Patents

Literature

48results about How to "Inhibit gas flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

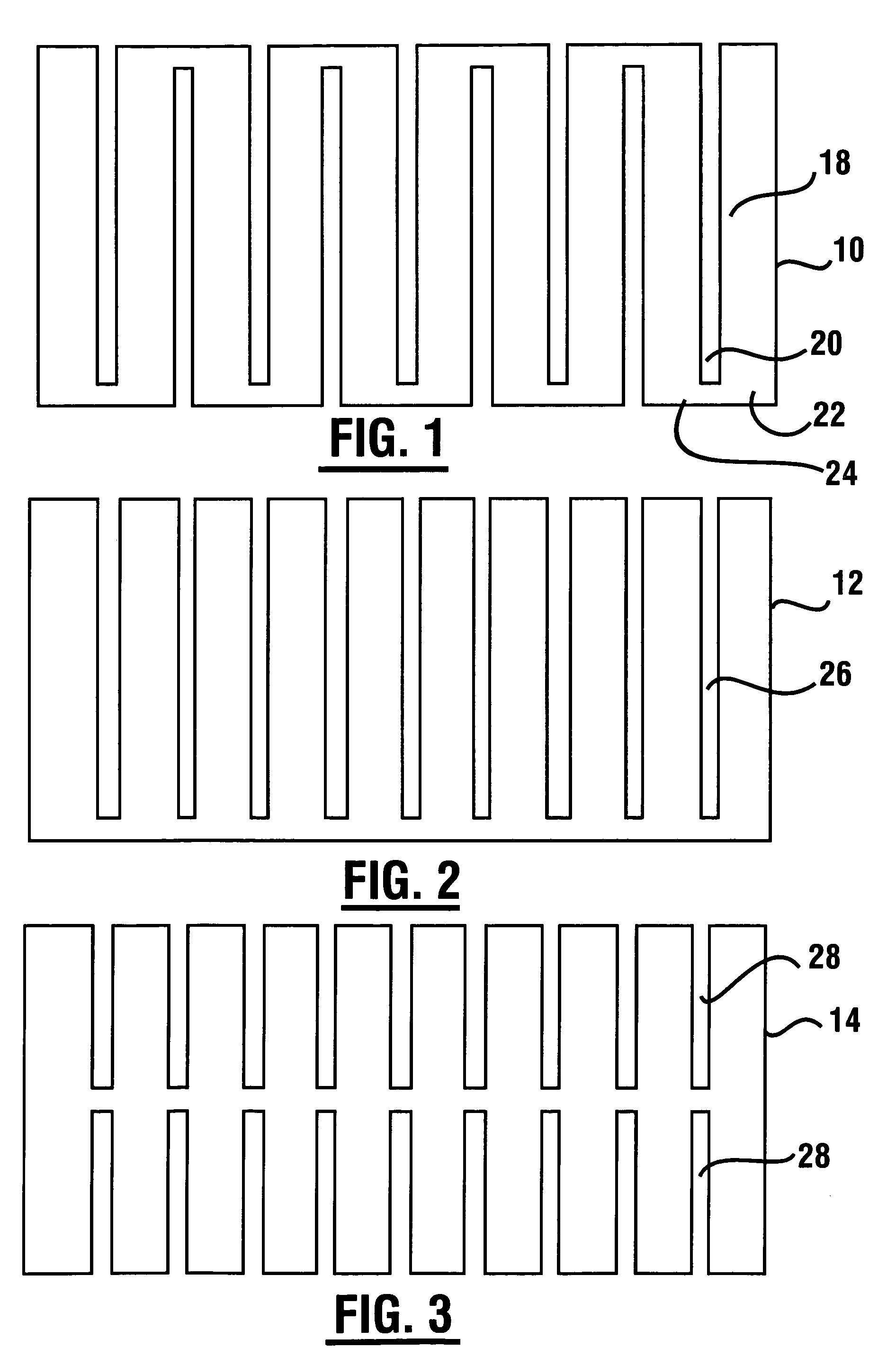

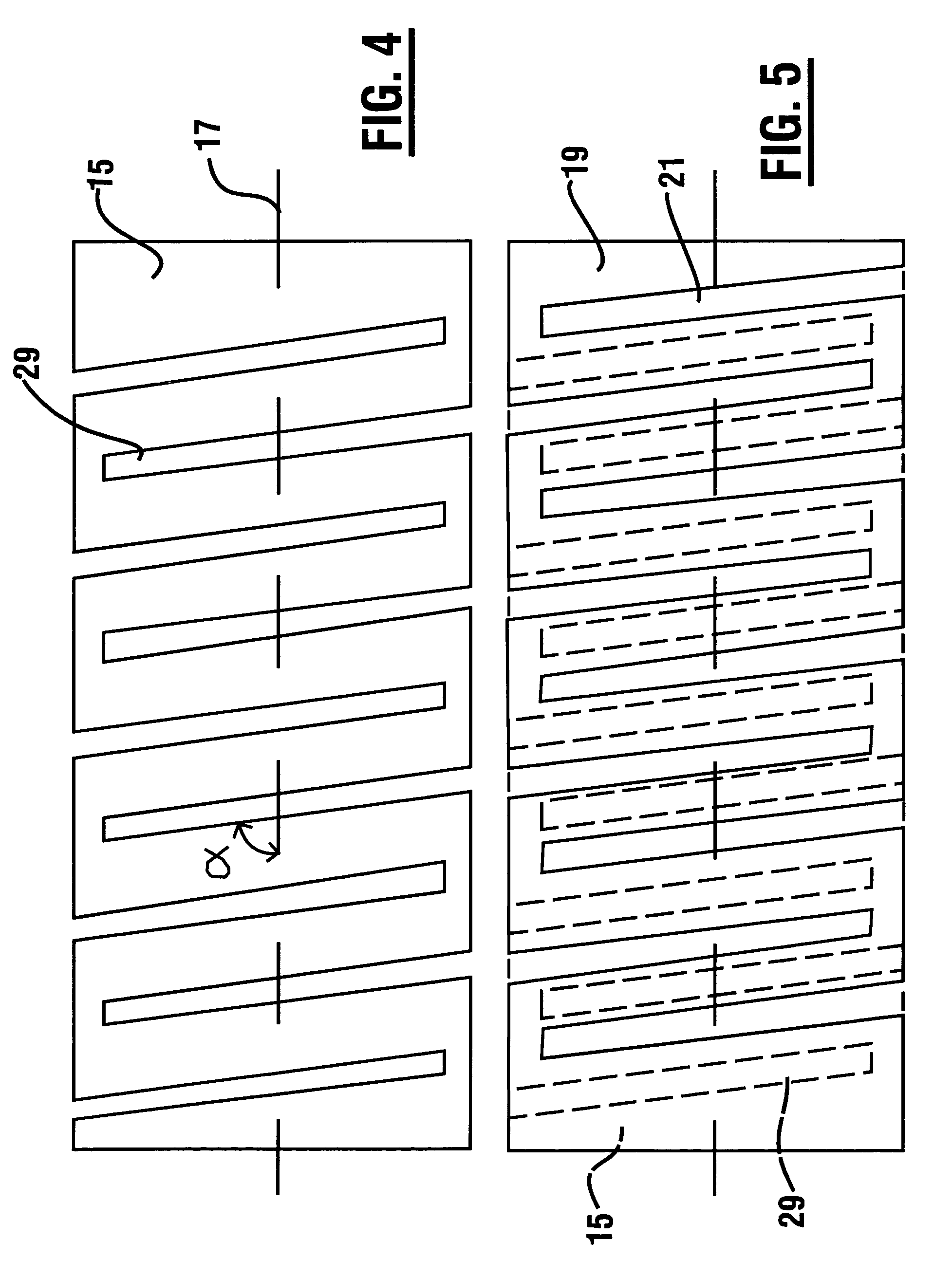

Resilient flexible pressure-activated seal

A resilient, flexible, pressure-activated, high-temperature seal is adapted to be interposed between high and low pressure regions to provide sealing between opposing surfaces of adjacent relatively movable structures. The seal comprises at least one C-shaped sheet element. The C-shaped element design enables the seal to be pressure-activated to provide a radially outward biasing force, responsive to a seal-activating pressure differential acting across the seal thereby increasing resiliency. A centrally-located, resilient core structure provides load bearing and insulating properties. In an exemplary embodiment where at least two seal elements are used, each layer has a cutout slot pattern and the remaining strip material pattern. The slots provide flexibility to the seal, enabling the seal to be manually contoured to seal around corners and curves. The strip material of each layer covers the slots in each adjacent layer to minimize leakage through the slots. Attached barrier strips can block interface leakage between the seal and the opposing surfaces.

Owner:UNITED STATES GOVERNMENT AS REPRESENTED BY THE ADMINISTATOR OF THE NAT AERONAUTICS & SPACE ADMINISTATION NASA GLENN RES CENT

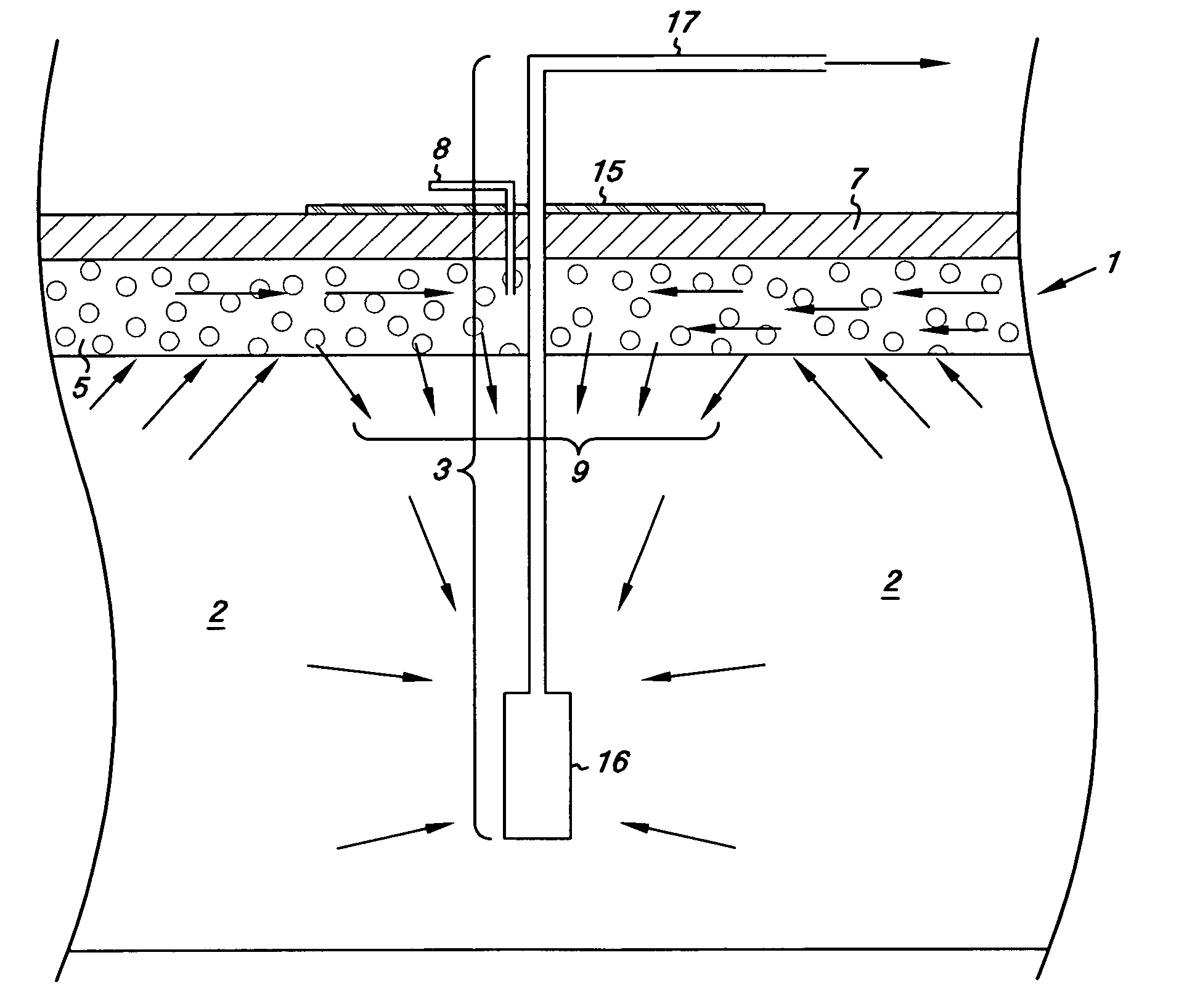

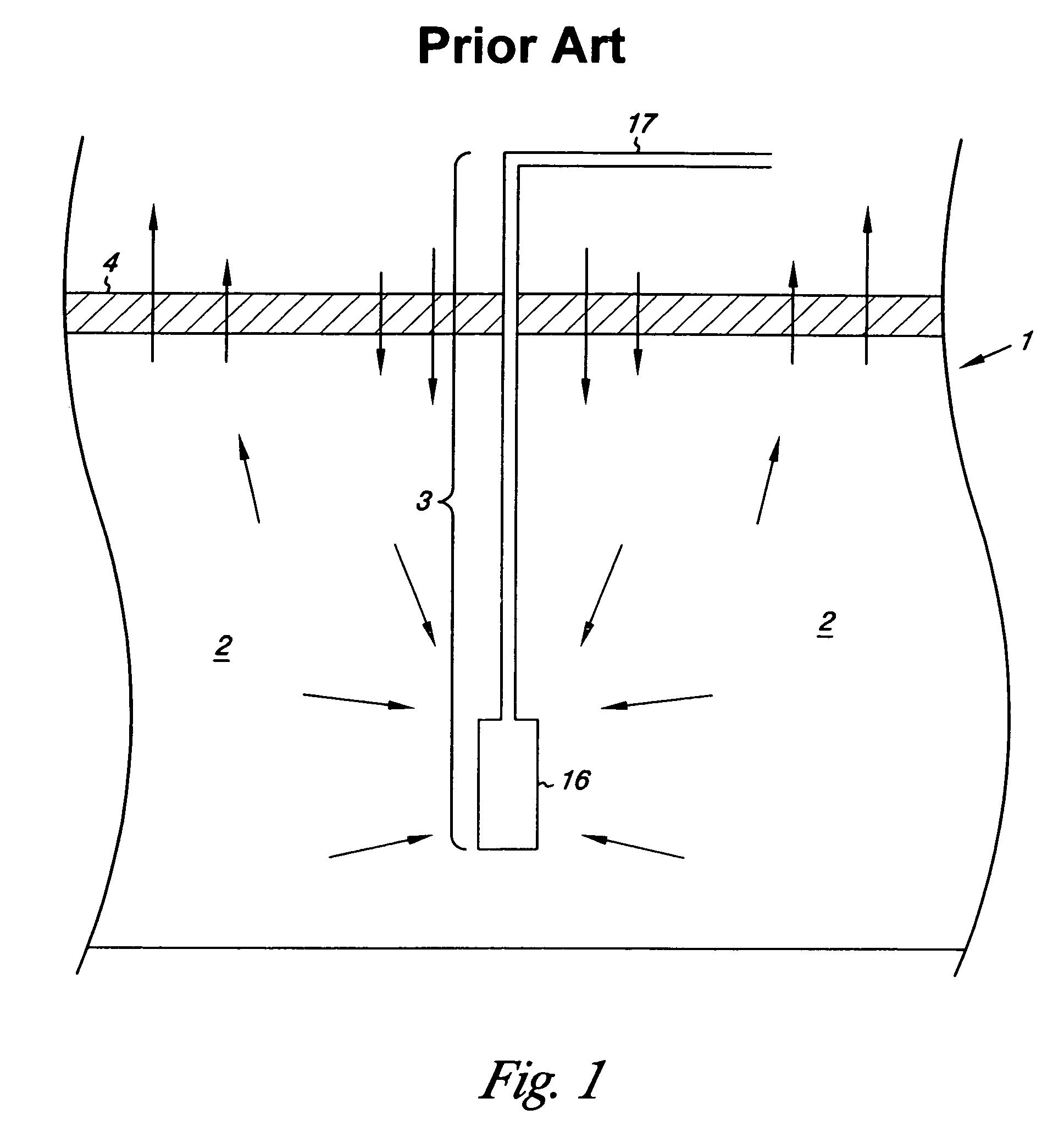

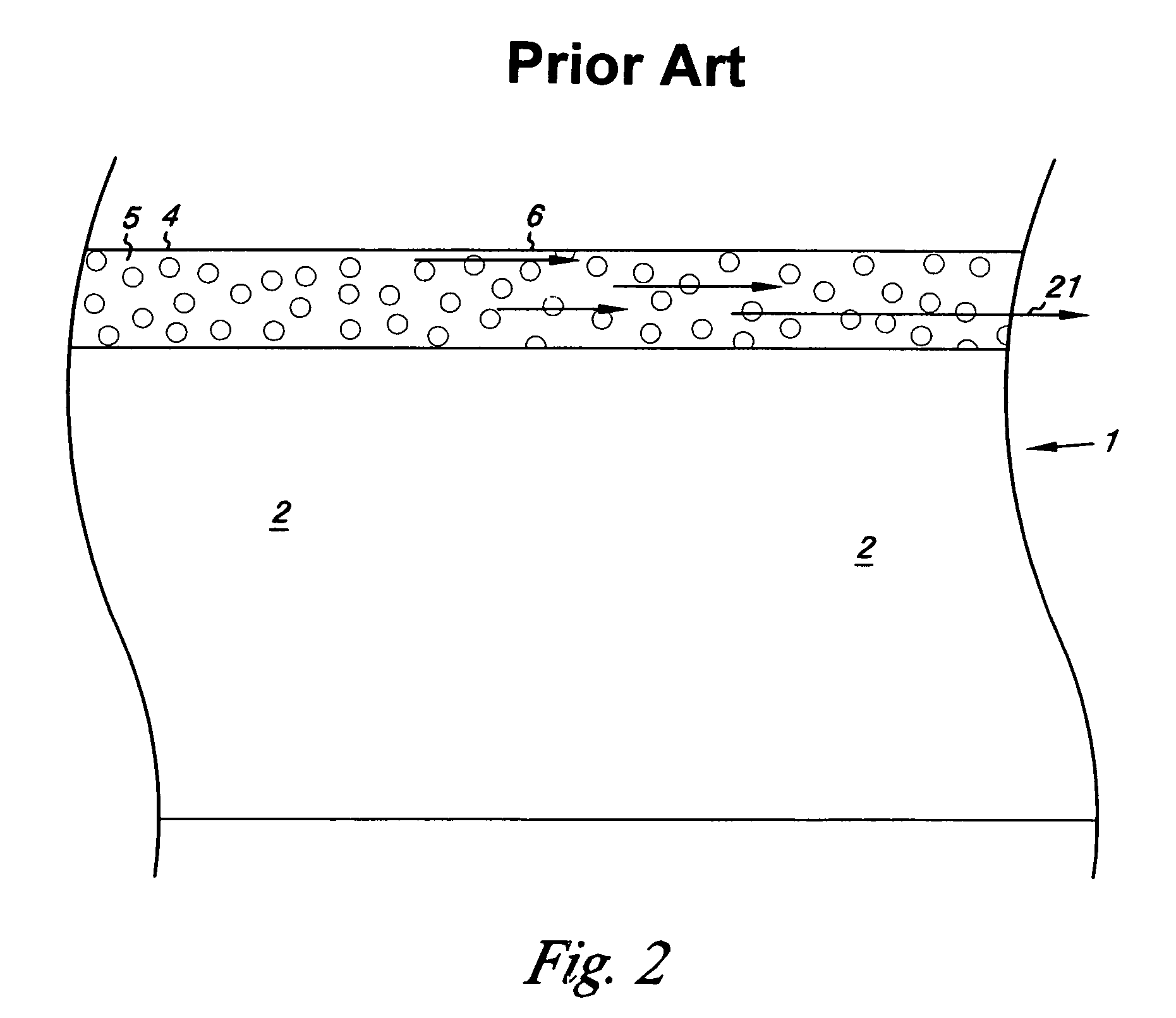

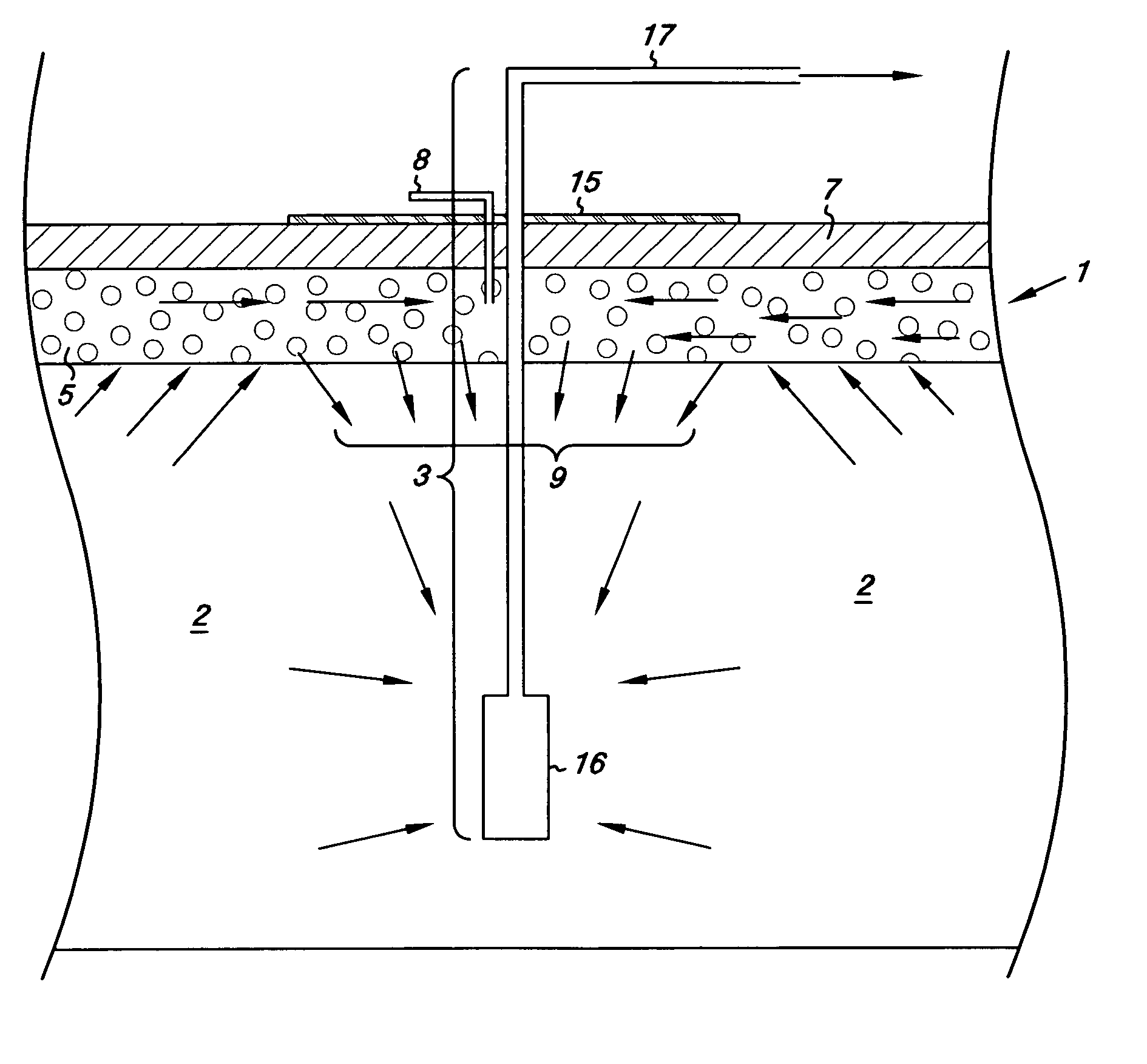

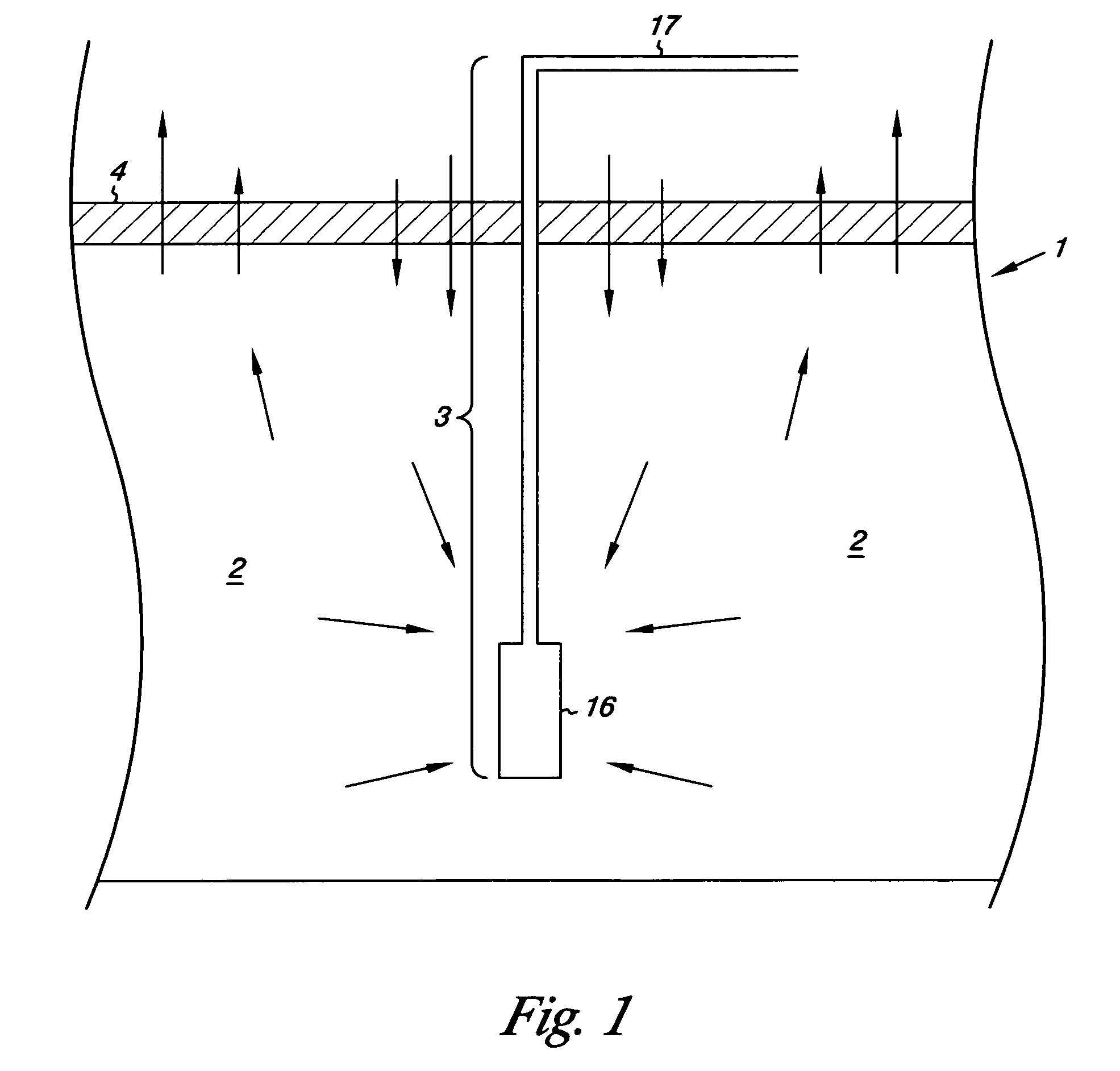

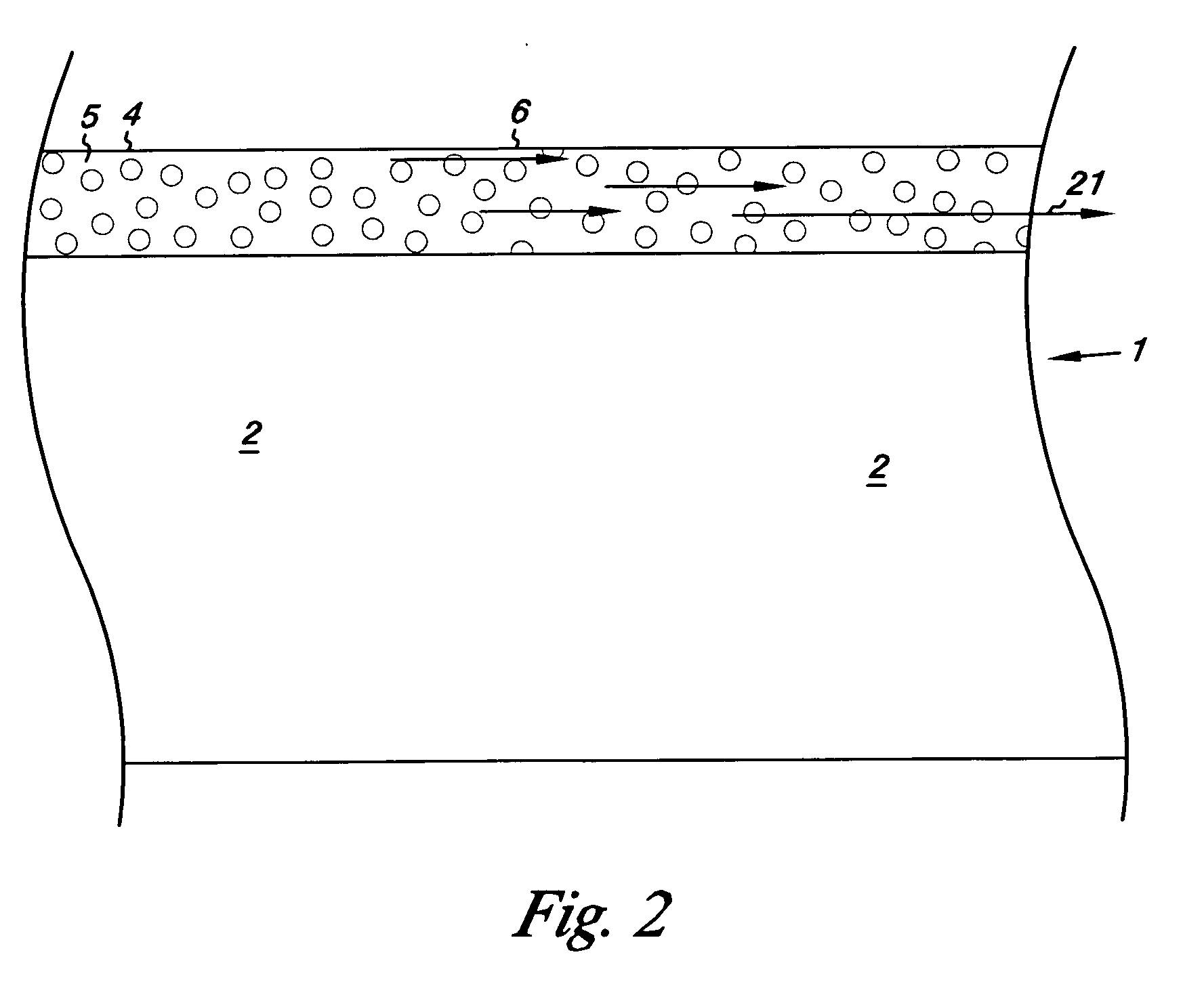

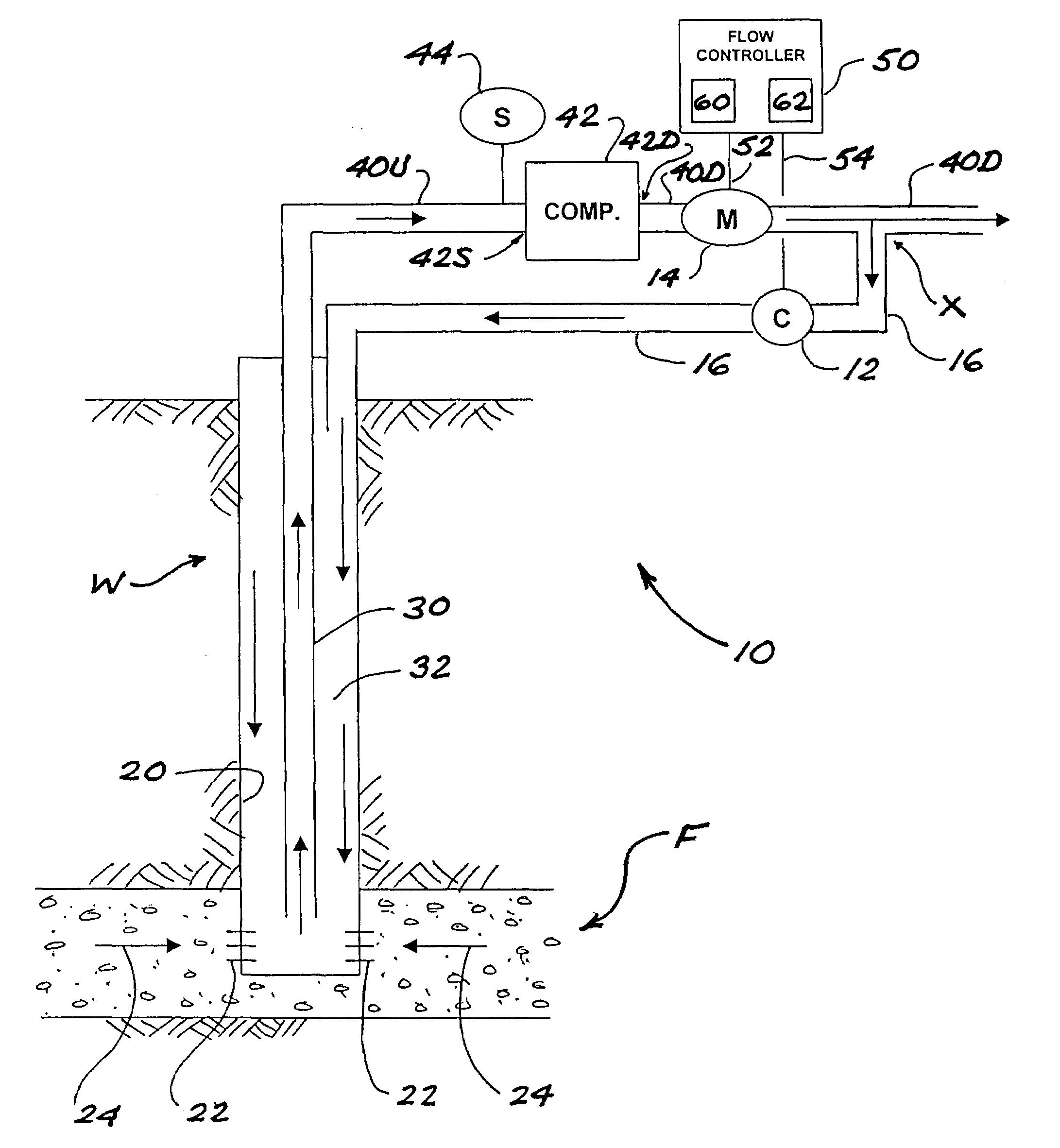

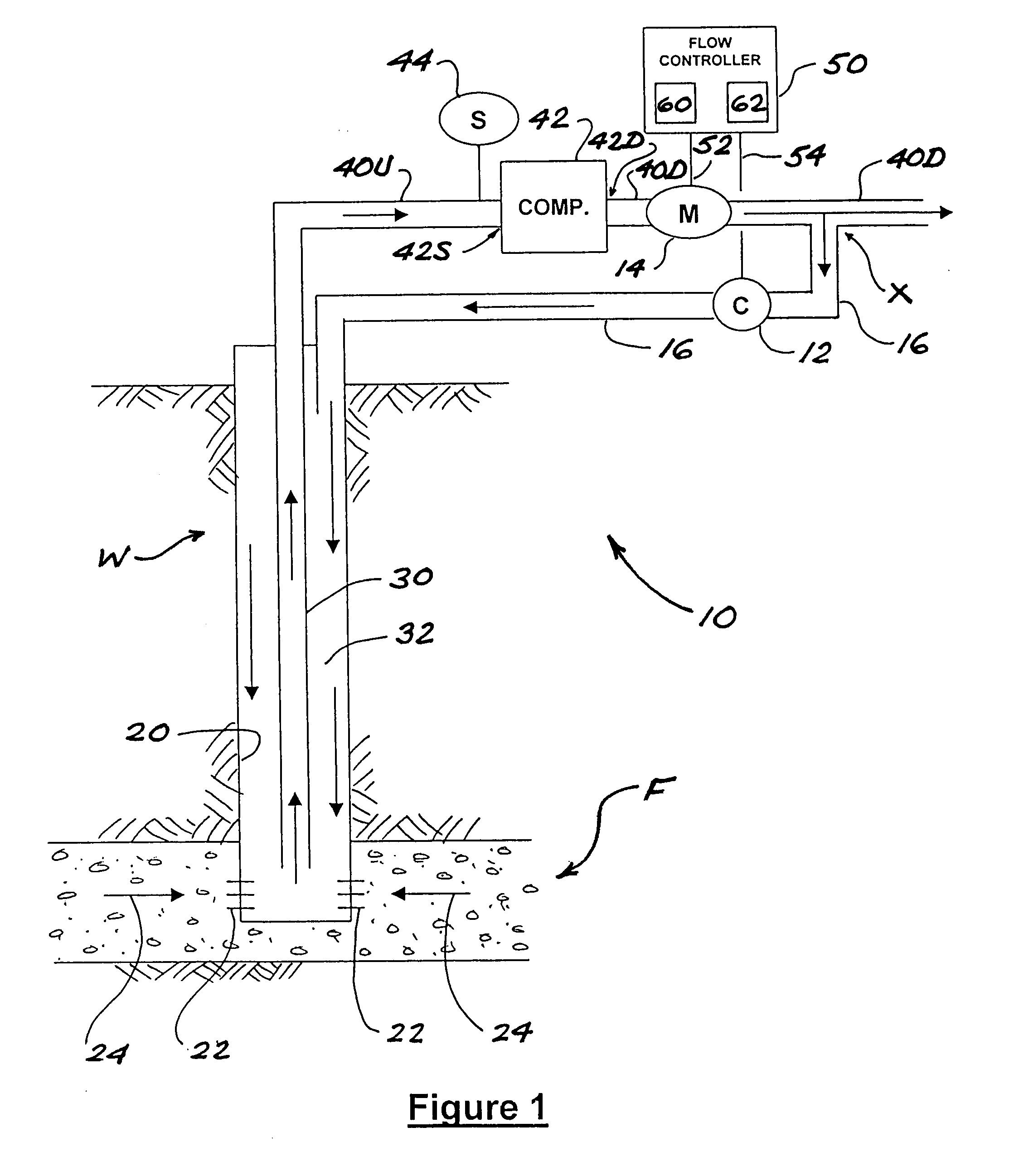

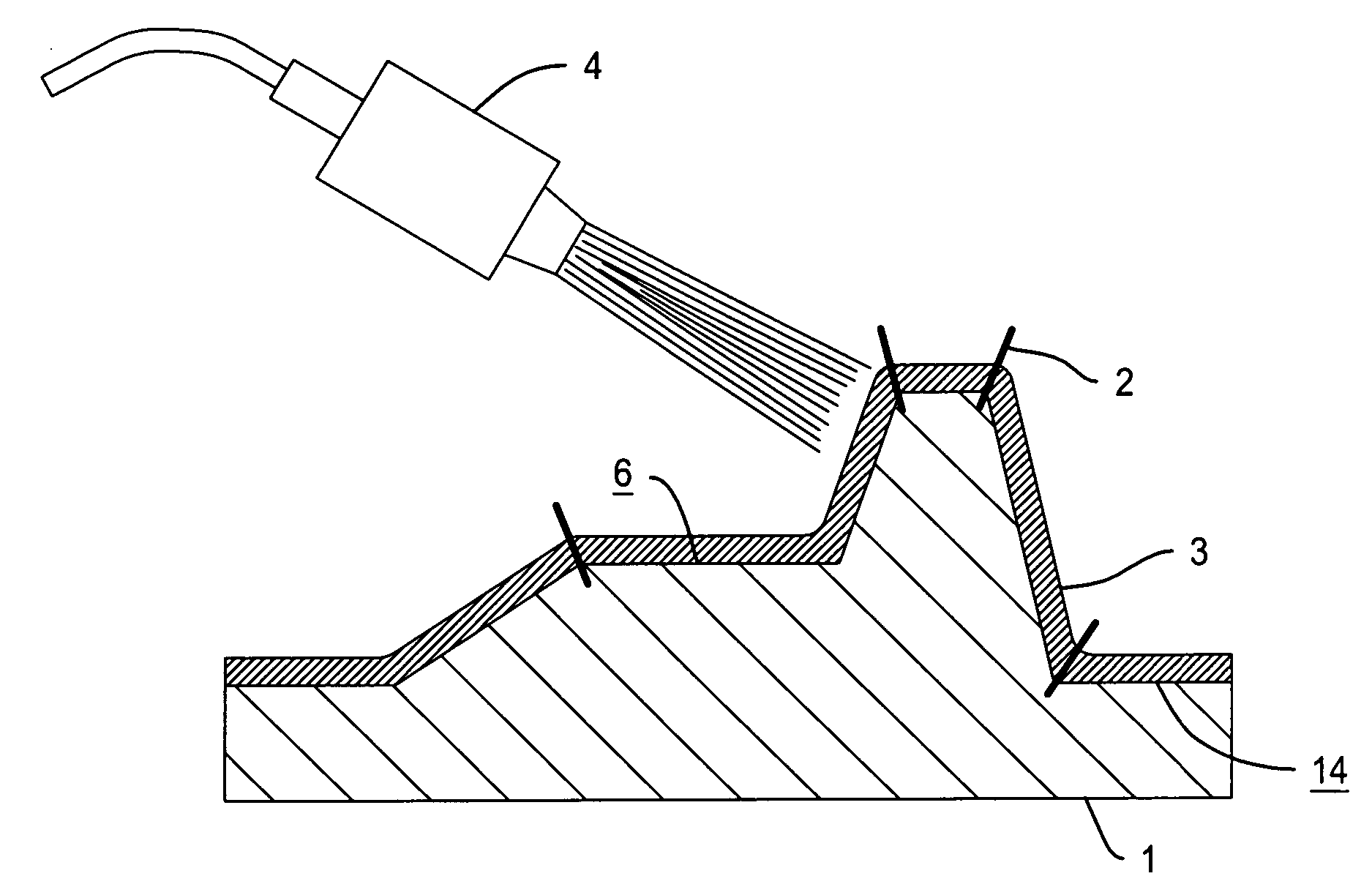

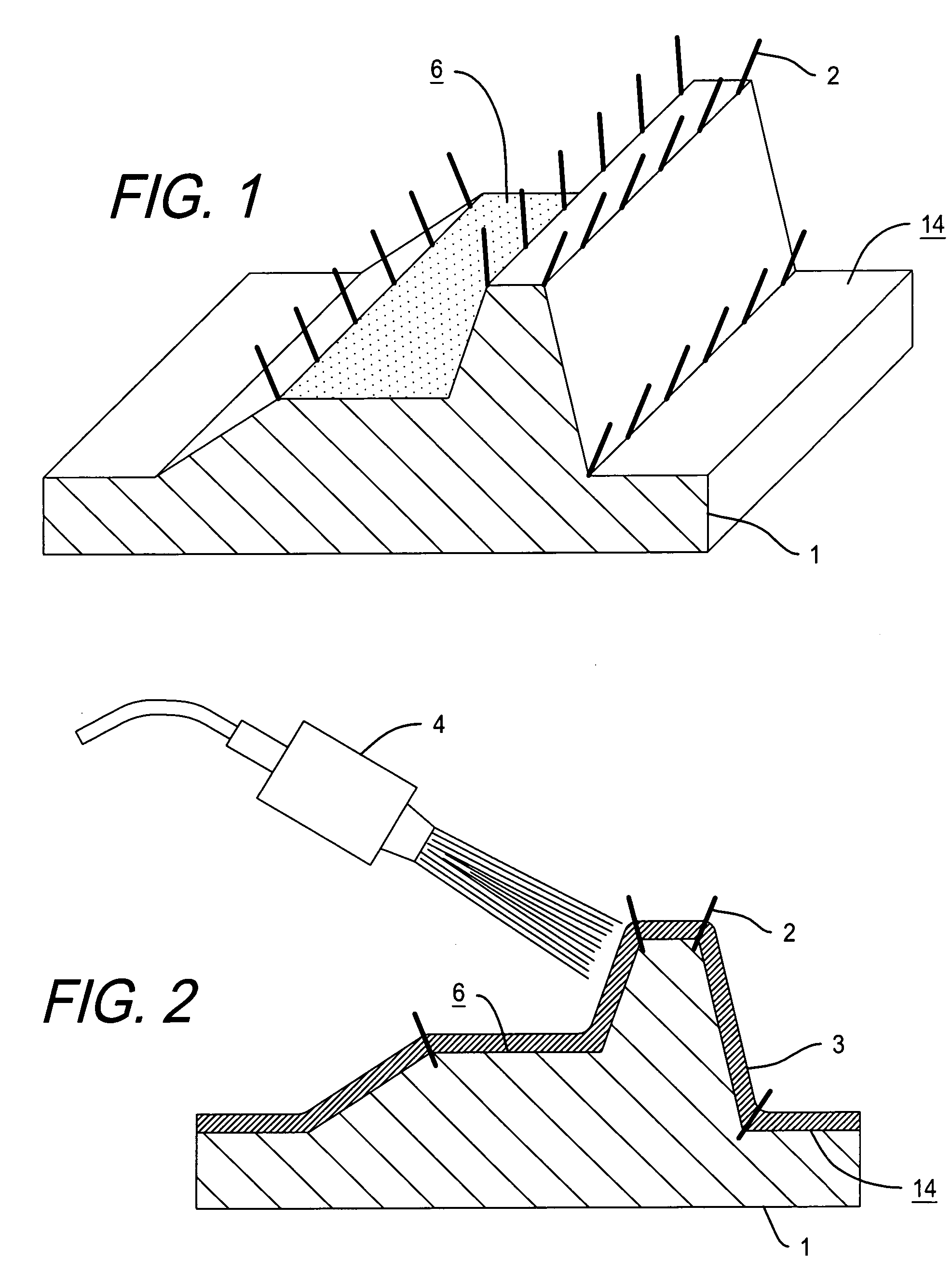

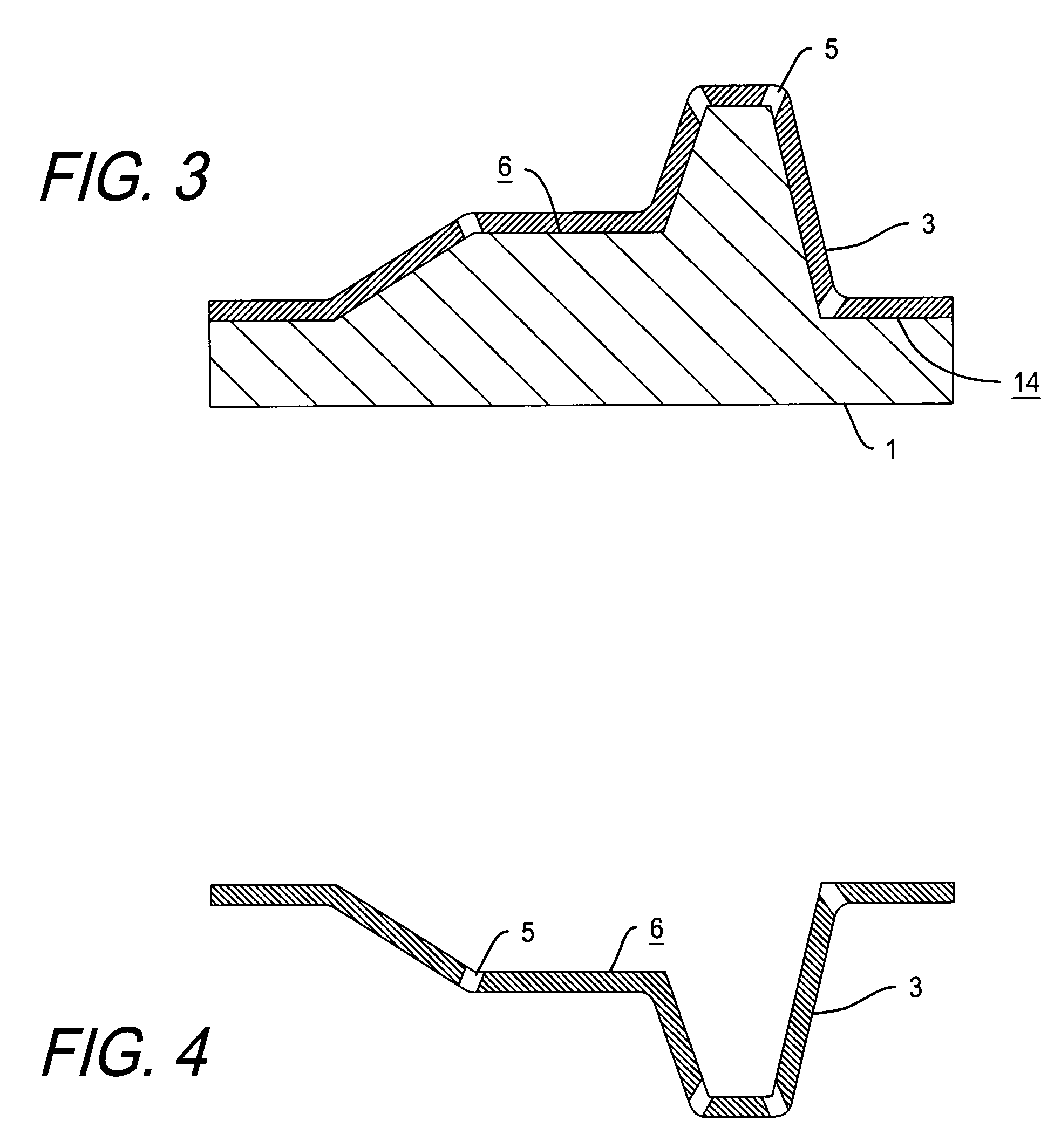

Landfill design and method for improved landfill gas capture

InactiveUS7198433B2Efficient collectionFacilitate methodMethane captureSolid waste disposalGas compositionAir entrainment

The invention provides an improved method of collecting biogas from a landfill that results in more complete collection of biogas produced in the landfill, and with less contamination with air. The method involves providing the landfill with an upper gas containment layer near the surface of the landfill to retard biogas escape and air entrainment into the landfill. Underneath the gas containment layer is provided a gas-permeable conductive layer. Underneath the conductive layer, a well withdraws biogas from the landfill. Withdrawal of biogas from the well creates a partial vacuum that draws gas from the gas-permeable conductive layer down through the waste mass to the well. If the rate of gas withdrawal from the well is too rapid, air will be entrained from the atmosphere into the gas-permeable conductive layer. But if the rate of gas withdrawal from the well is too slow, biogas may percolate through the gas-containment layer and the surface of the landfill to escape. Monitoring the gas composition of the gas-permeable layer allows one to determine quickly and continuously whether the rate of gas withdrawal from the well is too fast or too slow.

Owner:INST FOR ENVIRONMENTAL MANAGEMENT

Landfill design and method for improved landfill gas capture

InactiveUS20060034664A1Efficient collectionFacilitate methodMethane captureSolid waste disposalGas compositionAir entrainment

The invention provides an improved method of collecting biogas from a landfill that results in more complete collection of biogas produced in the landfill, and with less contamination with air. The method involves providing the landfill with an upper gas containment layer near the surface of the landfill to retard biogas escape and air entrainment into the landfill. Underneath the gas containment layer is provided a gas-permeable conductive layer. Underneath the conductive layer, a well withdraws biogas from the landfill. Withdrawal of biogas from the well creates a partial vacuum that draws gas from the gas-permeable conductive layer down through the waste mass to the well. If the rate of gas withdrawal from the well is too rapid, air will be entrained from the atmosphere into the gas-permeable conductive layer. But if the rate of gas withdrawal from the well is too slow, biogas may percolate through the gas-containment layer and the surface of the landfill to escape. Monitoring the gas composition of the gas-permeable layer allows one to determine quickly and continuously whether the rate of gas withdrawal from the well is too fast or too slow.

Owner:INST FOR ENVIRONMENTAL MANAGEMENT

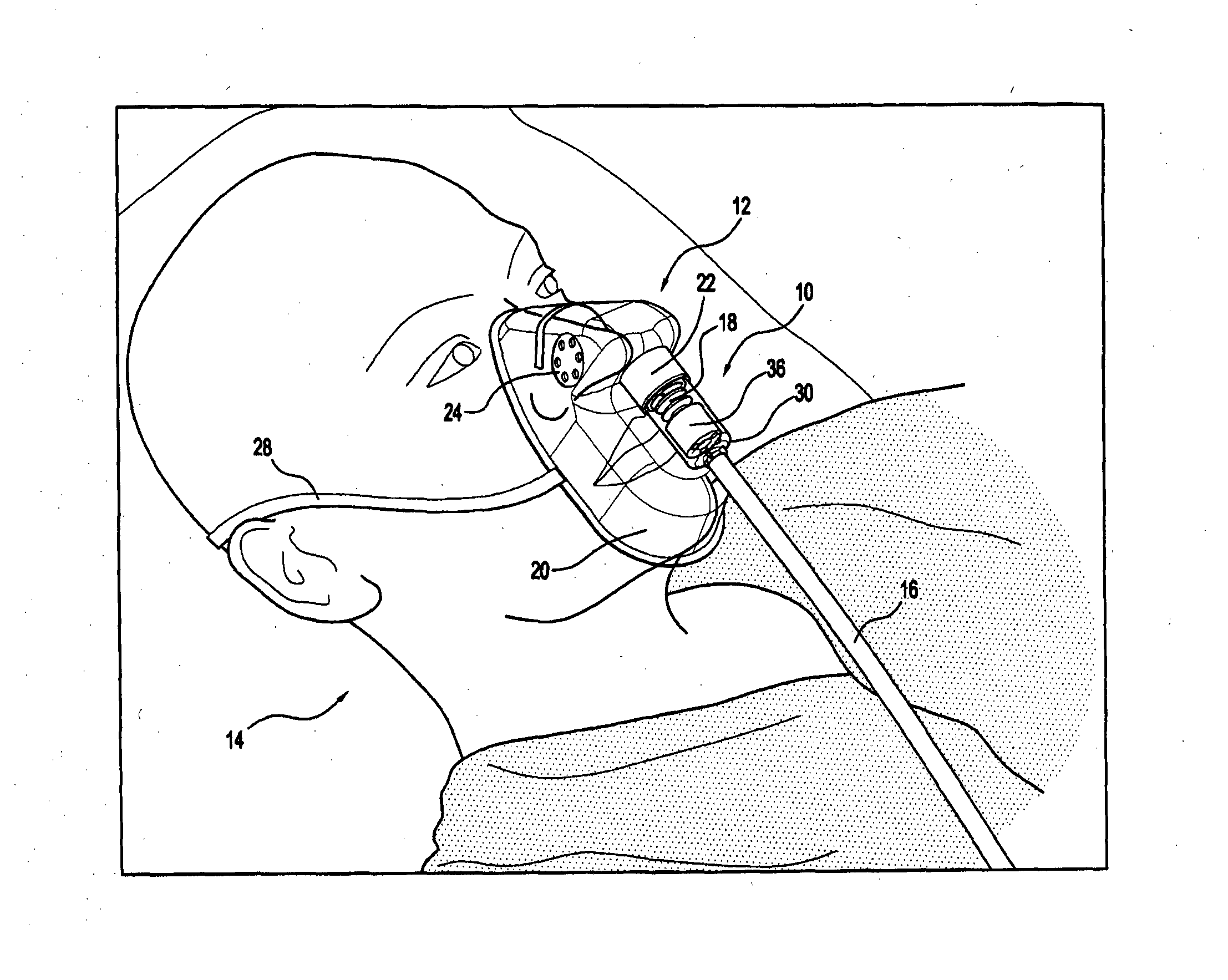

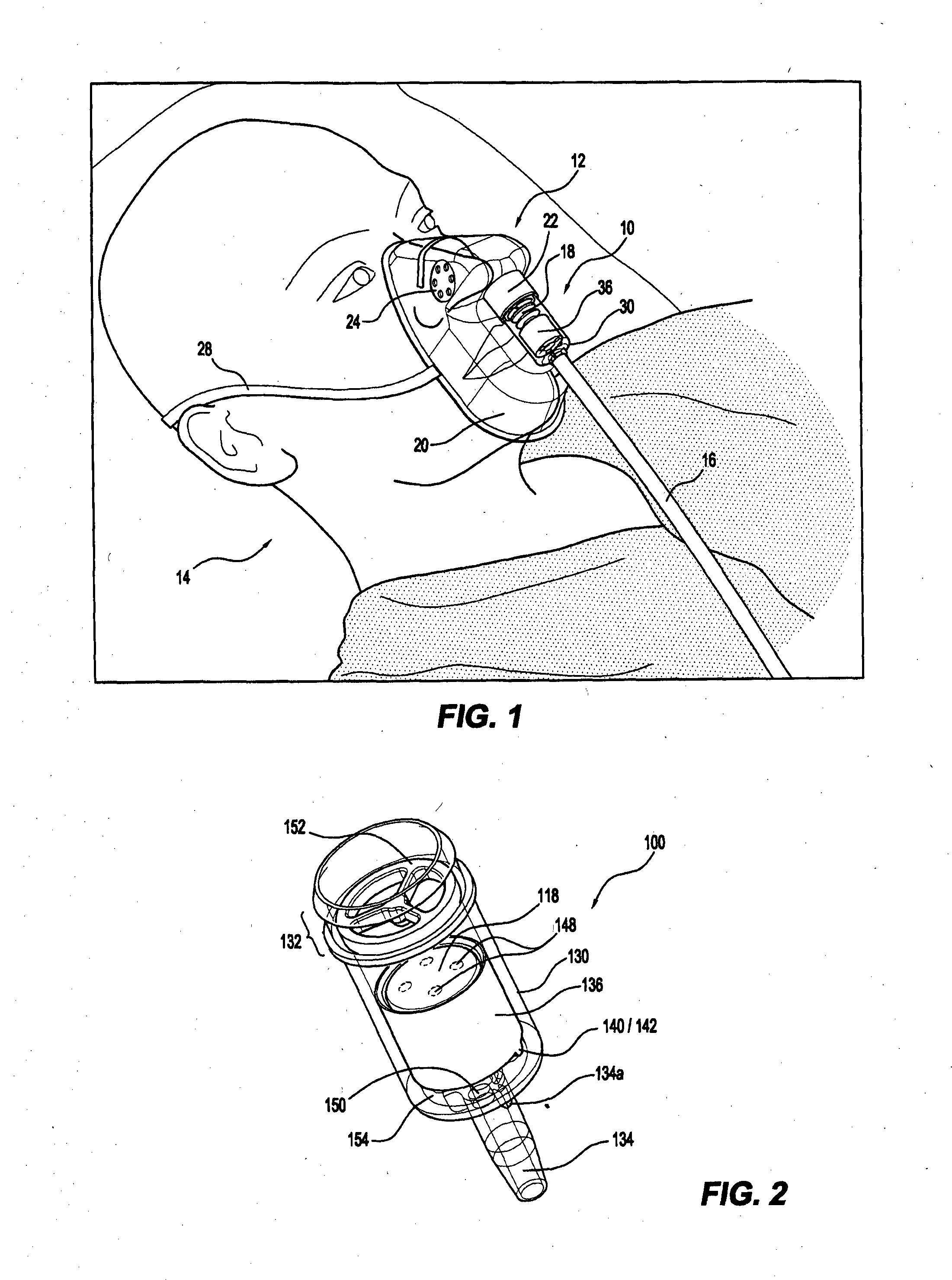

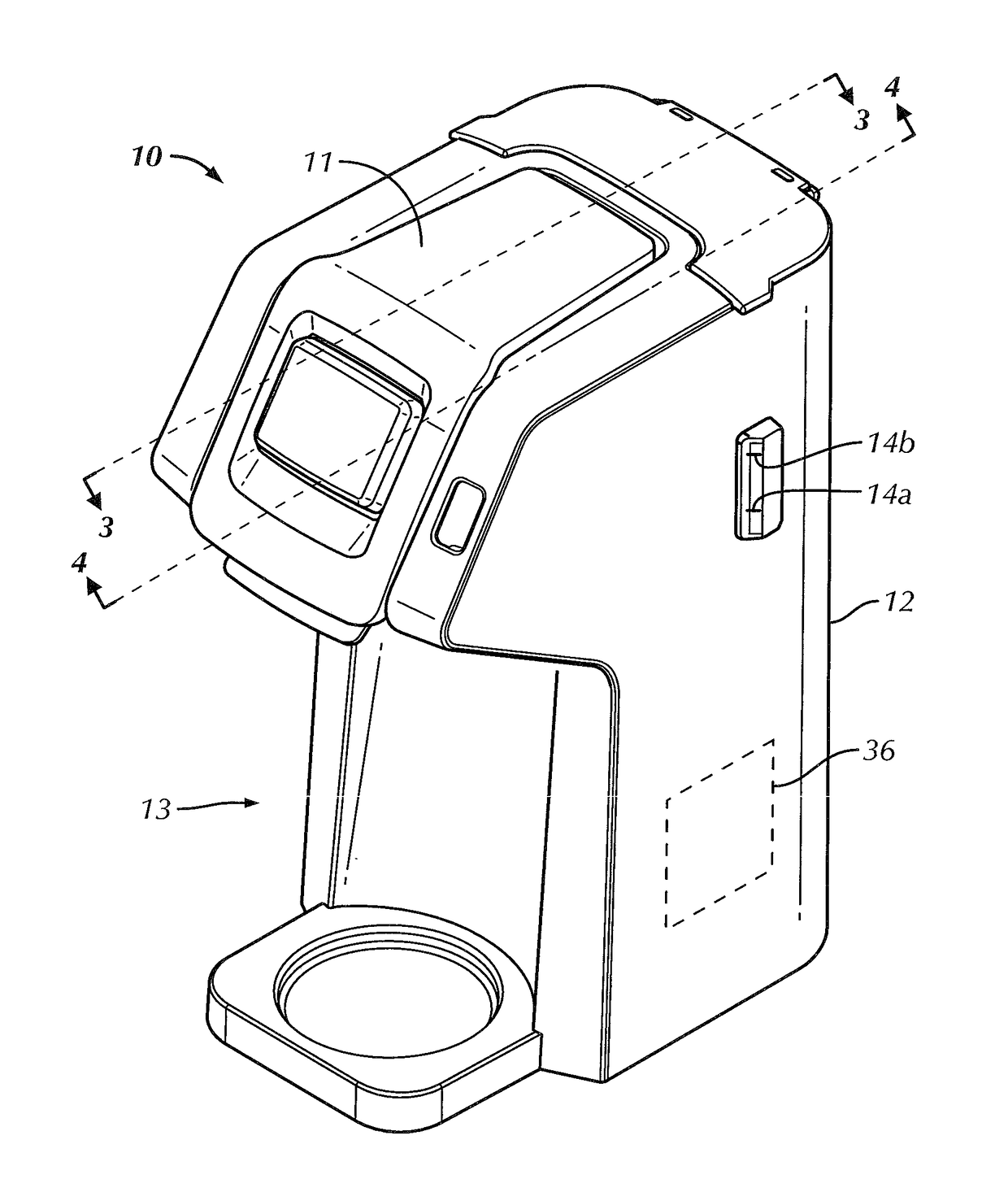

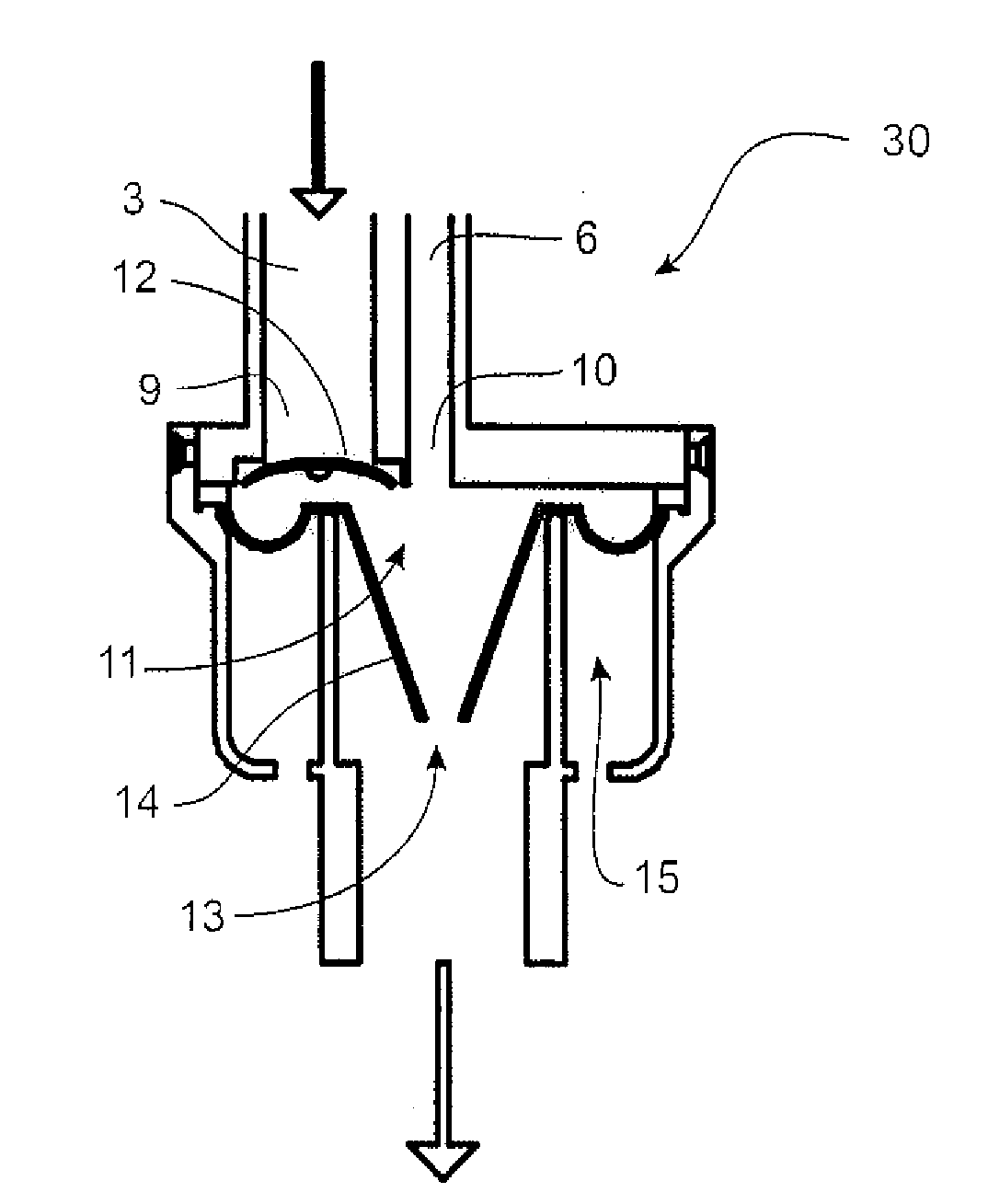

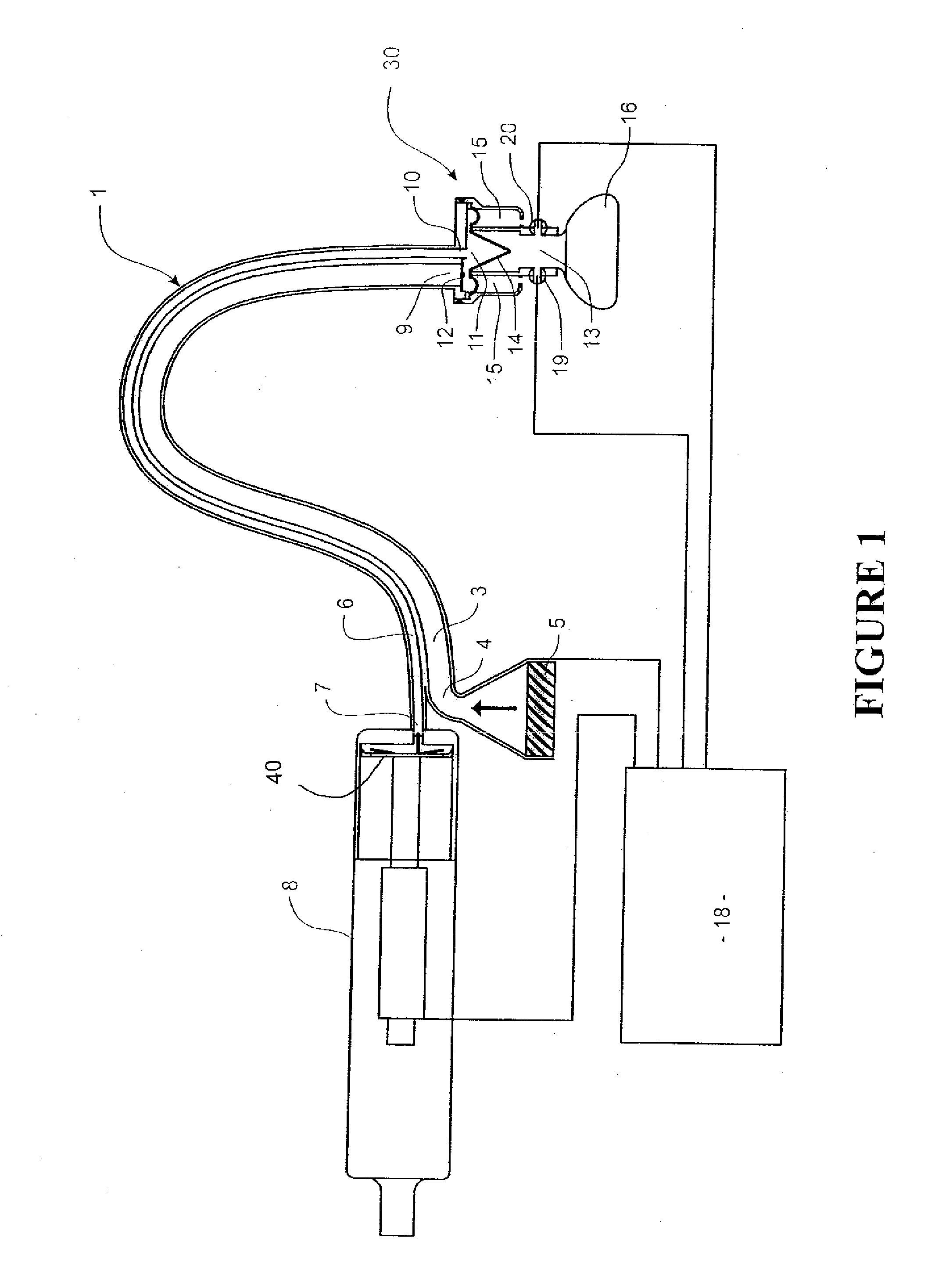

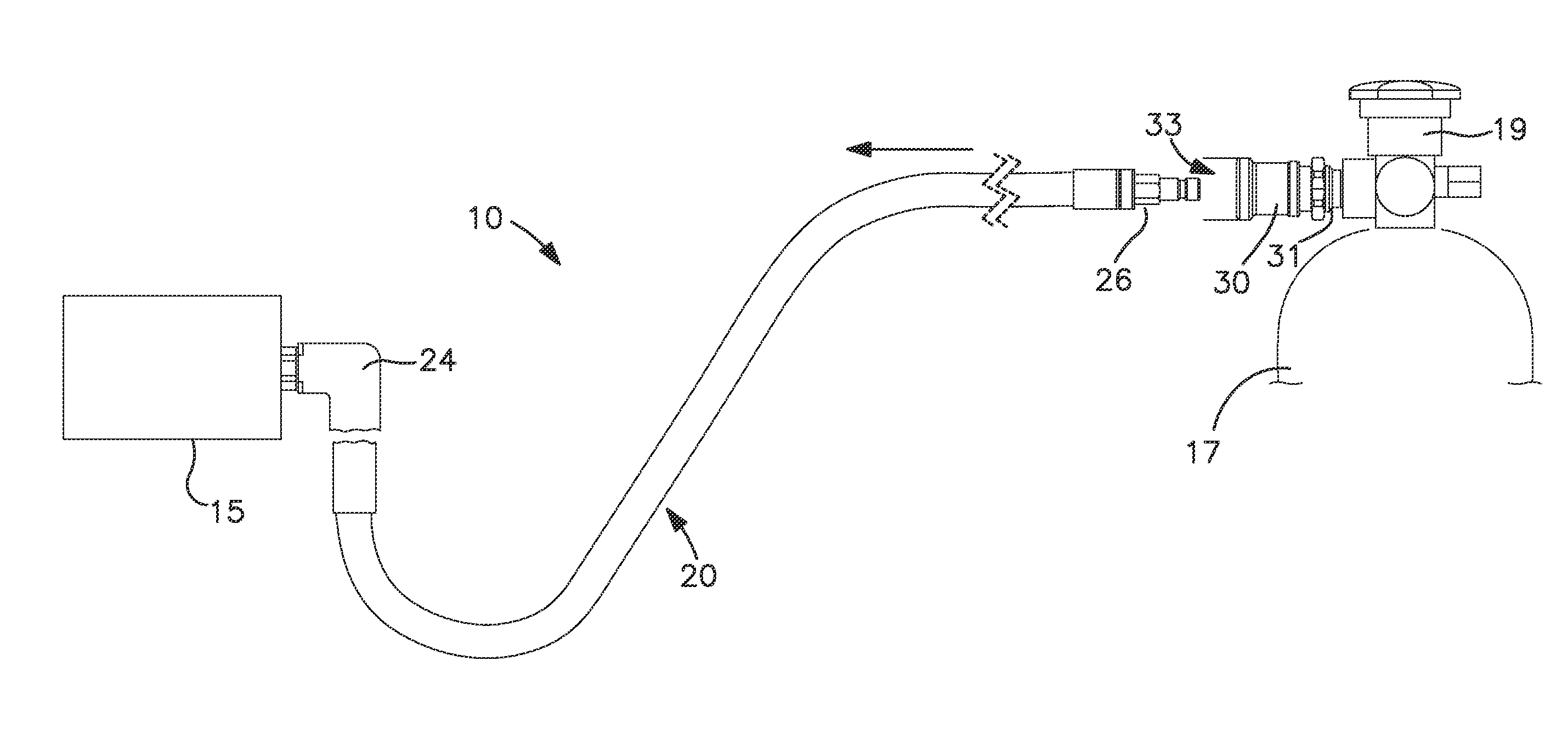

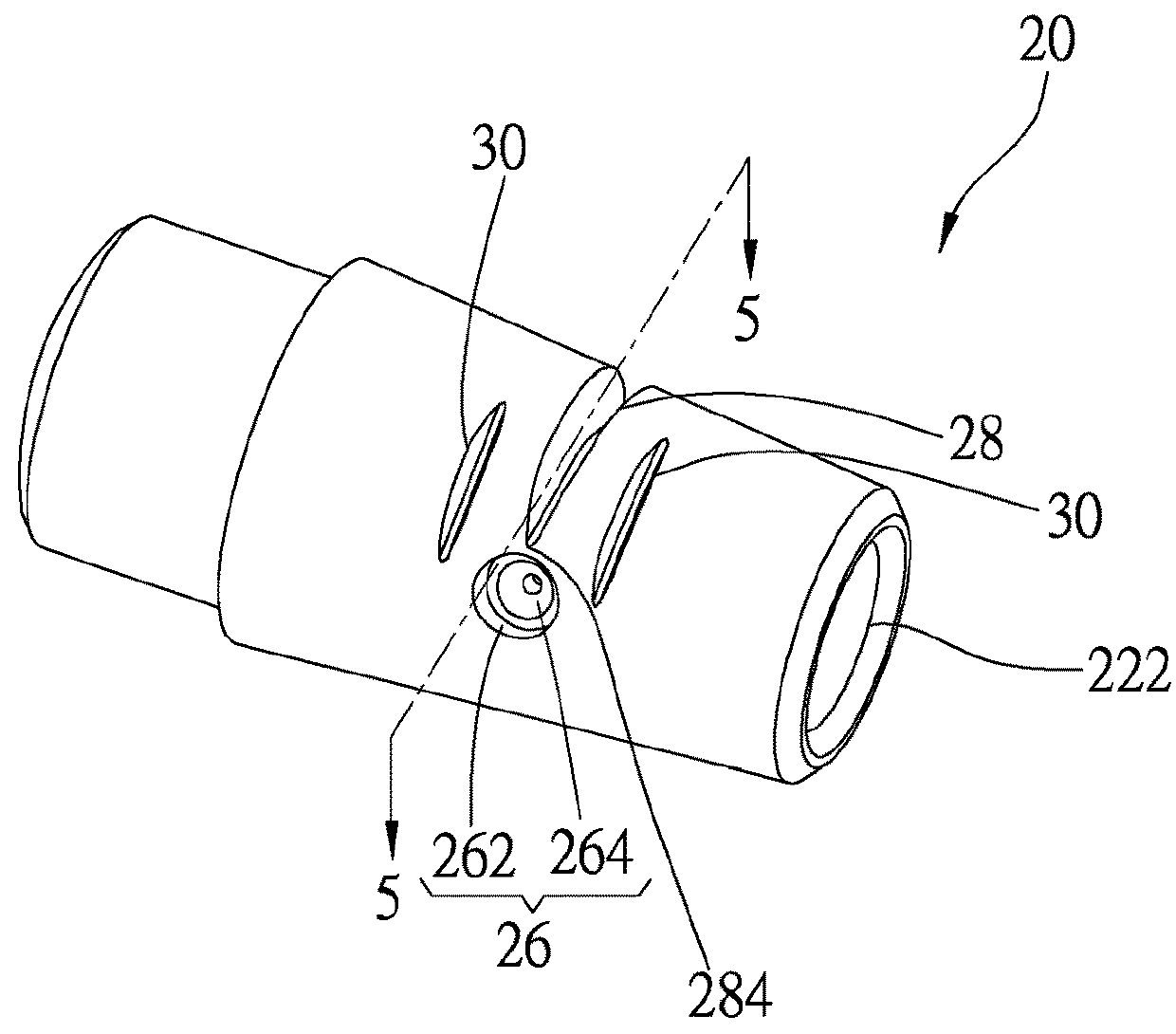

Gas flow indicator

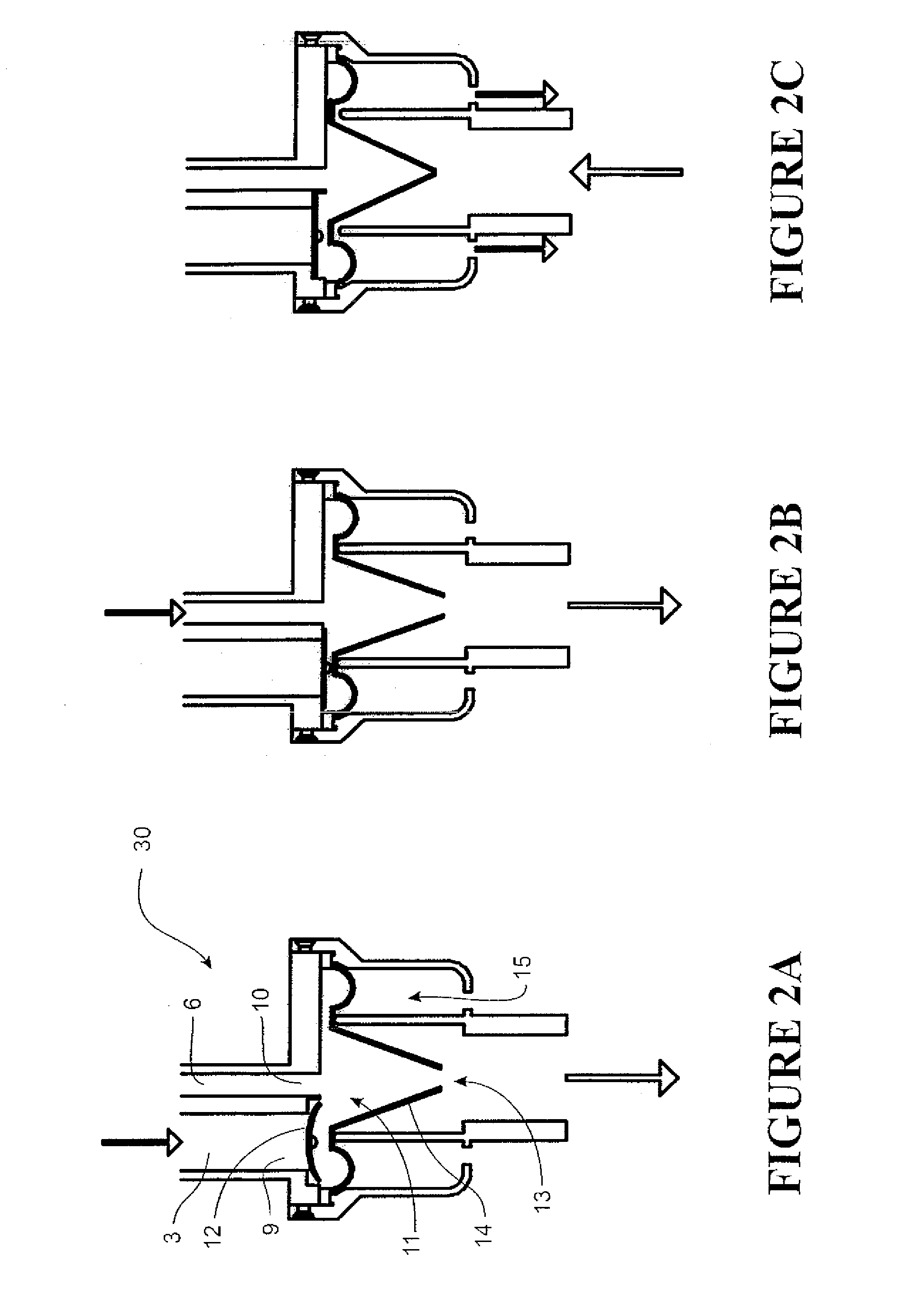

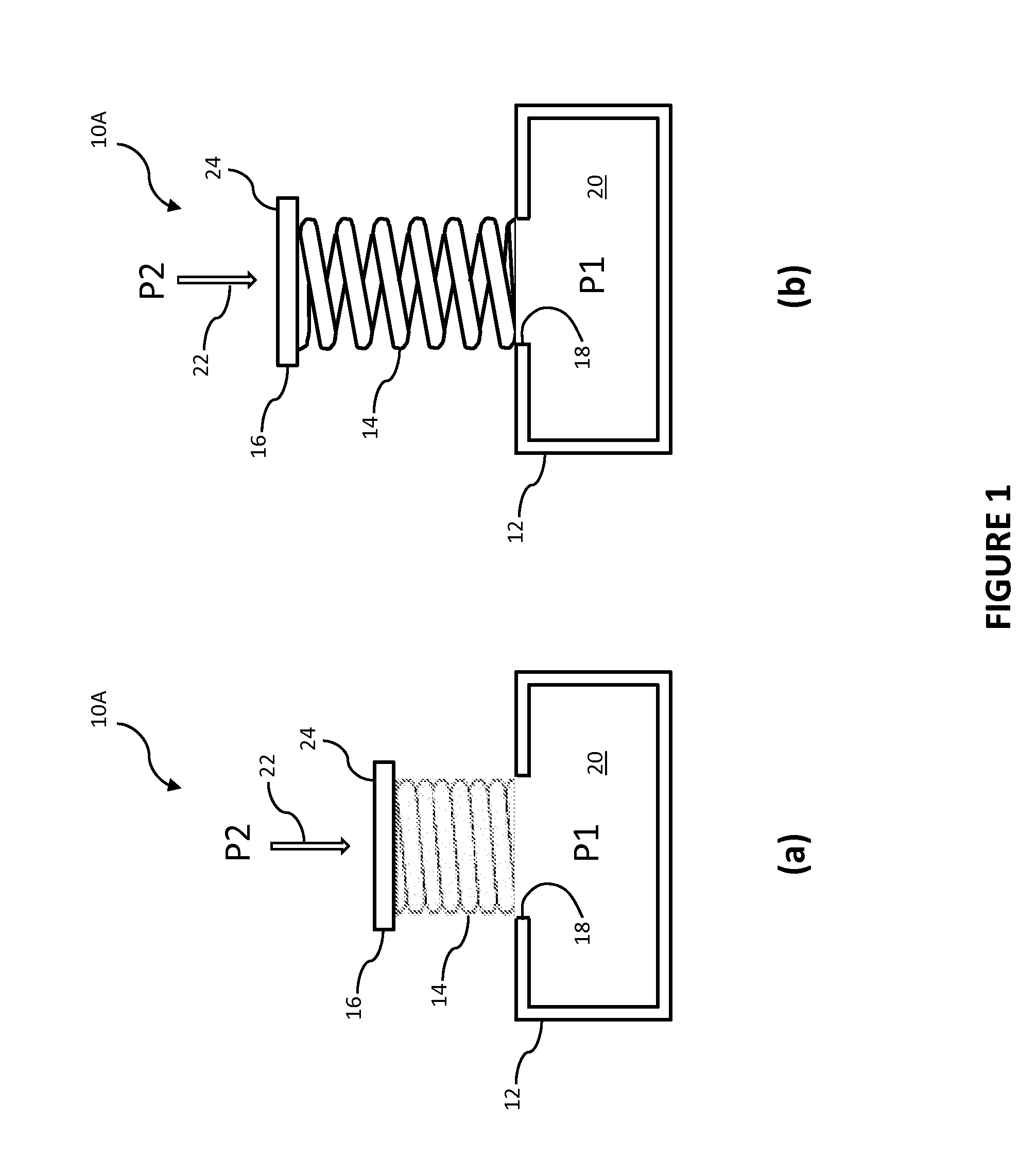

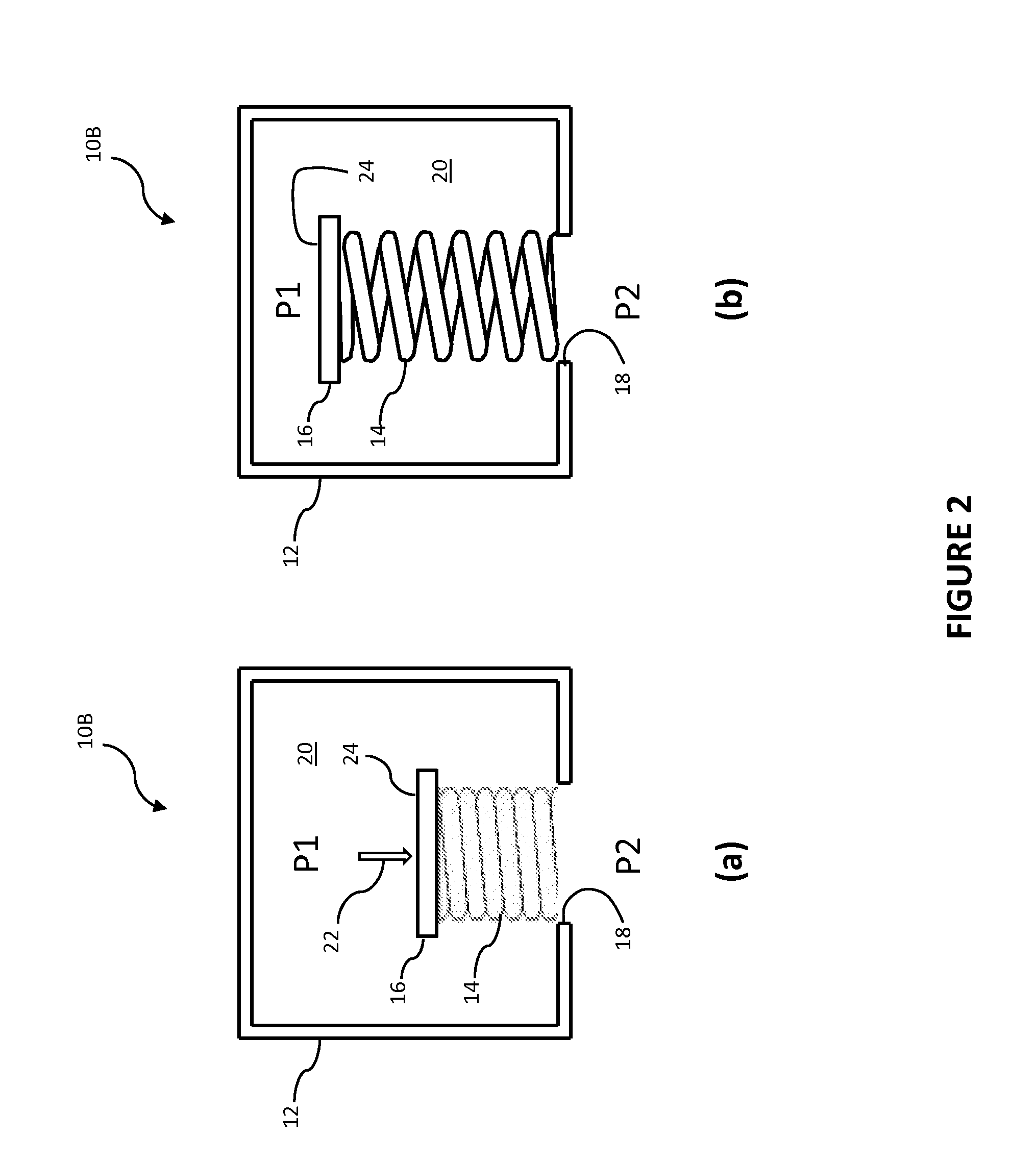

ActiveUS20150196723A1Inhibit gas flowRespiratory masksVolume/mass flow measurementEngineeringAirflow

A gas flow indicator apparatus (10) comprising: a gas flow chamber including at least one transparent portion (30) and at least one opaque portion (36); at least one inlet port (34); at least one outlet port (32); and, at least one gas flow signal means (18) movably disposed within the gas flow chamber. The gas flow indicator apparatus (10) being configured such that when no gas flow is present and / or when a predetermined gas flow rate has not been achieved, the signal means (18) is disposed substantially within one of the transparent portion (30) or the opaque portion (36), and wherein when gas flow is present and / or the predetermined gas flow rate has been achieved, the signal means (18) is moved to be disposed substantially within the other of the transparent portion (30) or the opaque portion (36). Gas delivery devices (12), systems (12) and / or conduits (16) incorporating the gas flow indicator apparatus (10) are also provided in accordance with the invention.

Owner:VPAS GRP

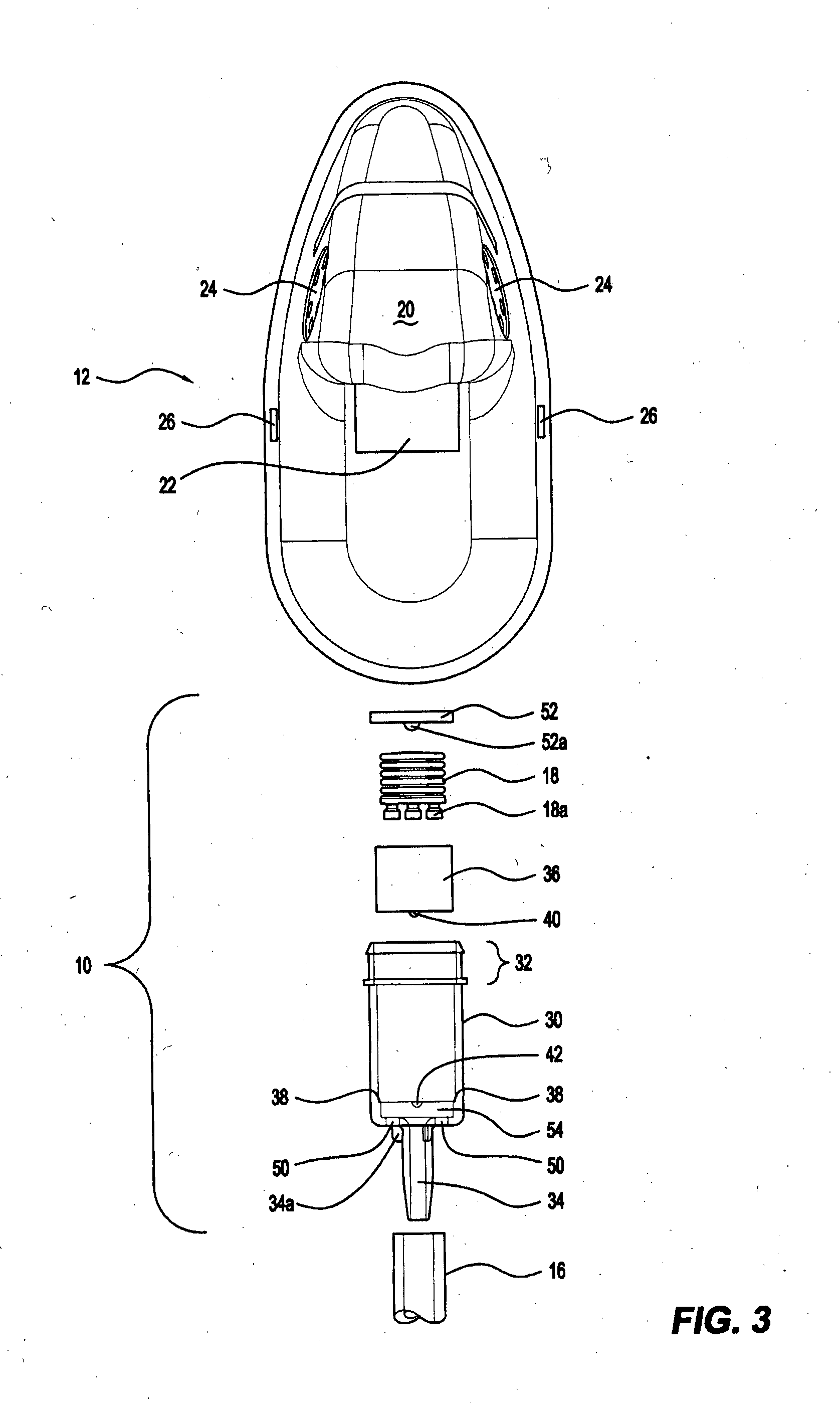

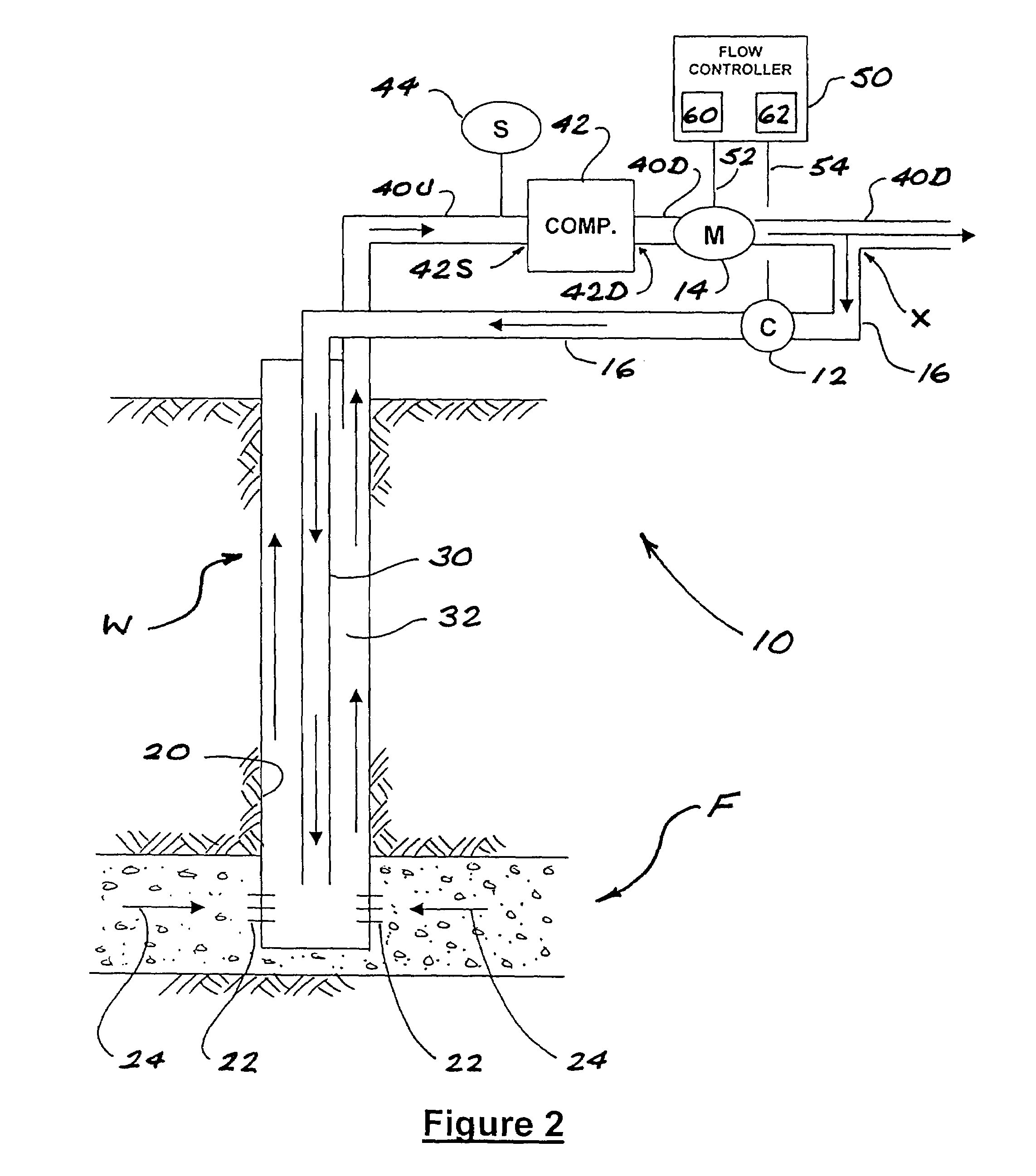

Apparatus and method for enhancing productivity of natural gas wells

ActiveUS6991034B2Extend product lifeReducing bottomhole pressureSurveyDrilling rodsProduct gasProcess engineering

A natural gas production system prevents liquid accumulation in the wellbore and minimizes friction loading in the wellbore by maintaining production gas velocity above a critical minimum velocity. A pressurized gas is injected into the well to supplement the flow of production gas such that the velocity of the total gas flow up the well exceeds the critical velocity. A choke is fitted to the gas injection line, and total gas flows are measured by a flow meter. A flow controller compares the measured total gas flow rate against the critical flow rate, and determines a minimum gas injection rate required to maintain the total gas flow rate at or above the critical flow rate. The flow controller then adjusts the choke to achieve the desired gas injection rate. The injection gas may be recirculated production gas from the well, or a gas from a separate source.

Owner:OPTIMUM PROD TECH INC

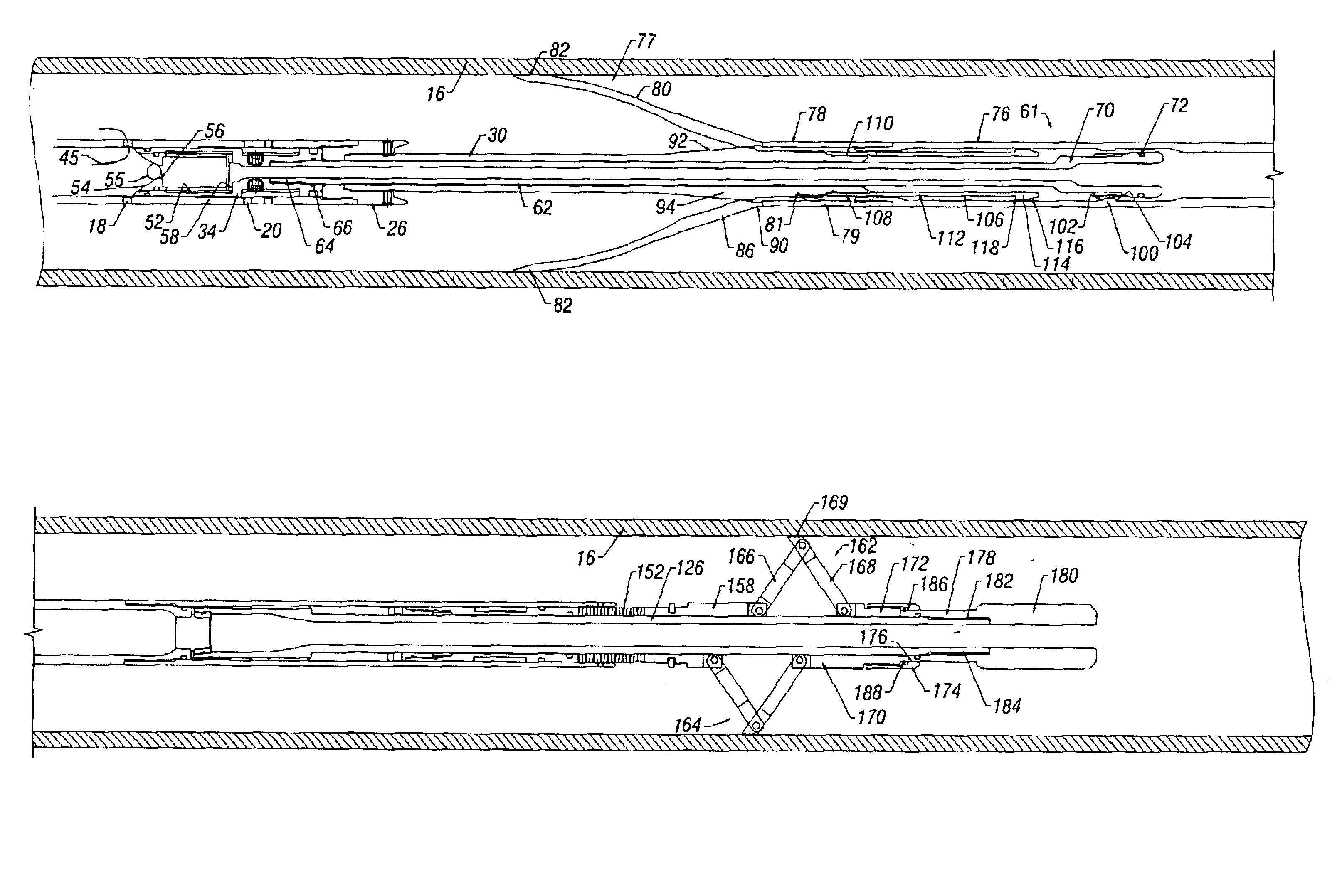

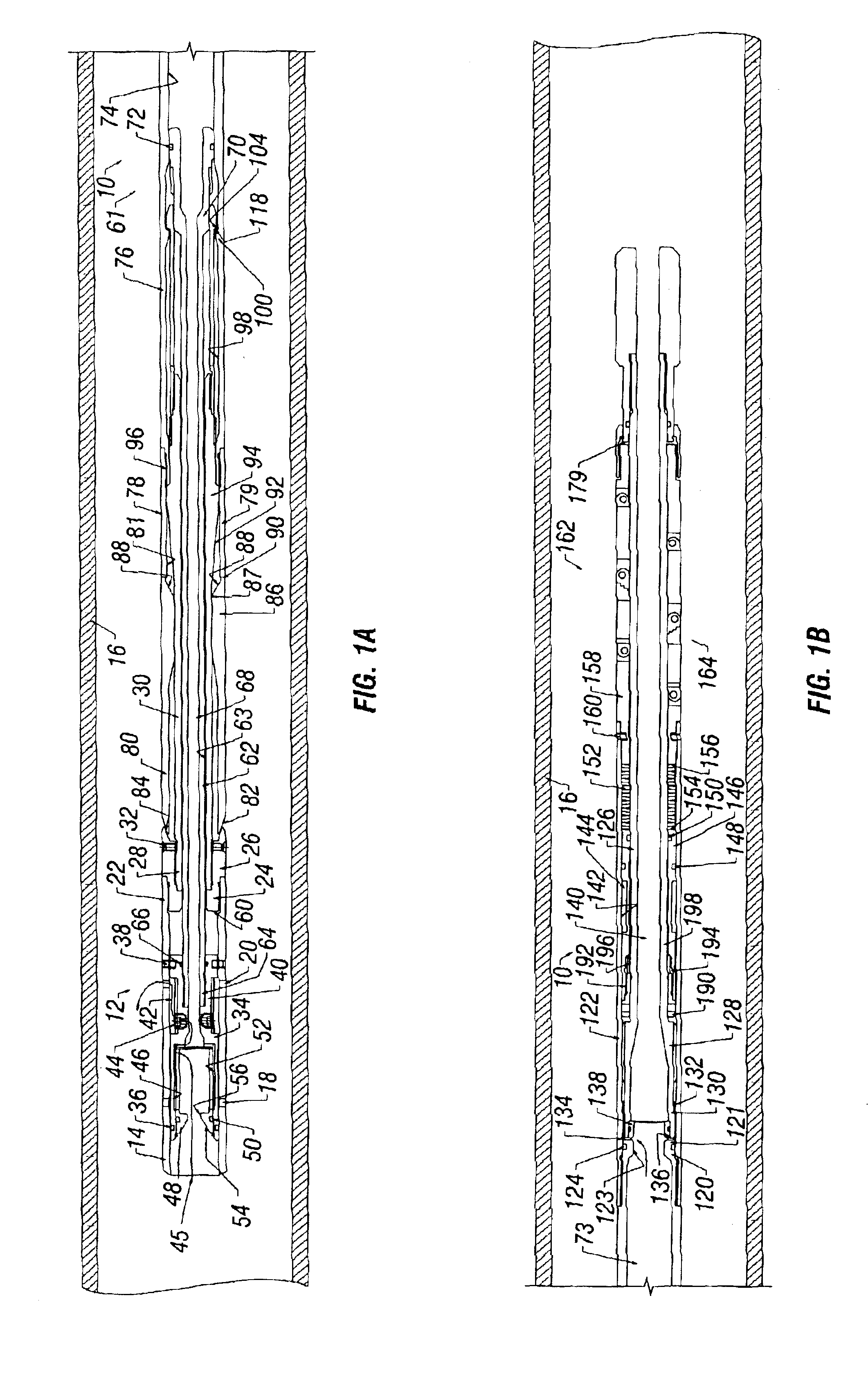

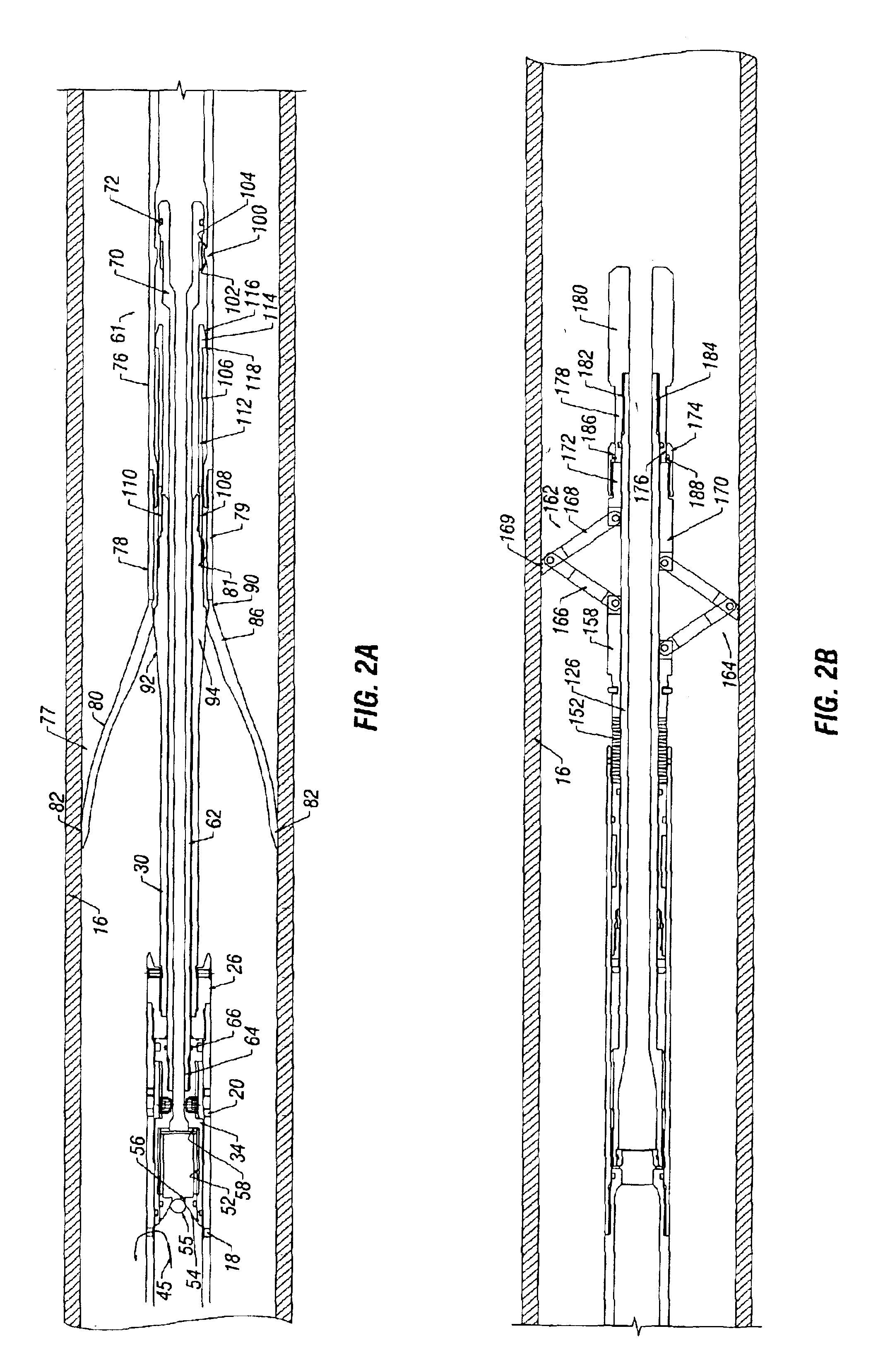

Re-enterable gravel pack system with inflate packer

InactiveUS6915845B2Minimizing necessary heightObstruction is producedDrilling rodsConstructionsHigh rateRe entry

A gravel packing system for re-entry of a screen assembly by a completion tool having an inflate packer as an isolation barrier for minimizing the necessary height of the gravel pack within the casing and thus maximizing the production interval of a well to permit a higher rate of production. The invention assures re-entry of tools to a gravel pack screen assembly for well completion following a gravel pack operation. A guiding and anchoring tool is run through a casing restriction and / or well tubing to a desired position below the restriction and / or tubing and within the casing and is actuated for anchoring. Guide fingers are formed downhole into a tool guiding configuration and the tool is left anchored within the well casing. Subsequently, a well completion tool is and guided into and latched within the guiding and anchoring tool and the inflate packer is set to enable optimum well production.

Owner:SCHLUMBERGER TECH CORP

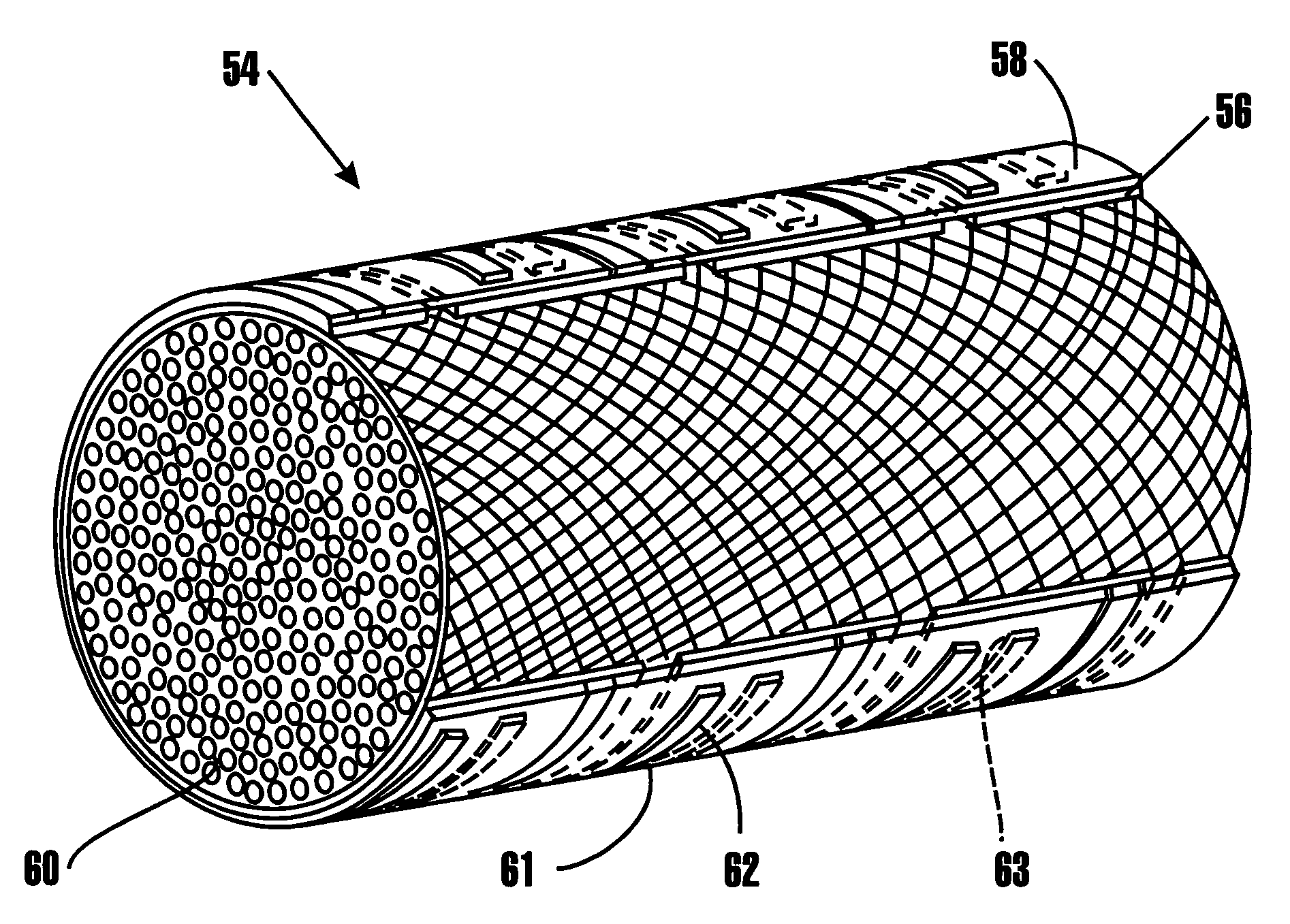

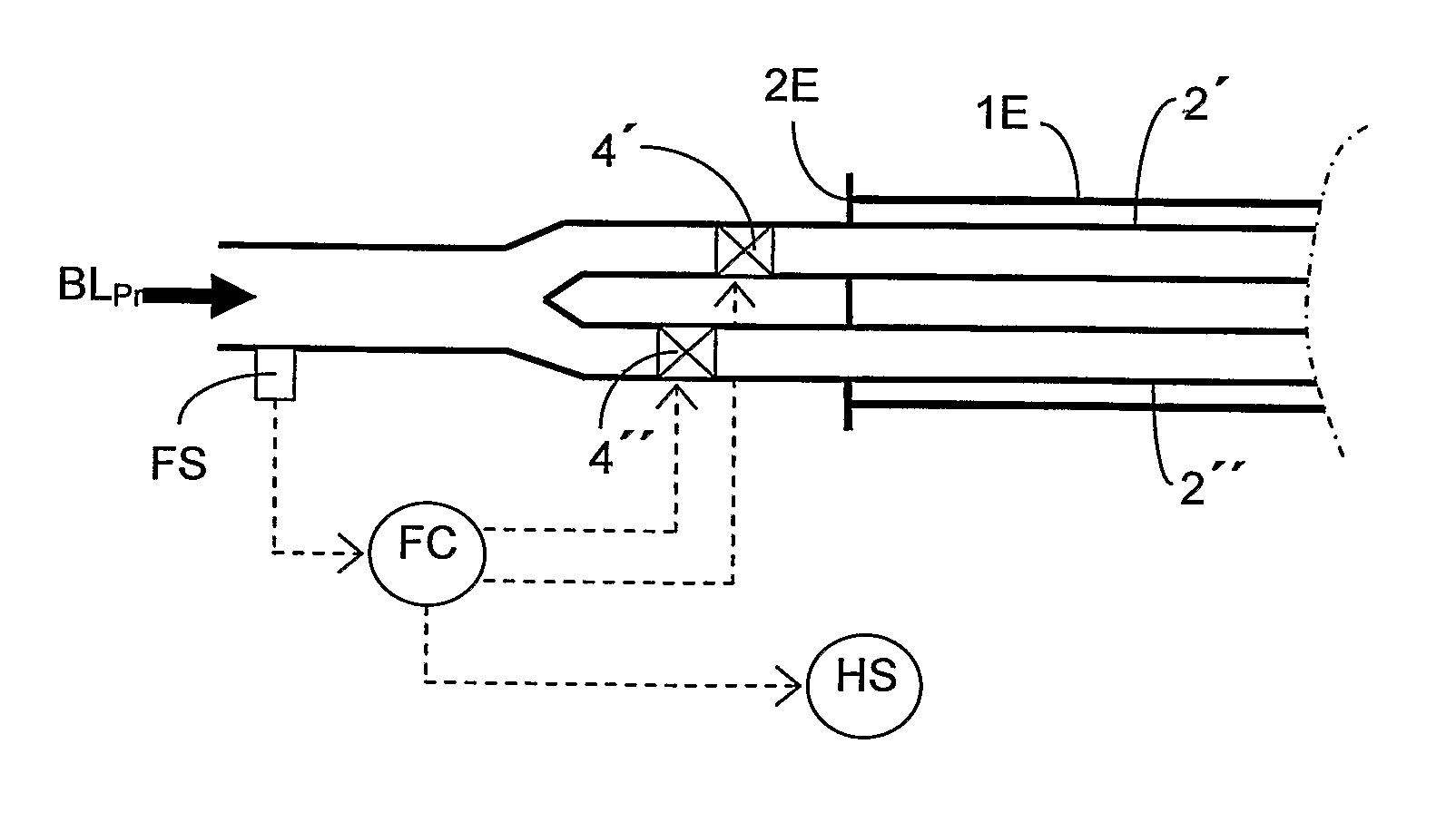

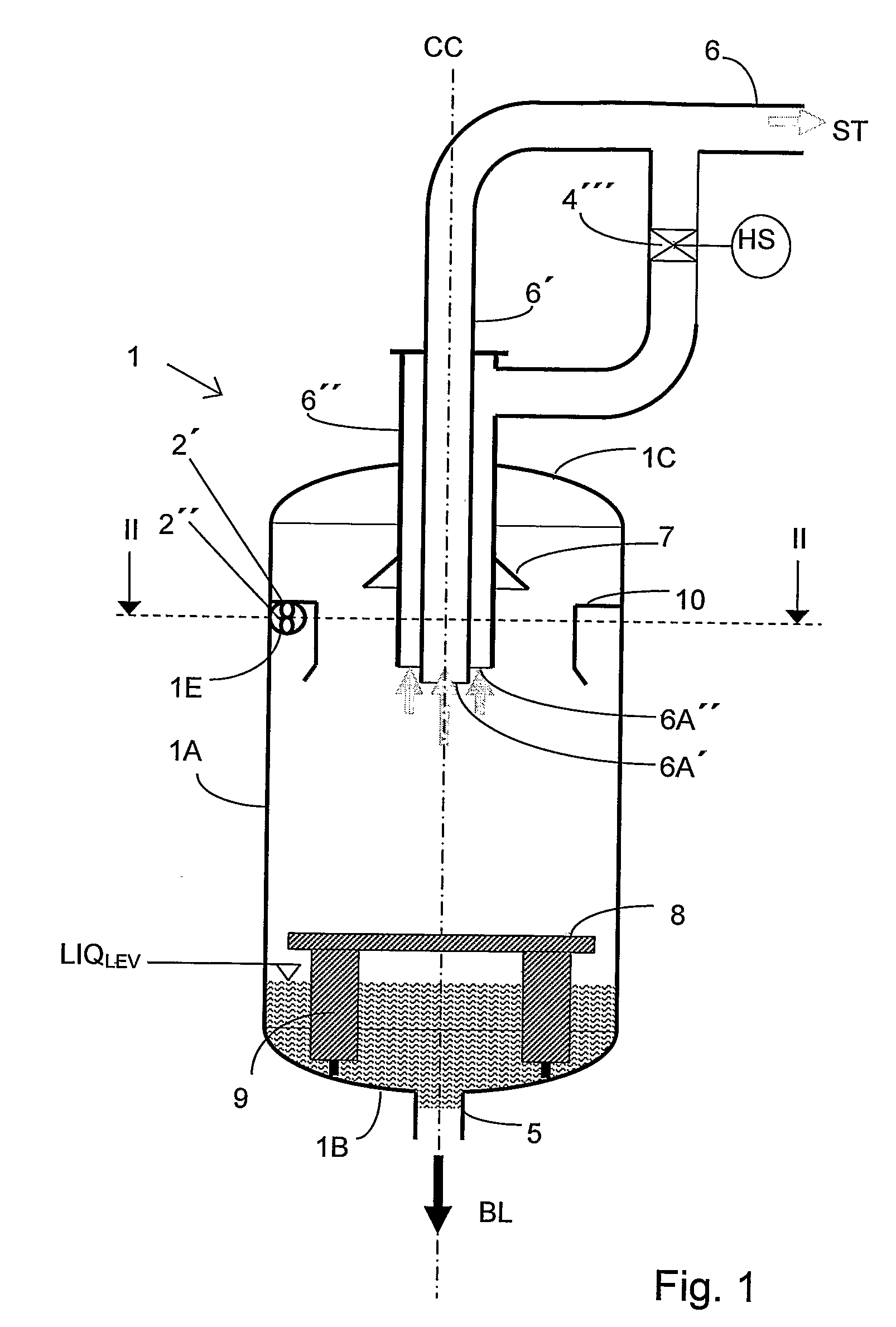

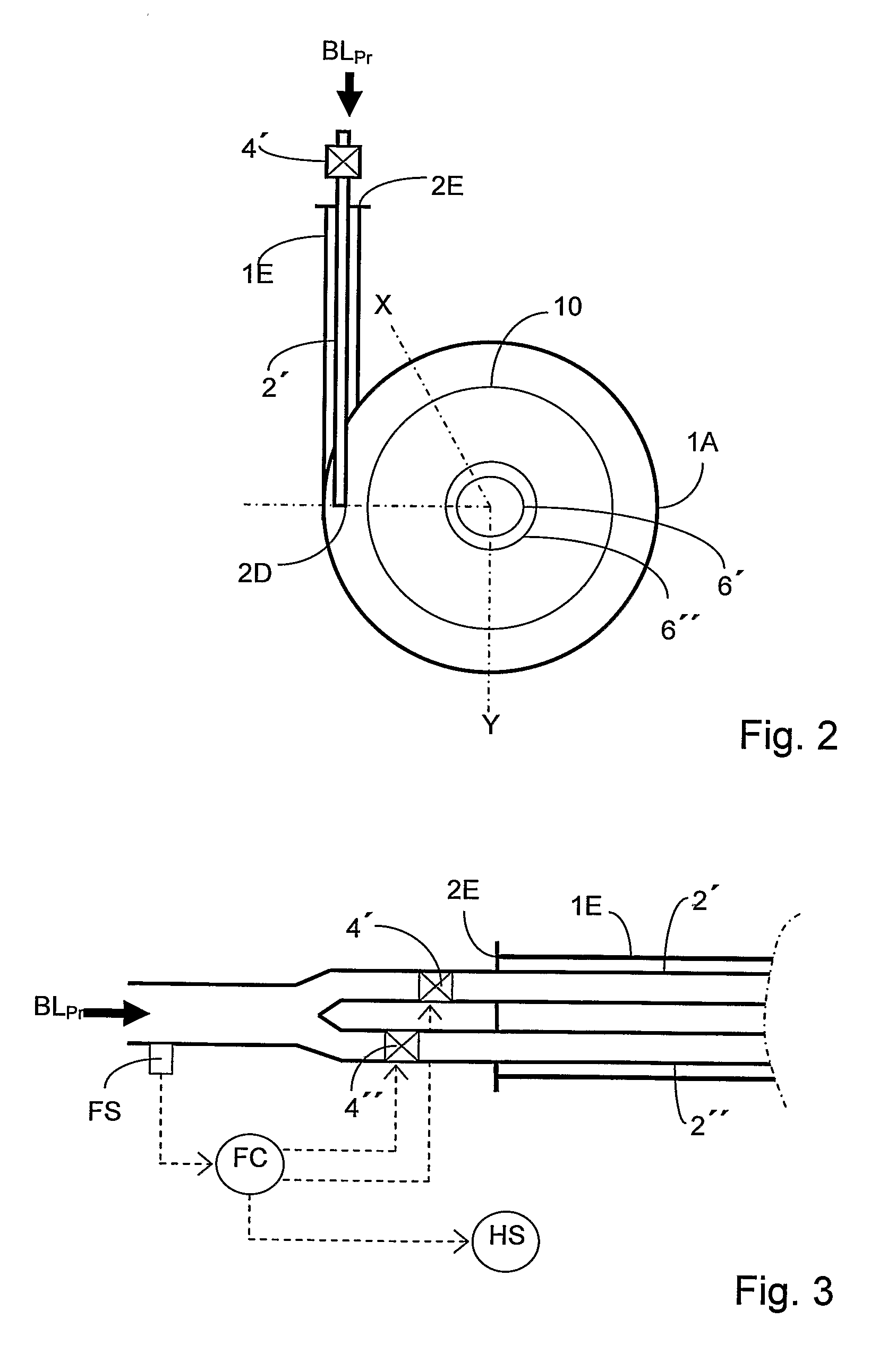

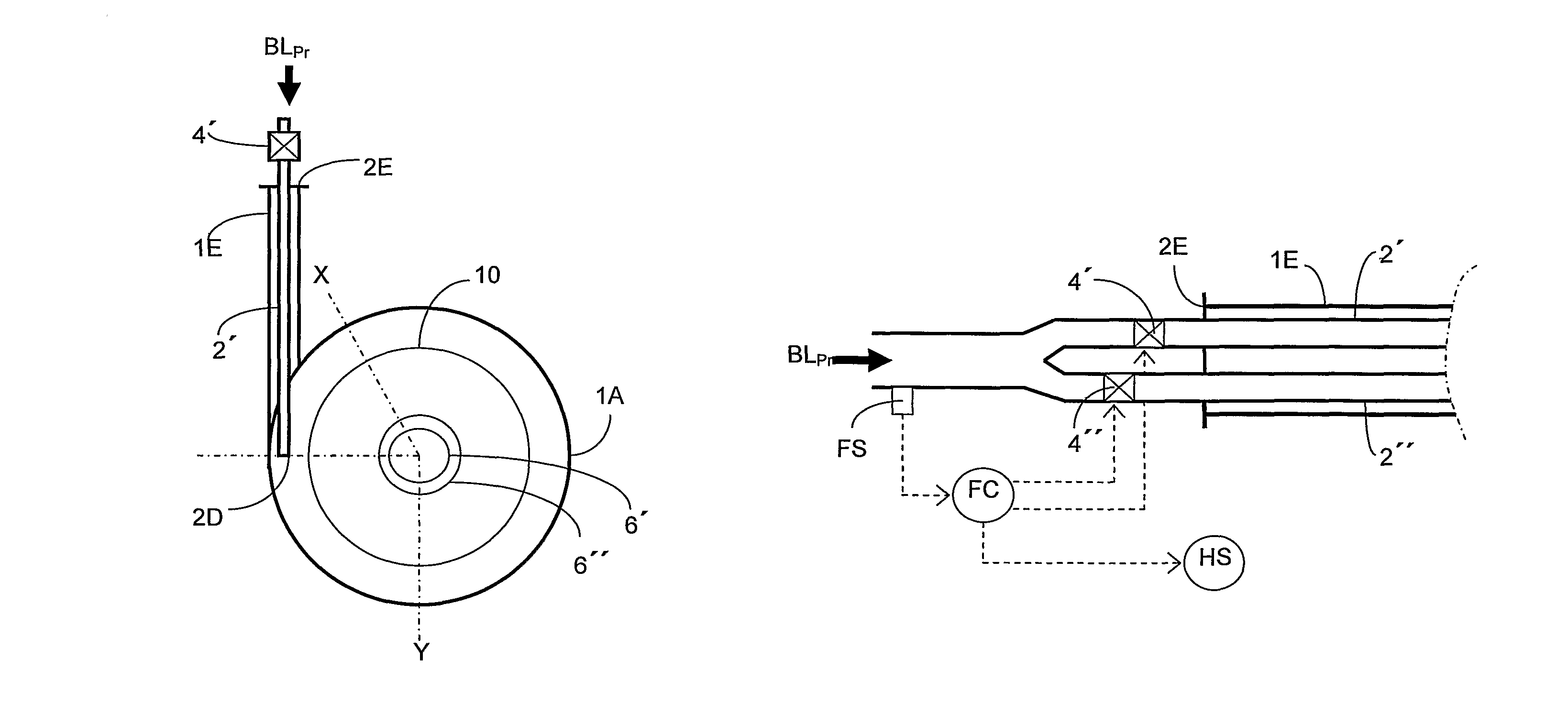

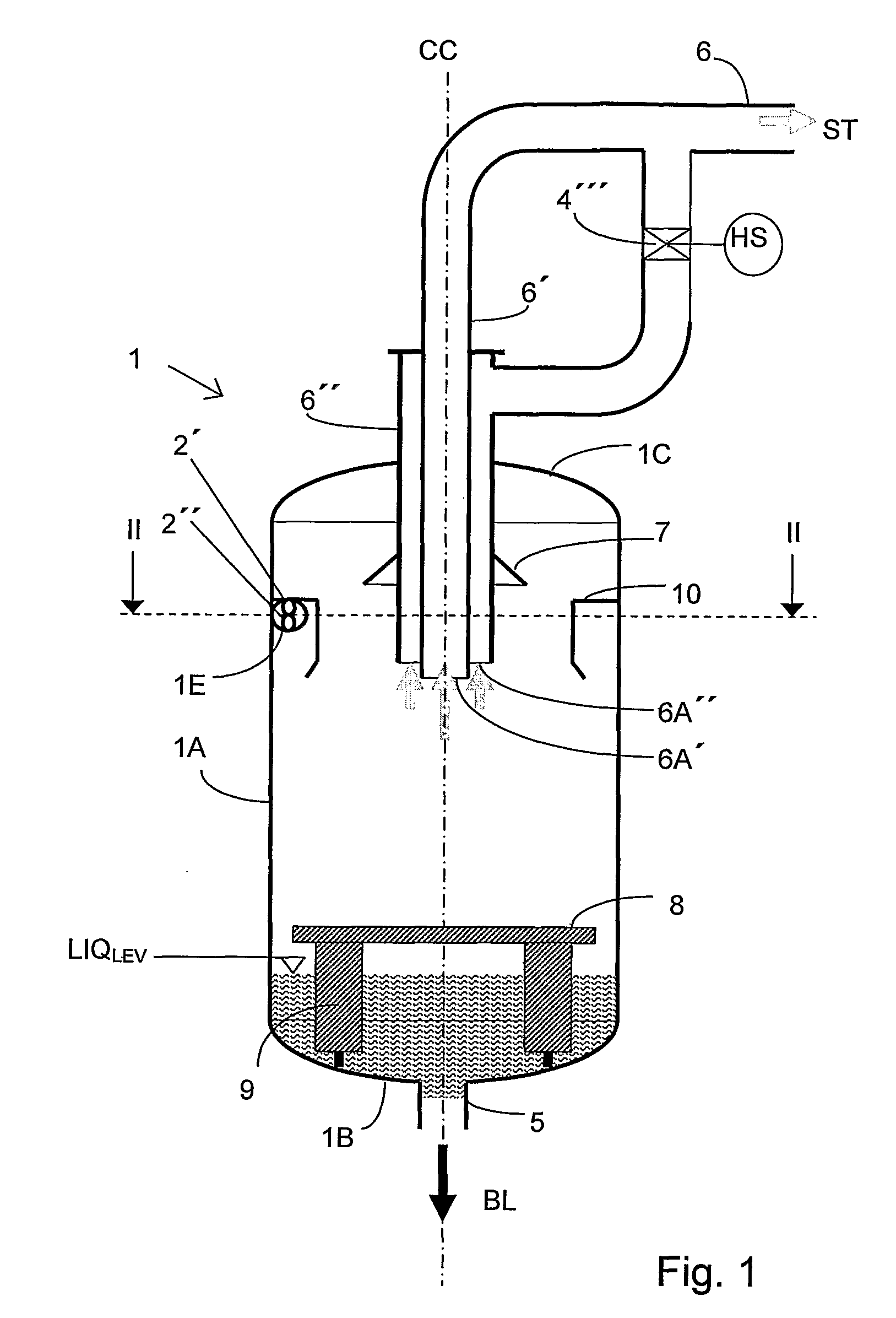

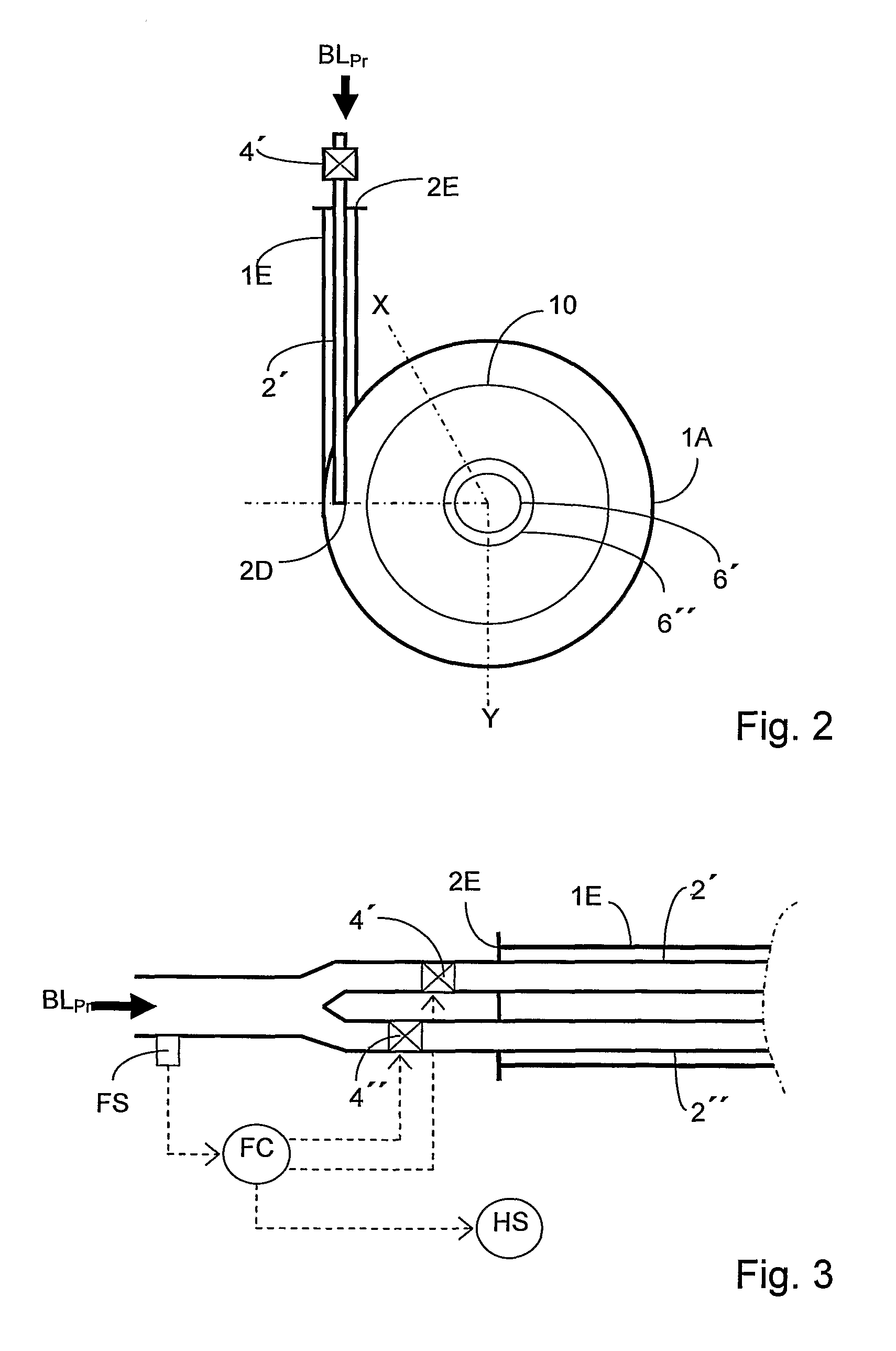

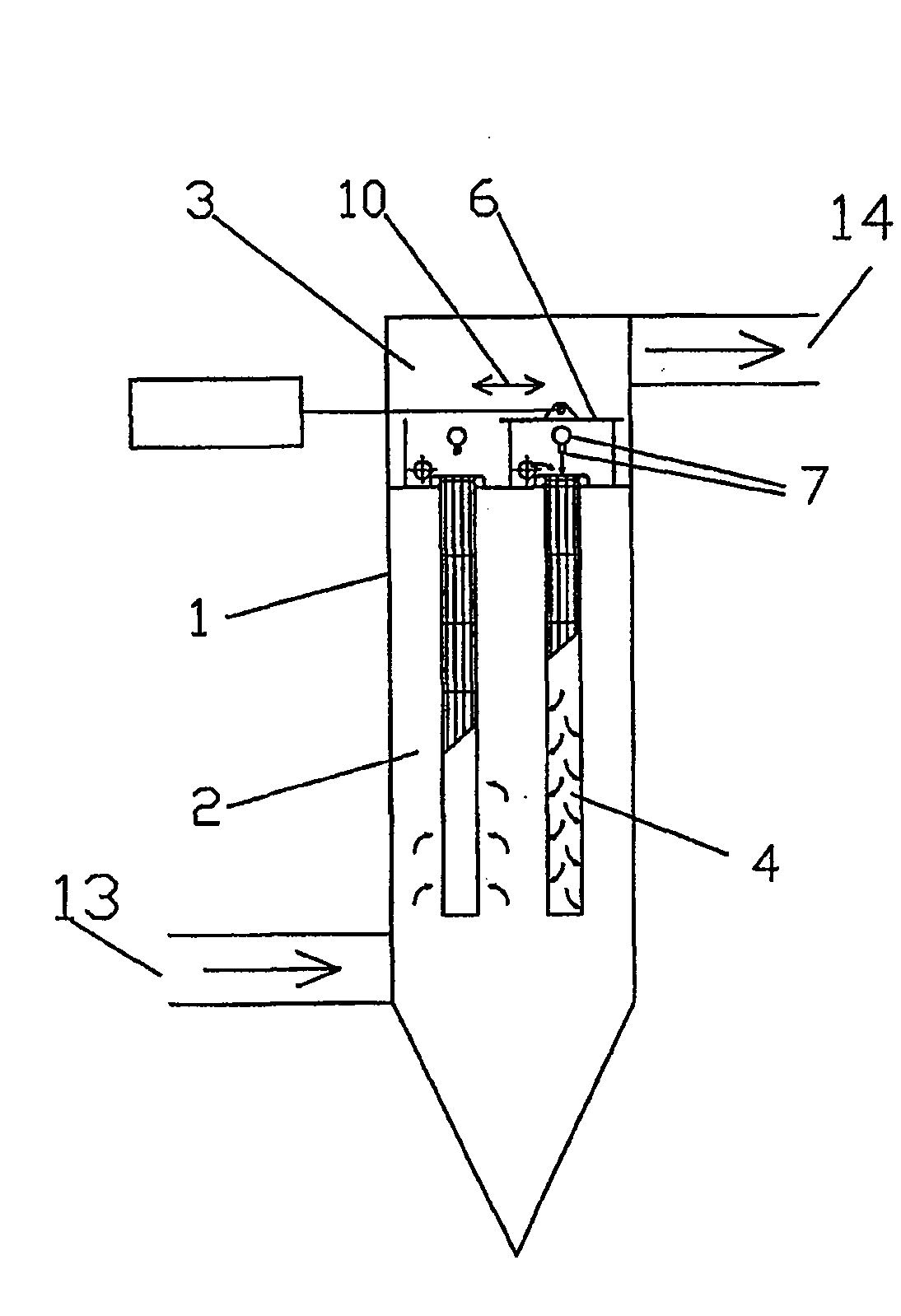

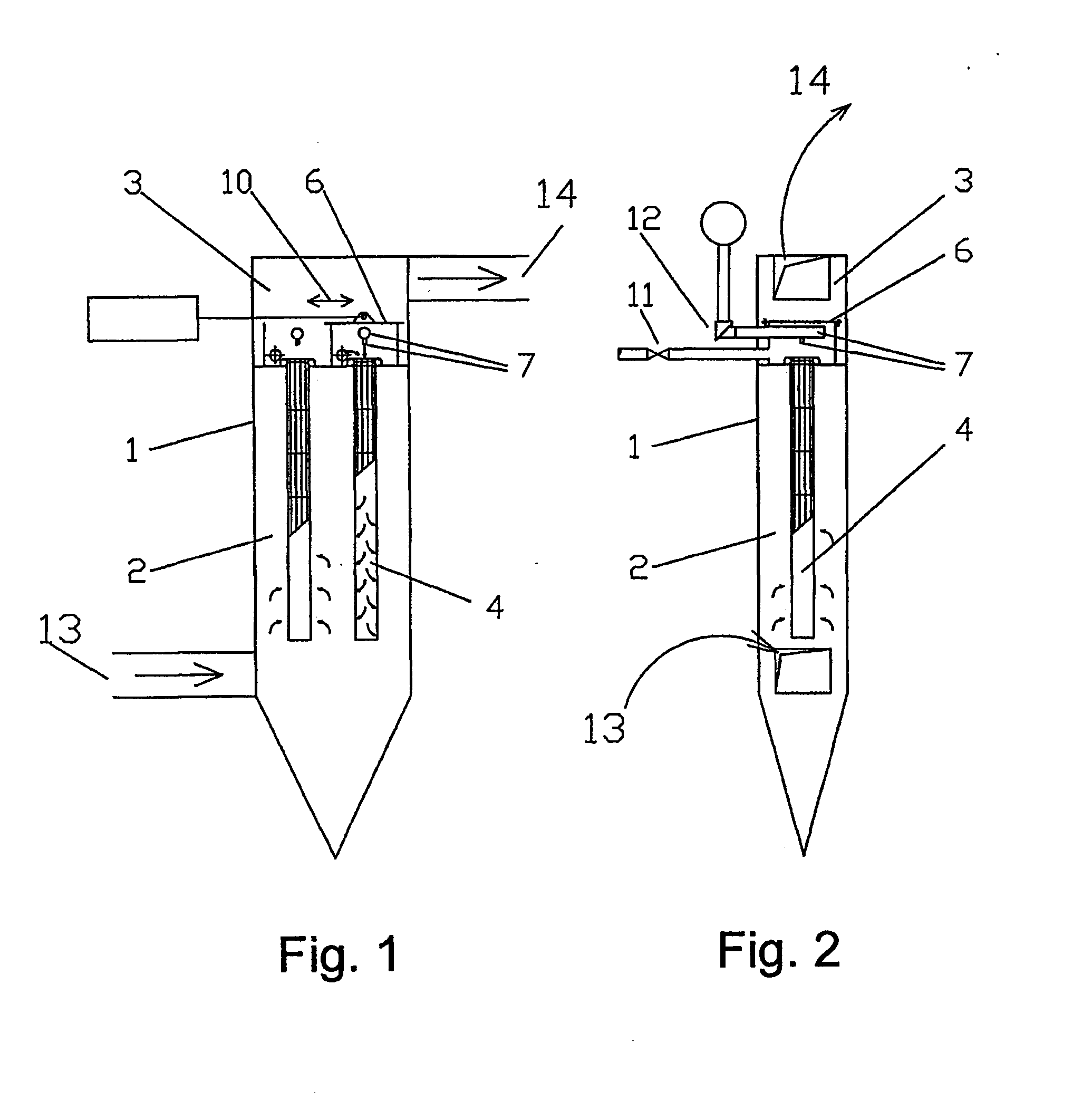

Cyclone with improved separation of gas from gas laden liquid streams also at reduced flow volumes

InactiveUS20110185894A1Eliminate the problemEfficient separationReversed direction vortexDispersed particle filtrationCycloneProduct gas

The cyclone is for separating gas from a gas laden liquid stream by pressure reduction of the liquid stream. The cyclone has a cylindrical casing, having a tangentially directed inlet arrangement for the gas laden liquid stream, a lower outlet line for liquid and an upper outlet line for vapor and gas. The inlet arrangement is connected to a common supply source (BLPR), and has at least two insertion pipes. The flow in at least one of these insertion pipes is controlled by at least one valve that depends upon an order of flow from the common supply source to maintain a flow velocity above a critical value.

Owner:METABO PAPER SWEDEN

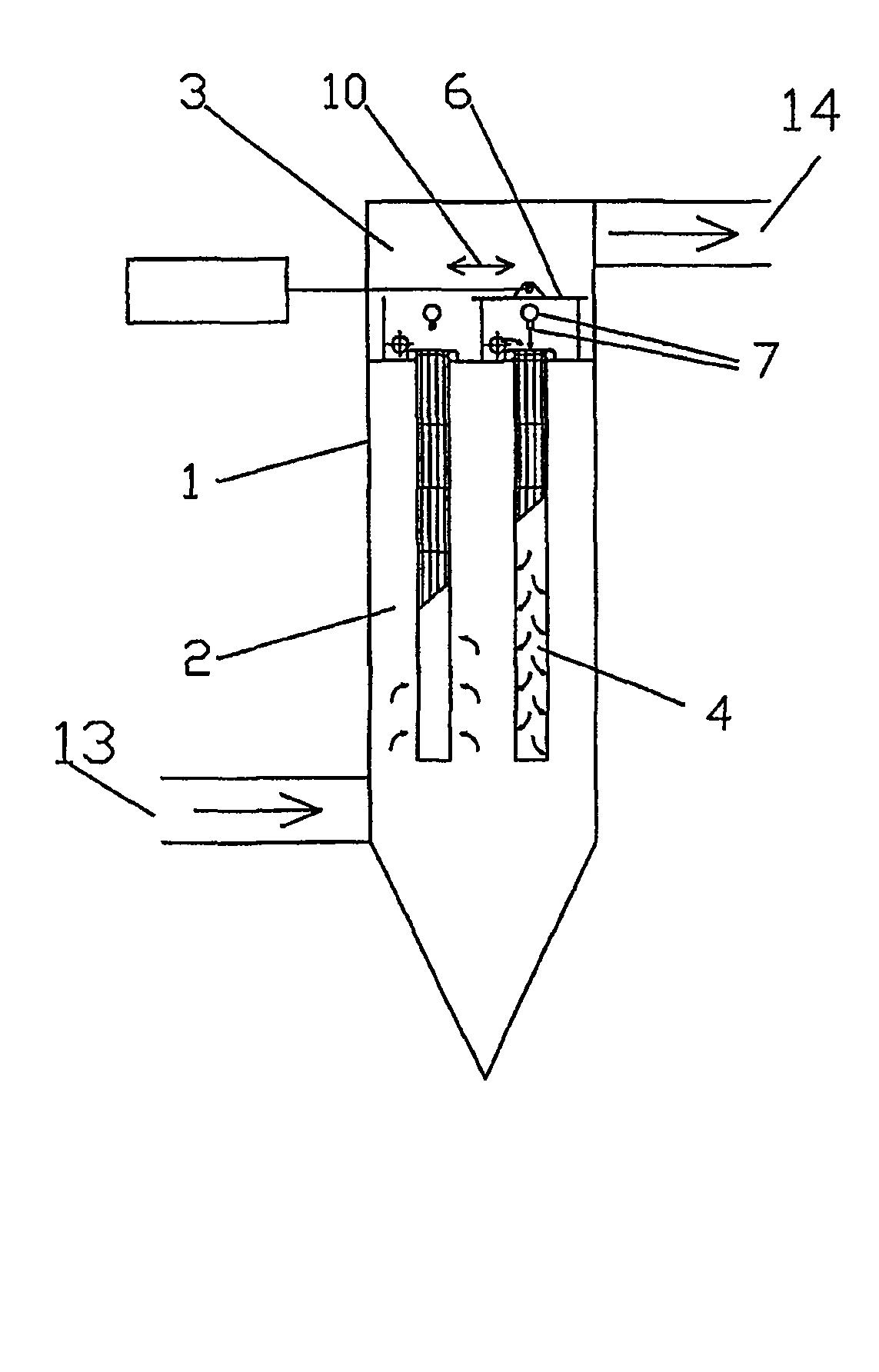

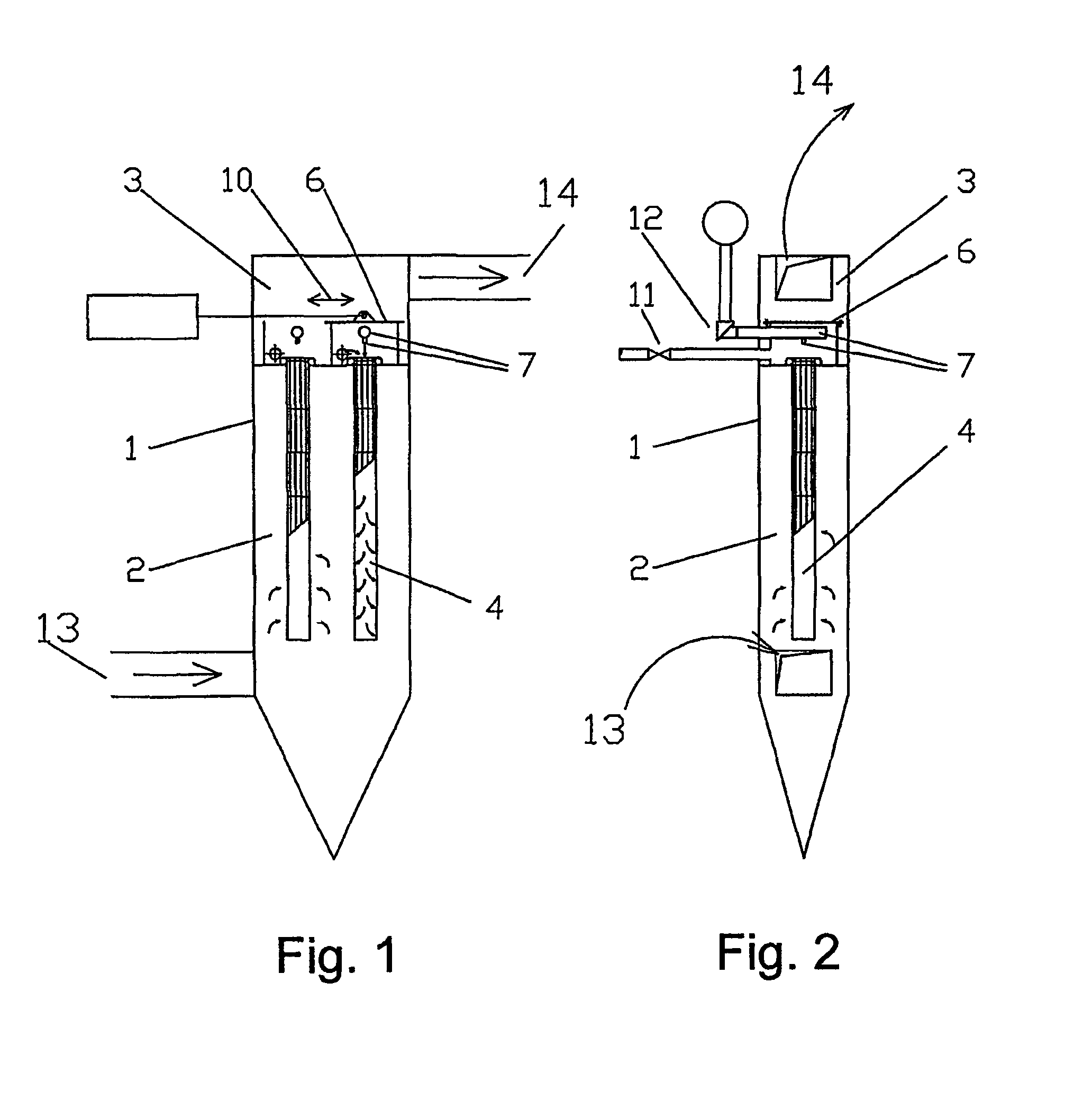

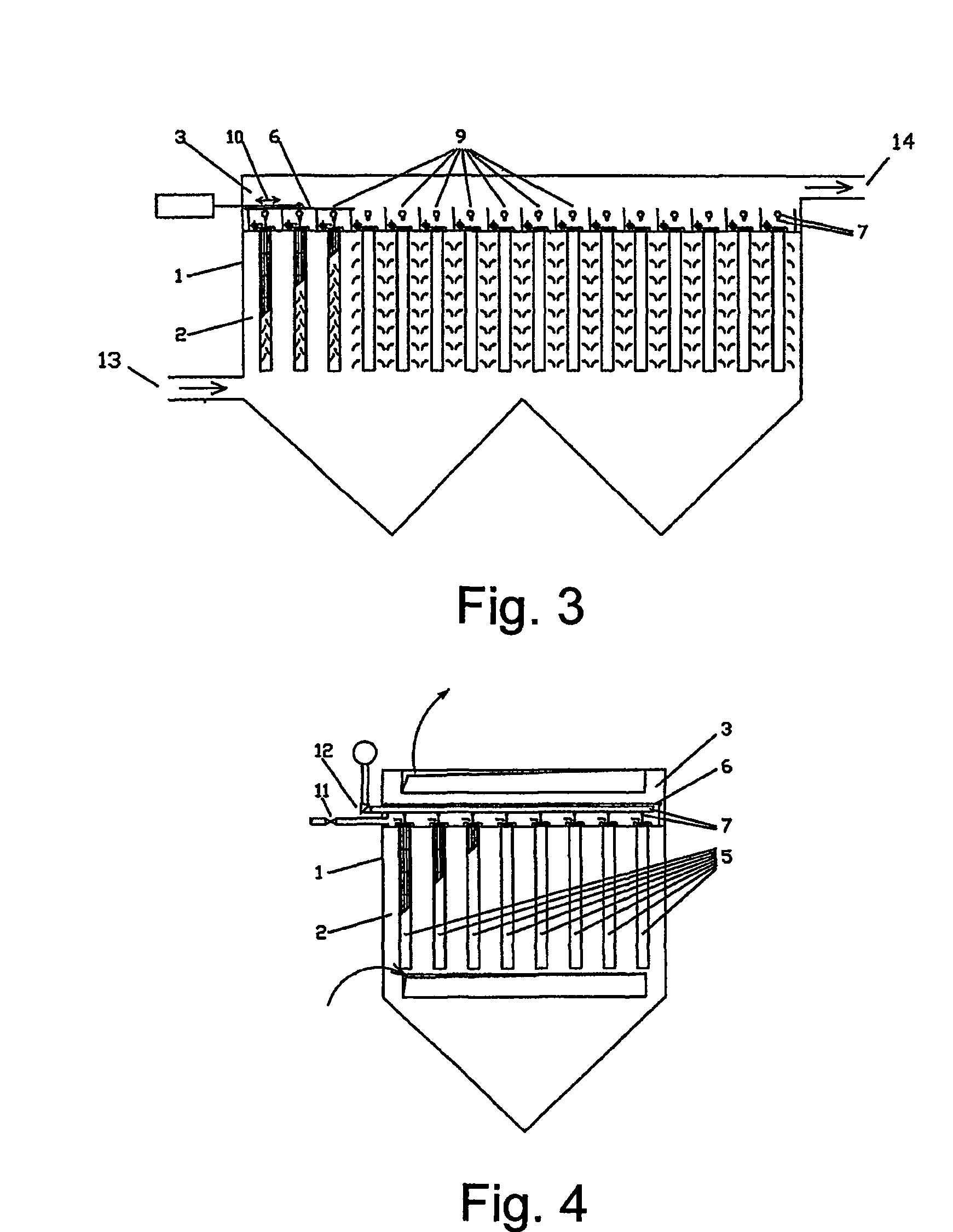

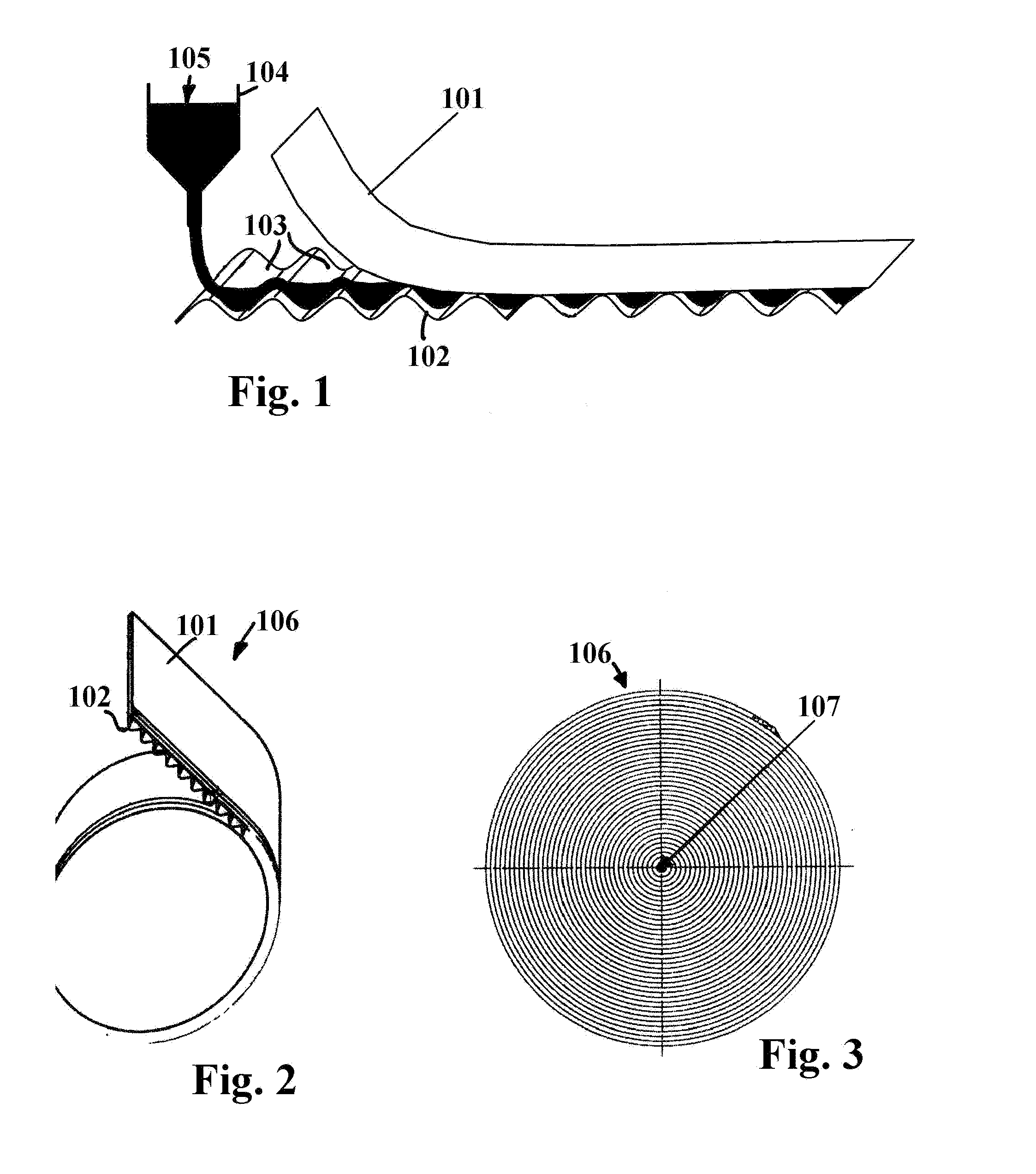

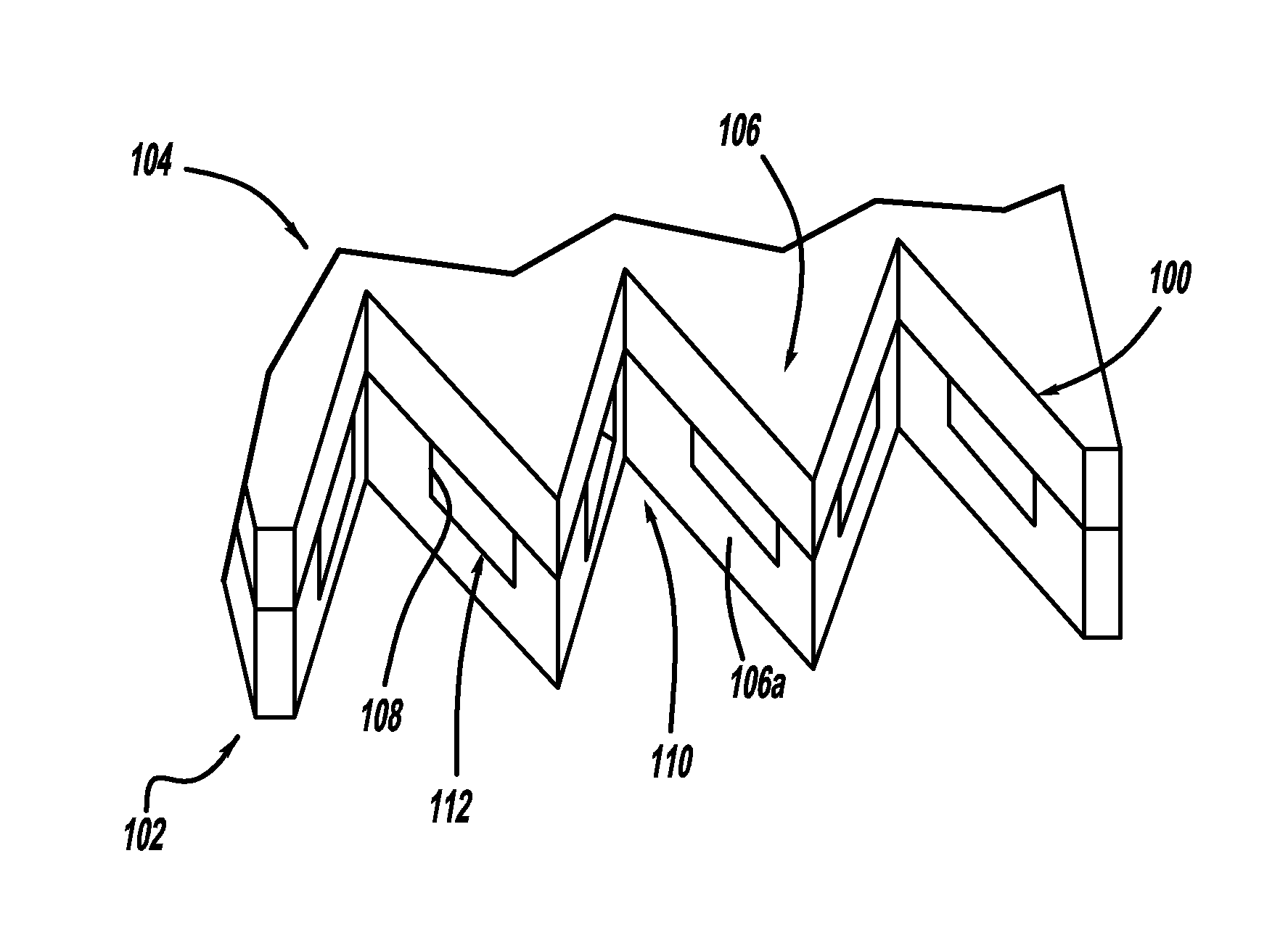

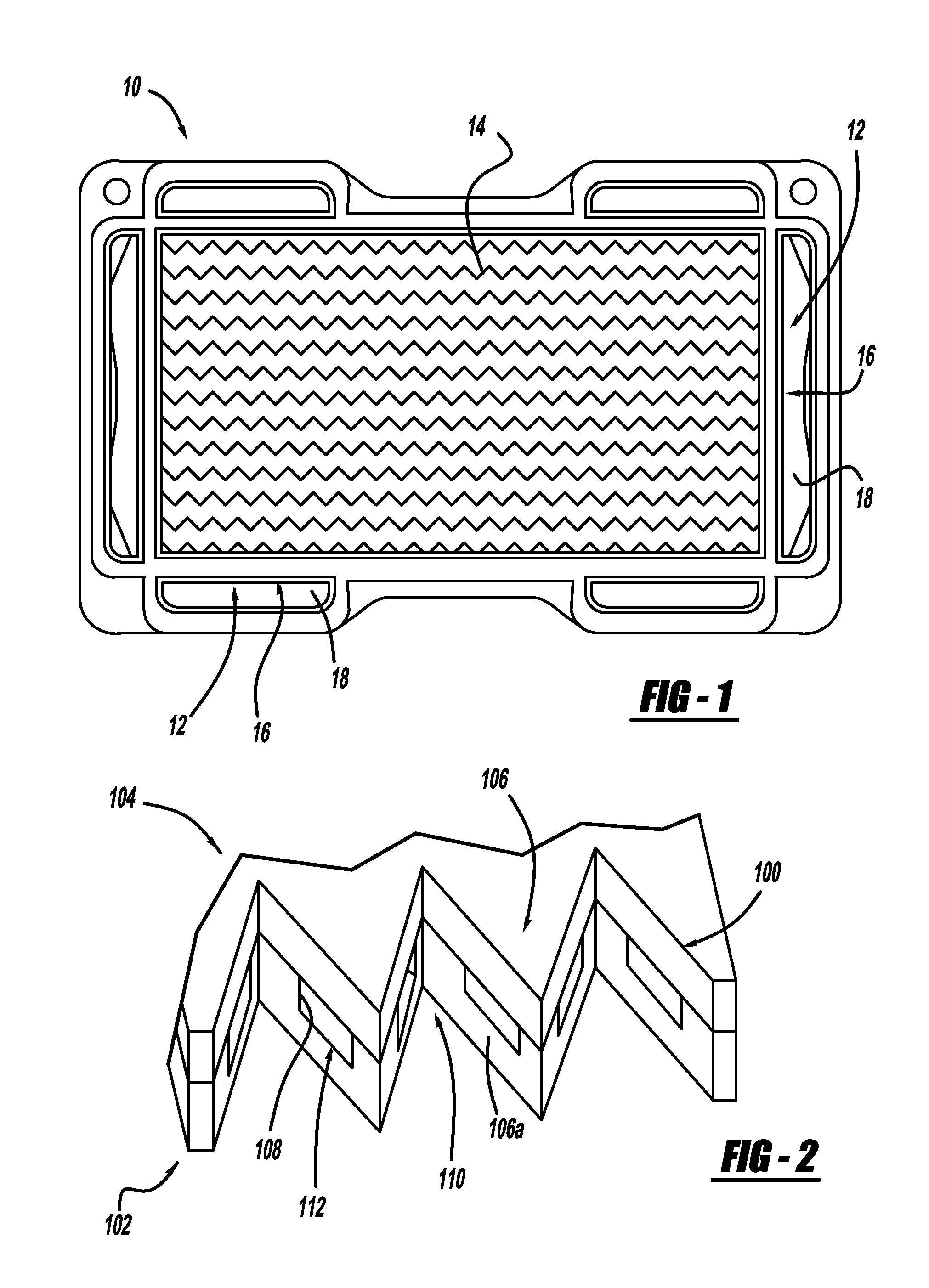

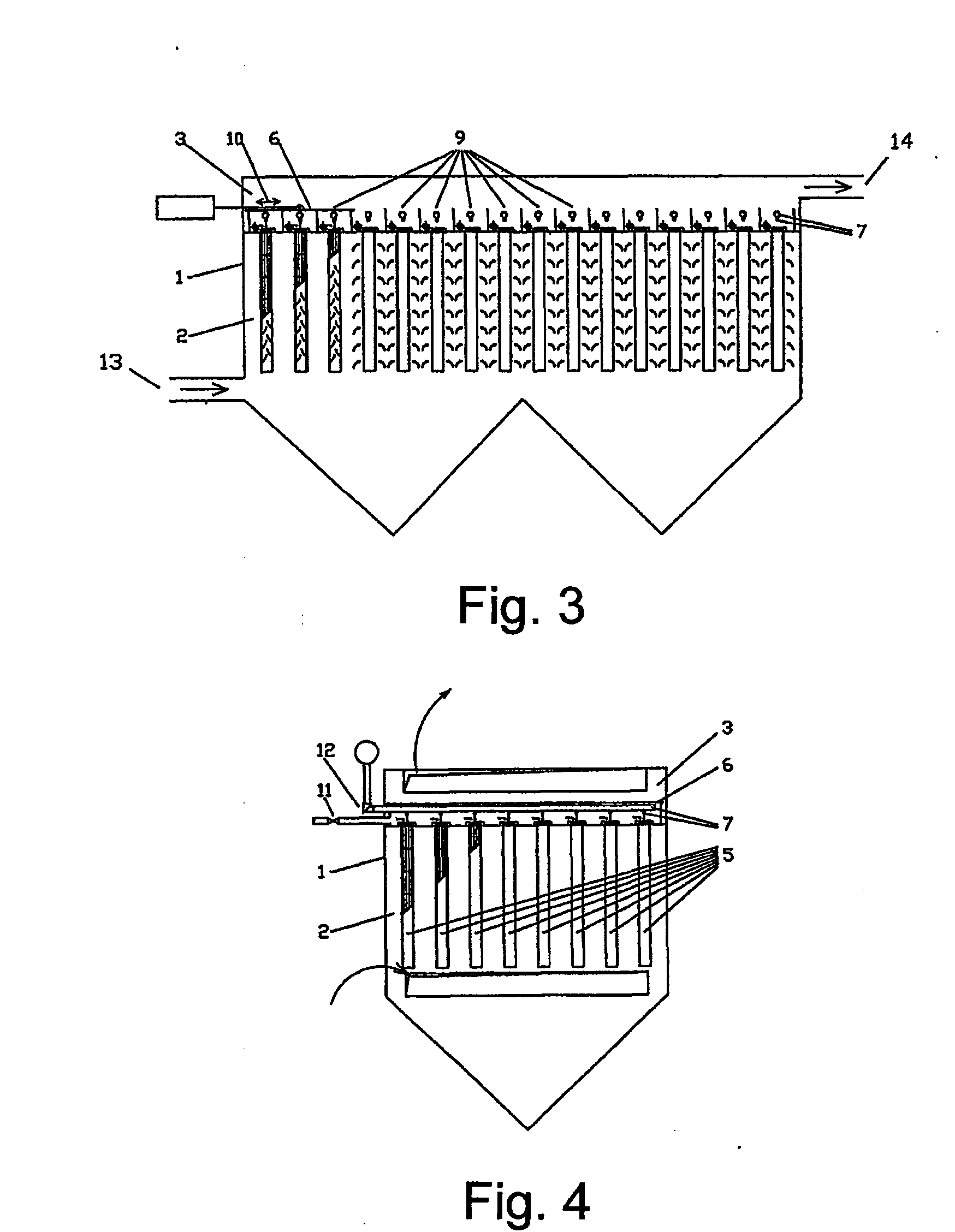

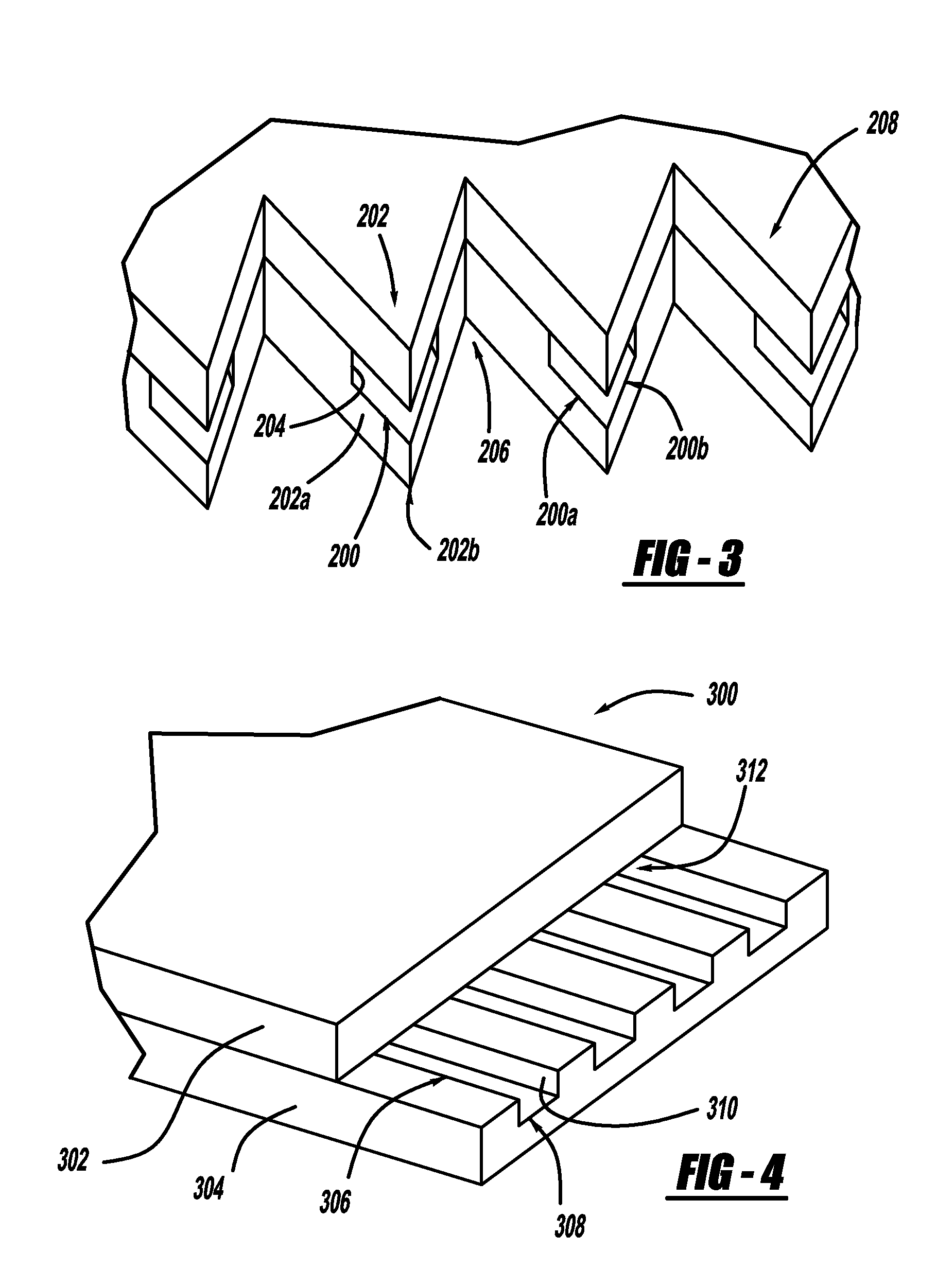

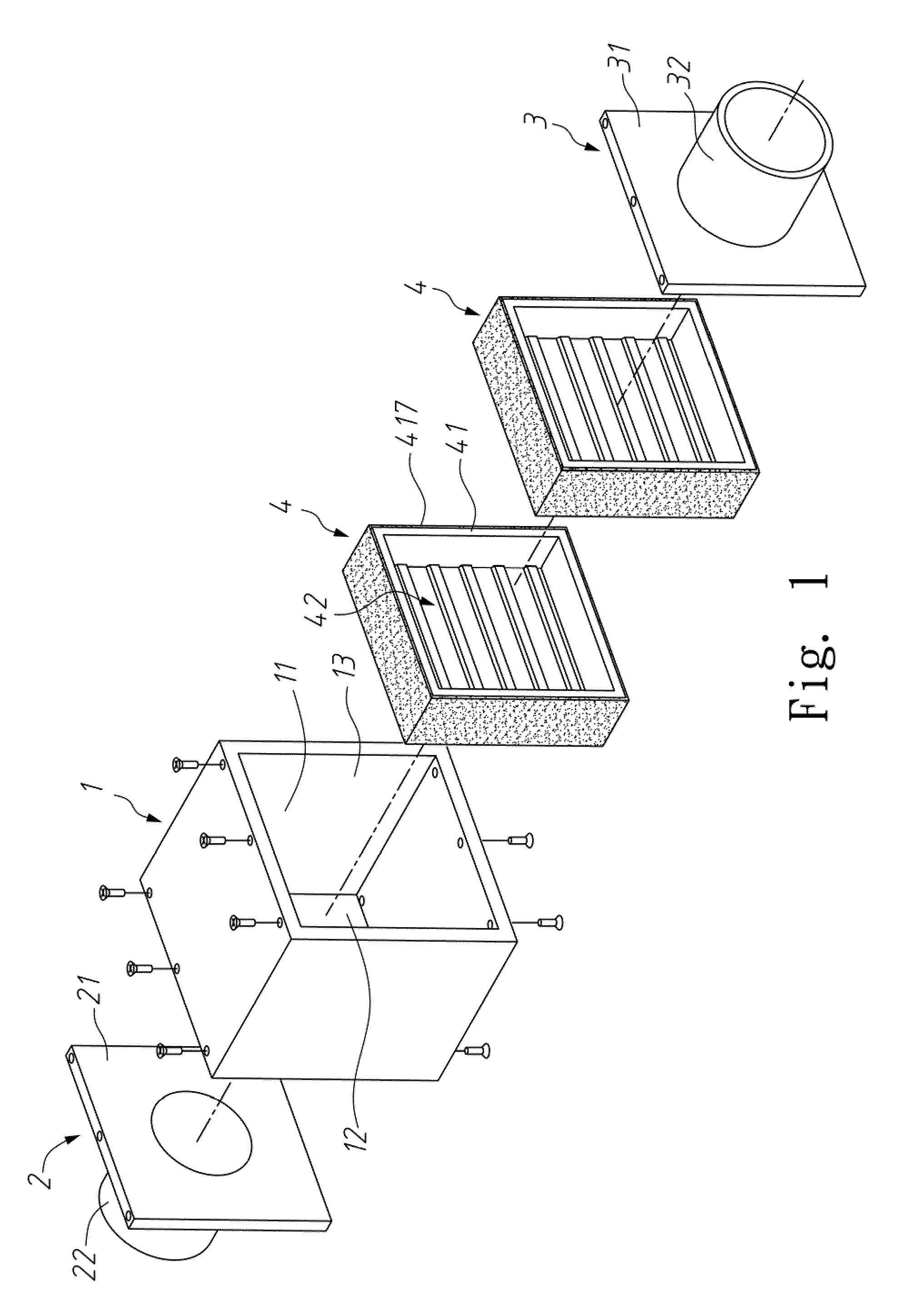

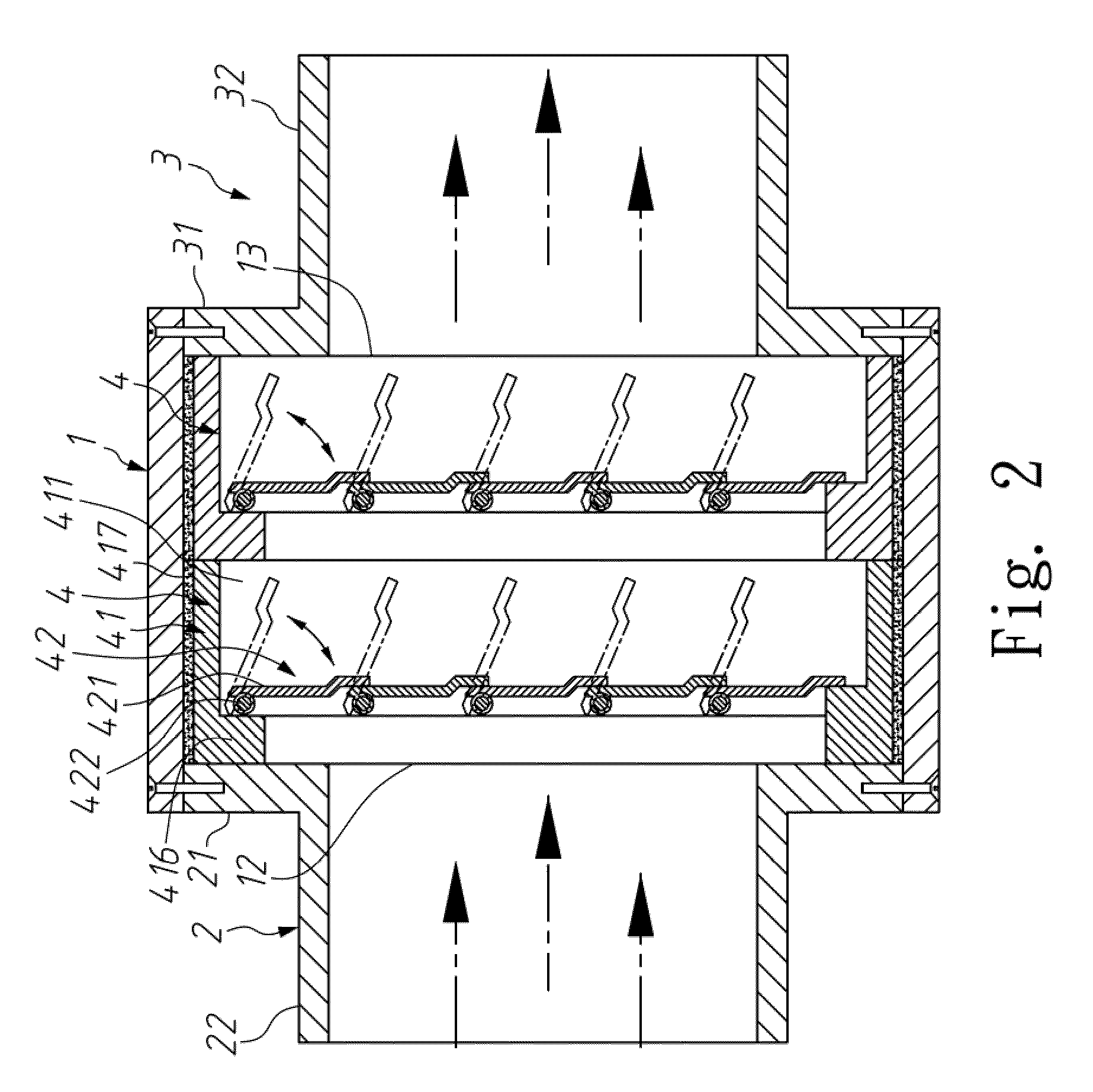

Cleaning process for cleaning filtration material of a gas filter and a device for carrying out the process

InactiveUS8021467B2Inhibit gas flowPrevent blastingCombination devicesAuxillary pretreatmentFiltrationCleaning methods

A cleaning process for filtration material of a gas filter is disclosed. A first step hinders the gas flow from passing through the filtration material by closing the clean gas side of a single segment or a row of filter segments. A second step provides a slow gas flow to the closed filter segments to cause a reverse gas flow through the filtration material. A third step opens an impulse valve for an ultra short time to create a compressed gas impulse for disengaging the particles which did not fall off the filtration material during the second step of the cleaning process. A fourth step shuts off the reverse flow gas supply. A device for separating one or several filter segments from the clean gas side of the filter filtration material is also disclosed.

Owner:ZIMMER SEBASTIAN

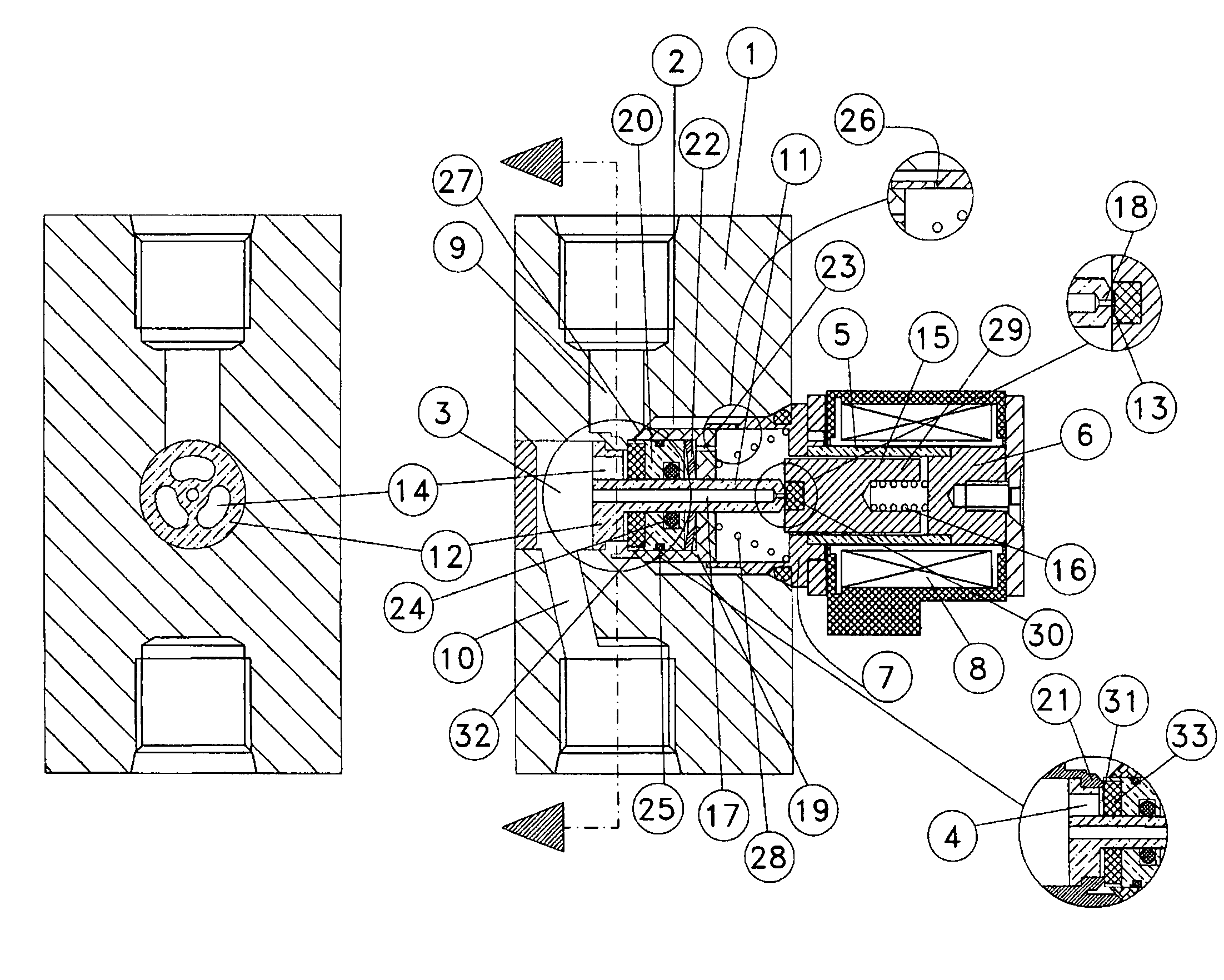

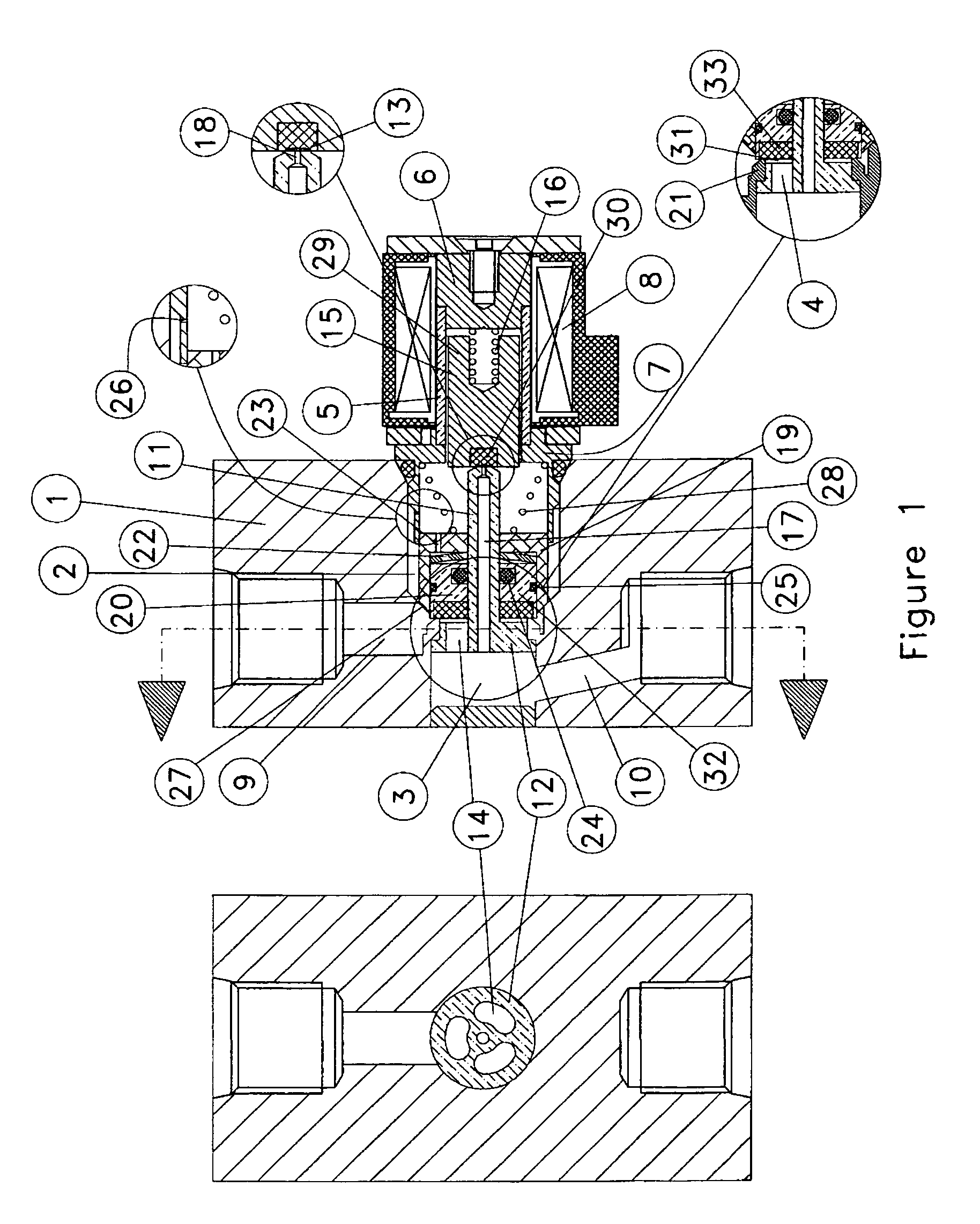

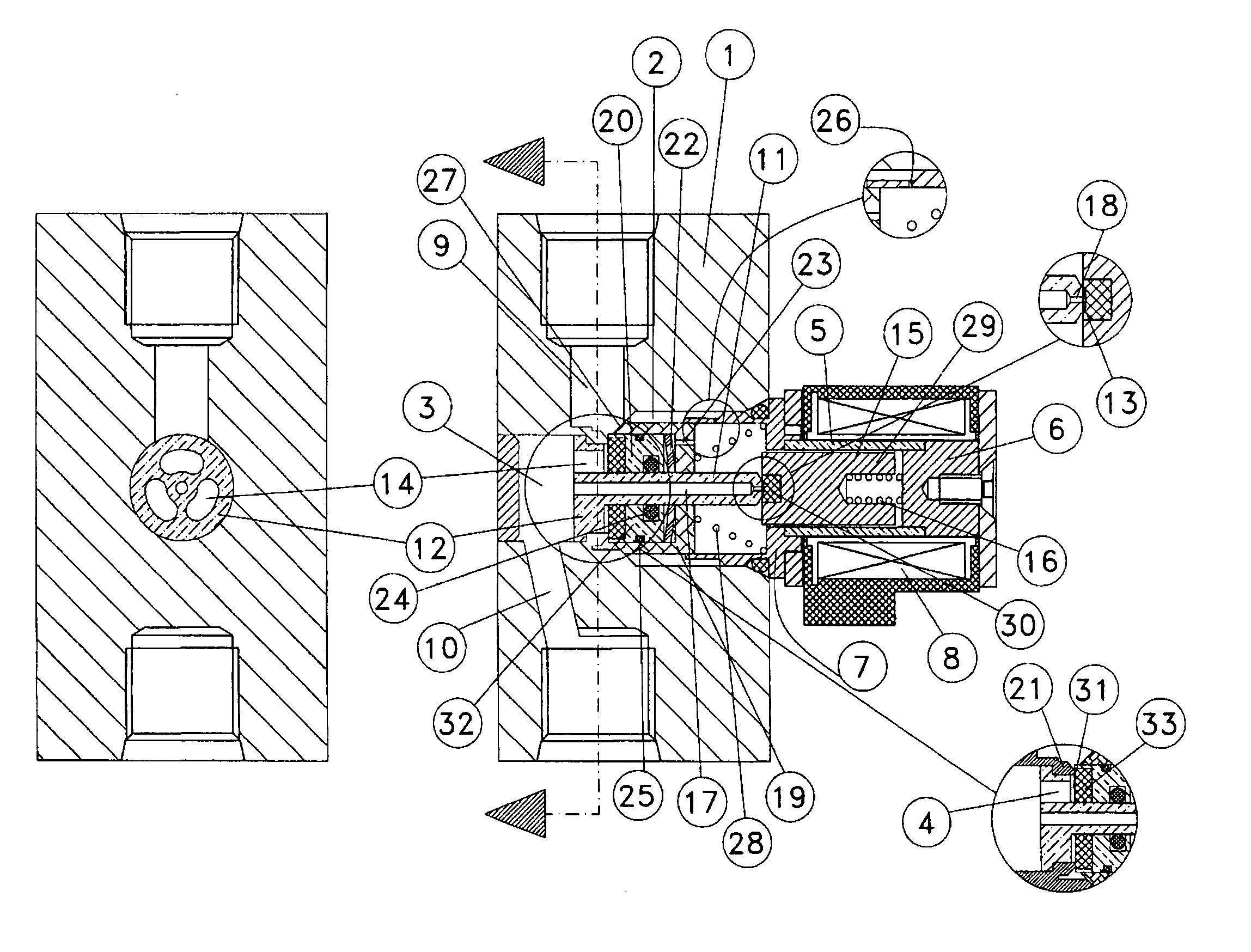

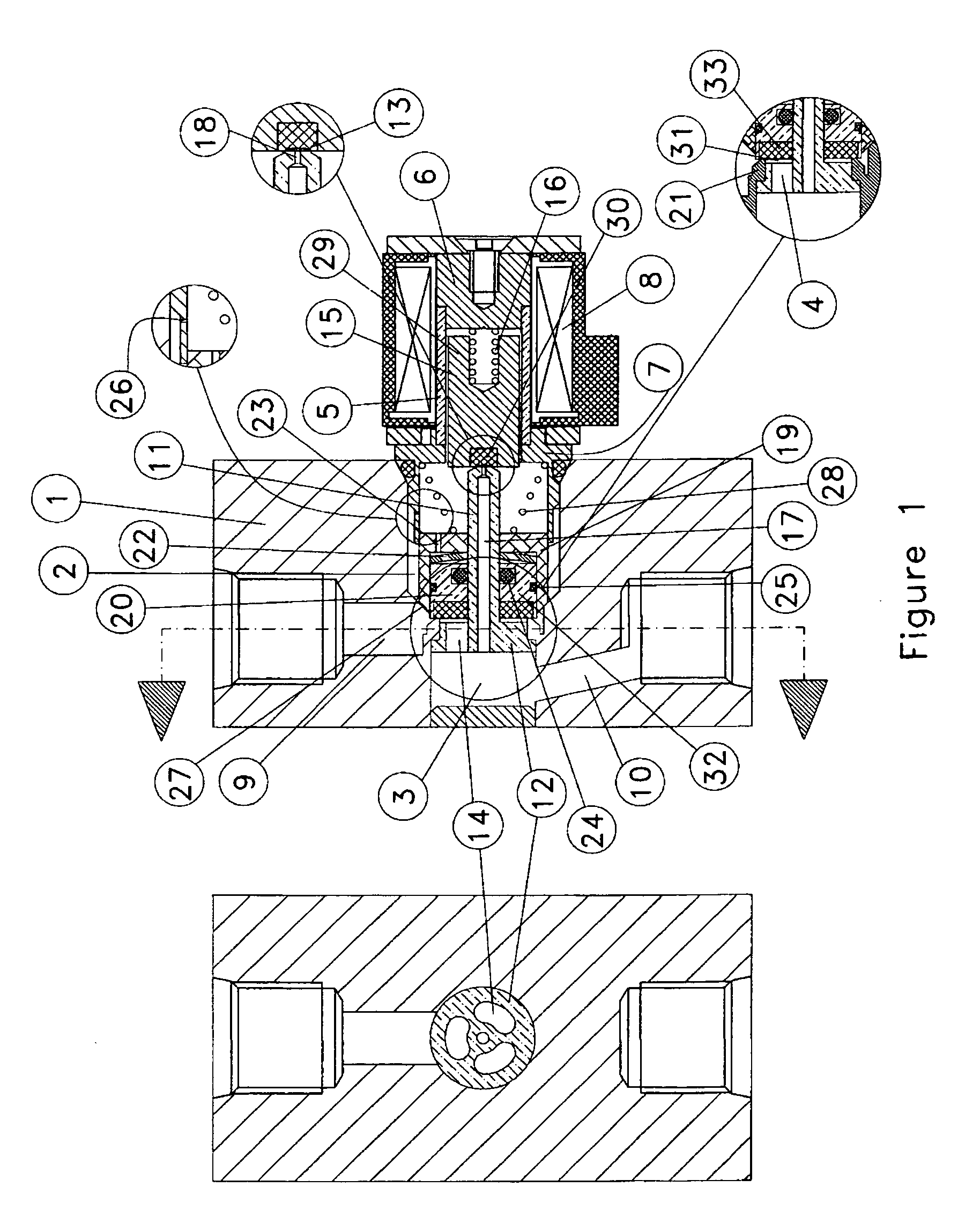

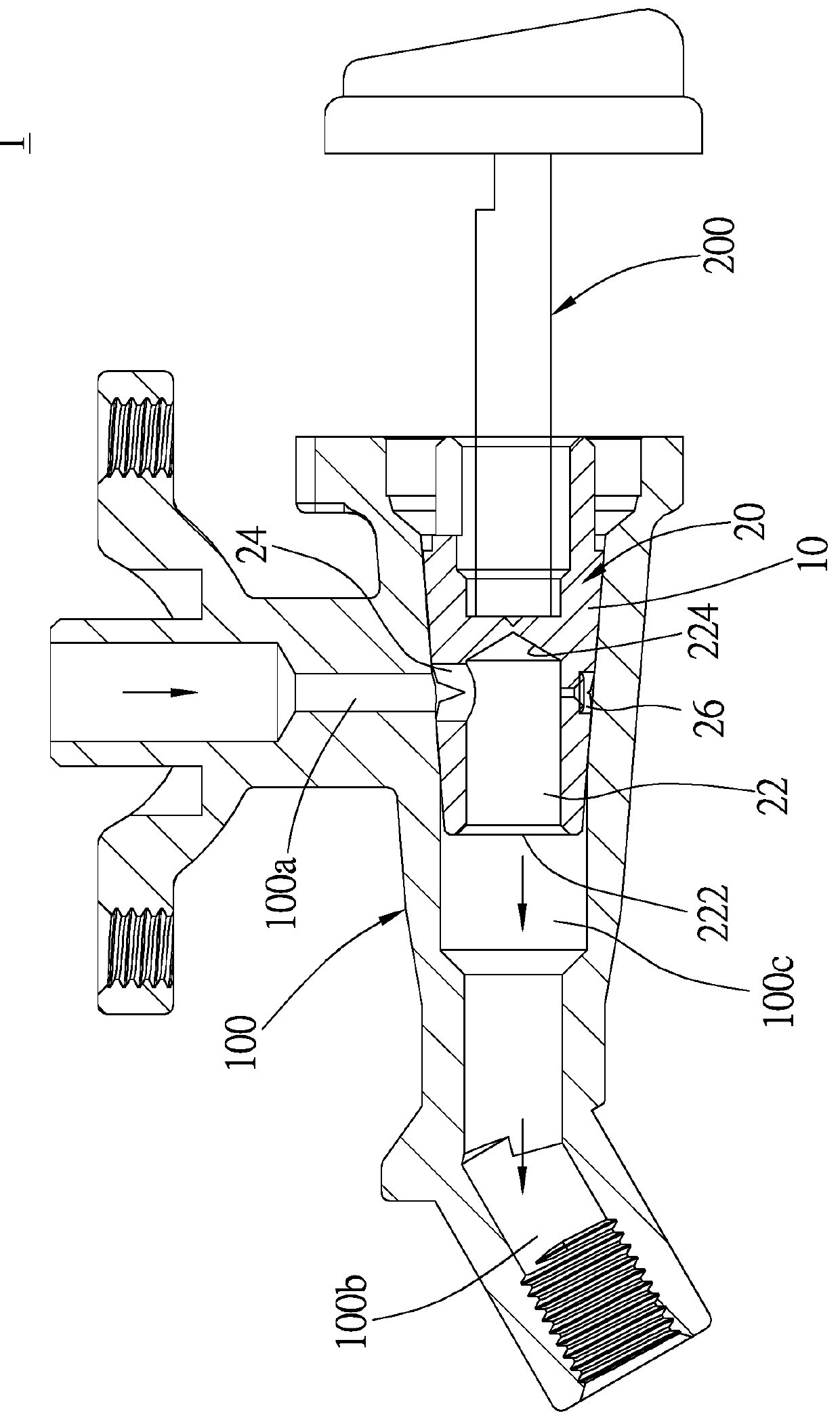

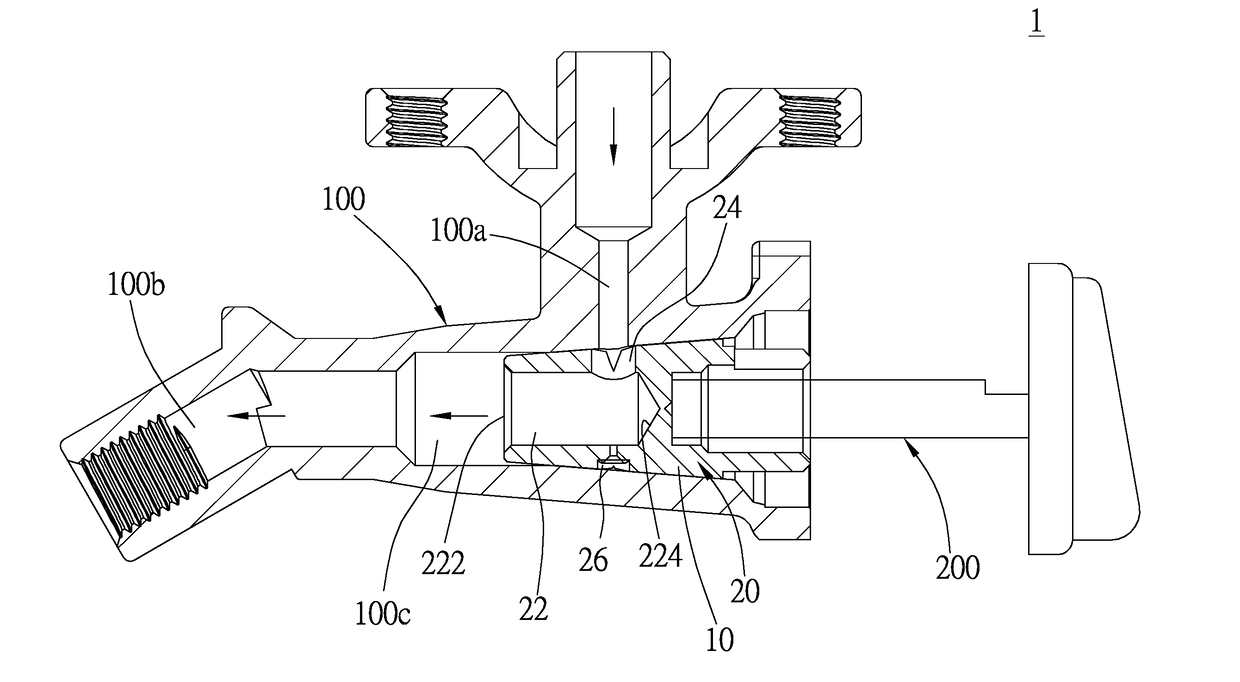

Solenoid isolation valve

InactiveUS7334770B2Avoid disadvantagesInhibit gas flowOperating means/releasing devices for valvesCombustion enginesIsolation valveSolenoid valve

An improved pilot-operated, “instant-on”, solenoid isolation valve discloses a new fluid passage route to save cost of drilling a longitudinal hole within the primary piston. Also, a new feature of primary piston assembly with a movable seal piston having a specific circumferential surface matching to valve body chamber to restrict fluid from front side into back side of the primary piston to produce pressure difference to induce instant valve open when solenoid is energized initially. It also introduces a channel hole in the flange of the sleeve assembly as a communication channel of supply of gas into the chambers of the back side of primary piston assembly. The diameter of the channel hole is not critical to determine in this new invent. As long as the size of the hole is smaller than that of the bleed hole, it can maintain pressure difference between the front side and back side of primary piston during valve opening operation. In addition, since the pilot piston and the primary piston assembly operate independently, the travel stroke of the primary piston assembly is unconstrained by the input electrical power.

Owner:WANG WEI CHING +2

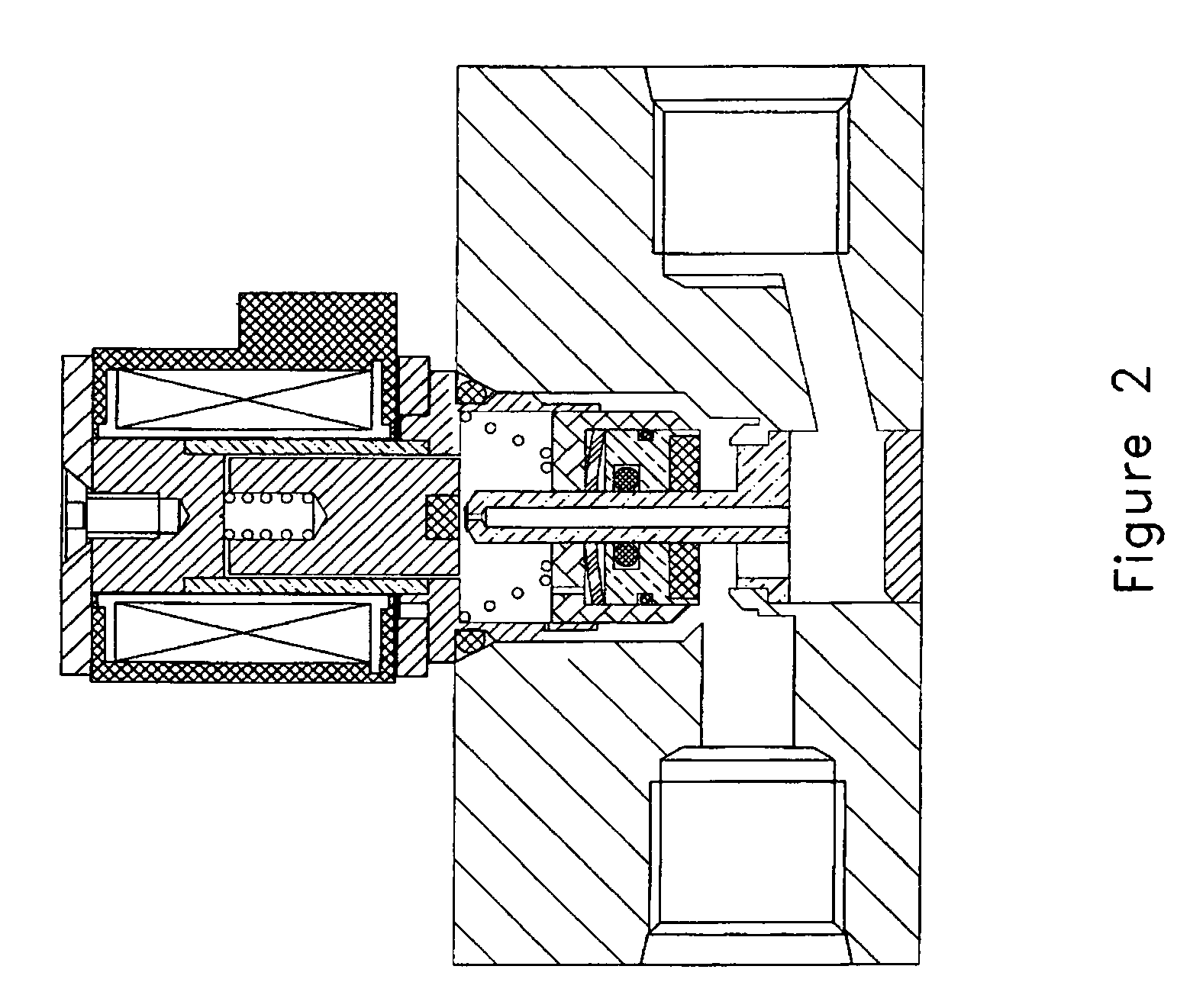

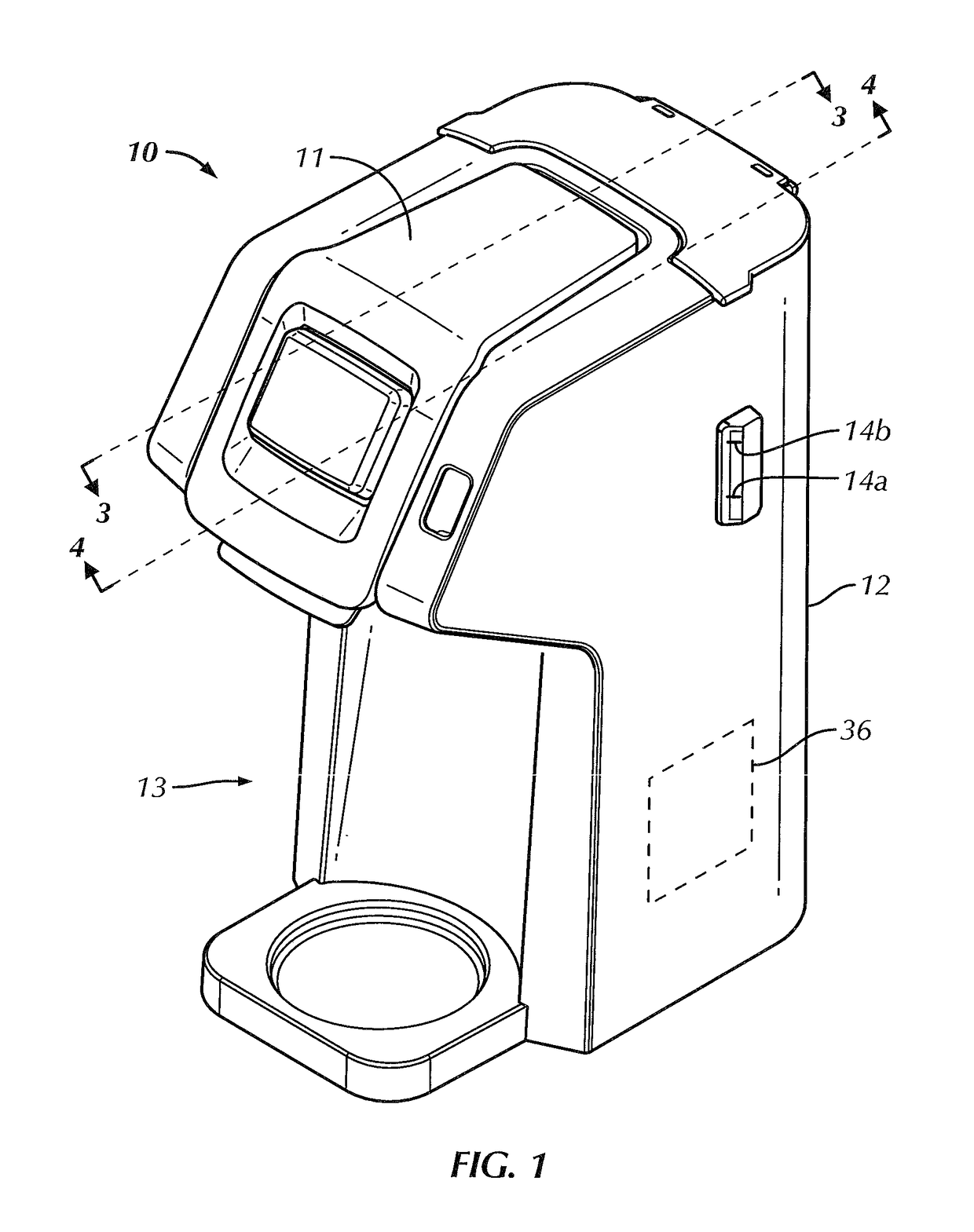

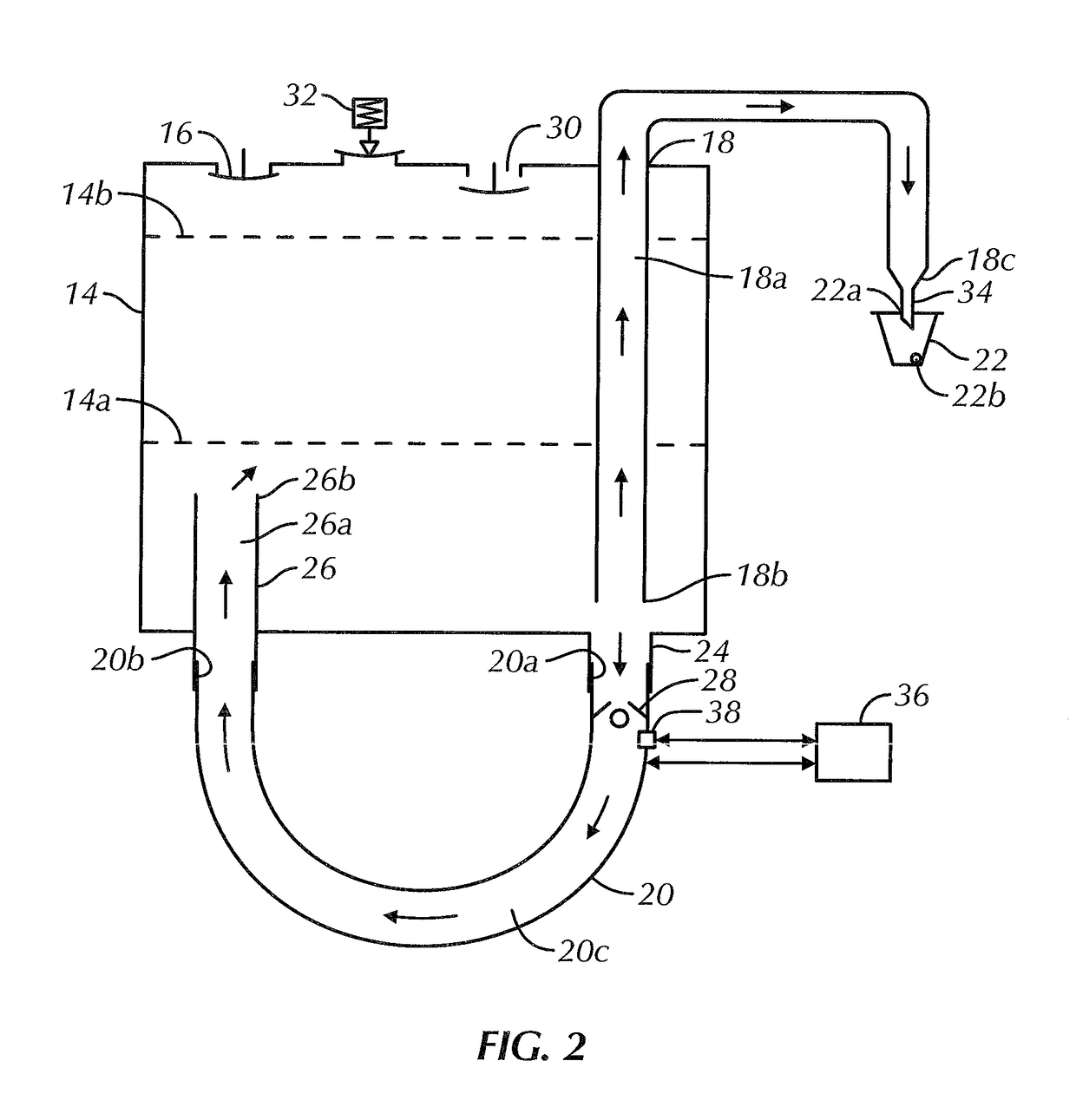

Single Reservoir Beverage Maker

Owner:HAMILTON BEACH BRANDS

Cyclone with improved separation of gas from gas laden liquid streams also at reduced flow volumes

InactiveUS8366802B2Efficient separationInhibit gas flowReversed direction vortexDispersed particle filtrationCycloneProduct gas

The cyclone is for separating gas from a gas laden liquid stream by pressure reduction of the liquid stream. The cyclone has a cylindrical casing, having a tangentially directed inlet arrangement for the gas laden liquid stream, a lower outlet line for liquid and an upper outlet line for vapor and gas. The inlet arrangement is connected to a common supply source (BLPR), and has at least two insertion pipes. The flow in at least one of these insertion pipes is controlled by at least one valve that depends upon an order of flow from the common supply source to maintain a flow velocity above a critical value.

Owner:METABO PAPER SWEDEN

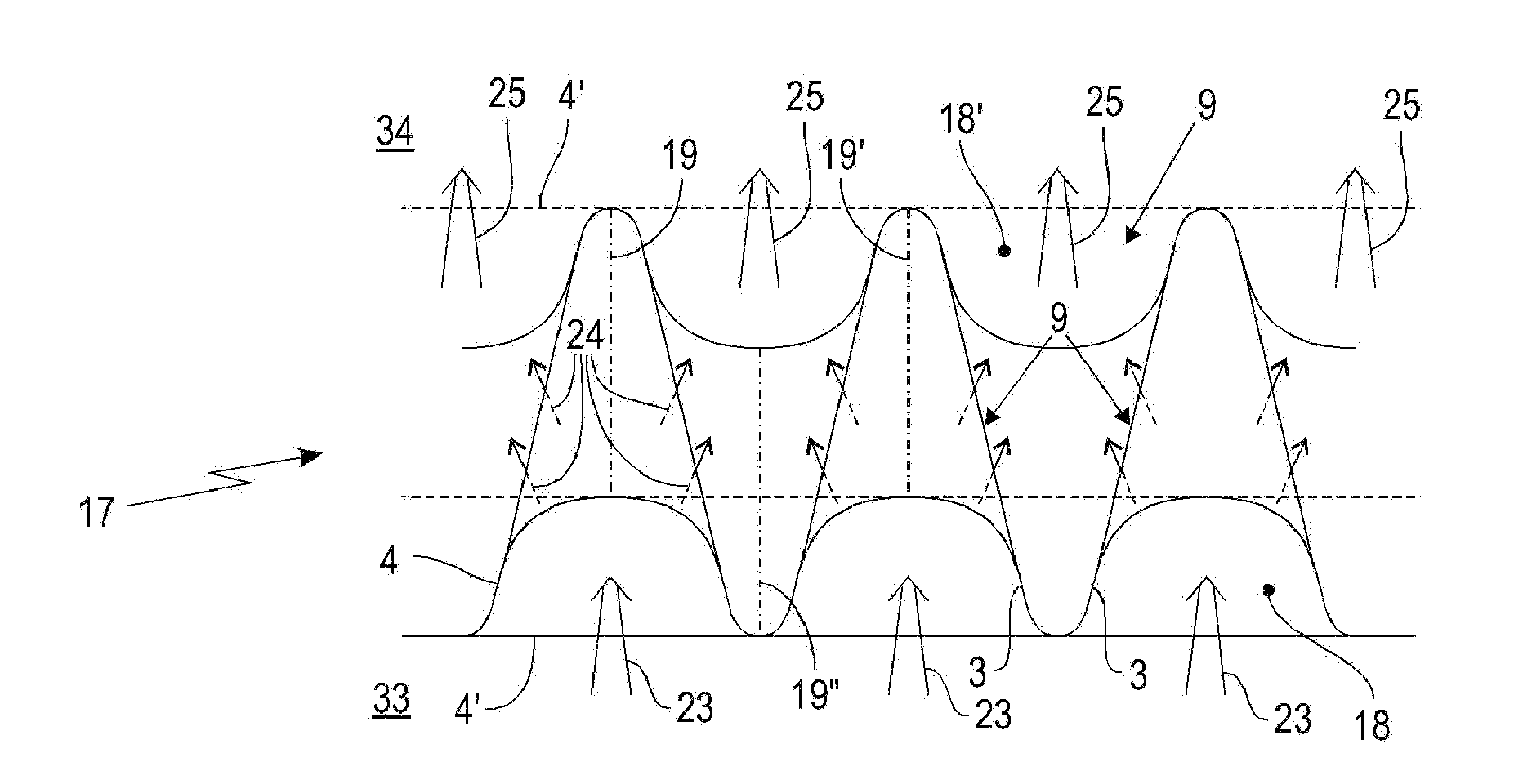

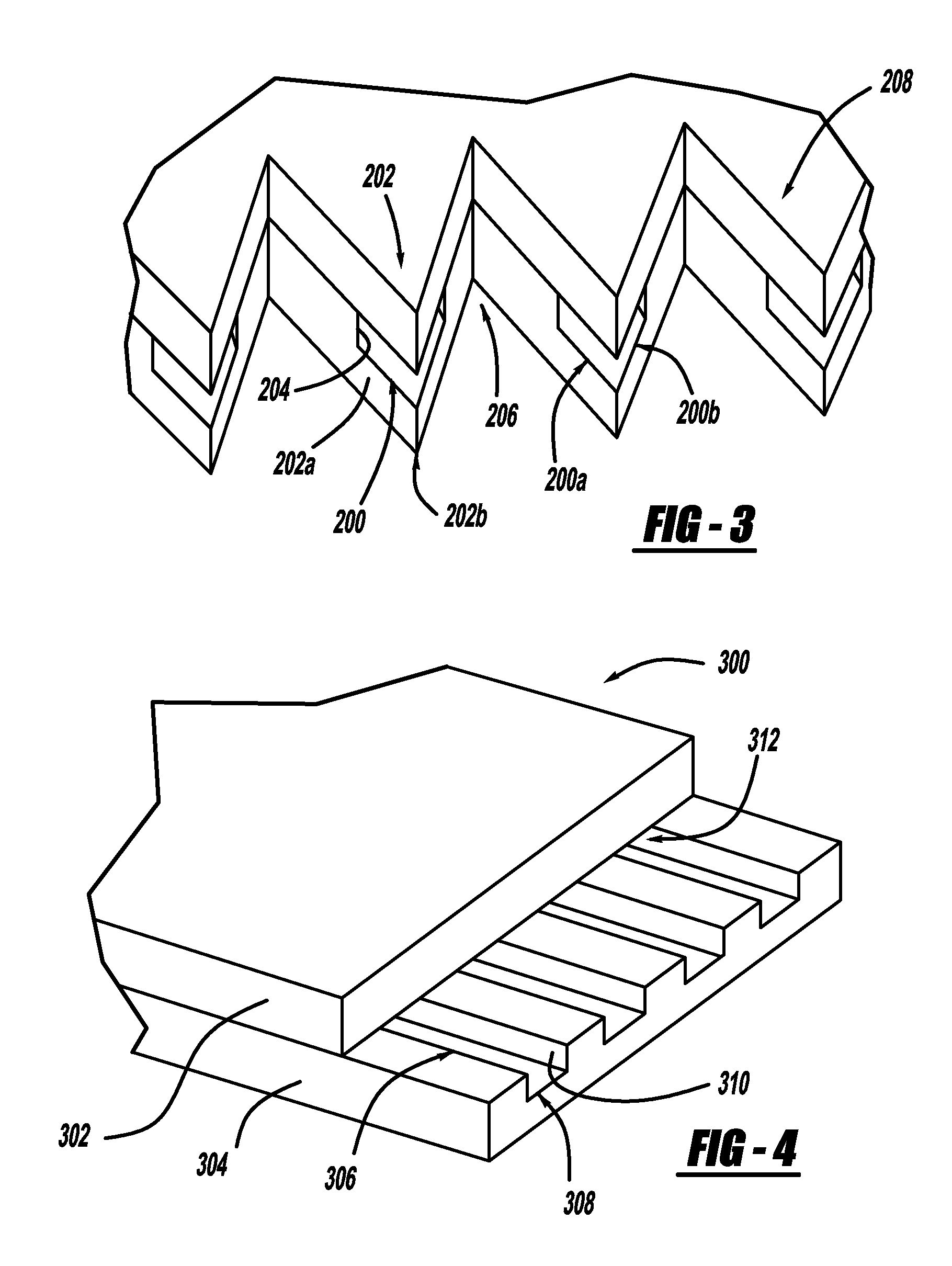

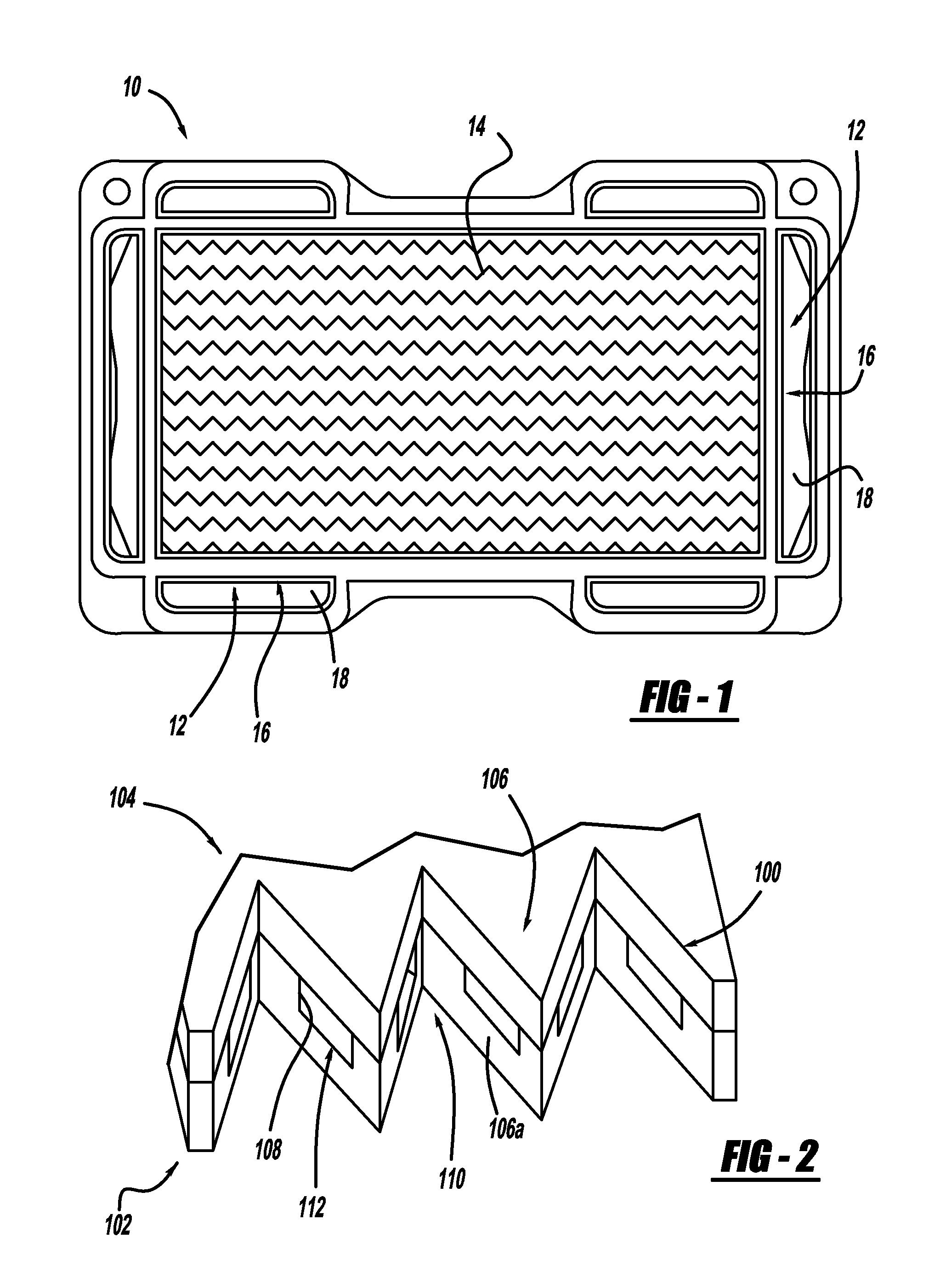

Ceramic filter element and method of manufacture

A method of manufacturing a ceramic diesel particle filter (DPF) and a DPF manufactured by the method, the DPF having a ceramic filter body (1) including gas channels (18, 18′) with planar and porous filter segments (3), which are provided for the exhaust gas stream (2) to flow through them transversely to the face of the filter segments (3). The filter body (1) is formed by sintering at least one ceramic-impregnated fiber web (4) in a firing step under heat such that fibers (5) of the fiber material are burned off and the ceramic material (6) is sintered together to form the porous filter segment (3) between its two surfaces (7, 8). At least one fiber web (4) is corrugated to form the gas channels (18, 18′) and rolled up to form the filter body (1), and the cross section of at least a portion of the gas channels (18, 18′) changes from an inlet end (33) to a discharge end (34).

Owner:MANN HUMMEL GMBH

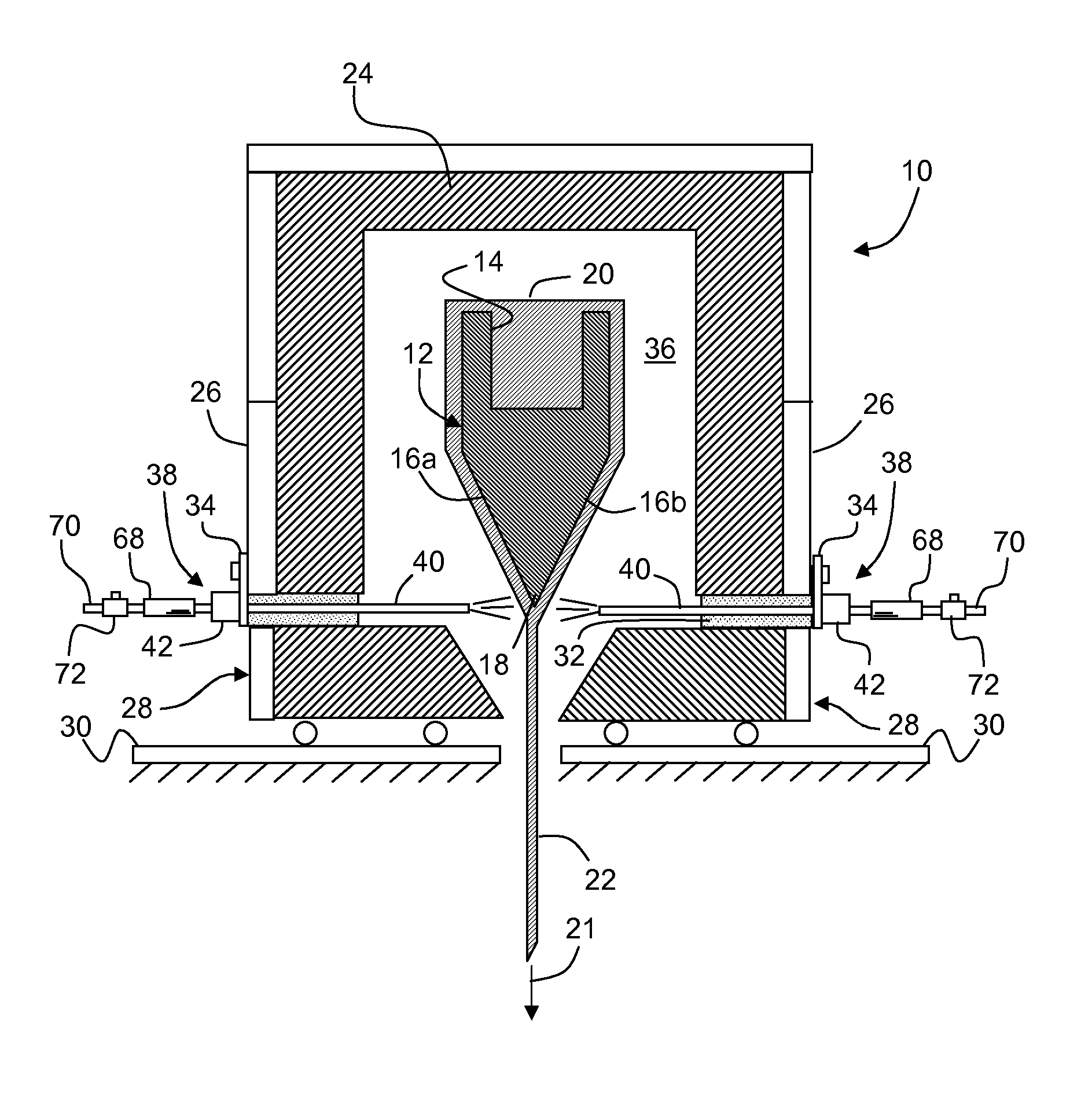

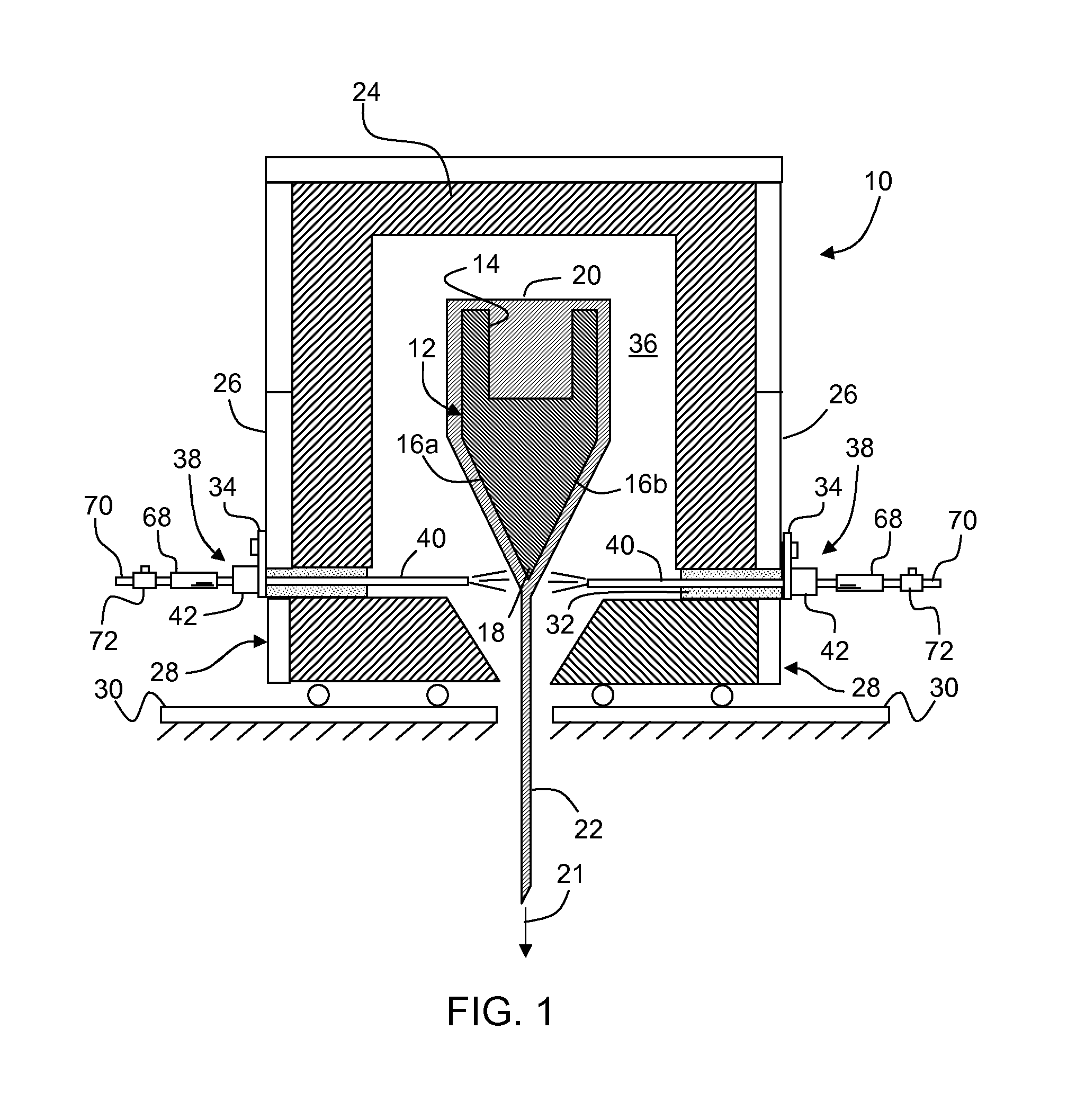

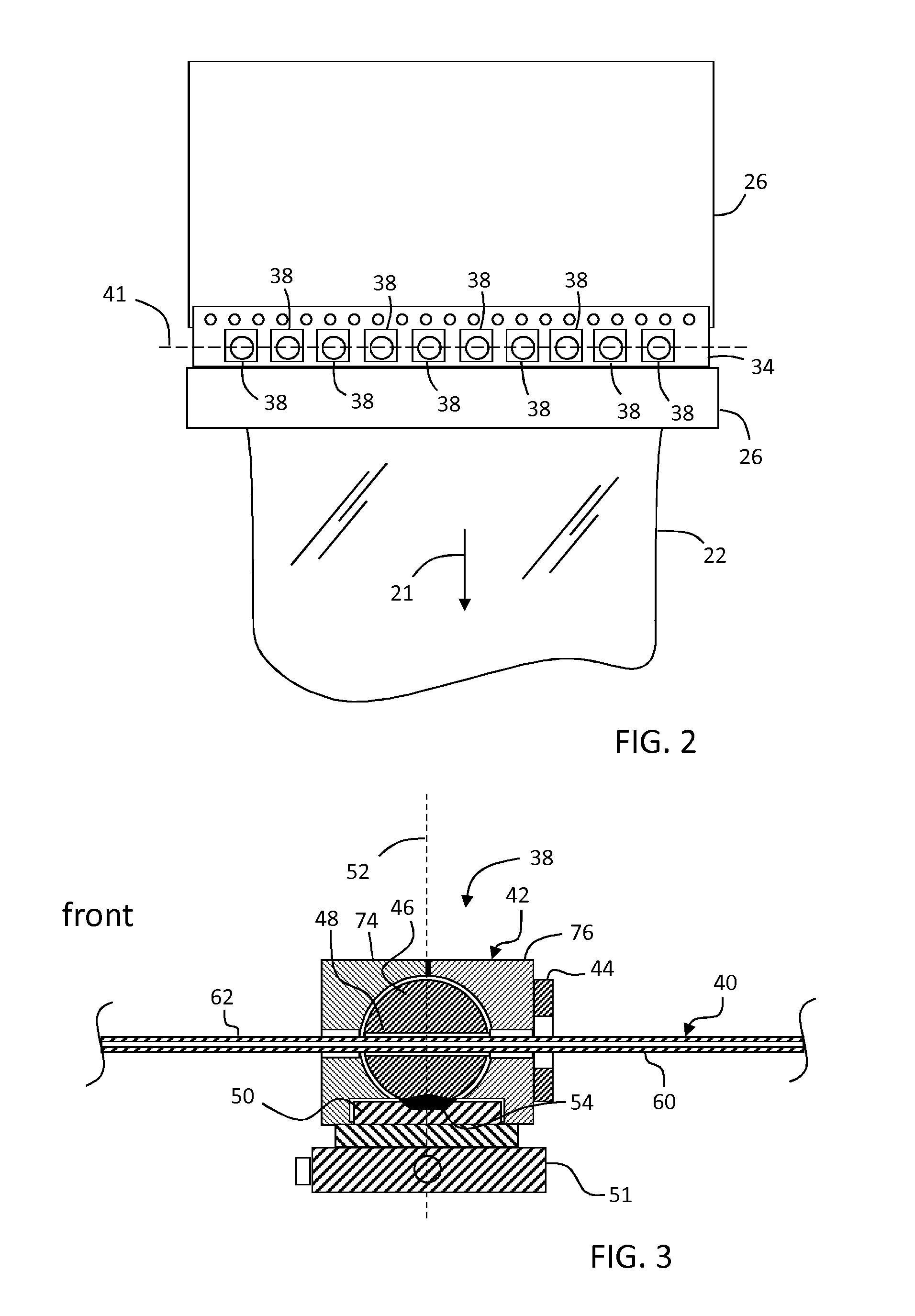

Apparatus and method for controlling thickness of a flowing ribbon of molten glass

ActiveUS8397536B2Inhibit gas flowGlass drawing apparatusGlass forming apparatusGlass sheetCooling pipe

In the formation of sheet material from molten glass, a cooling tube is positioned in the forming area for directing a flow of cooling gas on discrete portions of the molten glass proximate a draw line or root to control local thickness variations in the sheet and thereby provide a uniform glass sheet thickness across the width of the sheet. The cooling tube is disposed in a pivot member configured to rotate about at least one axis, thereby causing an end of the cooling tube to direct the cooling gas over a wide range of angular positions across a portion of the width of the molten glass flowing over and from a forming body.

Owner:CORNING INC

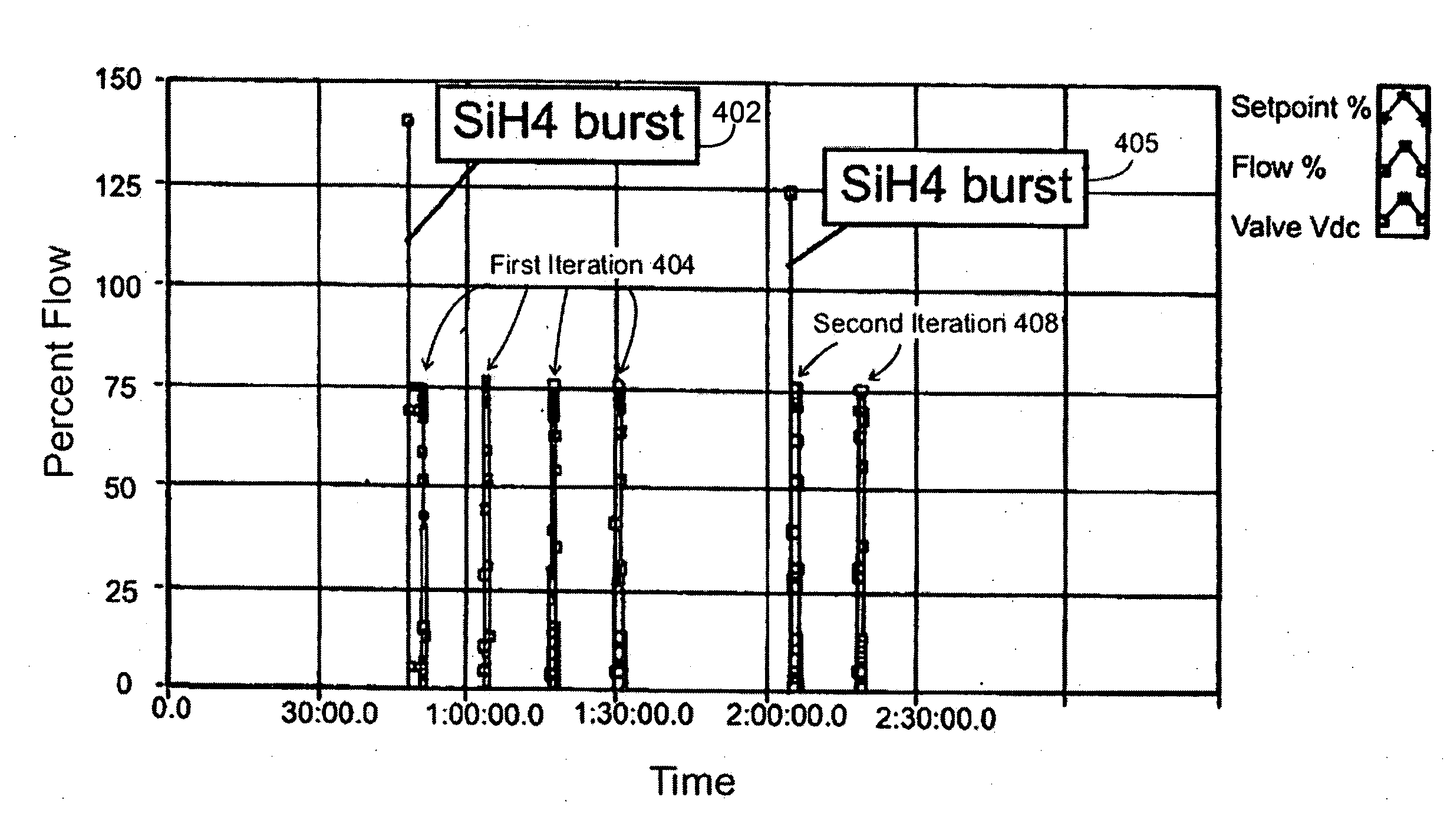

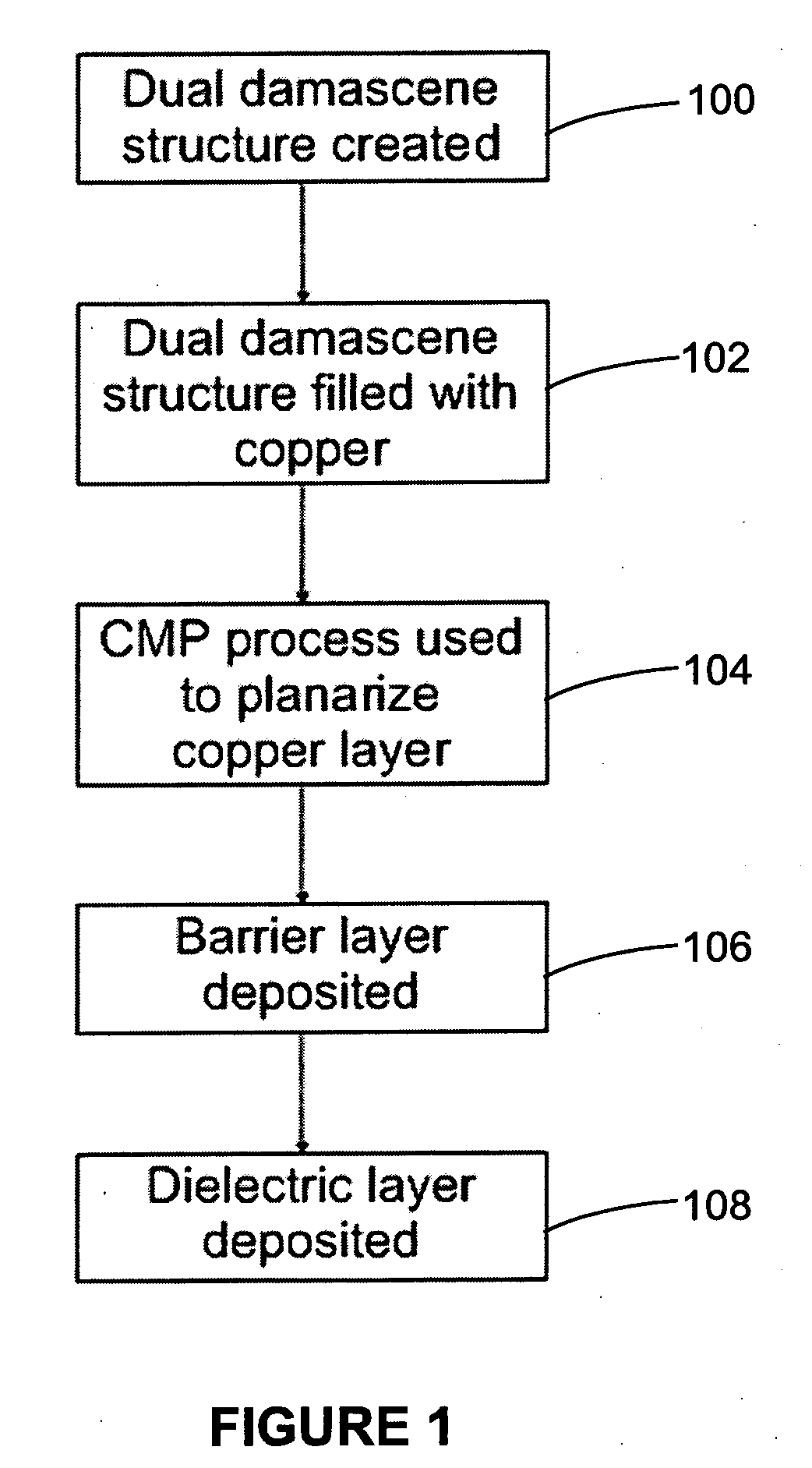

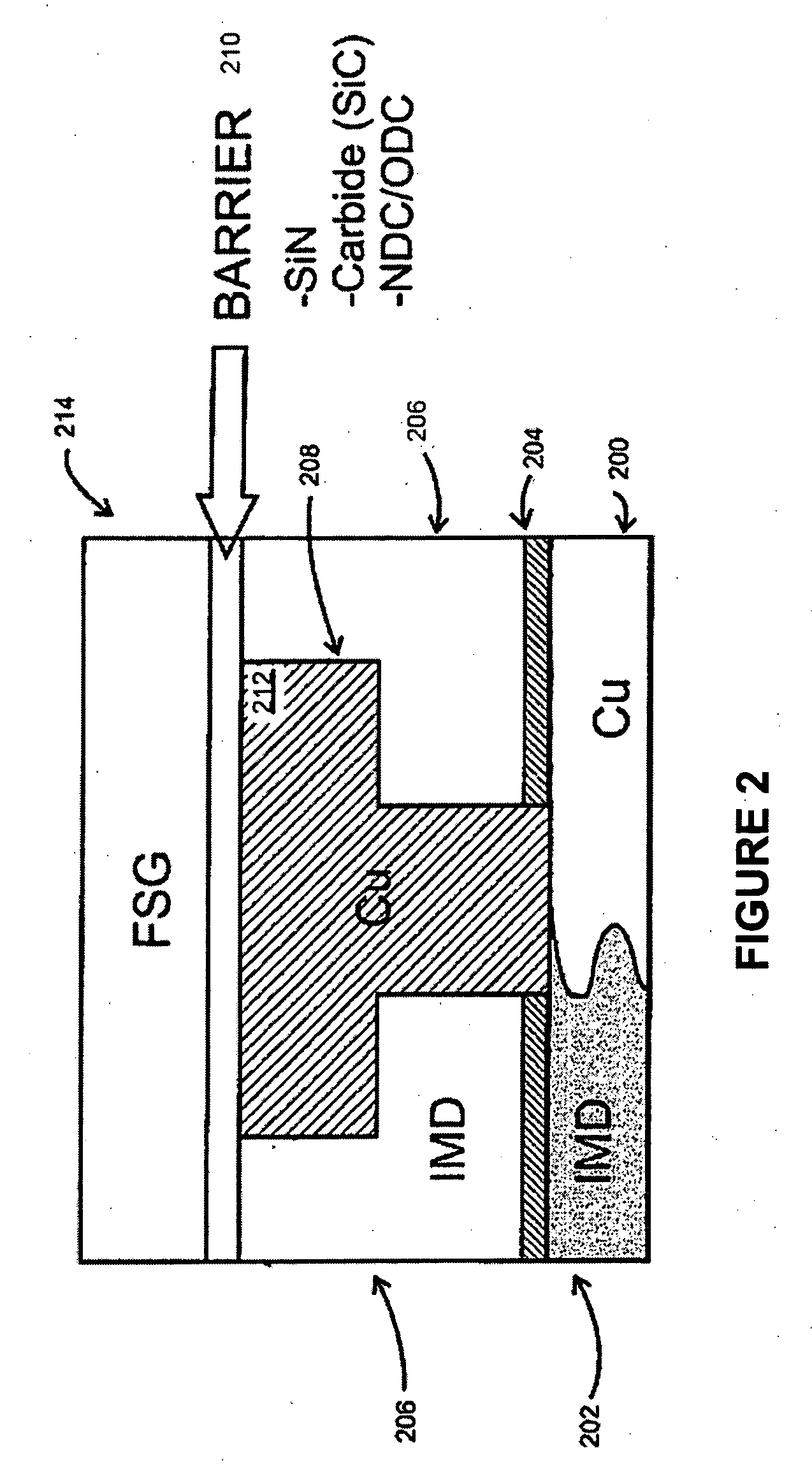

Method and apparatus for improving breakdown voltage of integrated circuits formed using a dielectric layer process

InactiveUS20070128860A1Easily use processImprove breakdown voltageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProcess engineeringSystem configuration

A method and apparatus for depositing a dielectric layer. The apparatus includes a semiconductor processing chamber configured for use in a dielectric layer deposition process, the semiconductor processing chamber being associated with at least a length, a width, a height, and a volume, one or more gas sources containing one or more gases used in the barrier layer deposition process, and one or more gas flow controllers coupled to the one or more gas sources, the one or more gas flow controllers configured to provide one or more controlled amounts of one or more gas flows to the semiconductor processing chamber during semiconductor processing. One or more gas lines coupled to the one or more gas flow controllers for receiving one or more gas flows from the one or more gas flow controllers, and a pumping system is coupled to the semiconductor processing chamber, the pumping system configured to remove a quantity of gas from either the semiconductor processing chamber or the one or more gas lines. A 3-way valve is coupled to the pumping system and the process chamber, the 3-way valve being configured to allow the one or more gas flows to be sent to the pumping system or to the process chamber.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Conduit

InactiveUS20140144447A1Avoid flowInhibit gas flowRespiratory masksBreathing masksTidal volumeCatheter

A conduit operative or to be operative between a patient interface and both (a) a tidal volume gas delivery device that can deliver controlled tidal volume gasses to a patient for the purposes of resuscitation and (b) a CPAP device for delivery of CPAP to the patient. The conduit comprises a primary lumen having an inlet operatively connectable with said tidal volume gas delivery device. Also provides is a secondary lumen having an inlet operatively connectable with the CPAP device. A manifold, via respective outlets of the primary and secondary lumens and a manifold outlet, allows fluid communication to be established between a patient interface and both the CPAP device and the tidal volume gas delivery device.

Owner:KUYPERS GILBERT JACOBUS +1

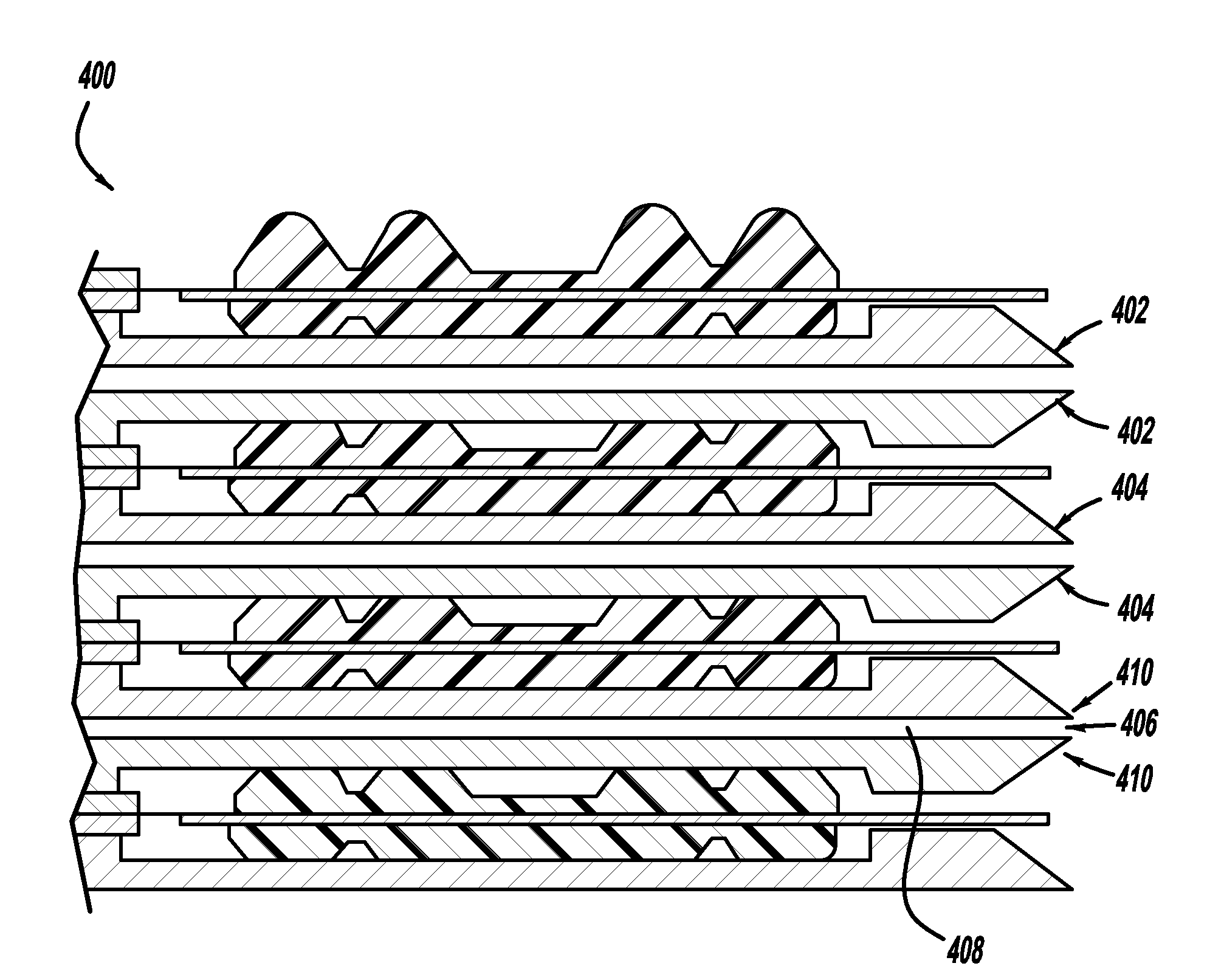

Fuel cell stack

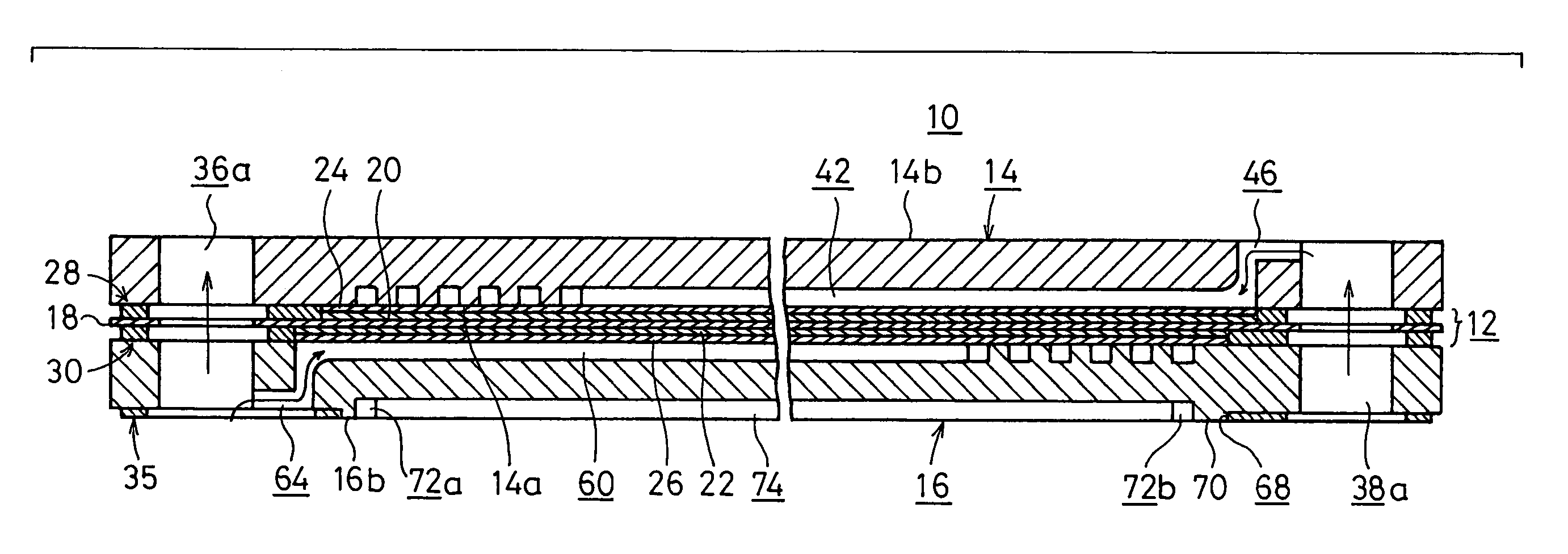

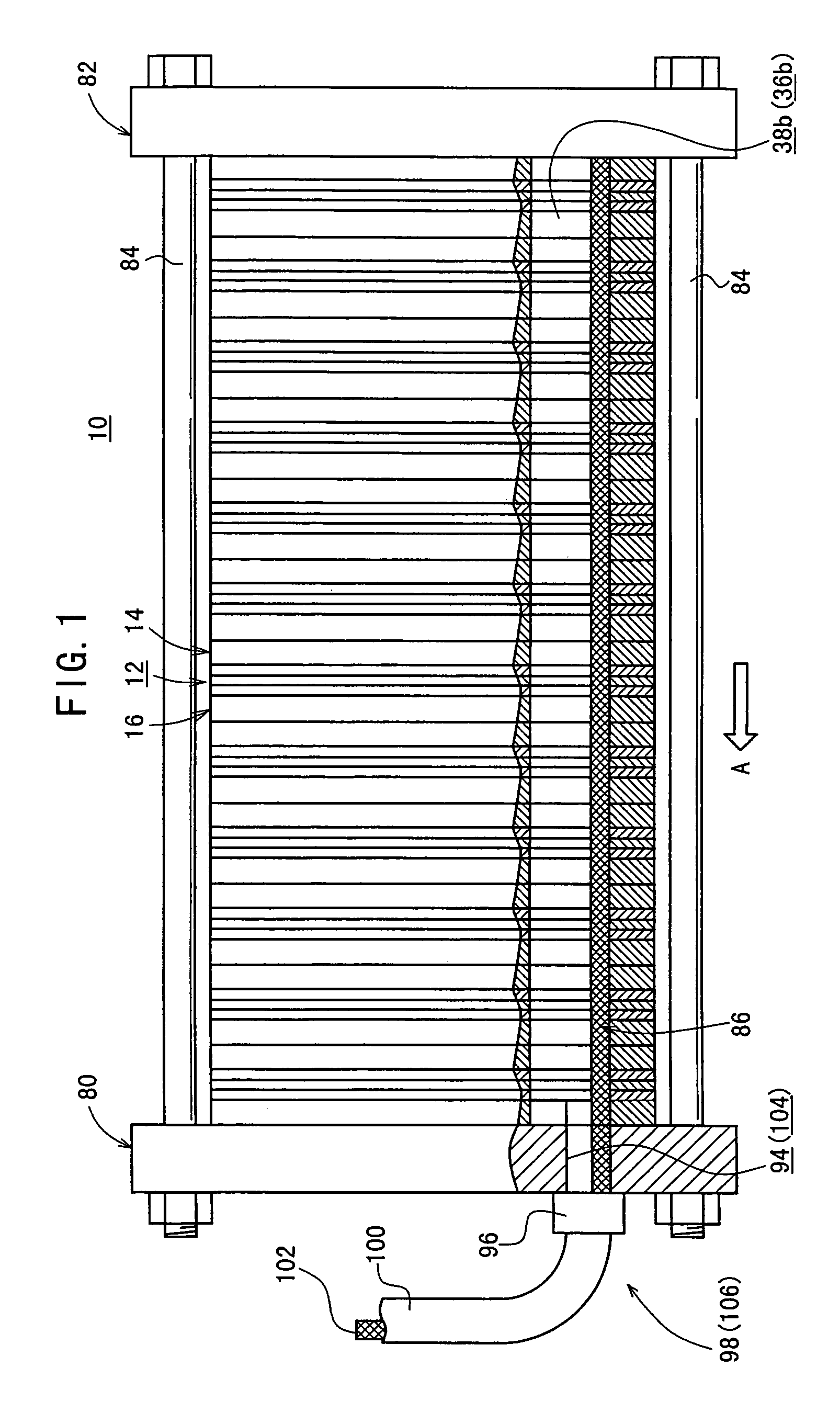

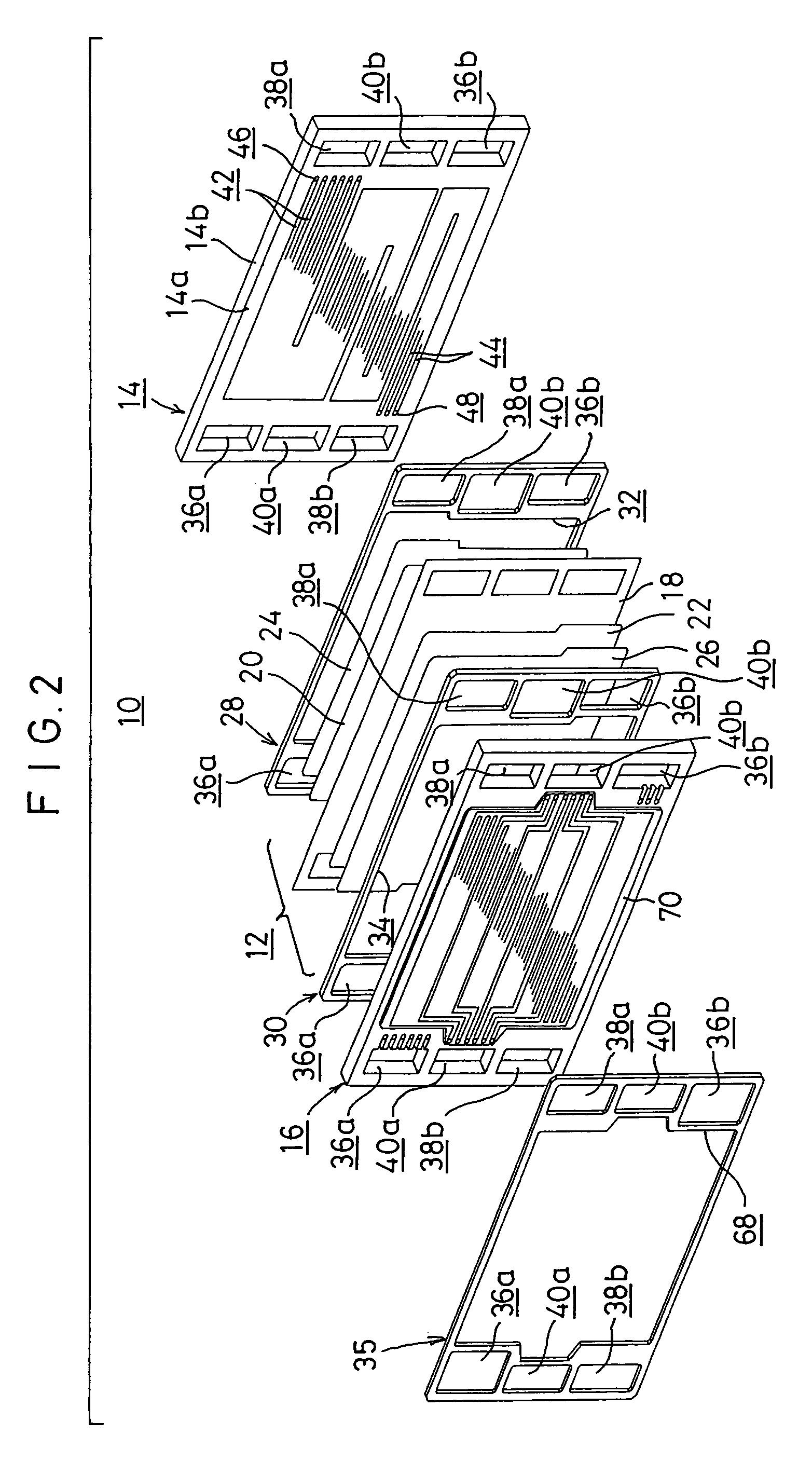

InactiveUS7527889B2Smoothly and reliably discharge waterAvoid waterFuel cells groupingWater management in fuel cellsFuel cellsEngineering

A fuel cell stack is provided with an outlet side oxygen-containing gas communication hole. First and second oxygen-containing gas flow passage grooves are provided in the direction of the gravity while meandering in the horizontal direction on a surface of a first separator. The second oxygen-containing gas flow passage grooves communicate with the outlet side oxygen-containing gas communication hole via second oxygen-containing gas connecting flow passages. The lowest position of the second oxygen-containing gas flow passage grooves 44 in the direction of gravity is higher than the bottom of the outlet side oxygen-containing gas communication hole 38b by the height h.

Owner:HONDA MOTOR CO LTD

Solenoid isolation valve

InactiveUS20070039591A1Inhibit gas flowReduce gas pressureOperating means/releasing devices for valvesCombustion enginesIsolation valveSolenoid valve

The disclosure of U.S. patent application Ser. No. 11 / 161,914 including the specification, drawings and abstract is incorporated herein by reference in its entirely. An improved pilot-operated, “instant-on”, solenoid isolation valve discloses a new fluid passage route to save cost of drilling a longitudinal hole within the primary piston. Also, a new feature of primary piston assembly with a movable seal piston having a specific circumferential surface matching to valve body chamber to restrict fluid from front side into back side of the primary piston to produce pressure difference to induce instant valve open when solenoid is energized initially. It also introduces a channel hole in the flange of the sleeve assembly as a communication channel of supply of gas into the chambers of the back side of primary piston assembly. The diameter of the channel hole is not critical to determine in this new invent. As long as the size of the hole is smaller than that of the bleed hole, it can maintain pressure difference between the front side and back side of primary piston during valve opening operation. In addition, since the pilot piston and the primary piston assembly operate independently, the travel stroke of the primary piston assembly is unconstrained by the input electrical power.

Owner:WANG WEI CHING +2

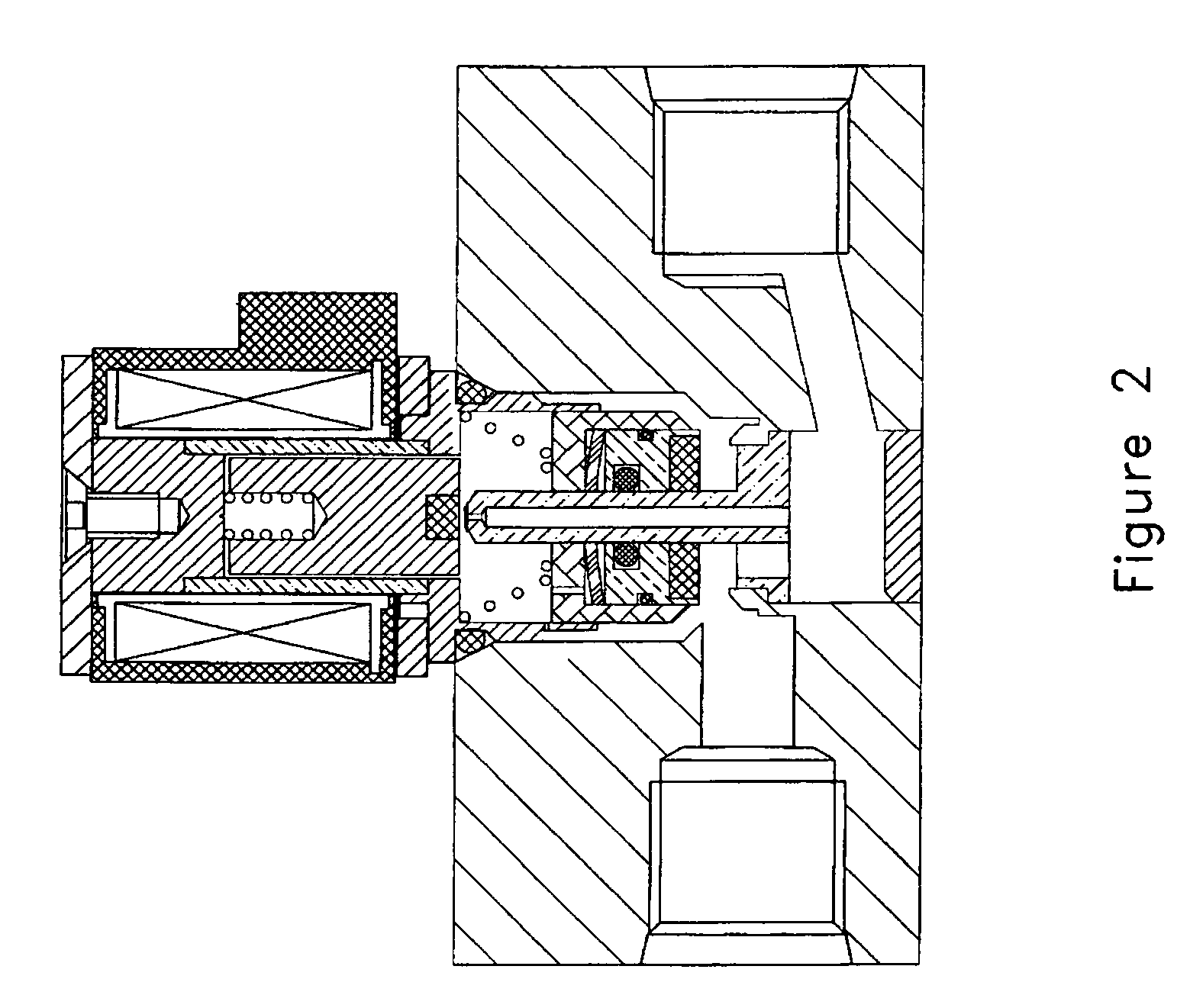

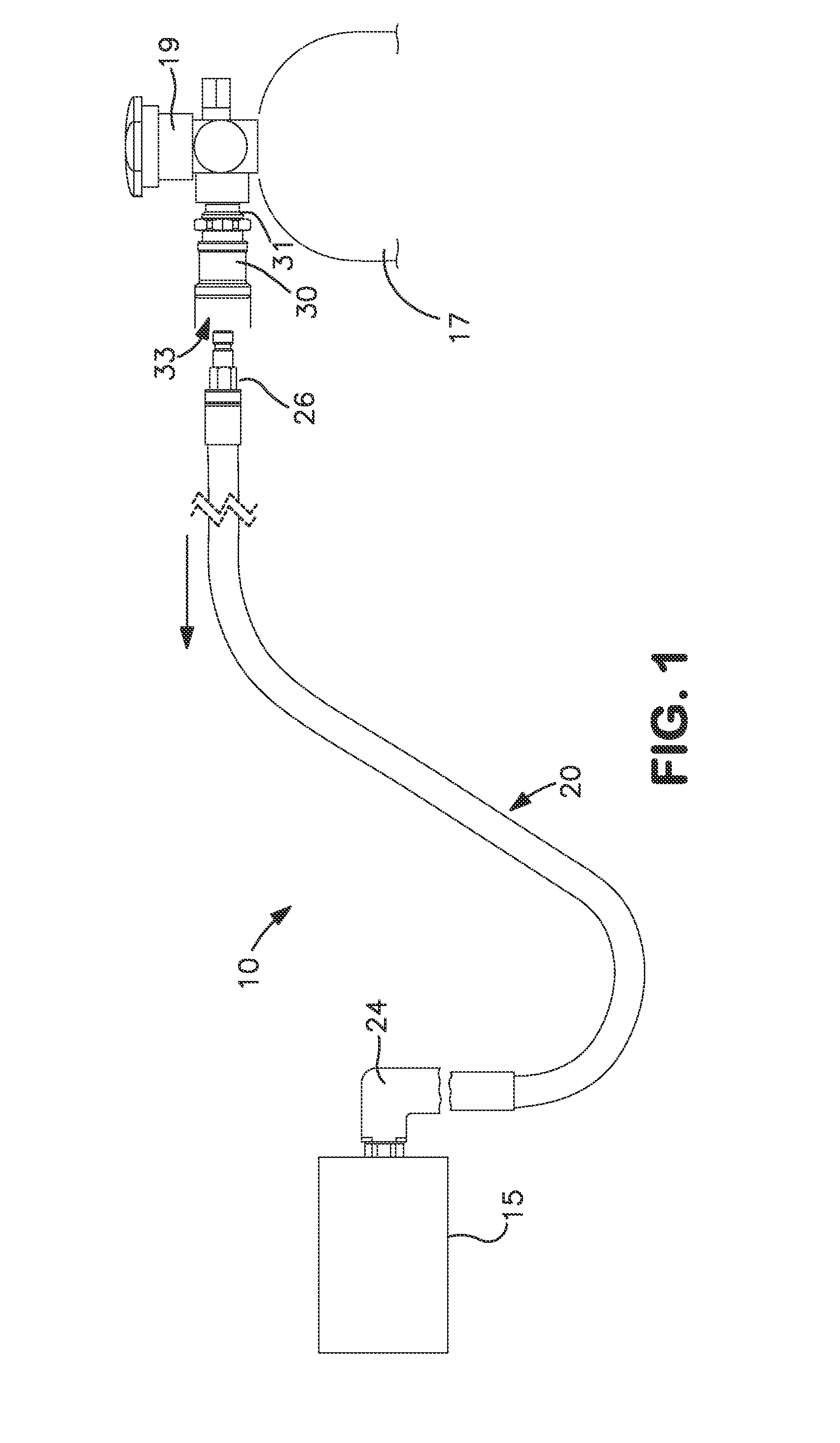

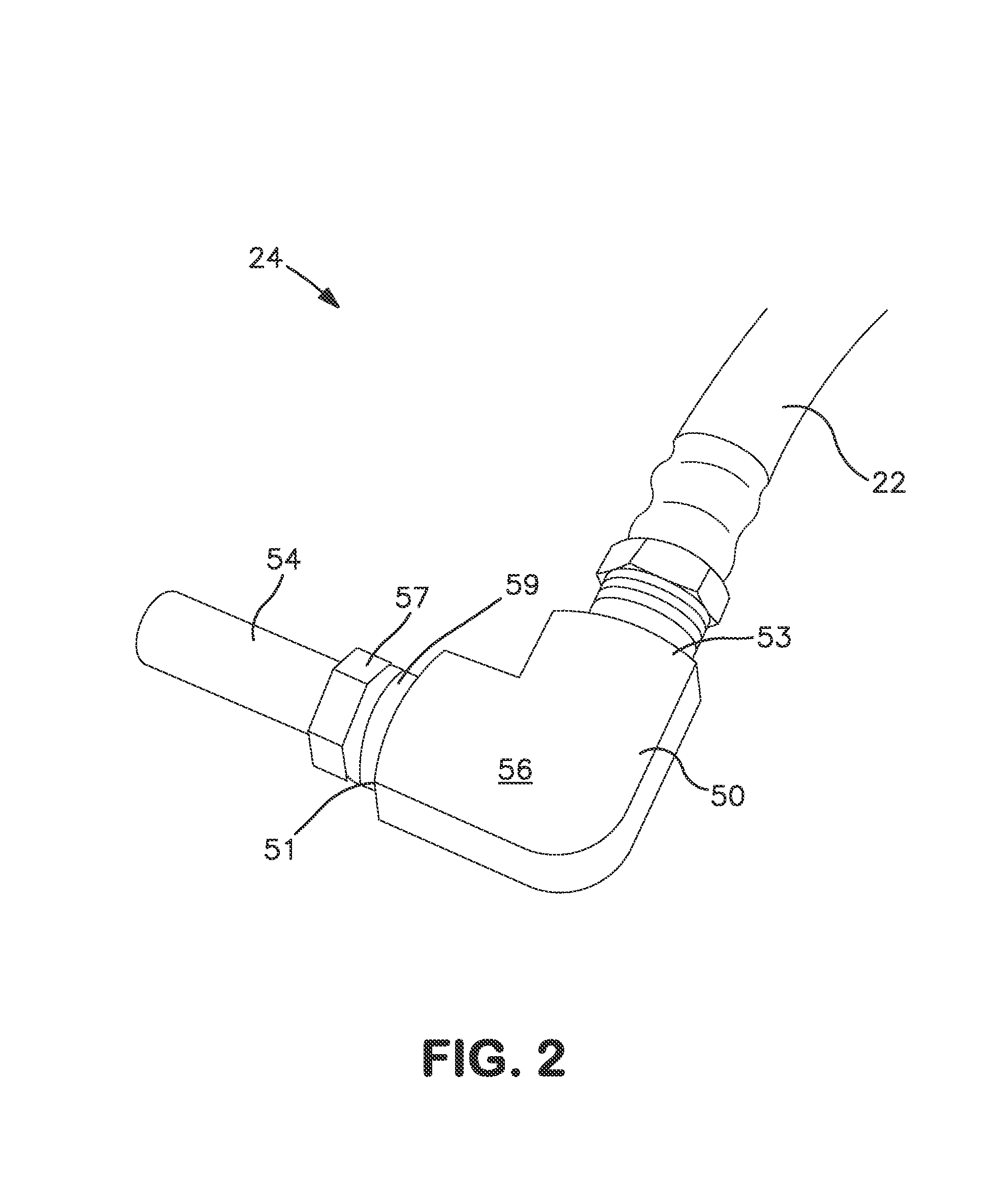

Connector assembly for medical gas applications

A connector assembly for connecting a medical gas cylinder with a medical gas delivery device is provided. The connector assembly includes a jacketed hose connected at one end to a gas delivery device adaptor and connected at the other end to a male quick coupling element that connects with a cylinder coupling valve assembly. The valve assembly includes a retainer body assembly and a retainer sleeve that define a female quick coupling portion adapted to receive the male type quick coupling element of the hose assembly. The gas delivery device adaptor is an elbow shaped body with an internally disposed 90 degree threaded bore from its distal end to its proximal end. An engagement stem projects from the distal end of elbow shaped body and is adapted to couple the gas delivery device to the jacketed hose via the 90 degree threaded bore.

Owner:PRAXAIR TECH INC

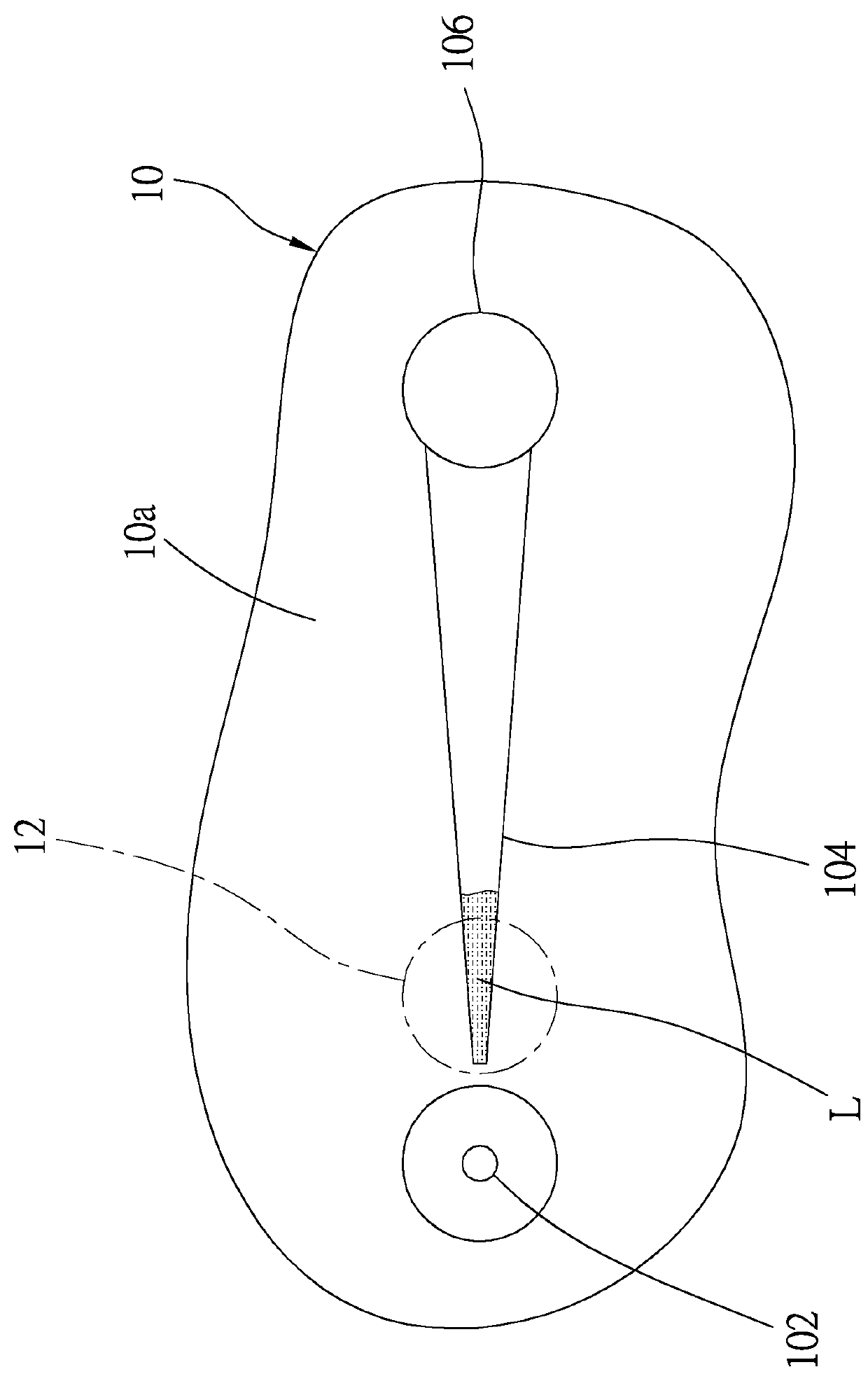

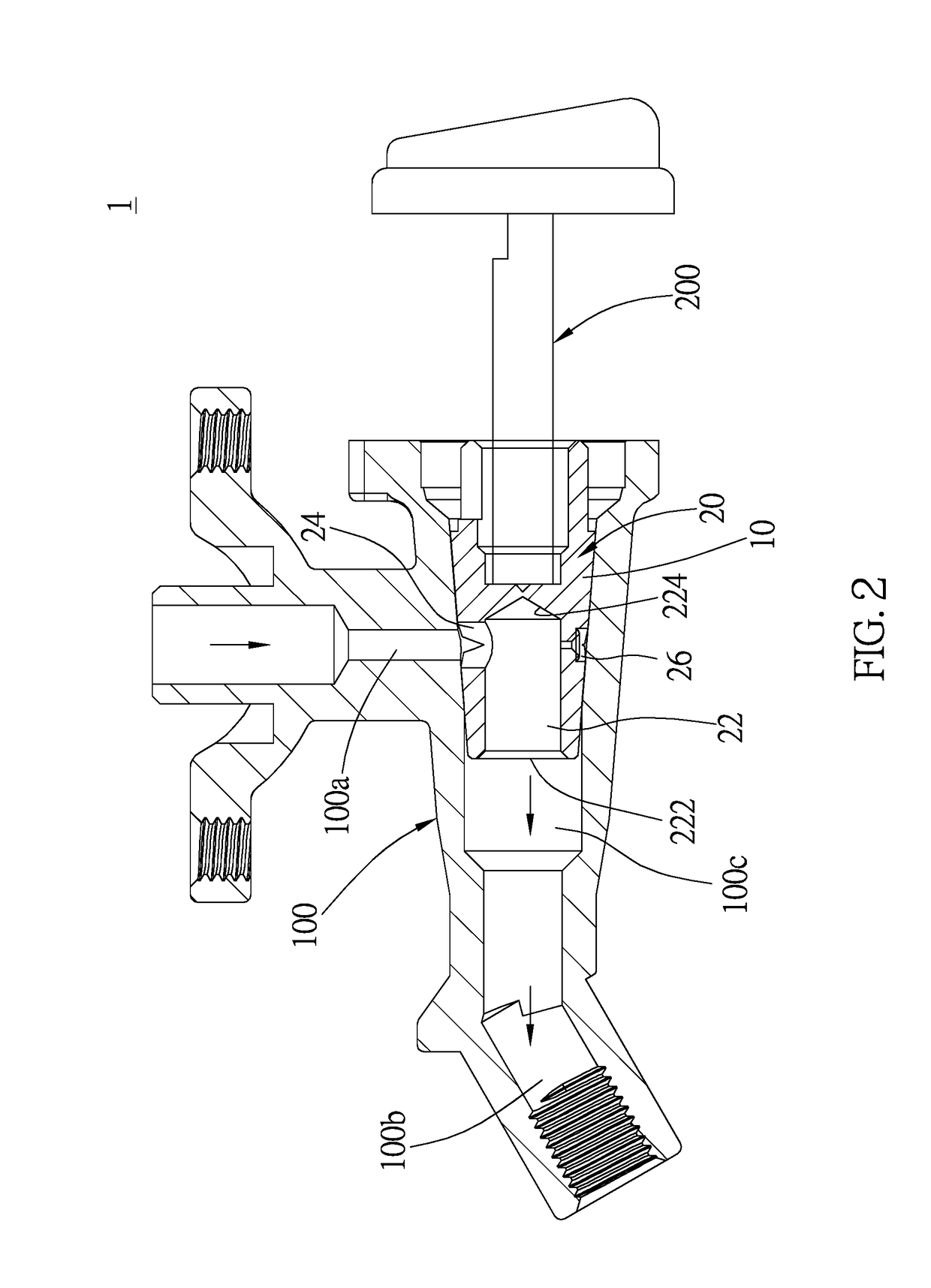

Plug member of gas valve

ActiveUS10006550B2Inhibit gas flowPrevented from dropping dramatically or being cut offPlug valvesFuel supply regulationEngineeringLubricant

A plug member of gas valve has an axial bore, a first bore, and a second bore, wherein the first bore and the second bore are located in a radial direction of the plug member, and communicate with the axial bore, respectively. A diameter of the first bore is larger than that of the second bore. A first guiding slot and at least one first oil groove are recessed into the outer peripheral surface of the plug member, wherein the first guiding slot has a first end communicating with the first bore, and a second end near the second bore without physically communicating with the second end. The at least one first oil groove is near the second end of the first guiding slot without physically communicating with the first guiding slot or the second bore. Whereby, the first oil groove provides space for receiving lubricant.

Owner:GRAND MATE

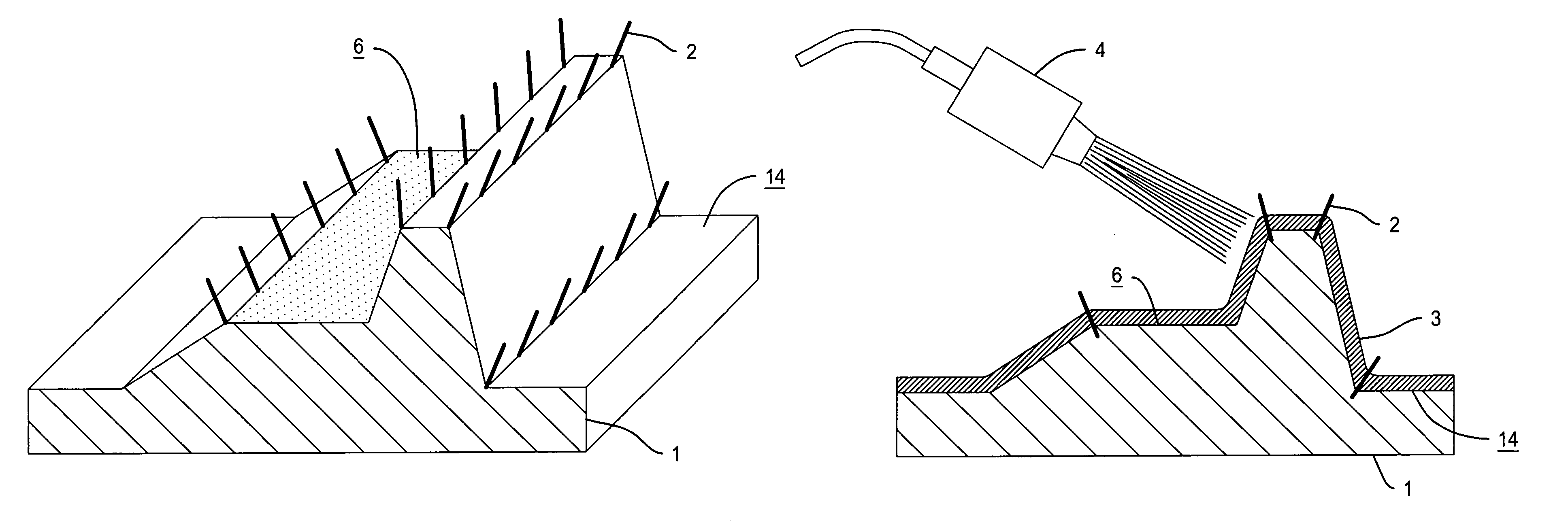

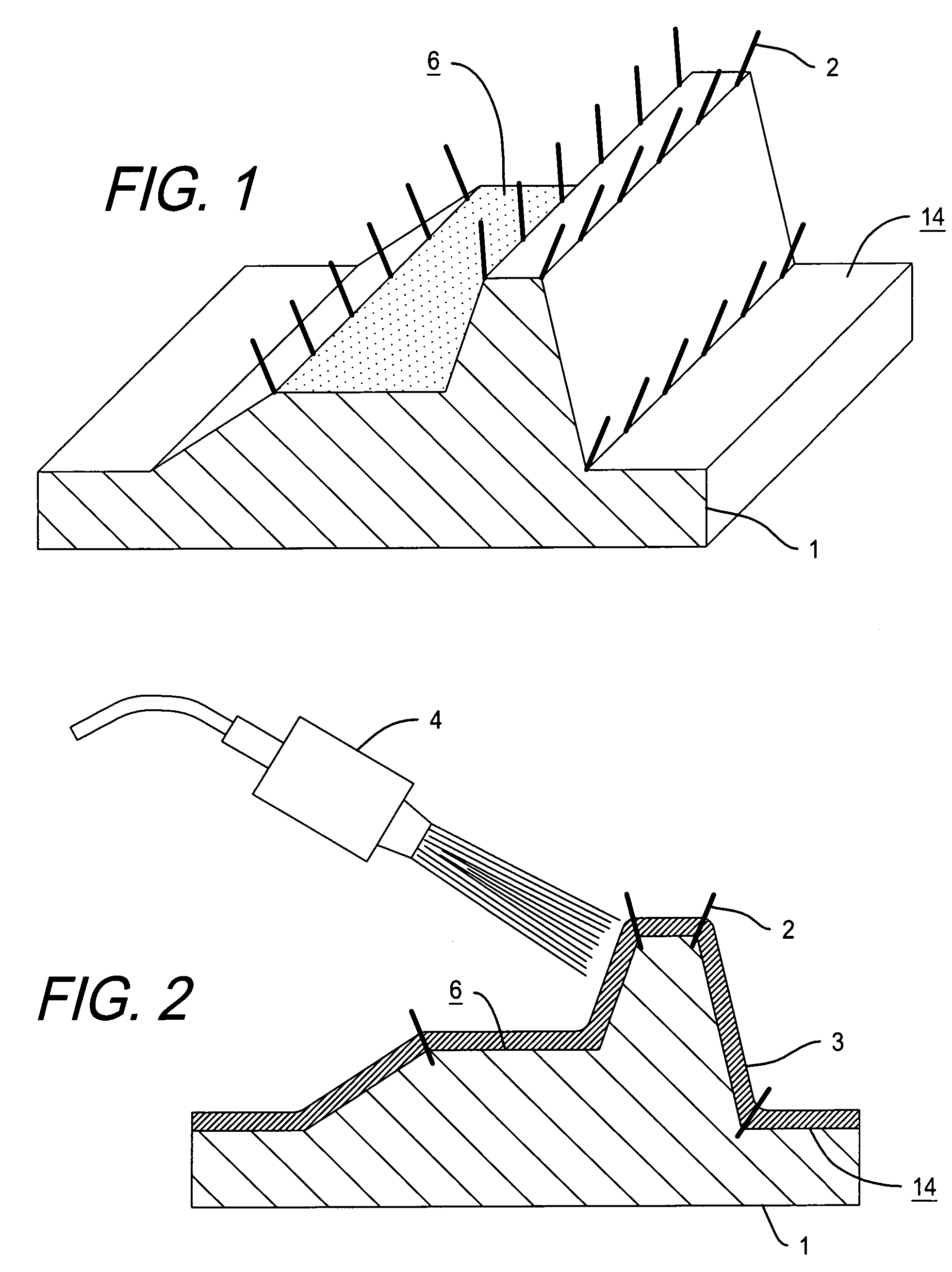

Method of venting a spray metal mold

ActiveUS20060086474A1Prevent spray metal buildupAvoid depositionFoundry mouldsFoundry coresMetallurgyMetal mold

The present invention relates to a novel method of venting a spray metal molding surface. More particularly the invention relates to a method of manufacturing a mold using a thermal spray process to produce a metal surface containing passages in the spray metal to vent fluid or gas from the forming surface. The present invention is primarily intended for mold tools, such as vacuum molds, injection molds or blow molds having vents or a multiplicity of holes in the forming surface to evacuate or supply gas in a mold.

Owner:GENIUS SOLUTIONS ENG

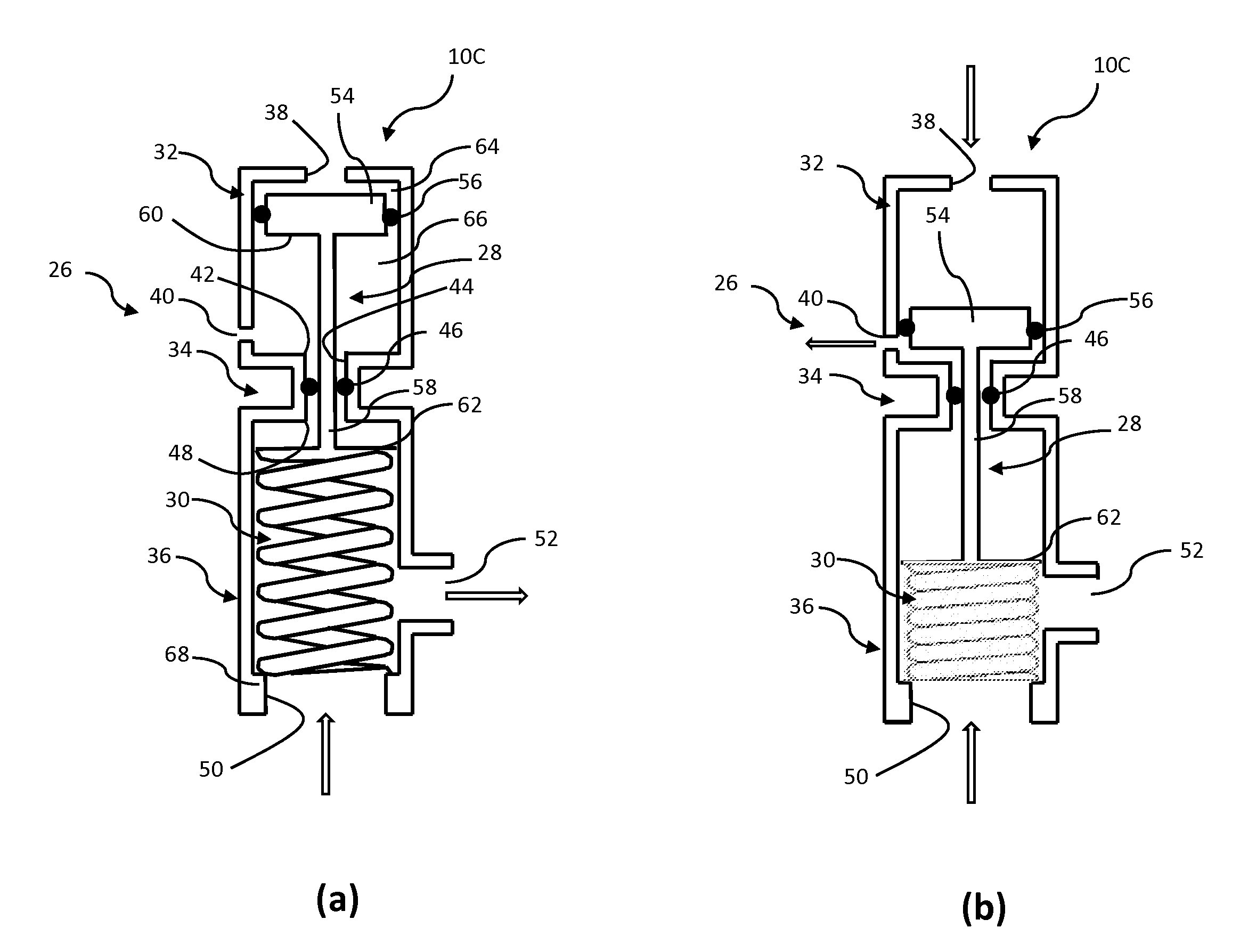

Water removal features for PEMfc stack manifolds

ActiveUS8168340B2Inhibit gas flowBenefit freeze durabilityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A bipolar plate includes angled facets oriented to form V-shaped projections on the plate edge. Liquid leaving the reactant channels is drawn back into the V-shaped grooves of the projections, leaving no liquid to obstruct the channel exit openings. The bipolar plate includes one portion of the bipolar plate offset from another portion of the bipolar plate so as to expose the reactant channels. The liquid is drawn toward the end portions of the reactant channels by capillary forces, while the gas flows can exit near the beginning of the offset portion. A fuel cell stack includes angled facets that are rotated to lie in the plane of the bipolar plate edges. The edges are chamfered so the channel exit openings of the reactant channels are at the tip portions thereof, thus allowing the liquid to flow away from the channel exit openings and the gas to exit freely.

Owner:GM GLOBAL TECH OPERATIONS LLC

Spring controlled valve

ActiveUS20140338763A1Improve the immunityInhibit gas flowOperating means/releasing devices for valvesFluid pressure control without auxillary powerEngineeringControl valves

Owner:PROPORTIONAIR INCORPORATED

Cleaning Process for Cleaning Filtration Material of a Gas Filter and a Device for Carrying Out the Process

InactiveUS20080307959A1Inhibit gas flowPrevent blastingCombination devicesAuxillary pretreatmentFiltrationProduct gas

A cleaning process for filtration material of a gas filter is disclosed. A first step hinders the gas flow from passing through the filtration material by closing the clean gas side of a single segment or a row of filter segments. A second step provides a slow gas flow to the closed filter segments to cause a reverse gas flow through the filtration material. A third step opens an impulse valve for an ultra short time to create a compressed gas impulse for disengaging the particles which did not fall off the filtration material during the second step of the cleaning process. A fourth step shuts off the reverse flow gas supply. A device for separating one or several filter segments from the clean gas side of the filter filtration material is also disclosed.

Owner:ZIMMER SEBASTIAN

Plug member of gas valve

ActiveUS20170114908A1Inhibit gas flowPrevented from dropping dramatically or being cut offPlug valvesFuel supply regulationEngineeringLubricant

A plug member of gas valve has an axial bore, a first bore, and a second bore, wherein the first bore and the second bore are located in a radial direction of the plug member, and communicate with the axial bore, respectively. A diameter of the first bore is larger than that of the second bore. A first guiding slot and at least one first oil groove are recessed into the outer peripheral surface of the plug member, wherein the first guiding slot has a first end communicating with the first bore, and a second end near the second bore without physically communicating with the second end. The at least one first oil groove is near the second end of the first guiding slot without physically communicating with the first guiding slot or the second bore. Whereby, the first oil groove provides space for receiving lubricant.

Owner:GRAND MATE

Water Removal Features for PEMFC Stack Manifolds

ActiveUS20090117432A1Inhibit gas flowBenefit freeze durabilityFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A bipolar plate includes angled facets oriented to form V-shaped projections on the plate edge. Liquid leaving the reactant channels is drawn back into the V-shaped grooves of the projections, leaving no liquid to obstruct the channel exit openings. The bipolar plate includes one portion of the bipolar plate offset from another portion of the bipolar plate so as to expose the reactant channels. The liquid is drawn toward the end portions of the reactant channels by capillary forces, while the gas flows can exit near the beginning of the offset portion. A fuel cell stack includes angled facets that are rotated to lie in the plane of the bipolar plate edges. The edges are chamfered so the channel exit openings of the reactant channels are at the tip portions thereof, thus allowing the liquid to flow away from the channel exit openings and the gas to exit freely.

Owner:GM GLOBAL TECH OPERATIONS LLC

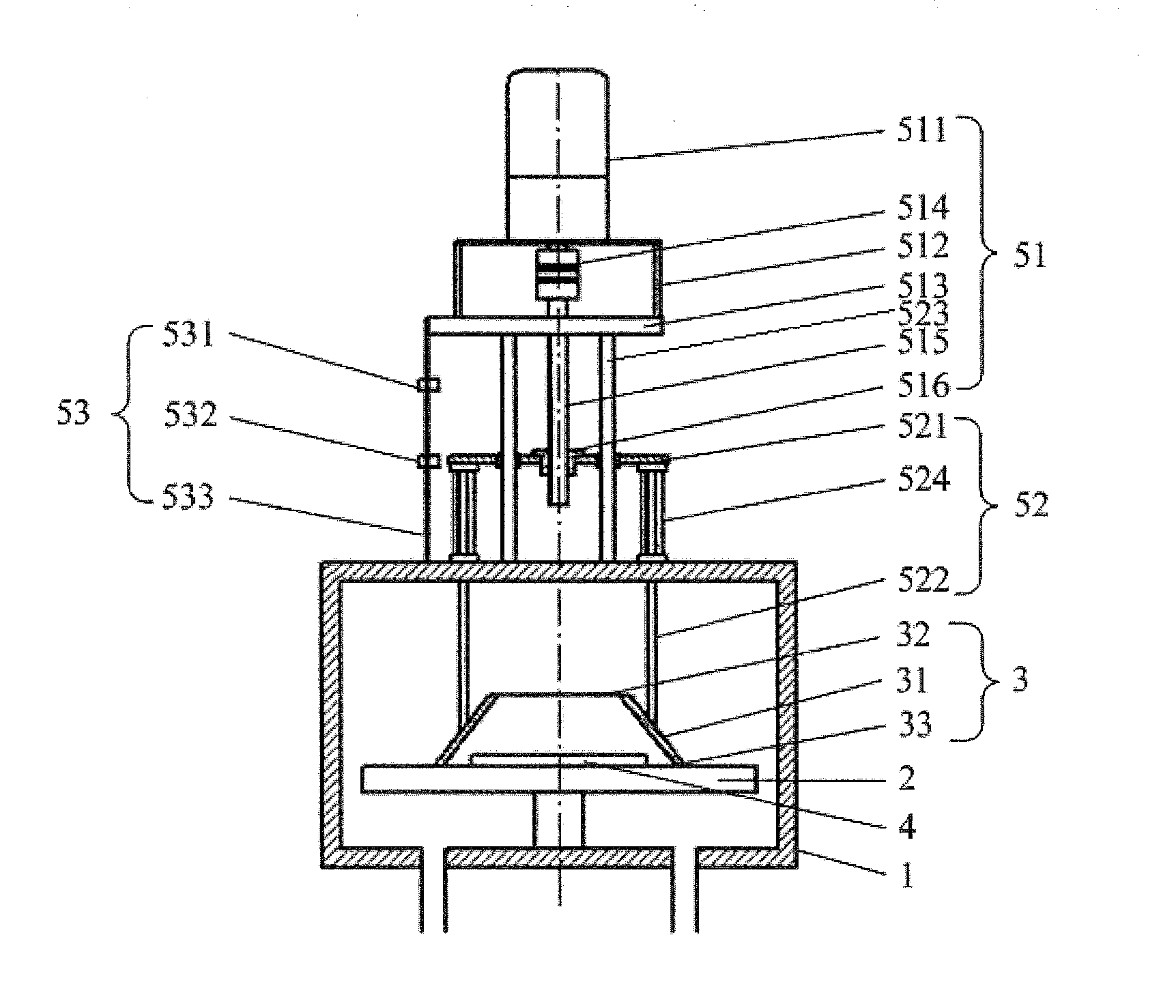

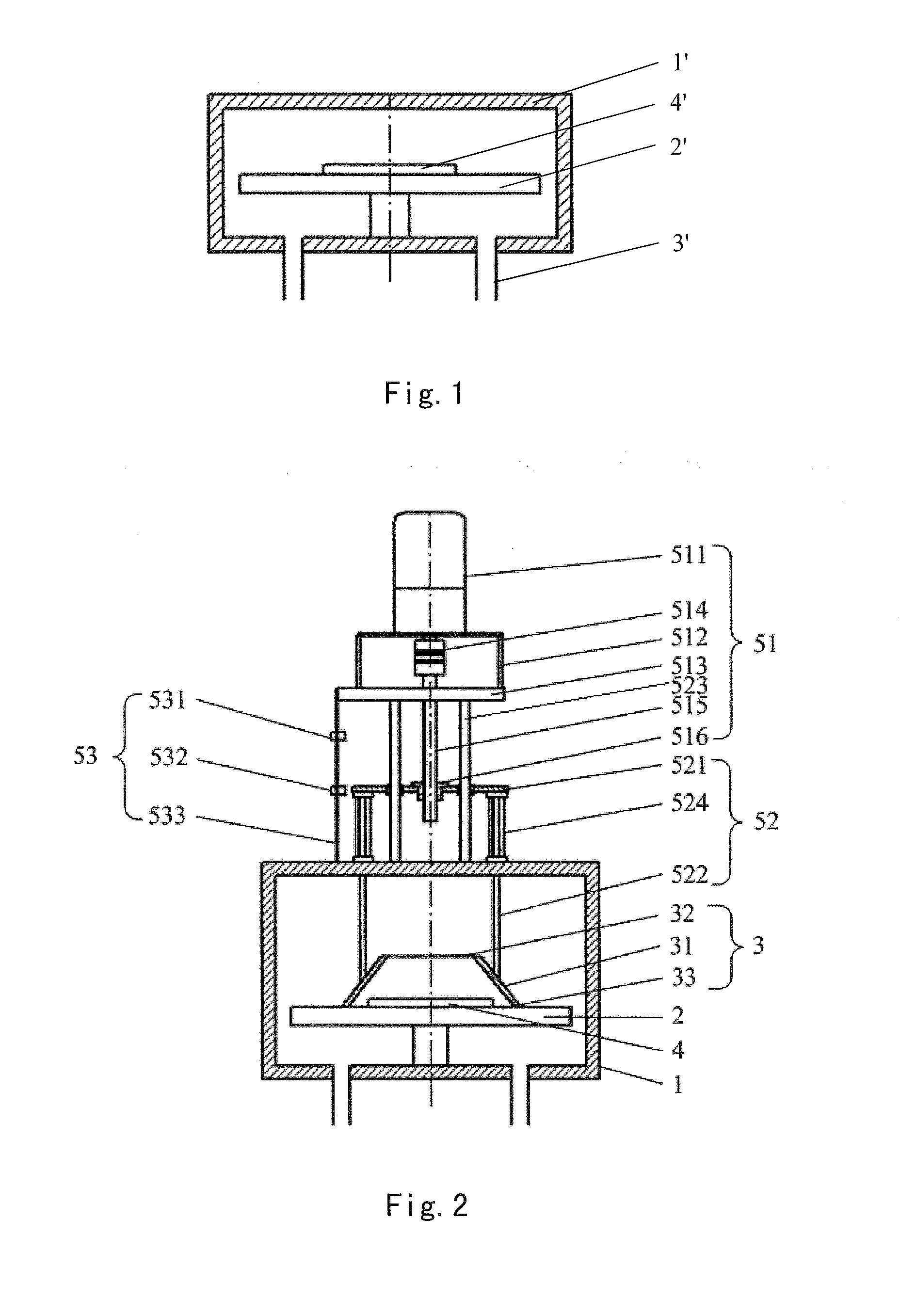

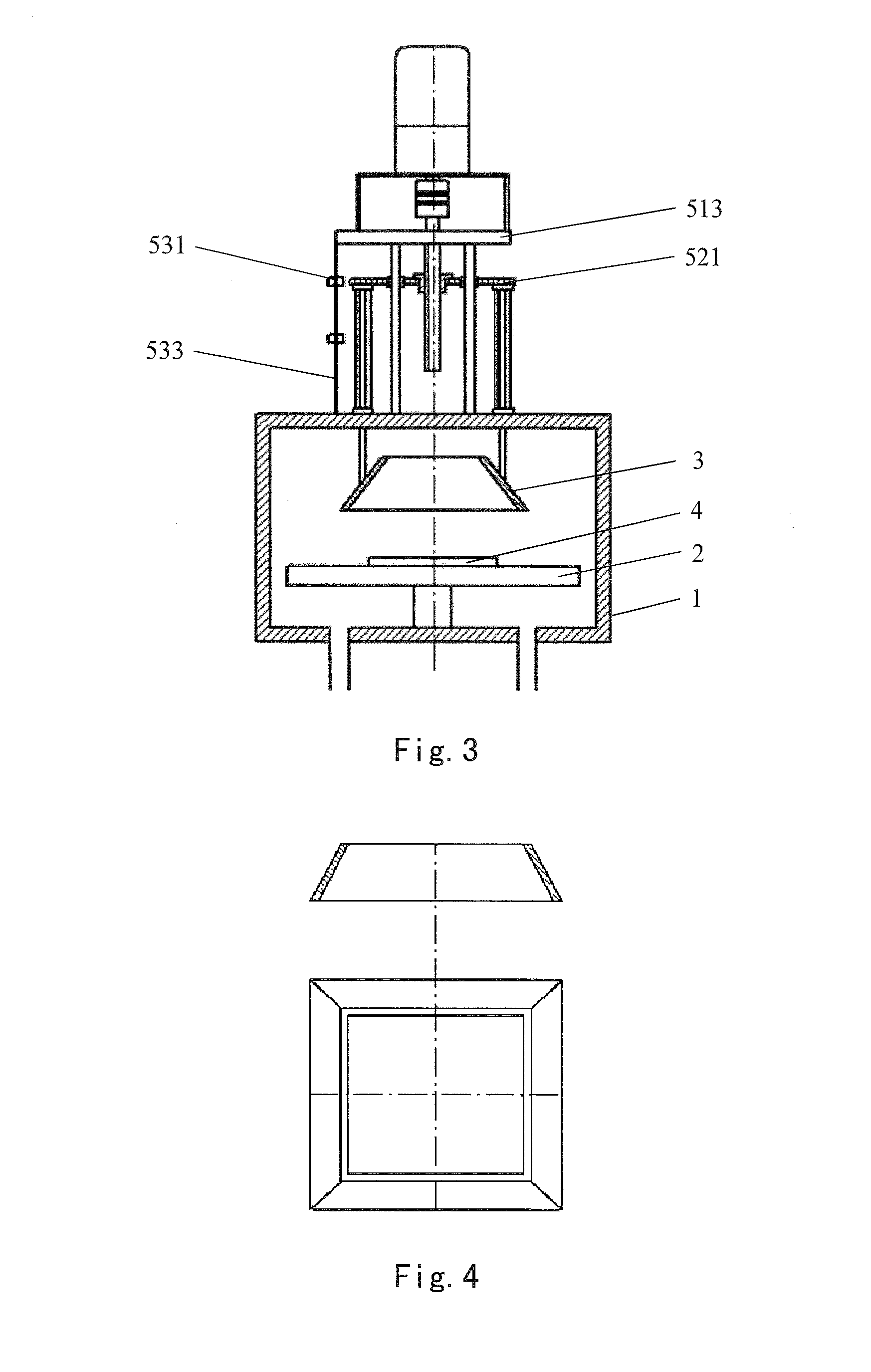

Vacuum drying apparatus and vacuum drying method using the same

ActiveUS20160238315A1Improve the phenomenonInhibit gas flowDrying solid materials without heatSolid-state devicesEngineeringMechanical engineering

An embodiment of the present invention provides a vacuum drying apparatus and a vacuum drying method. The vacuum drying apparatus includes a chamber in which a substrate table is arranged, the chamber being provided with a wind deflector therein, wherein the wind deflector comprises a top opening, a bottom opening and a body part connecting the top opening with the bottom opening. During the vacuum drying, the bottom opening is in tight contact with a surface of the substrate table, and there is a gap between the top Opening and the top of the chamber and a material on the substrate table is covered by the wind deflector.

Owner:BOE TECH GRP CO LTD

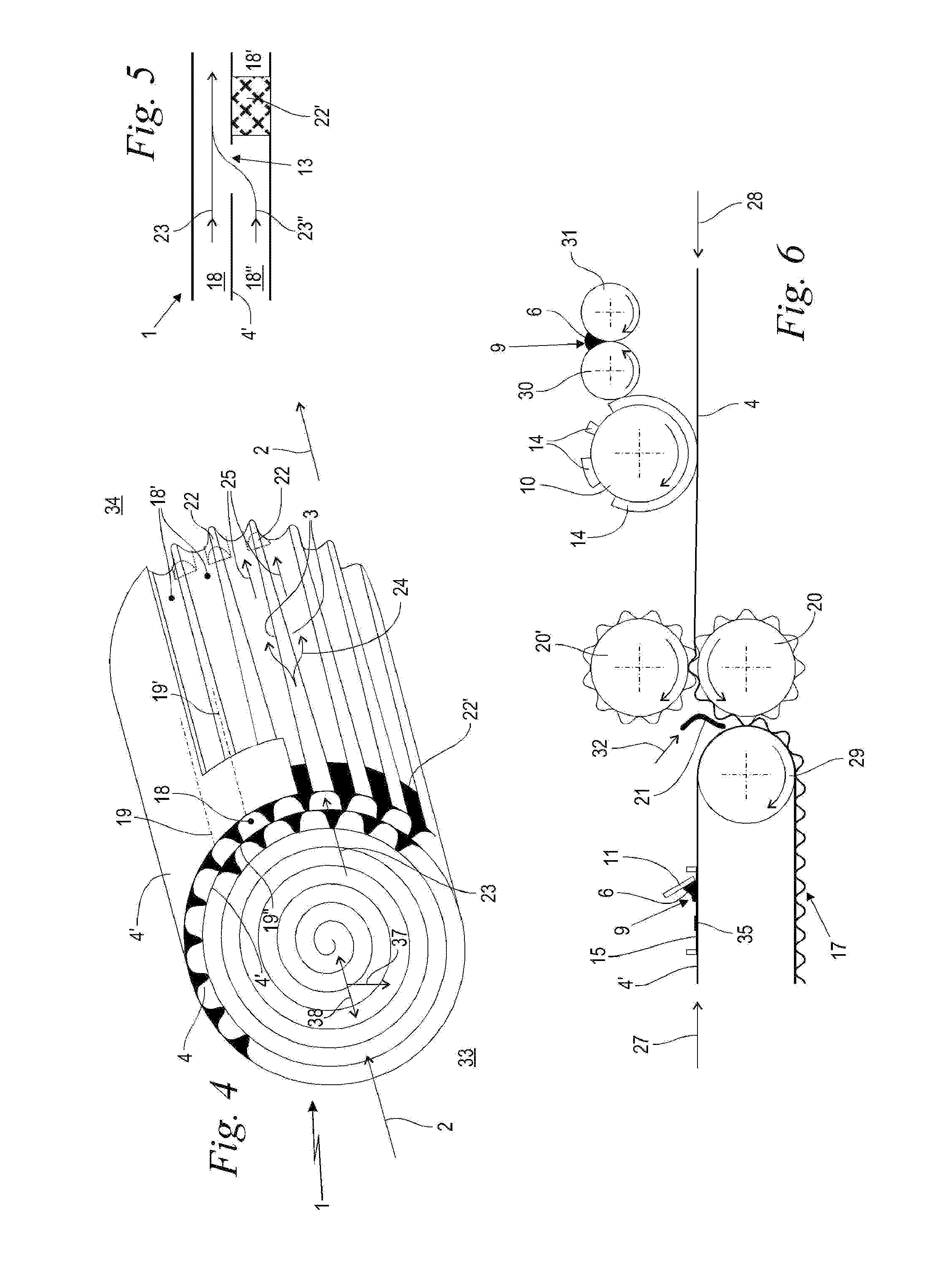

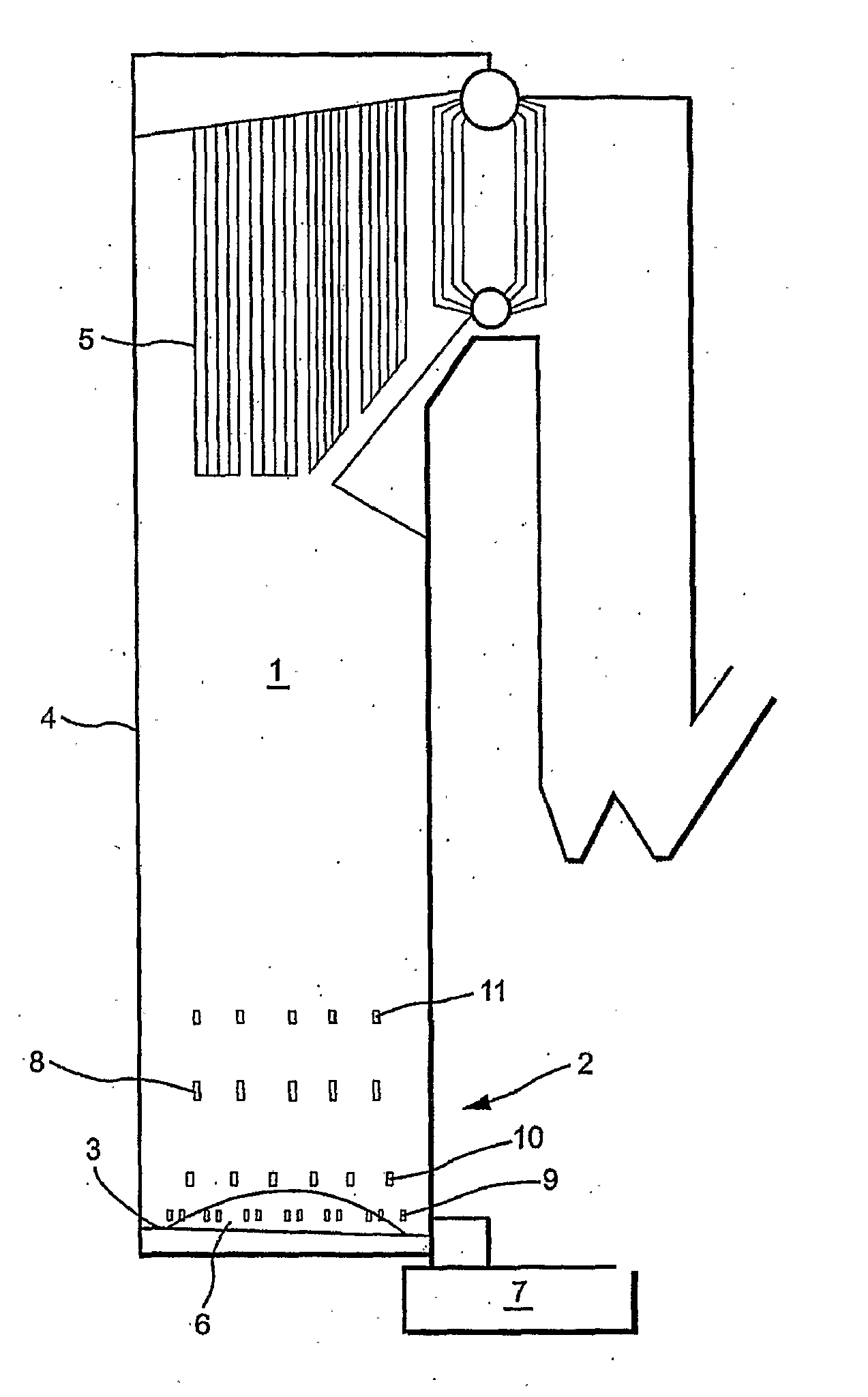

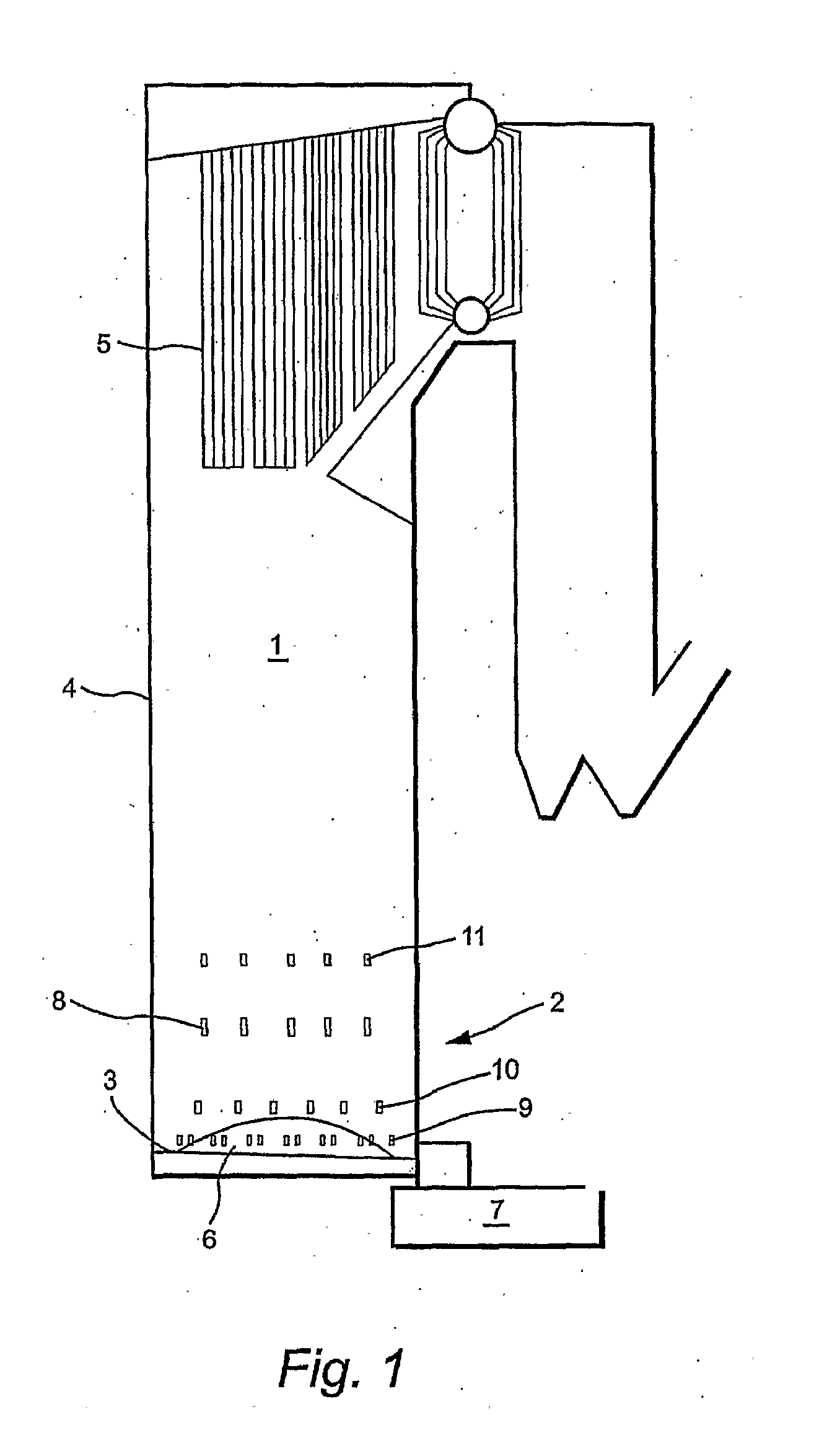

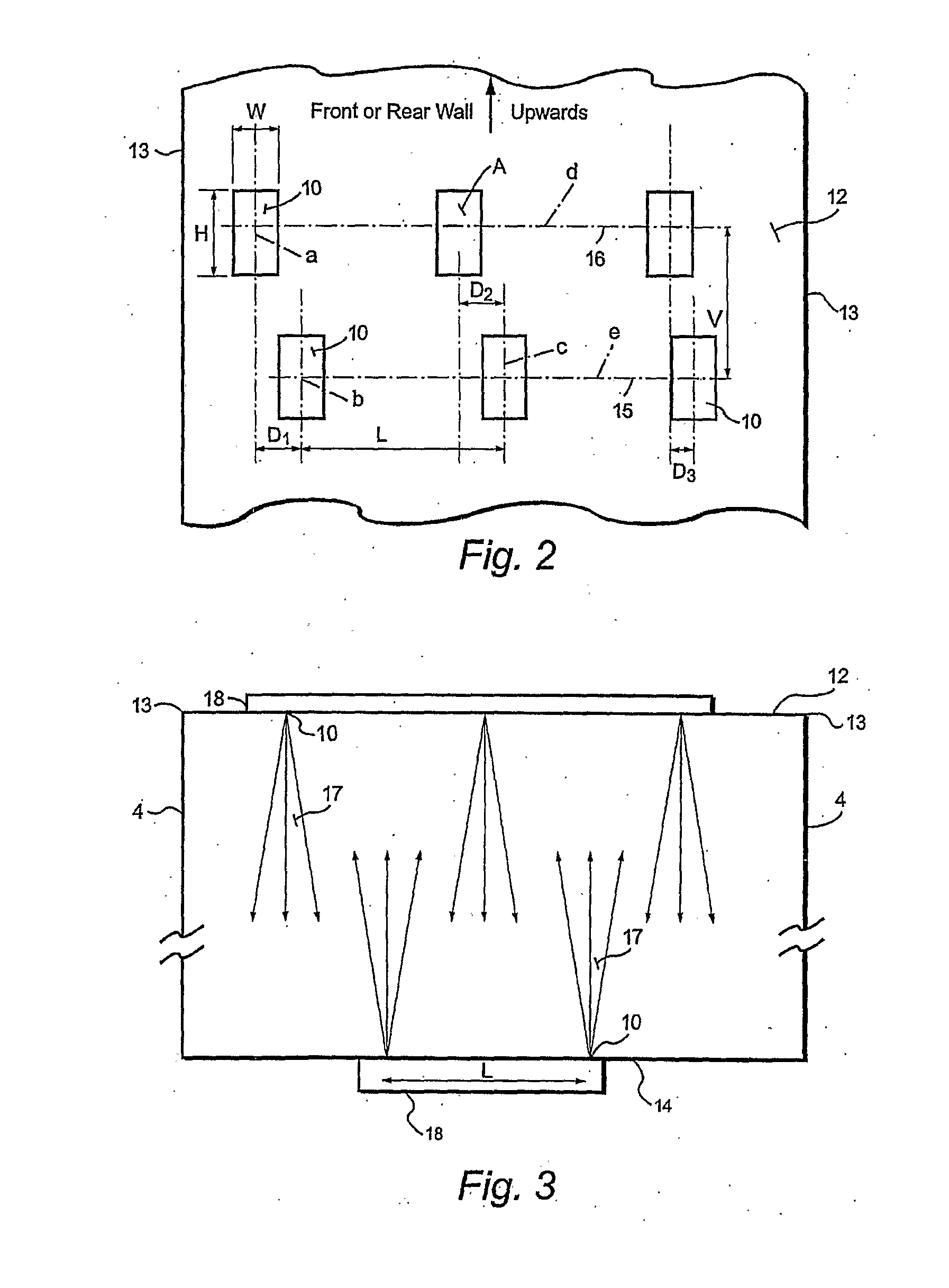

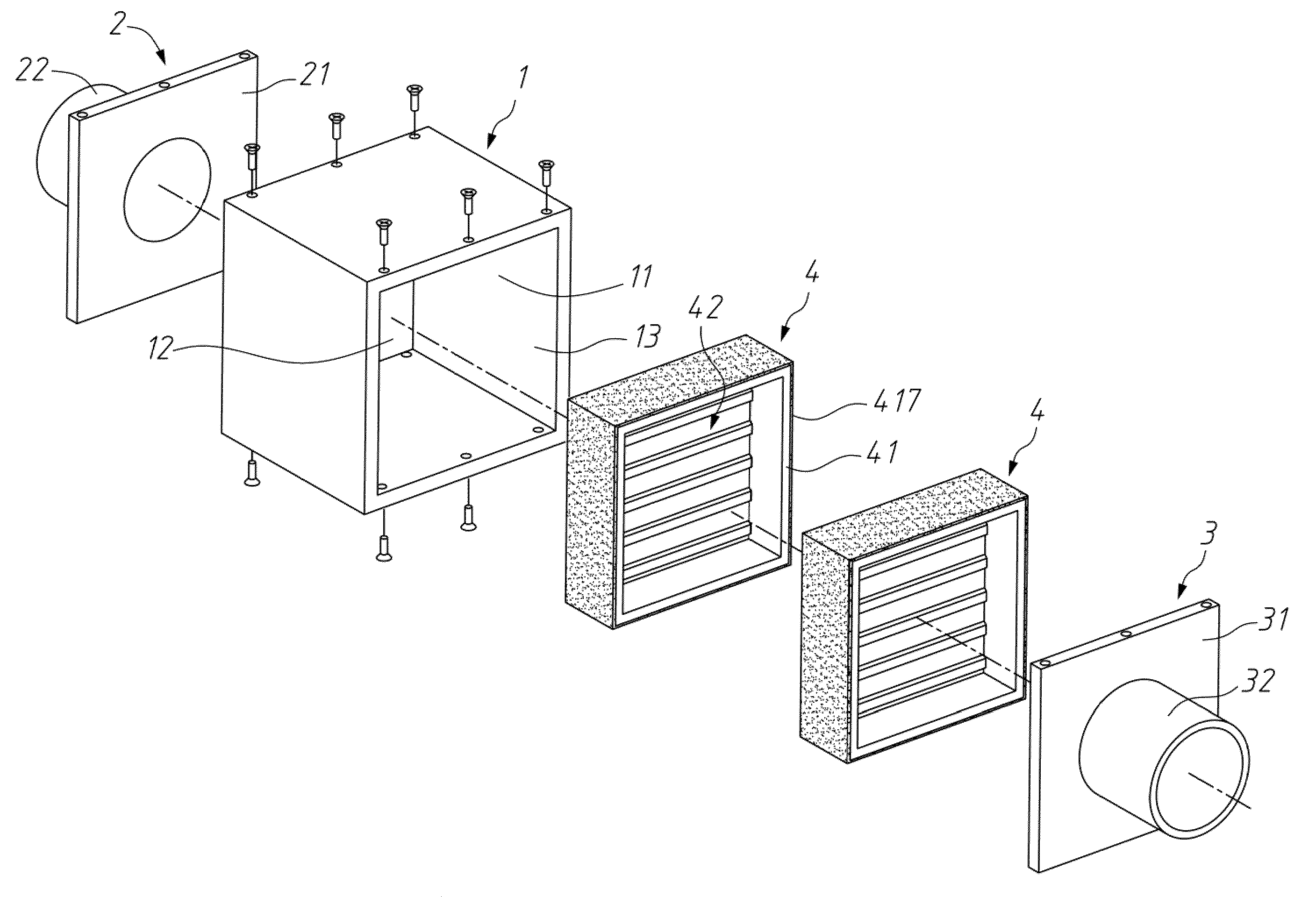

Combustion air system for recovery boilers, burning spent liquors from pulping processes

InactiveUS20100101463A1Reduce the amount requiredIncrease speedPulp liquor regenerationCasings/liningsLiquid wasteBlack liquor

An arrangement is disclosed for supplying an air jet form to the furnace of a recovery boiler, where the furnace has a front wall, a rear wall and side walls. Black liquor spraying devices are disposed on the furnace walls on one or several levels of the furnace. A plurality of air ports are located at several horizontal elevations for introducing air into the furnace from an air supply. In the arrangement for the secondary air flows, at least two horizontal air levels at different elevations are arranged above the lower primary levels and below the black liquor sprayer. Secondary air is supplied from two opposite walls. The secondary air ports on each of said first and second horizontal elevations comprise air ports for each horizontal elevation that project a pattern of large air jets into the furnace from said opposite walls and said secondary air ports further comprise a plurality of secondary air ports on at least one of the elevations that project smaller air jets into the furnace.

Owner:ANDRIZ OY

Backflow prevention device for bathroom air duct

InactiveUS20100099348A1Guaranteed uptimeAvoid problemsLighting and heating apparatusSpace heating and ventilation detailsBackflow prevention deviceEngineering

A backflow prevention device is connected to a bathroom air duct and includes a case having two opposite gas inlet-end opening and gas outlet-end opening; a gas inlet-end unit and a gas outlet-end unit respectively mounted to and communicating with the gas inlet-end opening and the gas outlet-end opening; and at least one backflow prevention unit mounted in the case. The backflow prevention unit includes a frame and a plurality of baffle plates pivotally mounted in the frame. The baffle plates are arranged in the frame from top to bottom to overlap with each other, and can be pivotally turned only in one way toward the gas outlet-end opening to an open position. Thus, gas in a bathroom is allowed to flow from the gas inlet-end opening to the gas outlet-end opening, while gas with bad odor in a public pipe shaft is prevented from flowing back into the bathroom.

Owner:WU JEN CHI +1

Method of venting a spray metal mold

ActiveUS7350558B2Prevent spray metal buildupAvoid depositionFoundry mouldsMoulding machinesMetallurgyMetal mold

Owner:GENIUS SOLUTIONS ENG

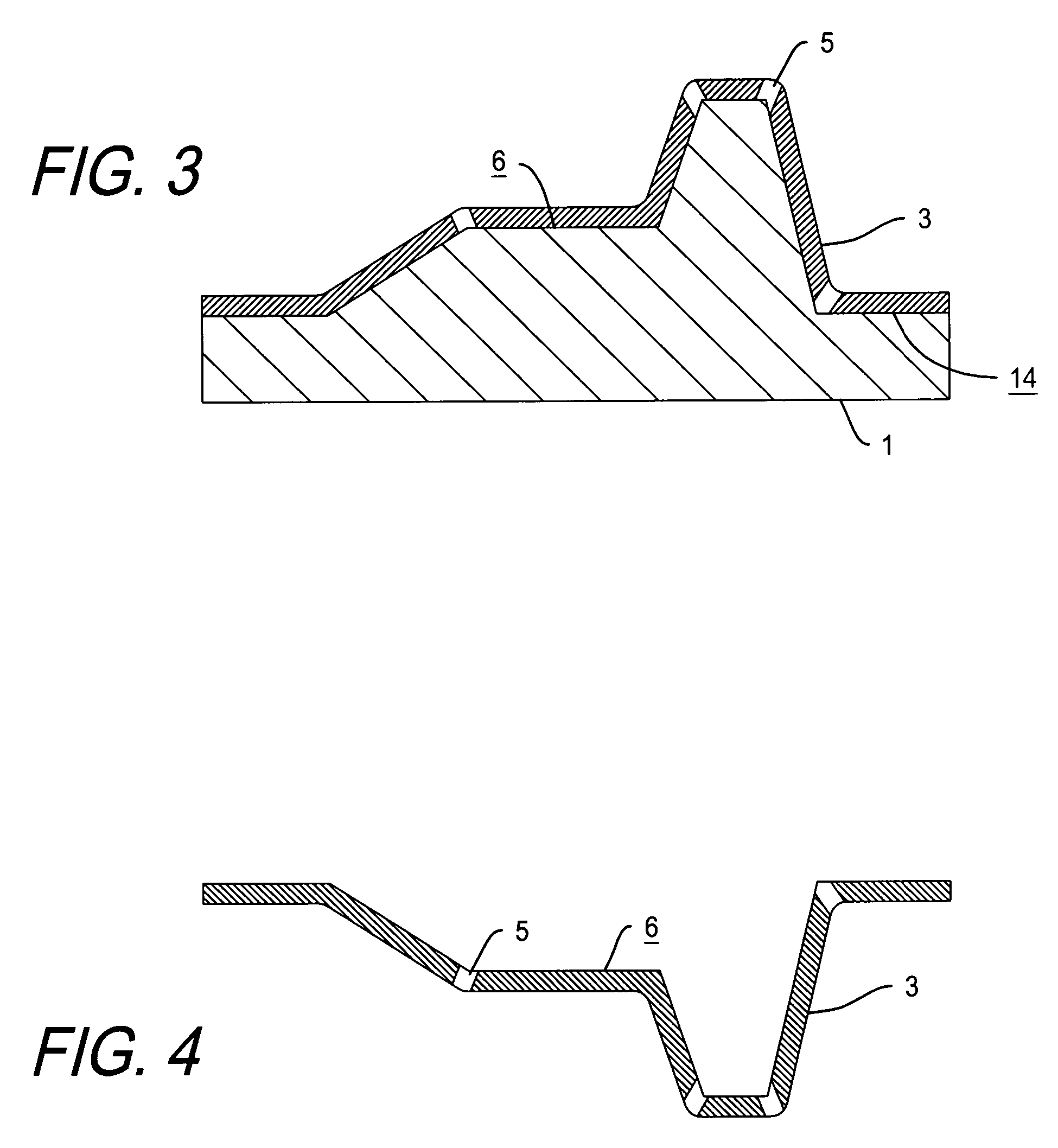

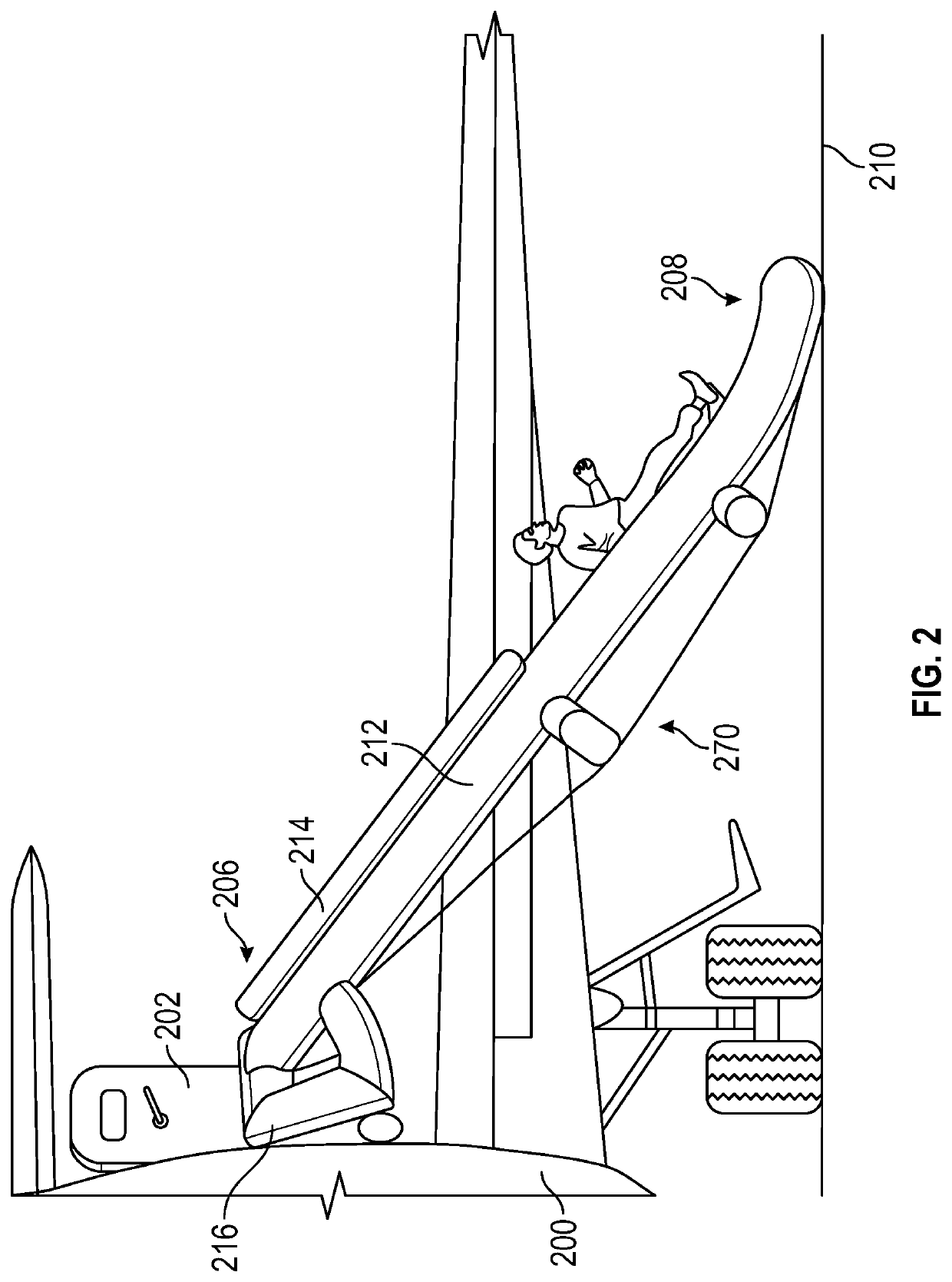

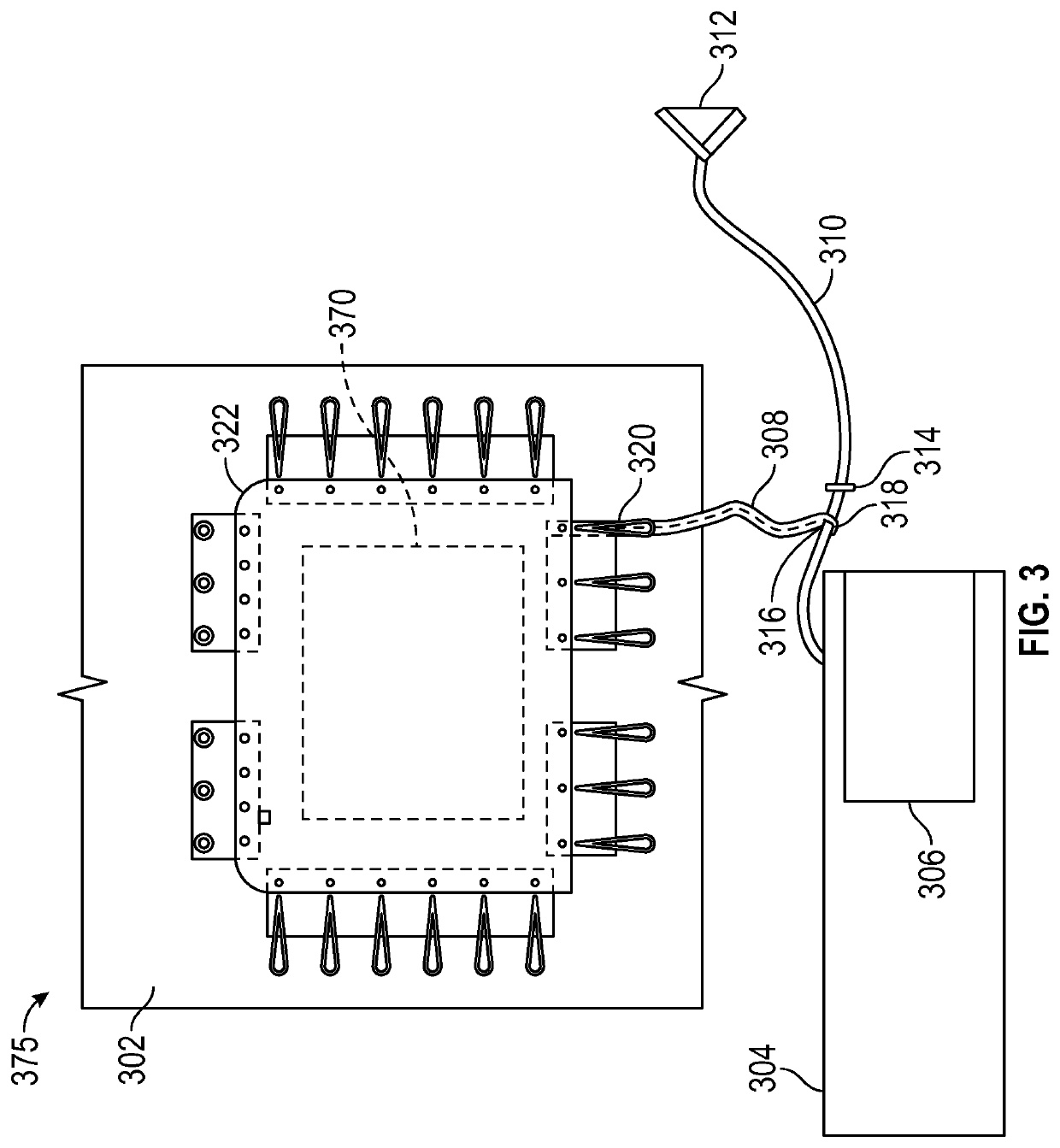

Solenoid-operated pressure-regulator modules for inflation systems and methods thereof

ActiveUS11119516B2Prevent openingInhibit gas flowAircraft ejection meansFluid pressure control using electric meansValve actuatorControl theory

Solenoid-operated pressure-regulator modules, aircraft inflatable slide assemblies, and methods for assembling solenoid-operated pressure-regulator modules are described. The solenoid-operated pressure-regulator modules include a primary inflation valve, a secondary inflation valve, a secondary valve actuator, a solenoid, an inflatable slide, and a gas source. The solenoid-operated pressure-regulator modules are configured to selectively enable a fluid connection between a gas source and an inflatable slide to enable inflation of the inflatable slide. The primary inflation valve includes a main cavity, a command cavity, an inlet through which a gas enters the main cavity, an outlet, a poppet that controls a gas flow from the inlet to the outlet, and a valve divider separating the main cavity from the command cavity. The secondary inflation valve is fluidly coupled to the outlet of the primary inflation valve. The primary and secondary inflation valves are configured to be simultaneously operated by operation of the solenoid.

Owner:THE BF GOODRICH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com