Disassembling and assembling system and disassembling and assembling method for power battery box with side edge having telescopic function

A technology for power batteries and battery boxes, which is applied in the direction of power devices, electric power devices, battery pack components, etc., can solve problems such as fast replacement of power batteries, and achieve small stress at fixed points, convenient disassembly and assembly, and good durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

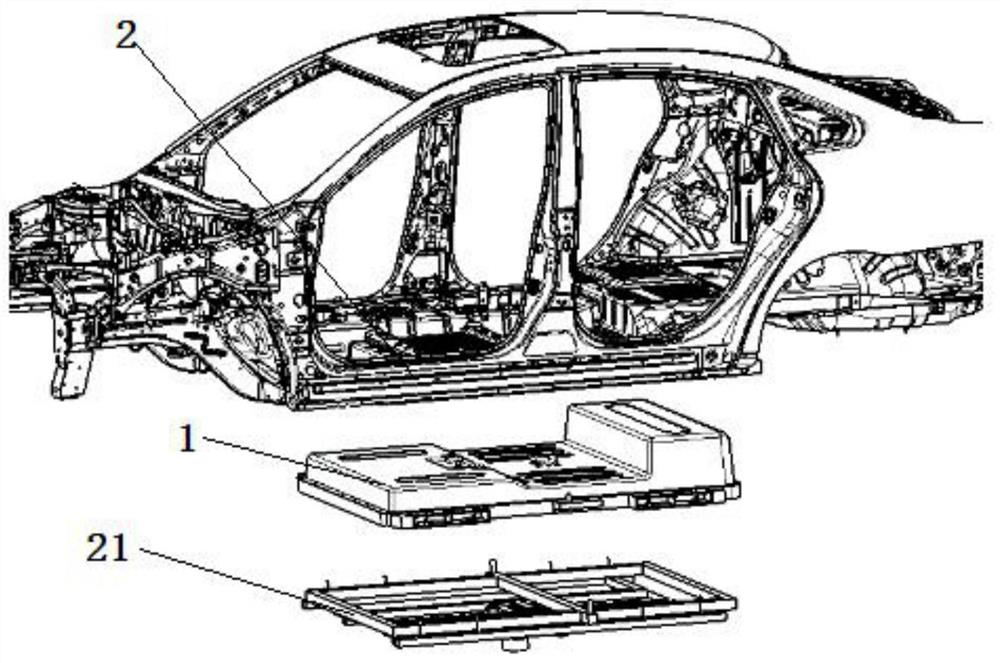

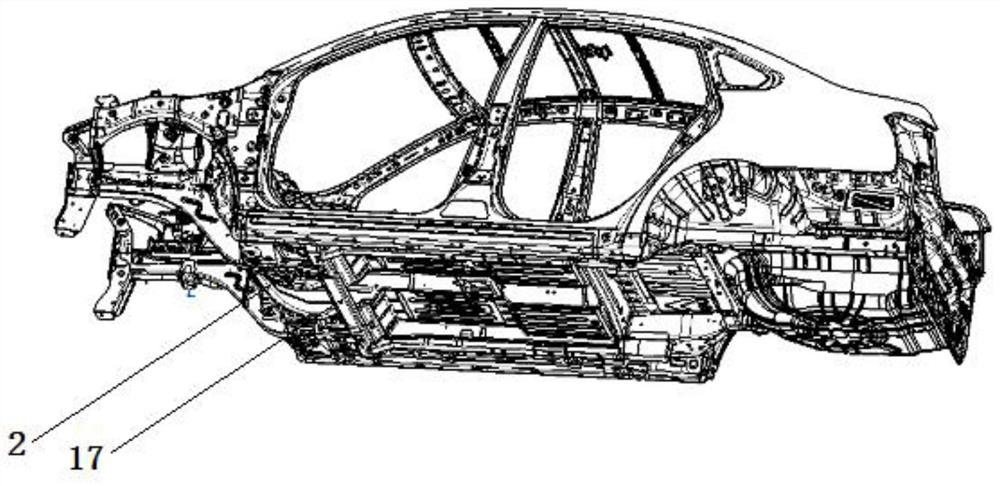

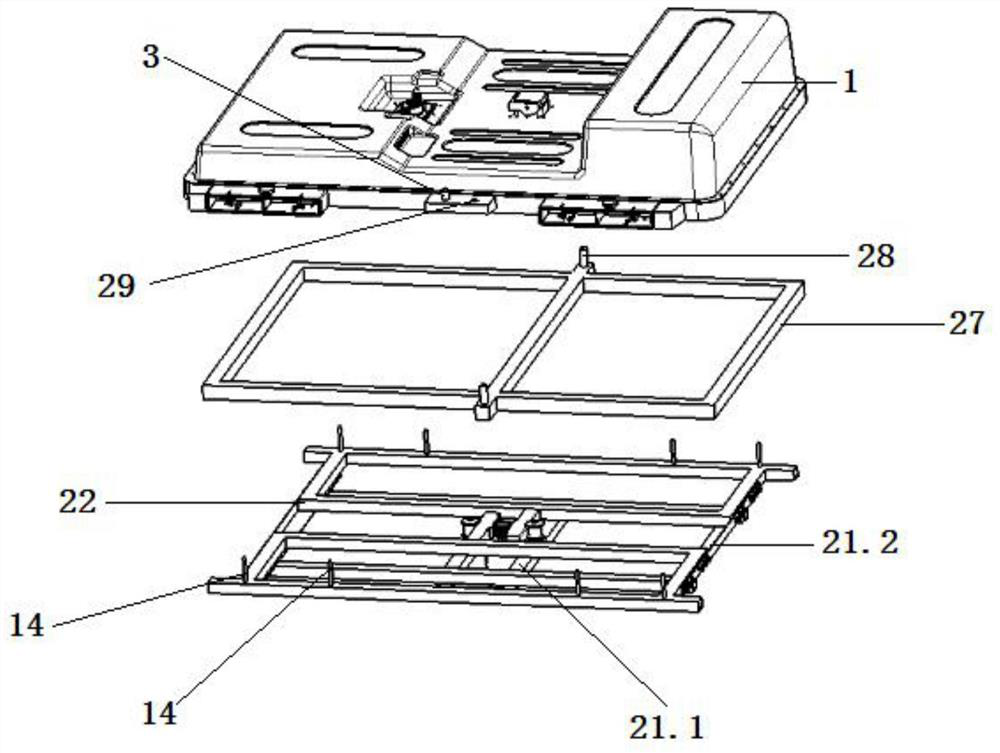

[0029] Such as figure 1 —The power battery box disassembly system with telescopic function shown in 12 includes the underbody assembly 2, the battery box 1 located under the underbody assembly 2, and the battery box 1 can be installed on the underbody assembly 2 or the battery box dismounting mechanism 21 for unlocking the battery box 1 from under the underbody assembly 2 and the battery box tray 27 for consigning the battery box 1 .

[0030]A positioning pin bracket 6 is respectively fixed on the middle surfaces of the left and right sides of the battery case 1 , and a positioning pin 3 arranged vertically upward is fixed on the positioning pin bracket 6 . The left and right sides of the battery box 1 are respectively fixed with two drawer-type telescopic structures arranged front and back. The drawer-type telescopic structure inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com