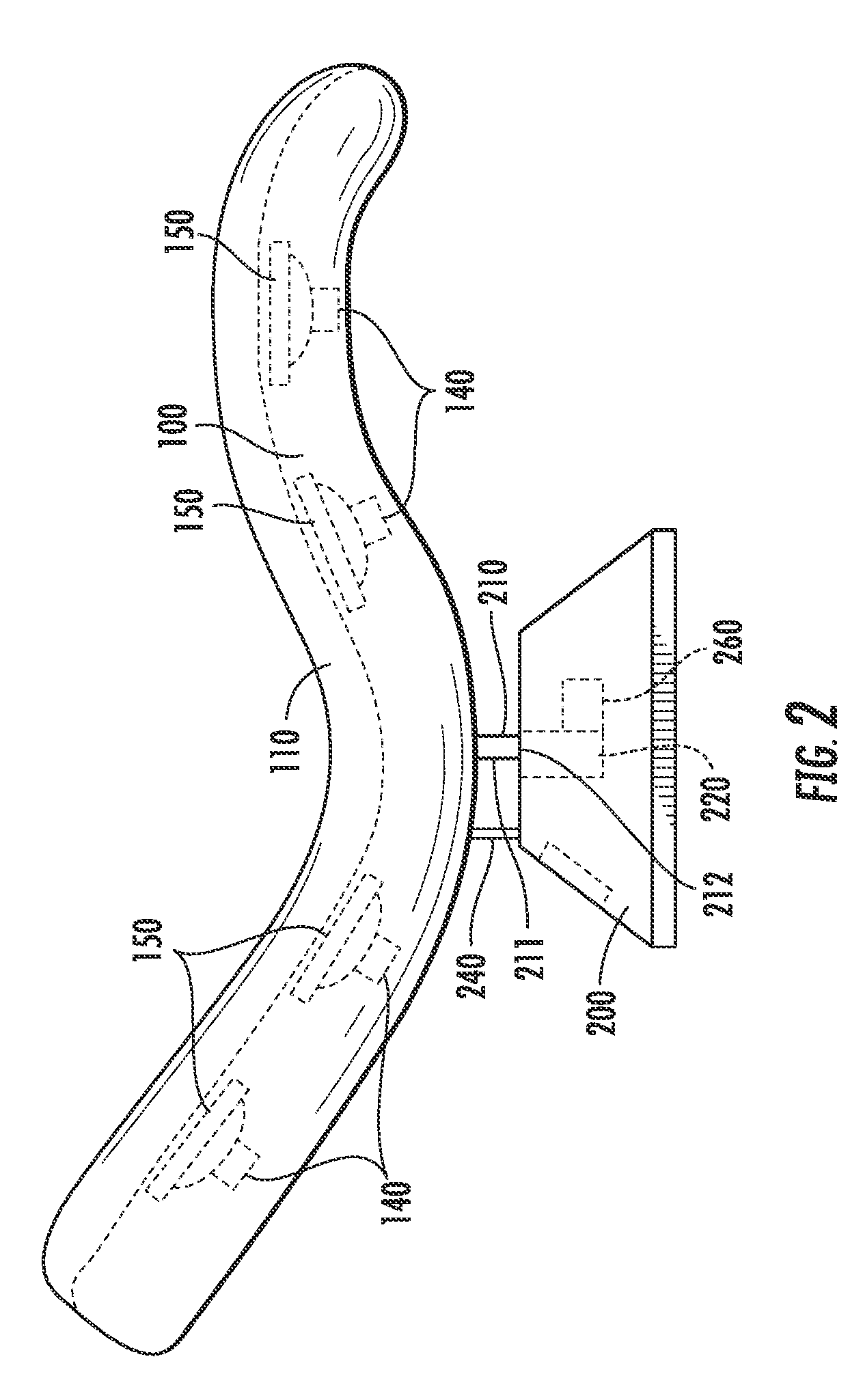

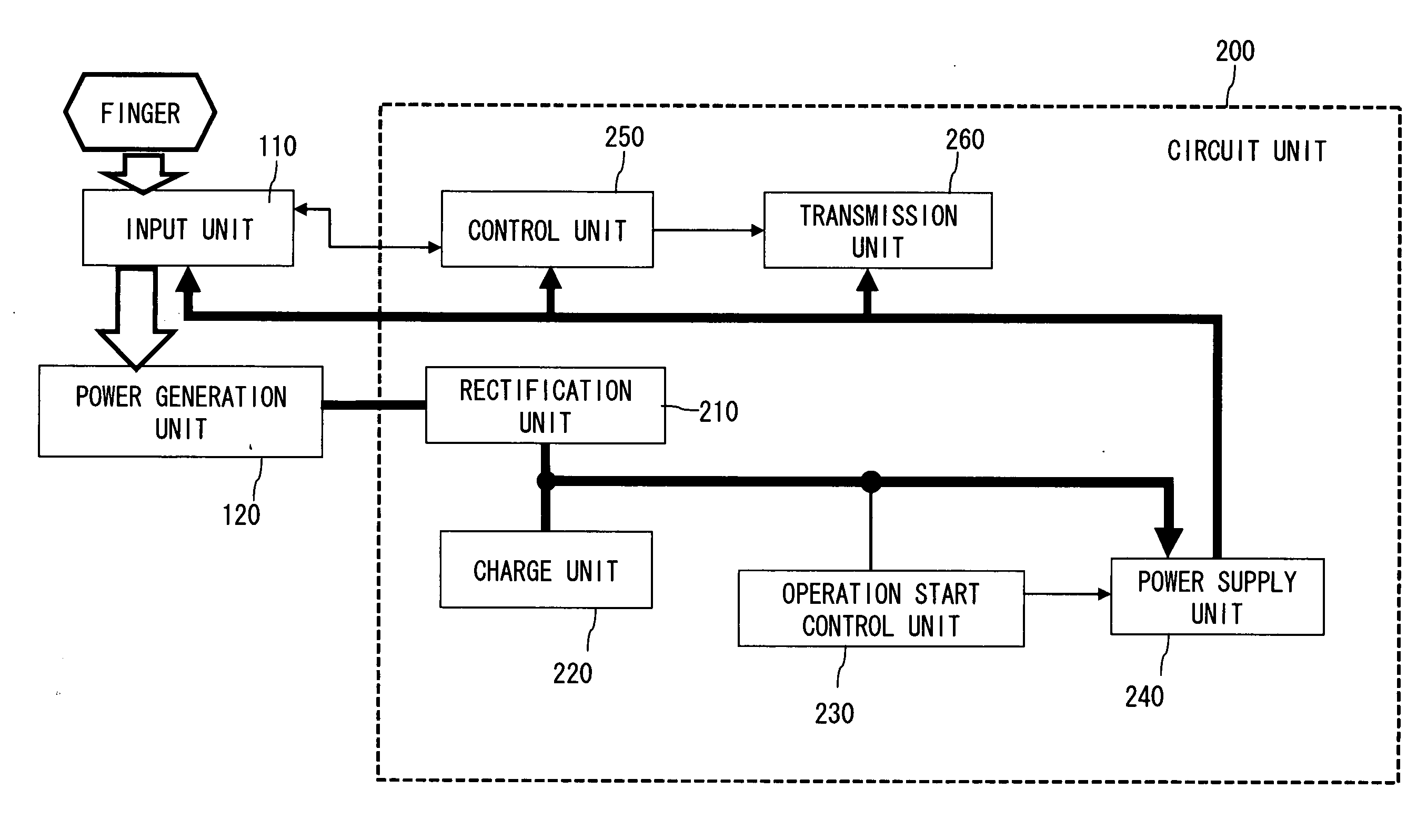

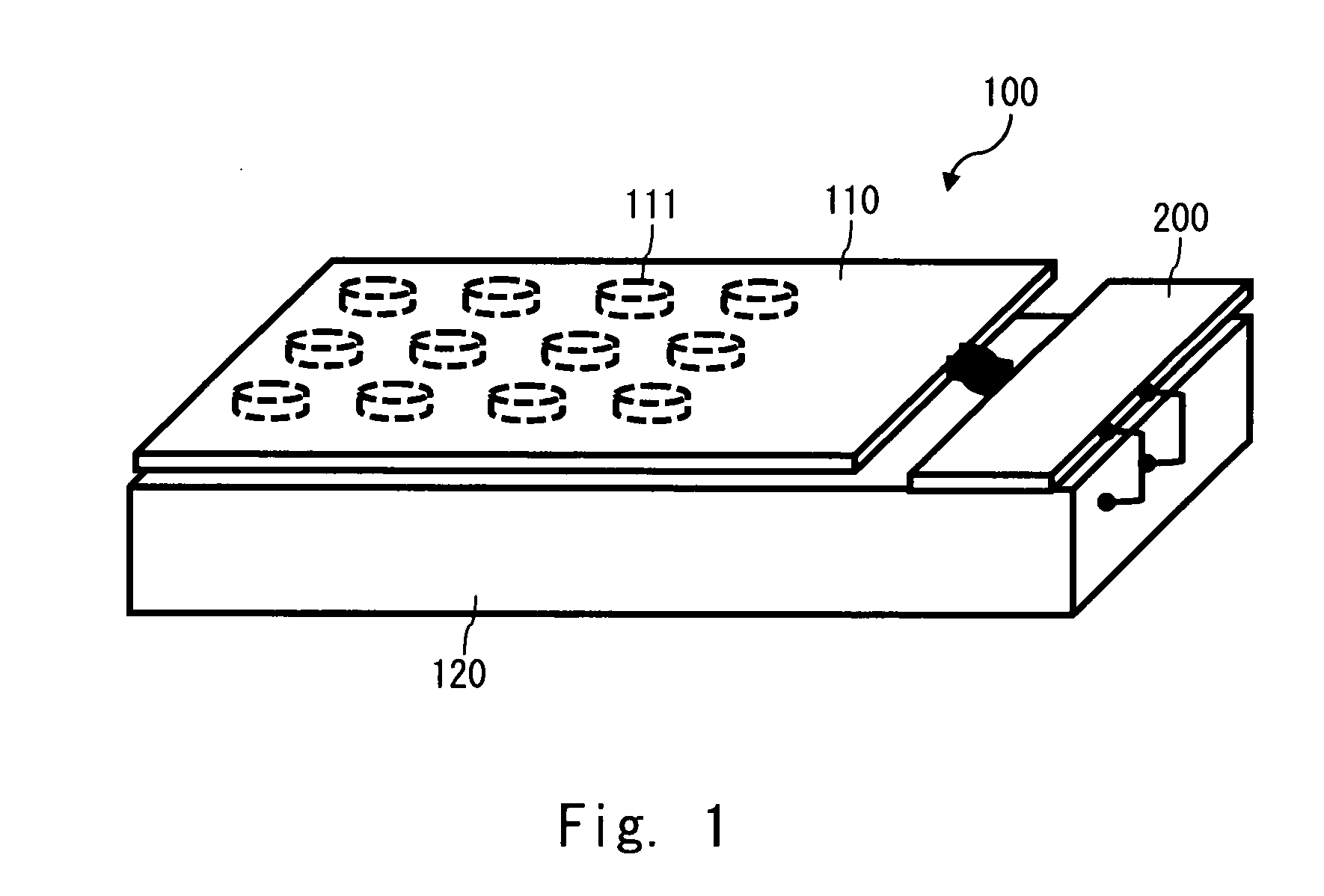

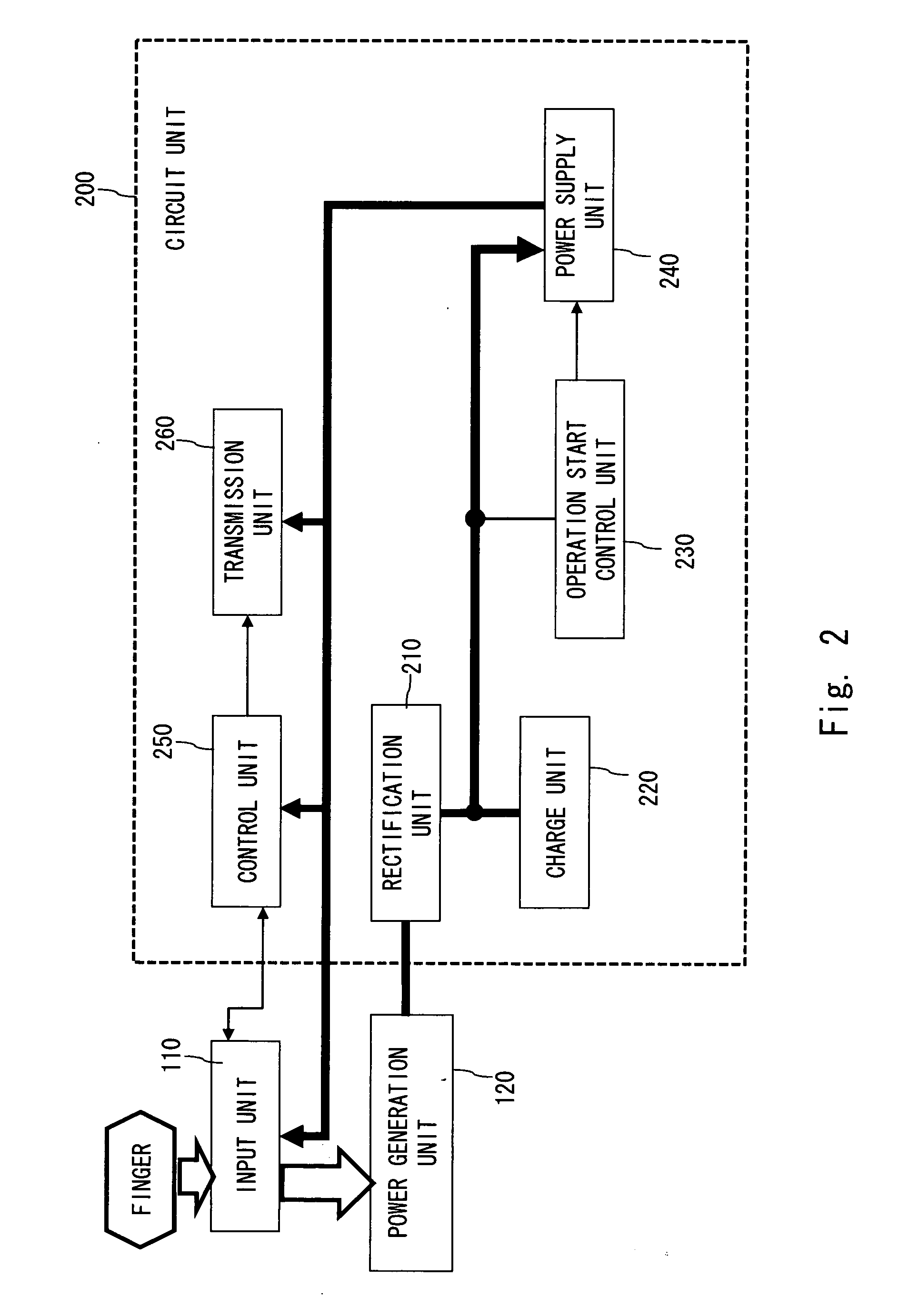

Manual control device with power generation function and remote control device with power generation function

InactiveUS20110109201A1Stable operationEase pressurePiezoelectric/electrostriction/magnetostriction machinesElectronic switchingElectricityDelayed time

A manual control device with a power generation function includes a manual input unit of a touch sensor type, a control unit that detects a direction input in the manual input unit and performs a control operation according to the direction, a power generation unit that is formed of piezoelectric material for power generation and arranged to a bottom side of the manual input unit, a charge unit that charges electric power from the power generation unit, and a power supply unit that supplies the electric power from the charge unit to the control unit. The operation start control unit supplies an operation instruction to the power supply unit after predetermined delay time since the electric power supply from the power generation unit to the charge unit is detected.

Owner:RENESAS ELECTRONICS CORP +1

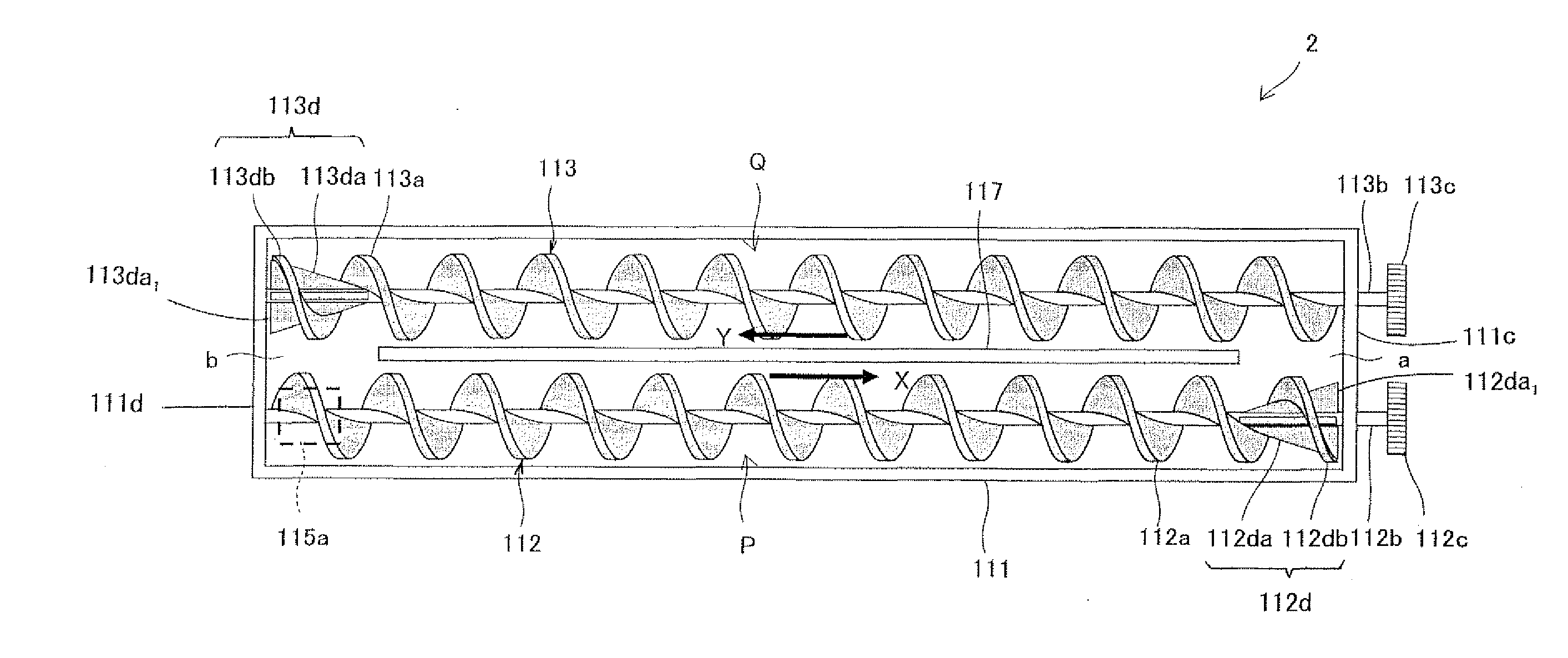

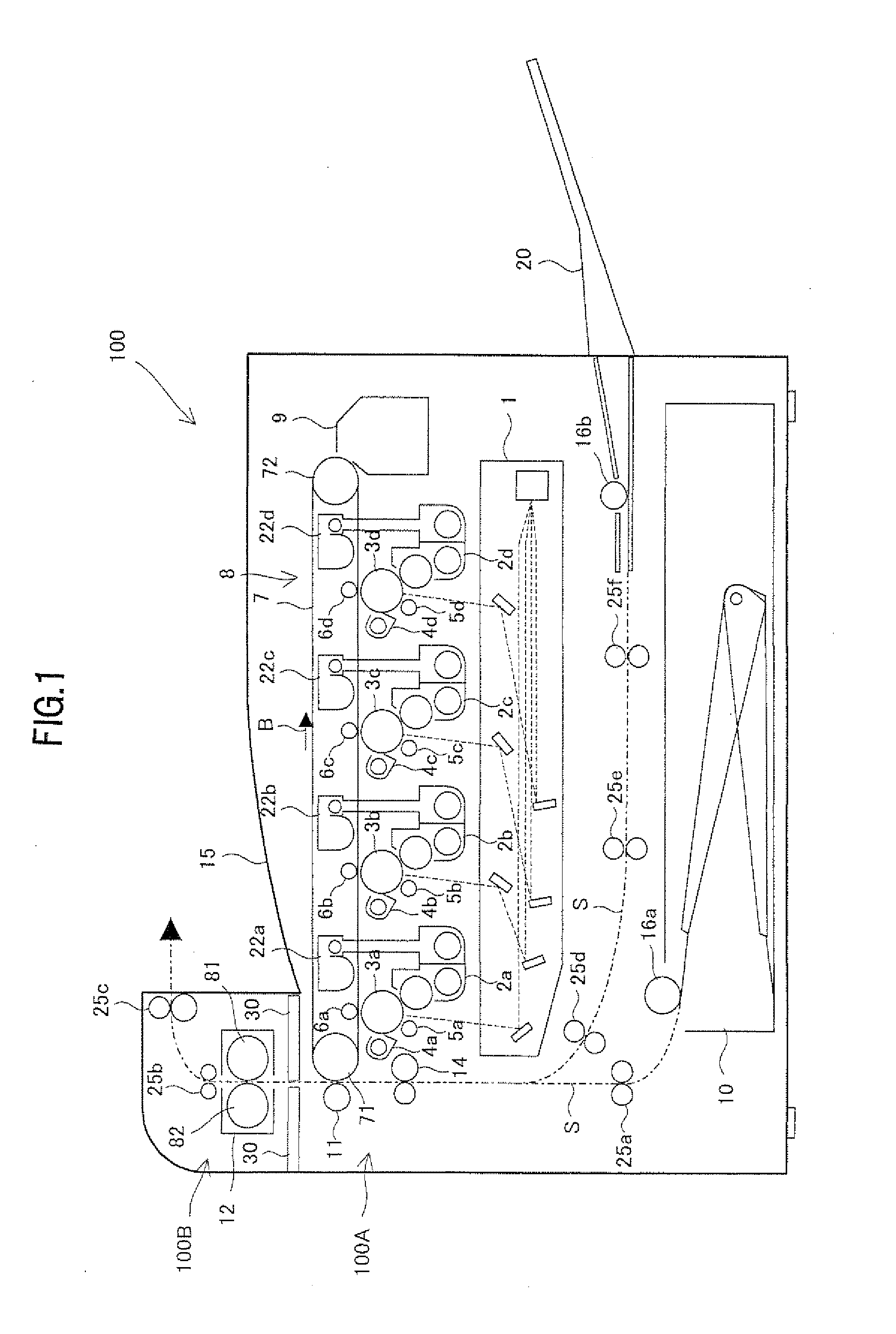

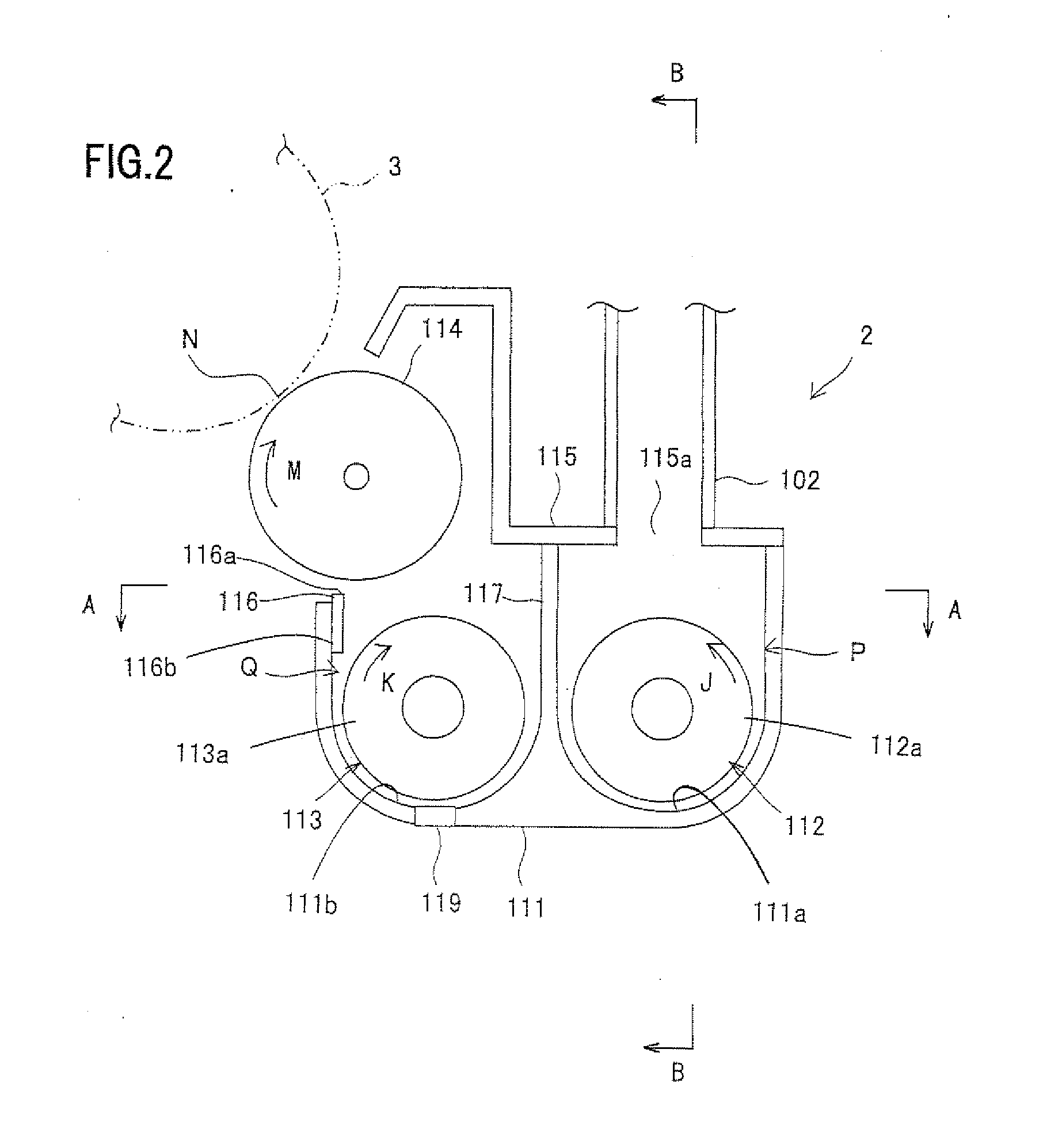

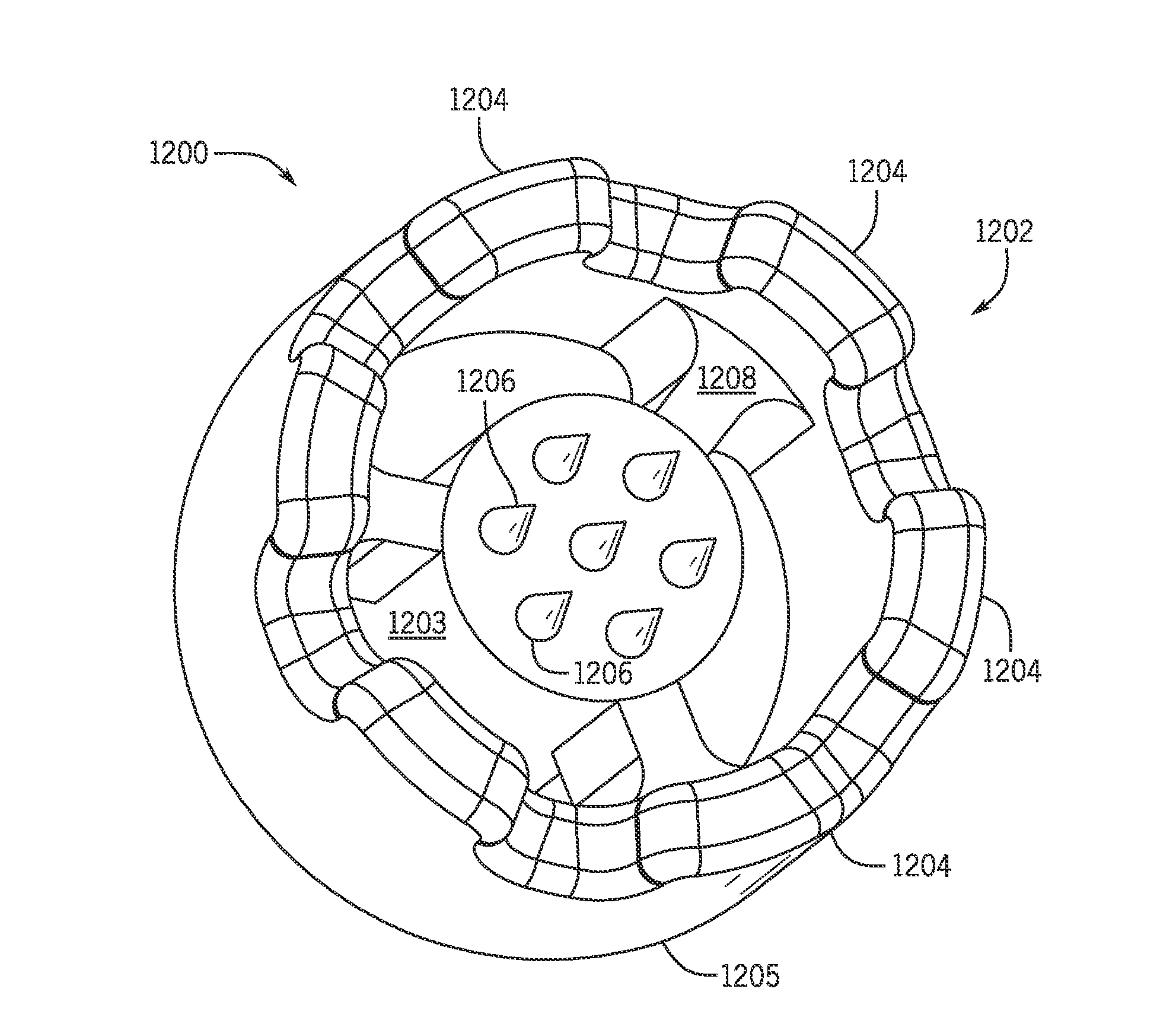

Developing device and image forming apparatus including the same

ActiveUS20110286770A1Satisfactory image densitySmooth circulationElectrographic process apparatusLatent imageHelical blade

A developing device to be installed in an electrophotographic image forming apparatus including a photoconductor drum that is to have an electrostatic latent image formed on a surface thereof, the developing device comprising: a developer vessell; a developing roller that is disposed in the developer vessel; first and second developer conveying passages; and first and second developer conveying helical members circulatory conveys the developer in the first and second developer conveying passages, whereinat least one of the first and second developer conveying helical members includes an end blade at one end at a downstream side in a conveying direction, whereinthe end blade includes a circumferential-direction agitating blade portion whose radial projecting size gradually increases toward the downstream side in the conveying direction; and a helical blade portion integrally wound around an outer periphery of the circumferential-direction agitating blade portion.

Owner:SHARP KK

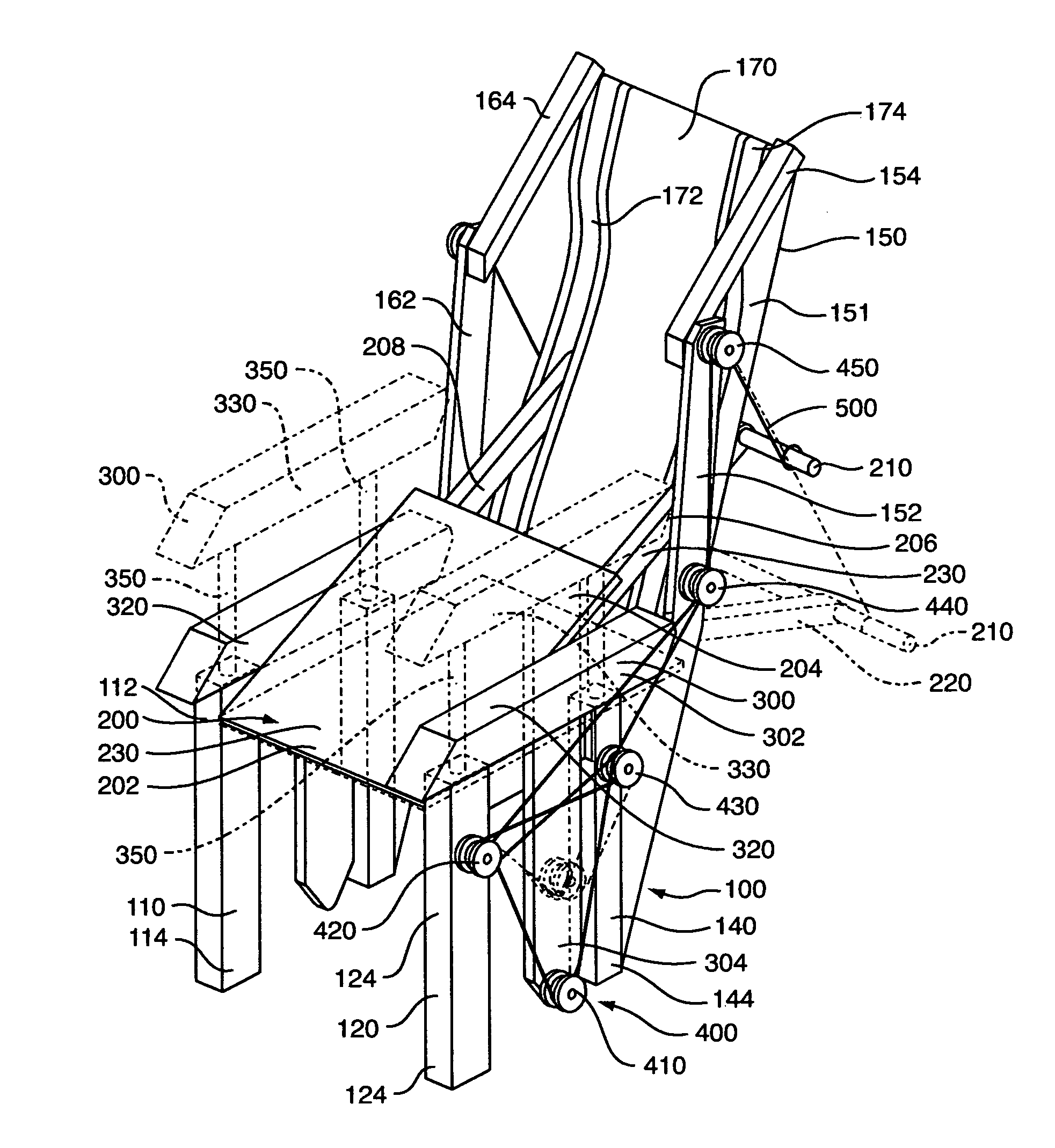

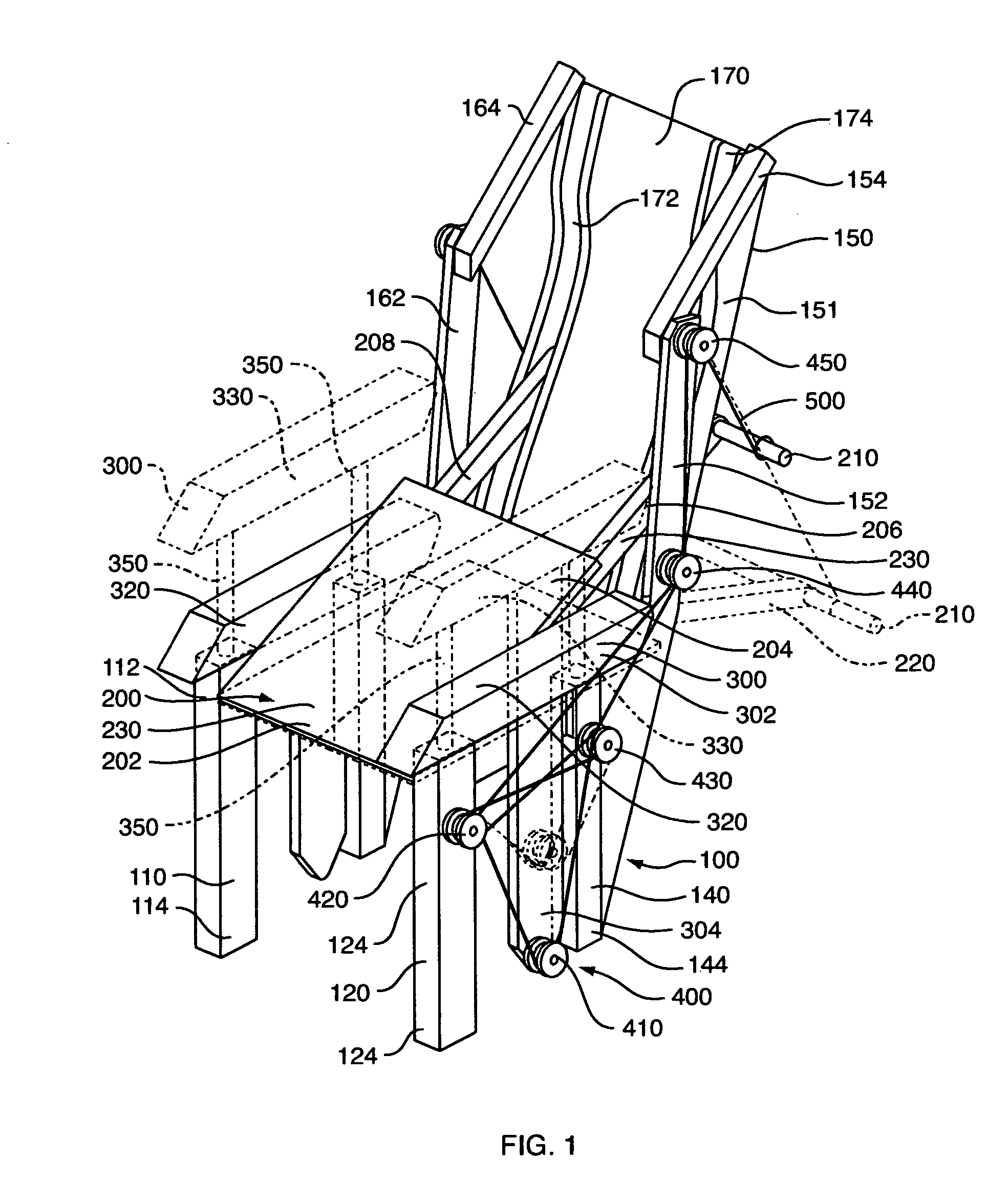

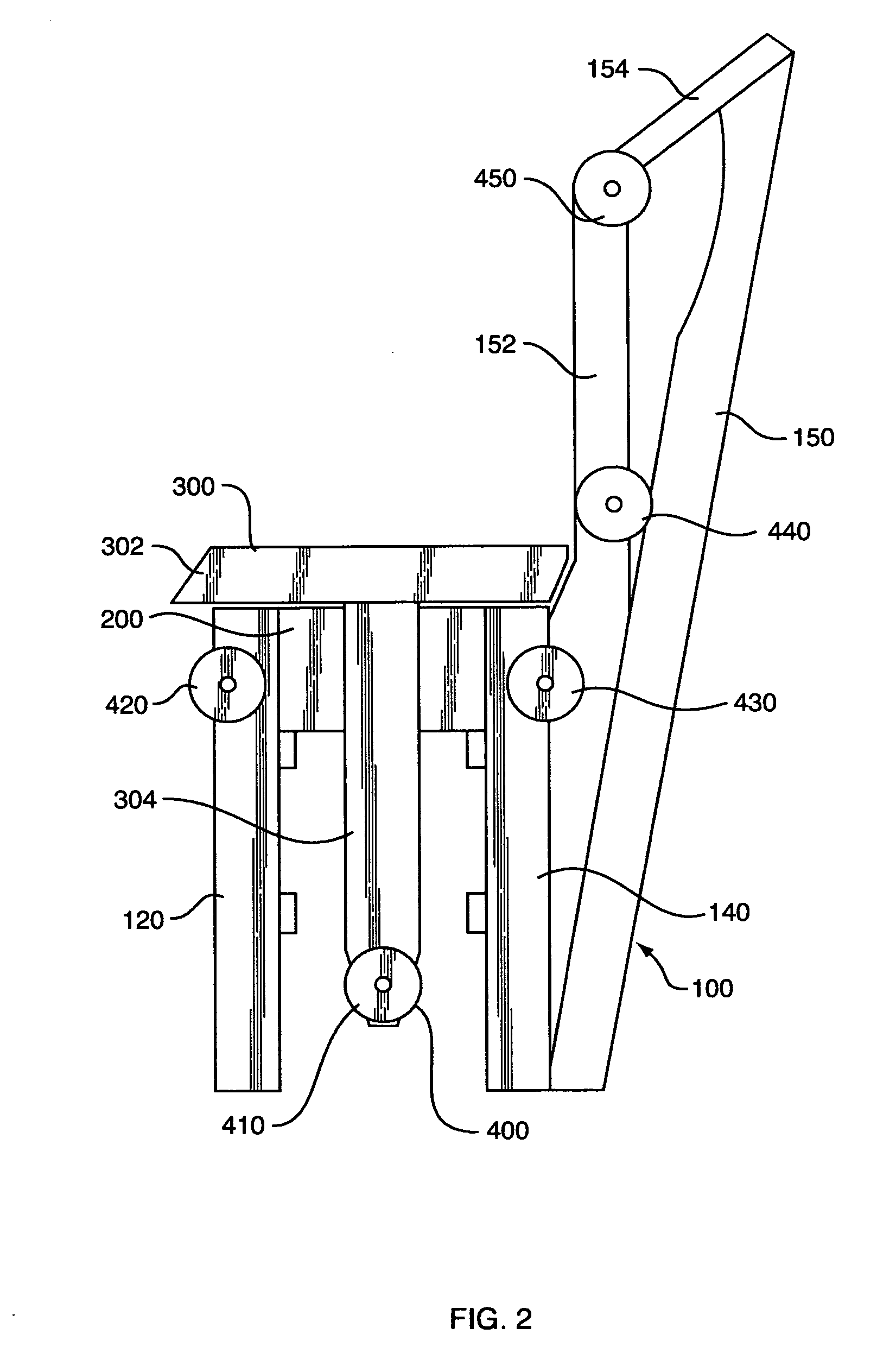

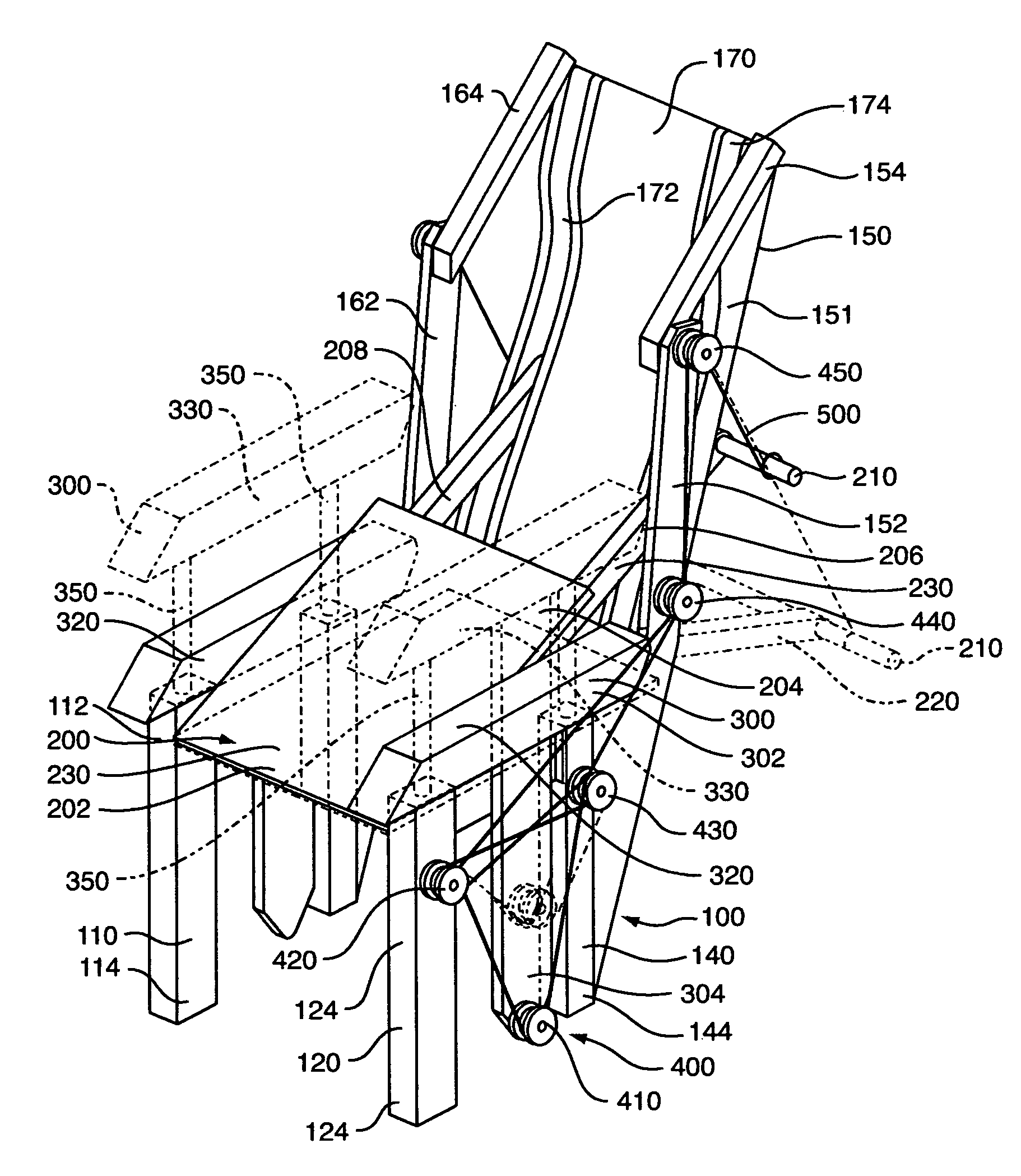

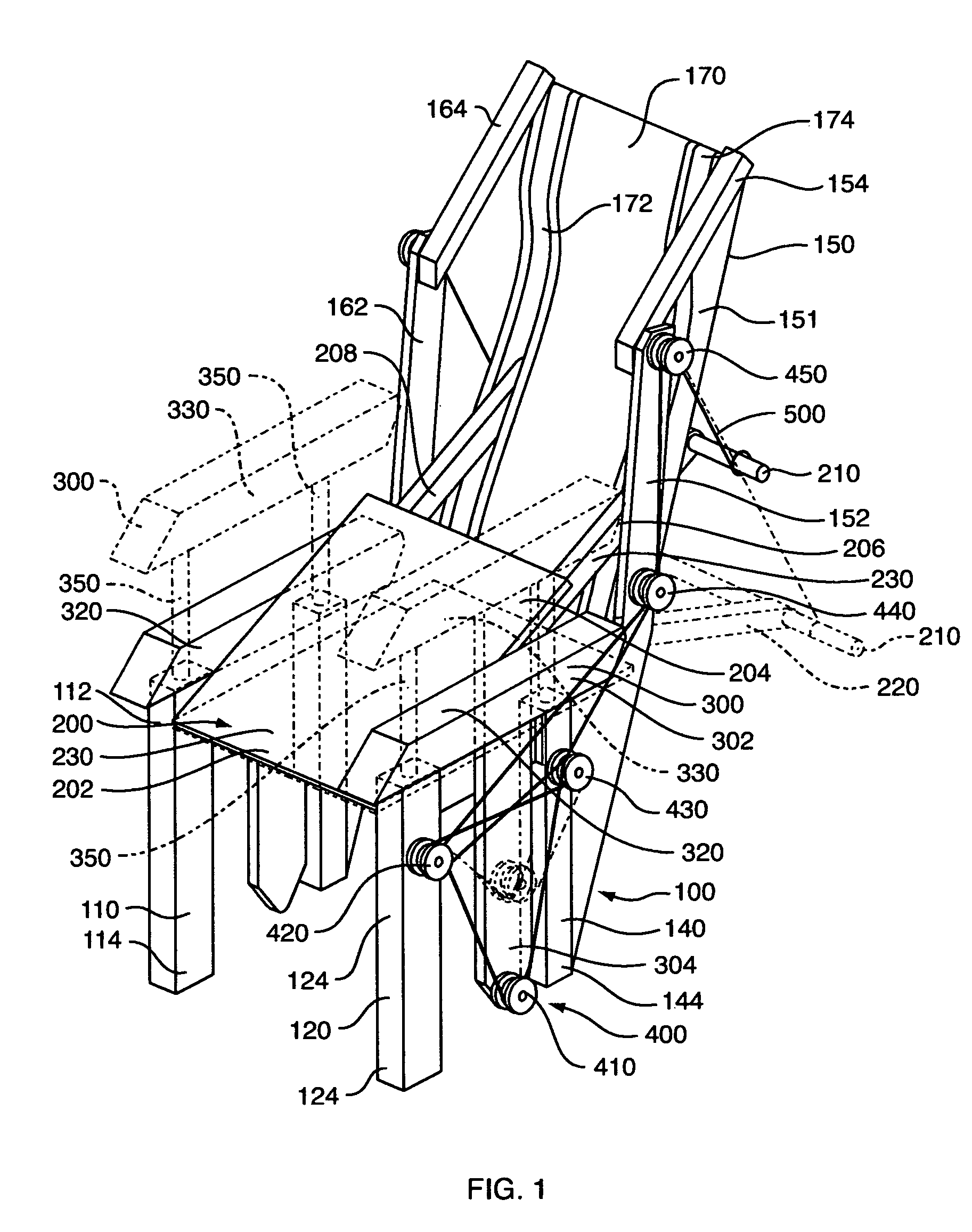

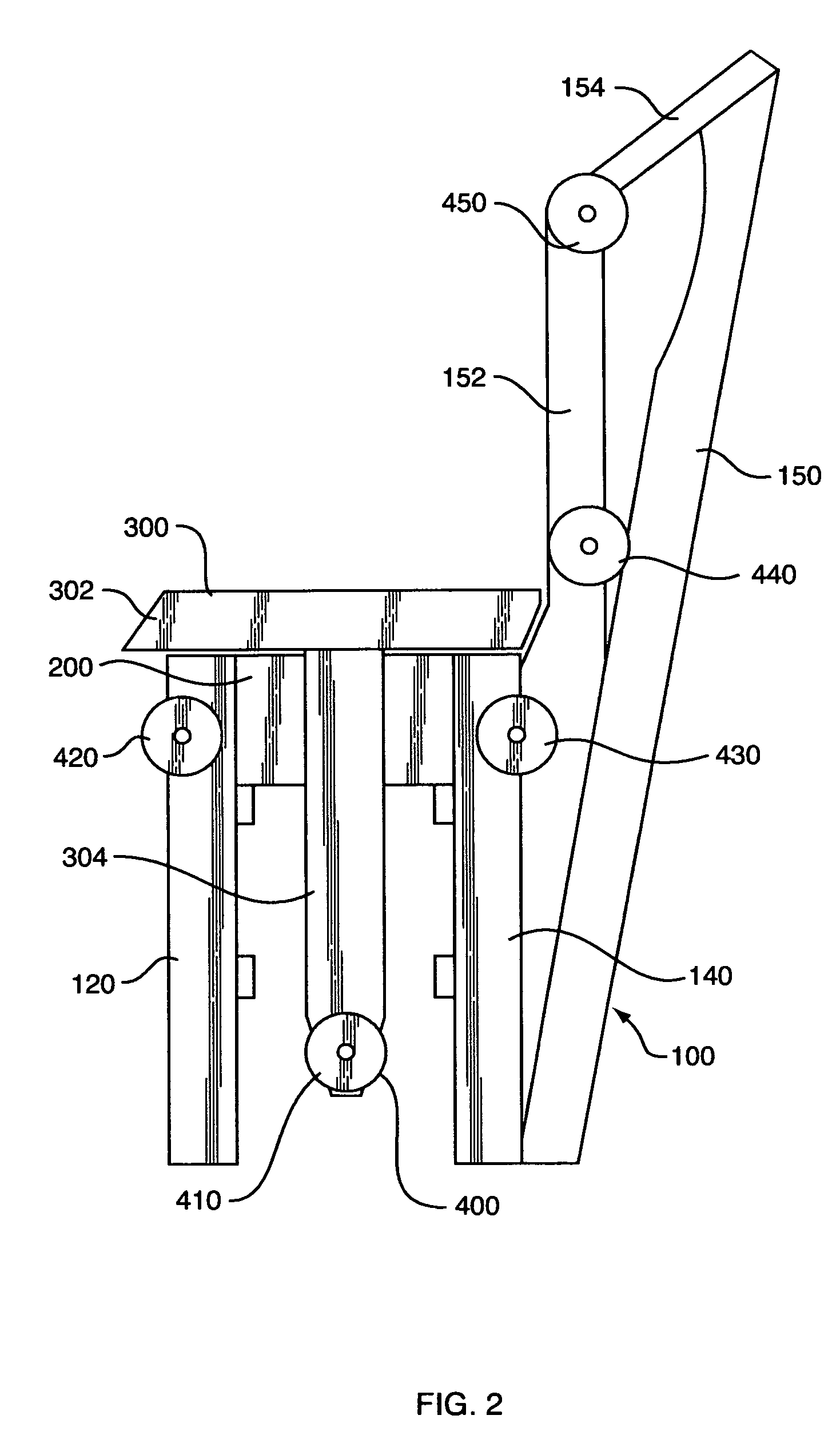

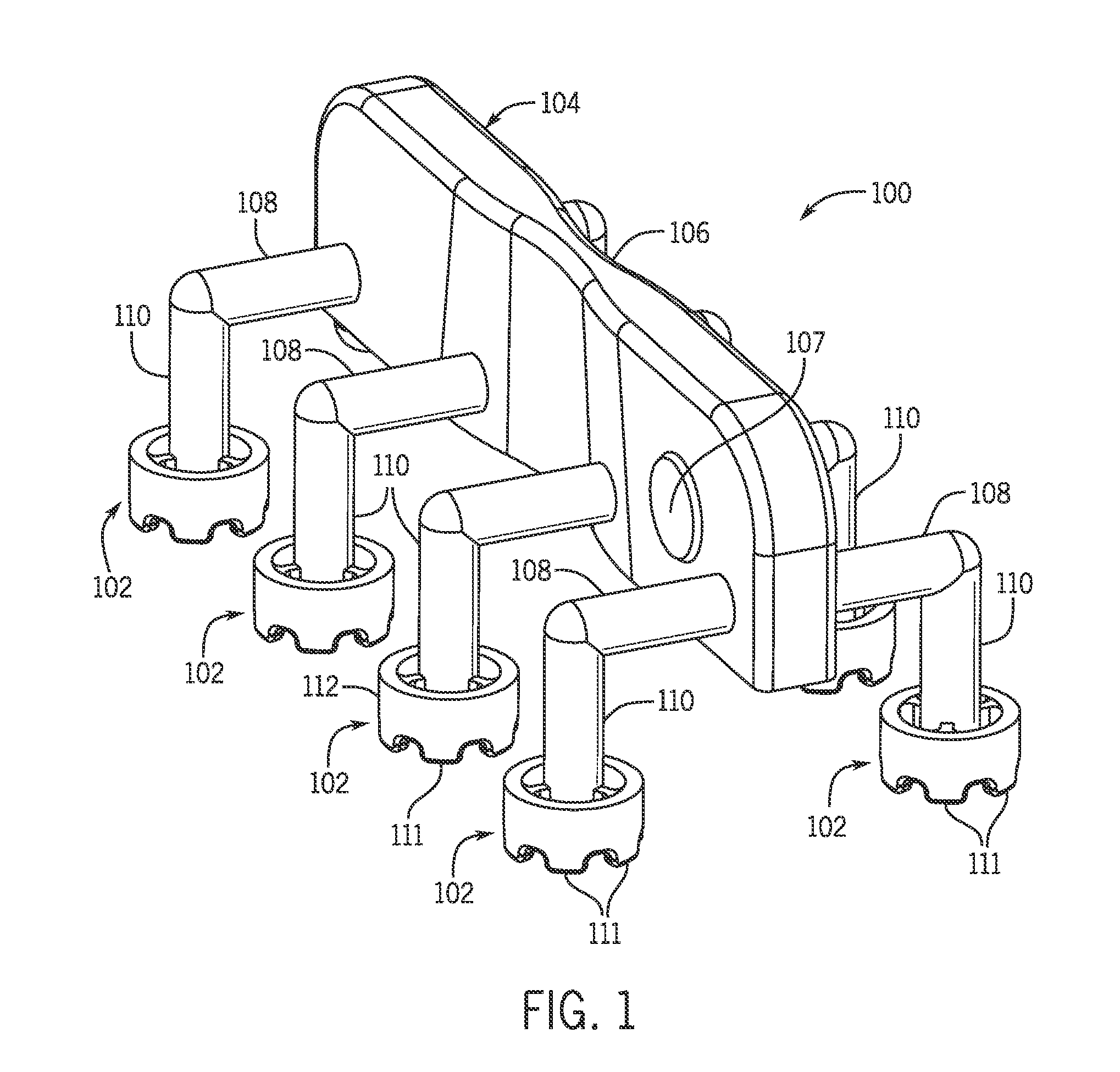

Chair lift

InactiveUS20100141003A1Great mechanical advantageSlow pressureOperating chairsWheelchairs/patient conveyanceRest positionBack rests

A lift chair is provided which includes a frame having four legs and a back rest portion. A seat has a front portion pivotally attached to the frame and has a rear portion which can be lifted upwardly. The seat movable from a first generally horizontal sitting position to a second angled lift position where the rear portion of said seat is lifted upwardly. Arm rests members are movably attached to opposite sides of the frame. Each arm rest member has a generally horizontal arm rest portion and a vertical activating rod member. The arm rests are movable from a first upper vertical position to a second lower vertical position. A rope and pulley system is provided which includes a pulley attached to a lower end of each activating rod and additional pulleys are attached to the frame. A rope is attached to the rear portion of the seat and extends around the pulleys. When a user pushes downwardly on the arm rests, the arm rests together with the rope and pulleys cause the rear portion of said seat to be lifted upwardly thus helping the user to stand up and get out of the chair.

Owner:COMBS JOHN A

Chair lift

InactiveUS7735926B1Slow pressureReduce pressureOperating chairsWheelchairs/patient conveyanceRest positionEngineering

A lift chair is provided which includes a frame having four legs and a back rest portion. A seat has a front portion pivotally attached to the frame and has a rear portion which can be lifted upwardly. The seat movable from a first generally horizontal sitting position to a second angled lift position where the rear portion of said seat is lifted upwardly. Arm rests members are movably attached to opposite sides of the frame. Each arm rest member has a generally horizontal arm rest portion and a vertical activating rod member. The arm rests are movable from a first upper vertical position to a second lower vertical position. A rope and pulley system is provided which includes a pulley attached to a lower end of each activating rod and additional pulleys are attached to the frame. A rope is attached to the rear portion of the seat and extends around the pulleys. When a user pushes downwardly on the arm rests, the arm rests together with the rope and pulleys cause the rear portion of said seat to be lifted upwardly thus helping the user to stand up and get out of the chair.

Owner:COMBS JOHN A

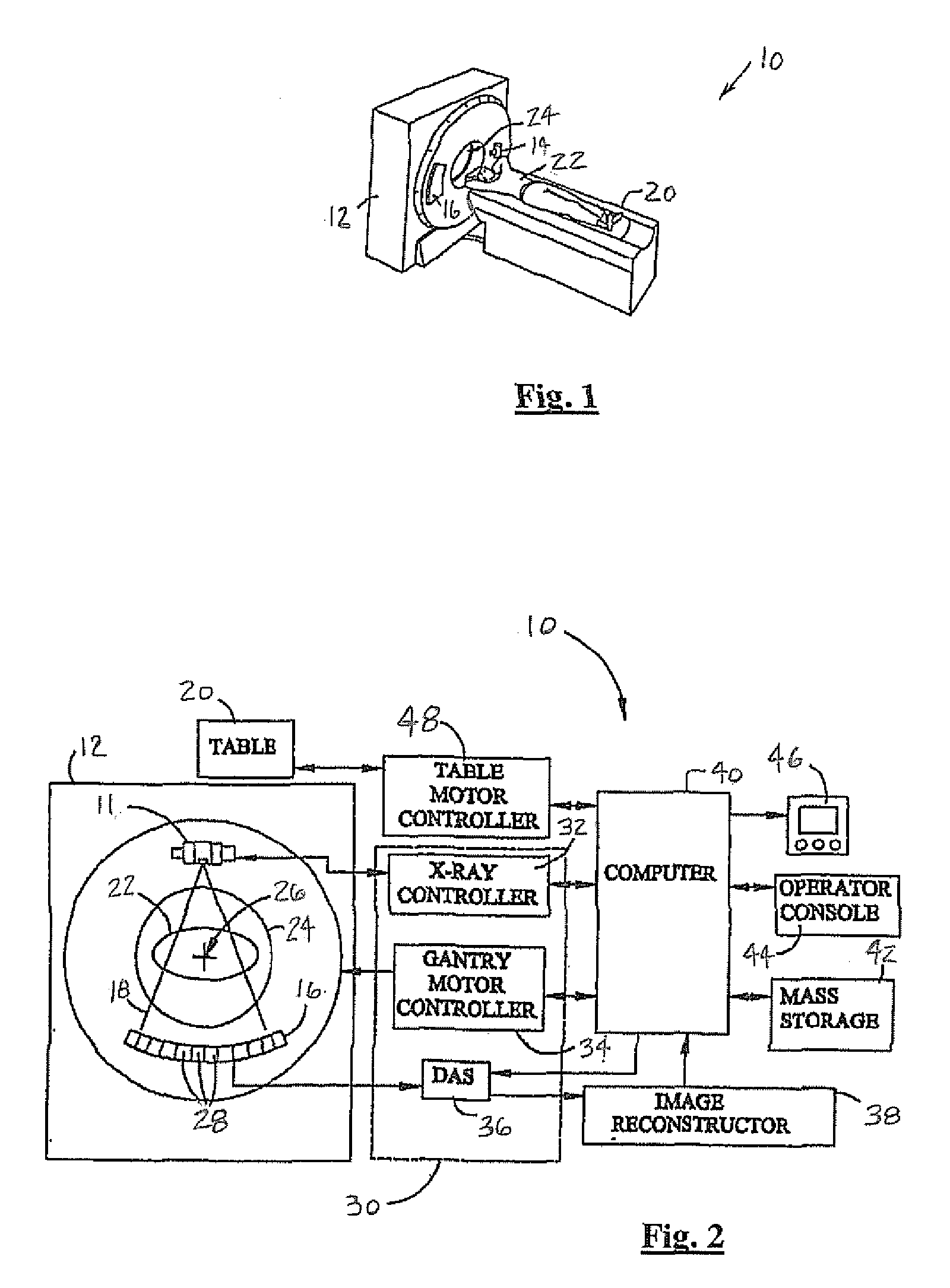

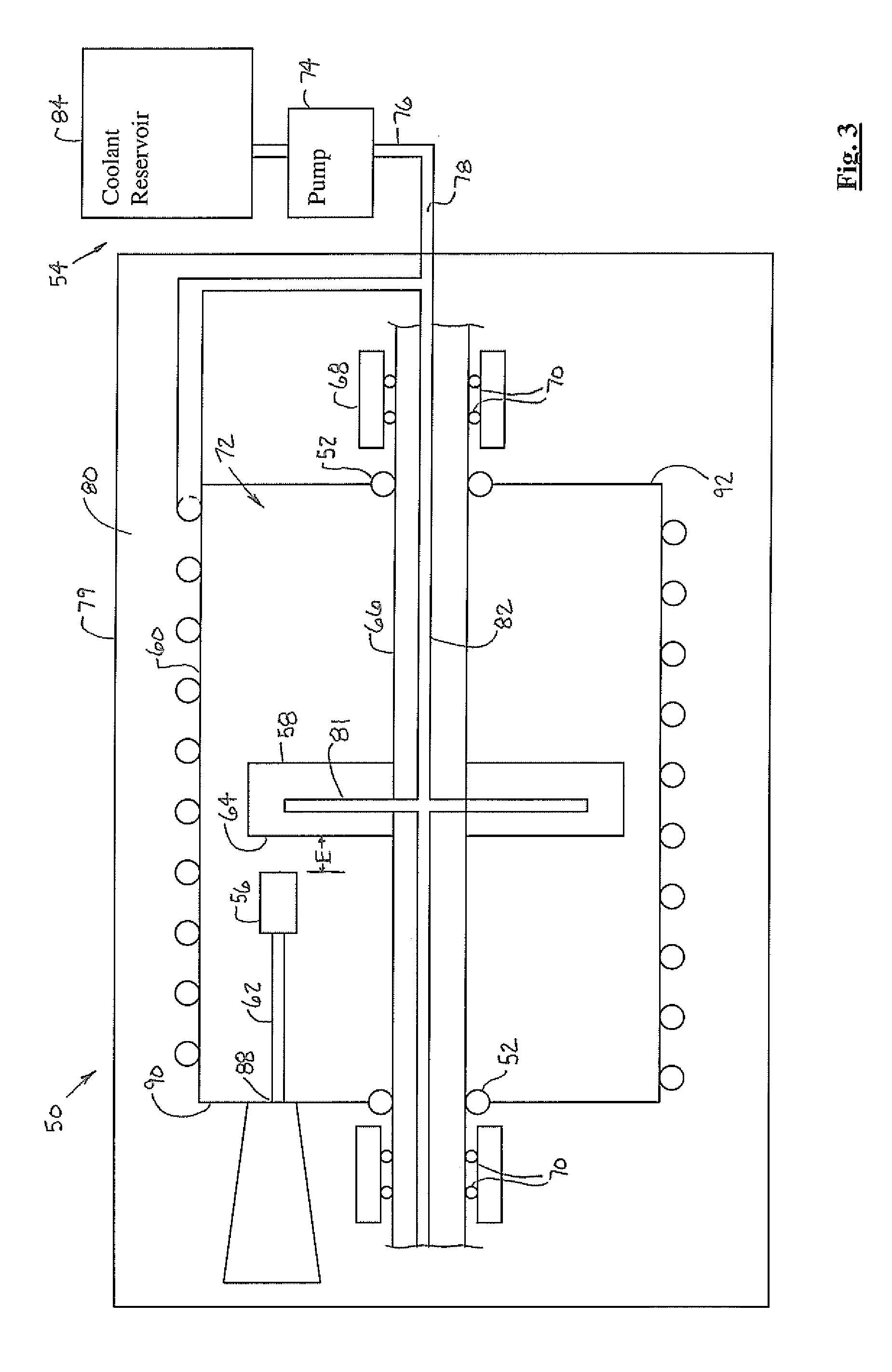

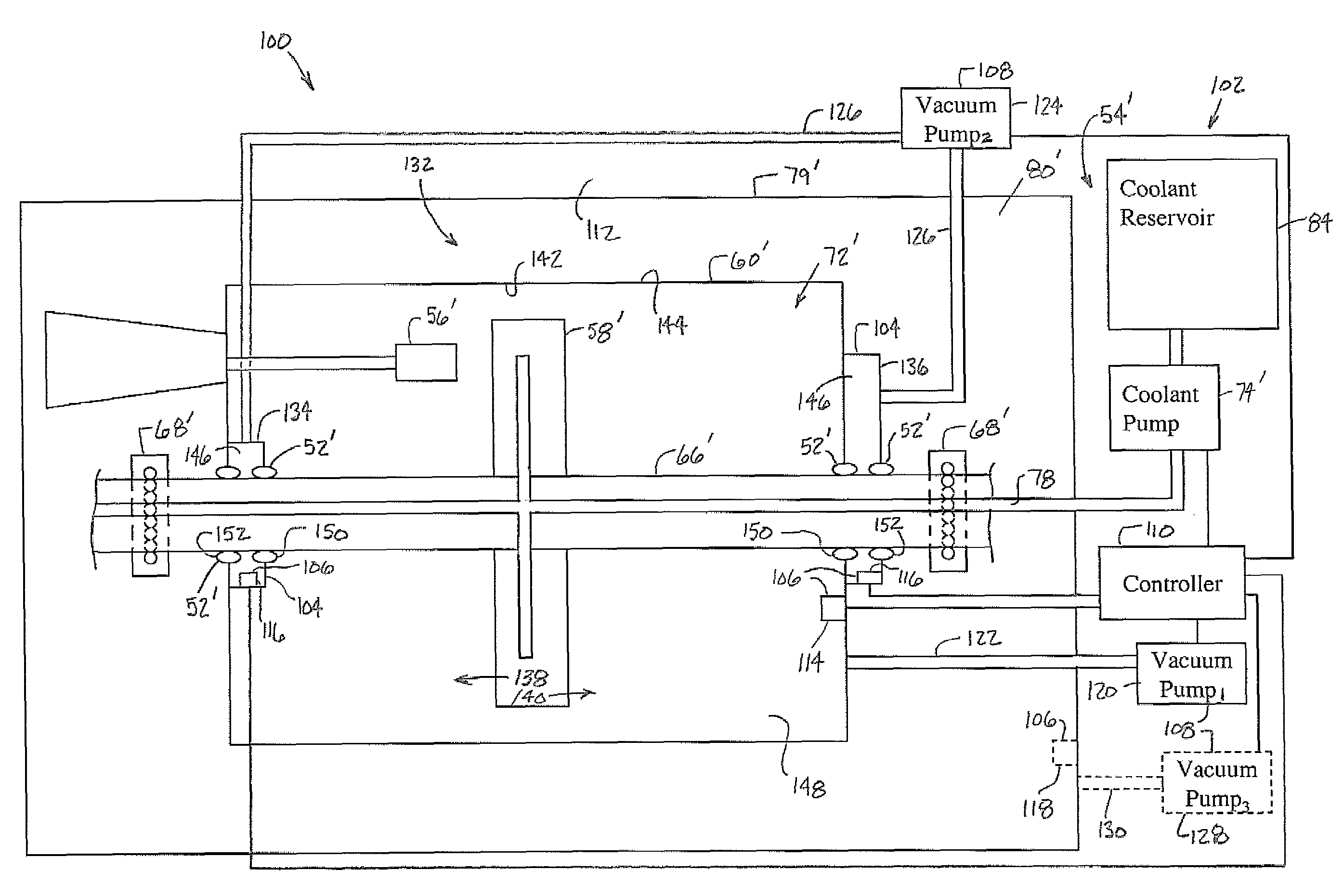

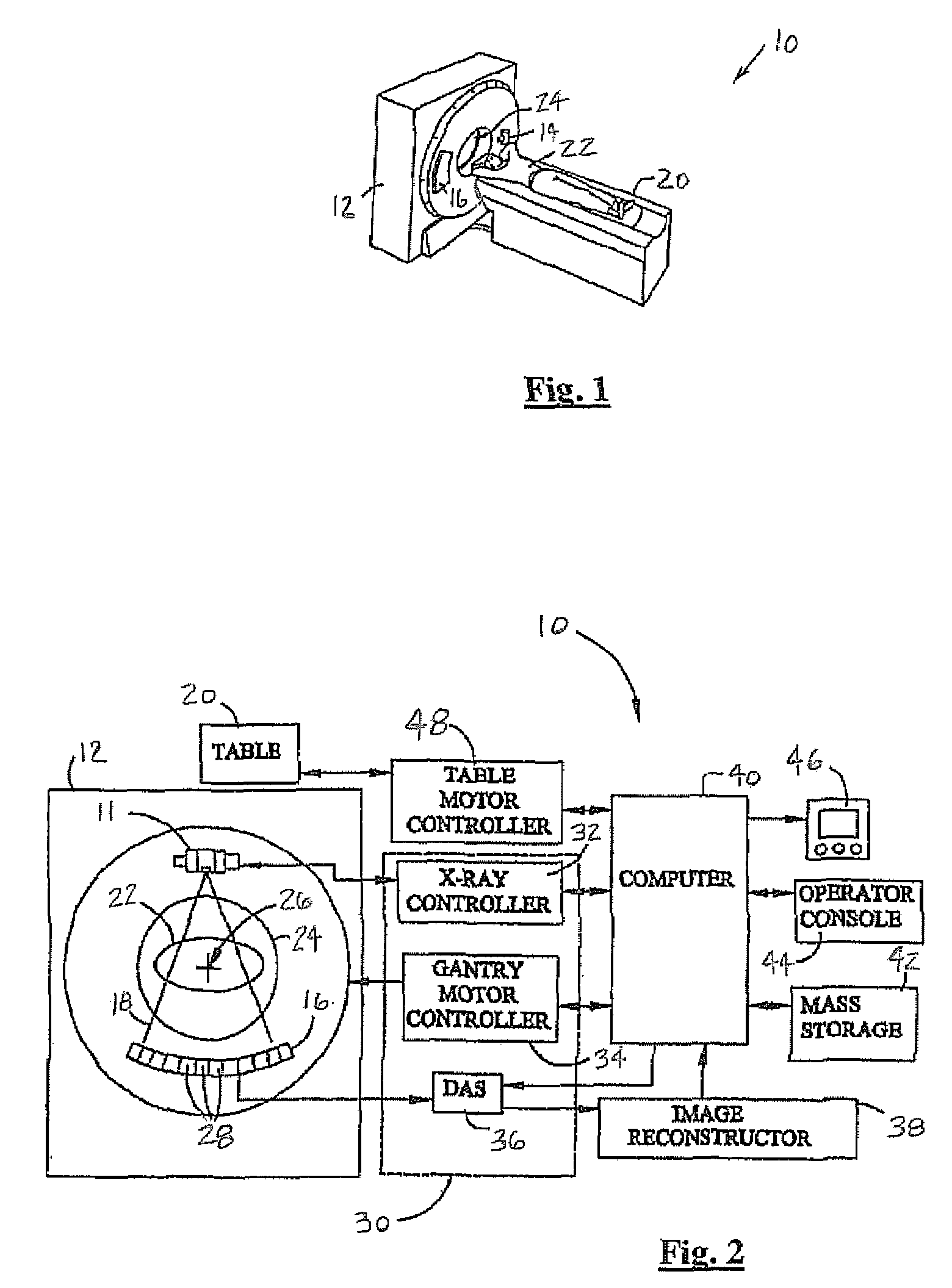

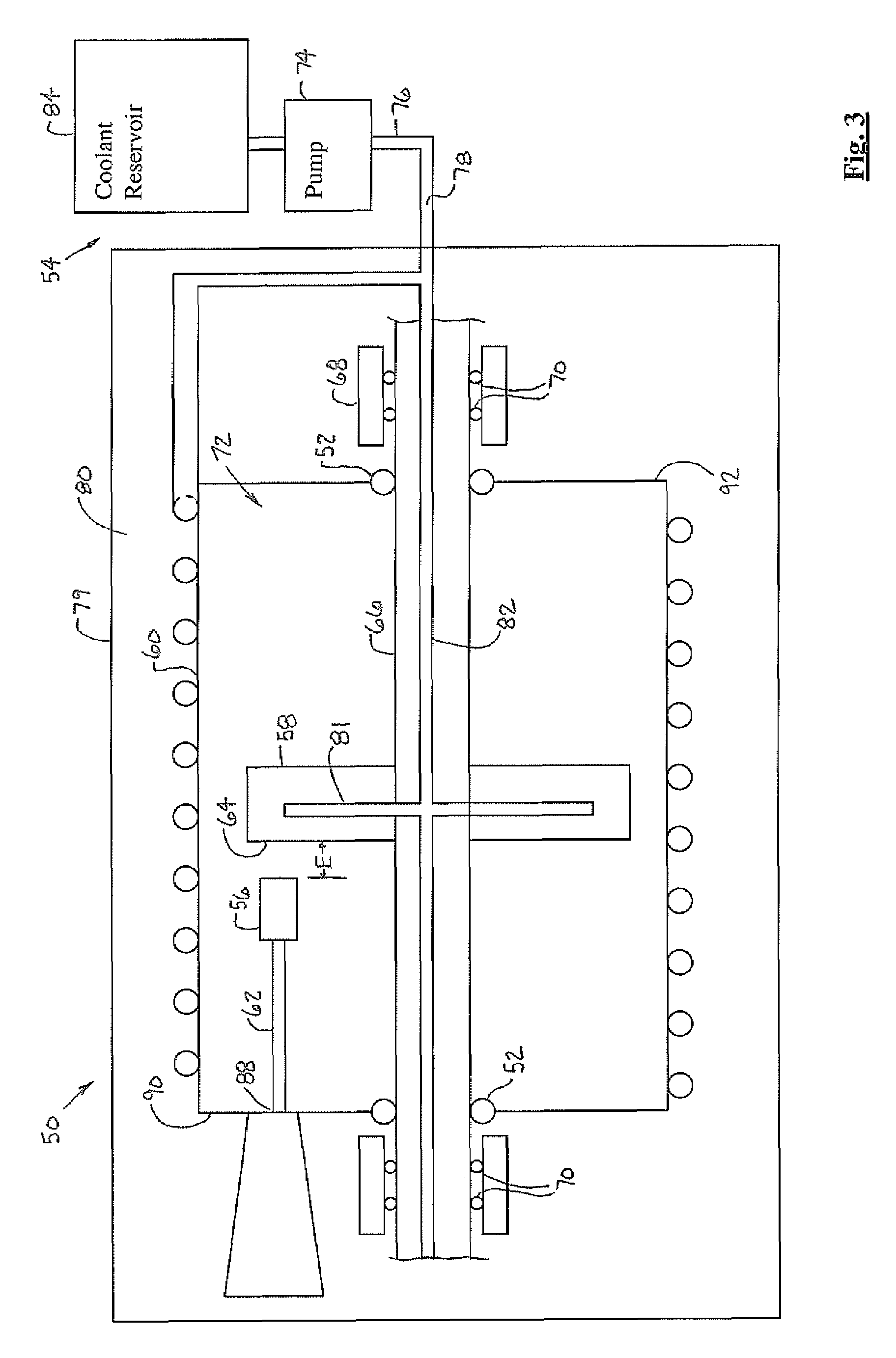

Cantilever and straddle x-ray tube configurations for a rotating anode with vacuum transition chambers

InactiveUS20060034425A1Obstruct passageOutput power is lessX-ray tube electrodesX-ray tube gas fillingComputed tomographyEngineering

An imaging tube assembly (11) for a computed tomography (CT) system (10) includes an insert (60) that has a vacuum chamber (72). An anode (58) resides within the vacuum chamber (72) and rotates on a shaft (66) via one or more bearing (70). In one embodiment, a seal (52) resides between the insert (60) and the shaft (66). The seal (52) prevents the passage of a gas (80) into the vacuum chamber (72). In another embodiment, a pressure transition chamber (104) is coupled to an insert (60″) and a shaft (66″). The pressure transition chamber (104) has an associated middle fluid pressure that is between an internal fluid pressure of the vacuum chamber (104) and an external fluid pressure of said insert (60″).

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Cleaning unit for an inkjet printing device

InactiveUS20040021726A1Prevent penetrationPrevent incrustation of the nozzle outletsPrintingInk printerEngineering

Owner:DURST PHOTOTECHN

Cantilever and straddle x-ray tube configurations for a rotating anode with vacuum transition chambers

InactiveUS7197115B2Obstruct passageOutput power is lessX-ray tube electrodesX-ray tube gas fillingComputed tomographyStraddle

An imaging tube assembly (11) for a computed tomography (CT) system (10) includes an insert (60) that has a vacuum chamber (72). An anode (58) resides within the vacuum chamber (72) and rotates on a shaft (66) via one or more bearing (70). In one embodiment, a seal (52) resides between the insert (60) and the shaft (66). The seal (52) prevents the passage of a gas (80) into the vacuum chamber (72). In another embodiment, a pressure transition chamber (104) is coupled to an insert (60″) and a shaft (66″). The pressure transition chamber (104) has an associated middle fluid pressure that is between an internal fluid pressure of the vacuum chamber (104) and an external fluid pressure of said insert (60″).

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

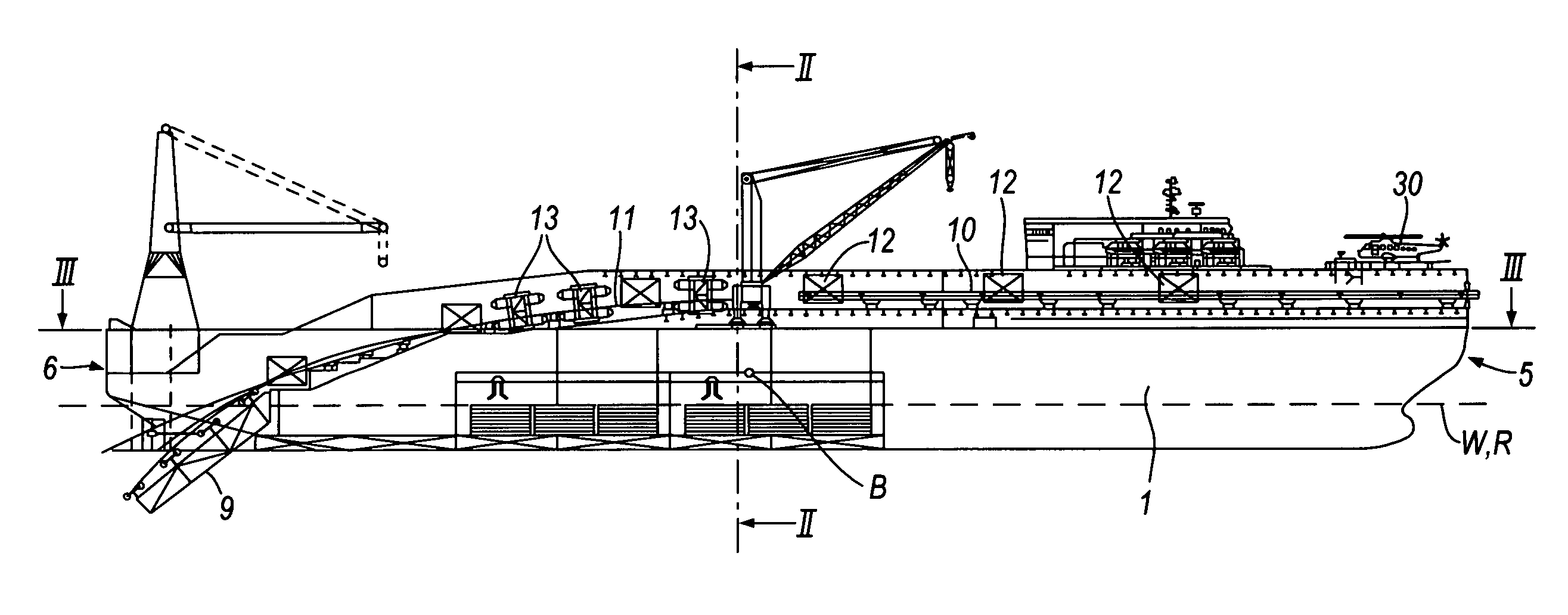

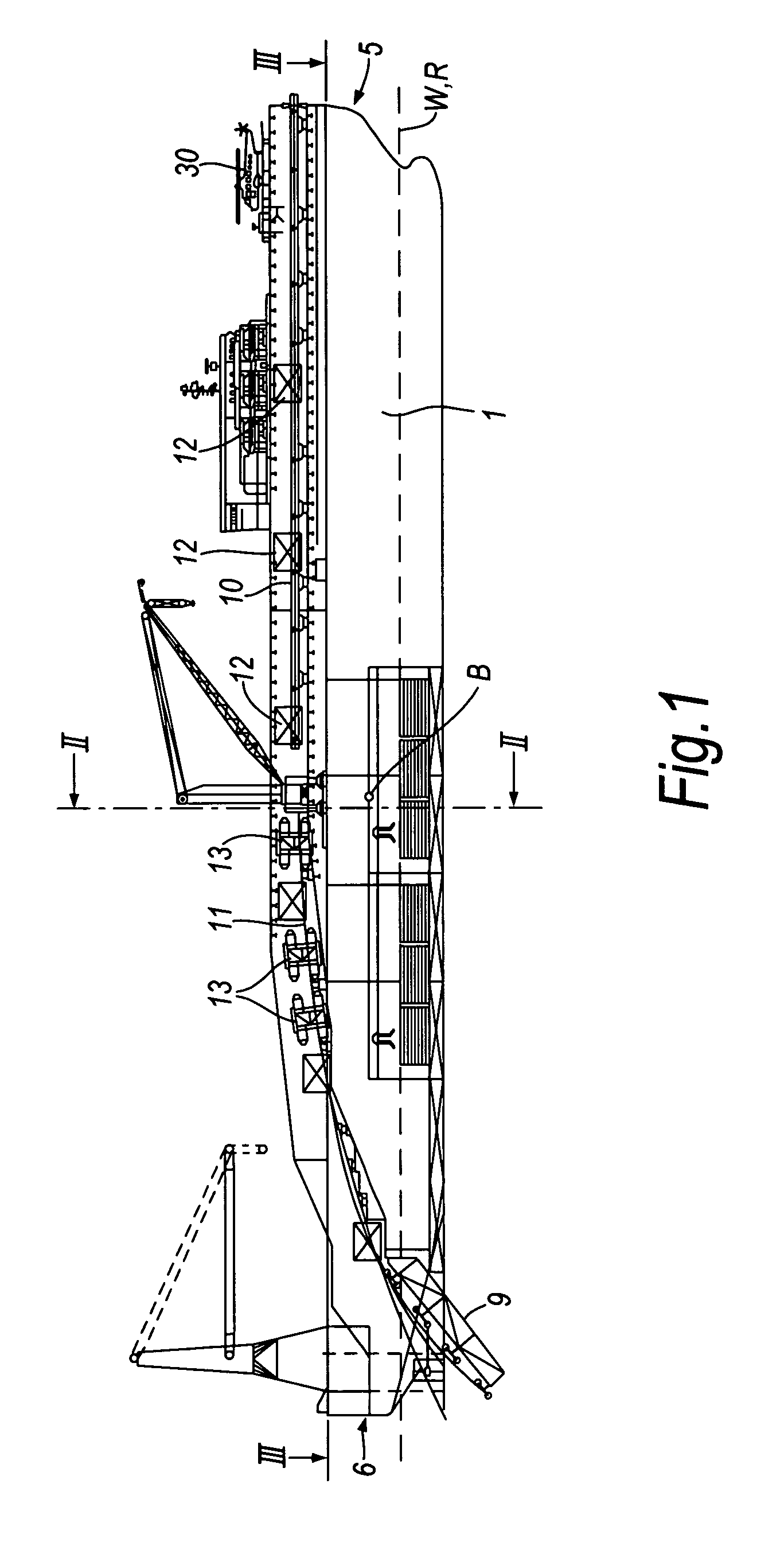

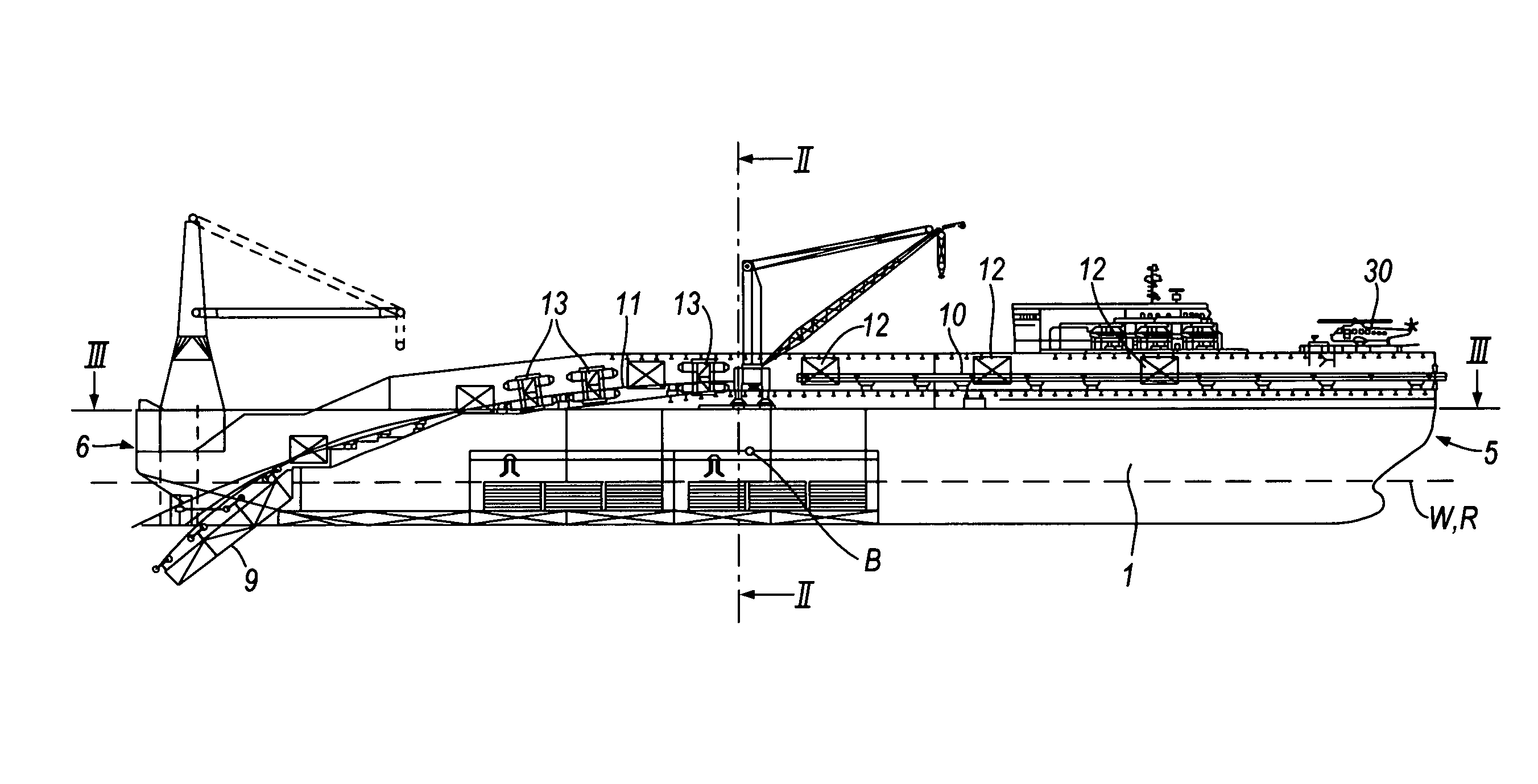

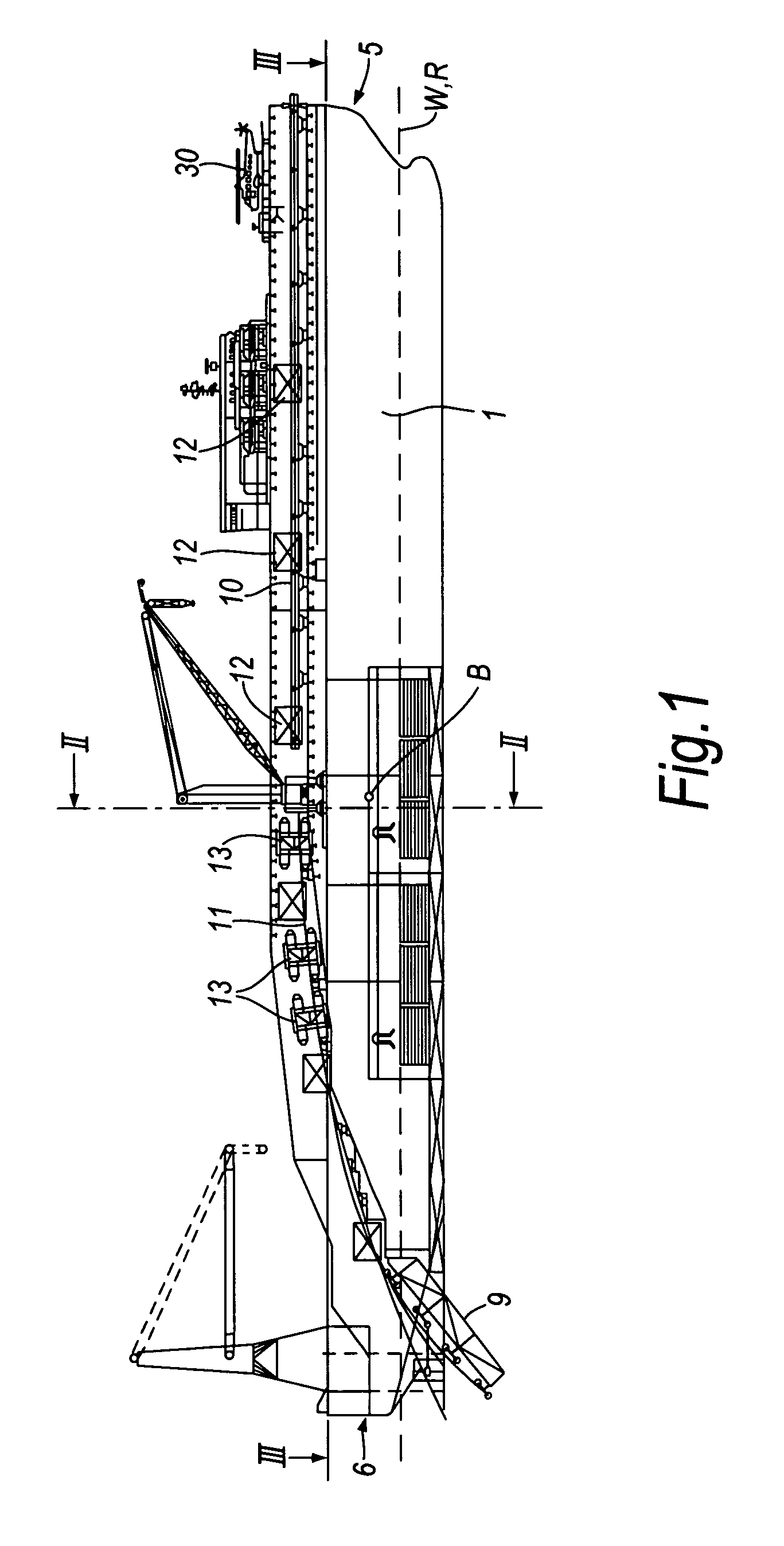

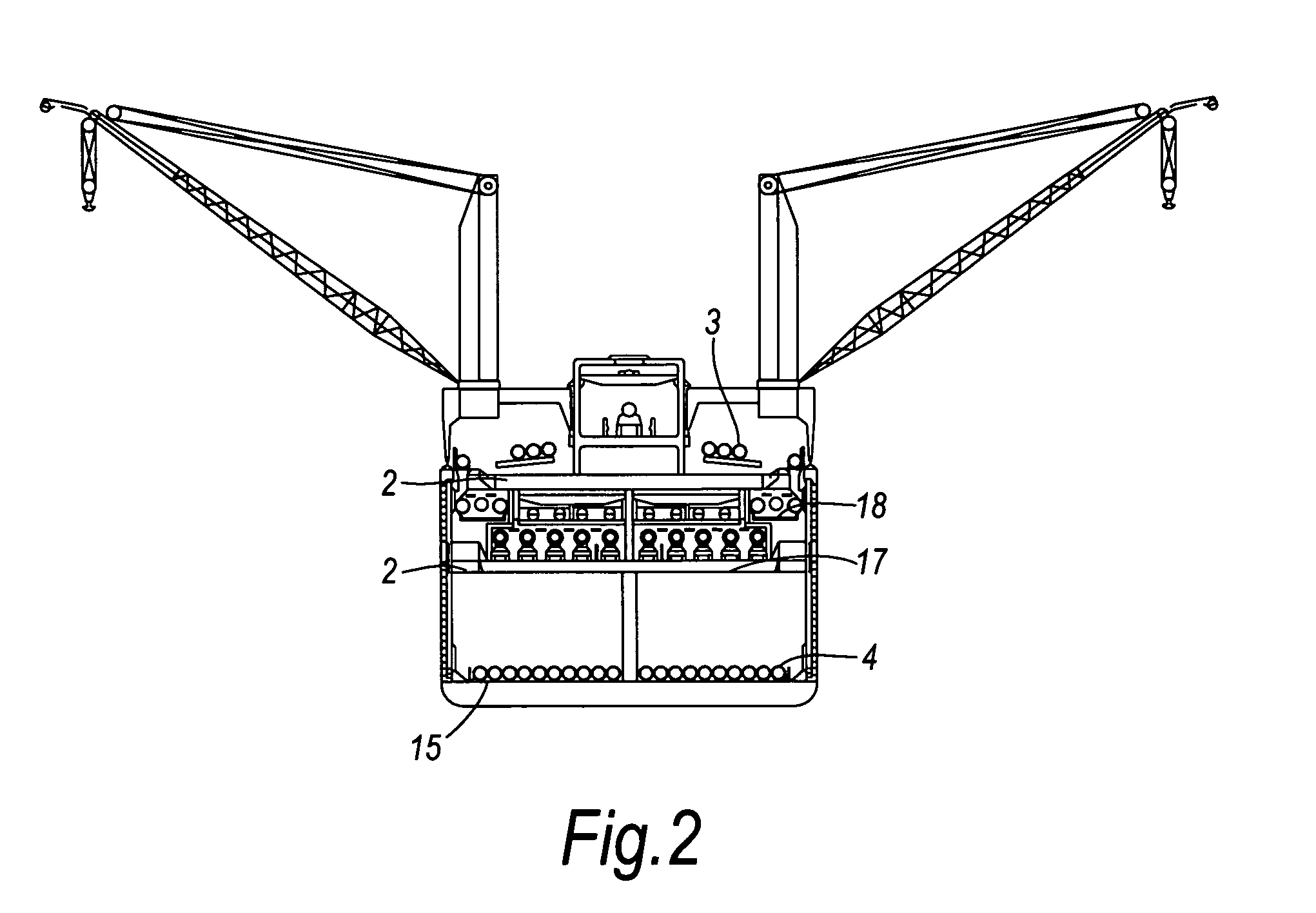

Undersea pipe-laying

ActiveUS20100080657A1Improve protectionImprove accessibilityPipe laying and repairPipe-laying vesselsOcean bottomMarine engineering

A monohull vessel for laying a pipeline includes tensioners 13 disposed along a Pipelaying path P. The pipelaying path P includes an upstream portion that is substantially horizontal and at least 10 m above the centre of rolling R of the vessel and, towards a stern end of the vessel hull, a downstream portion that is downwardly inclined and, in use, enters the water at a location inboard of the stern end of the vessel hull 1.

Owner:SAIPEM SPA

Induced Relaxation And Therapeutic Apparatus And Method

InactiveUS20110054240A1Improve responseSlow pressureMedical devicesSleep inducing/ending devicesEngineeringInstrumentation

Owner:BENDER EDDIE L

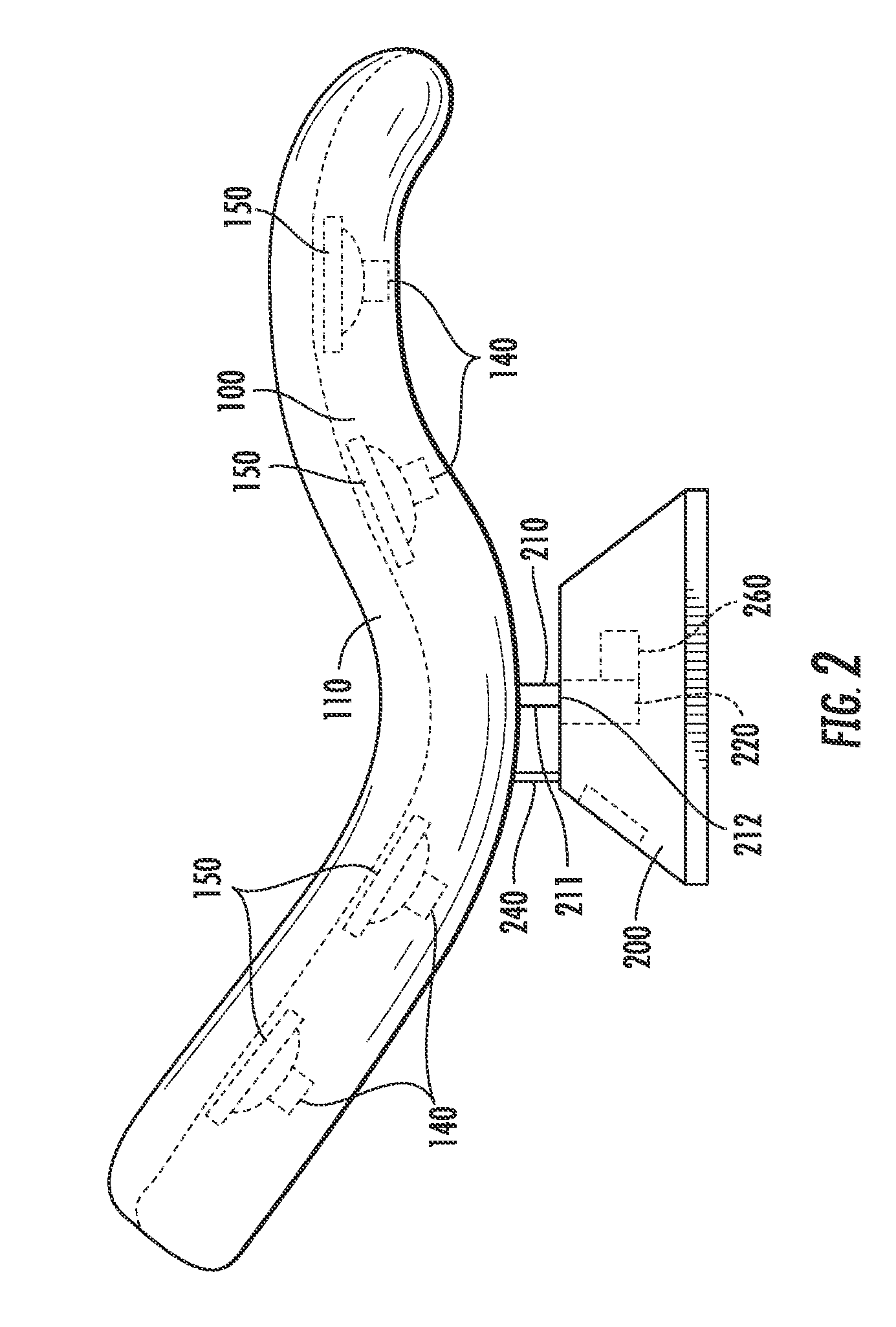

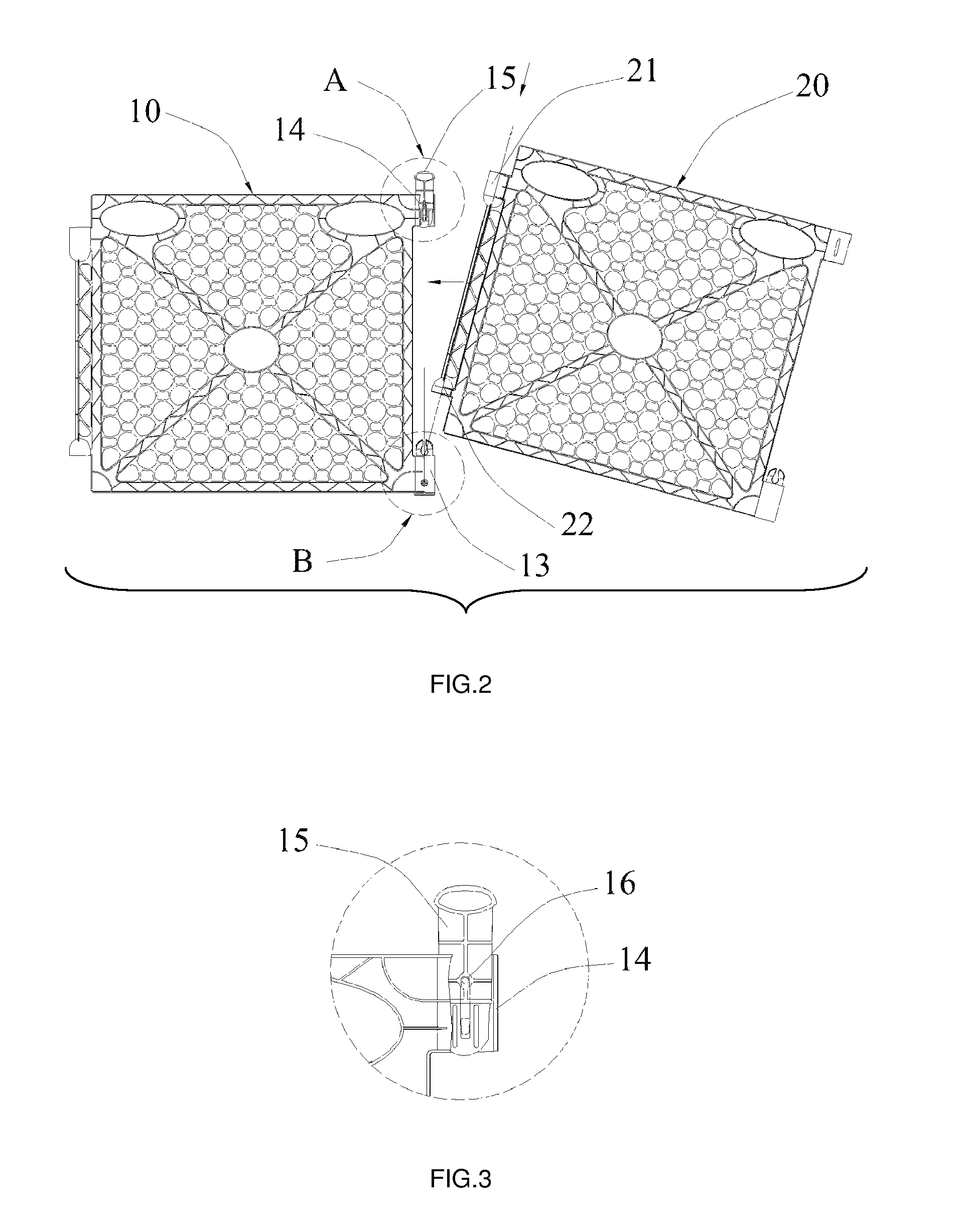

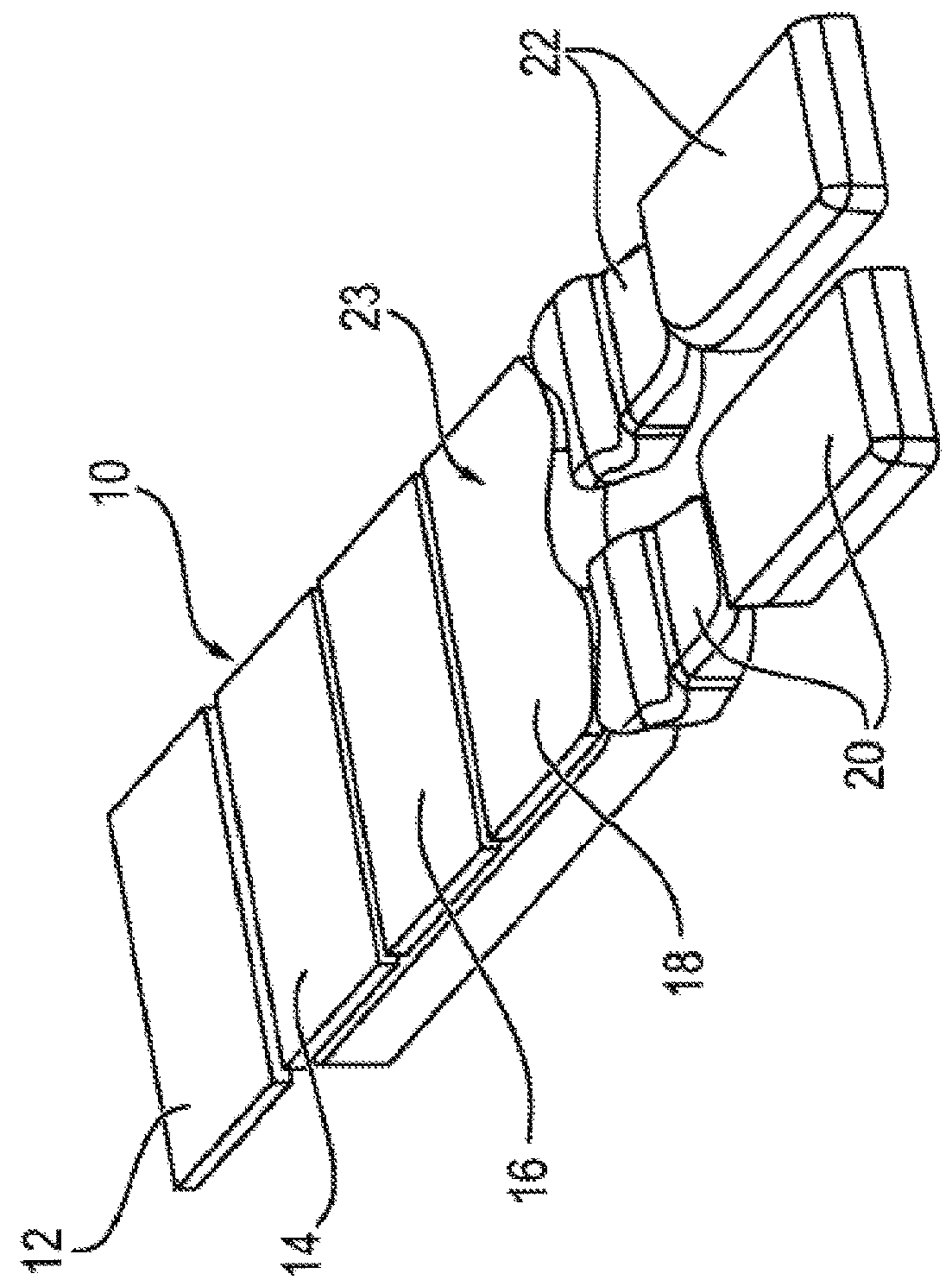

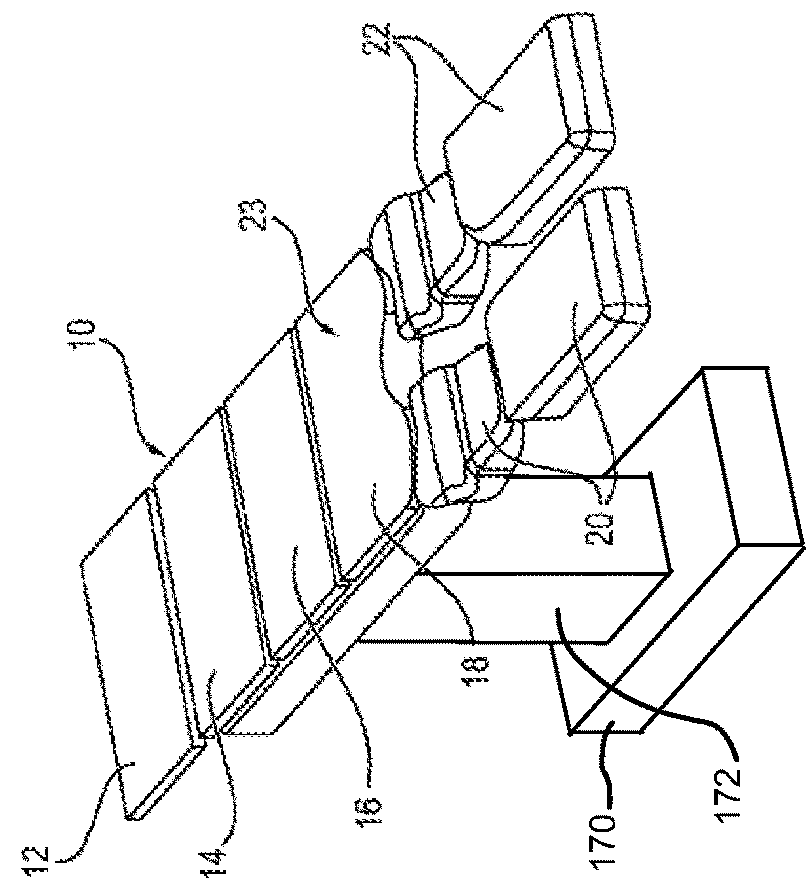

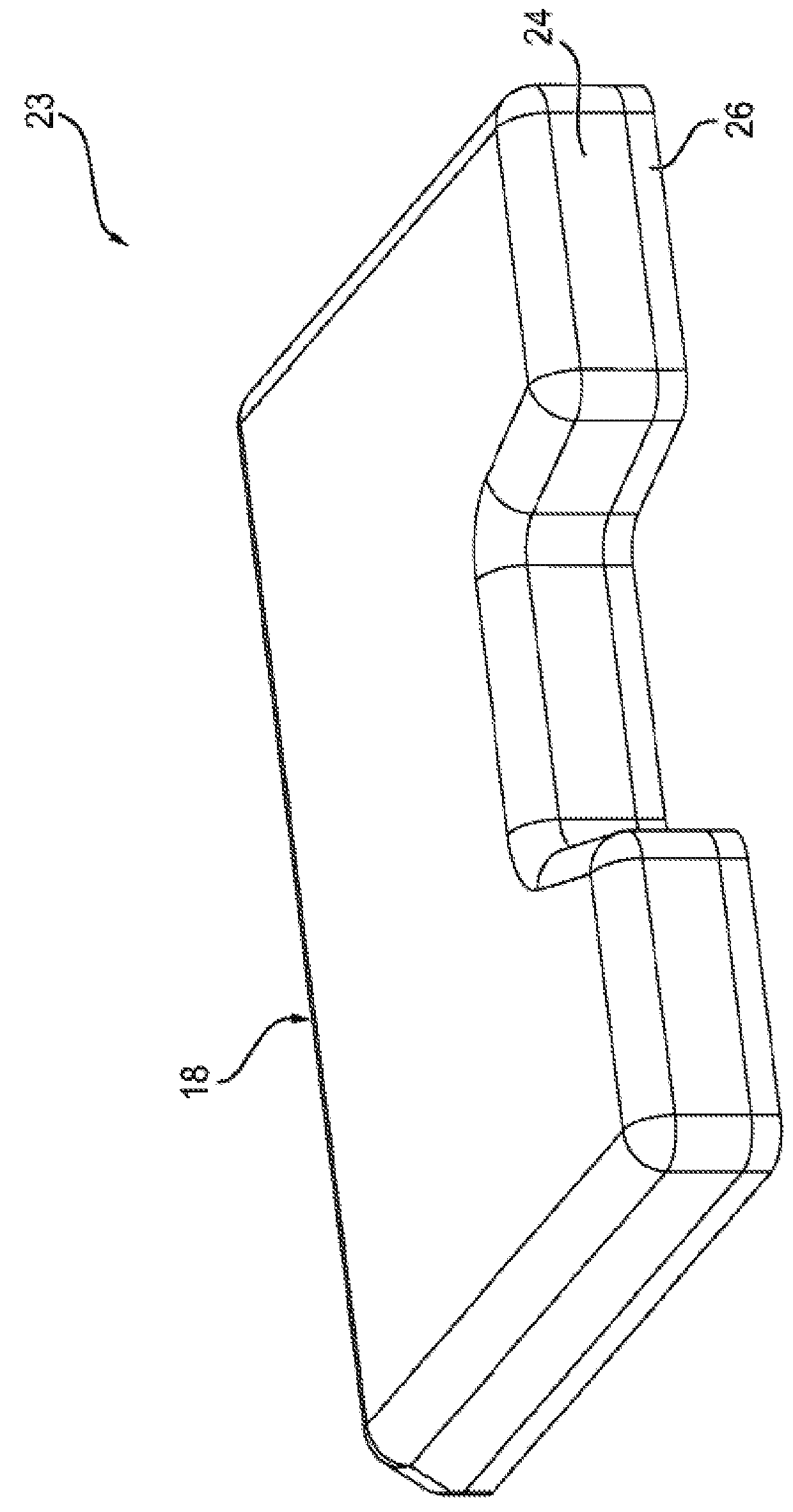

Fence for use by infants or pets

ActiveUS9215860B2Caring of the infants or pets can become easierSolve the lack of spaceFencingPasturing equipmentEngineeringCompanion animal

The present invention is a device for use by infants or pets which provides a fence for use by infants or pets to confine their activities within a restricted area so that caring of the infants or pets can become easier. The present invention comprises an assembly of fence plates rotatable in relation to each other, wherein the adjacent fence plates are assembled with each other by means of a rotating axle. The fence has a bottom portion which is disposed with fixing members. The present invention assembles a plurality of the fence plates to form a fence. The fence is fixed on the ground by the fixing members to prevent it from sliding. When infants or pets are put into an area restricted by the fence, they can enjoy sufficient rooms for activities. It is also possible to prevent the infants or pets from escaping out of the fence and to confine their activities within a restricted area, thus accidents due to absence of care could be avoided.

Owner:HSIEH ANDY MIN LUNG +1

Kneepad having an ergonomic notch

Owner:BLACK & DECKER INC

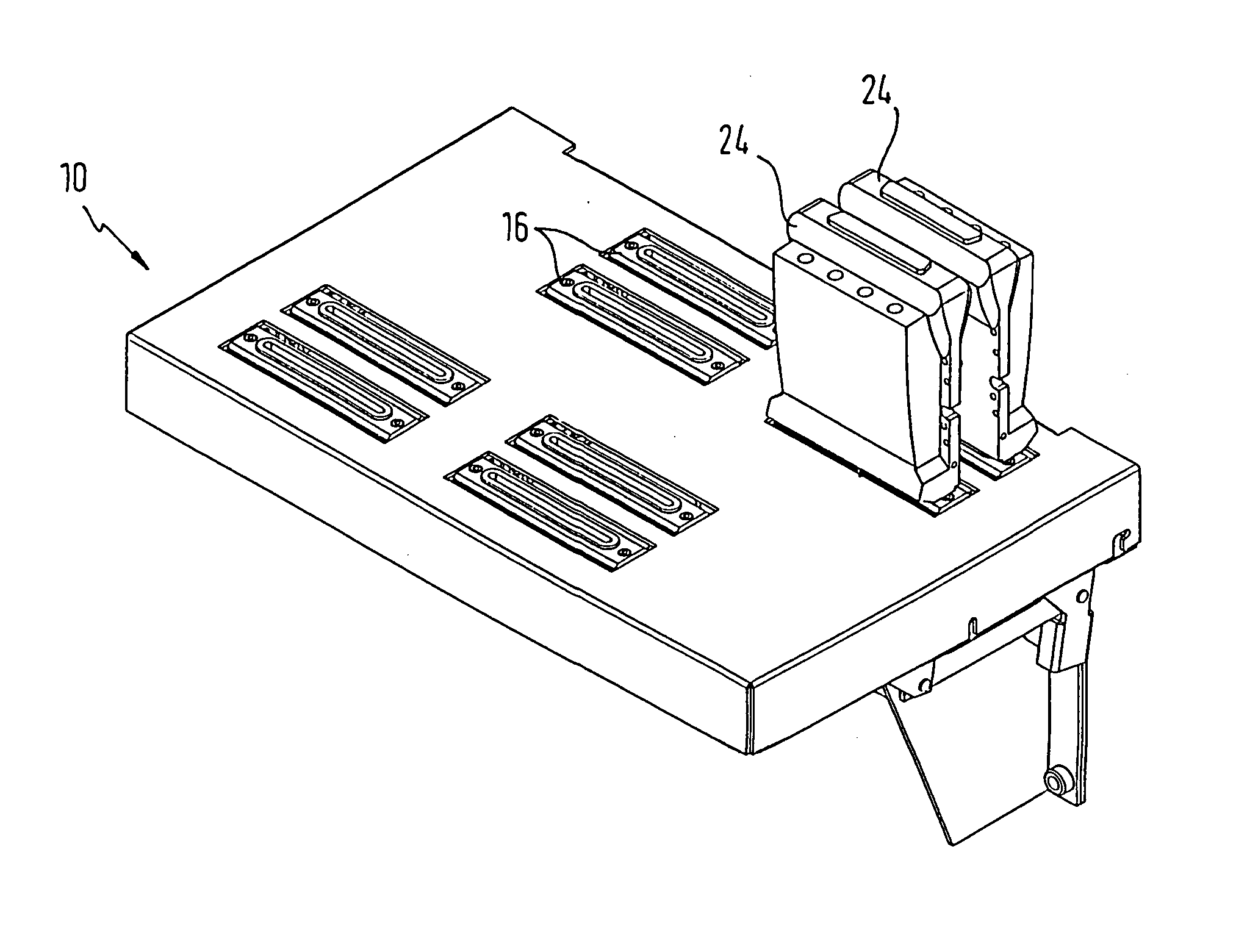

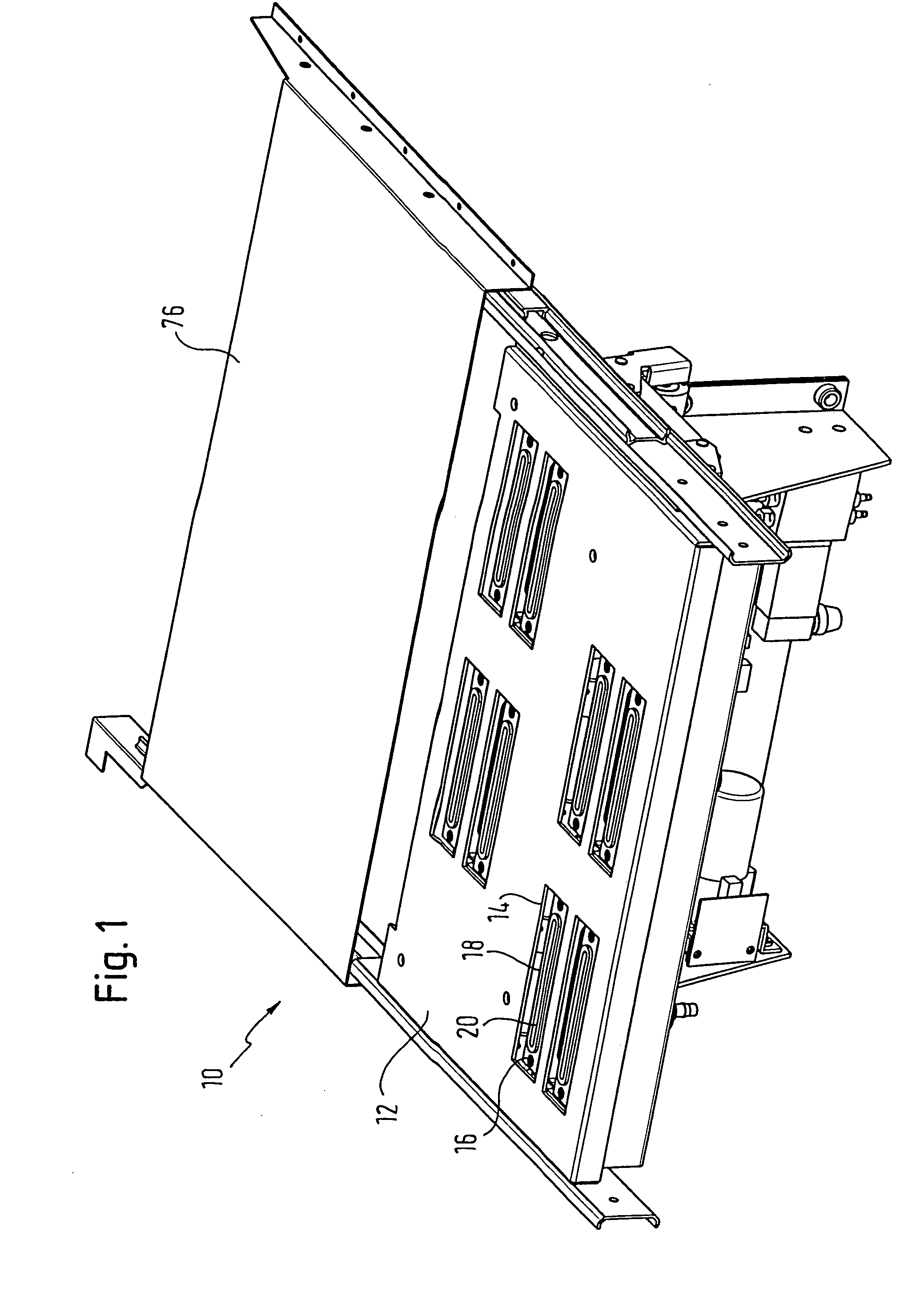

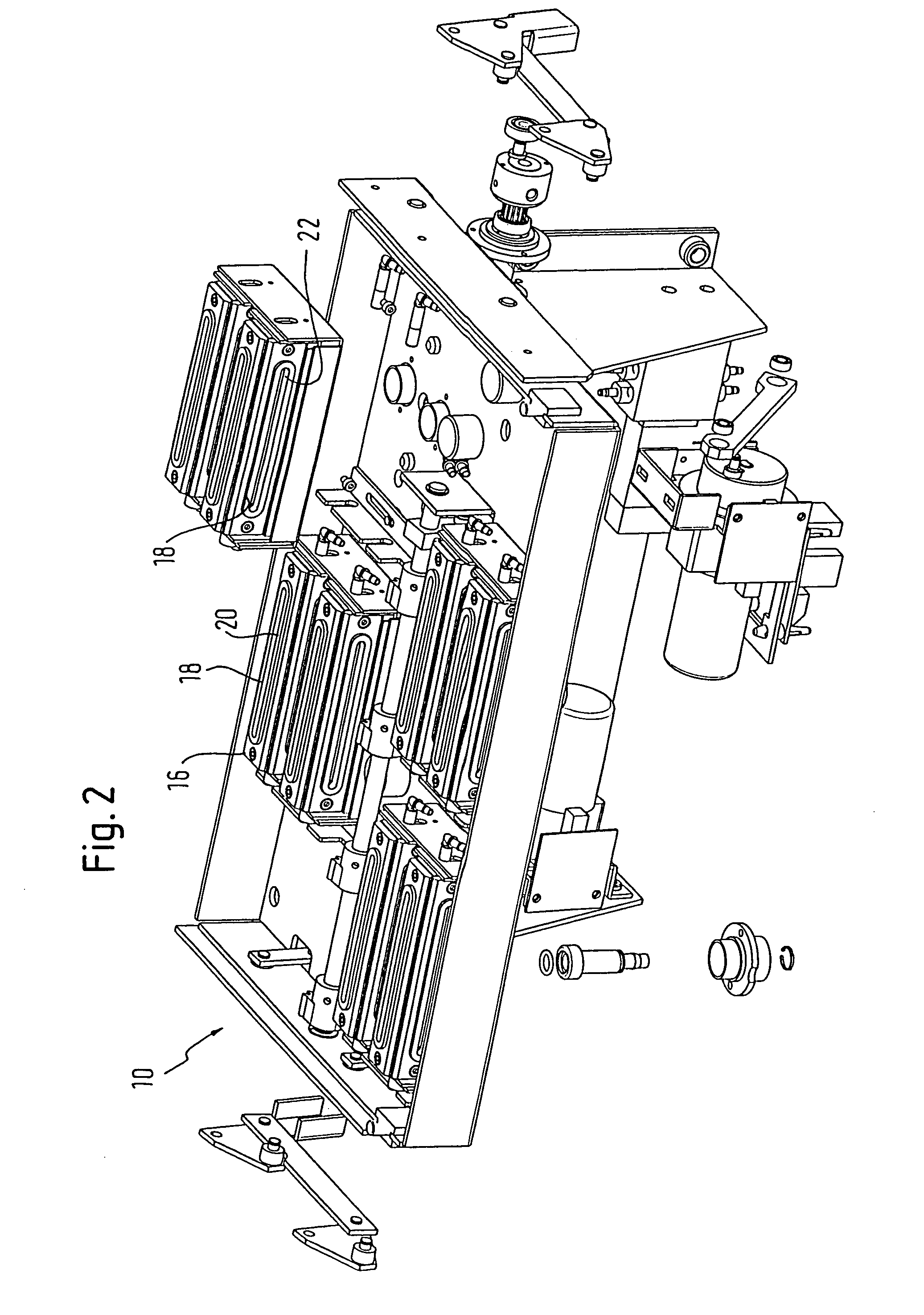

Device for heating a patient bearing area of an operating table

InactiveUS20180161198A1Optimize layoutReduce manufacturing costOperating tablesPatient positioning for diagnosticsThermodynamicsEngineering

Devices, arrangements, and methods for heating a patient bearing area of an operating table, including a heating element for heating a patient bearing area of an operating table, with a heating element for heating a fluid that transfers heat, an elastically deformable flow layer of the patient bearing area through which the heated fluid can flow, and a fluid-tight sealing layer of the patient bearing area arranged between a surface of the patient bearing area provided for contact with the patient and said flow layer. The device may include a flow circuit for the circulating, heat-bearing fluid formed as a closed path.

Owner:MAQUET GMBH

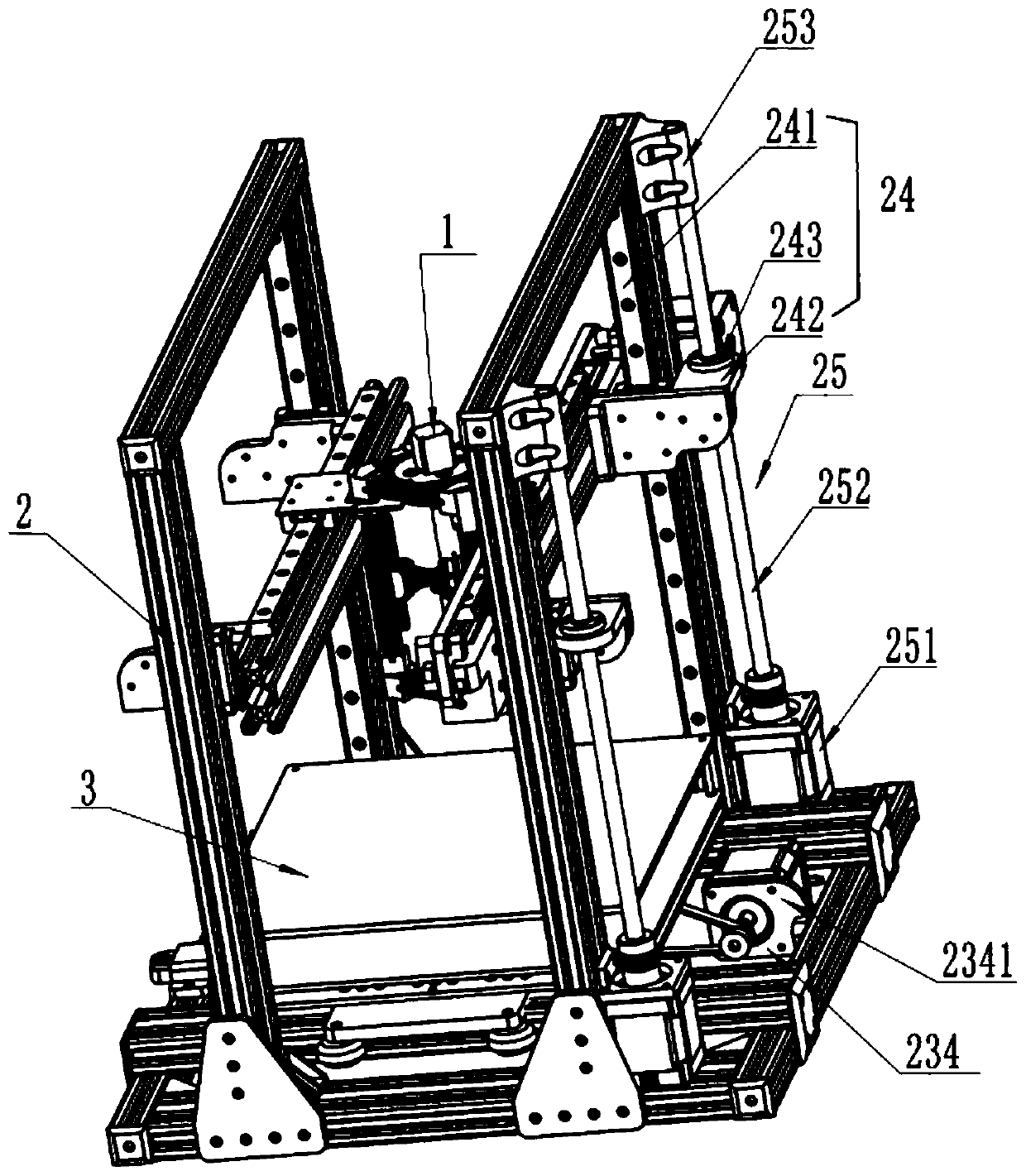

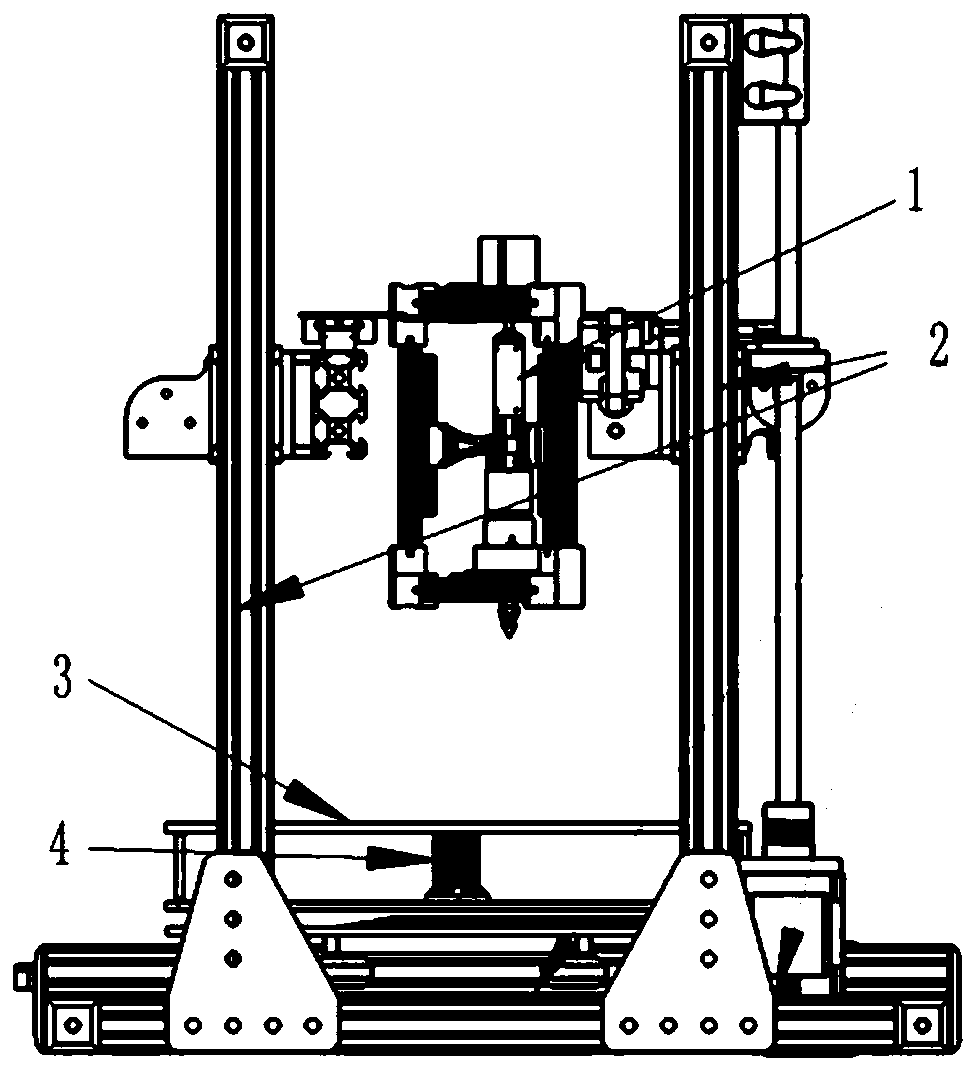

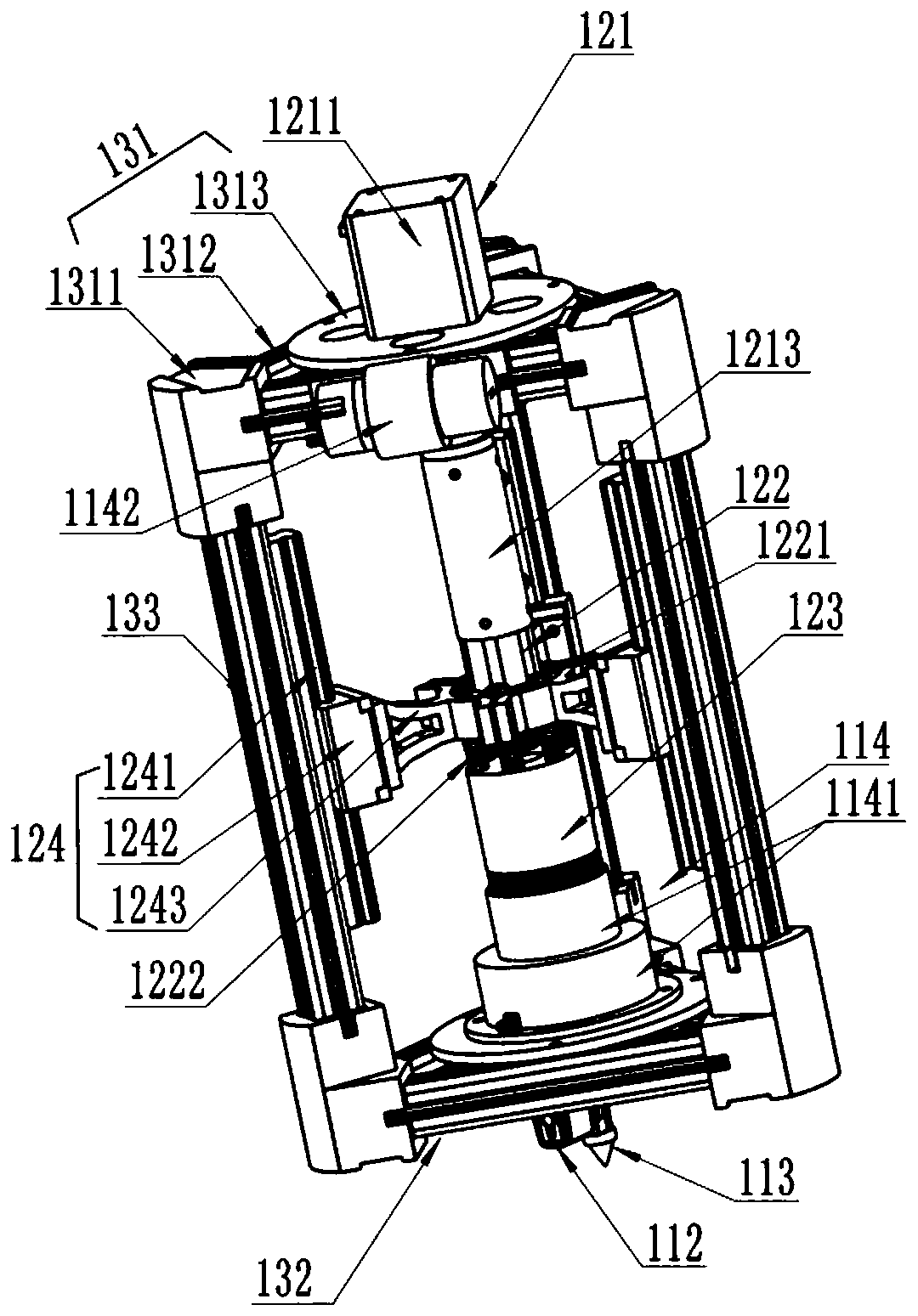

Magnetic control nano-forming micromechanical device and three-dimensional fiber forming method

ActiveCN110561749AMeet the needs of industrial quantitative productionEasy to operateAdditive manufacturing apparatus3D object support structuresFiberDevice form

The invention discloses a magnetic control nano-forming micromechanical device and a three-dimensional fiber forming method. The magnetic control nano-forming micromechanical device comprises a magnetic fluid preparation device for generating magnetic fluid, a three-dimensional control nano-stage for fixing the magnetic fluid preparation device, a working platform positioned below the magnetic fluid preparation device and a strong magnet positioned below the working platform. According to the magnetic control nano-forming micromechanical device and the spinning three-dimensional forming method, based on the magnetic spinning forming principle, the magnetic fluid extruded from a feeding nozzle of the magnetic fluid preparation device forms a liquid bridge under the action of the magnetic field of the strong magnet, and the liquid bridge is solidified to form nanofiber fibers. As the relative position between the feeding nozzle of the magnetic fluid preparation device and the strong magnet can be accurately controlled via the three-dimensional control nano-stage, three-dimensional fibers meeting the set arrangement requirements can be prepared based on the set forming track. The device has the characteristics of being easy to operate and high in control precision, can meet requirements of industrial quantitative production, and has a good application prospect in the field.

Owner:SICHUAN UNIV

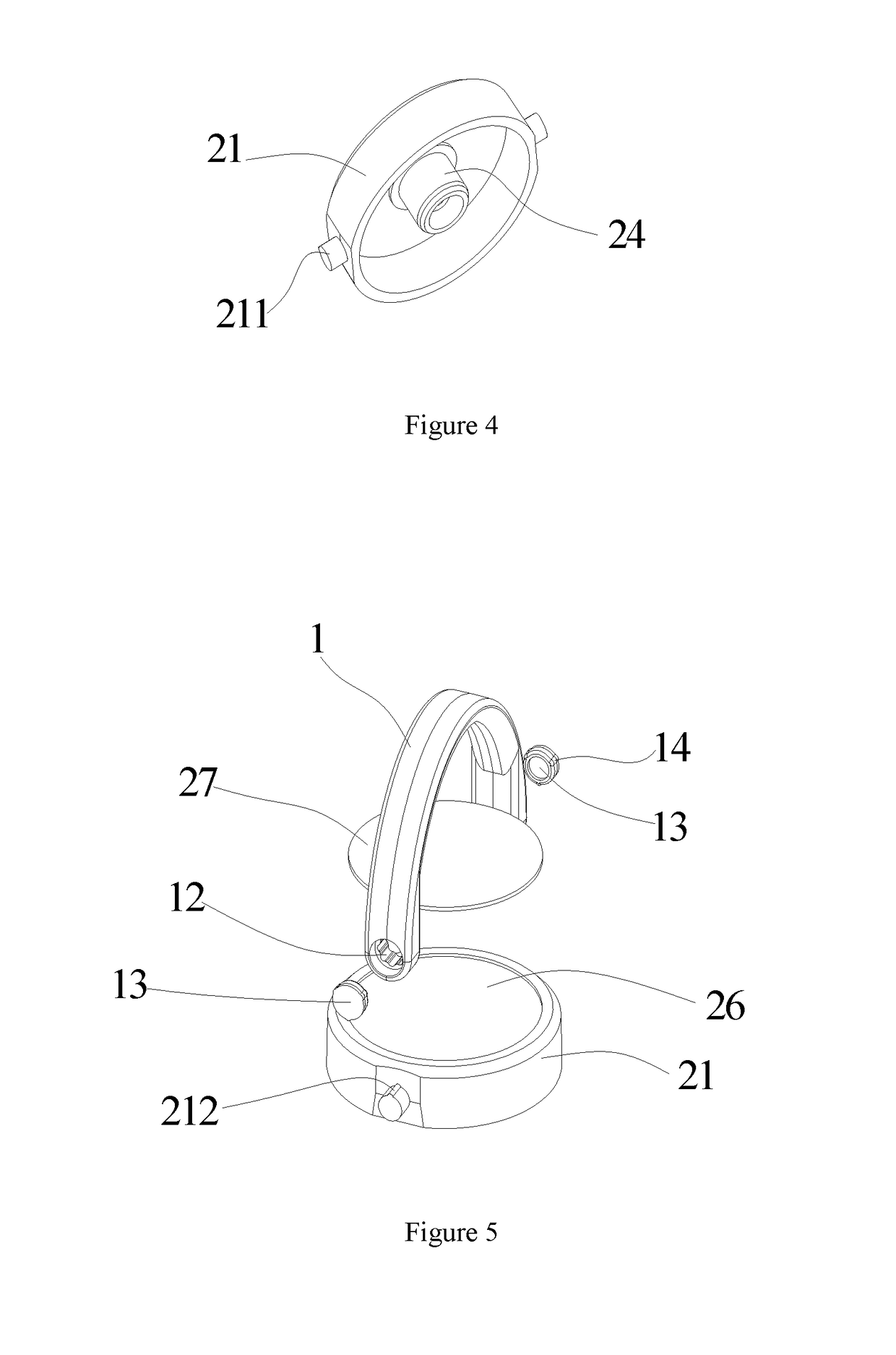

Rotary Ring Support

InactiveUS20180359346A1Improve user experienceSlow pressureCasings with display/control unitsCasings/cabinets/drawers detailsEngineeringFlat panel

Owner:CHEN LIFANG

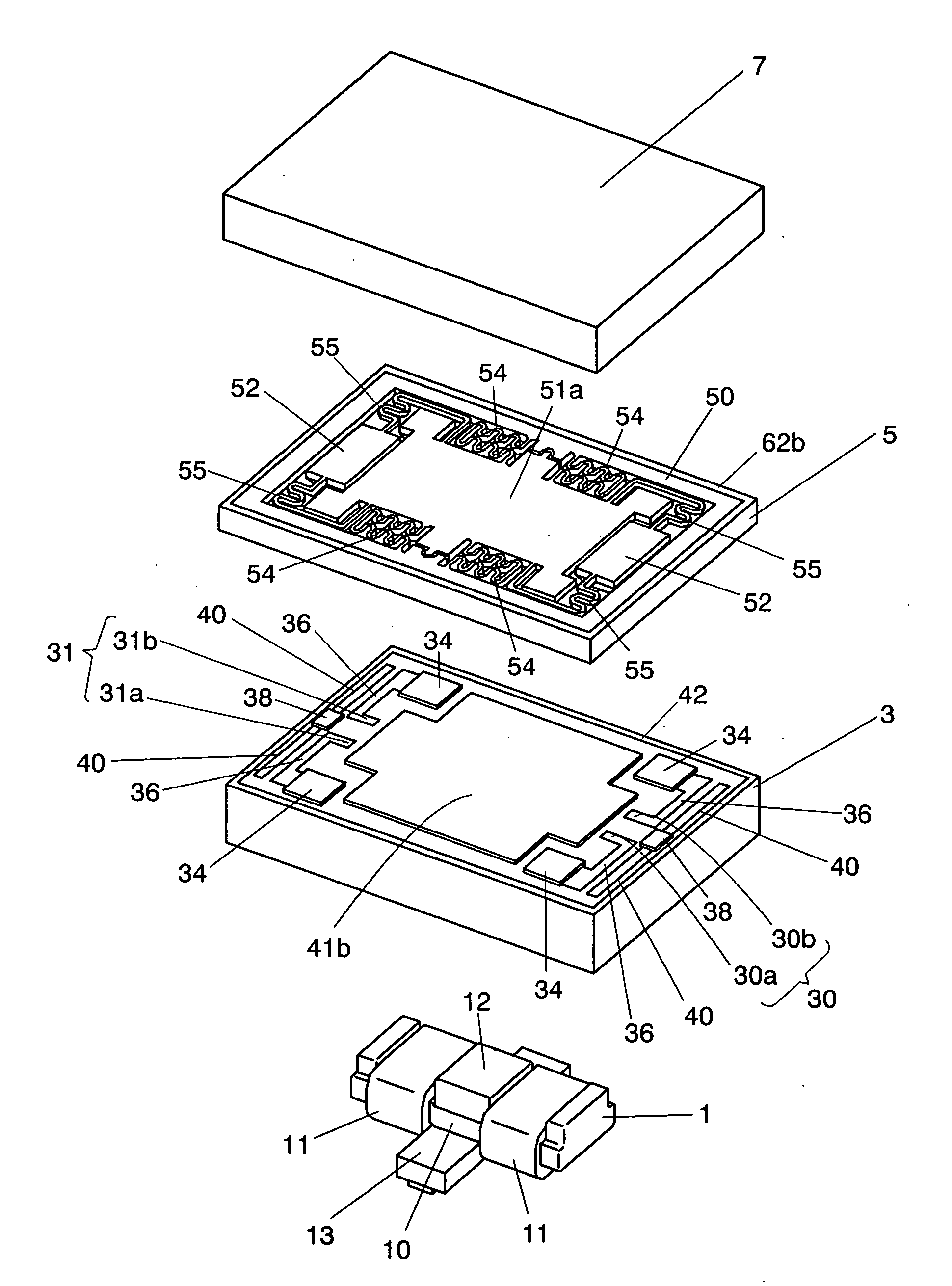

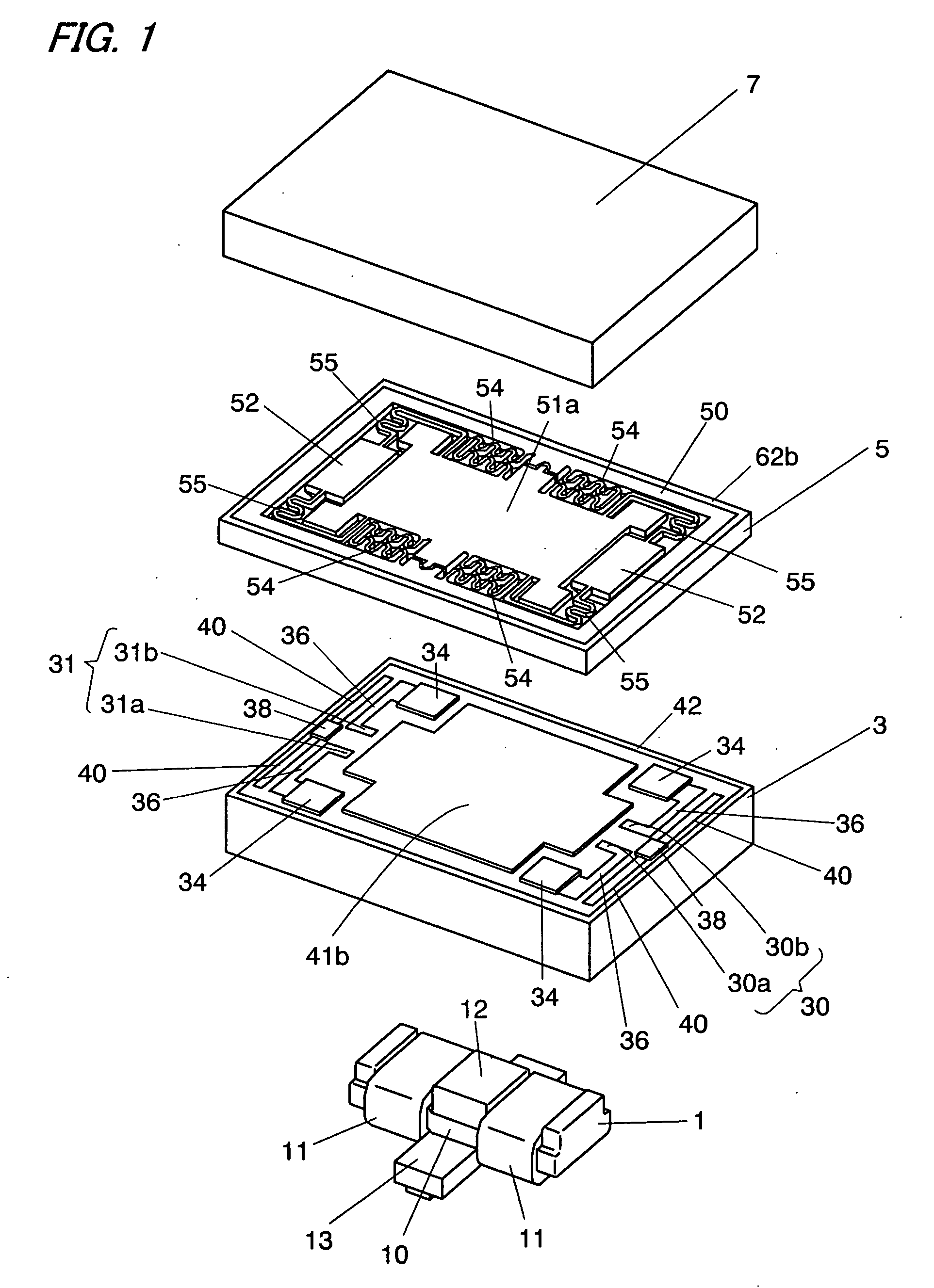

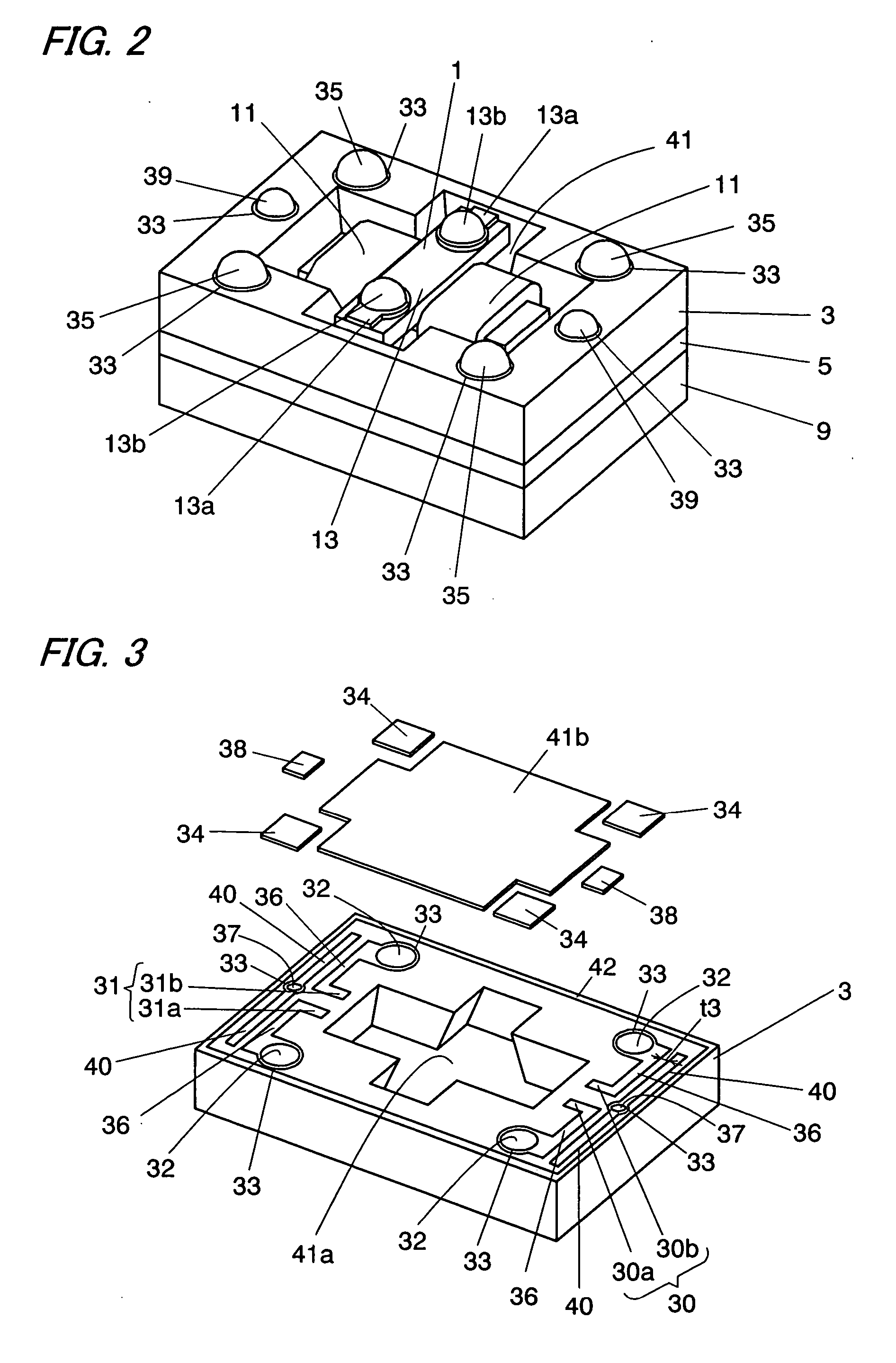

Micro relay

InactiveUS20060250201A1Slow pressureIncrease the lengthPiezoelectric/electrostriction/magnetostriction machinesSoldering apparatusEngineeringContact mechanism

The micro relay of the present invention comprises a base substrate 3, an armature block 5, and a cover 7. The base substrate 3 has a storage recess 41 for accommodating an electromagnetic device 1. The storage recess is composed of a hole 41a penetrating the base substrate 3 and a thin storage recess lid fixed on the one surface of the base substrate to close the hole. The electromagnetic device 1 is isolated from a contact mechanism by the storage recess lid 41b to increase the reliability of the contacts. The electromagnetic device 1 includes a yoke 10, a coil 11 wound around the yoke to generate a flux in response to an exciting current, and a permanent magnet 12 secured to the yoke to generate a flux flowing through an armature 51 and the yoke 10. Because the permanent magnet 12 is secured to the yoke 10, this micro relay can reduce the thickness.

Owner:MATSUSHITA ELECTRIC WORKS LTD

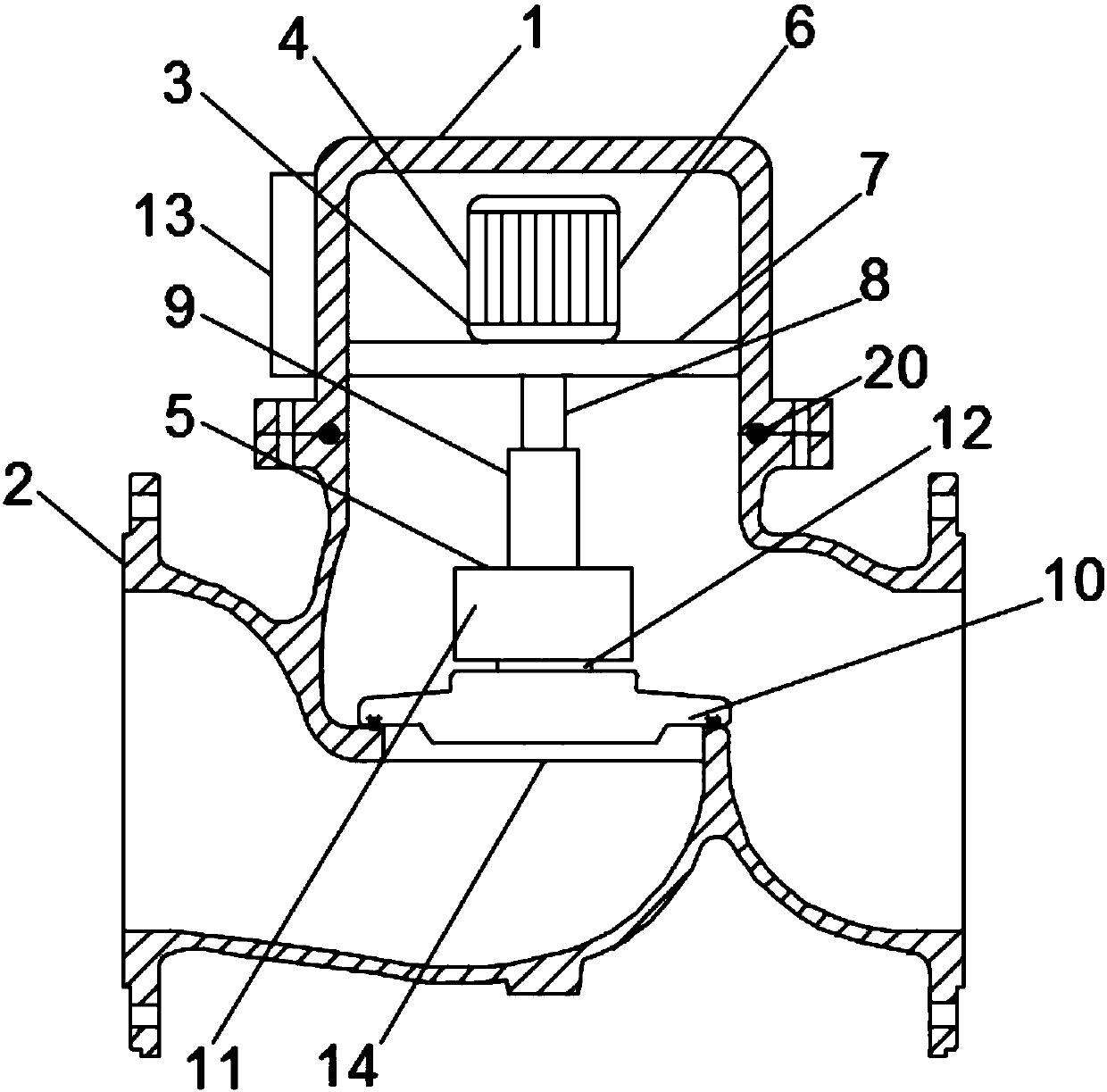

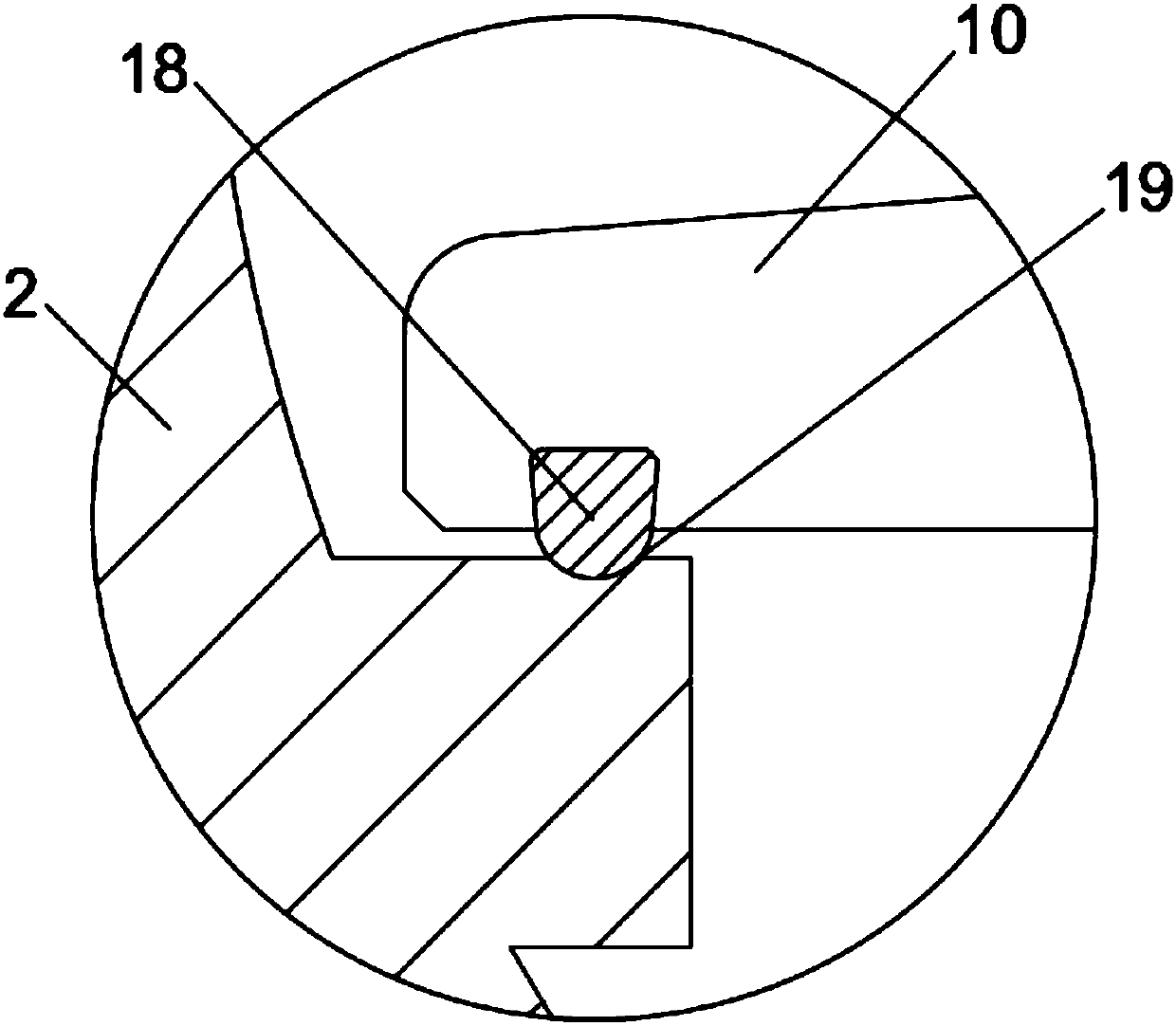

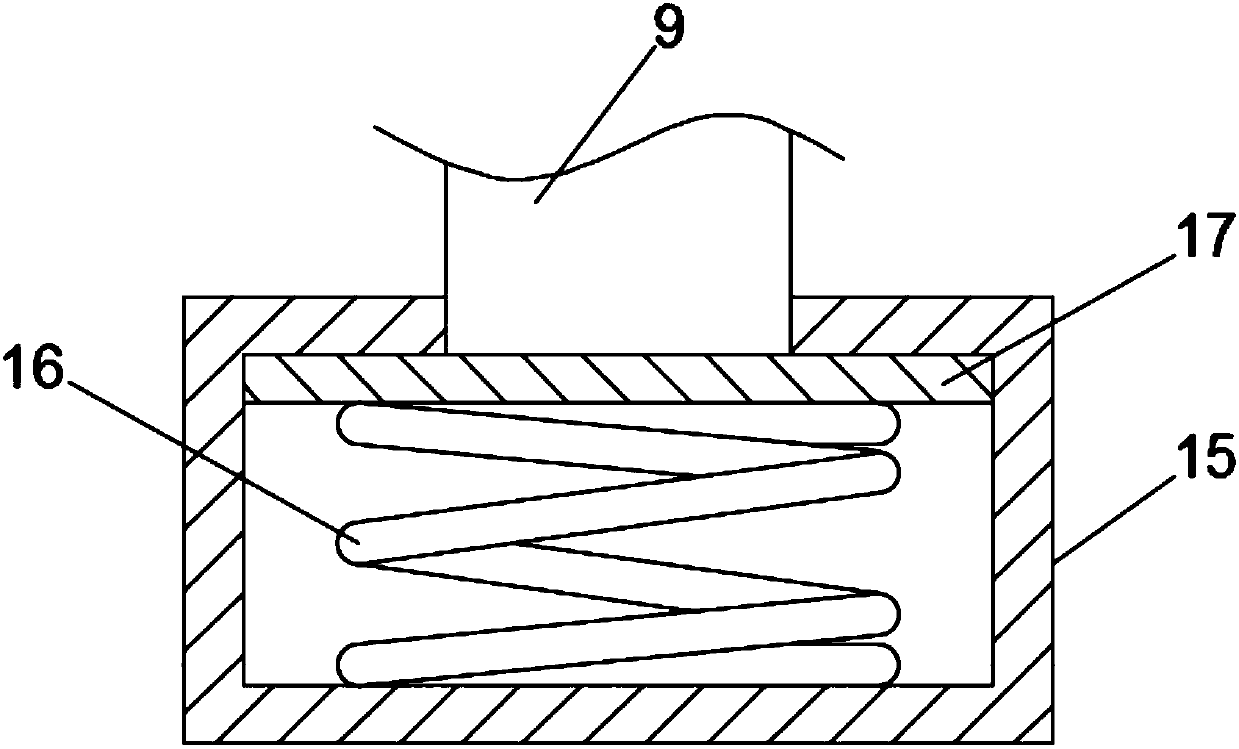

Piston type hydraulic control valve

InactiveCN107917193AImplement switchRealize automatic controlOperating means/releasing devices for valvesLift valvePull forceSpring force

The invention discloses a piston-type hydraulic control valve. The bonnet is fixed on the top of the valve body through bolts. A switch device is fixed inside the bonnet. The switch device includes a drive device and a control device. The drive device includes a drive motor, a mounting plate, Threaded rod and sleeve, the driving motor is fixed on the top of the mounting plate, the mounting plate is fixed inside the bonnet, the output shaft of the driving motor passes through the mounting plate and fixed with the threaded rod, and the connection between the output shaft of the driving motor and the mounting plate passes through The bearing is rotated and connected, and the end of the threaded rod away from the drive motor is sleeved in the sleeve. The inner side of the sleeve is provided with internal threads. This piston type hydraulic control valve controls the work of the drive motor through the control panel to realize the control of the valve body switch. Automatic control, through the buffer component to generate elastic force to support the spring applied by the sleeve, to prevent the damage of the pressure sensor caused by the instantaneous excessive tension of the sleeve, and also to make the pressure sensor bear the pressure more slowly, and the detection data is more accurate.

Owner:温州诚博阀门有限公司

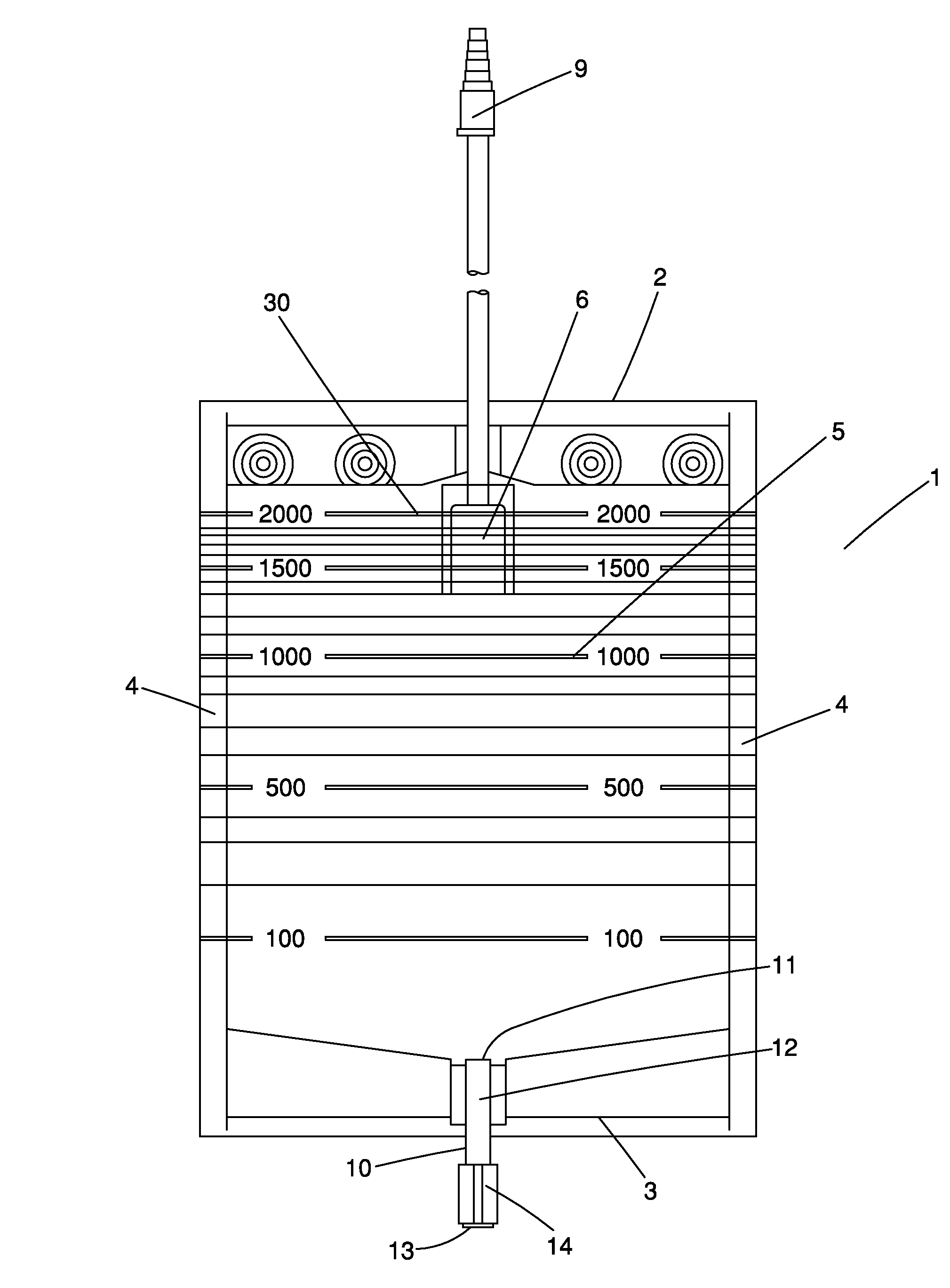

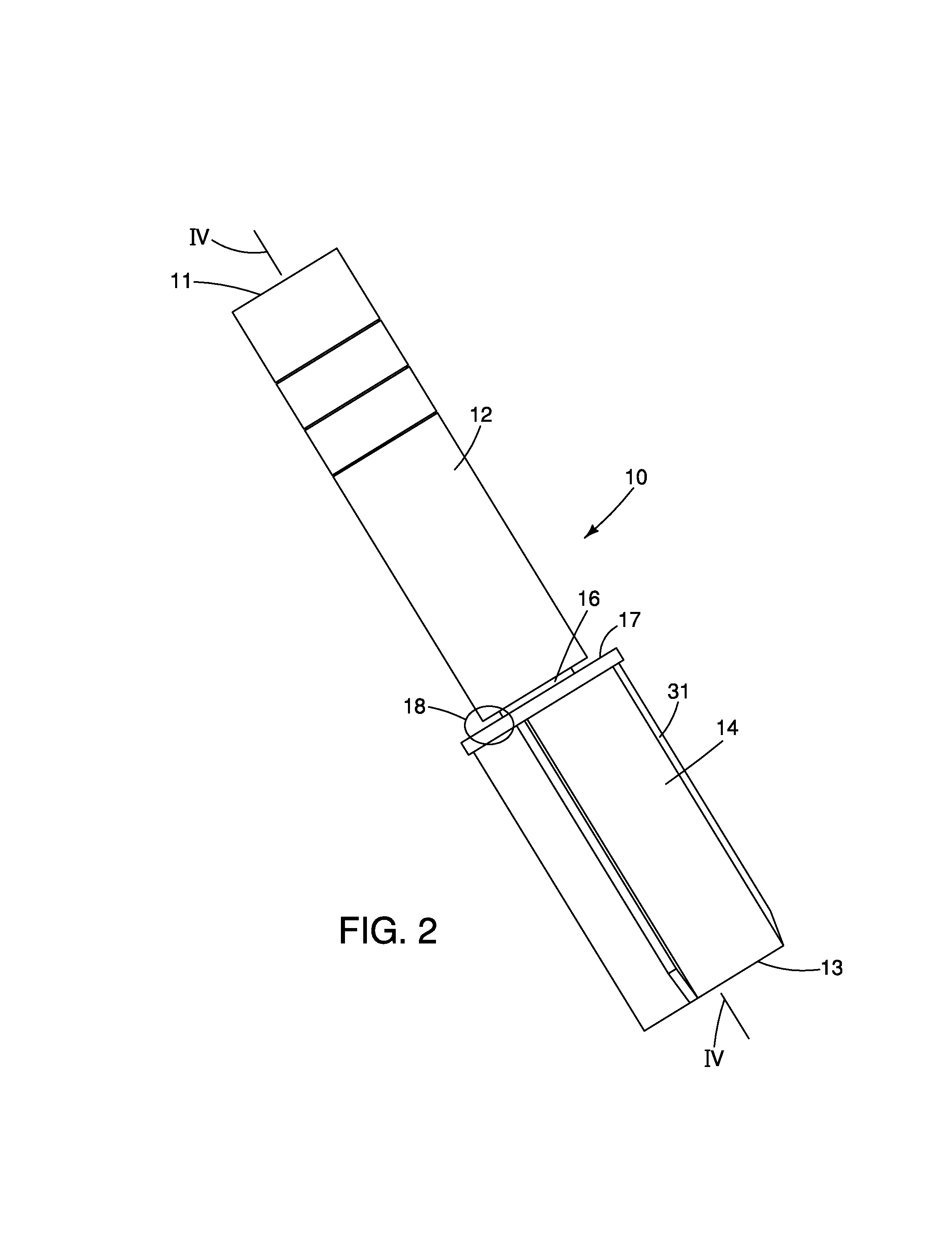

Disposable urine bag for collecting urine

A disposable urine bag is provided. The bag includes an upper delimiting edge, a lower delimiting edge and lateral delimiting edges defining a space in the bag. The lower delimiting edge includes a drain valve, whose first drain mouthing in a first hollow element communicates with the space in the bag, and whose second mouthing in a second element is situated outside the delimiting edges of the bag. The drain valve is a disposable valve including a seal between the first and the second element and at least one indicator situated in the area of the seal. A disposable urine bag is provided whereby the drain valve seal may be broken without using significant finger strength and without a risk of the user being soiled with urine.

Owner:UNOMEDICAL AS

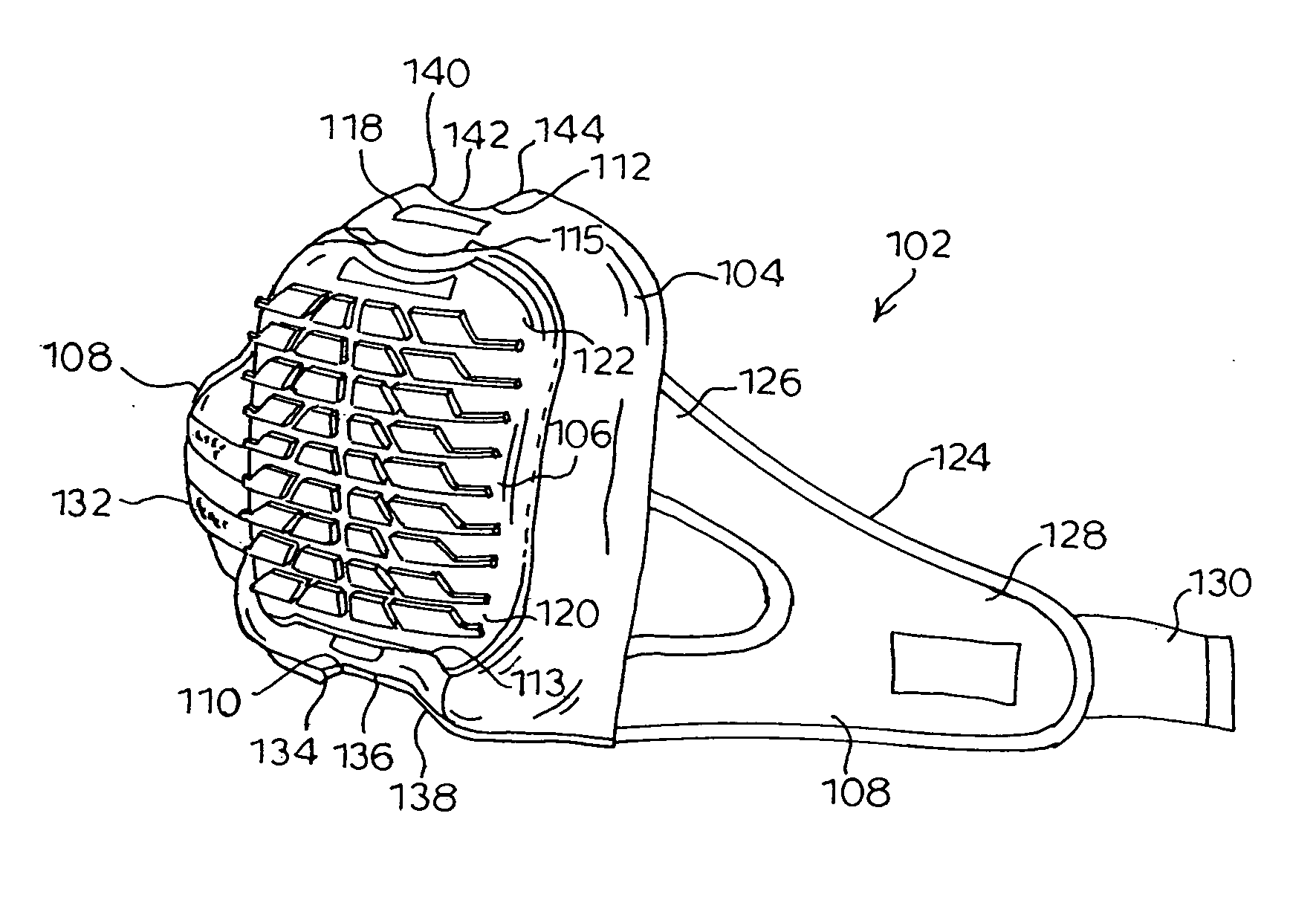

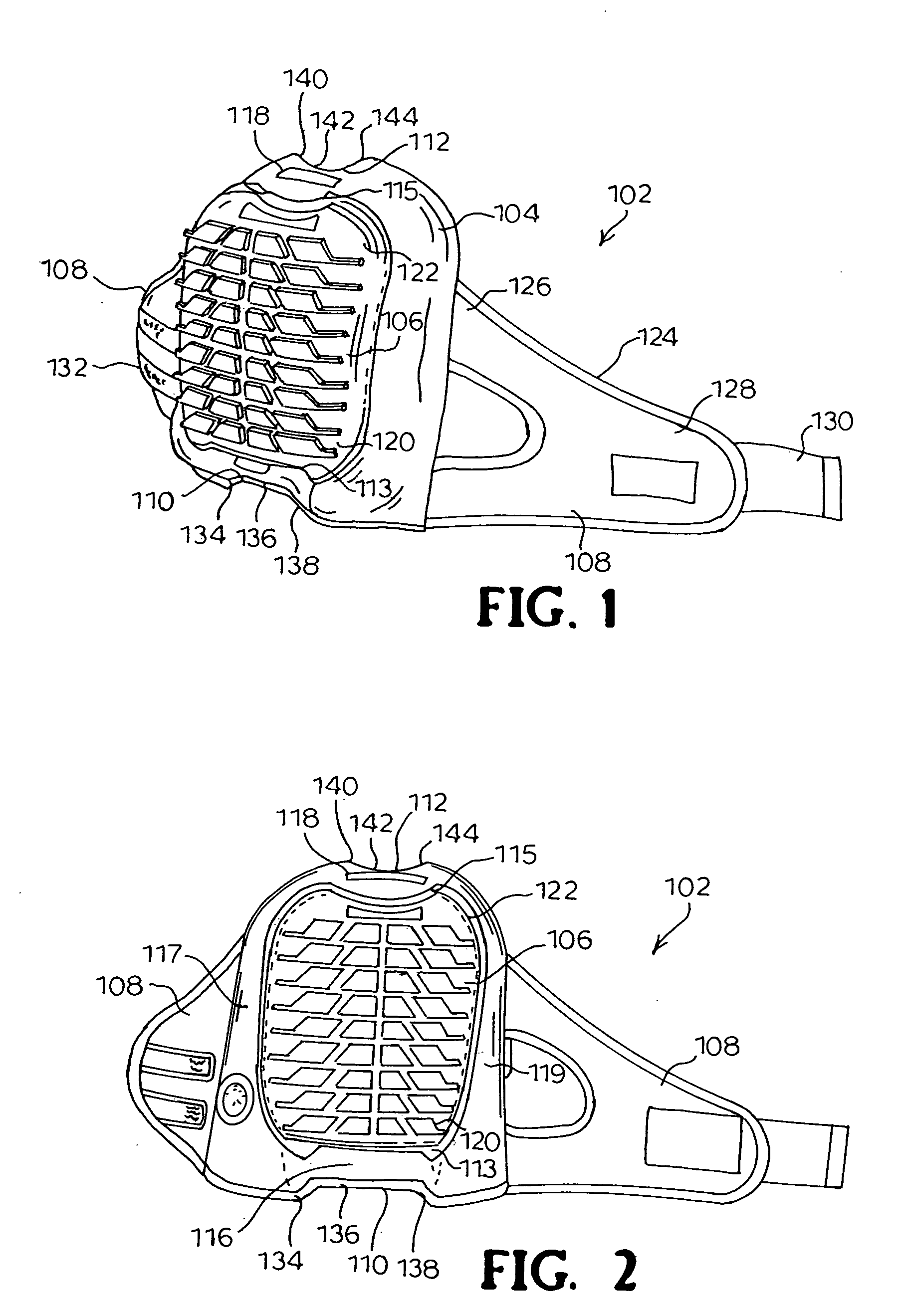

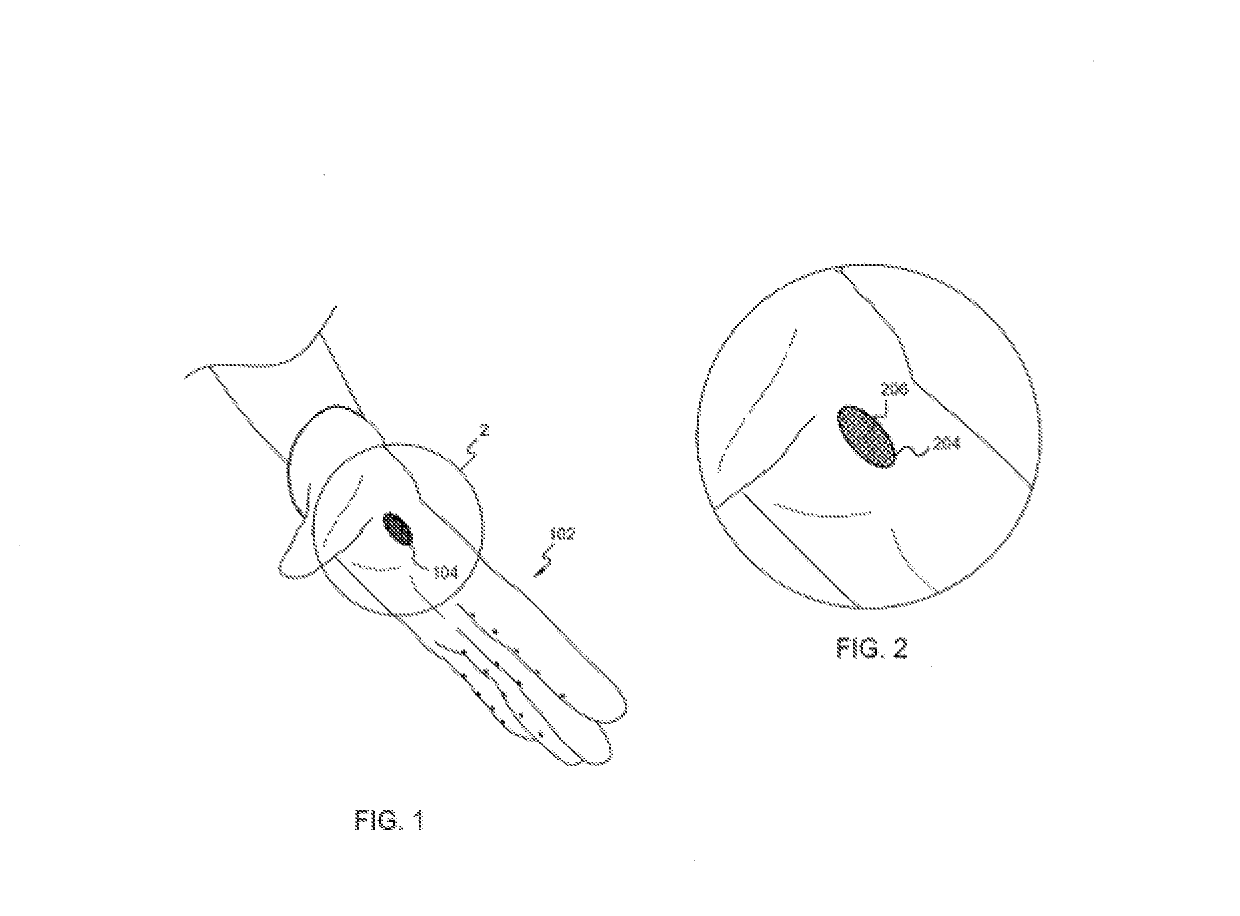

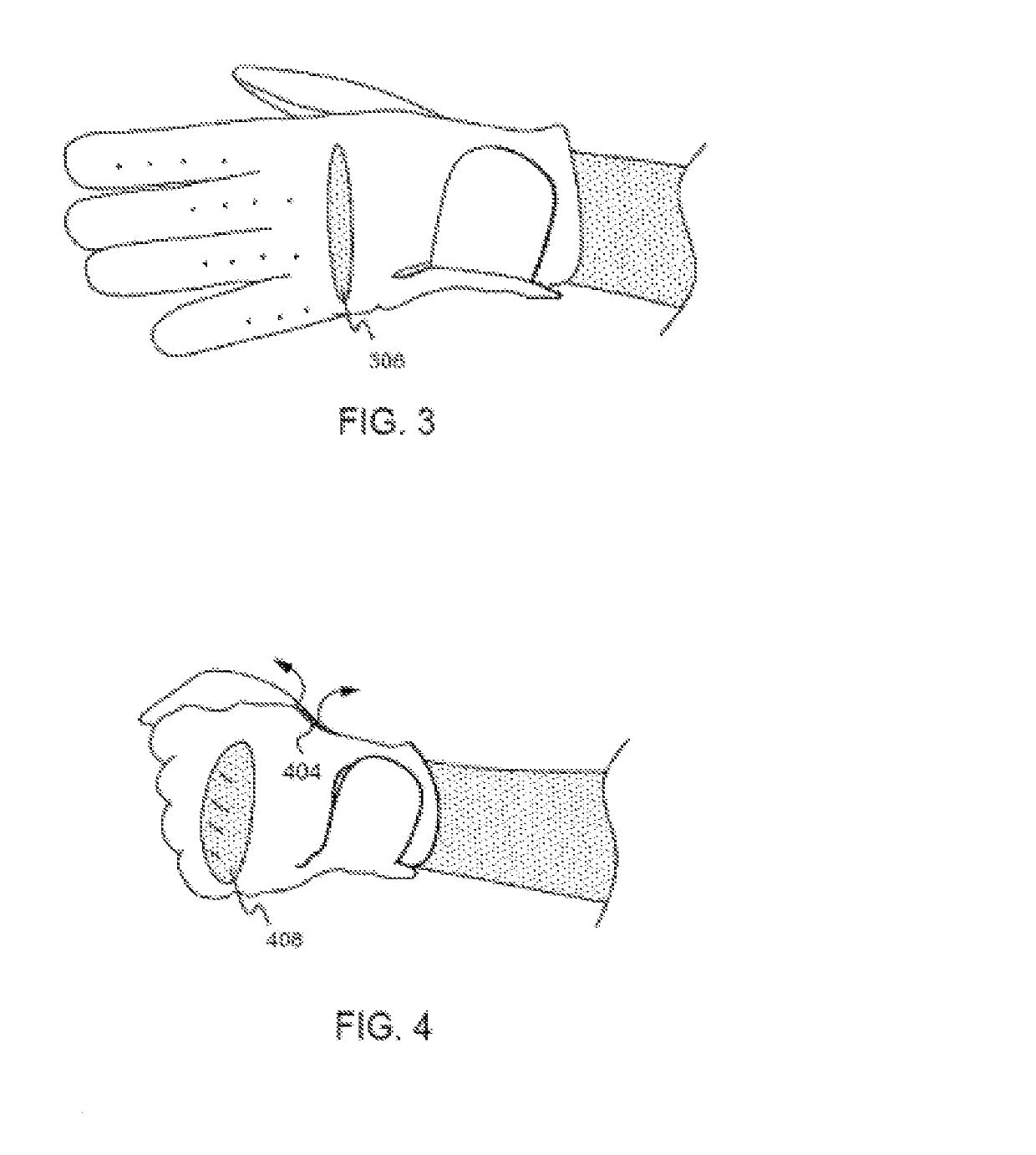

Golf glove with airflow vents

InactiveUS20190133221A1Effective gripMinimizing slippingGlovesProtective garmentIndex fingerSynthetic materials

A golf glove comprising a front section and a back section comprising of leather, cotton or synthetic material, substantially covering the front and back of the hand, a vent 104 covered with a mesh 206 positioned between the thumb and the index finger, and an open vent 306 in the knuckle region of the back section resulting in exposing the knuckles.

Owner:RAIKHY SAMMERJIT SINGH

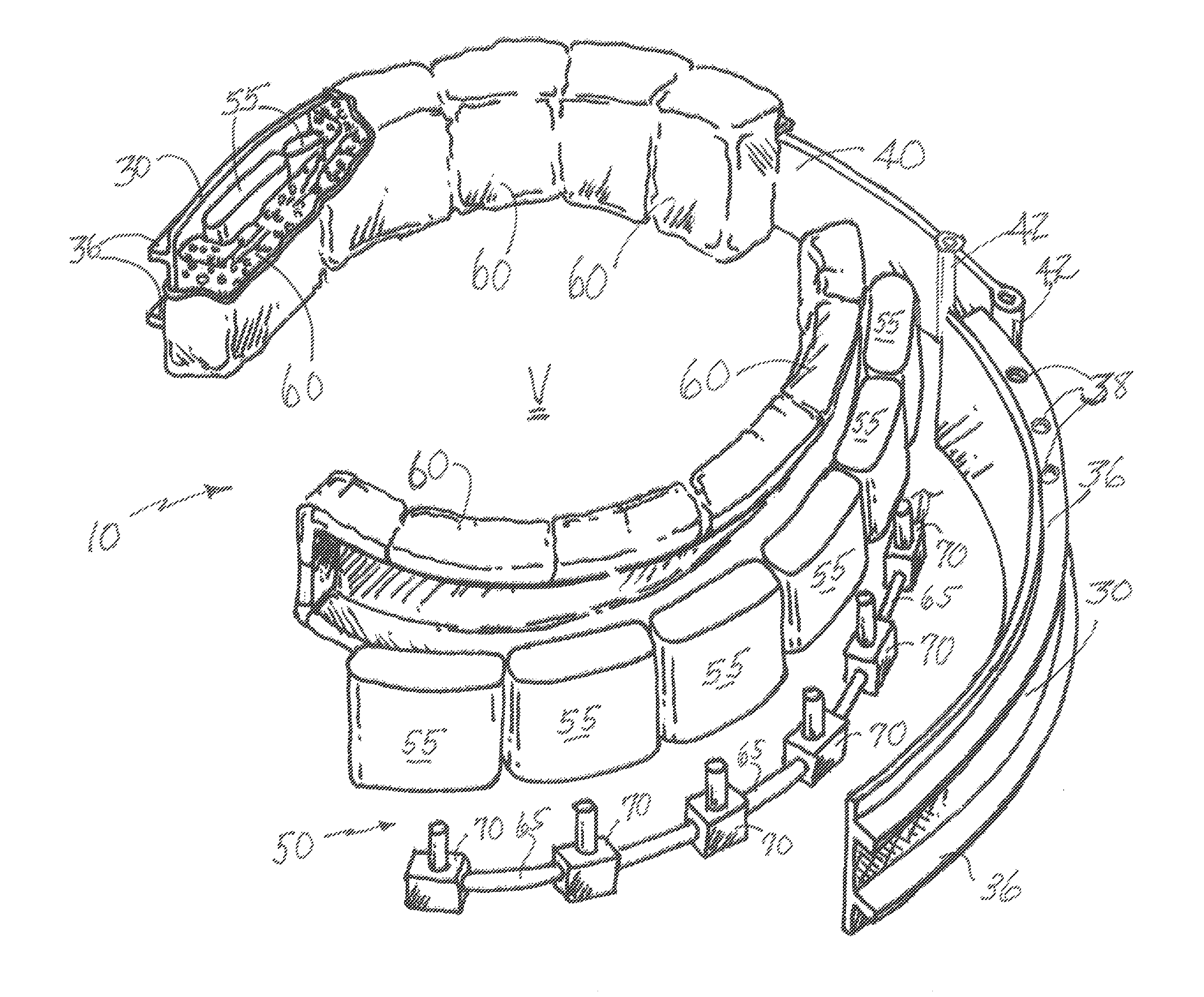

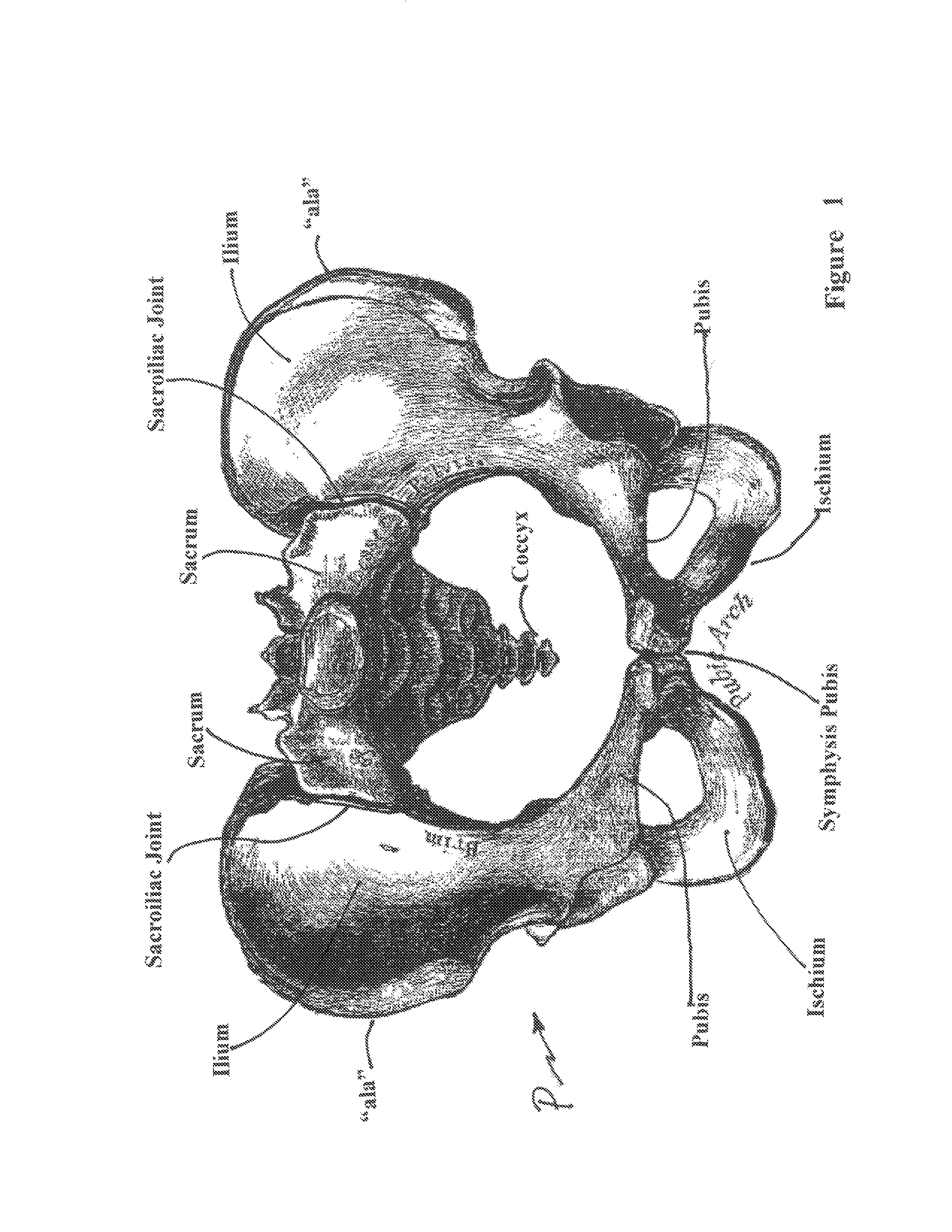

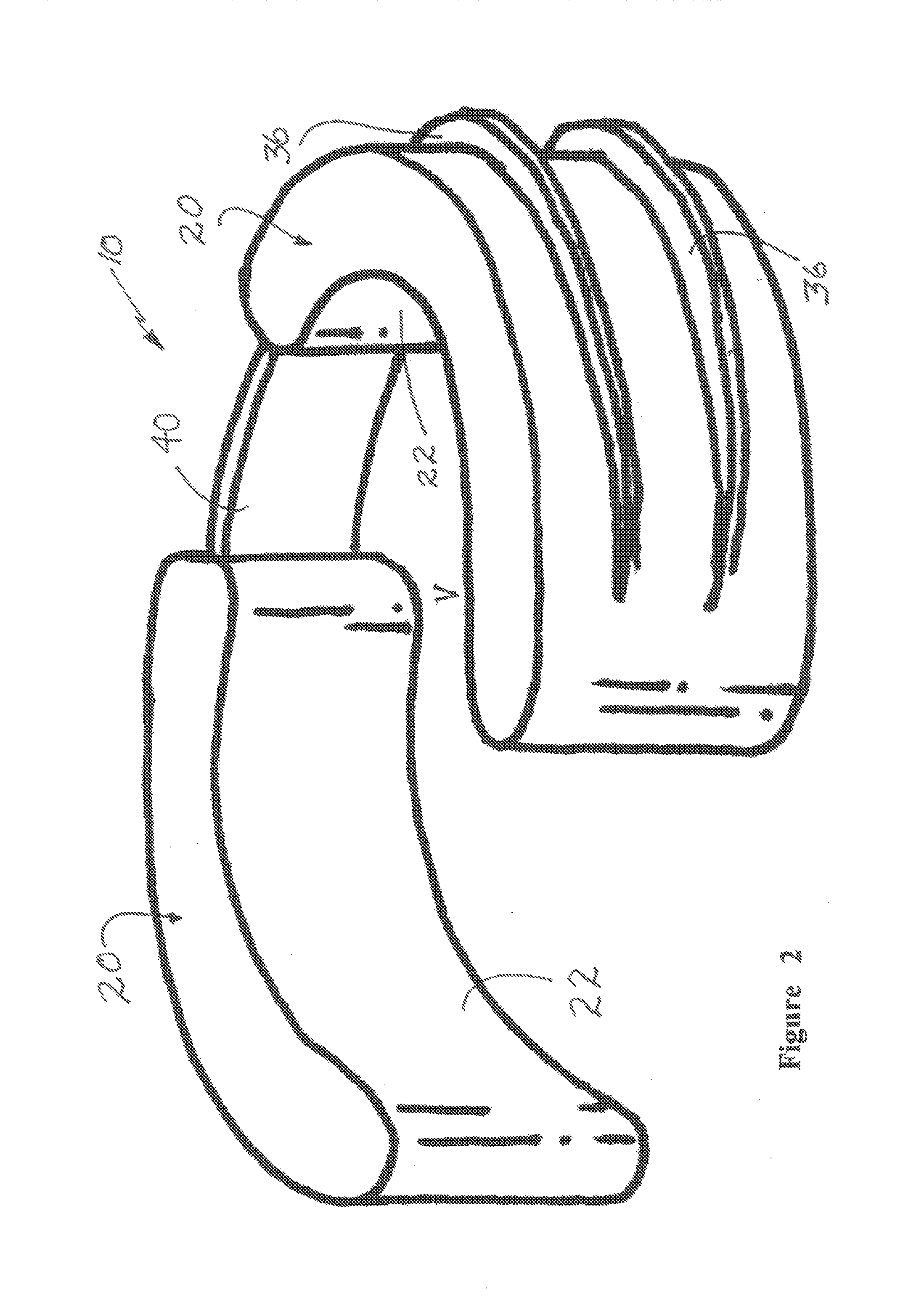

Birth ease method and device

ActiveUS9265527B1Increase and decrease volumeIncrease or decrease volumeDiagnostic recording/measuringSensorsObstetricsChild birth

A method for easing child birth and, more particularly, to a device for practicing the method for easing child birth and, most particularly, to a device for easing child birth controlled by the individual giving birth to the child. The device mechanically replaces a “manual” contact, which can be applied to the pelvis of a woman in labor, for the purpose of aiding the expulsion of the baby, and reduce the pain and discomfort associated with this process. The device mechanically compresses the ilium portion of the pelvis medially and posteriorly, simultaneously. The pressure applied by the device is under full control of the patient, so that pressure is applied slowly and progressively to a point of maximum comfort. The pressure is decreased immediately upon demand by the patient. The duration of the application of compression corresponds with the length of the contraction period for the woman.

Owner:SEVERSON GREGORY C +1

Undersea pipe-laying

ActiveUS8777517B2Improve protectionReduce tensionPipe laying and repairPipe-laying vesselsMarine engineeringSubmarine pipeline

A monohull vessel for laying a pipeline includes tensioners 13 disposed along a Pipelaying path P. The pipelaying path P includes an upstream portion that is substantially horizontal and at least 10 m above the center of rolling R of the vessel and, towards a stern end of the vessel hull, a downstream portion that is downwardly inclined and, in use, enters the water at a location inboard of the stern end of the vessel hull 1.

Owner:SAIPEM SPA

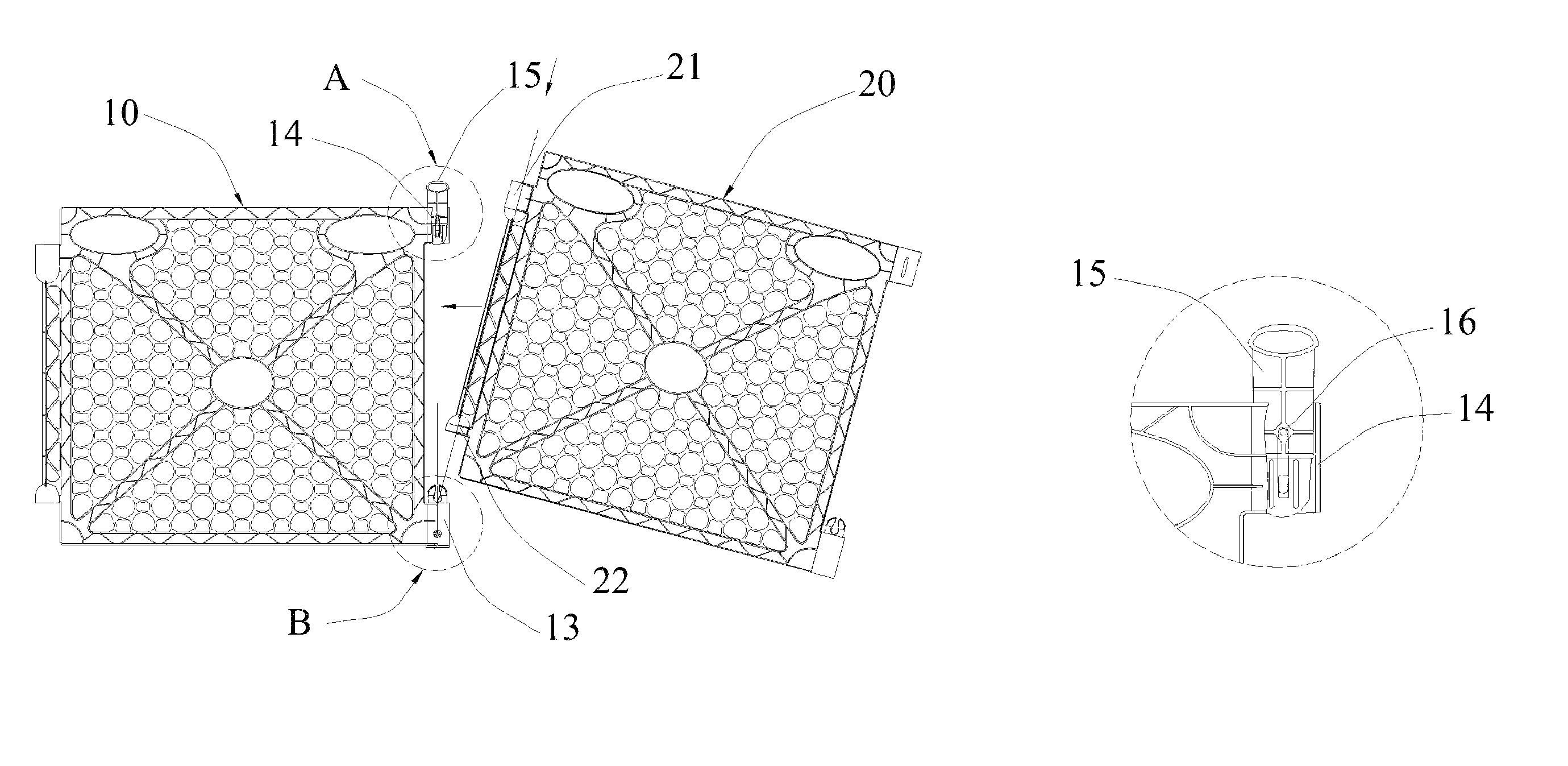

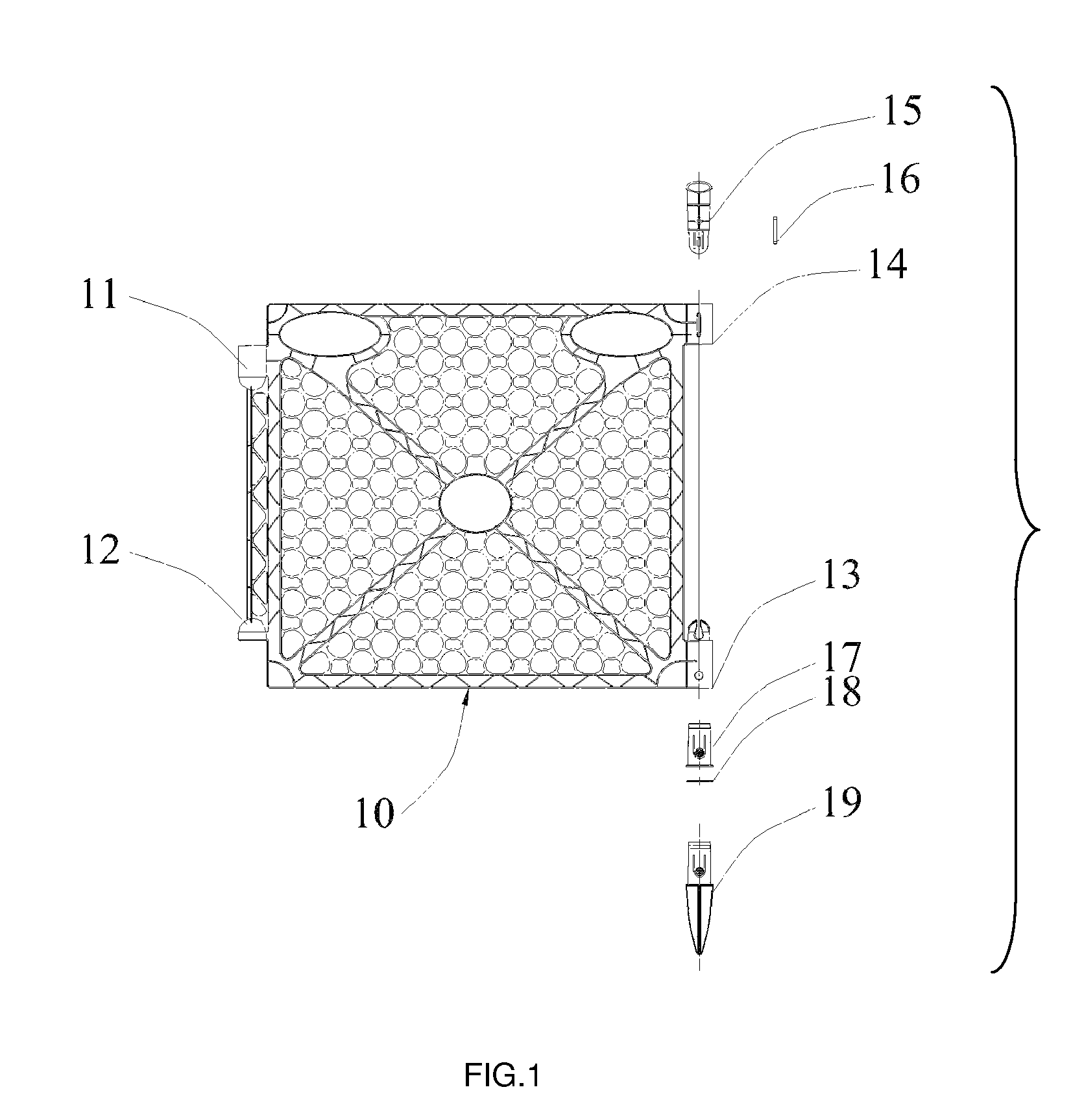

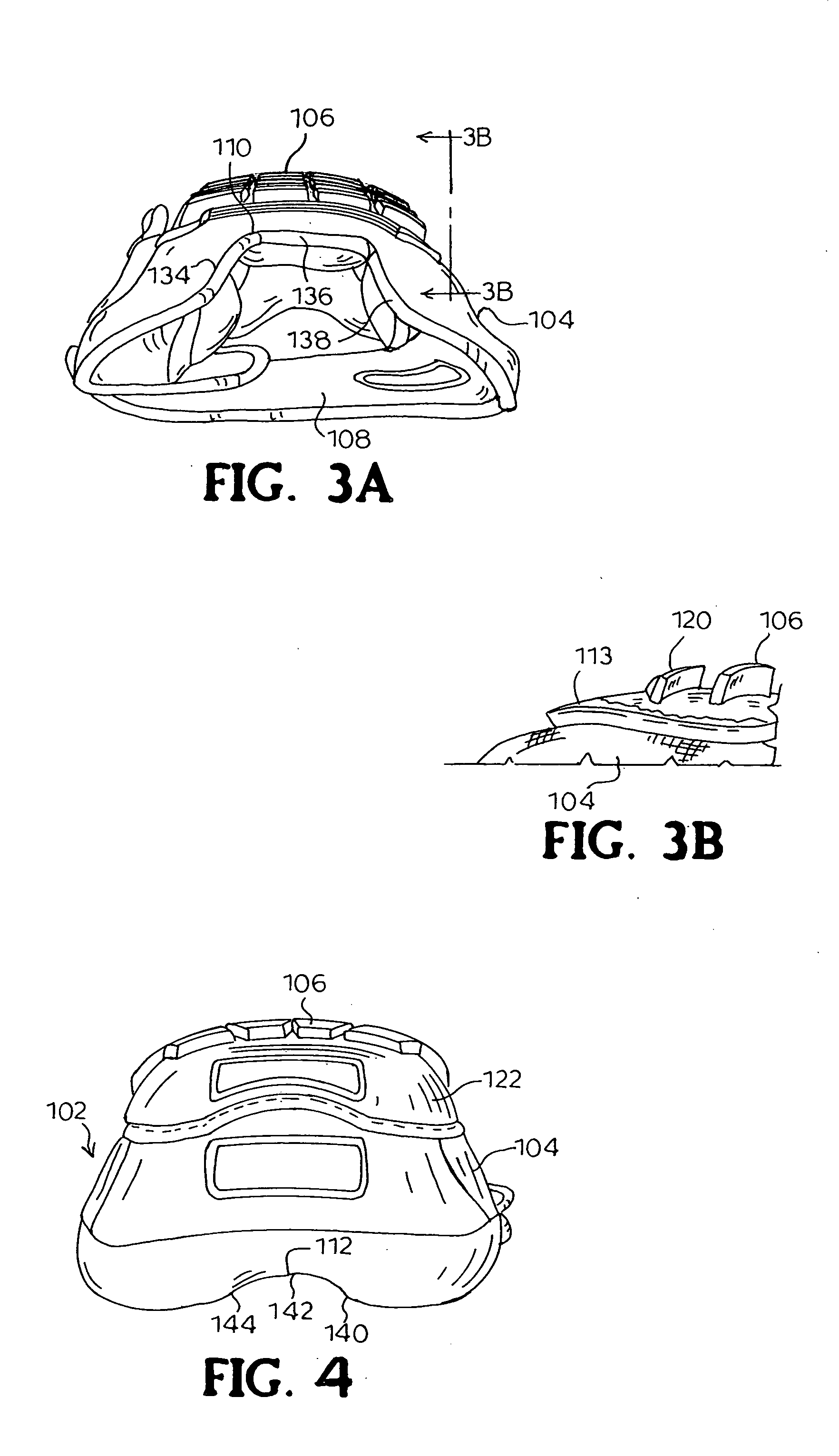

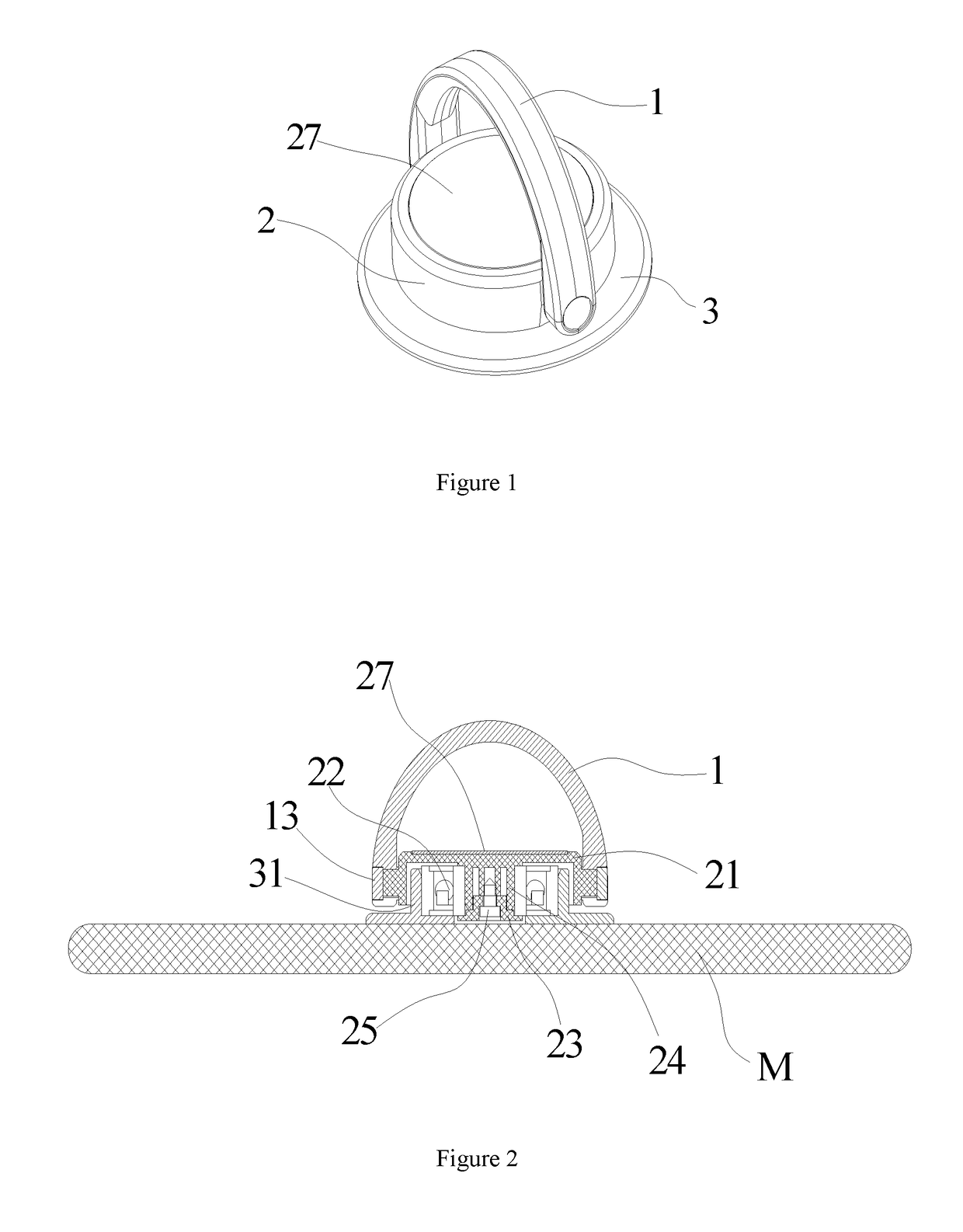

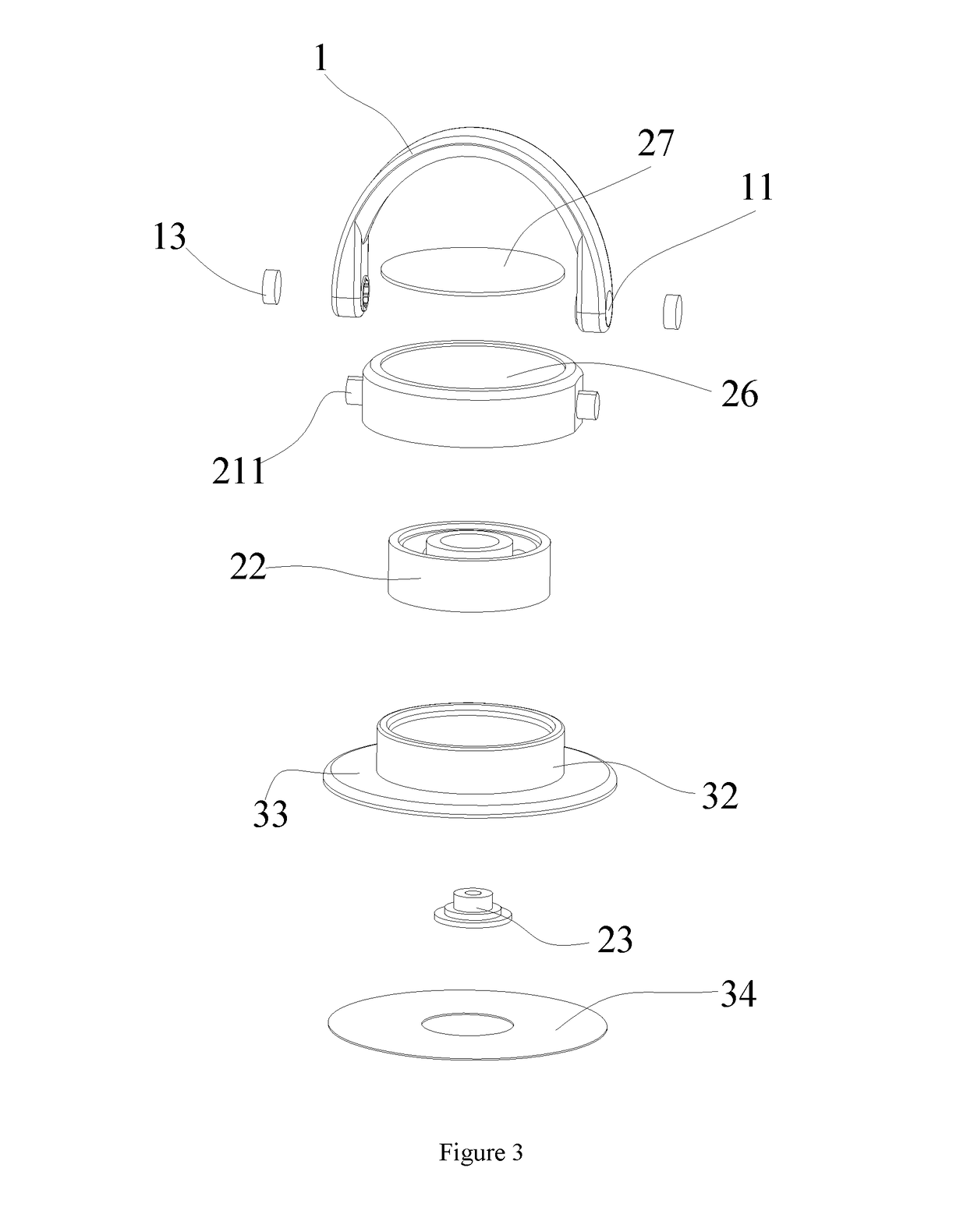

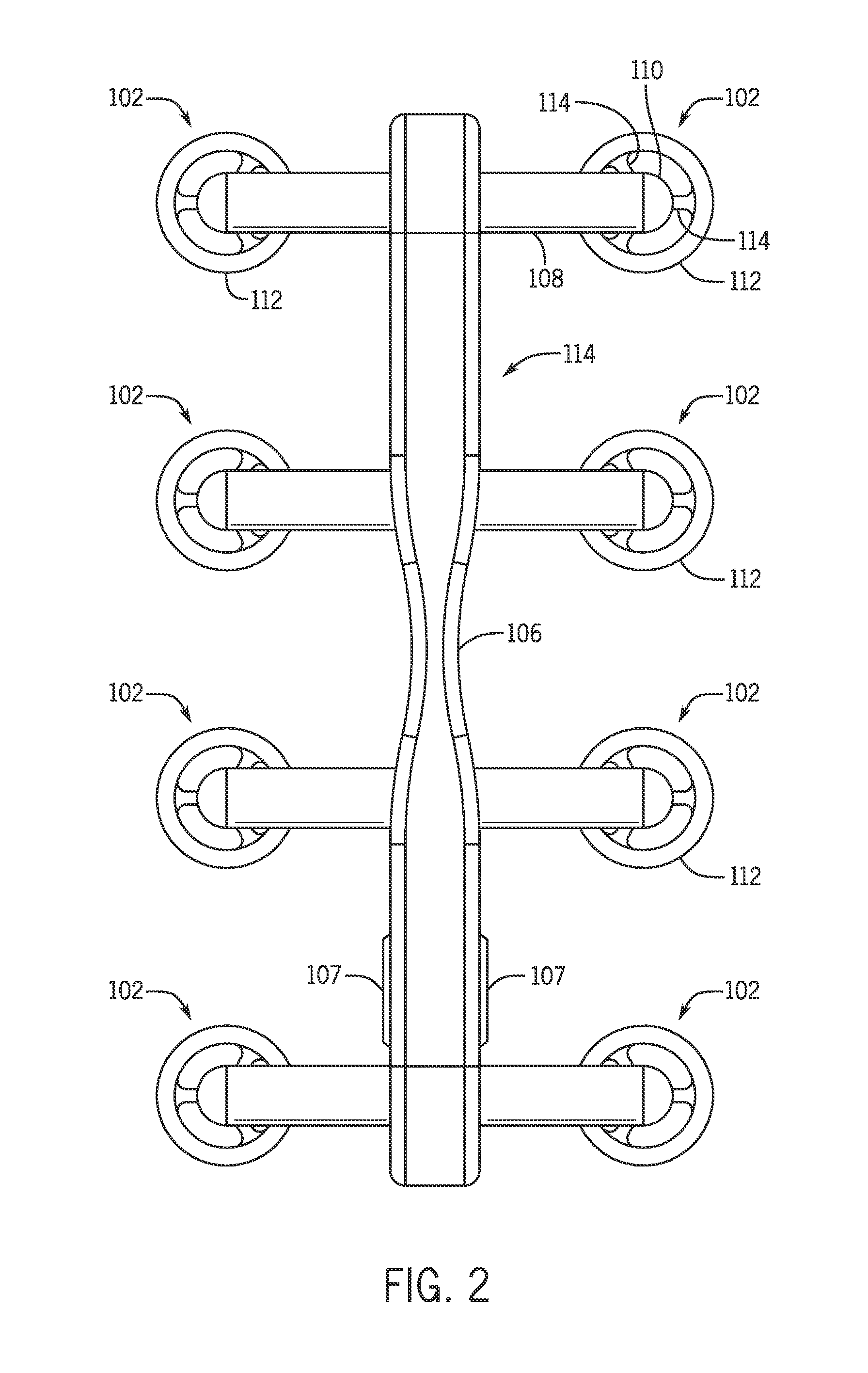

Allergy Skin Test Devices with Surrounding Pain-Reduction Structures

InactiveUS20160206333A1Less intimidateLess upsettingSurgeryDiagnostic recording/measuringBiomedical engineeringAllergy skin testing

An allergy skin testing device is disclosed that includes at least one central post having at least one sharp probe extending longitudinally from an end of the at least one central post, the at least one sharp probe being for administering an allergen to skin. For each central post, at least three dull probes substantially surround the at least one sharp probe, creating a “pain gate fence”, the at least three dull probes being for activating a pain gate effect affecting nerves of the skin while the at leat one sharp probe administers the allergen to the skin. The at least three dull probes extend further along the central post than the at least one sharp probe, so when all the probes are pressed against the skin using a gripping portion, the plurality of dull probes press into the skin before the at least one sharp probe penetrates the skin.

Owner:HARISH ZIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com