Patents

Literature

57results about How to "Avoid vibration and noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

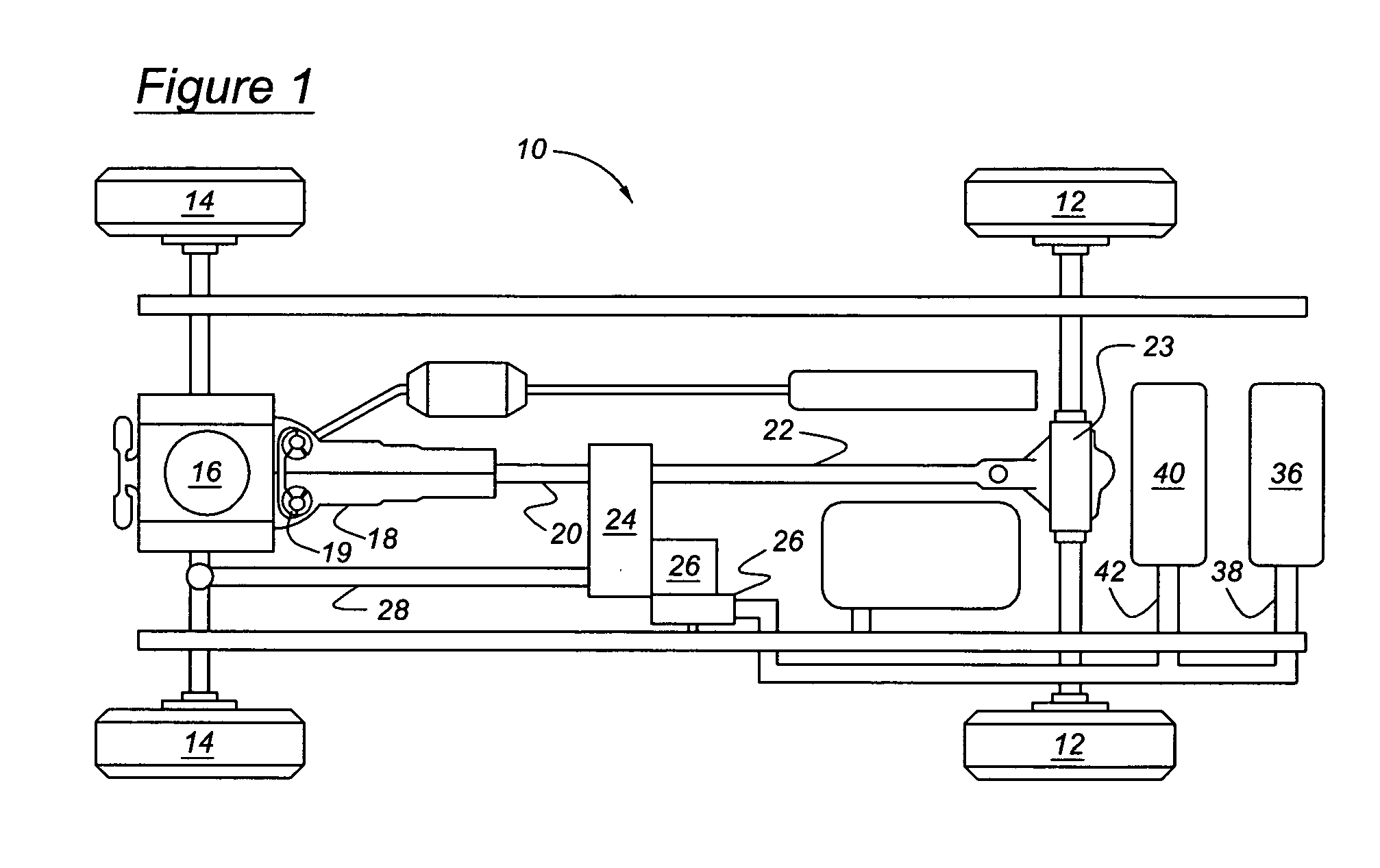

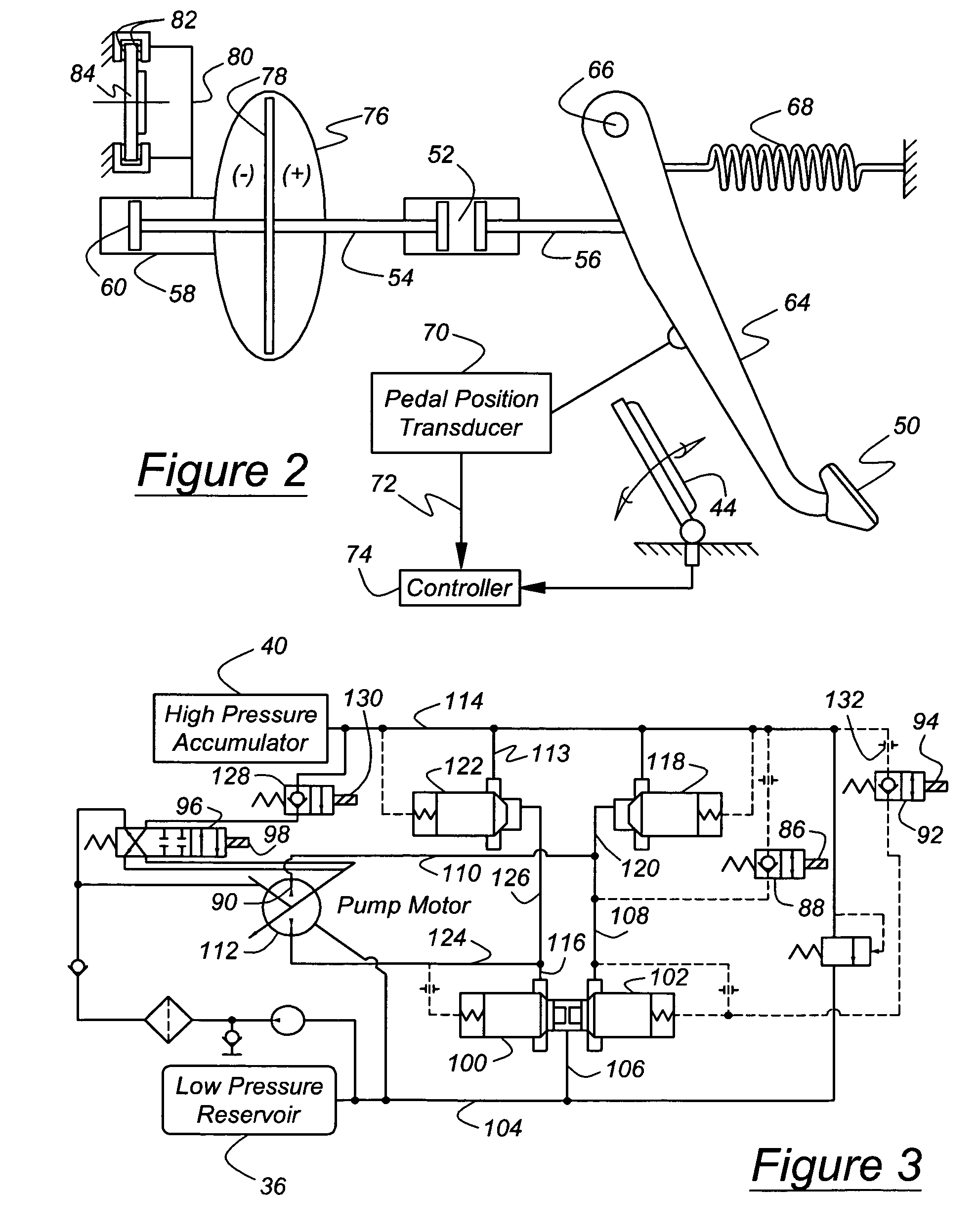

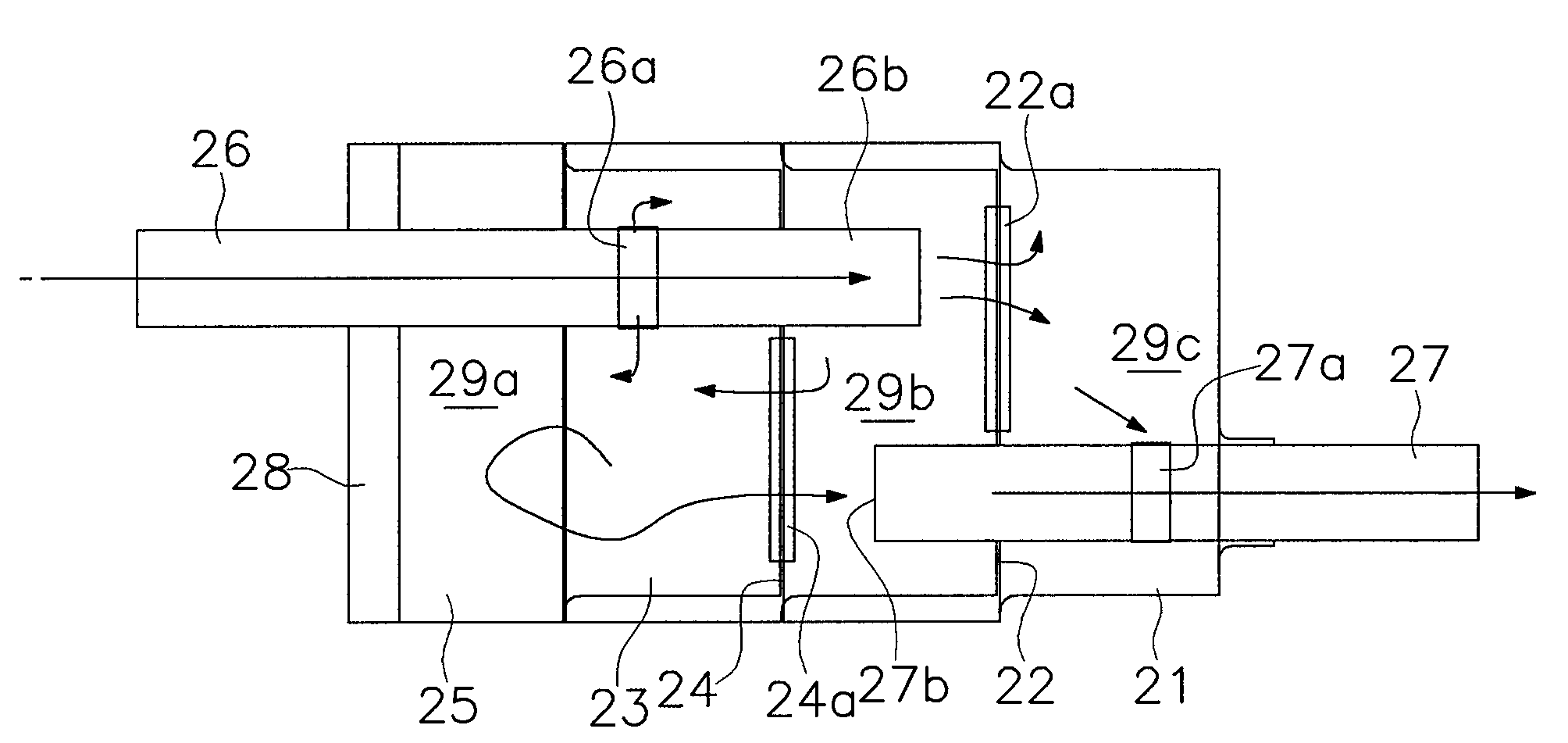

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS7082757B2Avoid vibration and noiseSlow pressureAuxillary drivesBraking element arrangementsMobile vehicleTransmitted power

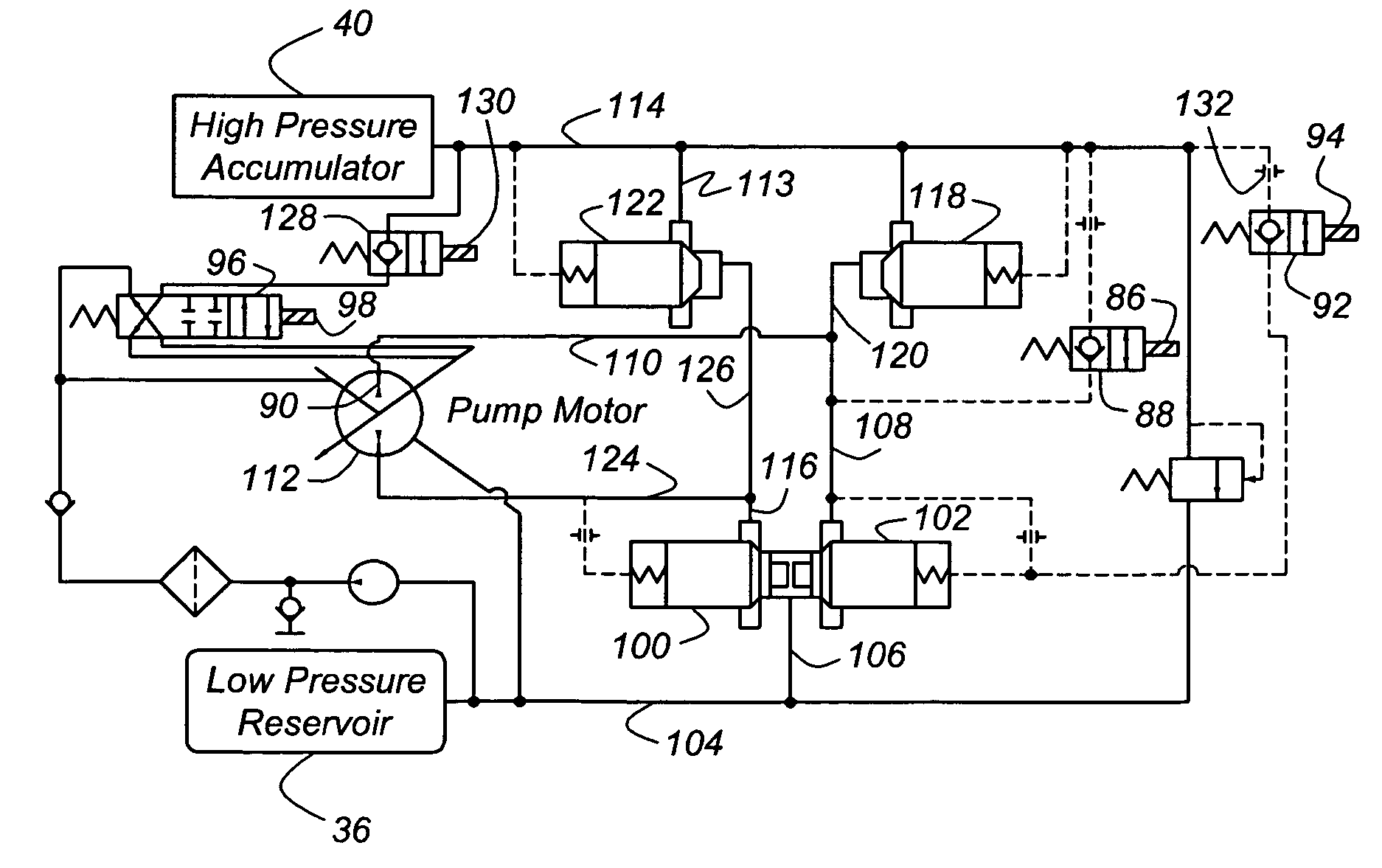

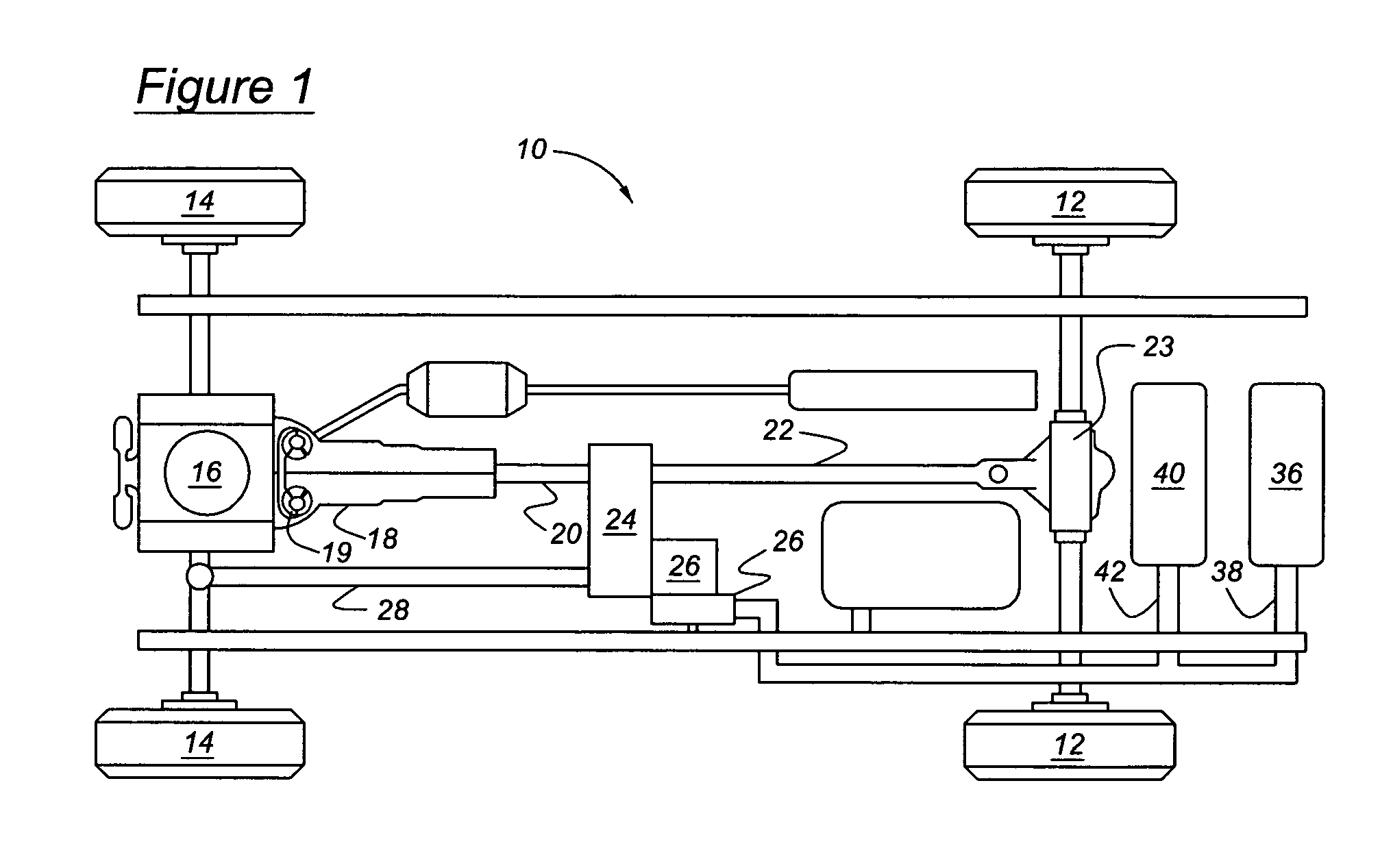

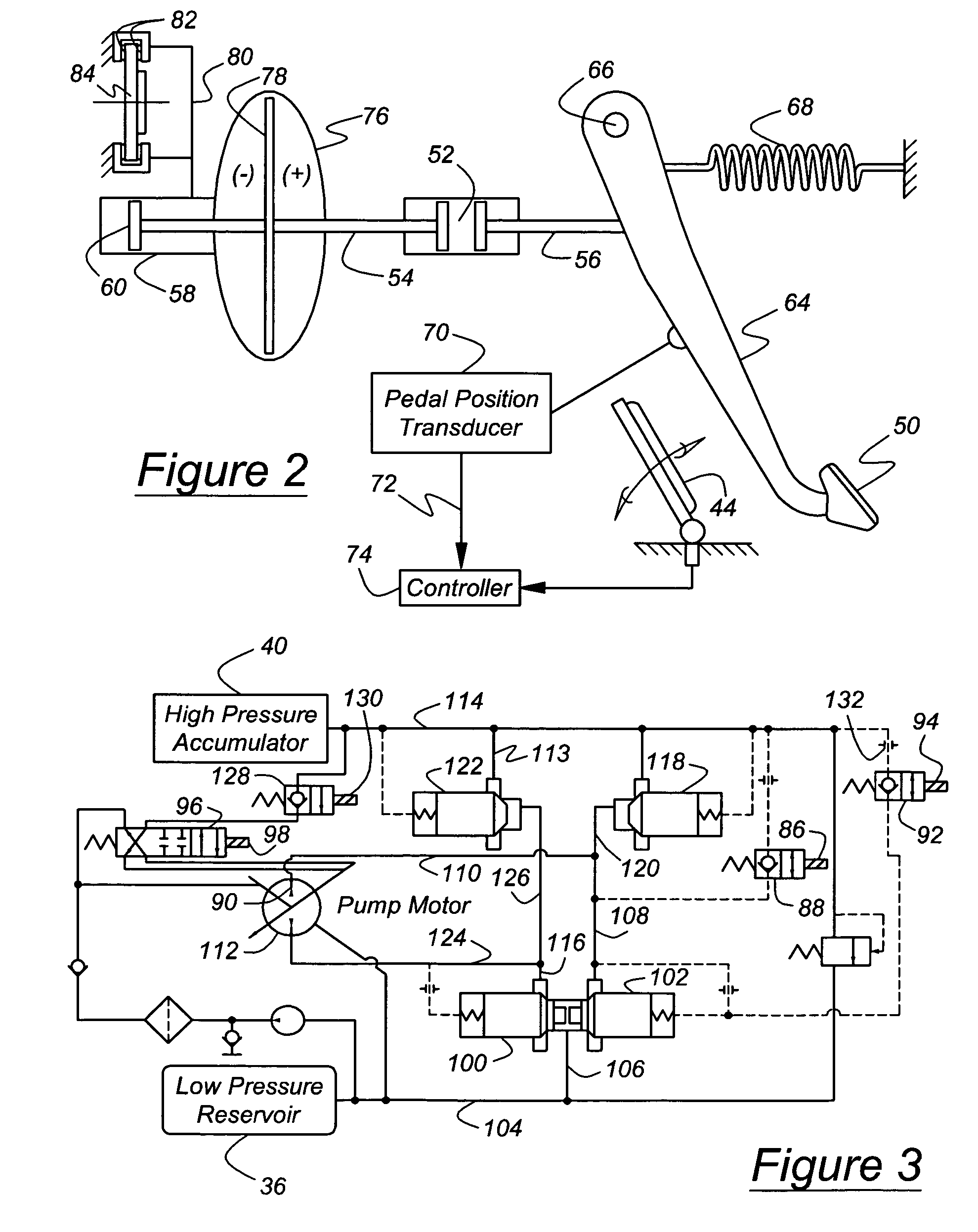

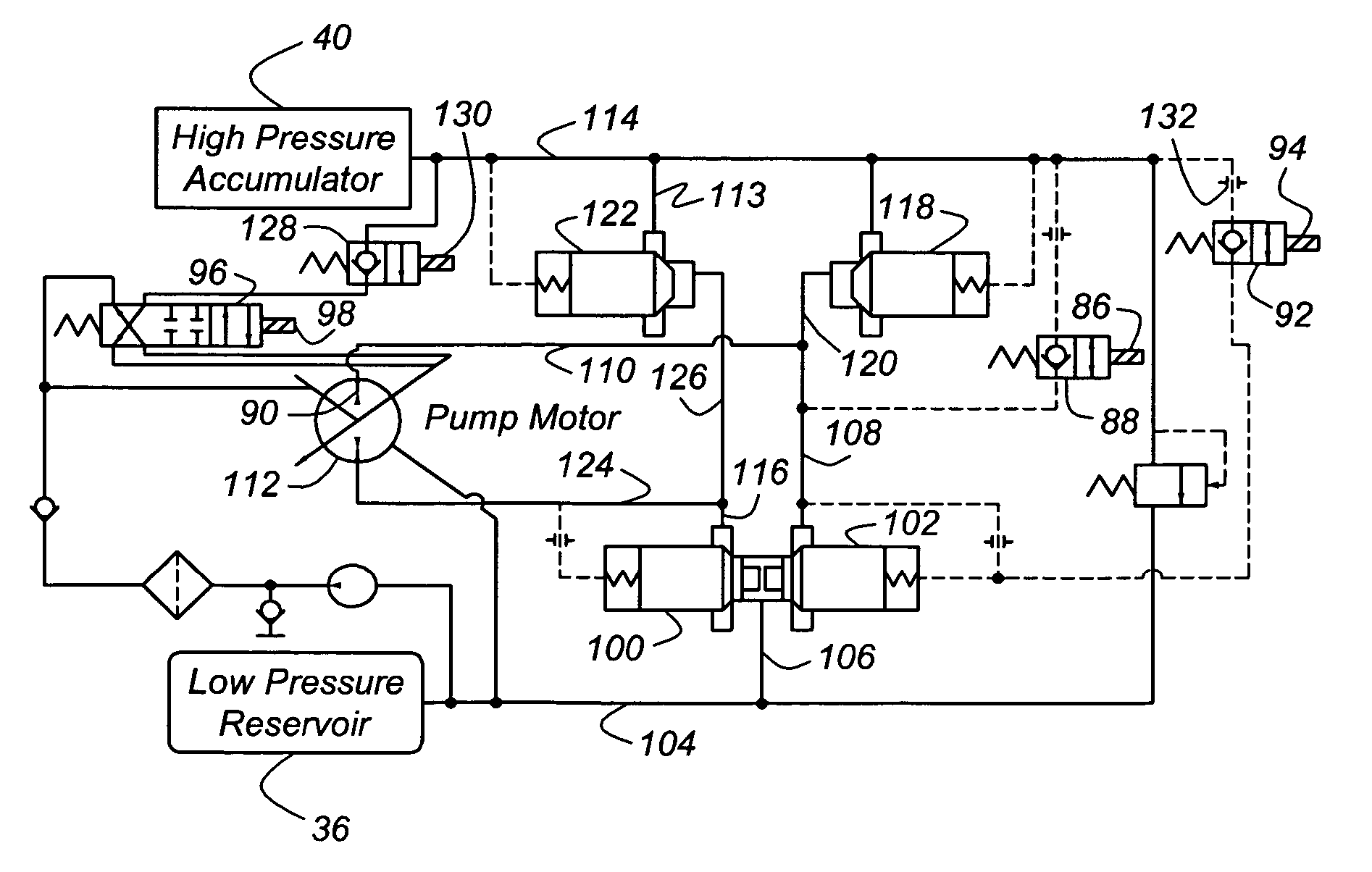

A system for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation.

Owner:FORD GLOBAL TECH LLC

Pump/motor operating mode switching control for hydraulic hybrid vehicle

ActiveUS20060000208A1Slow pressureAvoid cavitationAuxillary drivesBraking element arrangementsTransmitted powerEngineering

A system according to this invention for transmitting power hydraulically to and from the wheels of a motor vehicle includes an accumulator containing fluid at relatively high pressure, a reservoir containing fluid at lower pressure, and a pump / motor driveably connected to the wheels and having an inlet, an outlet, and a variable volumetric displacement for pumping fluid between the accumulator and the reservoir. A first circuit connects the inlet to the reservoir and the outlet to the accumulator. A second circuit, which connects the inlet to the accumulator and the outlet to the reservoir, includes a first path having a low flow rate capacity, a second path having a higher flow rate capacity. A controller switches between pumping operation and motoring operation, opens and closes the first path during motoring operation, and reduces the displacement before switching between pumping operation and motoring operation. The first path includes a first valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a first orifice arranged in series with the first valve having a relatively low flow rate capacity. The second path, arranged in parallel with the first path between the accumulator and the inlet, includes a second valve responsive to the controller for opening and closing a connection between the accumulator and the inlet, and a second orifice arranged in series with the second valve having a higher flow rate capacity than that of the first orifice.

Owner:FORD GLOBAL TECH LLC

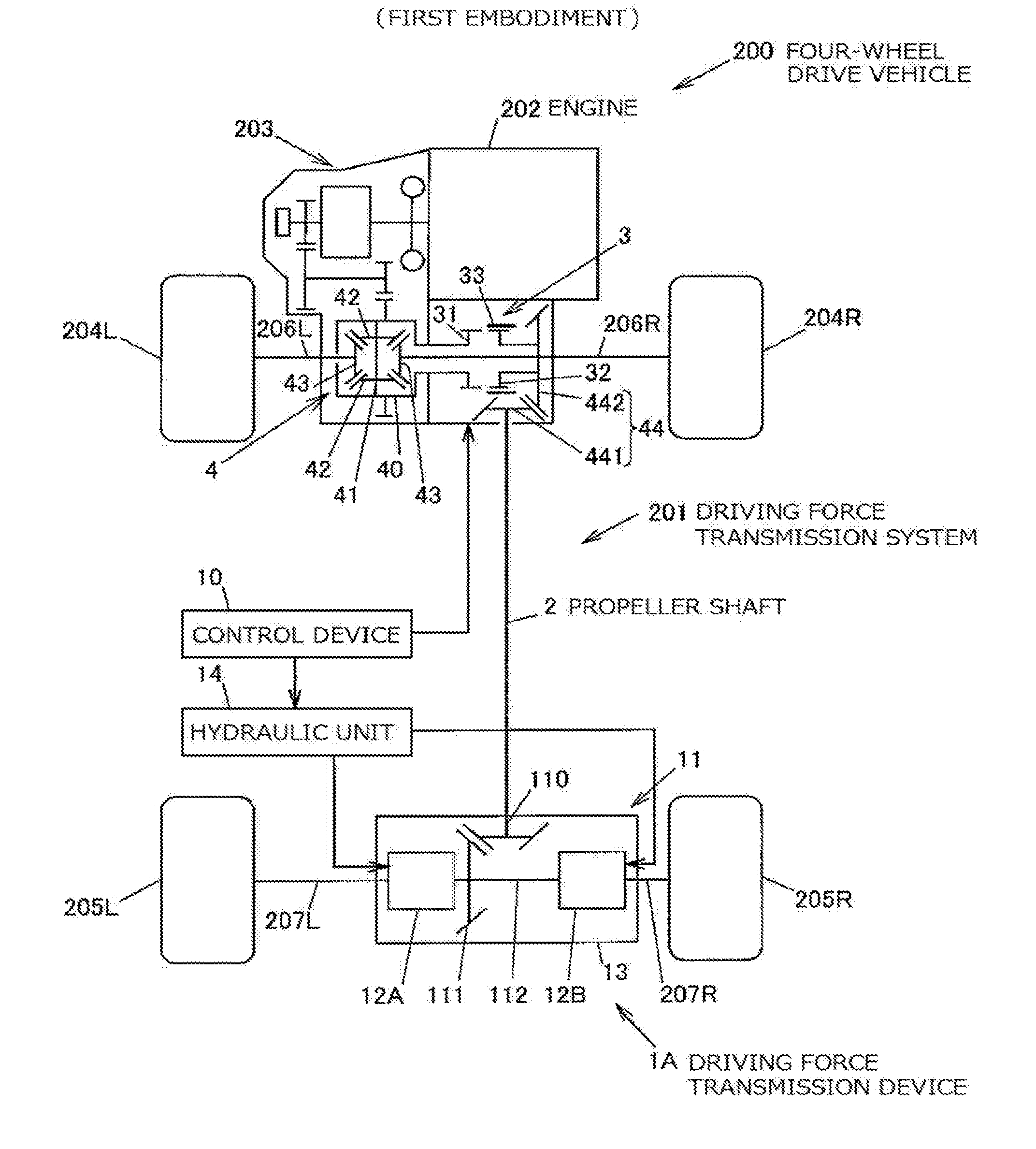

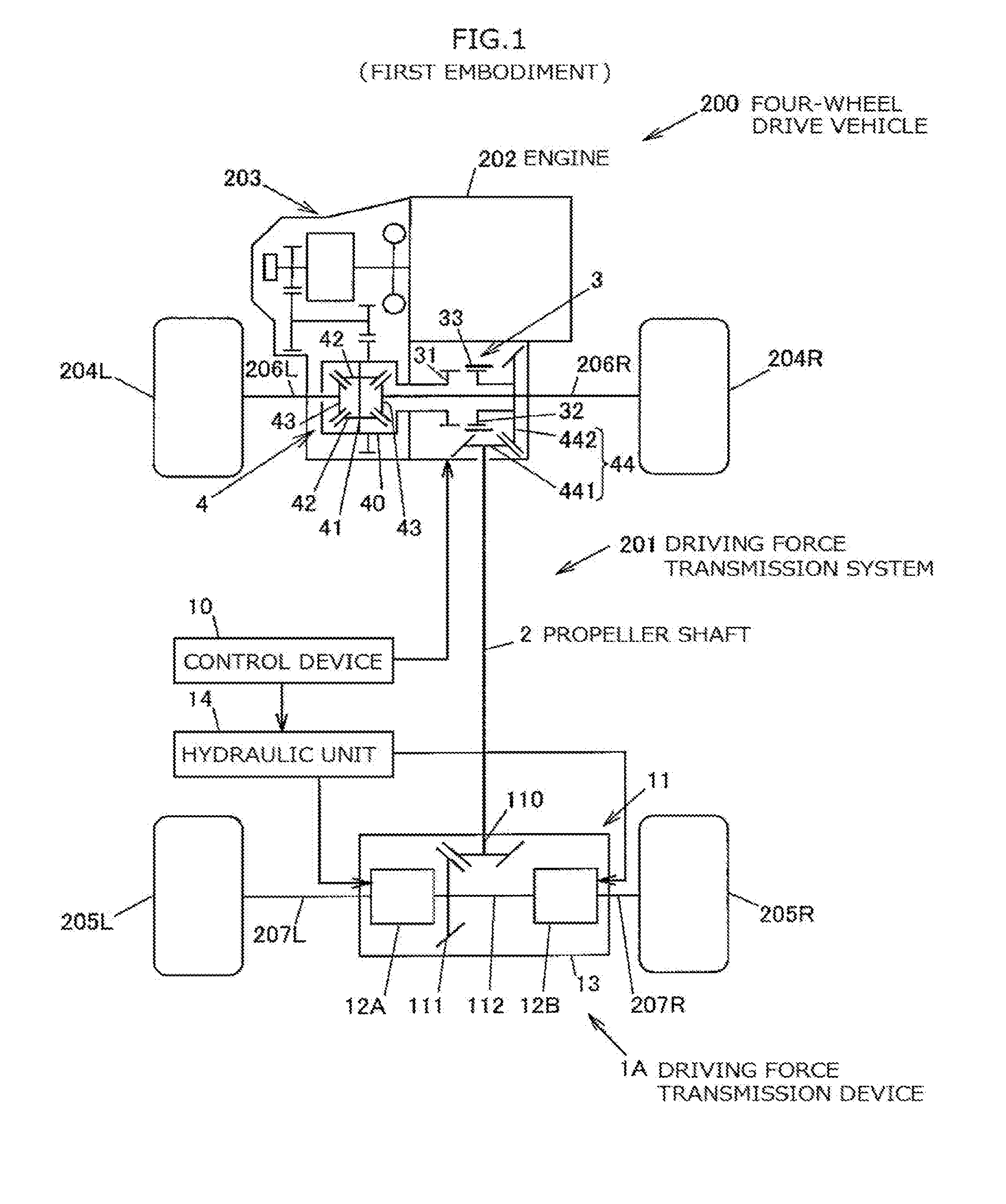

Four-wheel drive vehicle and control device for four-wheel drive vehicle

ActiveUS20160280064A1Avoid vibration and noiseReduced stabilityMechanical actuated clutchesFluid actuated clutchesDrive shaftPropeller

Provided is a control device for a four-wheel drive which can maintain driving stability while restraining noise and vibration. A control device includes: a second control device that, when at least one of front wheel has slipped, engages a dog clutch after rotating a propeller shaft by a rotational force transmitted via first and second friction clutches; and a third control device that, if a predetermined condition is satisfied when the front wheels are not slipping, engages the dog clutch after rotating the propeller shaft by the rotational force transmitted via the first and second friction clutches. The time required to synchronize the dog clutch by the third control device is longer than that required to synchronize the dog clutch by the second control device.

Owner:JTEKT CORP

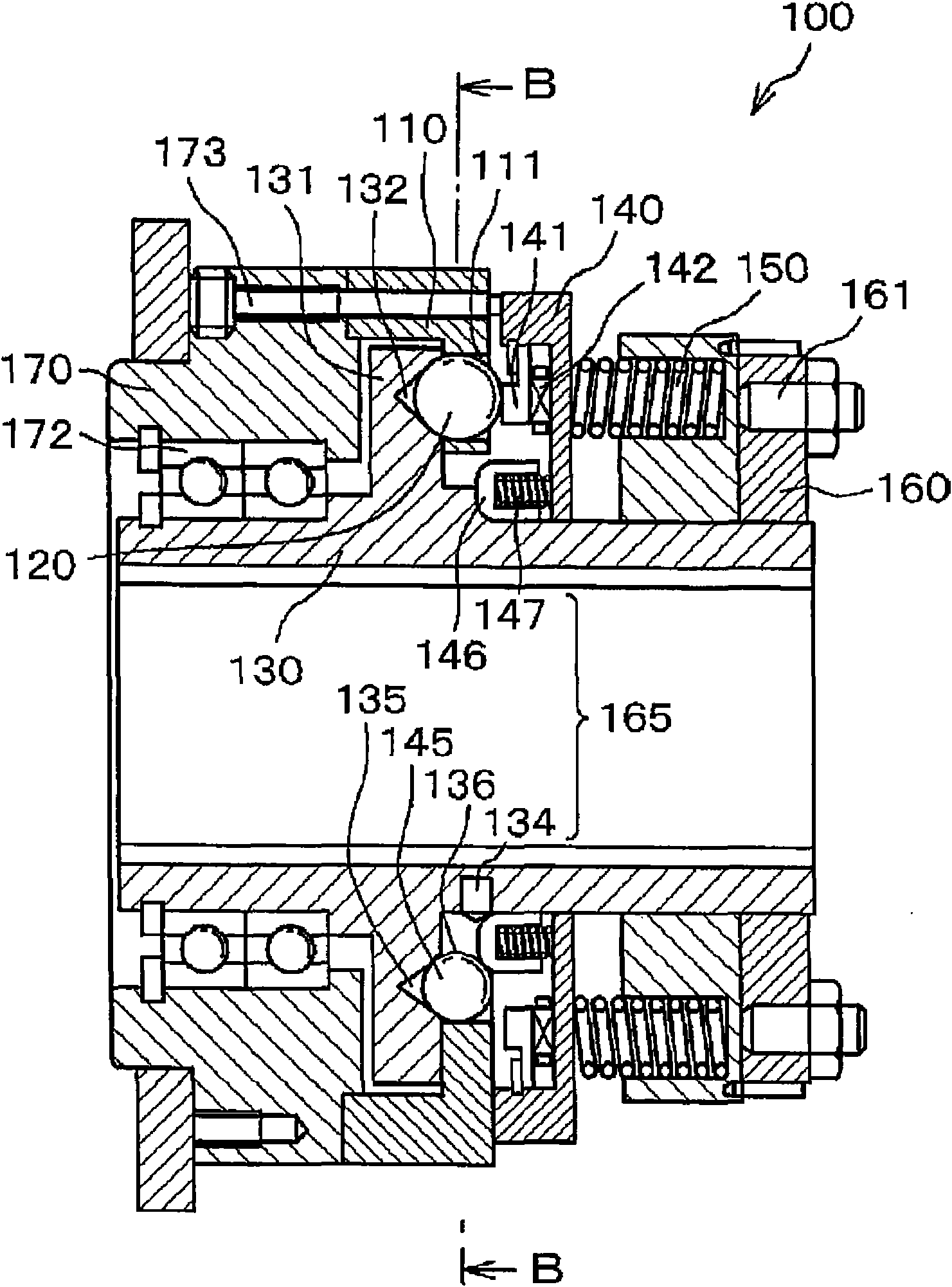

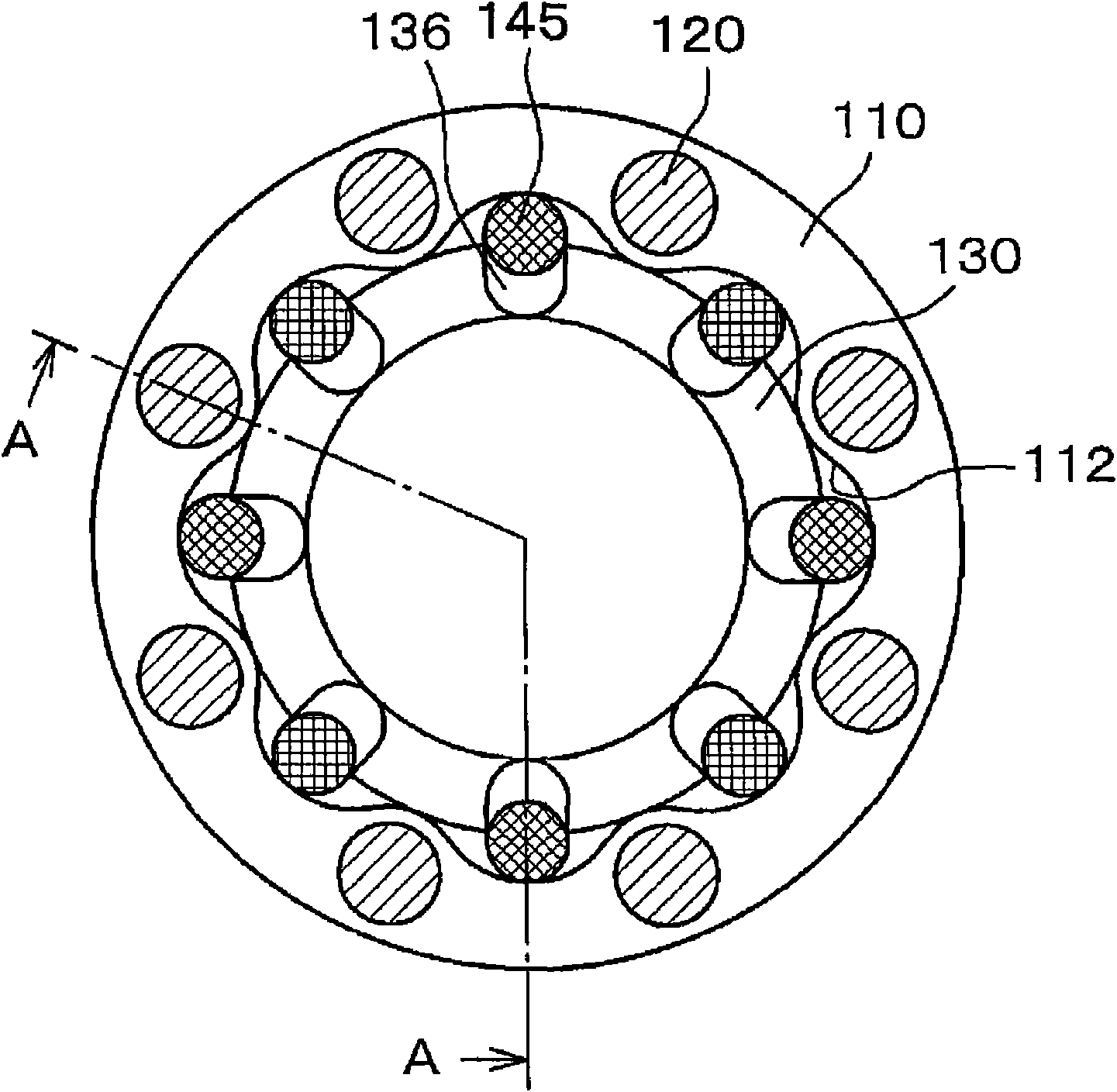

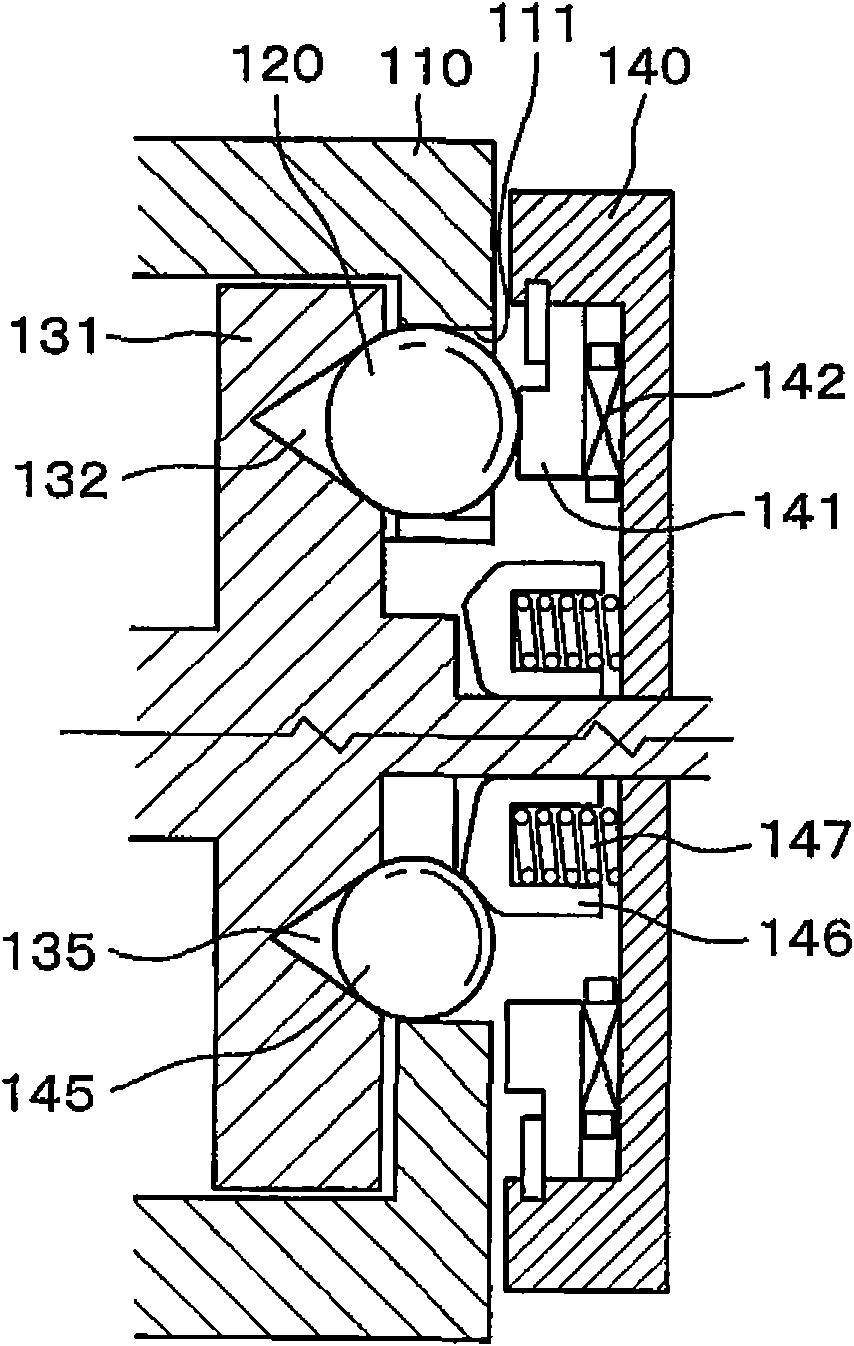

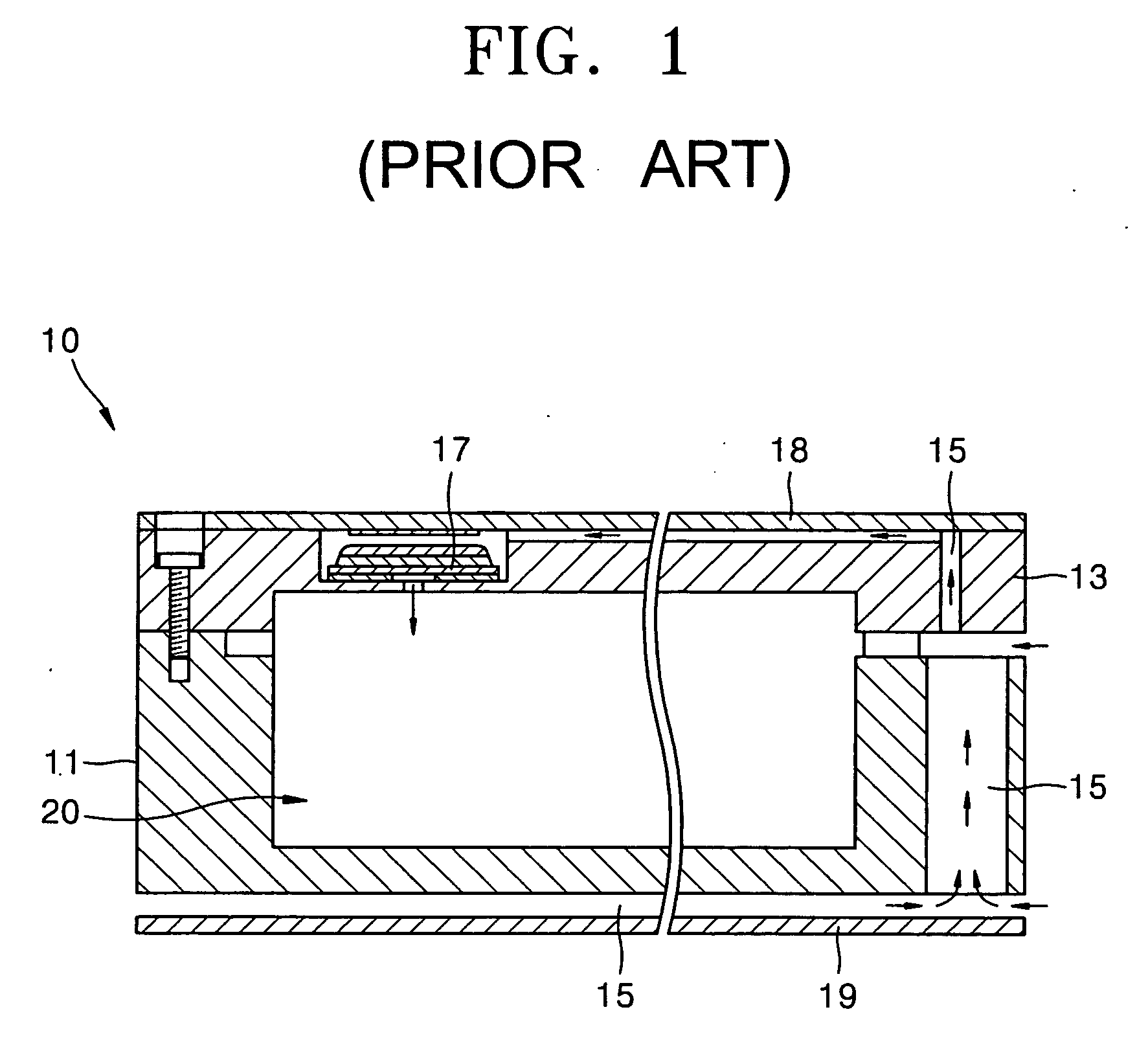

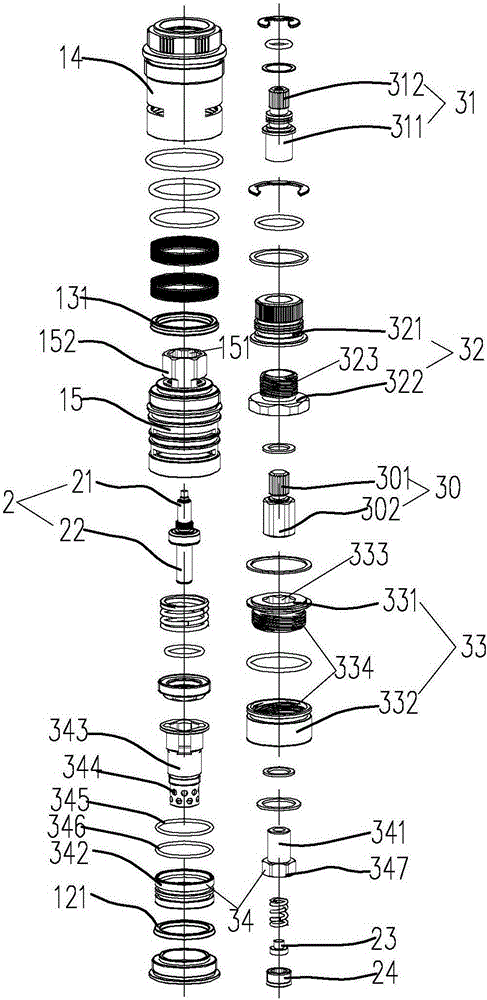

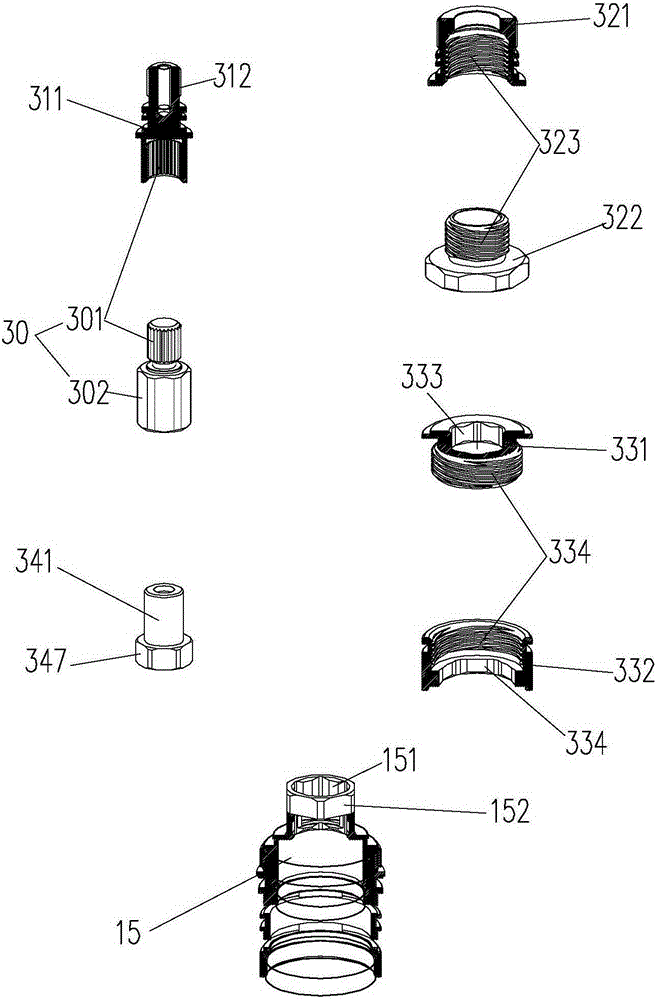

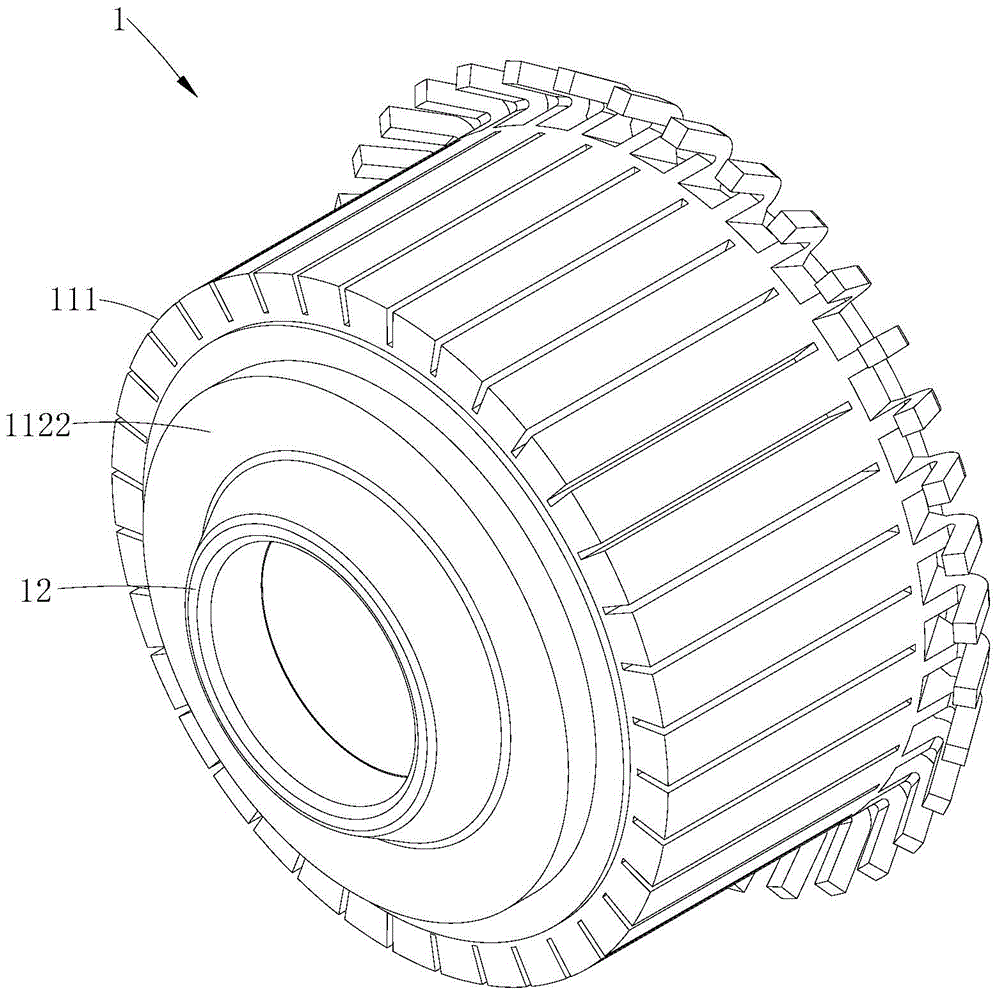

Overload protection device

InactiveCN101561020AAvoid vibration and noiseAccurate working torqueAutomatic clutchesRetaining ringFlange

The invention provides a overload protection device, capable of keeping the rotary drive partition state and preventing from generating the vibration and noise because of the transference the path of the push pressure and accurately setting the operation torque and making a holding mechanism work reliably. the overload protection device has a central flange (110), a hub flange (131) and a push compressed plate for pushing a steel ball (120) to rotate and drive, wherein a holding mechanism (165) for keeping the partition in the over loading comprises a retaining ring (146) mounted at the central flange side of the push pressure plate (140) and a holding ball (145) arranged at the internal circumstance side of the central flange (110).

Owner:TSUBAKI E&M +1

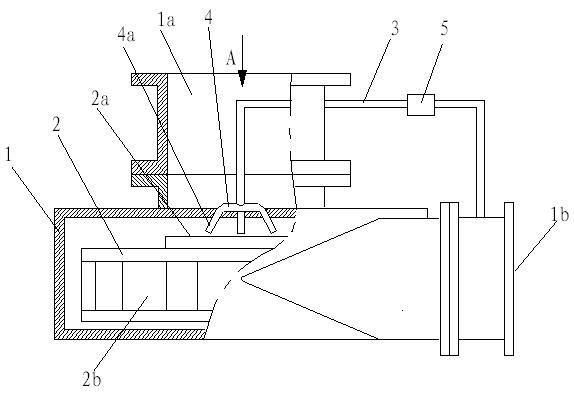

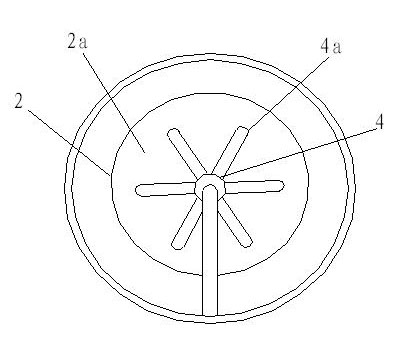

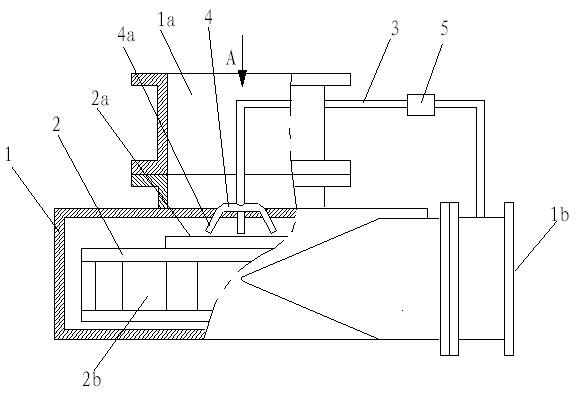

Anti-cavitation centrifugal pump

InactiveCN101968064AAvoid cavitationAvoid vibration and noisePump componentsPumpsCentrifugal pumpCost savings

The invention discloses an anti-cavitation centrifugal pump comprising a pump shell, an impeller and an injecting device, wherein the pump shell is provided with a pump inlet and a pump outlet; the impeller comprises an impeller inlet and an impeller outlet; the injecting device comprises an injecting pipe and a spray nozzle, wherein a liquid inlet of the injecting pipe is communicated with an outlet of the impeller; and the spray nozzle just faces to a low-pressure area of the impeller inlet and is communicated with a liquid outlet of the injecting pipe. In the invention, a small amount of high-pressure water is led back to the impeller inlet, and injected the high-pressure water just facing to the low-pressure area of the impeller inlet through the spray nozzle, the pressure of a high-pressure area and the low-pressure area is enhanced by utilizing smaller fluid amount, the pressure intensity of the low-pressure area of the impeller inlet of the centrifugal pump is effectively increased and the centrifugal pump is prevented from generating cavitation, thereby the vibration and the noise and property reduction of the centrifugal pump and the damage of flow passage components, caused by the cavitation, can be avoided; the invention has small utilization amount of high-pressure liquid by pointedly injecting high-pressure and high-flow liquid and rarely influences the liquid striking amount and the efficiency of the centrifugal pump, thereby ensuring that the centrifugal pump can normally operate; and in addition, the invention has the advantage of using and maintaining cost saving.

Owner:CHONGQING UNIV

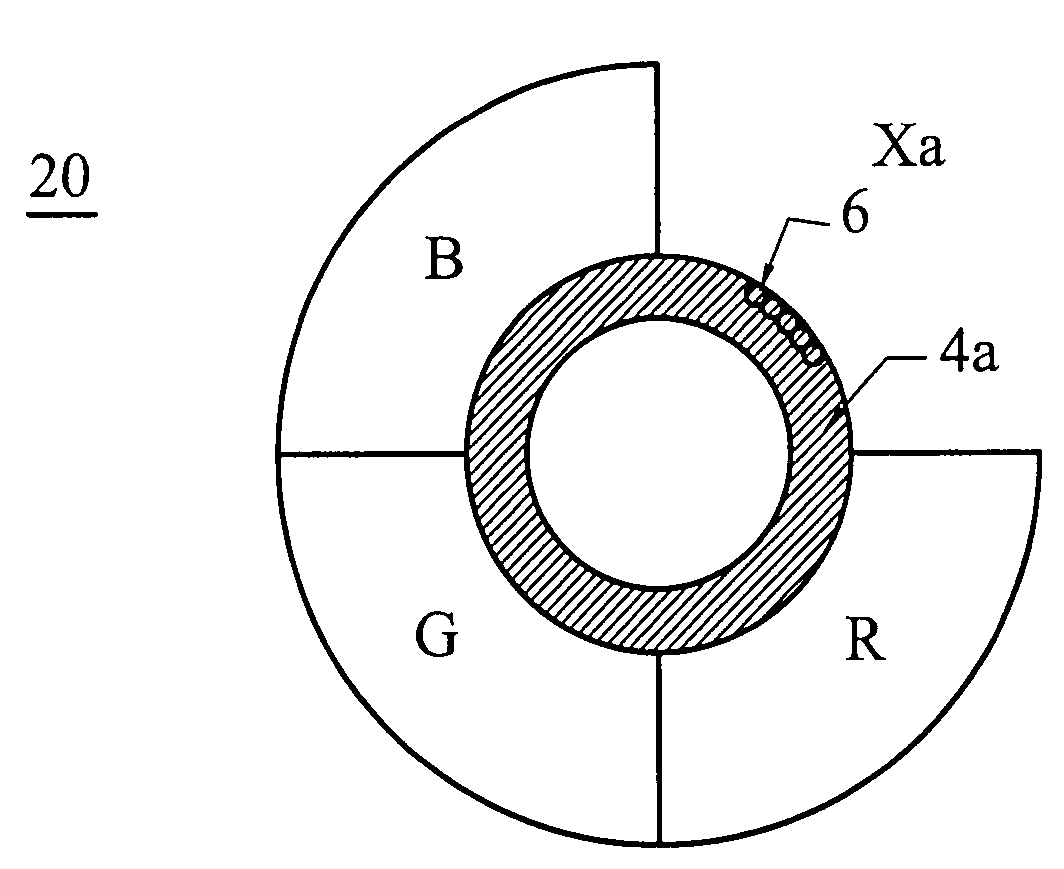

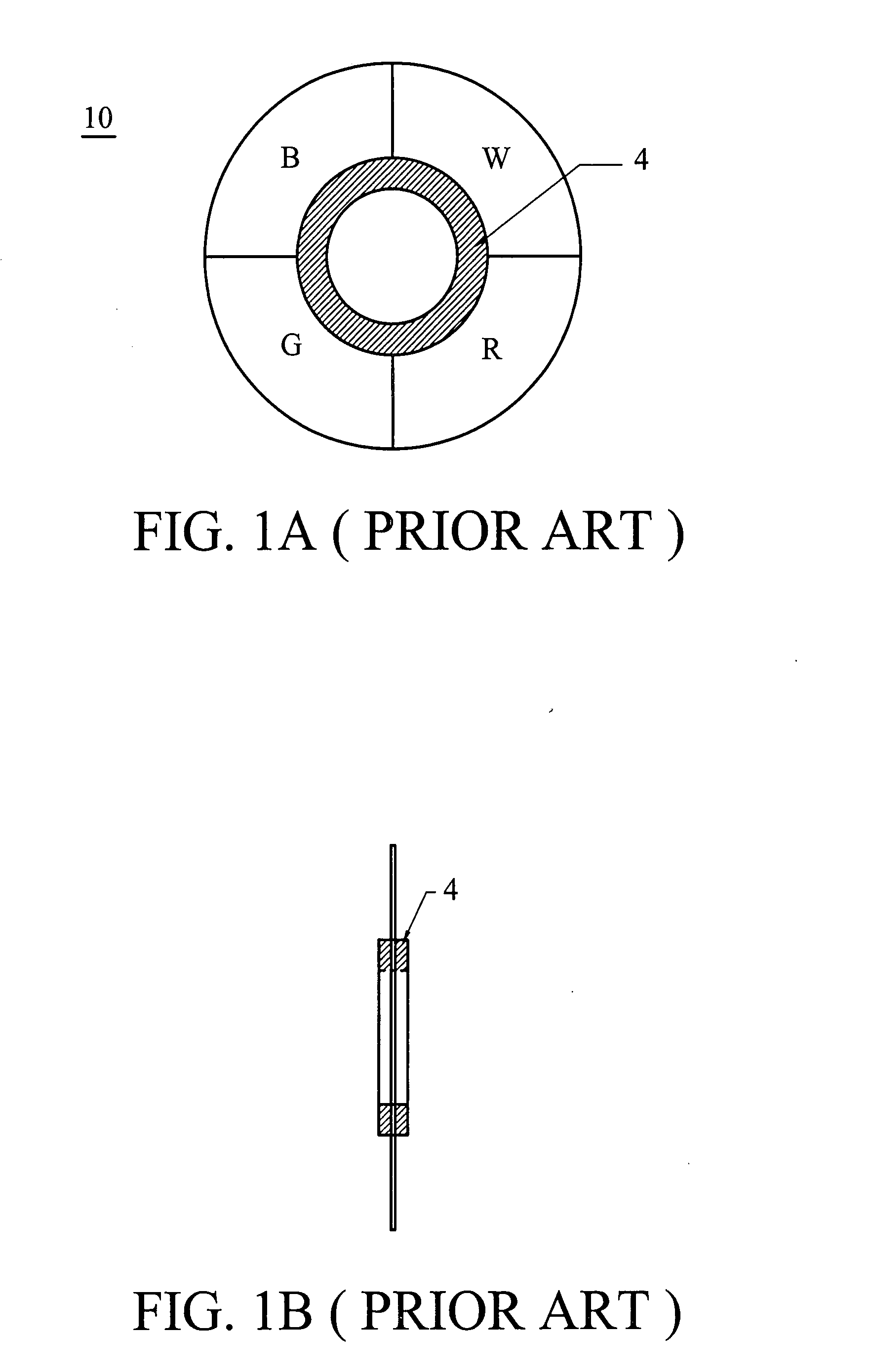

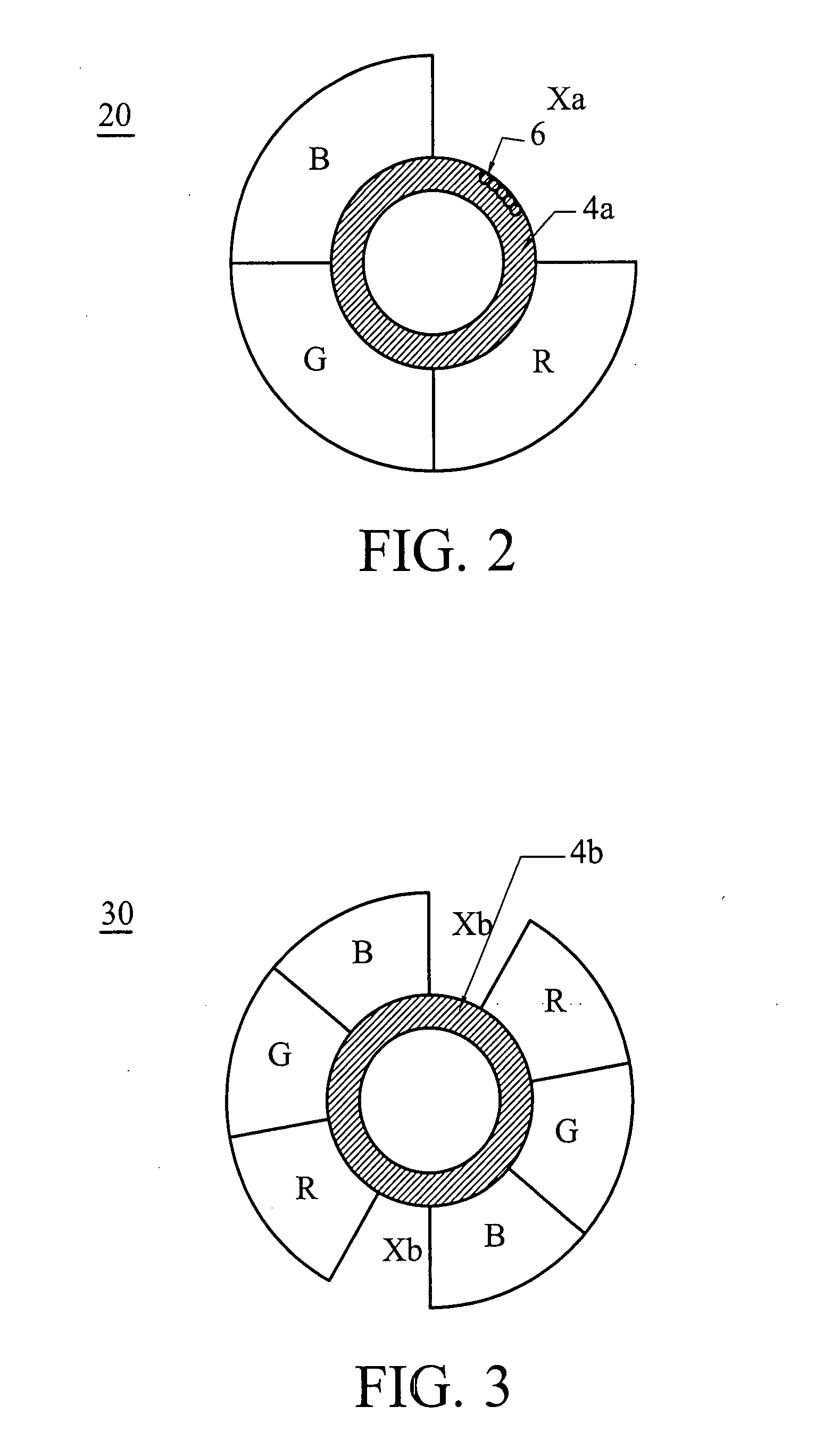

Projection system and color wheel thereof

InactiveUS20070273841A1Increase image brightnessDecrease in light transmission rate can be preventedProjectorsColor photographyLight beamProjection system

A projection system for forming an image, comprising a light source generating light beam; a color wheel used for performing color separation on the light beam of the light source, comprising a motor having a shaft, a carrier pivoted to the shaft of the motor, and a plurality of color filters fixedly disposed at the periphery of the carrier to form at least one gap; and a digital micromirror element used for reflecting the performed filtered light beams of the light source from the color wheel to form the image.

Owner:DELTA ELECTRONICS INC

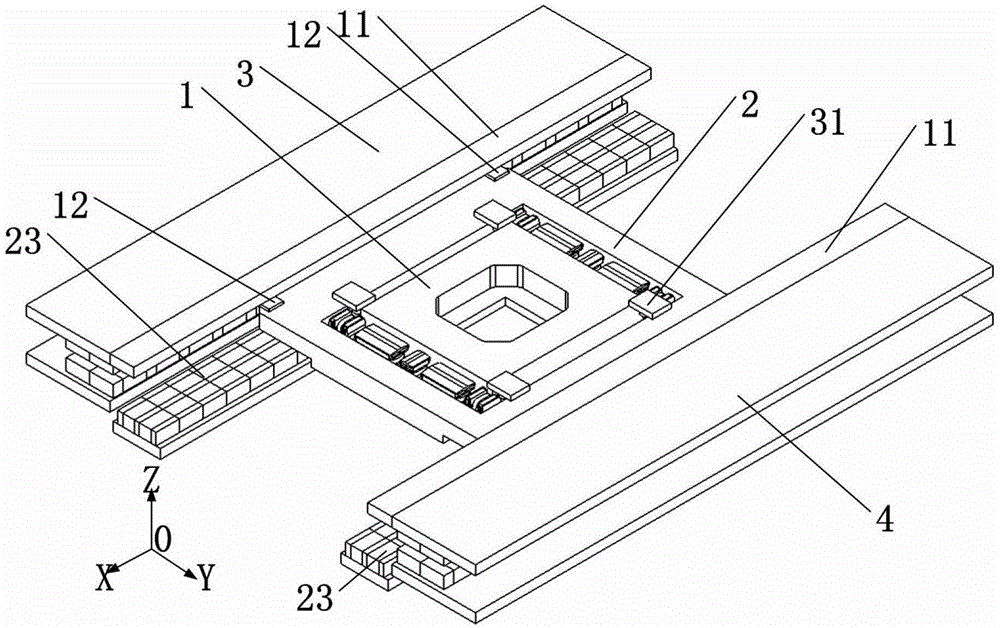

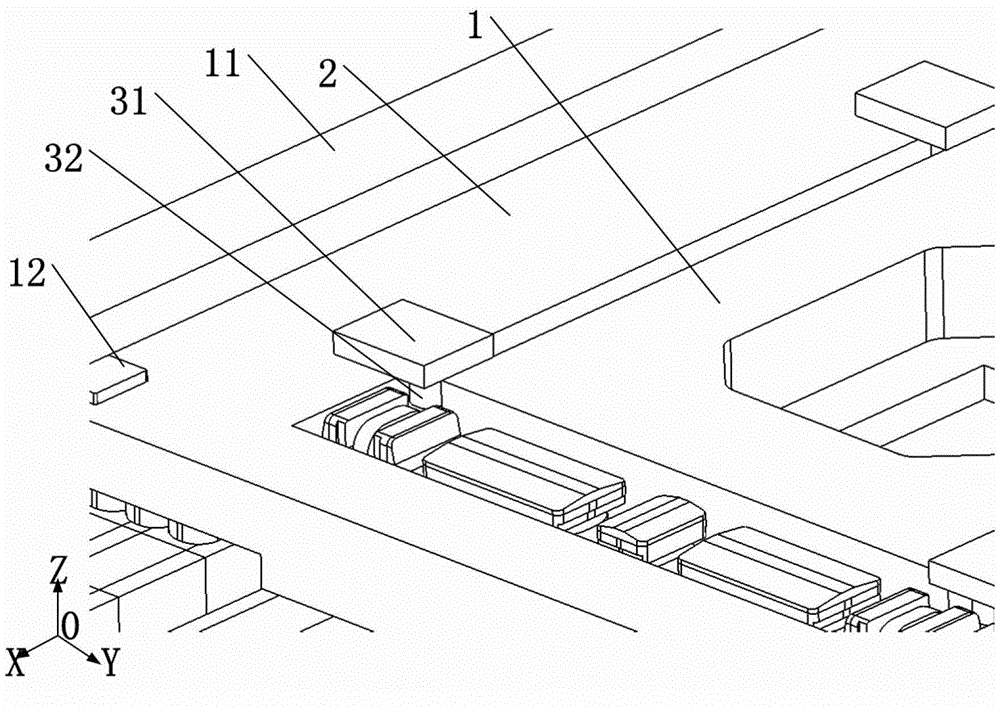

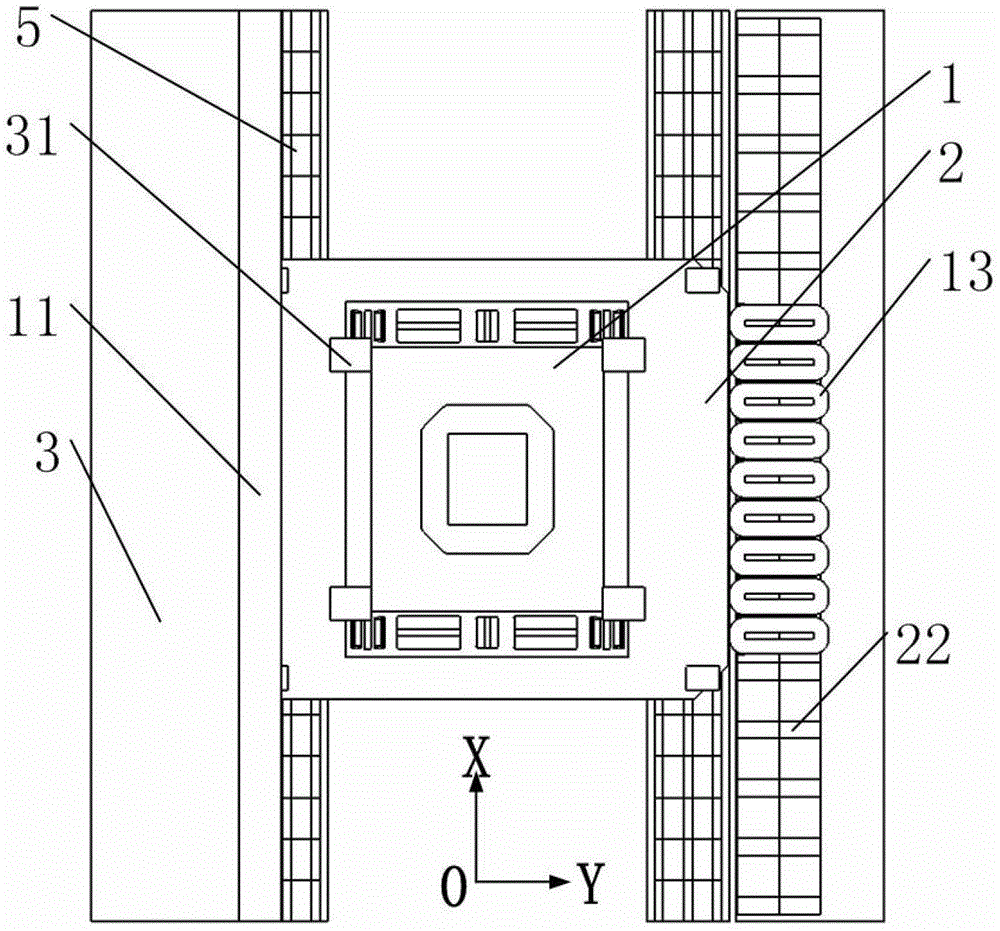

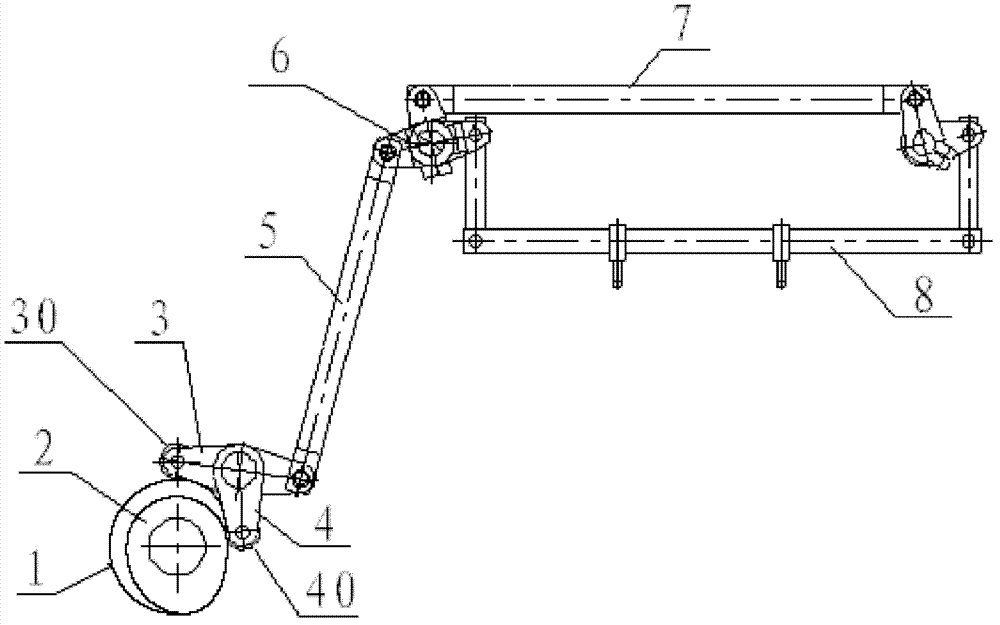

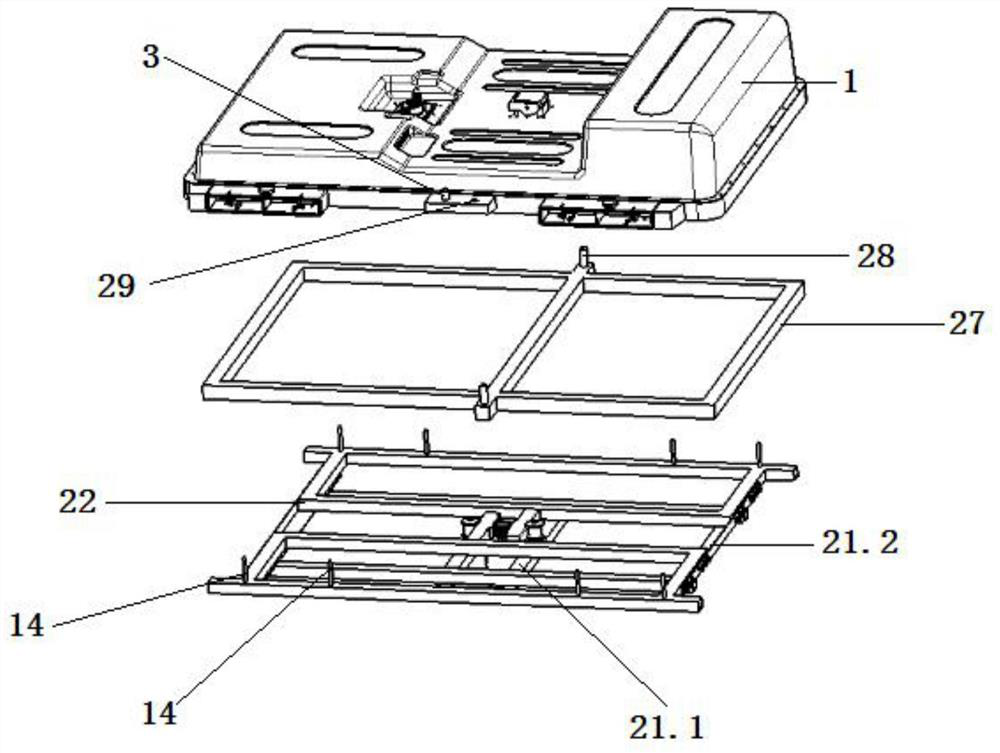

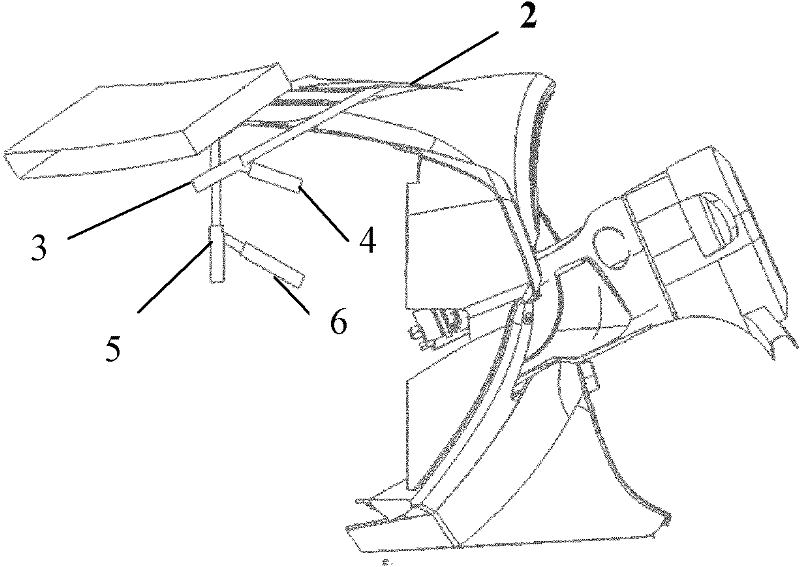

Mask platform system with six-degree-of-freedom coarse drive platform

ActiveCN103186058ASimple system structureAvoid vibration and noisePhotomechanical exposure apparatusMicrolithography exposure apparatusProduction rateSix degrees of freedom

A mask platform system with a six-degree-of-freedom coarse drive platform is mainly used in a photoetching system. The system comprises the coarse drive platform, a fine drive platform and a rack, wherein the coarse drive platform comprises a coarse drive platform body, a drive device and a coarse drive platform gravity balance component, the coarse drive platform body is arranged at the outer part of the fine drive platform to surround the fine drive platform in the middle, and the drive device comprises two groups of X-direction linear motors distributed symmetrically around the direction of an X-axis and four groups of two-degree-of-freedom linear motors driving a Y-direction and a Z-direction to achieve the six-degree-of-freedom motion of the coarse drive platform. The six-degree-of-freedom coarse drive platform and the six-degree-of-freedom fine drive platform are matched, so that the speed, acceleration and control bandwidth of a mask platform are increased and the requirements of high motion precision and location precision are met while the posture of the mask platform is regulated, and furthermore, the production rate, the alignment precision and the resolution ratio of a photoetching machine are improved.

Owner:TSINGHUA UNIV +1

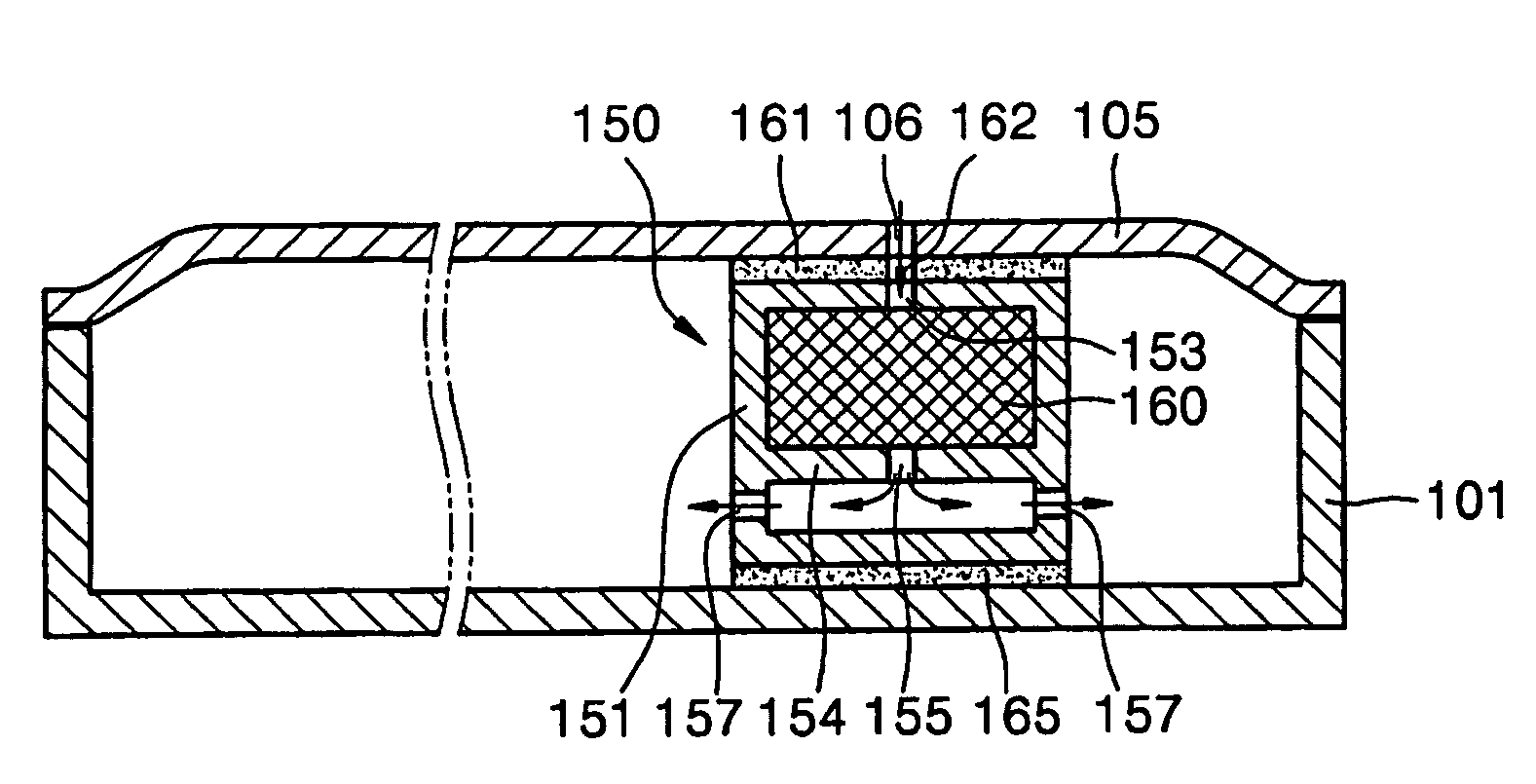

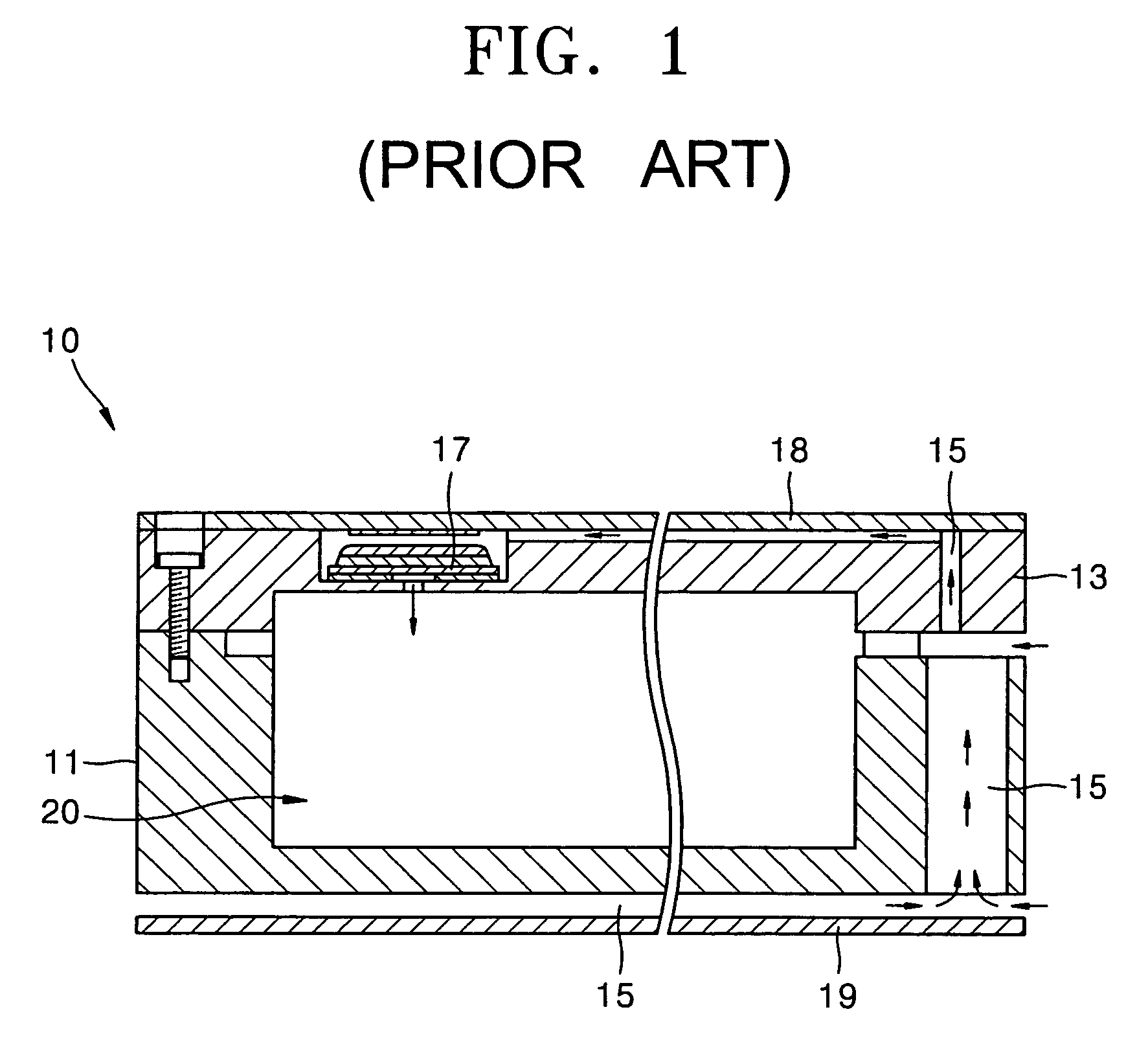

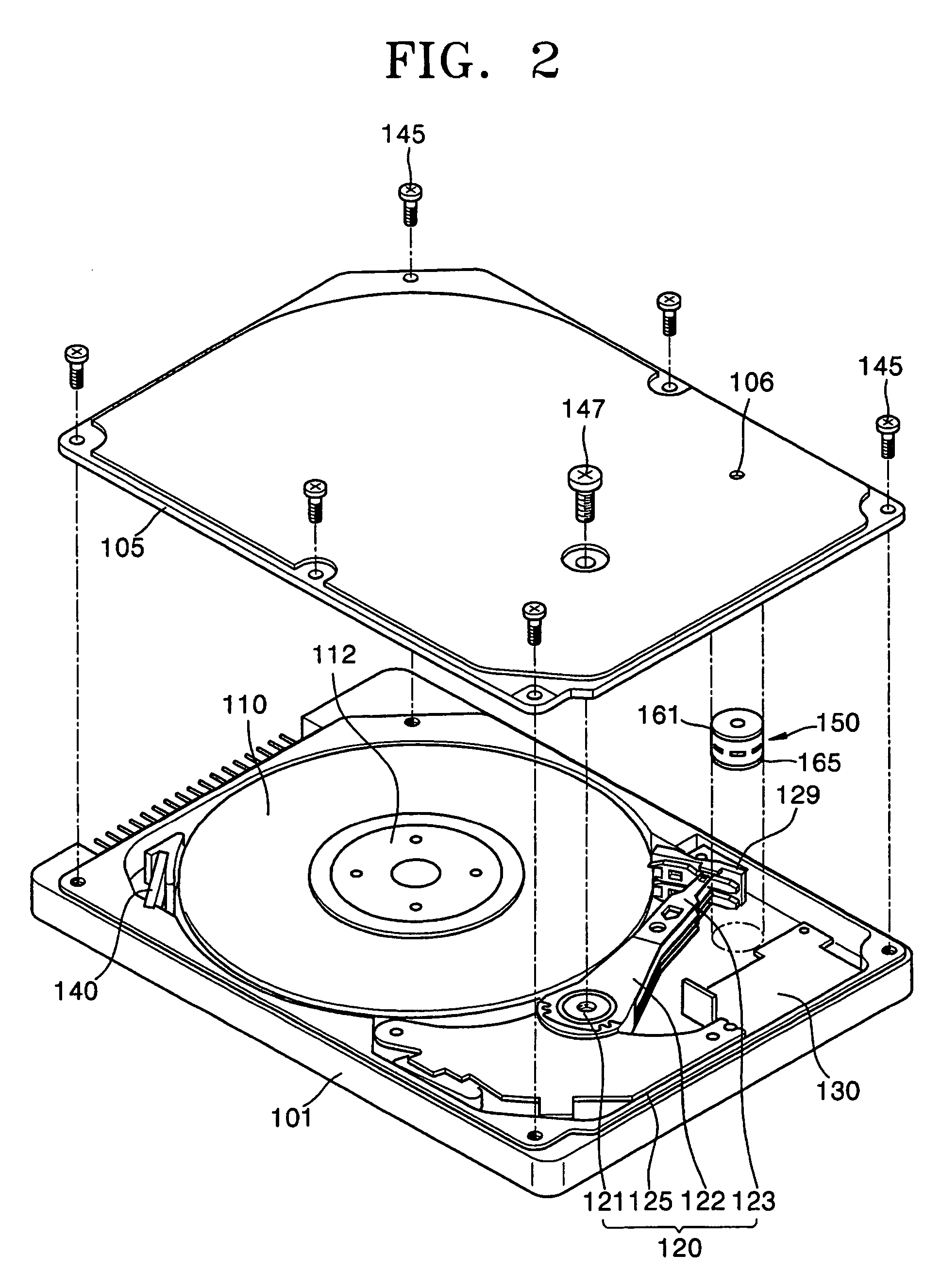

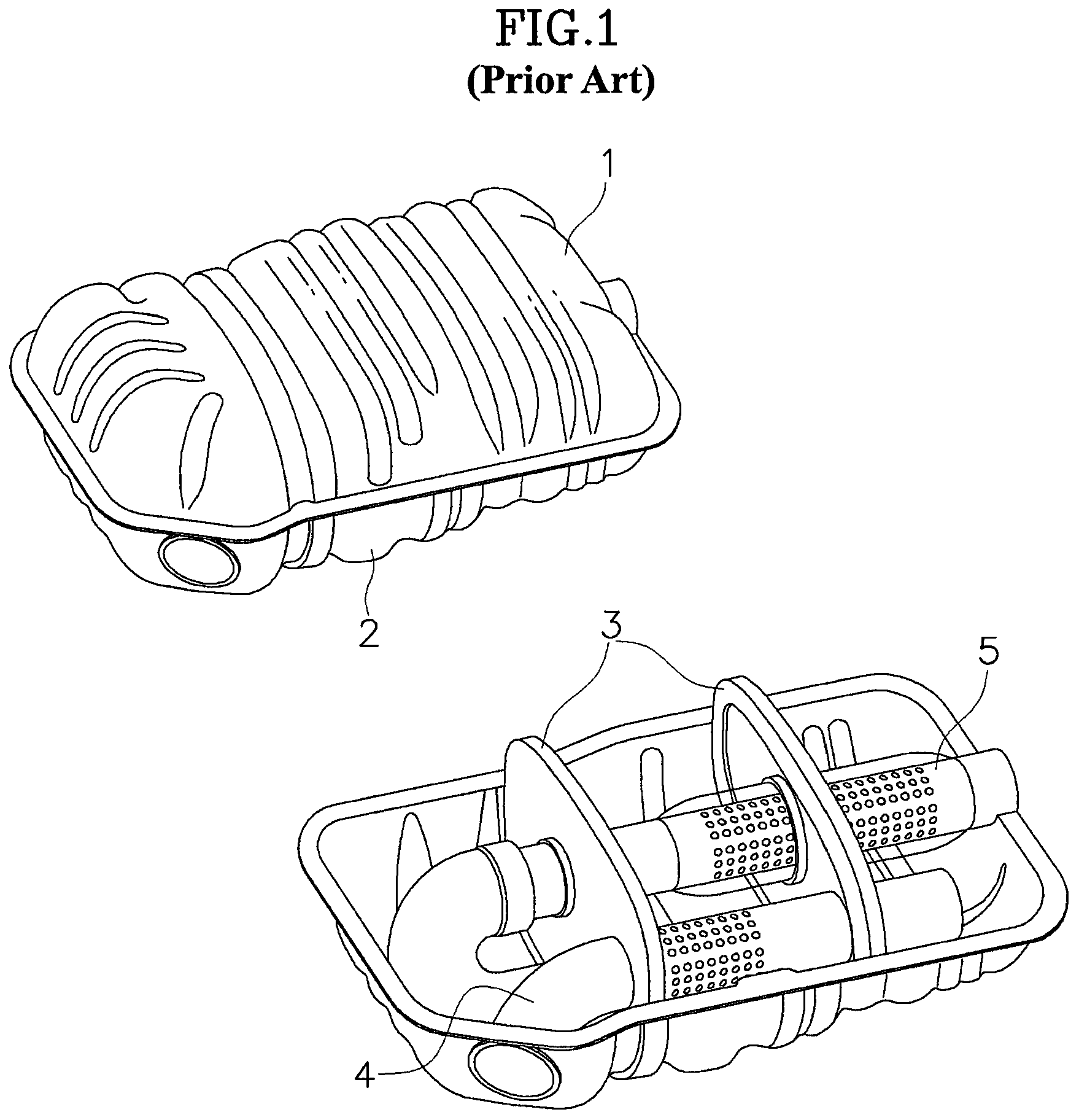

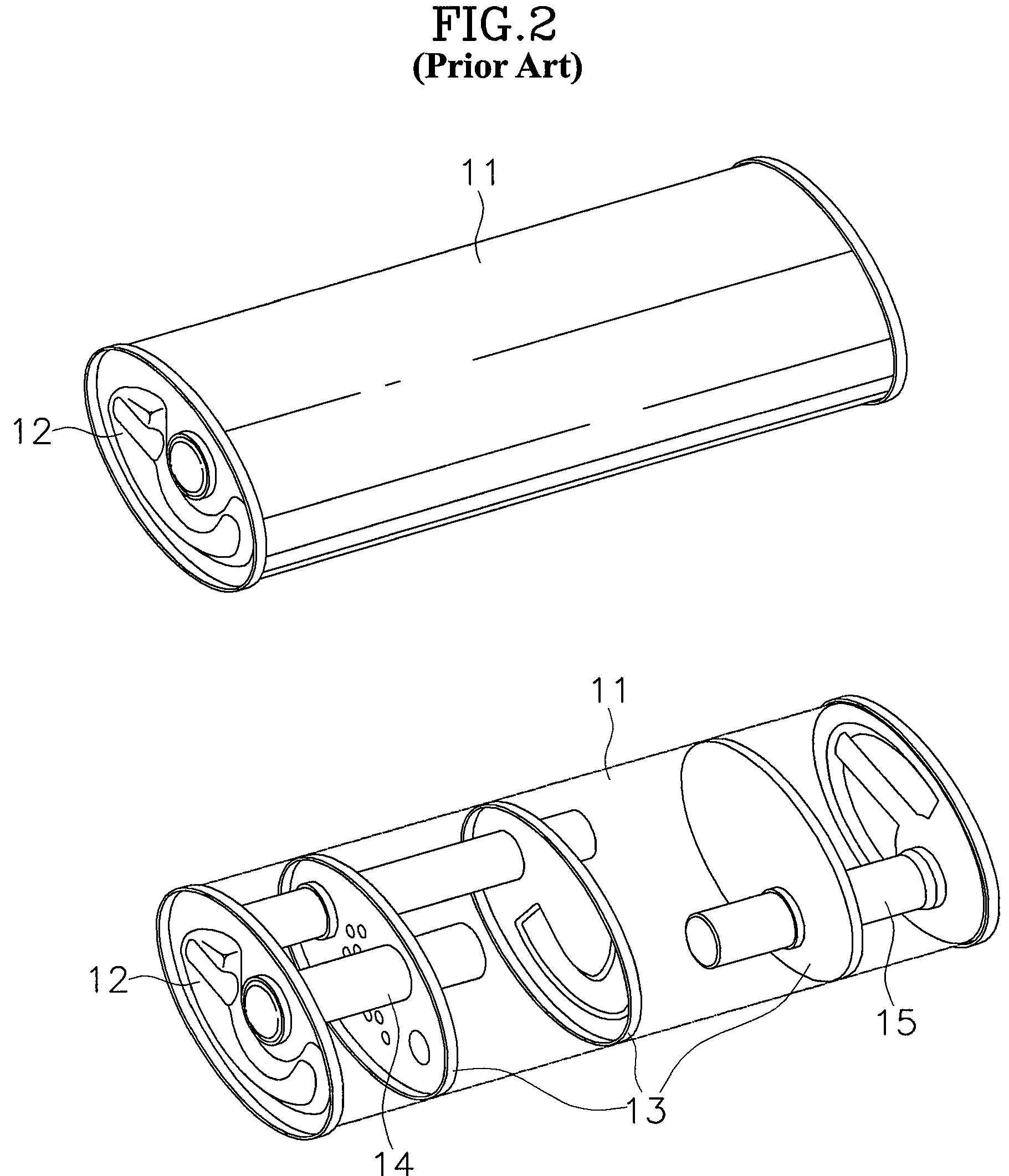

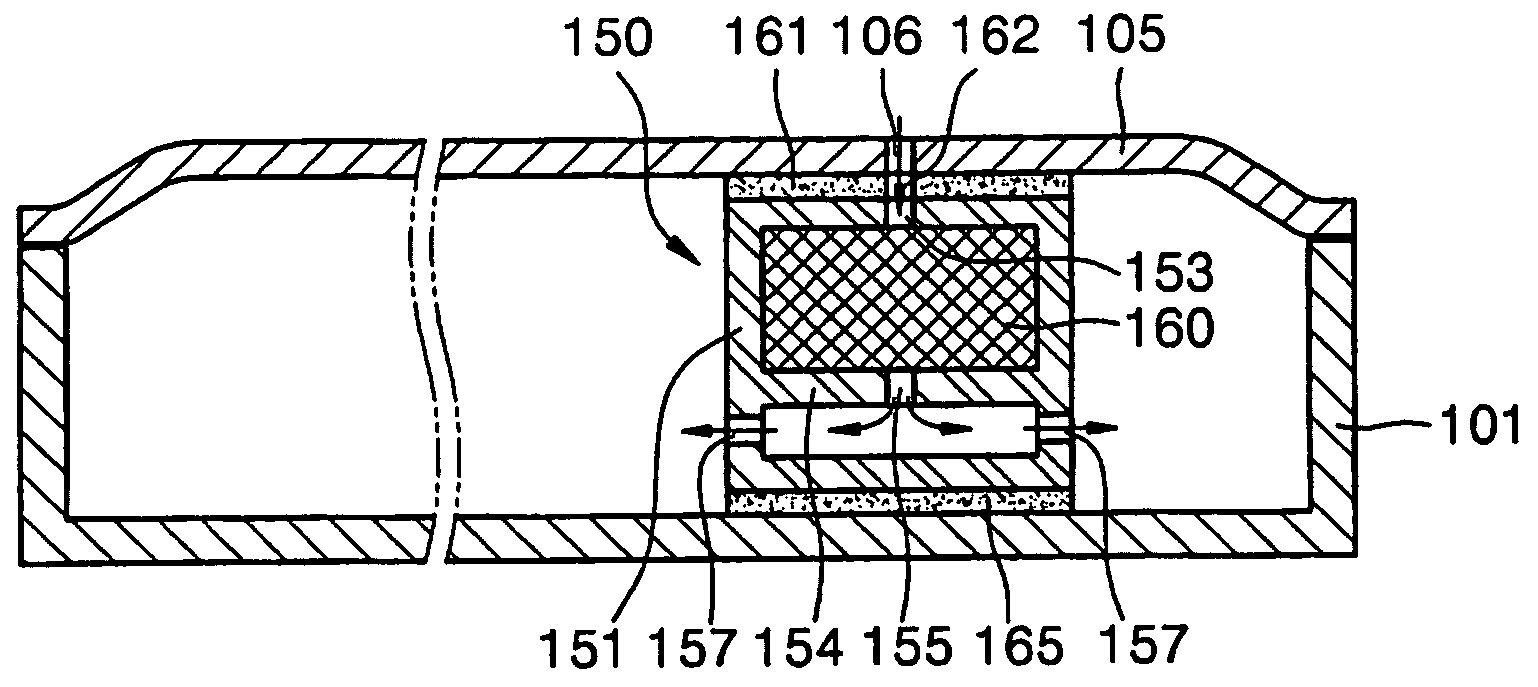

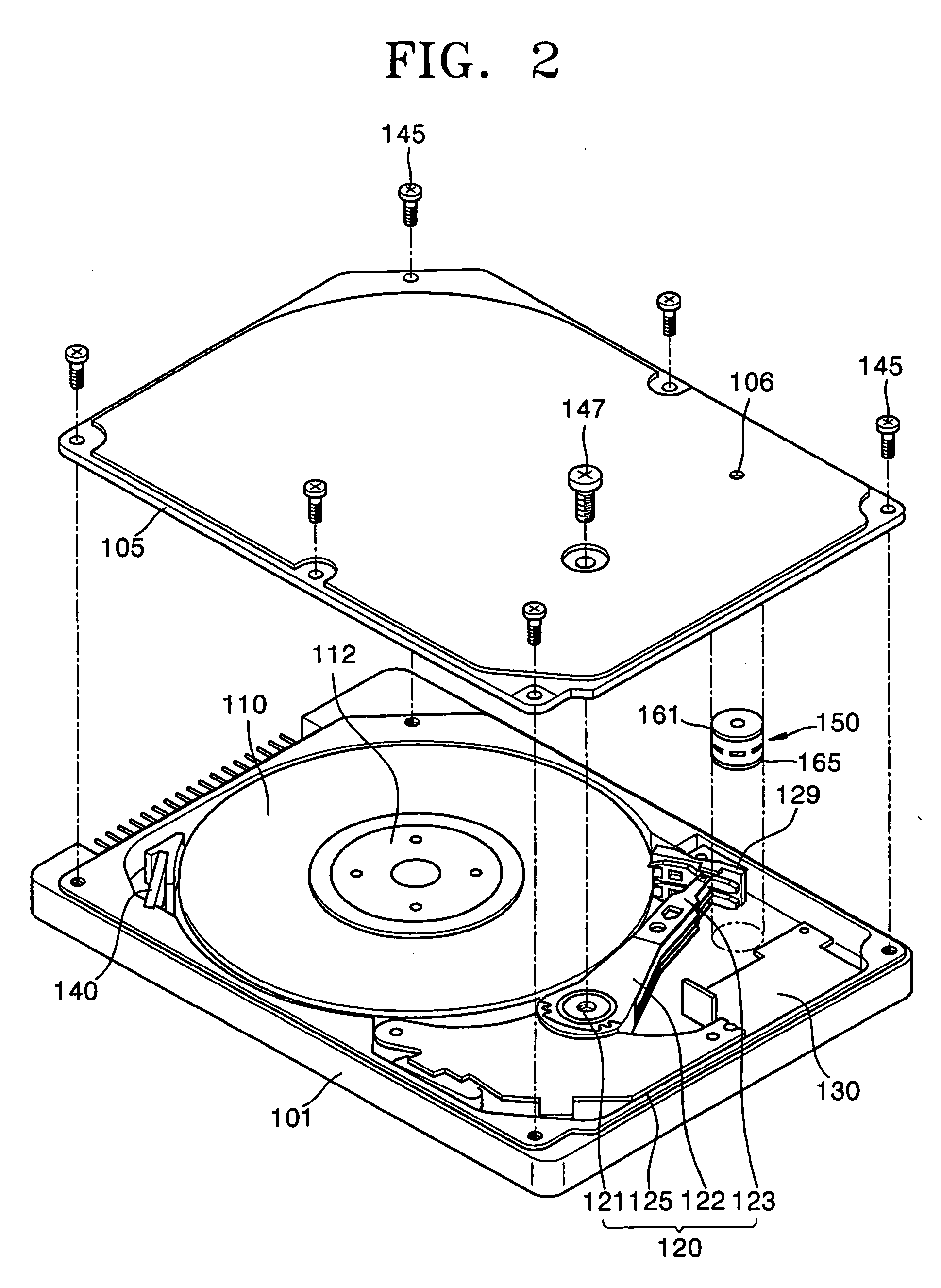

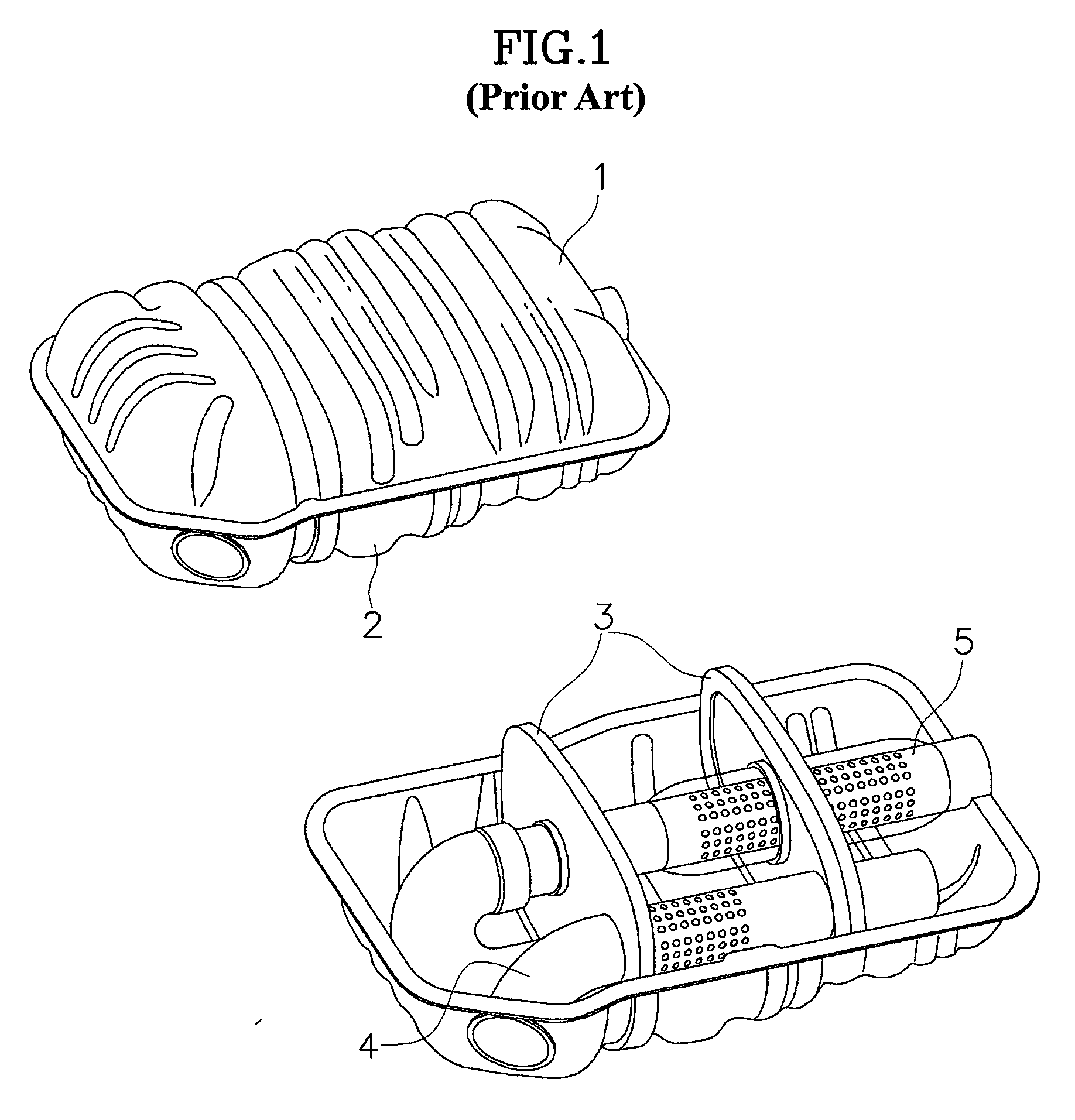

Hard disk drive having breather filter

InactiveUS7486474B2Avoid vibration and noiseApparatus for flat record carriersUndesired vibrations/sounds insulation/absorptionHard disc driveBreather

A hard disk drive including: a base; a disk pivotally installed in the base to store data; an actuator installed in the base to move a read / write head to a predetermined position of the disk; a cover assembled with the base and having an air hole for making internal / external pressures of the hard disk drive equal to each other; and a breather filter interposed between the cover and the base in order to filter air introduced through the air hole of the cover. An upper portion of the breather filter is tightly coupled to the cover and a lower portion of the breather filter is tightly coupled to the base.

Owner:SAMSUNG ELECTRONICS CO LTD

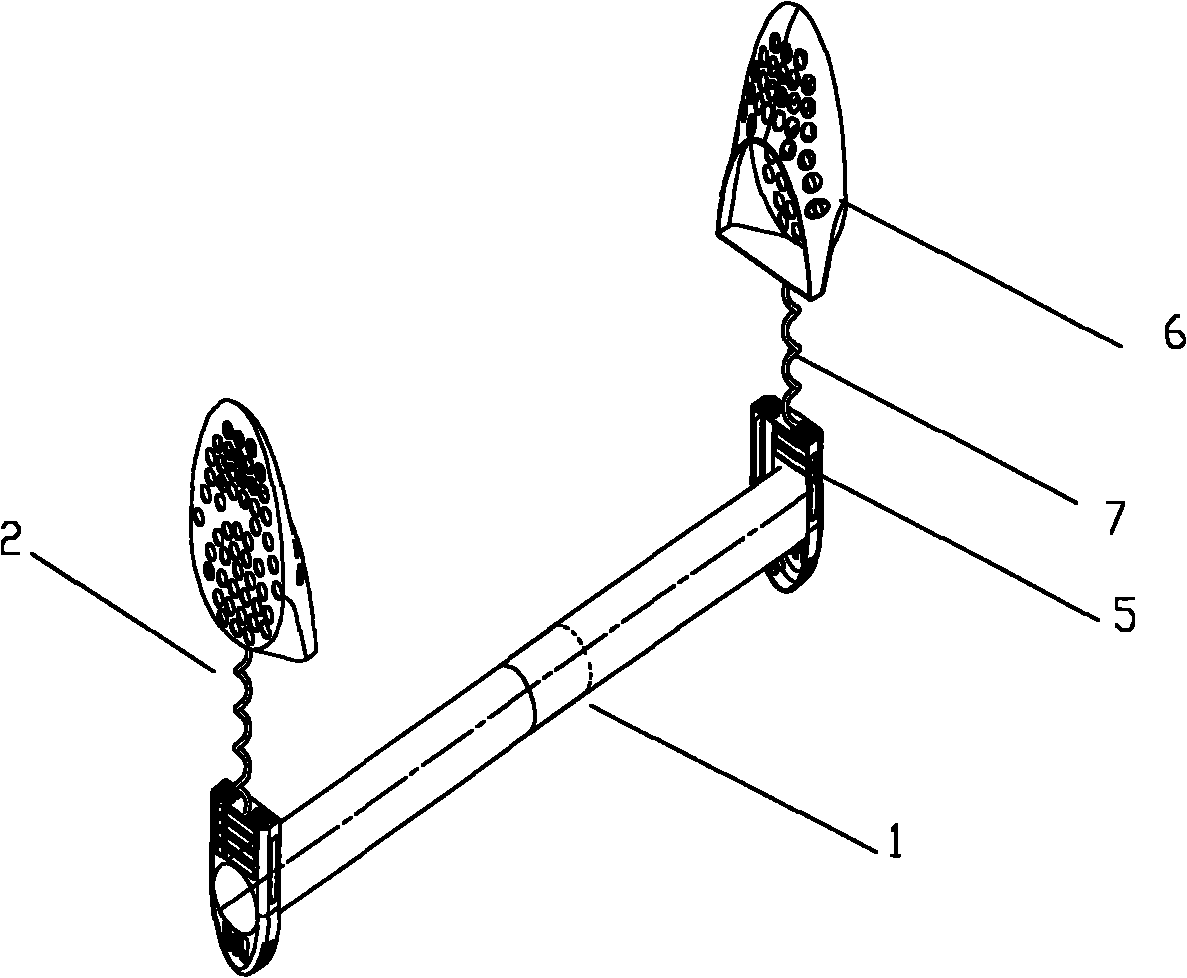

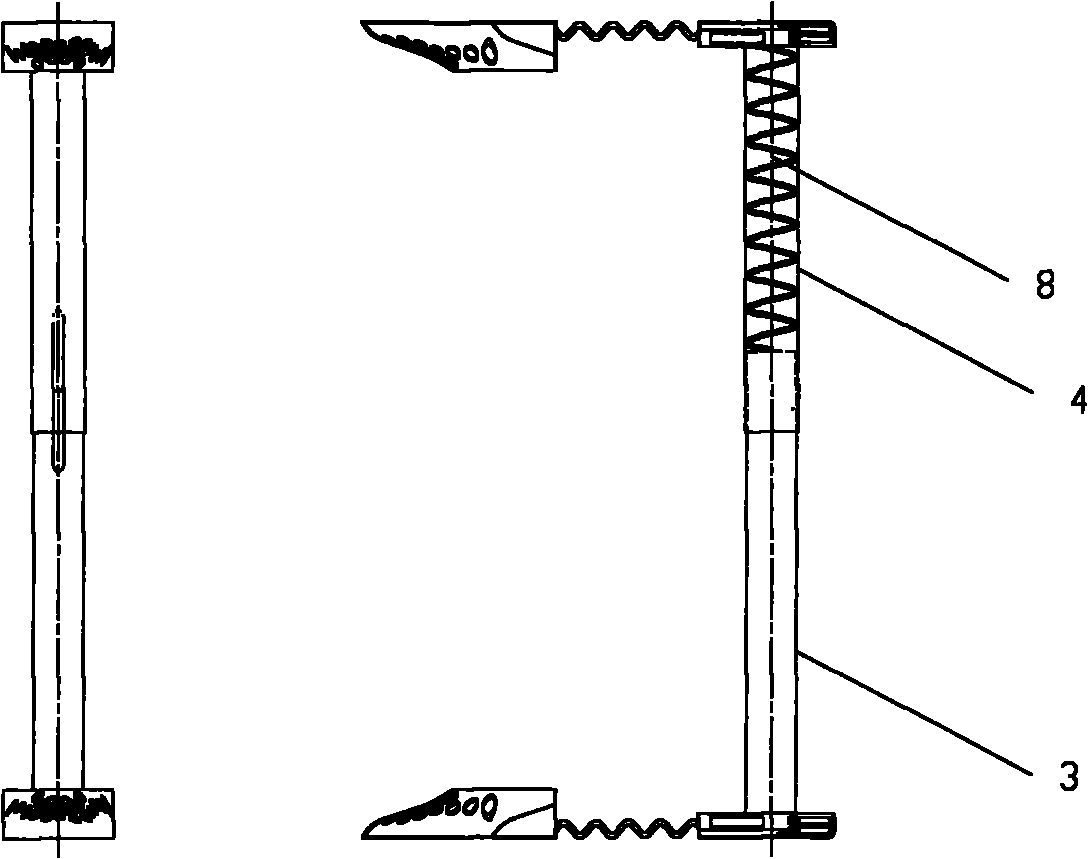

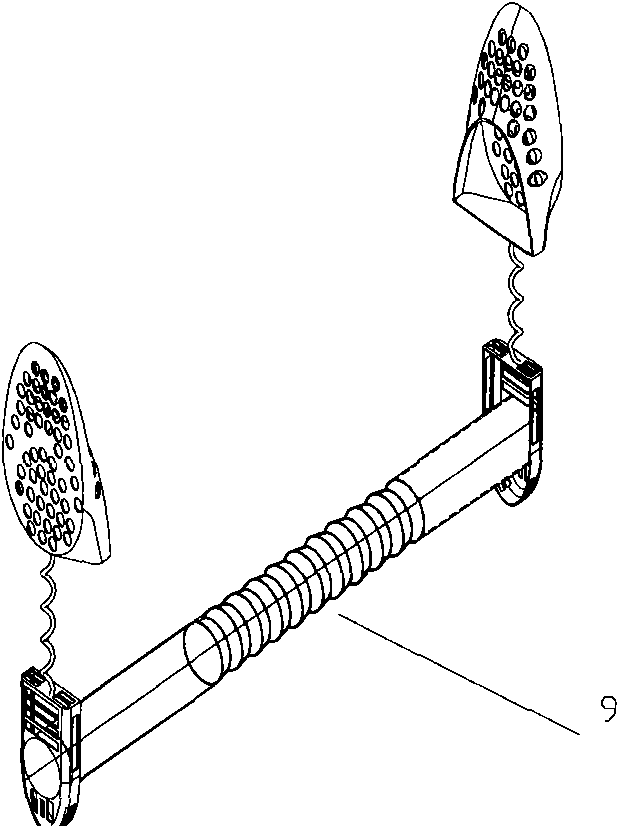

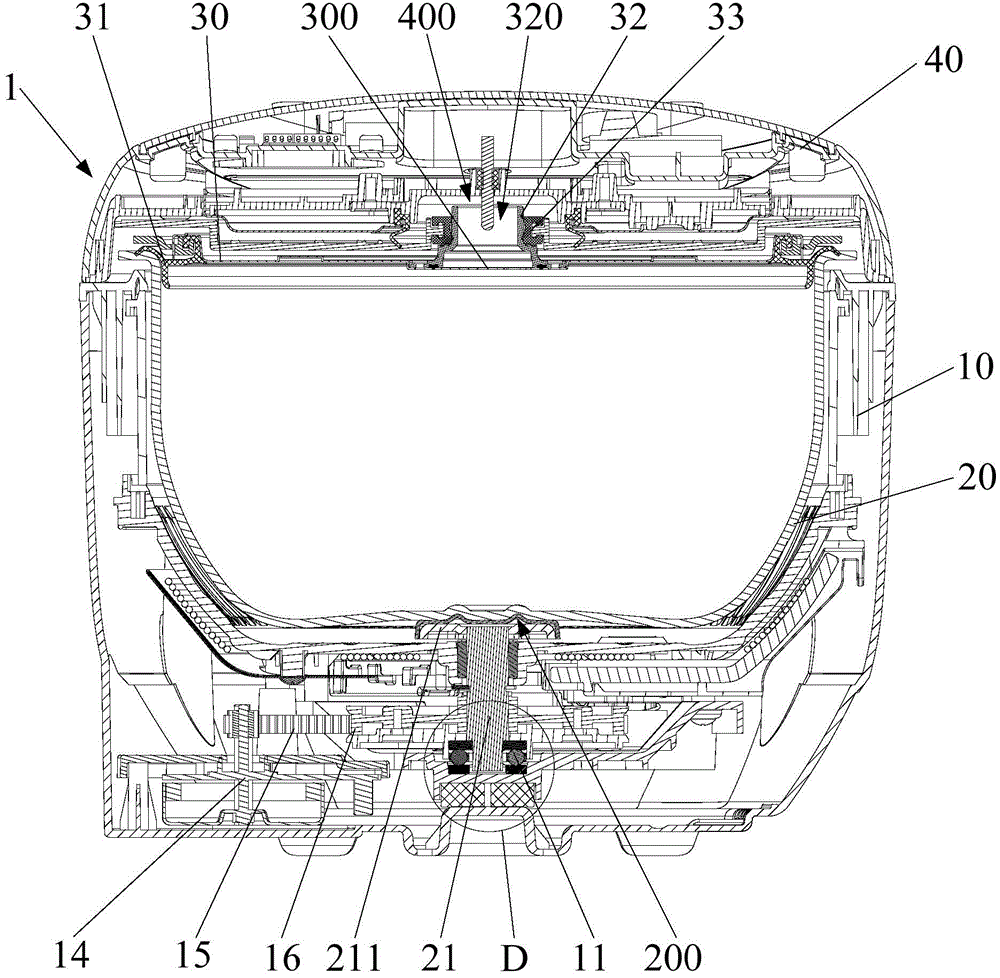

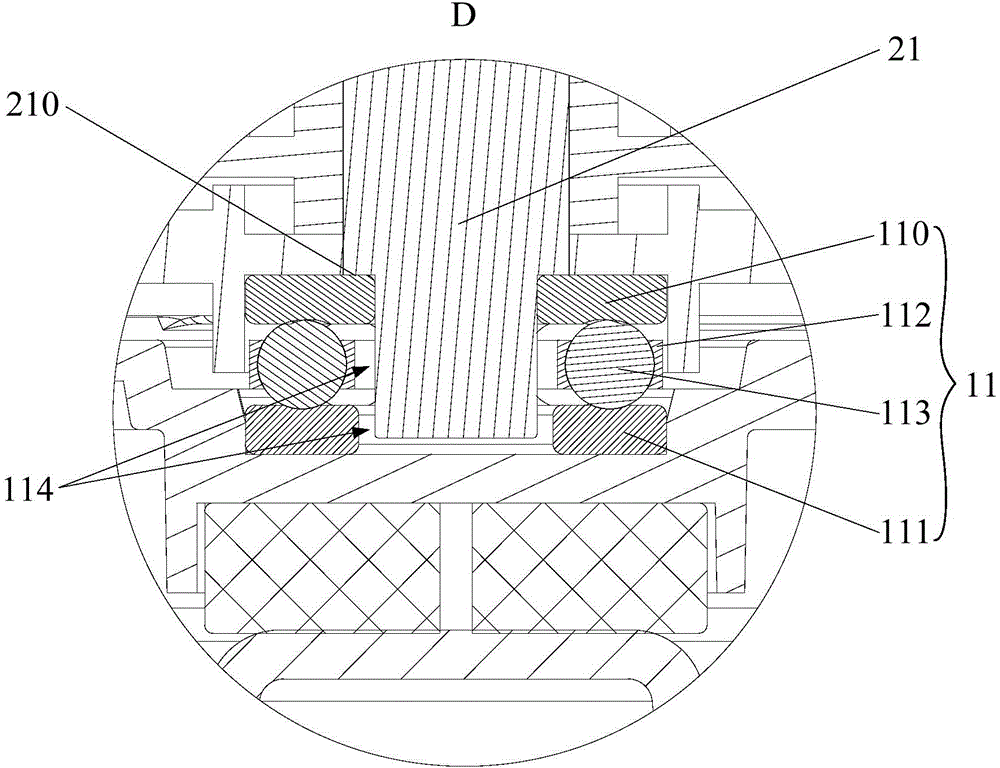

Shoe cleaning device used on washing machine and washing machine employing same

ActiveCN102108616AAvoid vibration and noiseEnhance the impact of water flowOther washing machinesTextiles and paperUser needsEngineering

The invention relates to a shoe cleaning device used on a washing machine and a washing machine employing the shoe cleaning device and particularly relates to a shoe cleaning device used for washing machines of different types and volumes. The shoe cleaning device comprises at least one pair of shoe supporting units for fixing shoes and an ejector rod unit connected and fixed with the shoe supporting units. Each shoe supporting unit comprises a heel support and a toe support, and the ejector rod unit is retractable in the length direction. When a user needs to wash shoes, the shoes are sleeved on the shoe supporting units and the length of the retractable ejector rod unit can be regulated according to the diameter size of an internal barrel of the washing machine to be matched with the diameter of the internal barrel. The shoe cleaning device can be applied to the washing machines with different sizes, has the advantages of thorough cleaning, low noise and deformation prevention of shoes, and meets the requirements of the user for shoes cleaning.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

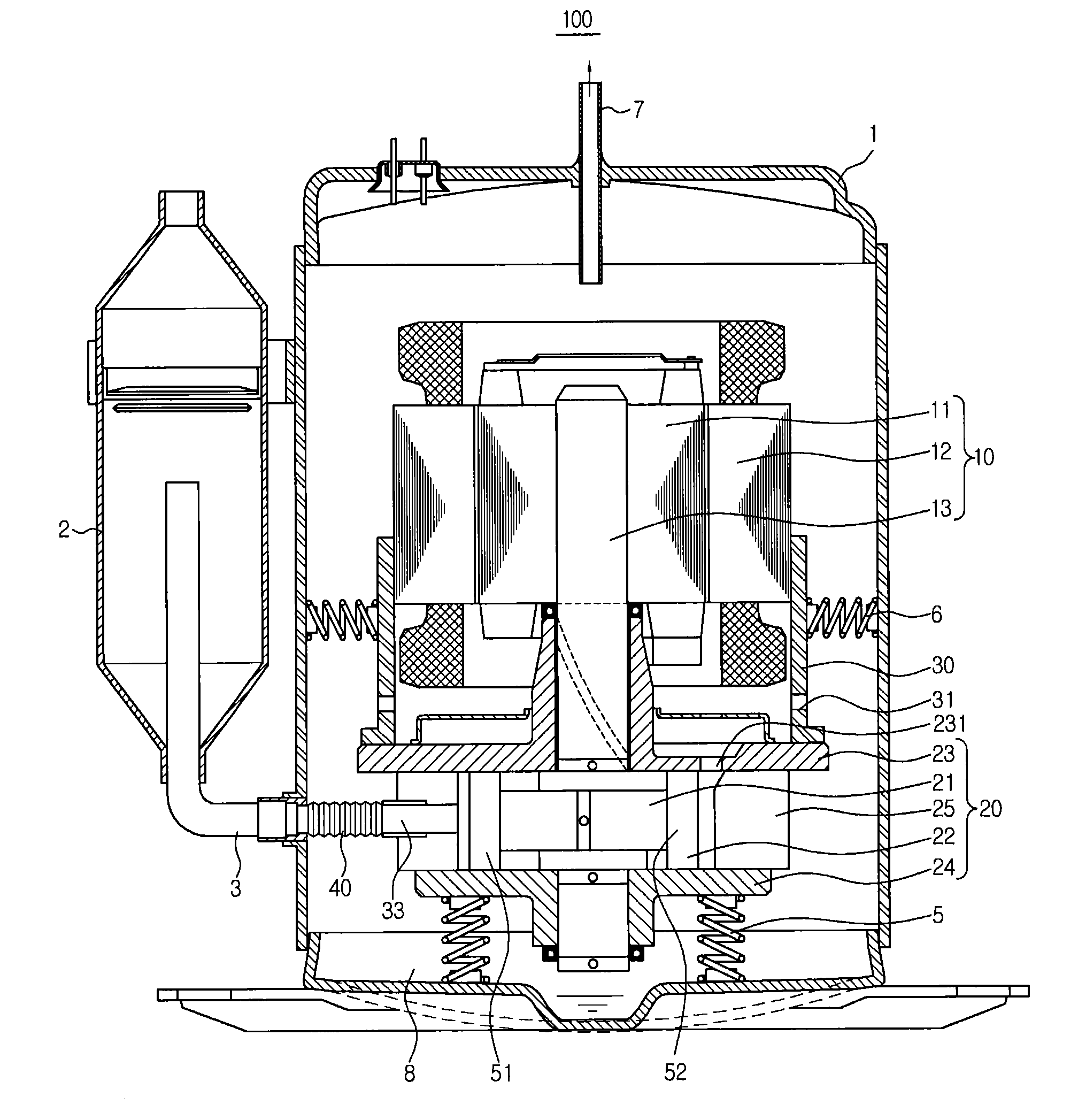

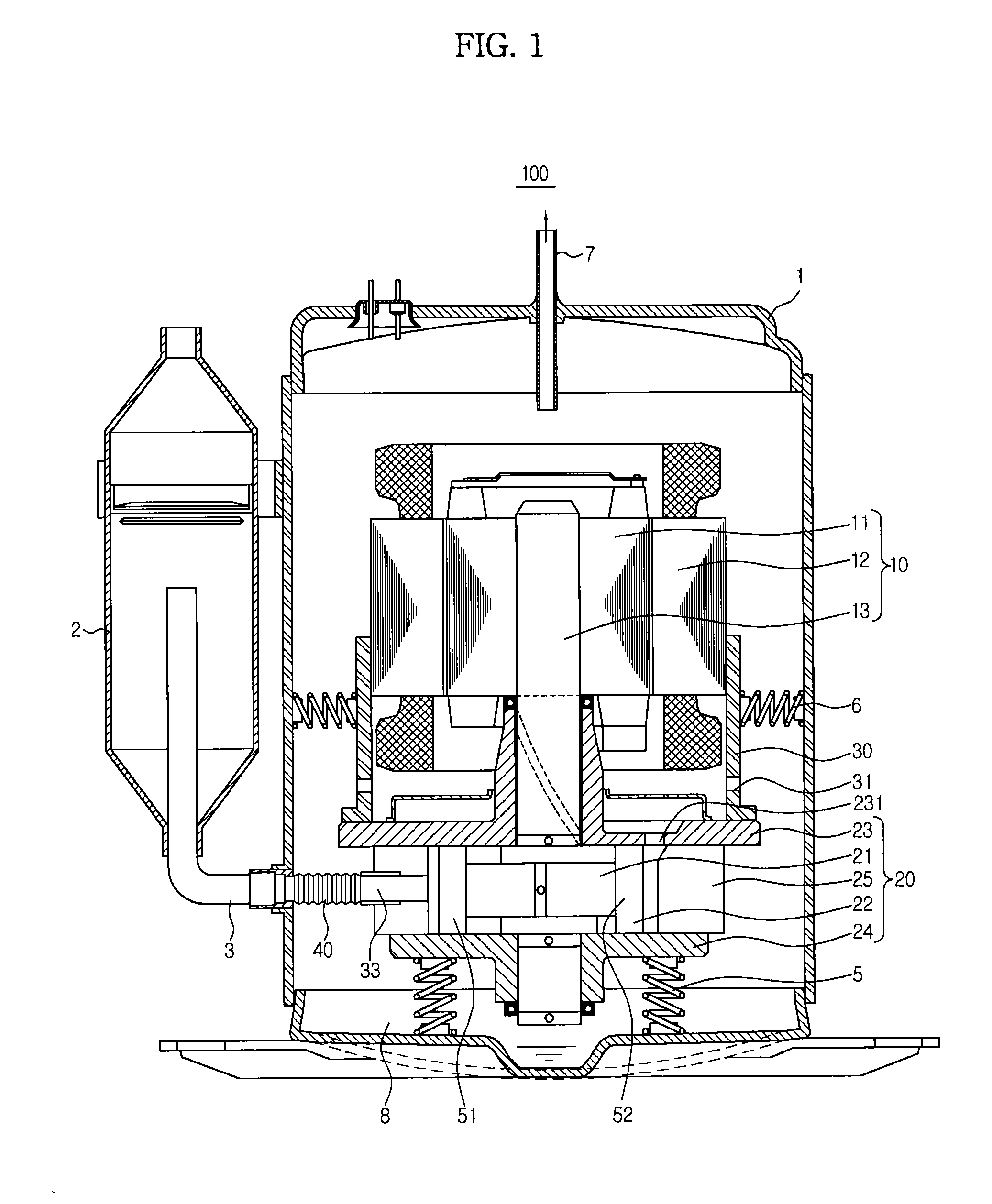

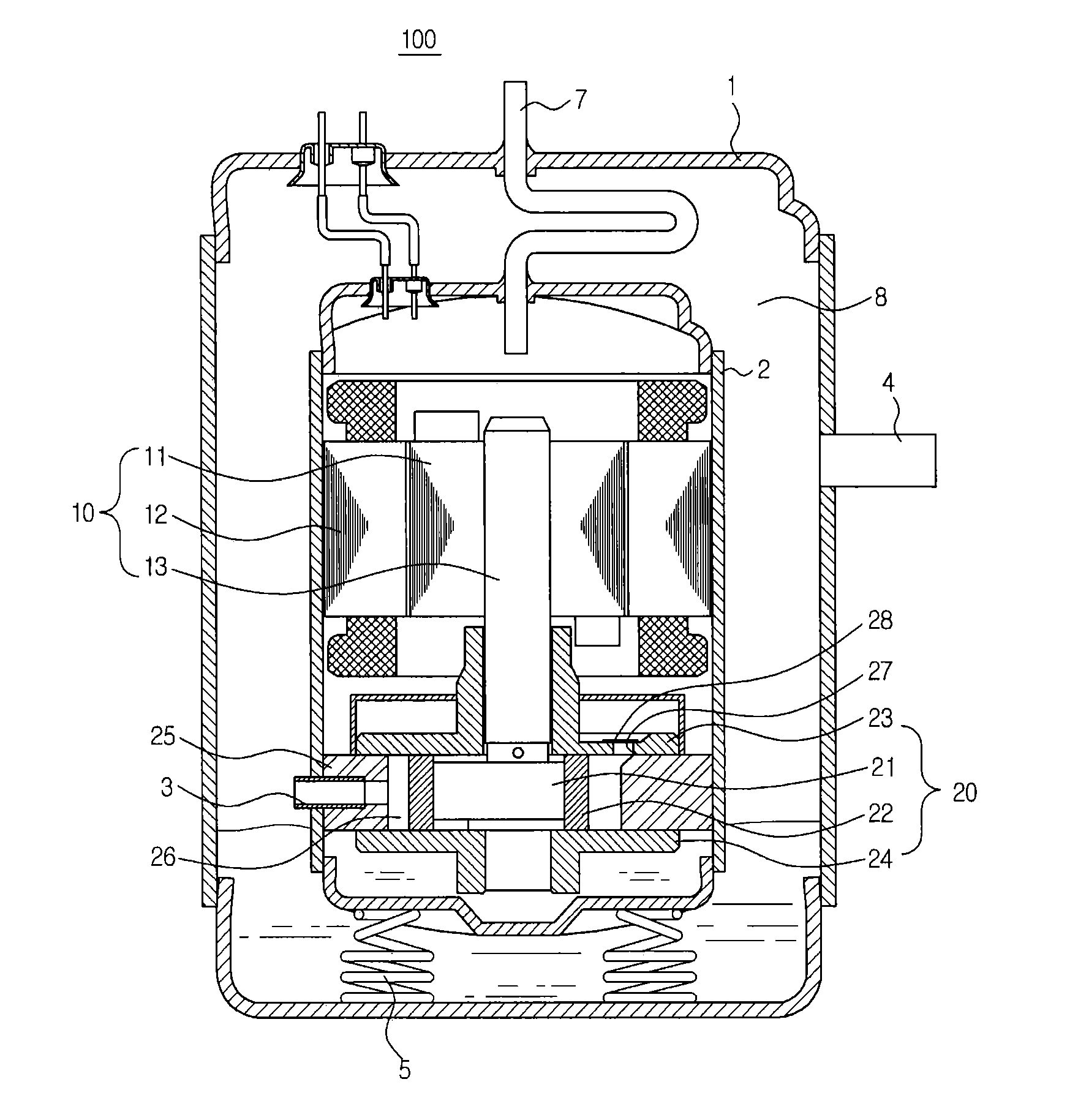

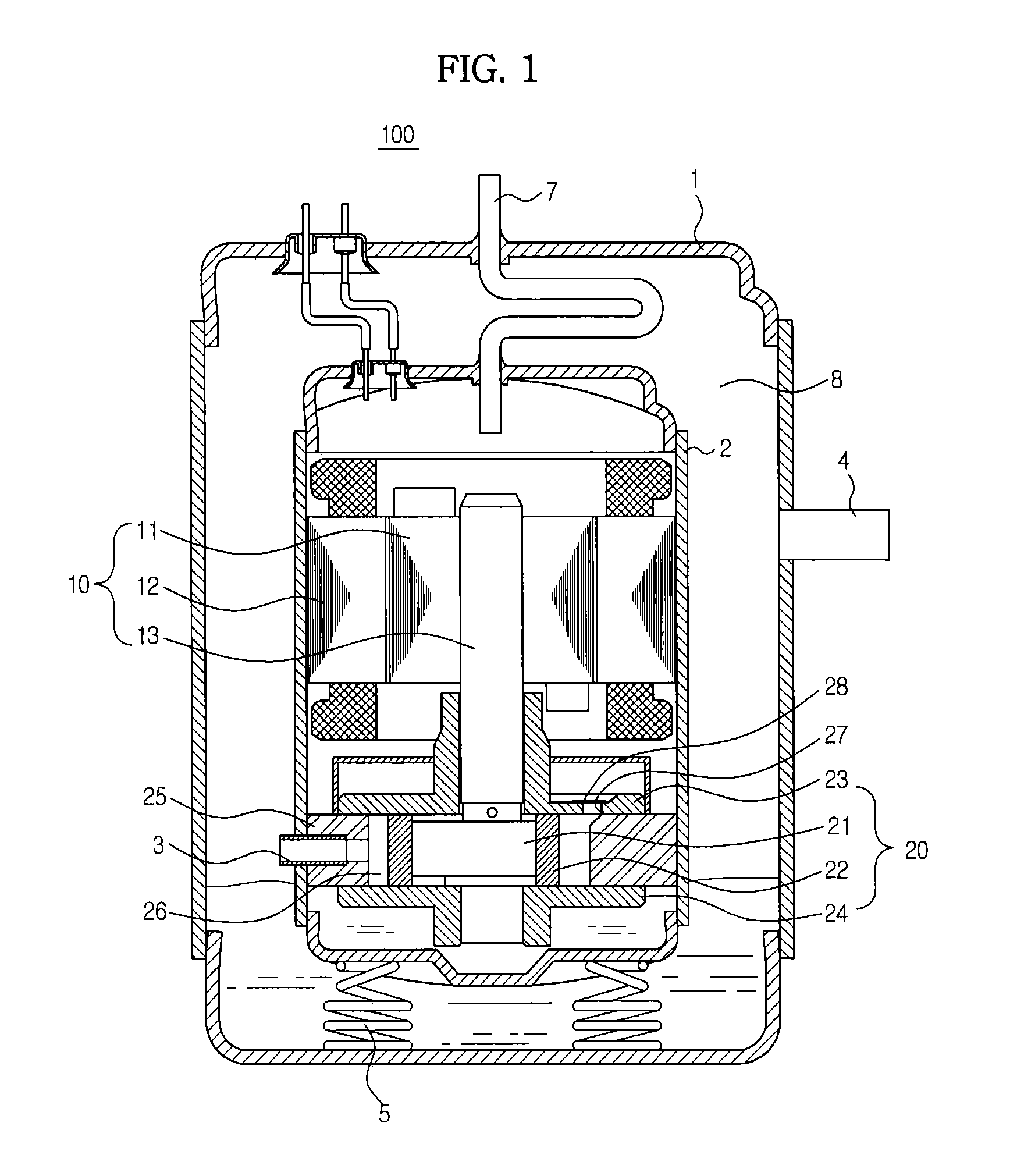

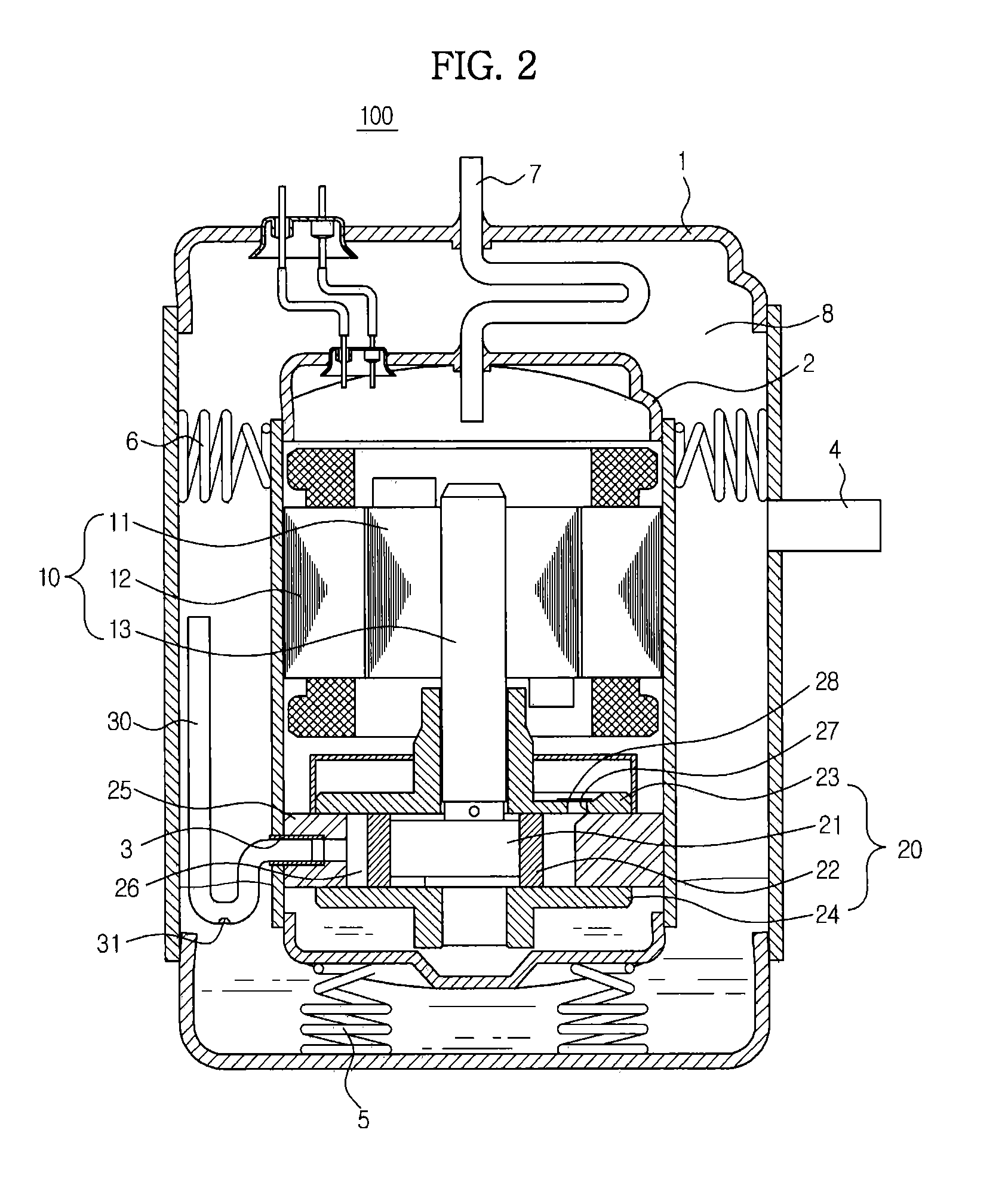

Rotary compressor and manufacturing method thereof

InactiveUS20130129539A1Improve performanceReduce vibration and noiseRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRotary compressor

A rotary compressor having a reduced vibration and noise thereof, and capable of minimizing the deformation of components to improve the performance and the reliability, thereby providing applications for various fields other than for an air conditioner

Owner:SAMSUNG ELECTRONICS CO LTD

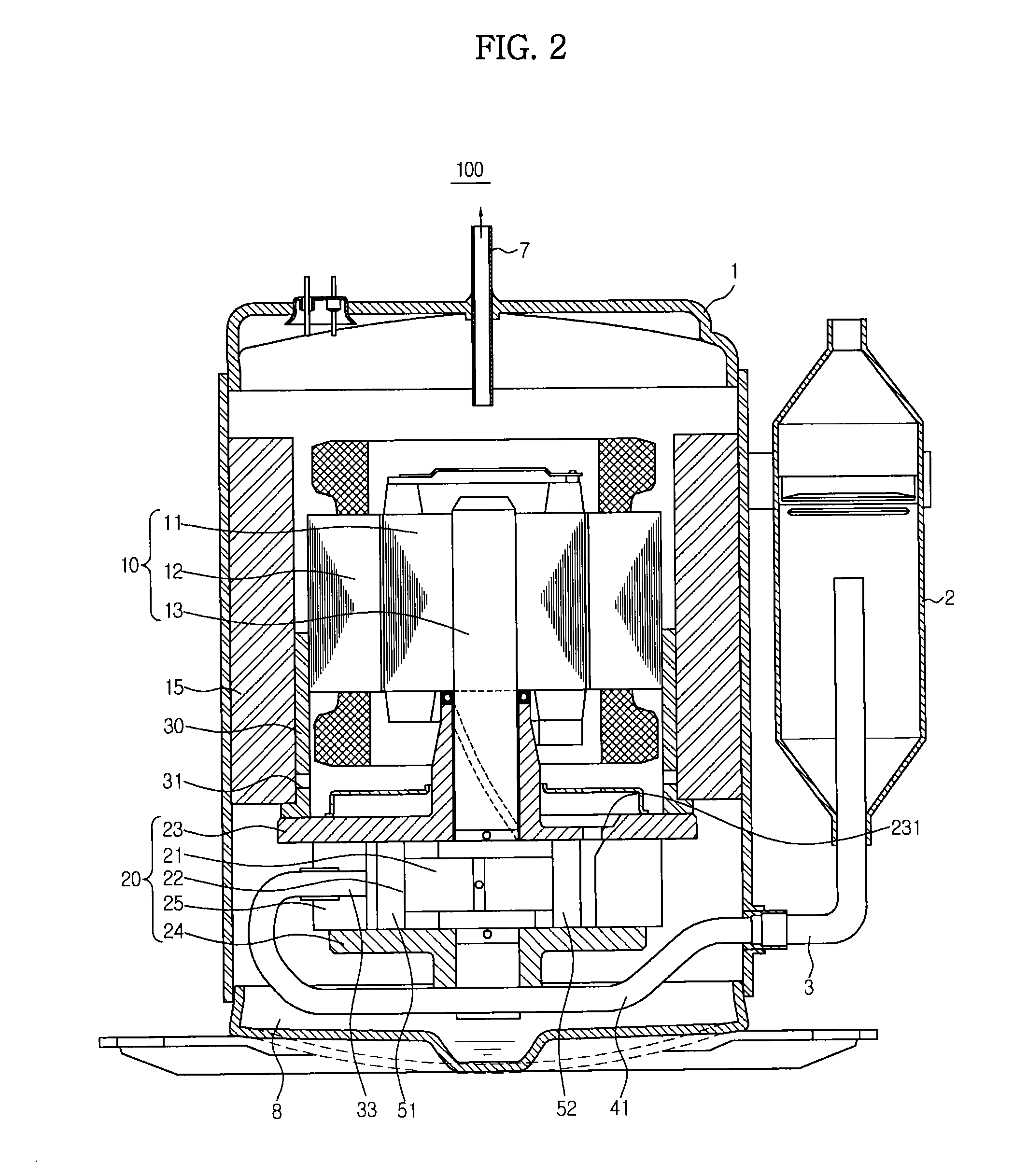

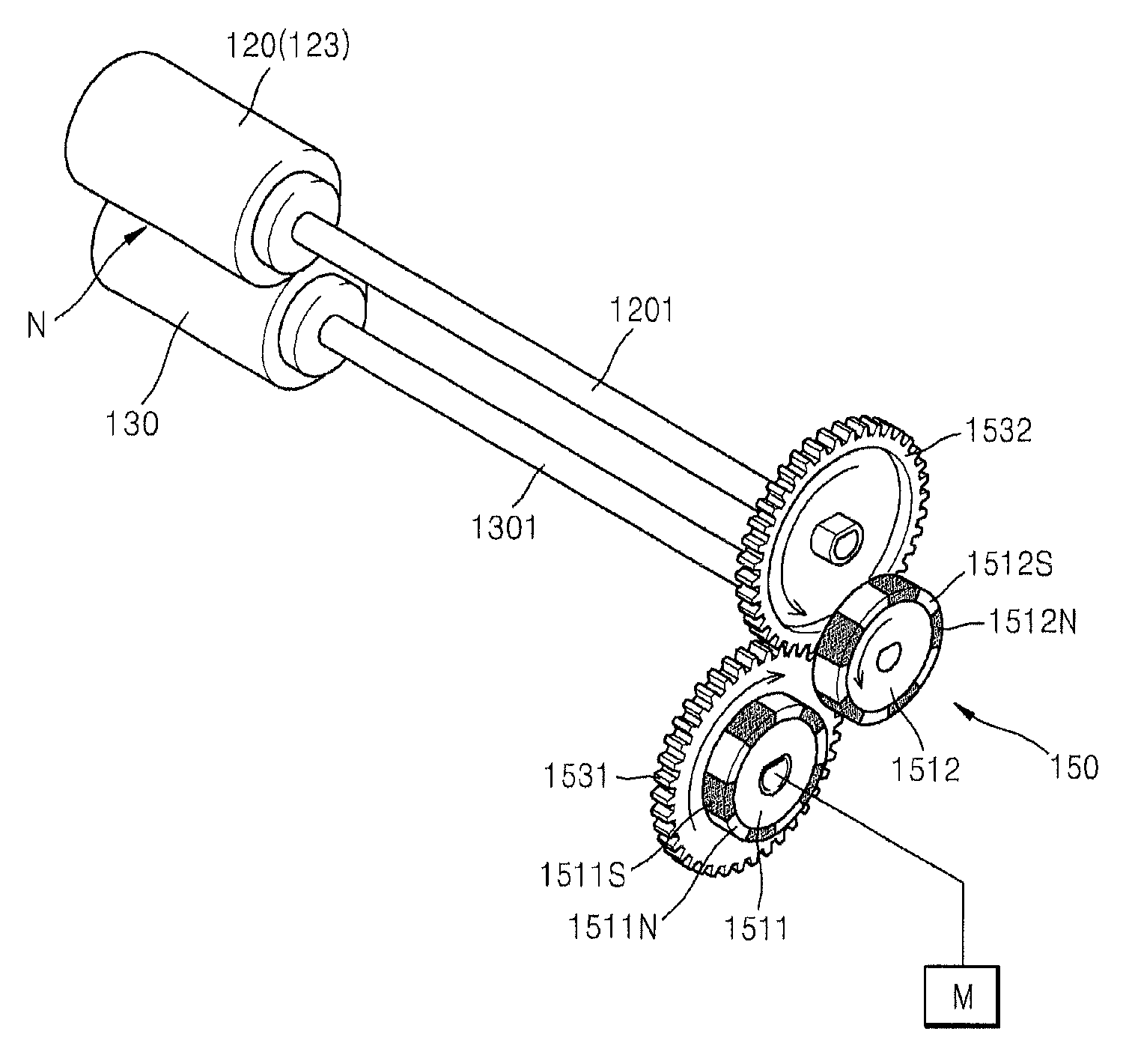

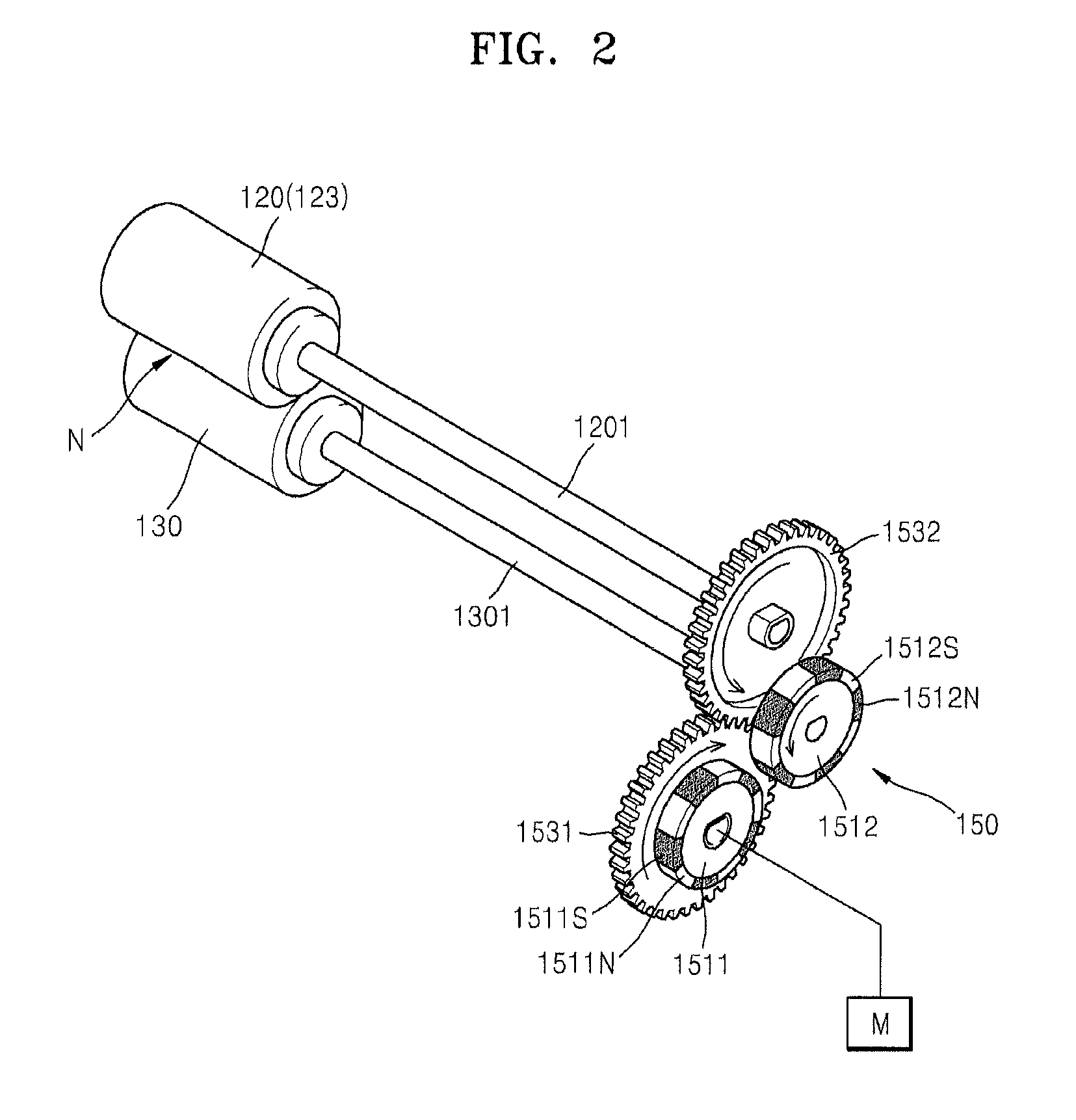

Paper feeding apparatus and image forming apparatus including the same

InactiveUS9067735B2Avoid vibration and noiseSimple structureElectrographic process apparatusOther printing apparatusImage formationFriction force

Owner:HEWLETT PACKARD DEV CO LP

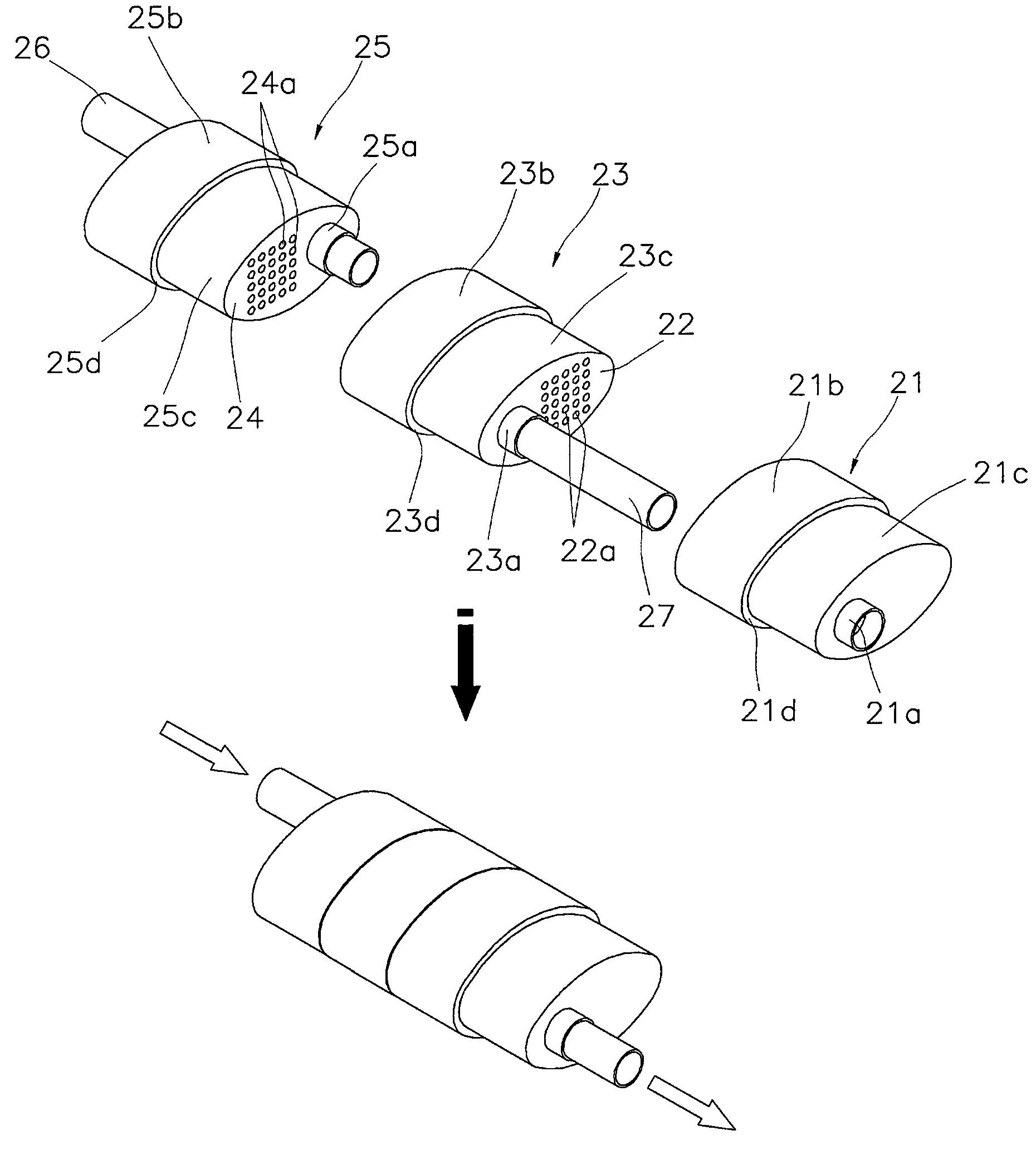

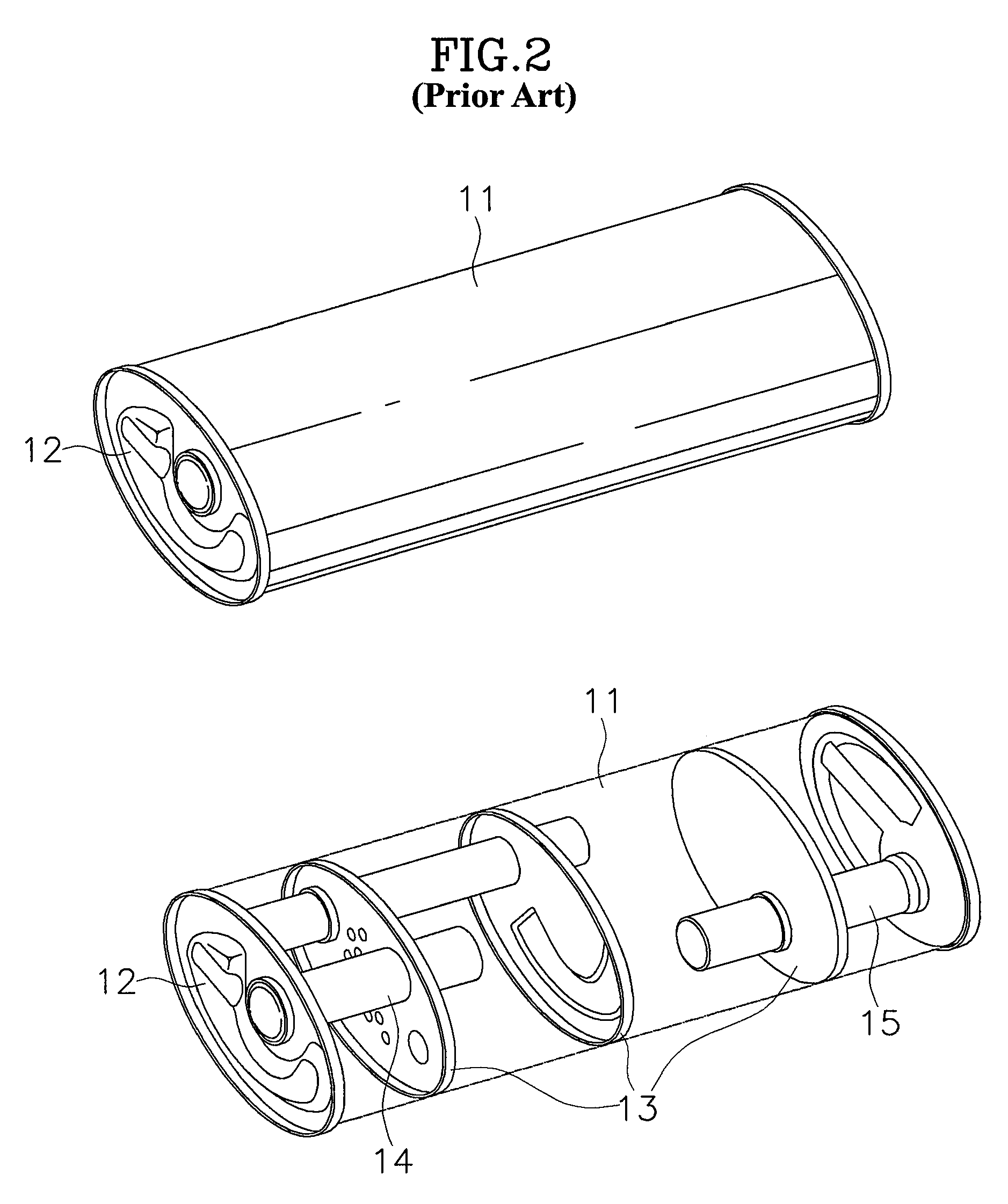

Muffler for vehicle

A muffler of a vehicle includes a first muffler body so as to form a first chamber, at least a second muffler body including a housing, one end portion opened and the other end portion closed, wherein one of the second muffler bodies is fitted into the other end portion of the first member to form a second chamber and the other second muffler bodies are fitted into each other through the one end portions in series to form third chambers if more than one second muffler bodies are assembled, an inflow pipe to connect the outside with the first, second and / or third chamber by passing the one end portion of the first muffler body, and an outflow pipe to communicate the first, second, and / or third chamber with the outside by passing through the other end portion of the last second muffler body.

Owner:HYUNDAI MOTOR CO LTD

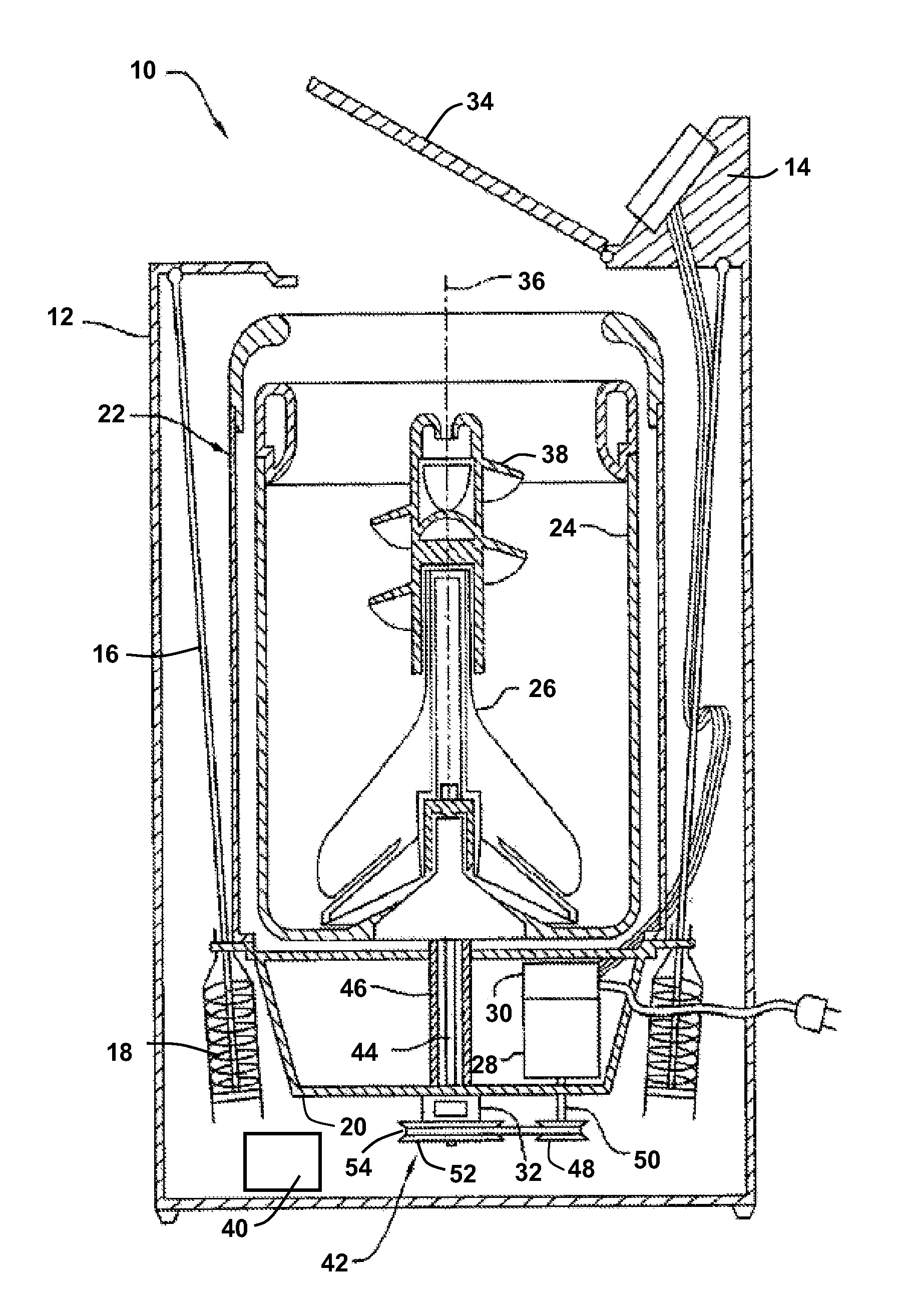

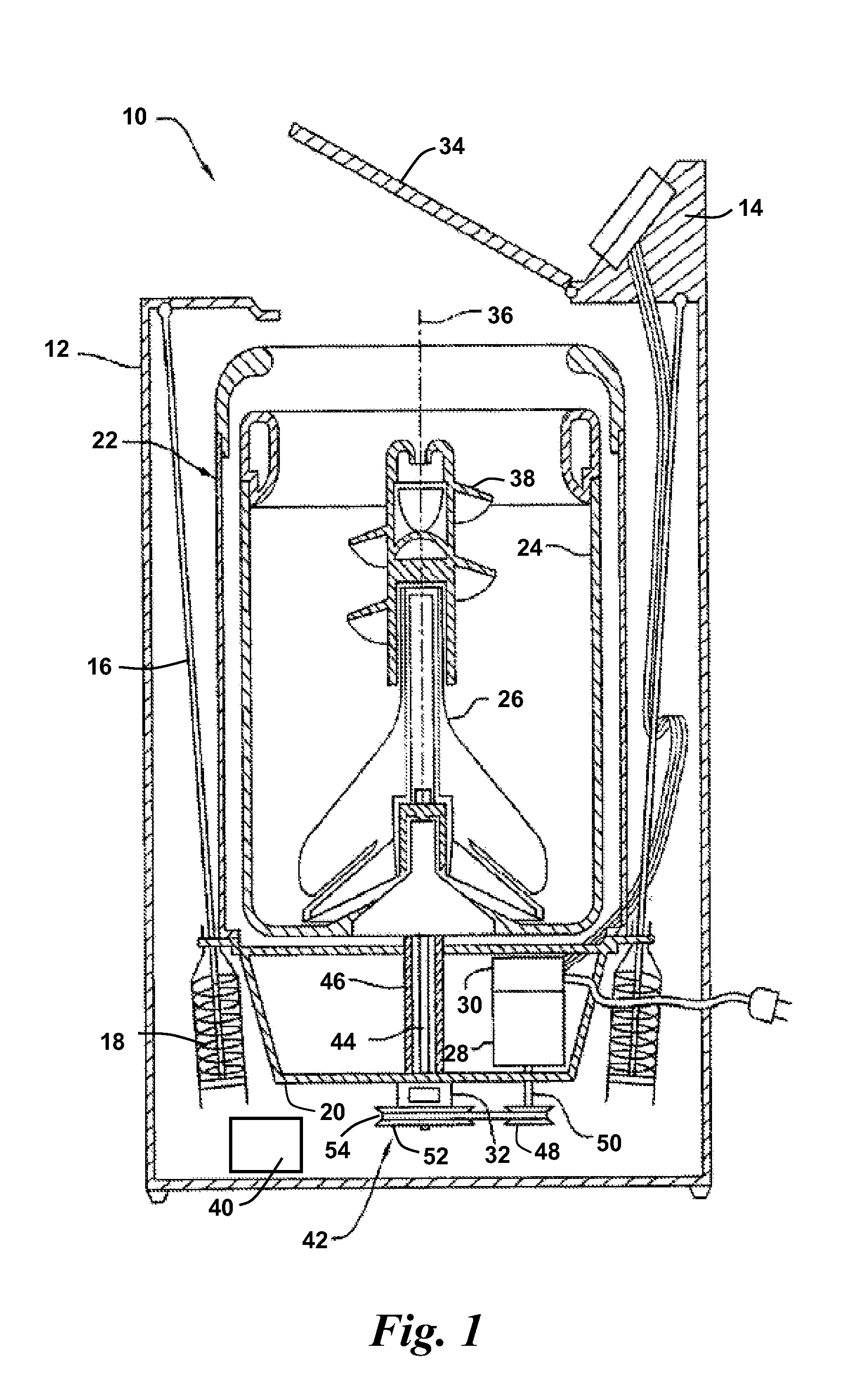

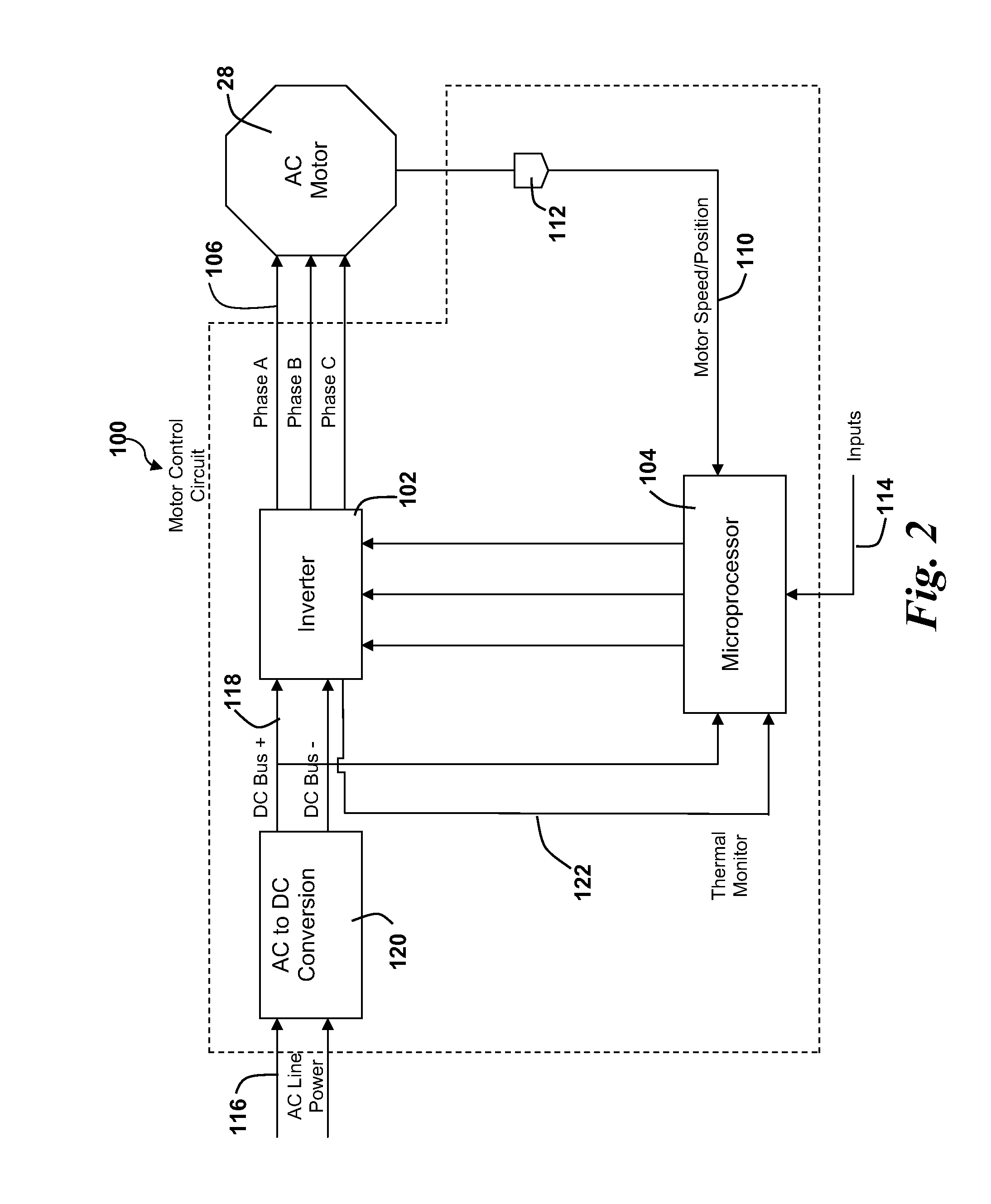

Washing machine with improved method of braking to a non-zero speed

ActiveUS20120112683A1Reduce speedAvoid vibration and noiseSingle-phase induction motor startersSynchronous motors startersReceiptBrake torque

A method of braking a washing machine from an operational speed to a reduced non-zero speed is provided (as well as a washing machine incorporating the method) for a washing machine driven by one of a synchronous or asynchronous motor. Upon receipt of a speed reduction signal, the motor rotating magnetic fields are collapsed for a defined time period. After the defined time period, DC braking voltage is applied to the motor stator windings at a controlled ramp-up rate to an amplitude to generate a controlled ramped braking torque on the motor until the motor has slowed to a defined reduced speed. Thereafter, the amplitude of the DC braking voltage is set to 0V and the motor is soft started to an amplitude and reduced frequency needed to maintain the defined reduced speed.

Owner:HAIER US APPLIANCE SOLUTIONS INC

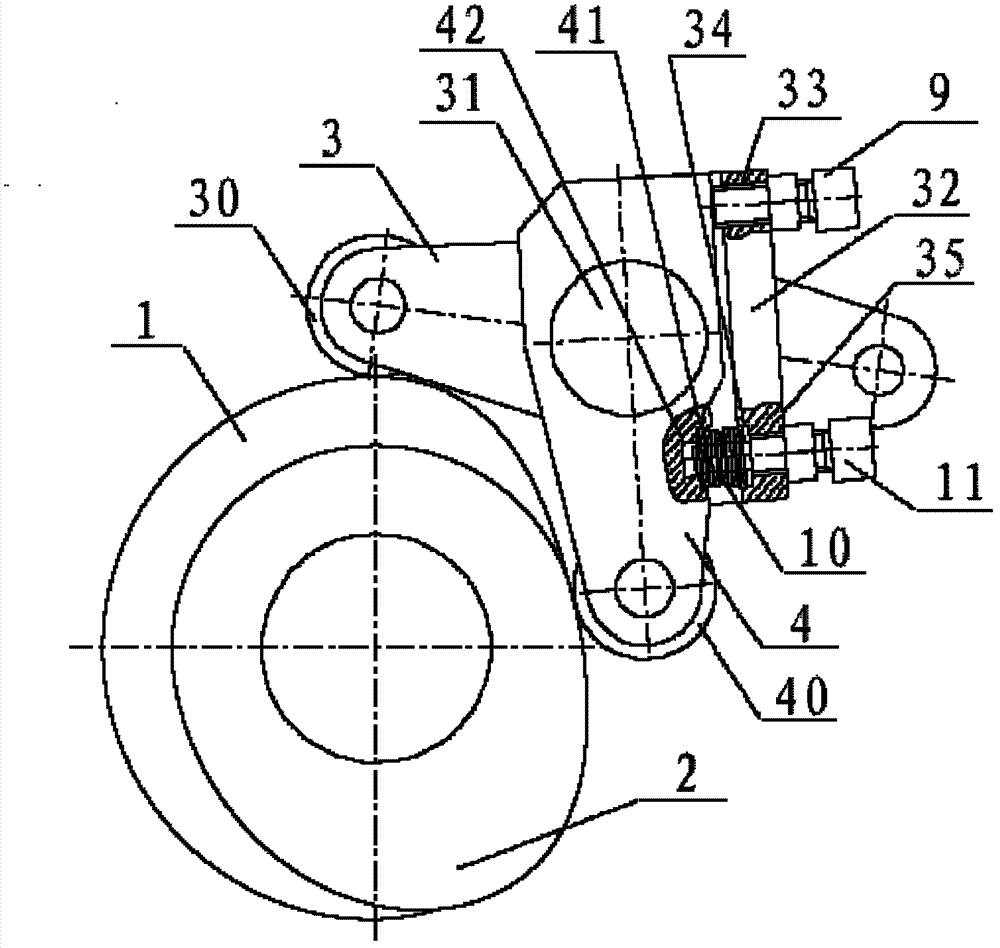

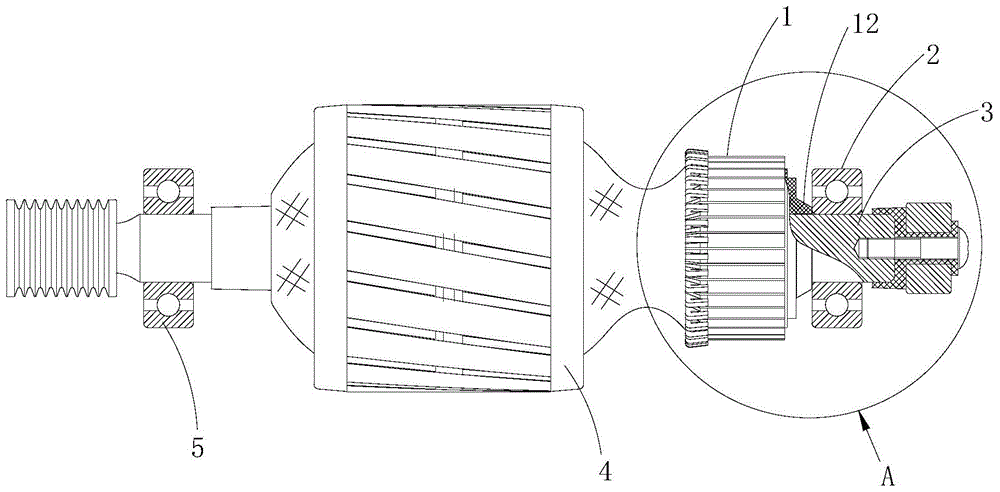

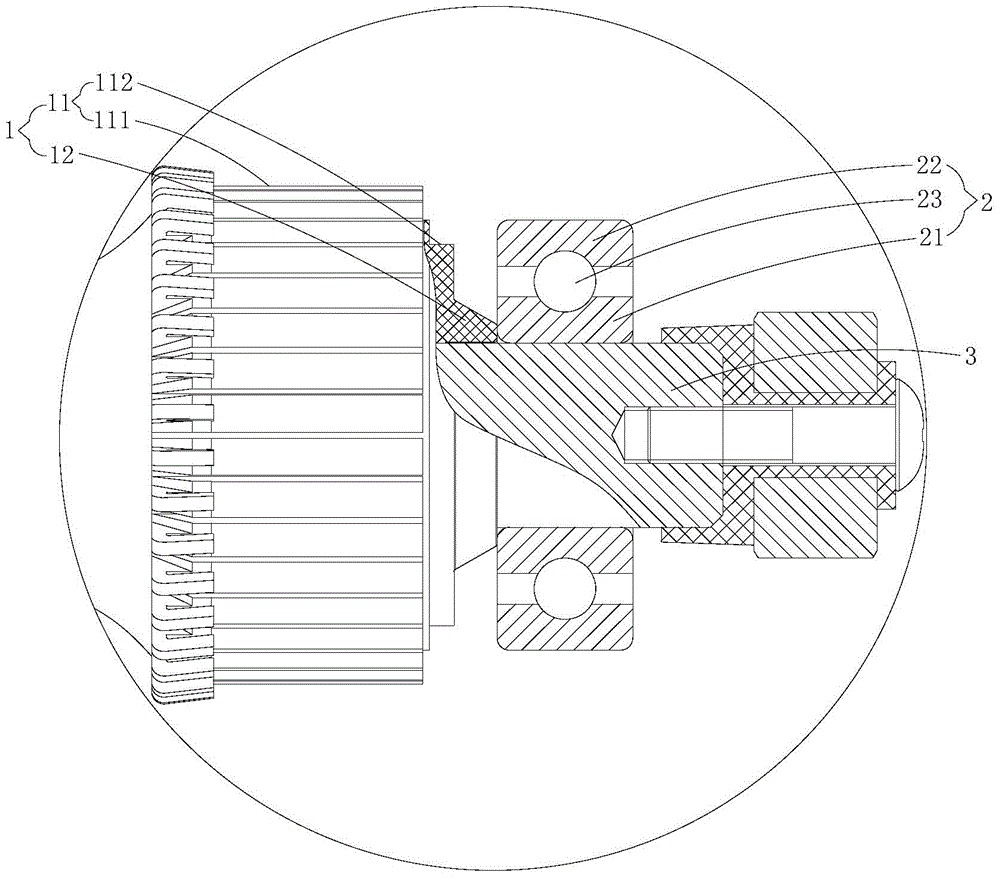

Conjugate cam driving mechanism with error compensation function

The invention discloses a conjugated cam driving mechanism with an error compensation function. The conjugated cam driving mechanism comprises a main cam, an auxiliary cam, a first lower oscillating bar, a second lower oscillating bar, an angle modulating screw and a belleville spring. The second lower oscillating bar is arranged on the front surface of the first lower oscillating bar, the upper end of the second lower oscillating bar is fixed onto an oscillating axle of the first lower oscillating bar, the second lower oscillating bar and the first lower oscillating bar form a T-shaped oscillating bar, a guiding blind hole is arranged on a side surface of the second lower oscillating bar back to the auxiliary cam, a compensation block is perpendicularly connected onto the front surface of the first lower oscillating bar, a limiting blind hole which is opposite to the guiding blind hole and is coaxial with the guiding blind hole is arranged on the lower portion of the compensation block, and a threaded through hole parallel to the limiting blind hole is arranged on the upper portion of the compensation block; the angle modulating screw is screwed in the threaded through hole of the first lower oscillating bar, and an end of the angle modulating screw is abutted to the side surface of the second lower oscillating bar back to the auxiliary cam; and the belleville spring is arranged between the guiding blind hole of the second lower oscillating bar and the limiting blind hole of the first oscillating bar.

Owner:SHANGHAI YOCO PRINTING MACHINERY

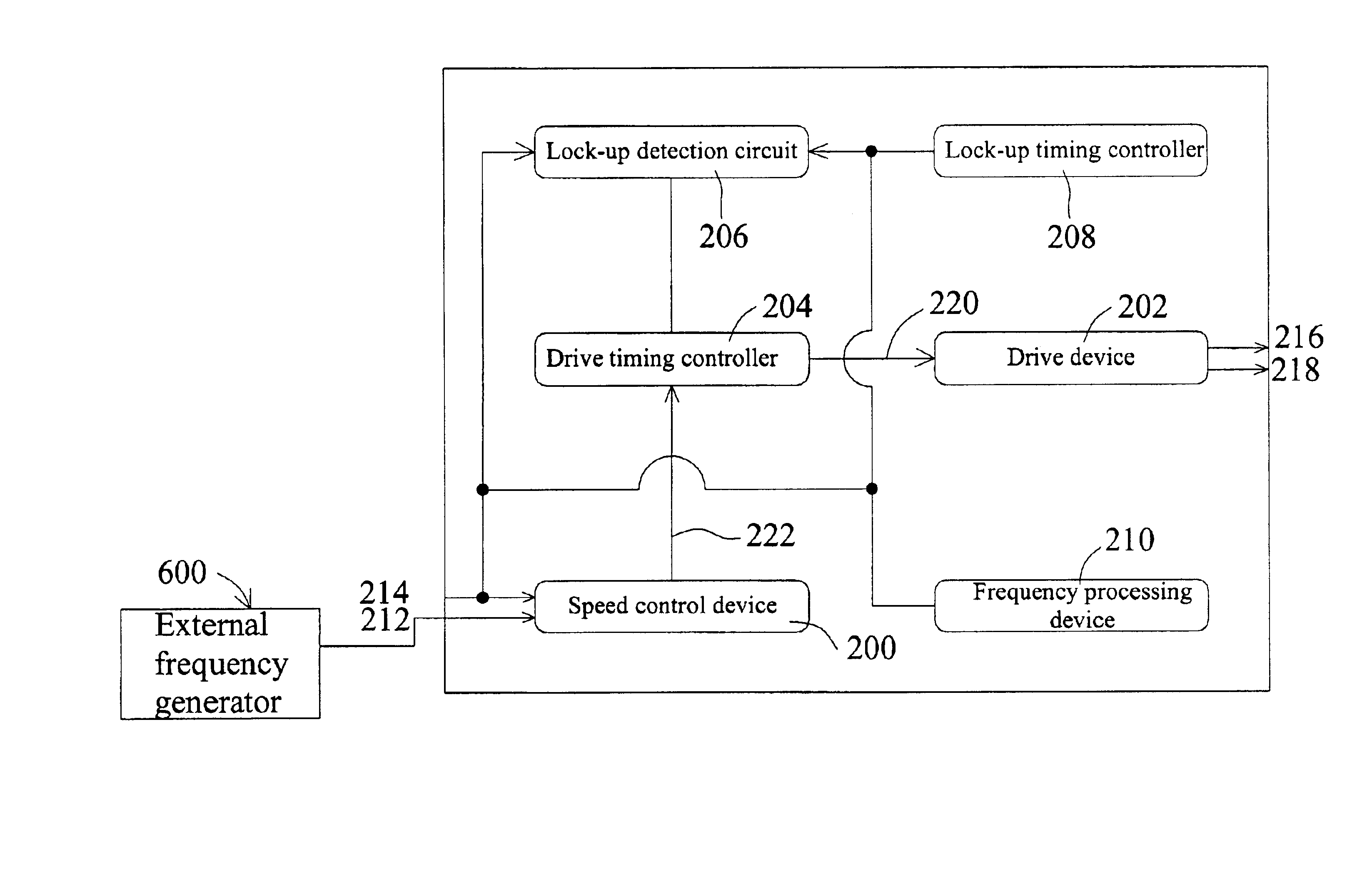

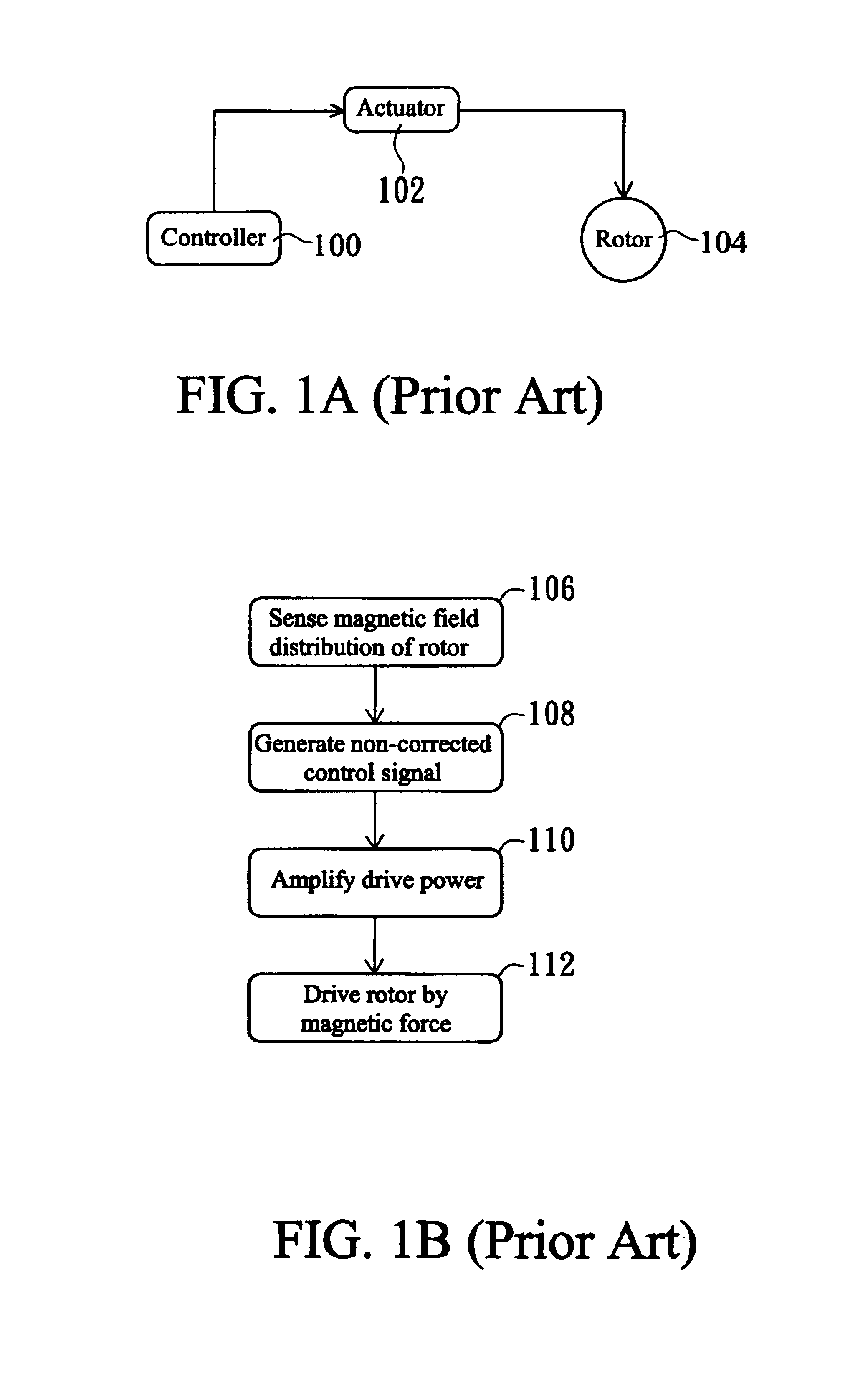

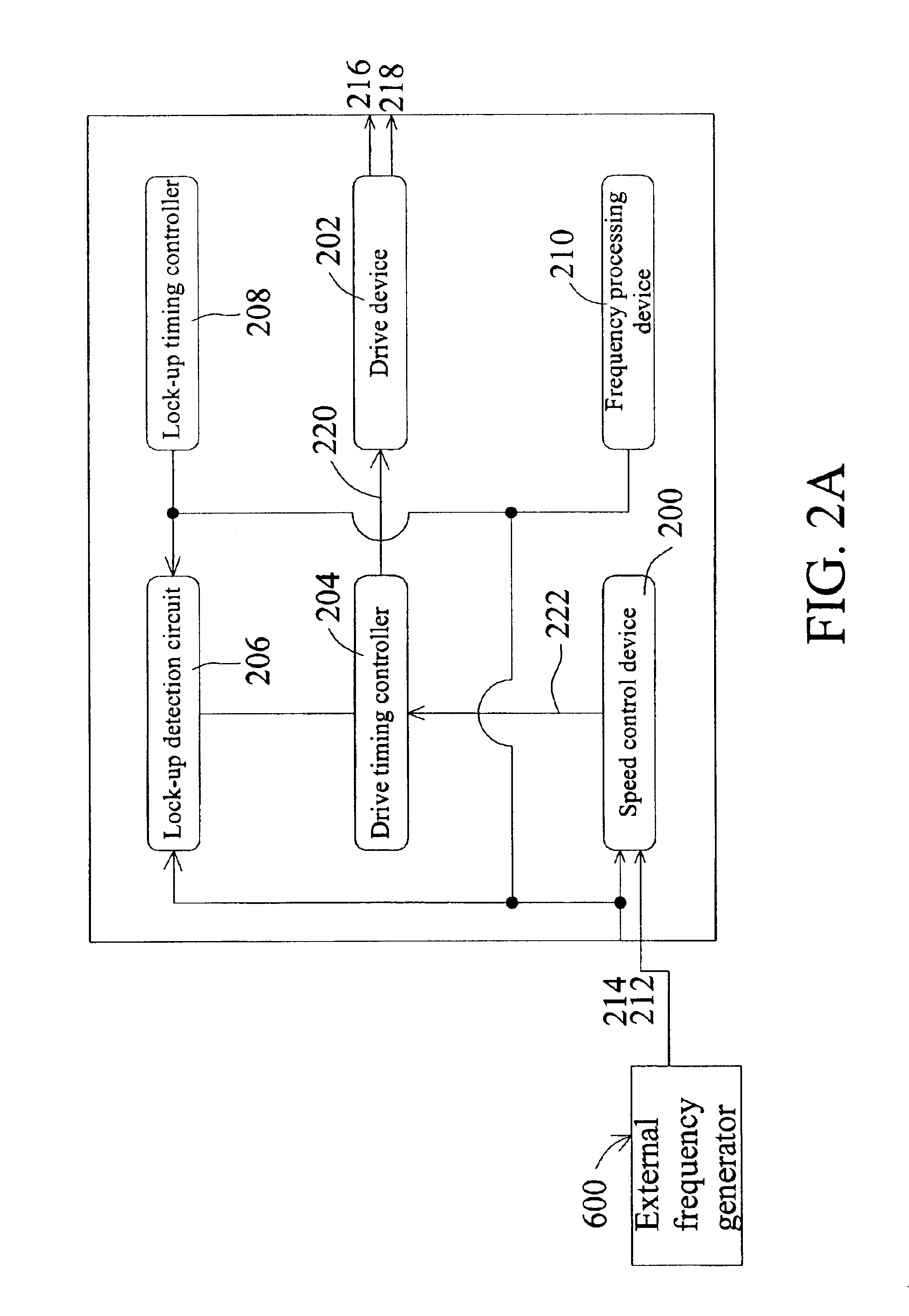

Motor drive circuit and method with frequency setting and correcting functions

ActiveUS6933699B2Increase manufacturing yieldAvoid vibration and noiseSingle-phase induction motor startersMotor/generator/converter stoppersMotor drivePulse-width modulation

A motor drive circuit and method with frequency setting and correcting functions. The drive circuit includes a speed control device, which simultaneously receives a sense signal and a rotation frequency signal. A pulse width modulation signal capable of modulating a duty ratio may be generated by a pulse width modulation method. The pulse width modulation signal is then transferred to a drive timing controller that generates a timing control signal to control output timing of a power drive signal for the drive circuit. Meanwhile, a sensor is used to detect a motor and to generate a correction sense signal, which is immediately fed back to the speed control device to form a closed loop control, so that the rotation frequency of the motor may be automatically corrected and set.

Owner:PROLIFIC TECH INC

Electric cooker and control method thereof

The invention provides an electric cooker and a control method of the electric cooker. The electric cooker comprises a cooker body provided with an axial thrust bearing, a rotation driving device, a temperature controller and an electromagnet, wherein the electromagnet is connected with the temperature controller, and when the rotation driving device works, a controller controls the electromagnet to drive the temperature controller to move downwards, so that the temperature controller is separated from an inner pot, and therefore, the problems that the inner pot is scratched and the temperature controller is worn due to the fact that the inner pot contacts the temperature controller to have friction are solved; a rotation shaft is connected to the central position of the lower bottom wall of the inner pot, is connected with the rotation driving device, and drives the inner pot to rotate, and the lower end of the rotation shaft is supported by the axial thrust bearing, so that the rotation driving device only transmits the torque but does not bear the gravity of the inner pot, therefore, the damage speed of the rotation driving device is decreased, and the vibration and noises are prevented from being transmitted to the inner pot; a seal ring is arranged on the periphery of a cover board, and connected with the open end of the inner pot in a sealing manner, a rotation bracket is connected to the central position of the upper board surface of the cover board, the upper end of the rotation bracket is connected with a cooker cover, and the cover board rotates together with the inner pot.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

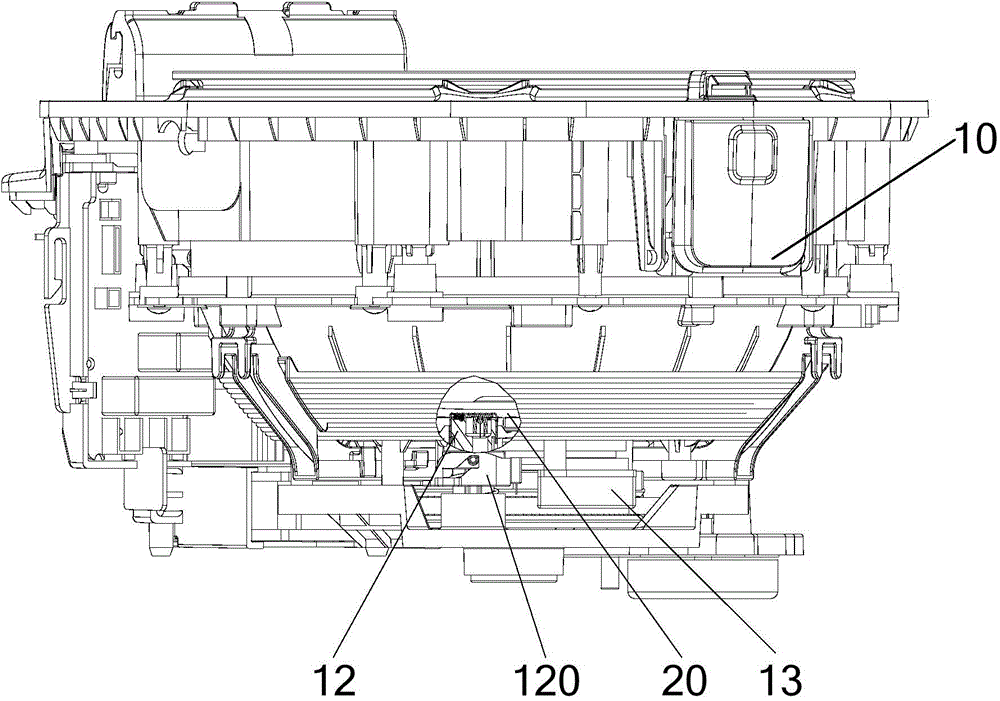

Rotary compressor

ActiveUS20130115122A1Reduce noiseReduce vibrationRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringMechanical engineering

A rotary compressor having an improved supporting structure and a smaller size thereof, reducing the vibration and noise and providing various fields of application other than an air conditioner, the rotary compressor provided with a compression part and a driving part and including a first case forming an external appearance of the rotary compressor, a second case provided inside the first case and provided with the compression part and the driving part at an inner side thereof, and a supporting member configured to support the second case and provided at an inner side of the first case.

Owner:SAMSUNG ELECTRONICS CO LTD

Hard disk drive

InactiveUS20050168868A1Avoid vibration and noiseApparatus for flat record carriersUndesired vibrations/sounds insulation/absorptionHard disc driveBreather

A hard disk drive including: a base; a disk pivotally installed in the base to store data; an actuator installed in the base to move a read / write head to a predetermined position of the disk; a cover assembled with the base and having an air hole for making internal / external pressures of the hard disk drive equal to each other; and a breather filter interposed between the cover and the base in order to filter air introduced through the air hole of the cover. An upper portion of the breather filter is tightly coupled to the cover and a lower portion of the breather filter is tightly coupled to the base.

Owner:SAMSUNG ELECTRONICS CO LTD

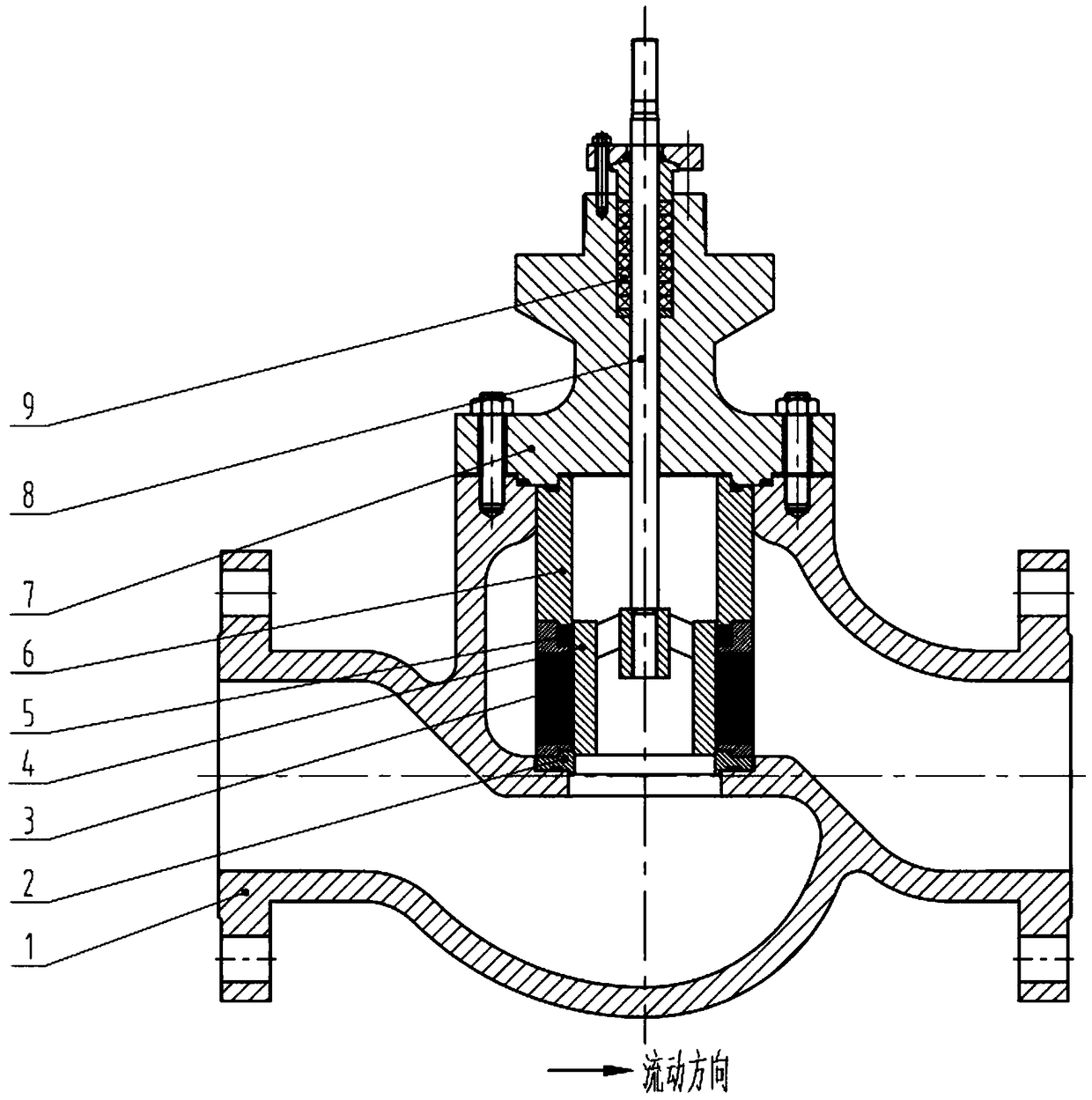

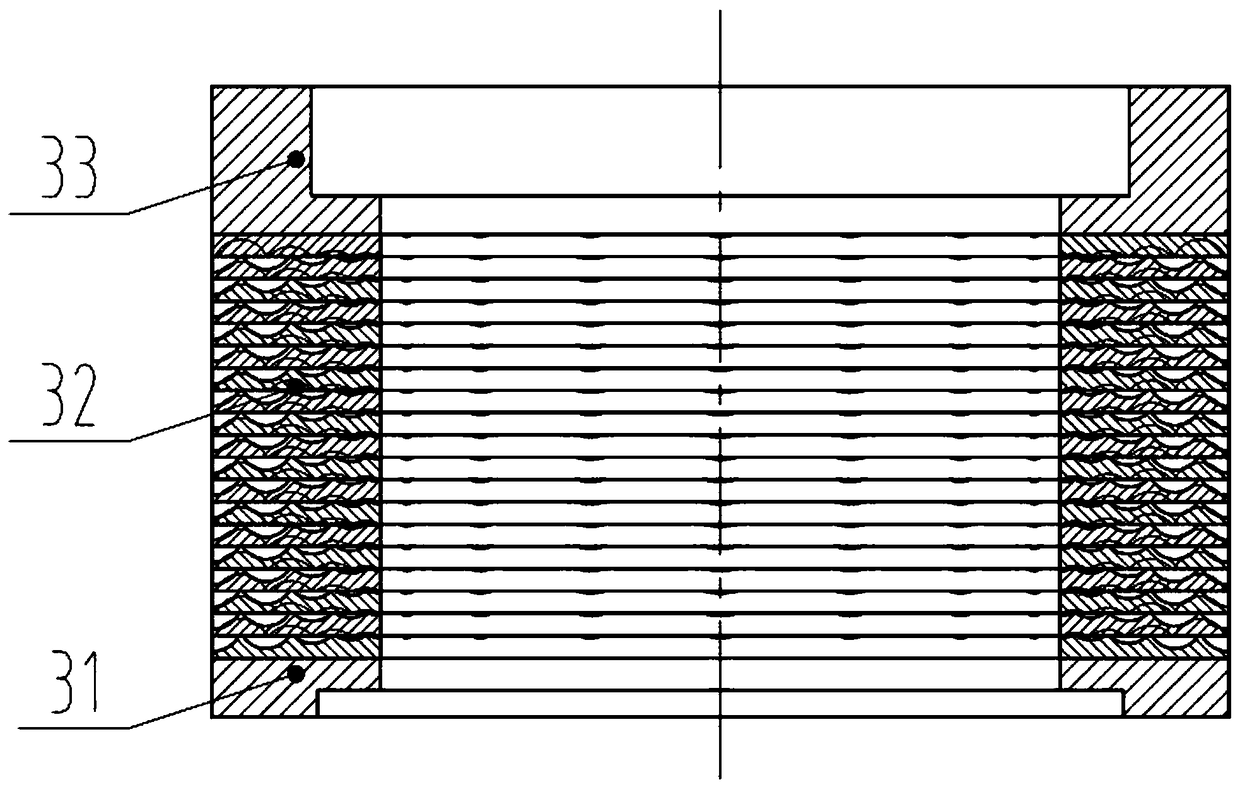

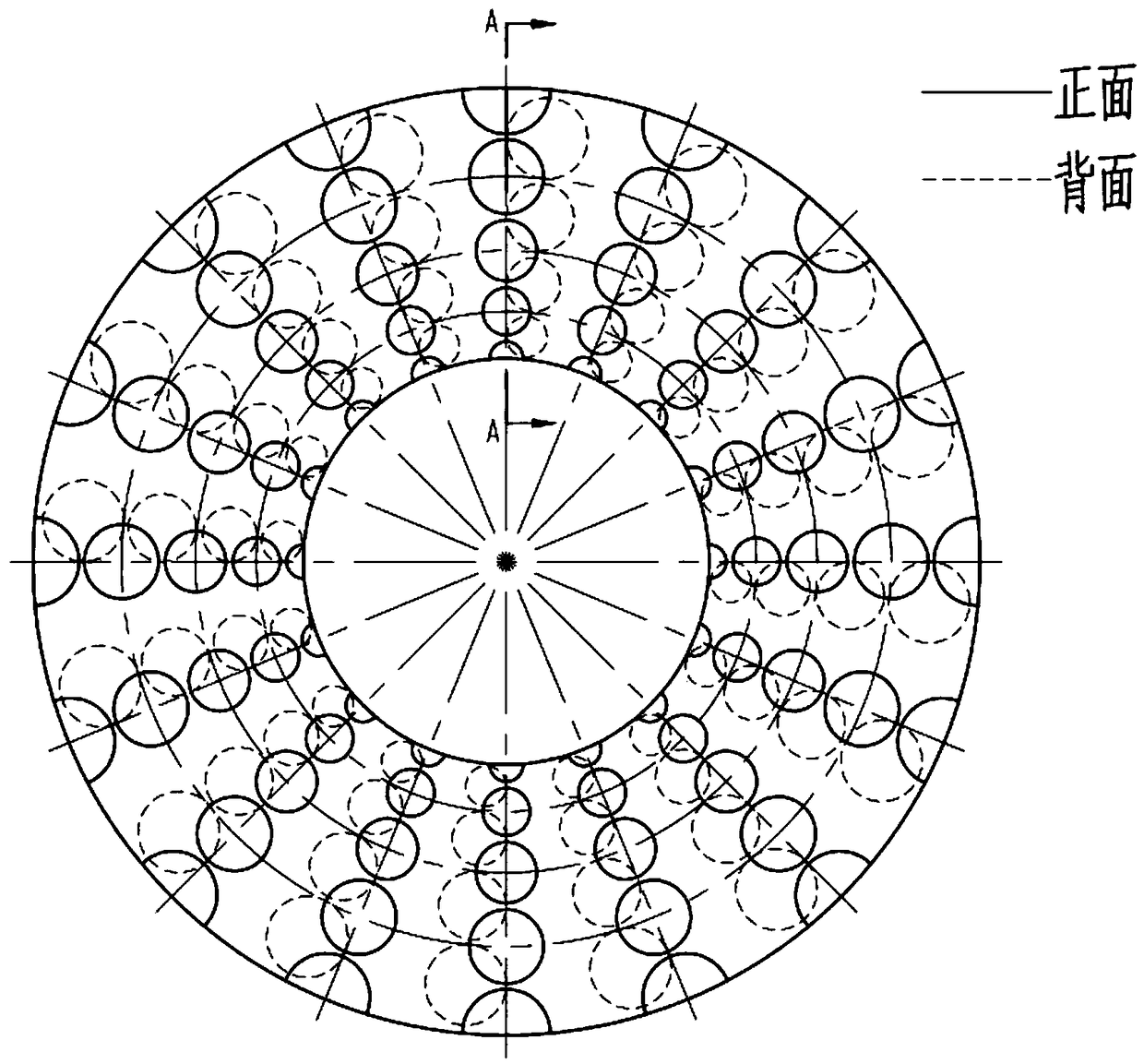

Maze type sleeve regulating valve

ActiveCN108953754AAvoid cavitationAvoid vibration and noiseValve members for absorbing fluid energyLift valveEngineeringPressure reduction

The invention relates to a maze type sleeve regulating valve. The maze type sleeve regulating valve comprises a valve body, a valve seat, a maze assembly, a valve element, a balance sealing ring, an upper sleeve, a valve cover, a valve rod and a sealing assembly. The maze type sleeve regulating valve realizes stable multi-stage pressure reduction through circular slots with different diameters, which are distributed on front and back surfaces of discs. The diameters of the circular slots are gradually increased from inside to outside; and after each disc is fixed, the circular slot formed between every two adjacent discs co-acts to form a runner with an over-flow section gradually increasing from inside to outside. The runner which can be gradually widened can effectively avoid occurrenceof harm such as cavitation, and can prevent the valve from generating vibrations and noises. Besides, compared with an existing maze type regulating valve, the maze type sleeve regulating valve has the advantages of being simple in manufacturing process, convenient to mount, safe and reliable, and the like, realizes reducing processing working hours, and reduces the cost.

Owner:JIANGSU UNIV

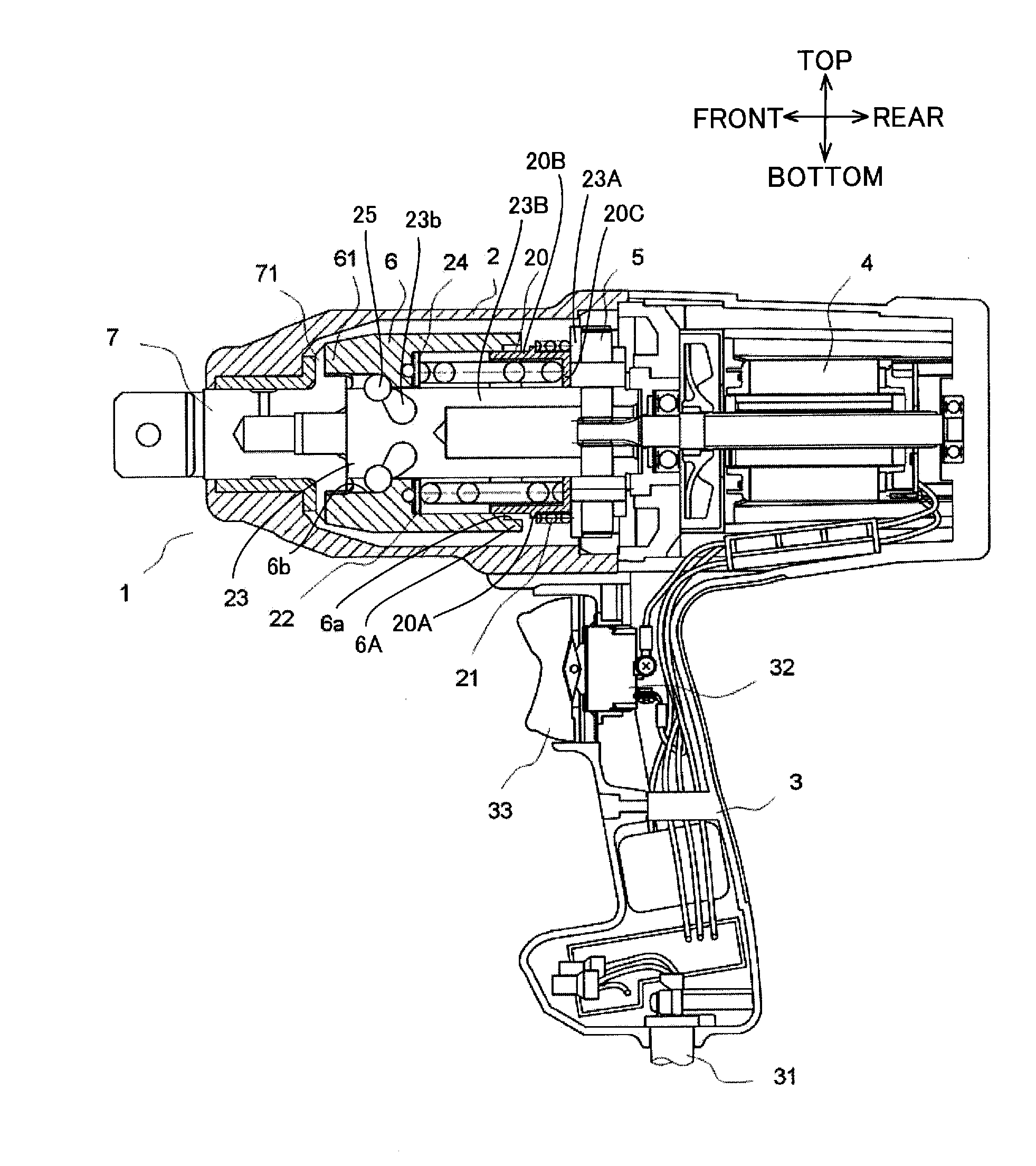

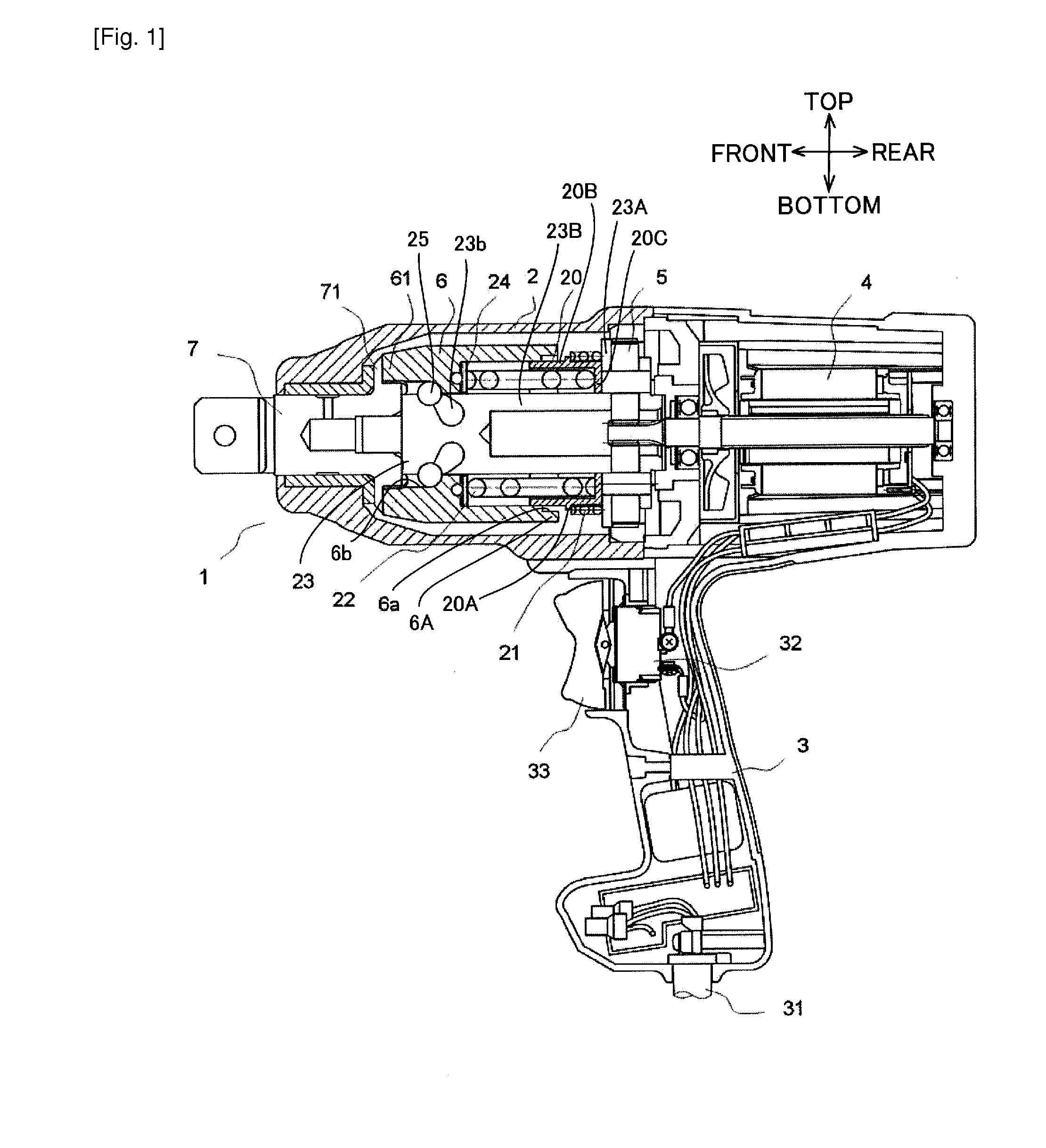

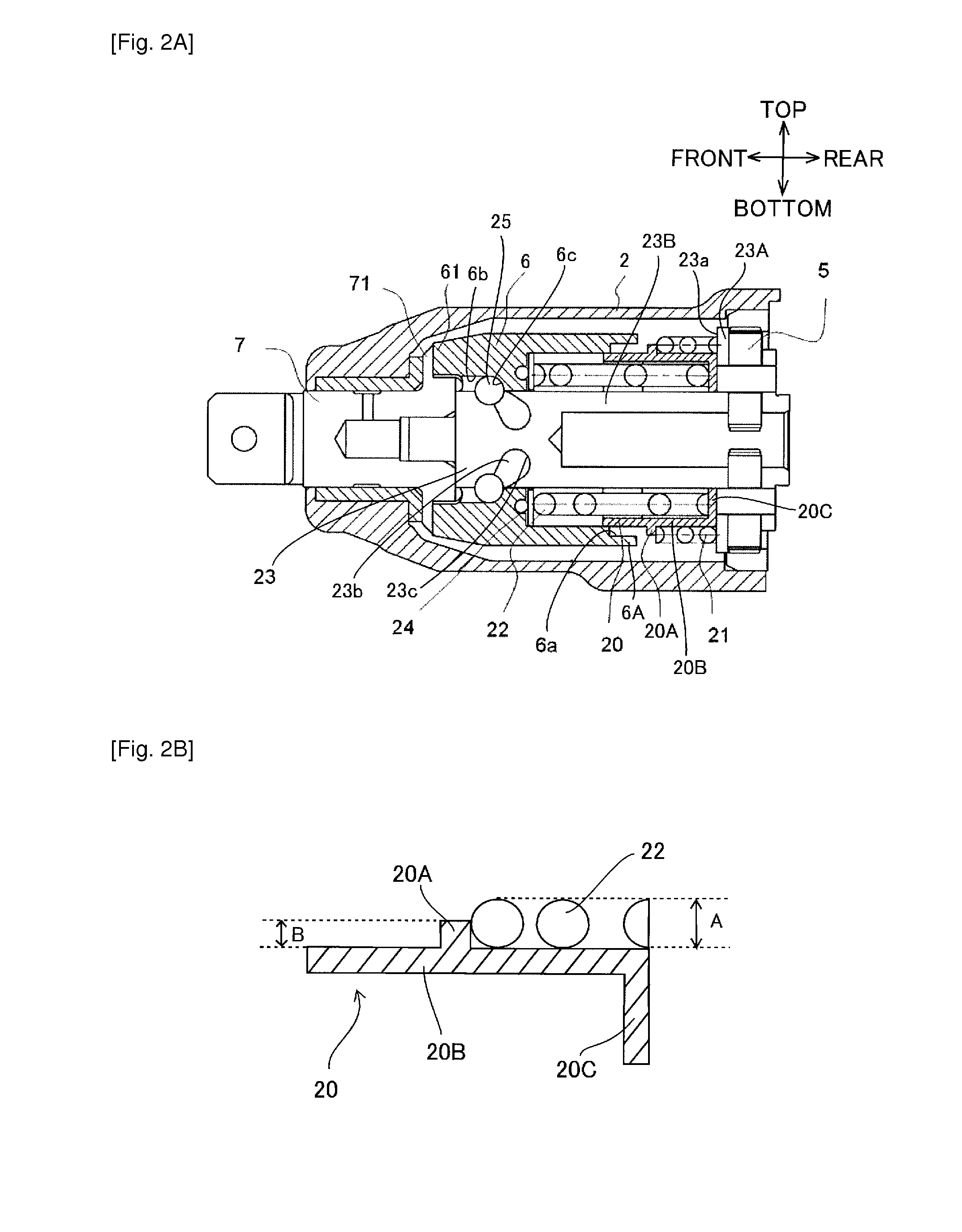

Rotational Impact Tool

A rotational impact tool including: a motor; a spindle; a hammer; a first resilient member; and an anvil. The motor generates a drive force. The spindle rotates in a rotating direction upon transmission of the drive force from the motor. The spindle has an axis extending in an axial direction that includes a first direction and a second direction opposite to the first direction. The hammer moves in the rotational direction and in the axial direction relative to the spindle to generate a rotational impact force. The first resilient member urges the hammer in the first direction. The anvil transmits the rotational impact force to an end bit. The rotational impact tool further includes a second resilient member. The second resilient member is disposed at a position radially outward of the first resilient member and is configured to abut the hammer when the hammer moves in the second direction.

Owner:HITACHI KOKI CO LTD

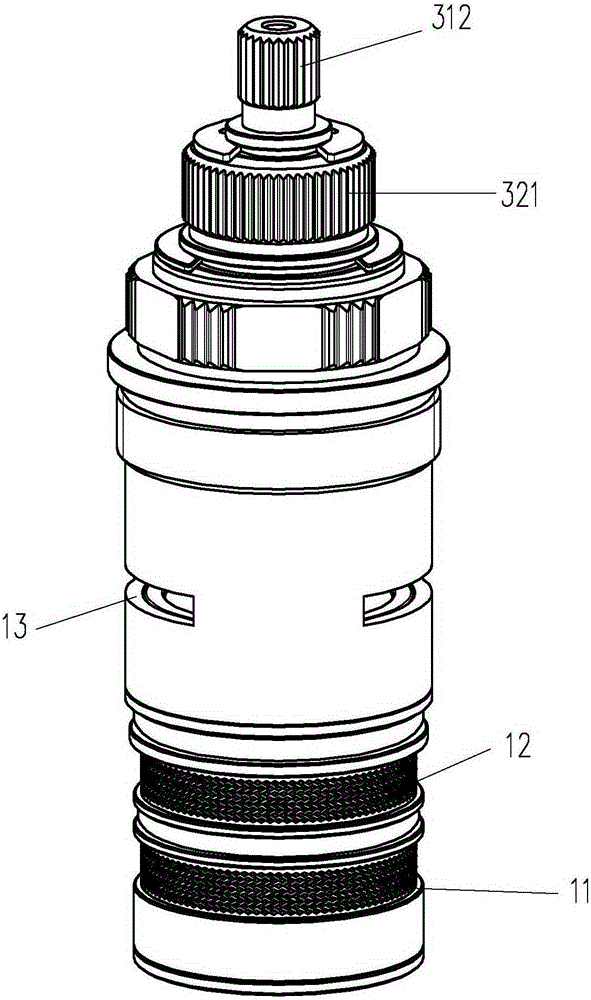

Double-handle coaxial temperature control valve element

ActiveCN106609864AMeet usage habitsWater temperature is accurateOperating means/releasing devices for valvesTemperatue controlTemperature controlThermal water

The invention provides a double-handle coaxial temperature control valve element. The double-handle coaxial temperature control valve element comprises a valve body, a thermosensitive element and an adjusting component. The valve body is provided with a cold water inlet, a hot water inlet and a mixed water outlet. The thermosensitive element is provided with a temperature sensing end and a telescopic end. The temperature sensing end gets close to the mixed water outlet and is used for sensing the outlet water temperature information of the mixed water outlet and transmitting the information to the telescopic end. The adjusting component is provided with a first rotary adjusting part and a second rotary adjusting part which are coaxially arranged from top to bottom. The first rotary adjusting part is in linkage with a flow adjusting part. When the first rotary adjusting part is rotated, the flow adjusting part can open or close the mixed water outlet. The second rotary adjusting part is in linkage with a temperature adjusting part. When the second rotary adjusting part is rotated, the temperature adjusting part can adjust the water passing area of the cold water inlet and the hot water inlet. According to the double-handle coaxial temperature control valve element, the upper rotary adjusting part is used for opening the mixed water outlet, and the lower rotary adjusting part is used for adjusting the outlet water temperature.

Owner:ZHANGZHOU SOLEX SMART HOME CO LTD

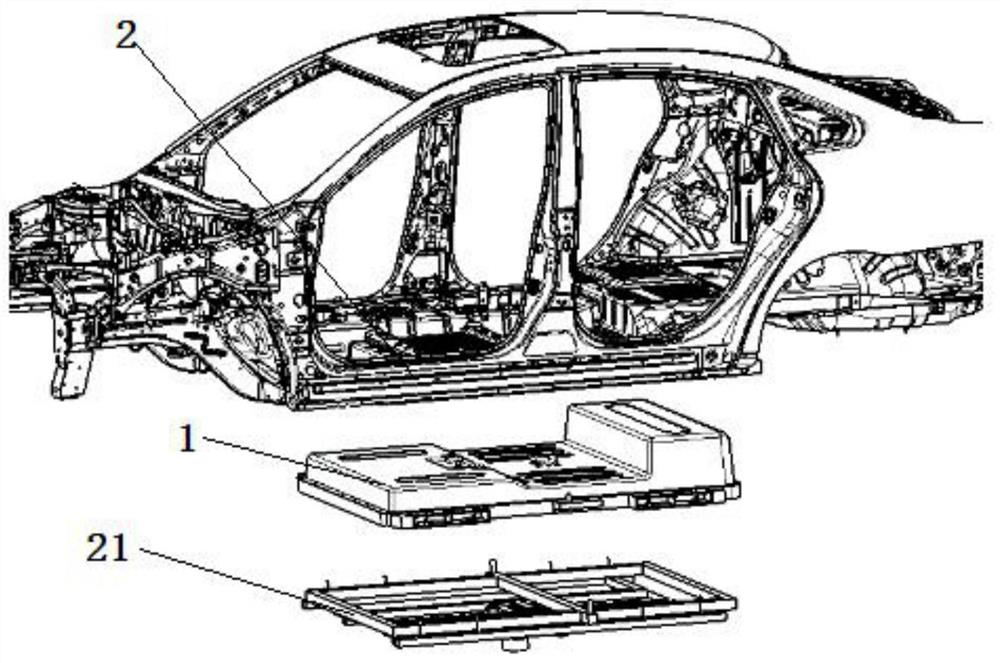

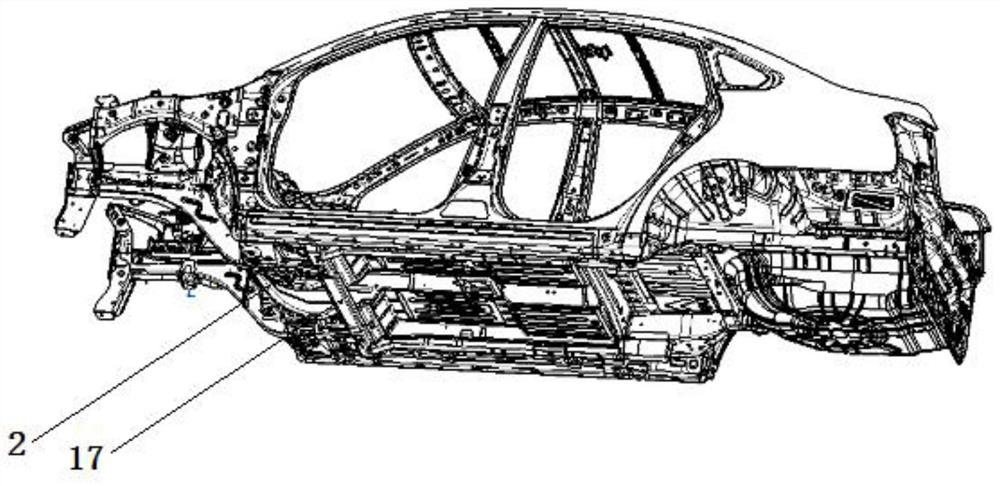

Disassembling and assembling system and disassembling and assembling method for power battery box with side edge having telescopic function

ActiveCN113561839AFix jitterQuick releaseCharging stationsElectric propulsion mountingPower batteryEngineering

The invention discloses a disassembling and assembling system and method for a power battery box with the side edge having a telescopic function. The disassembling and assembling system comprises a vehicle body bottom plate assembly, a battery box body located below the vehicle body bottom plate assembly and a battery box disassembly and assembly mechanism capable of enabling the battery box body to be installed below the vehicle body bottom plate assembly or enabling the battery box body to be unlocked from the lower portion of the vehicle body bottom plate assembly. The battery box body is provided with a drawer type telescopic structure which can be matched and fixed with a vehicle body bottom plate assembly; the drawer type telescopic structure comprises a fixed box body which is fixed on the side surface of the battery box body, a sliding box body which is matched with the fixed box body and can translate towards the inner side or the outer side of the fixed box body relative to the fixed box body, and a battery box positioning clamping groove matched with the sliding box body is formed in the bottom of the vehicle body bottom plate assembly. The battery box disassembling and assembling mechanism comprises a shifting fork frame capable of moving left and right and a shifting fork rod arranged on the shifting fork frame and used for driving the sliding box body to move left and right, and a shifting fork sliding groove and a shifting fork hole which correspond to each other, can be matched with the shifting fork rod and drive the sliding box body to slide are formed in the fixed box body and the sliding box body respectively.

Owner:DONGFENG MOTOR GRP

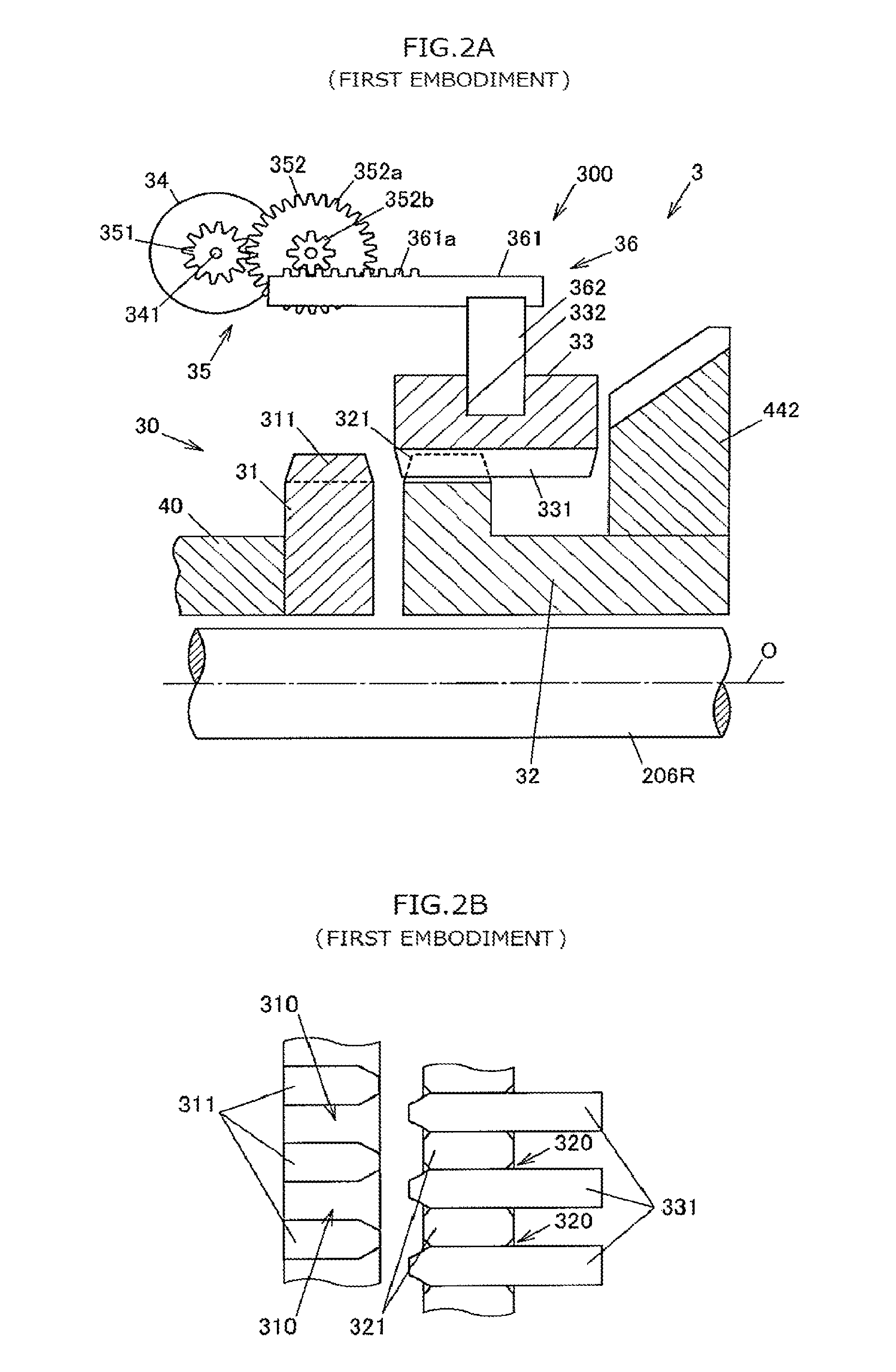

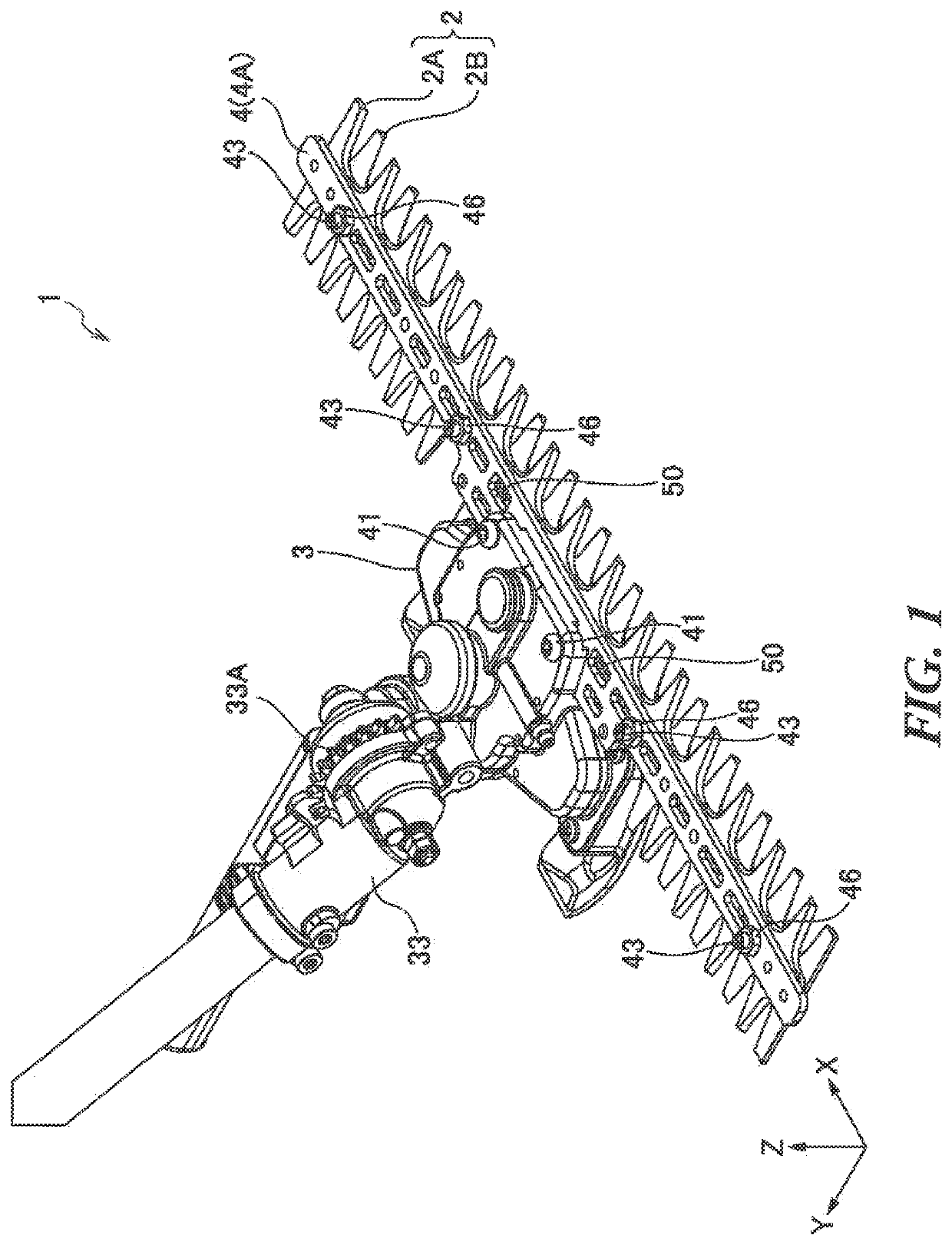

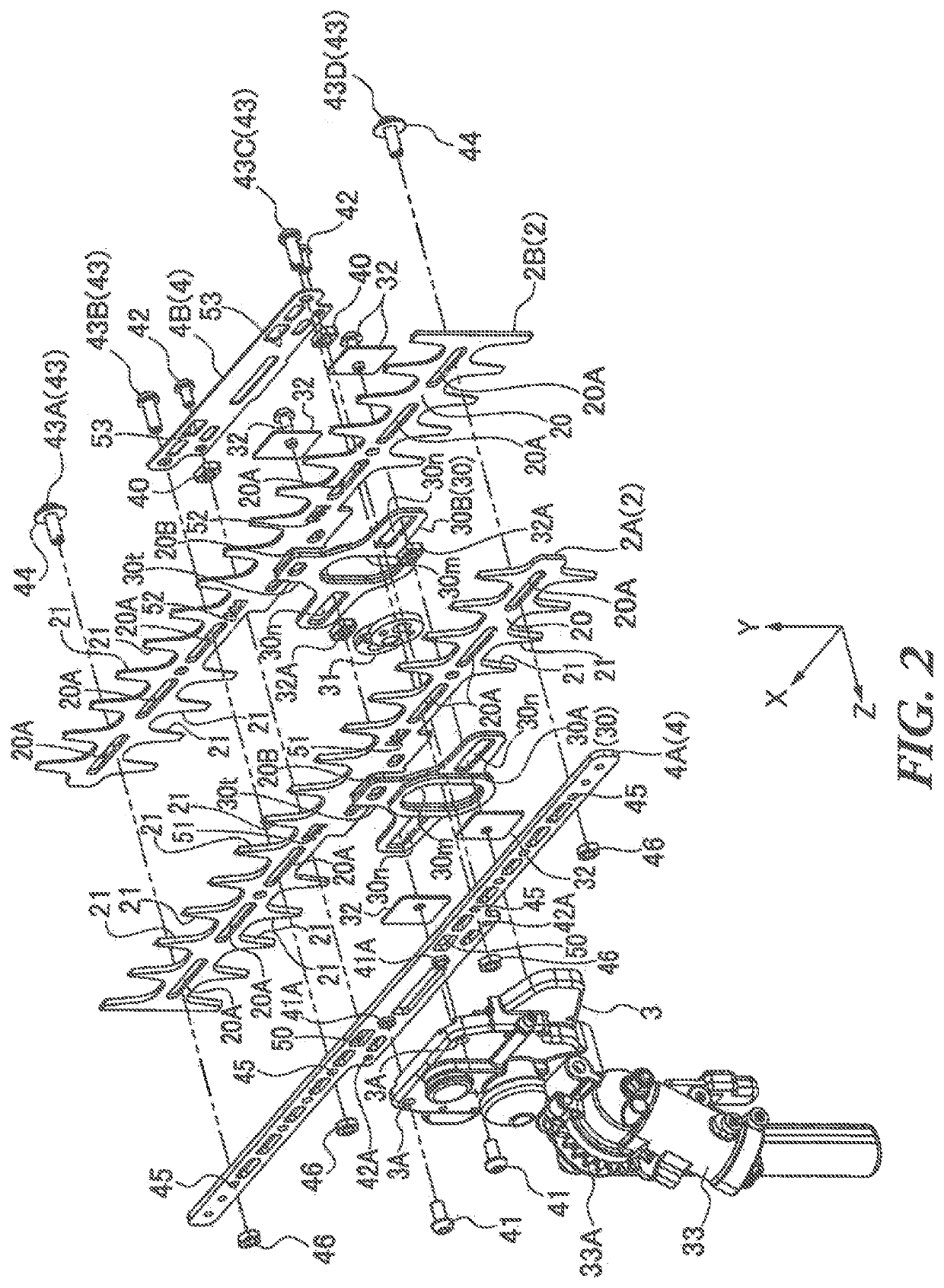

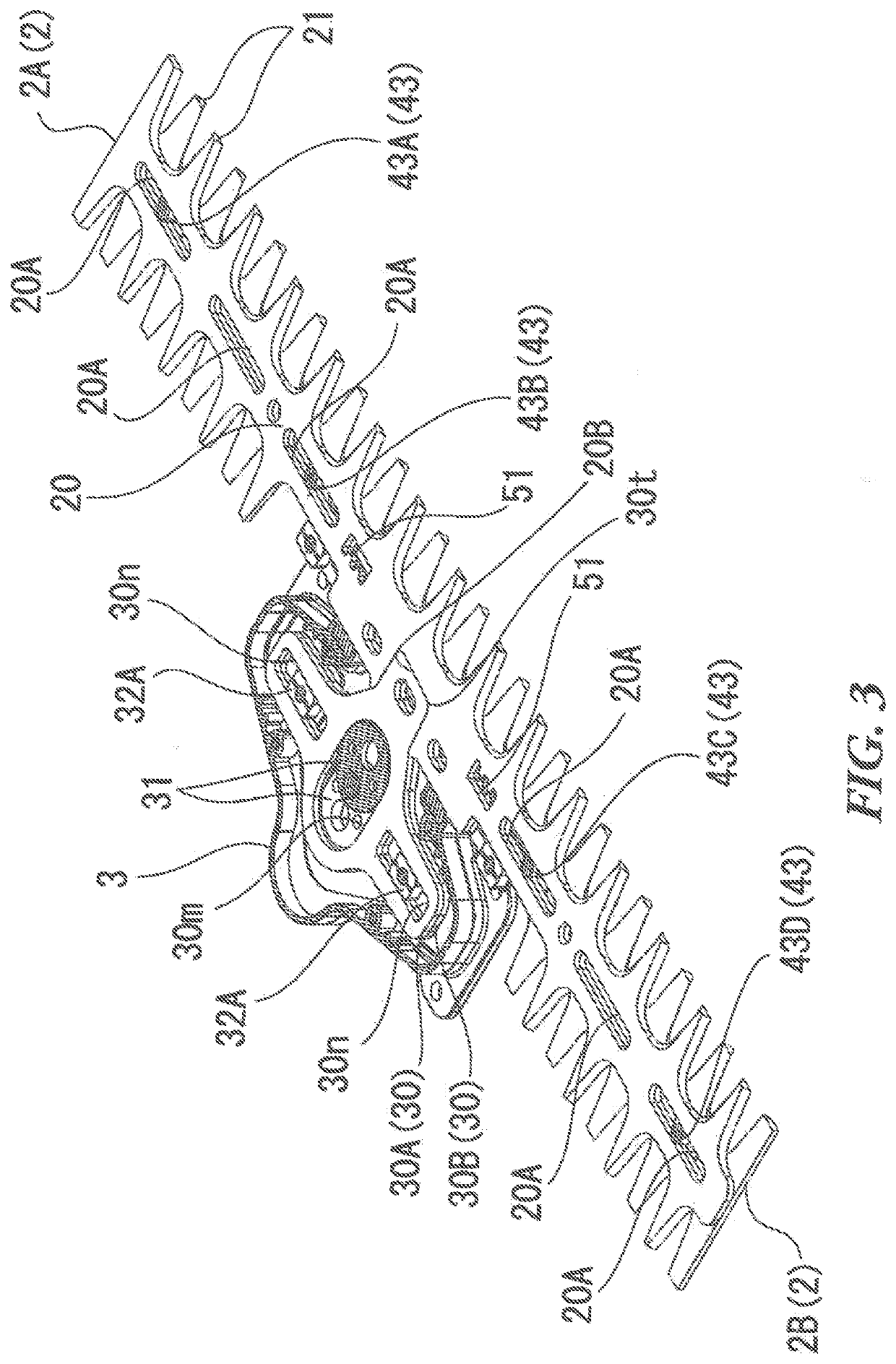

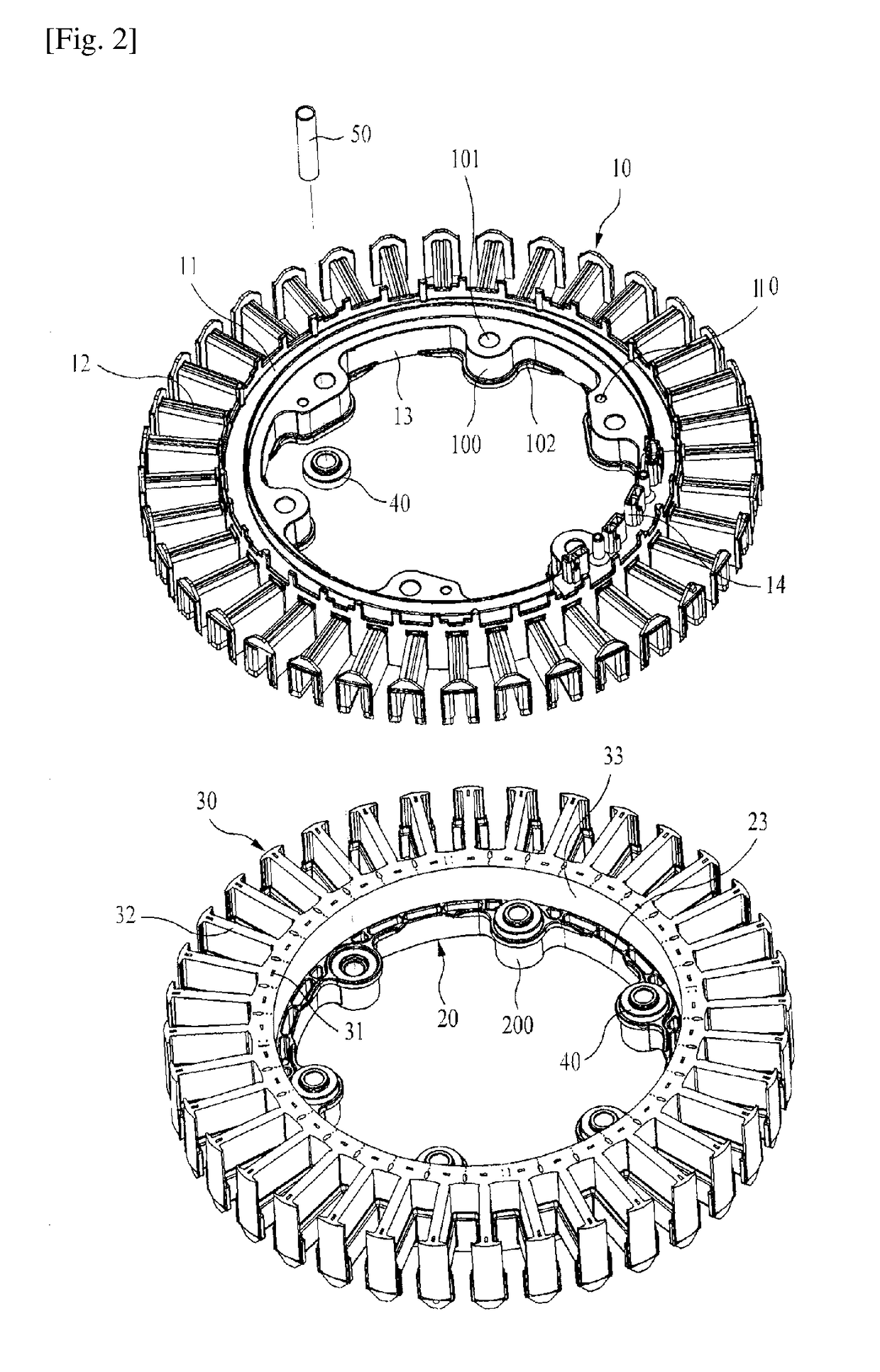

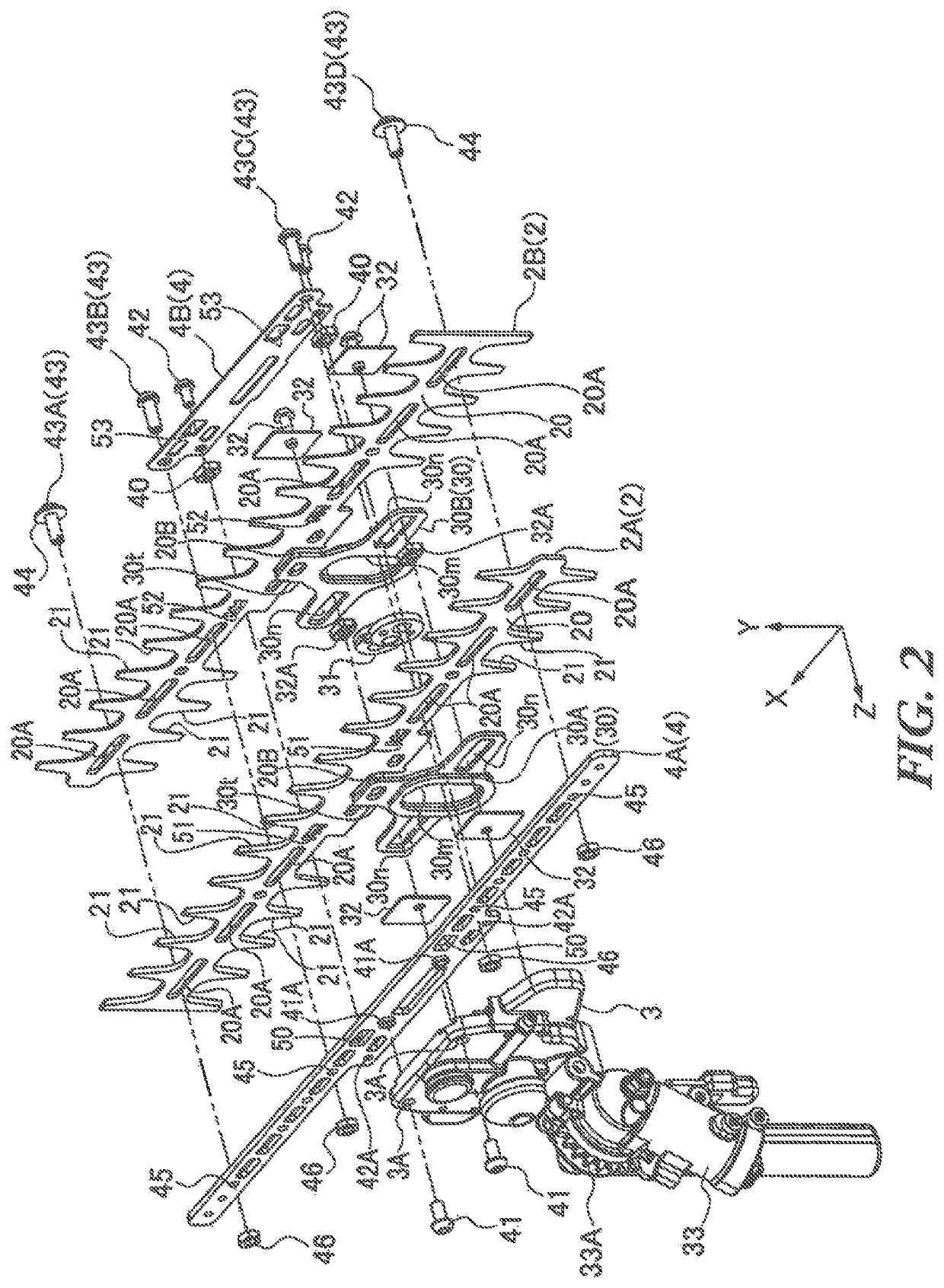

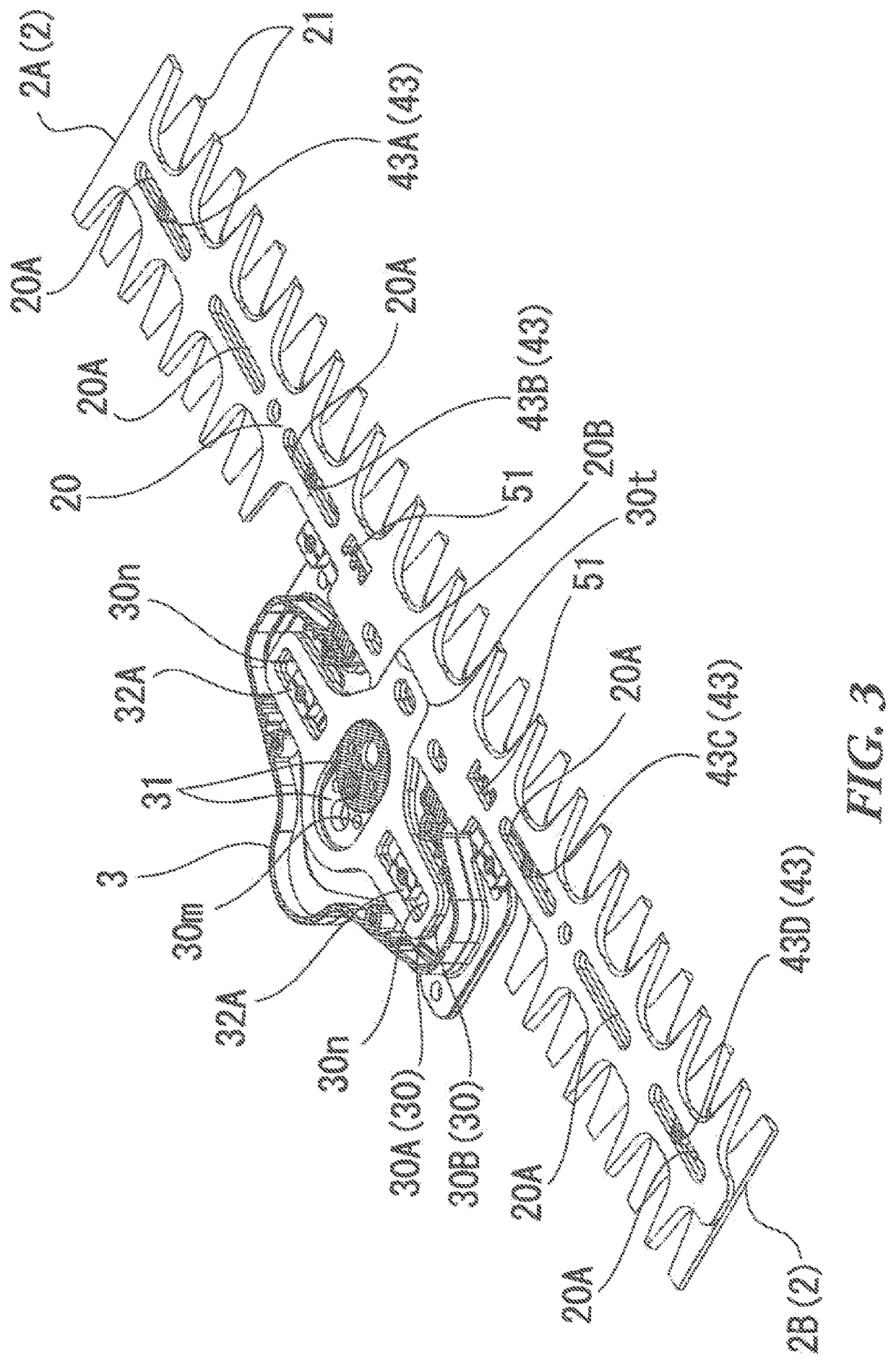

Reciprocating blade apparatus and handheld working machine

ActiveUS20210029887A1Smoothly reciprocatedPreventing vibration and noiseHedge trimming apparatusMowersRotational axisReciprocating motion

A reciprocating blade apparatus includes a pair of reciprocating blades stacked on one another in a thickness direction, and a transmission case including a power train configured to reciprocate the pair of reciprocating blades. The power train includes a pair of eccentric cams, and a pair of reciprocating members including fitting holes in which the eccentric cams are fitted, respectively. The pair of reciprocating members is guided to be able to move along an axis line which is parallel to a moving direction of the pair of reciprocating blades and runs through a rotation axis of the eccentric cams.

Owner:YAMABIKO CORP

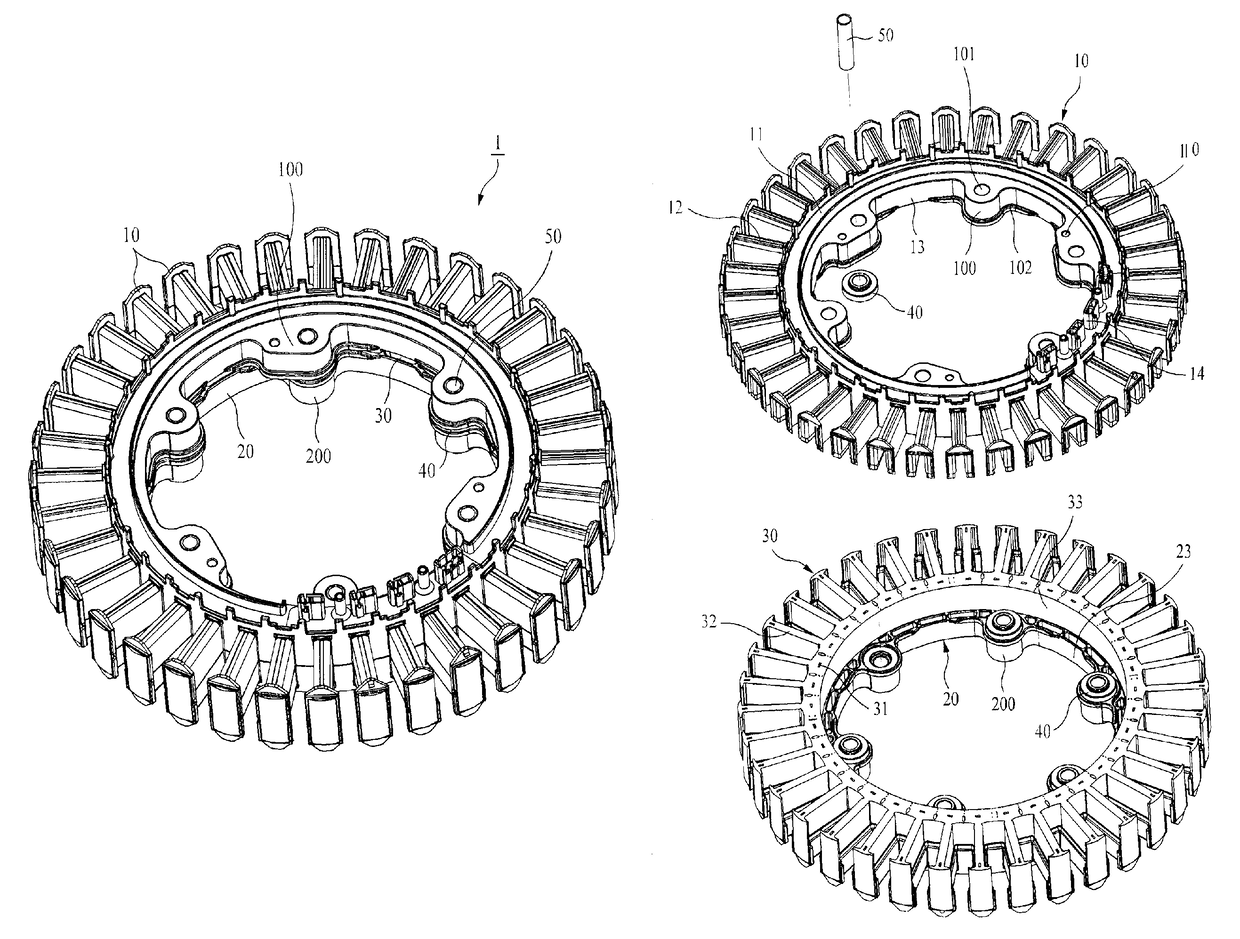

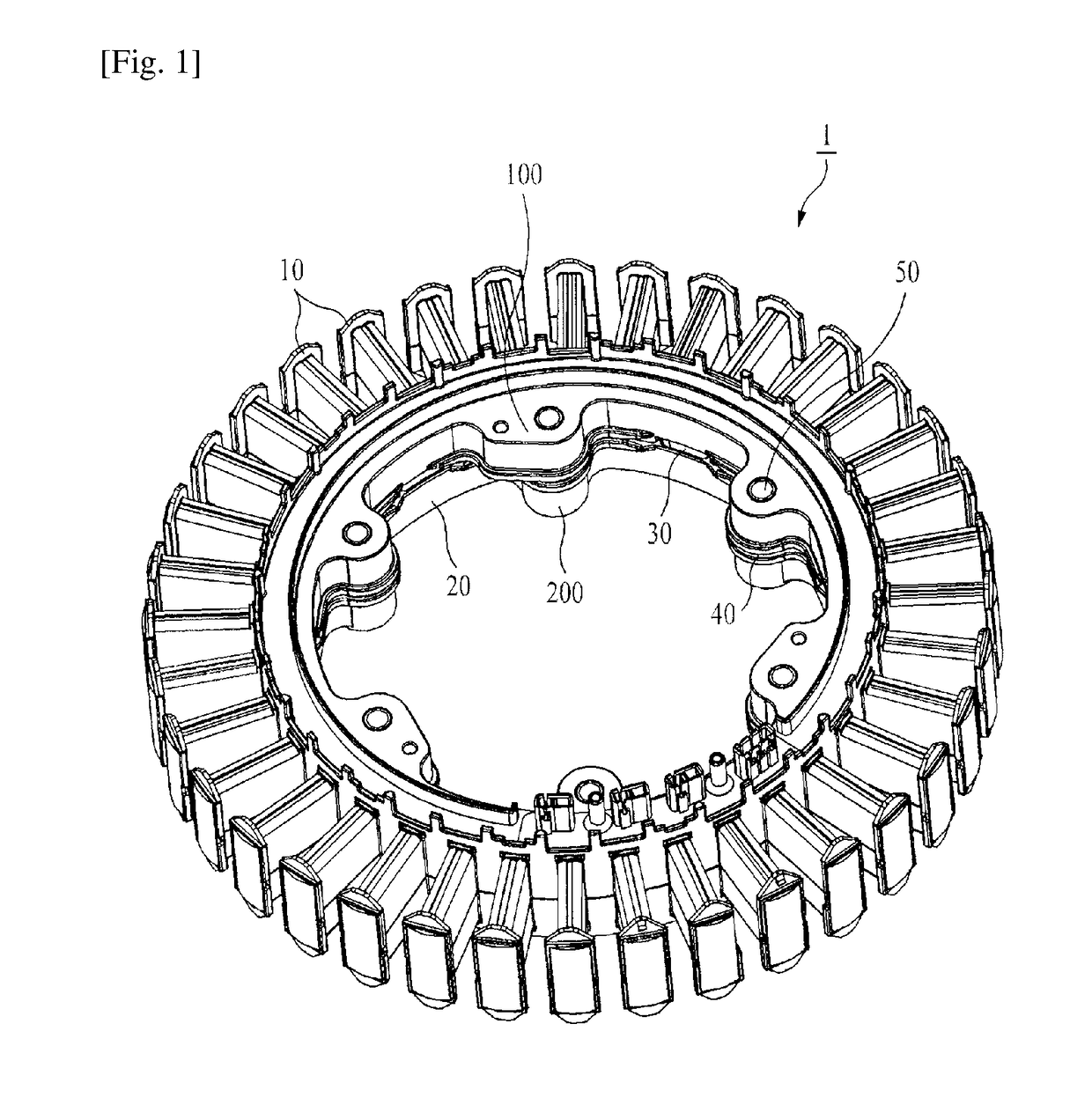

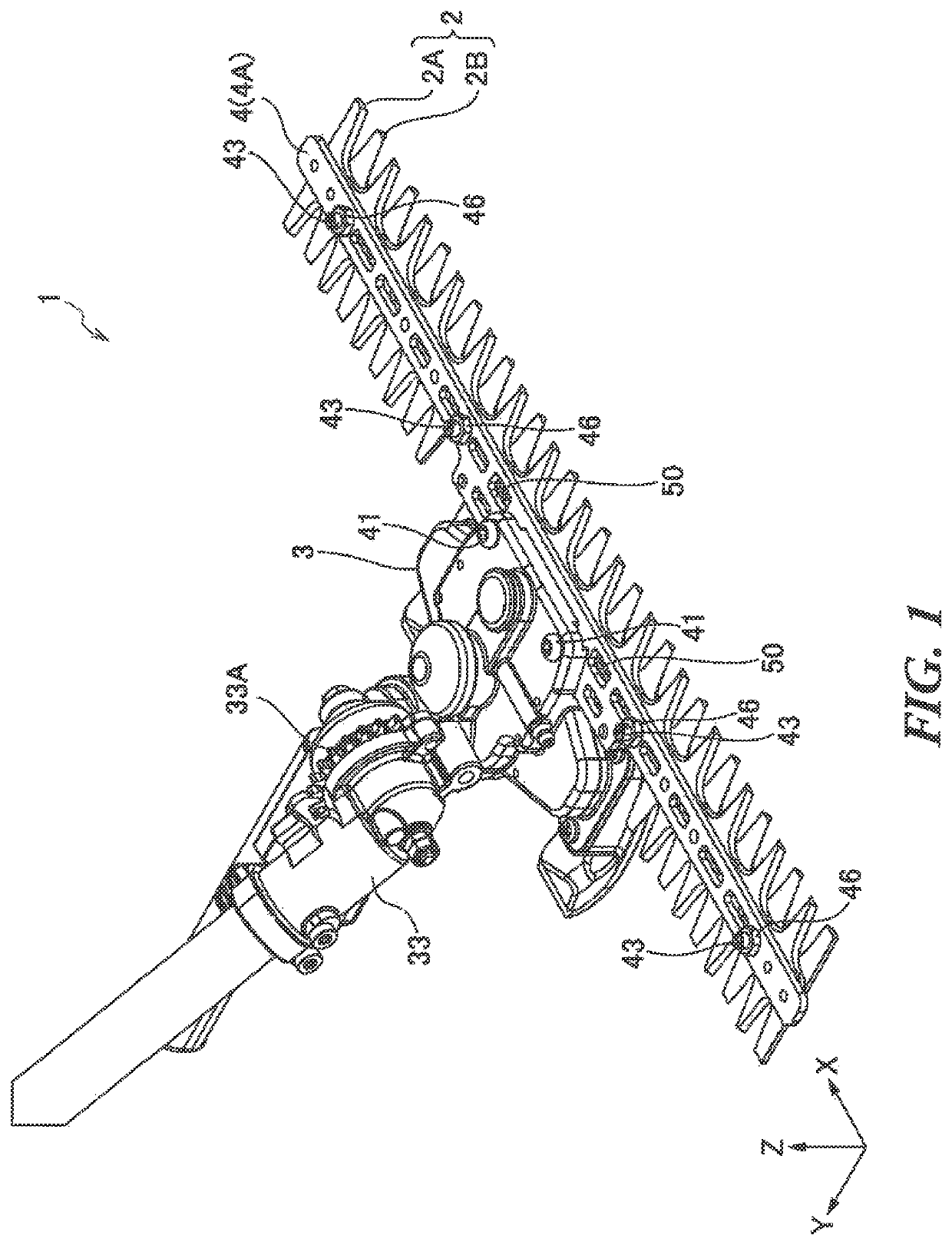

Stator of motor for washing machine

ActiveUS10135313B2Avoid vibration and noiseReduce manufacturing costMagnetic circuit stationary partsMagnetic circuit characterised by insulating materialsEngineeringMechanical engineering

Disclosed is a stator of a motor for a washing machine including: a stator core manufactured by a plurality of steel sheets laminated on top of each other, the stator core having a core base and a plurality of teeth radially formed on the core base; an upper insulator which covers the upper parts of the core base and the teeth to insulate them, the upper insulator having least three upper fastening parts which are formed therein and each of which has an upper fastening hole; and a lower insulator which covers the lower parts of the core base and the teeth to insulate them, the upper insulator having least three upper fastening parts which are formed therein and each of which has a lower fastening hole.

Owner:NEW MOTECH

Reciprocating blade apparatus and handheld working machine

ActiveUS11272671B2Smoothly reciprocatedPreventing vibration and noiseHedge trimming apparatusMowersRotational axisReciprocating motion

A reciprocating blade apparatus includes a pair of reciprocating blades stacked on one another in a thickness direction, and a transmission case including a power train configured to reciprocate the pair of reciprocating blades. The power train includes a pair of eccentric cams, and a pair of reciprocating members including fitting holes in which the eccentric cams are fitted, respectively. The pair of reciprocating members is guided to be able to move along an axis line which is parallel to a moving direction of the pair of reciprocating blades and runs through a rotation axis of the eccentric cams.

Owner:YAMABIKO CORP

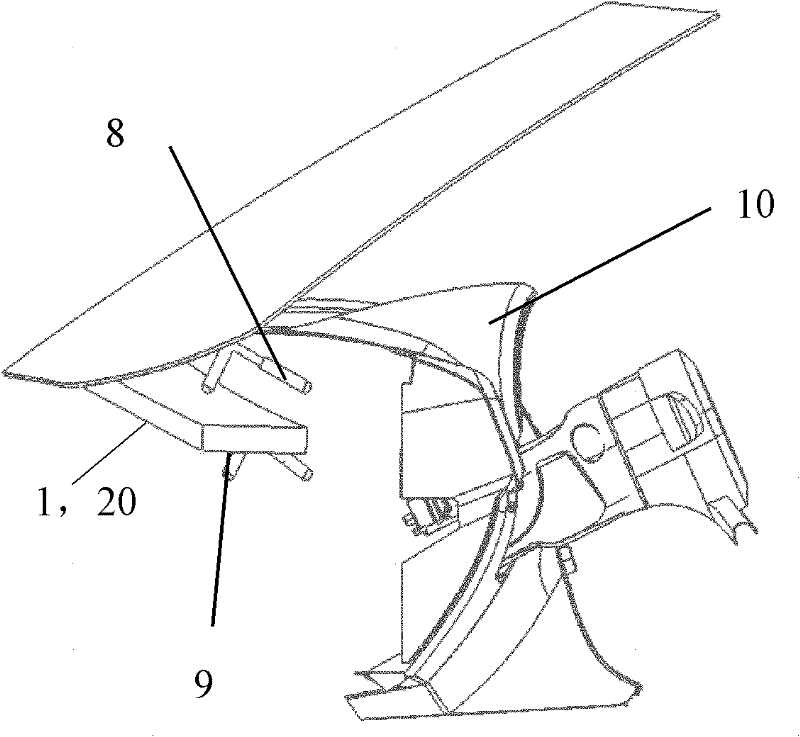

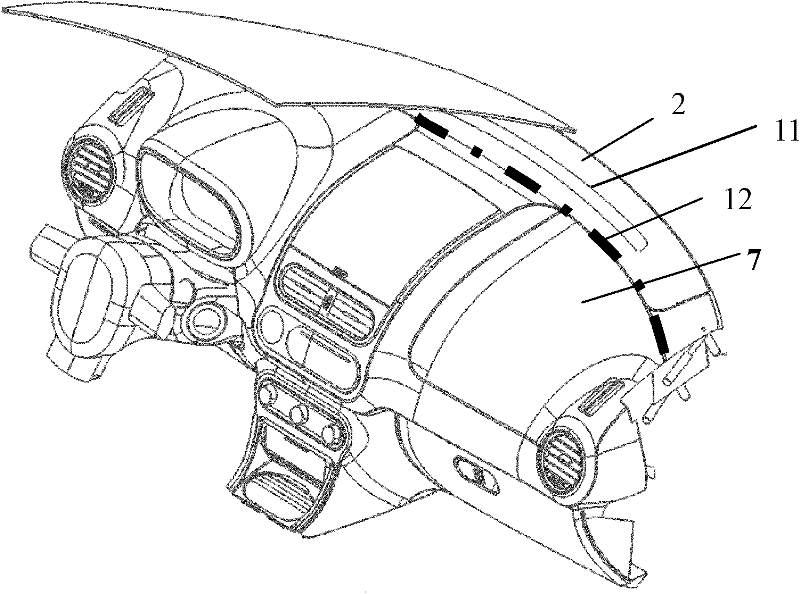

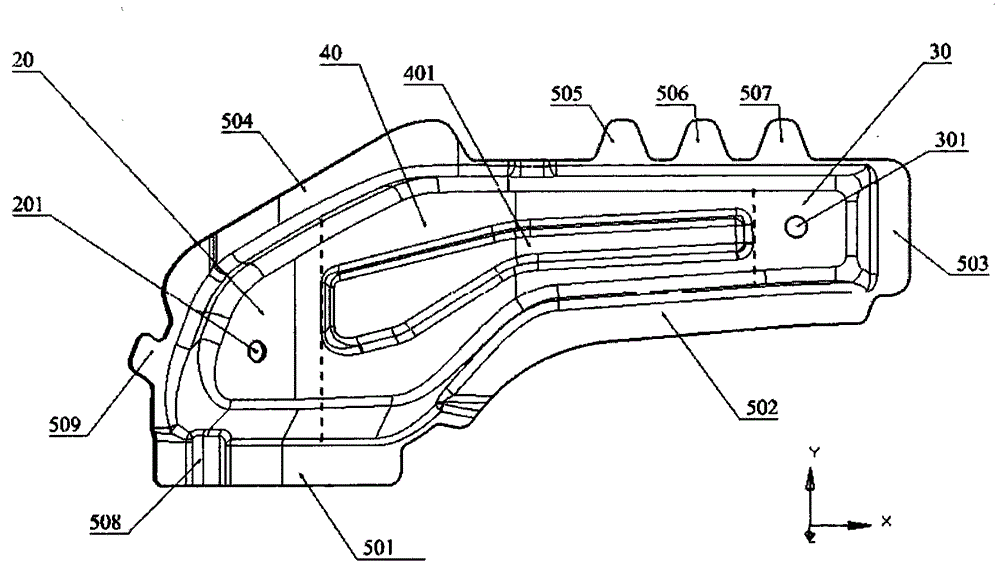

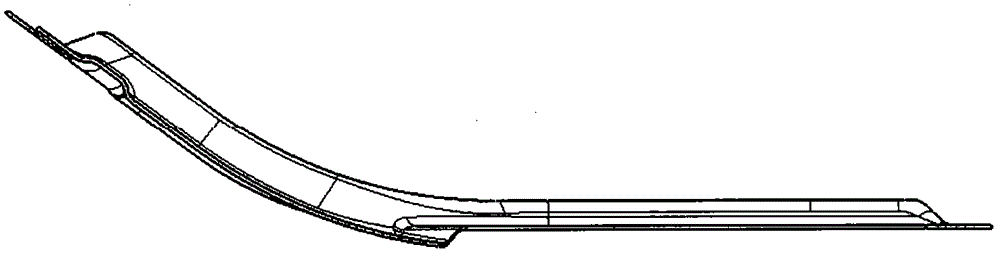

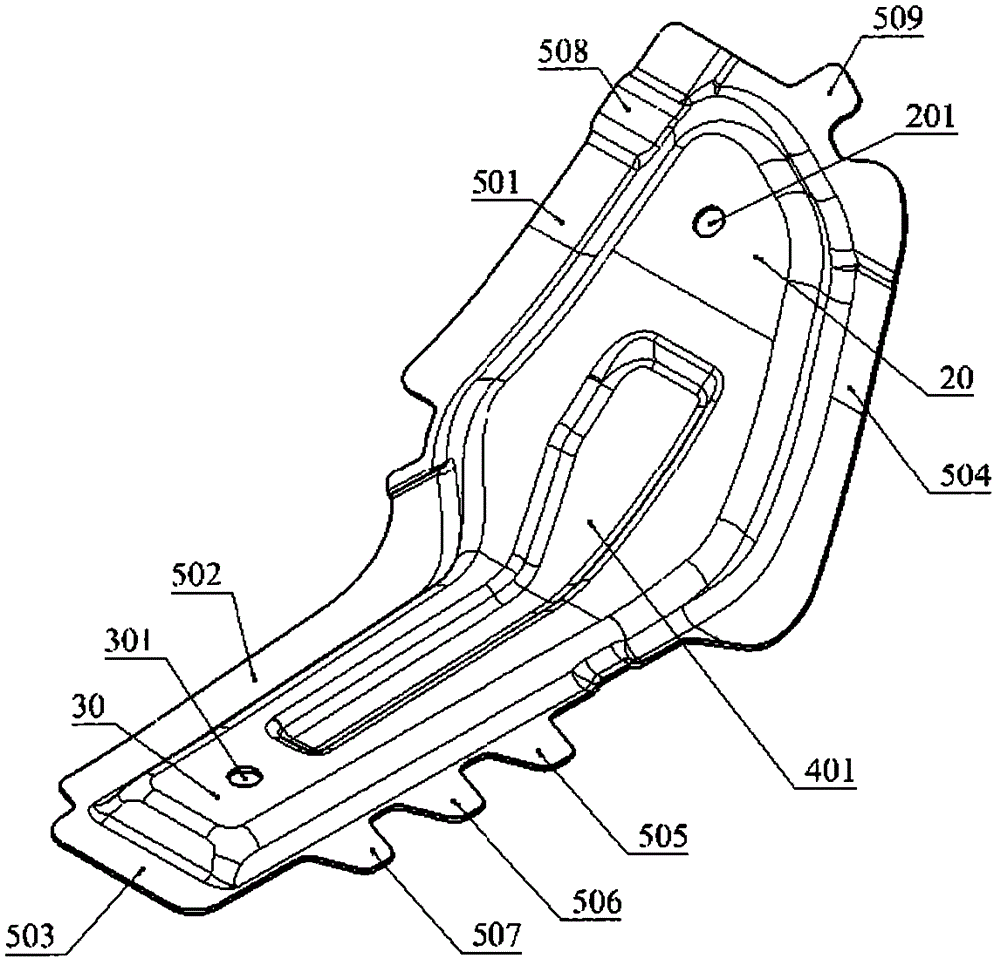

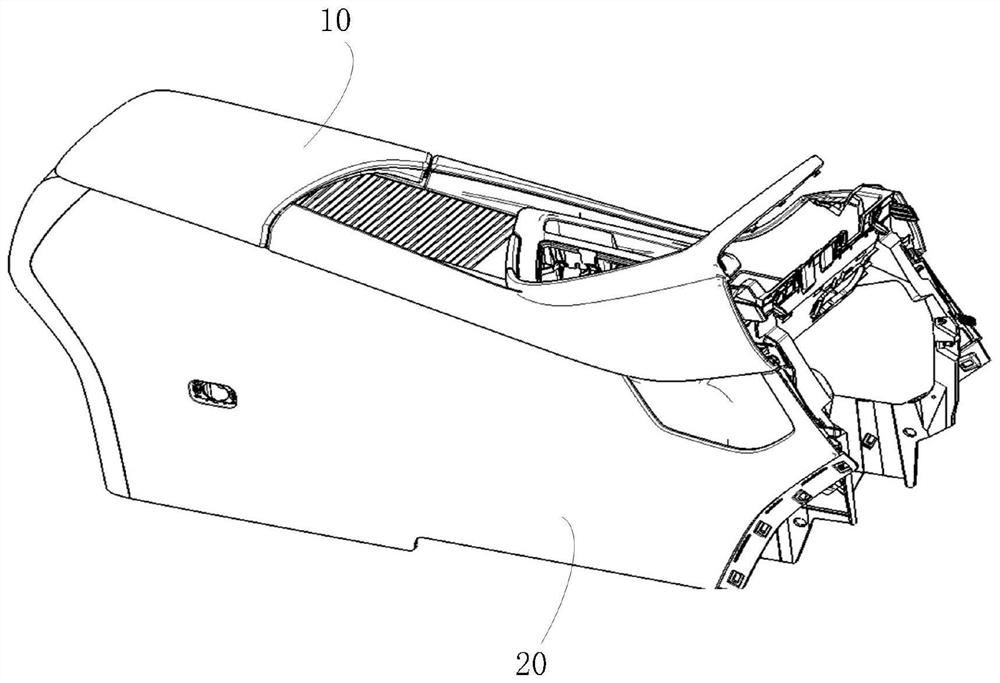

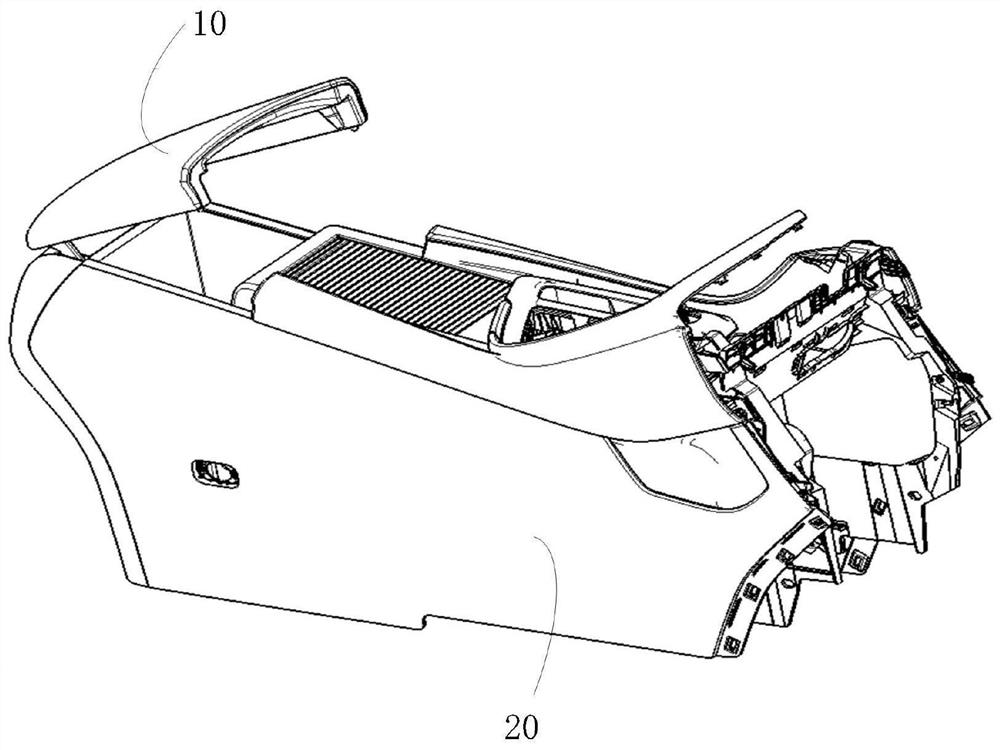

Folding interior trim part for vehicle

InactiveCN102452320AAvoid vibration and noisePrevent jumpingAntiglare equipmentDashboardsElectricitySolar cell

The invention discloses a folding instrument board, which is arranged on a vehicle body, and comprises an instrument board (10) and a telescopic solar cell plate (1) or a telescopic sunshade (20), wherein the instrument board (10) comprises a fixed instrument board body (7) and a folding area (2) of which the initial position is close to a front windshield; the solar cell plate (1) is arranged below the folding area (2) of the instrument board; and the solar cell plate (1) or the telescopic sunshade (20) and the folding area (2) of the instrument board (2) are respectively controlled by at least one group of electric push rod assemblies (9 and 8). When a vehicle stops in the sun, the solar cell plate can be started to charge a storage battery on the vehicle so as to meet the requirements of electricity utilization of subsequent running or other electric appliances.

Owner:SHANGHAIK YANFENG JINQIAO AUTOMOTIVE TRIM SYSTEMS CO LTD

Muffler for vehicle

ActiveUS20090308687A1Avoid vibrationAvoid noiseSilencing apparatusMachines/enginesEngineeringMuffler

A muffler of a vehicle includes a first muffler body so as to form a first chamber, at least a second muffler body including a housing, one end portion opened and the other end portion closed, wherein one of the second muffler bodies is fitted into the other end portion of the first member to form a second chamber and the other second muffler bodies are fitted into each other through the one end portions in series to form third chambers if more than one second muffler bodies are assembled, an inflow pipe to connect the outside with the first, second and / or third chamber by passing the one end portion of the first muffler body, and an outflow pipe to communicate the first, second, and / or third chamber with the outside by passing through the other end portion of the last second muffler body.

Owner:HYUNDAI MOTOR CO LTD

Passenger vehicle cab floor reinforcing plate and floor assembly

InactiveCN105882766AEnhance structural rigidity and strengthAvoid vibration and noiseSuperstructure subunitsAutomotive engineeringFlange

The invention provides a passenger vehicle cab floor reinforcing plate and a floor assembly and relates to the technical field of vehicle body structure. The passenger vehicle cab floor reinforcing plate comprises a reinforcing plate body plate vertically distributed along a vehicle, and a welded flange welded and attached around the body plate according to the molded surface of a cab floor. A swelling structure of the reinforcing plate body plate and the cab floor form an integrated cavity section, rigidity and strength of the cab floor can be effectively improved, NVH performance of the vehicle is effectively improved, the cavity section can improve bending strength of the vehicle when the vehicle is collided from the front side, and the deformation degree of the cab floor during collision is reduced. The passenger vehicle cab floor reinforcing plate is stable in structure, good in forming performance, precise in welding and positioning, convenient to weld and capable of effectively improving NVH performance and collision safety of the vehicle.

Owner:JINHUA VOCATIONAL TECH COLLEGE

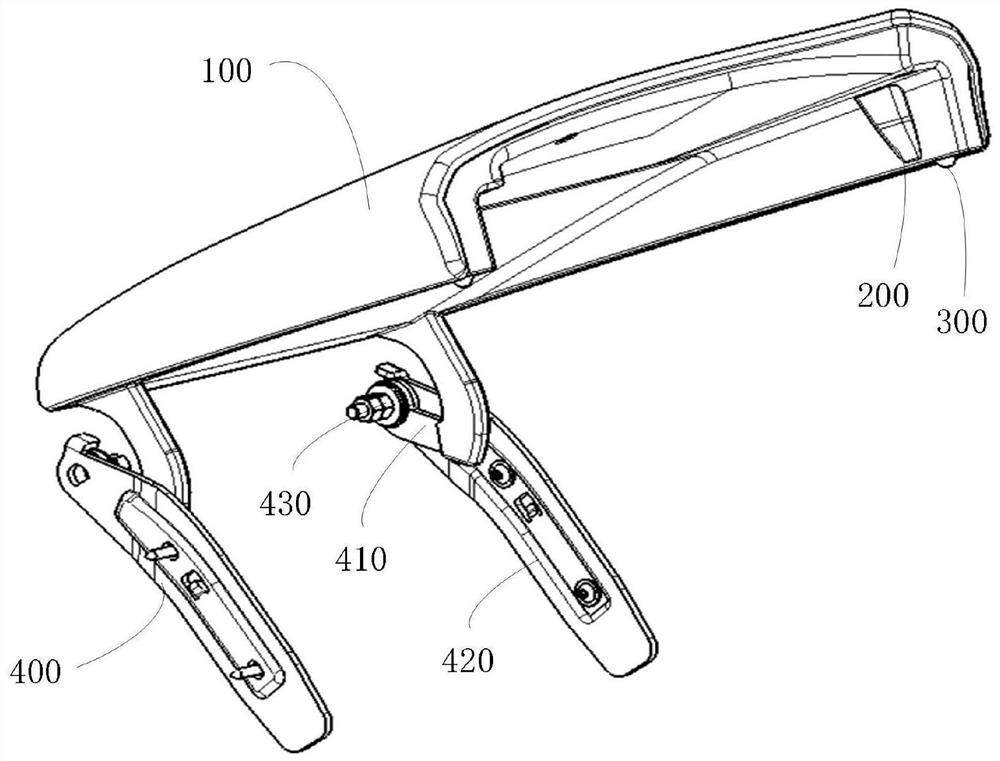

Armrest assembly structure and automobile auxiliary instrument panel assembly

The invention relates to an armrest assembly structure and an automobile auxiliary instrment panel assembly. The armrest assembly structure comprises an armrest body, a buffer limiting structure and ahinge connecting structure. The buffer limiting structure comprises a buffer protruding structure and a buffer clamping structure which are arranged at the bottom of the front end of the handrail body, the buffer protruding structure is used for being correspondingly matched with the top face of the auxiliary instrument board body, and the buffer clamping structure is used for being correspondingly matched with the side wall of the auxiliary instrument board body in a clamping mode; a hinge connecting structure which comprises an upper hinge arm arranged on each of the two sides of the bottomof the rear end of the handrail body in a protruding mode, a lower hinge arm used for being connected with the two sides of the auxiliary instrument board body, and a friction damping rotating structure used for hinging the upper hinge arms and the lower hinge arms. According to the armrest assembly structure, the problems of troublesome unlocking operation and complex structure caused by configuring a lock catch structure at the front end of the handrail in related technologies can be solved.

Owner:DONGFENG VISTEON AUTOMOTIVE TRIM SYST CO LTD

Commutator and motor

ActiveCN105071176AIncrease productivityAvoid vibration and noiseRotary current collectorDC commutatorEngineeringInjection moulding

The invention is suitable for the field of motors, and discloses a commutator and a motor. The commutator comprises a commutator body and a positioning protrusion structure, wherein the positioning protrusion structure is convexly arranged at one axial end of the commutator body and is used for axially positioning a first bearing; the commutator body comprises a commutating sheet and a molded part; the molded part is molded at the inner side of the commutating sheet in an injection manner; and the positioning protrusion structure is fixed at the end part, toward the first bearing, of the molded part. The positioning protrusion structure is additionally arranged on the commutator body, so that the axial positioning effect on the first bearing is realized; and the displacement phenomenon of the first bearing is prevented. The positioning protrusion structure is fixed at the end part of the molded part, so that the support coordination relationship between the positioning protrusion structure and a rotating shaft does not need to be specially designed; the problems of great installation difficulty and low installation efficiency of the commutator due to the fact that the positioning protrusion structure and the rotating shaft are in over-tight fit are avoided; and meanwhile, the problems of vibration and abnormal noise generated by the motor in the running process due to the fact that the positioning protrusion structure and the rotating shaft are fitted too loosely are avoided.

Owner:FOSHAN WEILING WASHER MOTOR MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com