Conjugate cam driving mechanism with error compensation function

A technology of conjugate cam and drive mechanism, which is applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problem of not being able to ensure the close fit of the auxiliary cam and the roller, so as to prevent vibration and noise, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

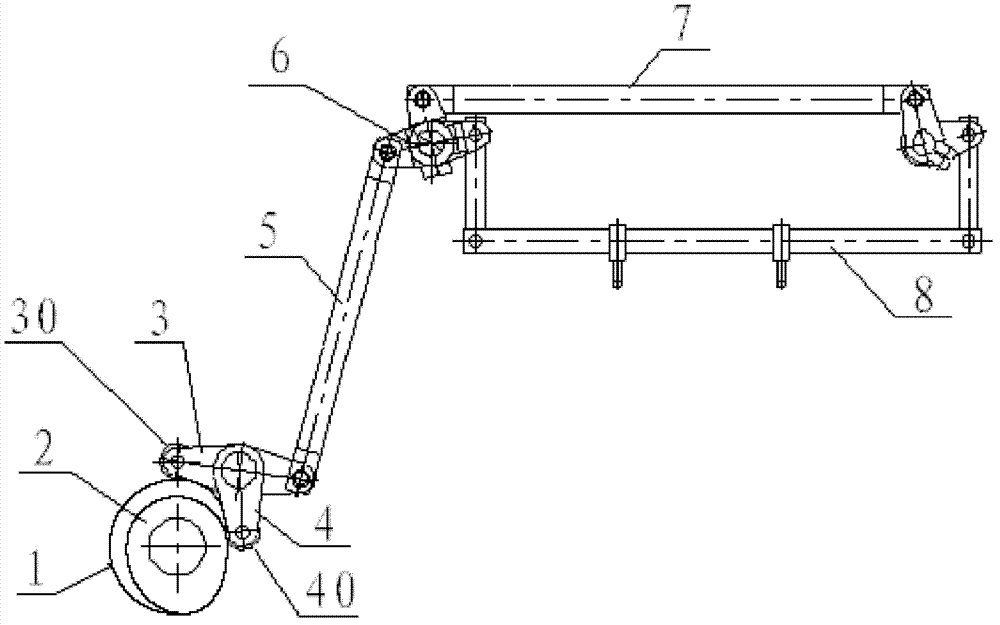

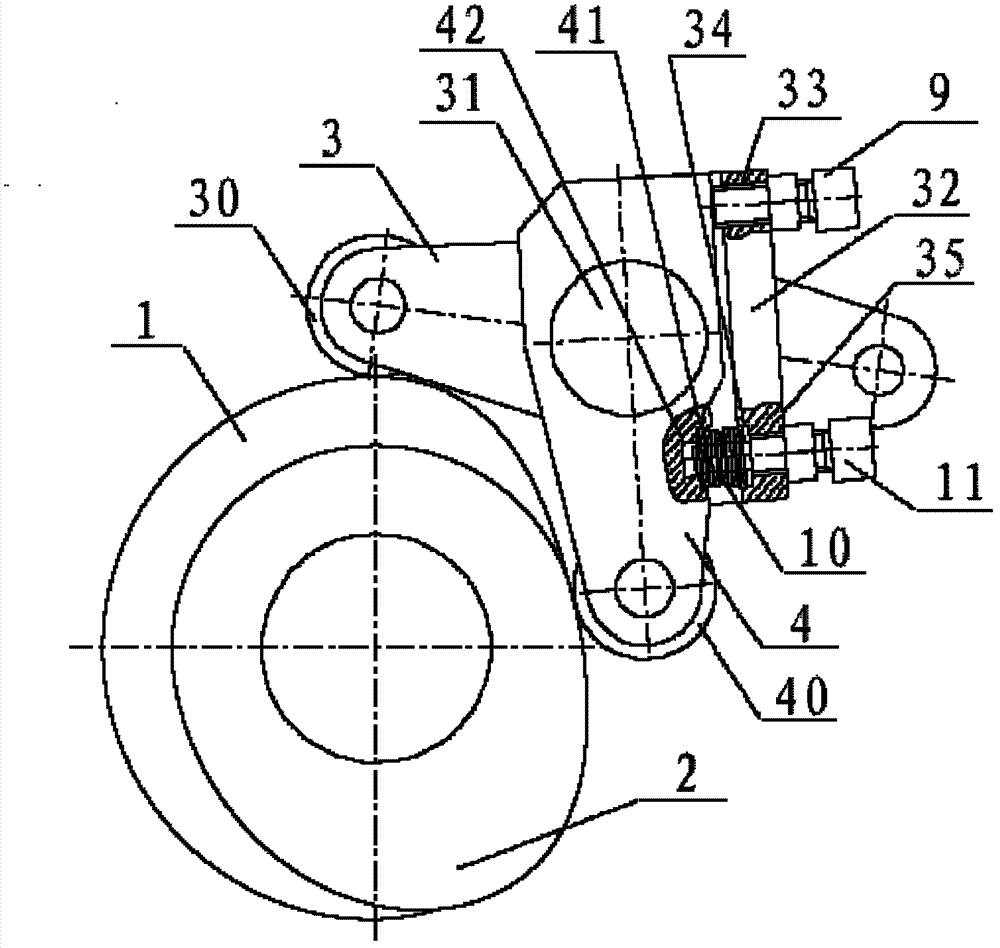

[0011] see figure 2 combined reference figure 1 , the conjugate cam driving mechanism with error compensation of the present invention includes a main cam 1, a secondary cam 2, a first lower swing link 3, a second lower swing link 4, a lower link 5, a pair of upper swing links 6. A pair of upper connecting rods 7, finished frame 8, an angle adjustment screw 9, a butterfly spring 10, and a pressure adjustment screw 11, among which:

[0012] The auxiliary cam 2 is installed on the transmission shaft of the main cam 1, and the outer peripheral curve of the auxiliary cam 2 is different from that of the main cam 1, so that the main cam 1 and the auxiliary cam 2 form a group of conjugate cam pairs;

[0013] The rotation center hole of the first down swing link 3 is sleeved on a swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com