Maze type sleeve regulating valve

A sleeve regulating valve and labyrinth type technology, applied in the field of regulating valve, can solve the problems of long production cycle, high machining accuracy and high manufacturing cost, and achieve the effects of simple manufacturing process, reduced production cycle and lower product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

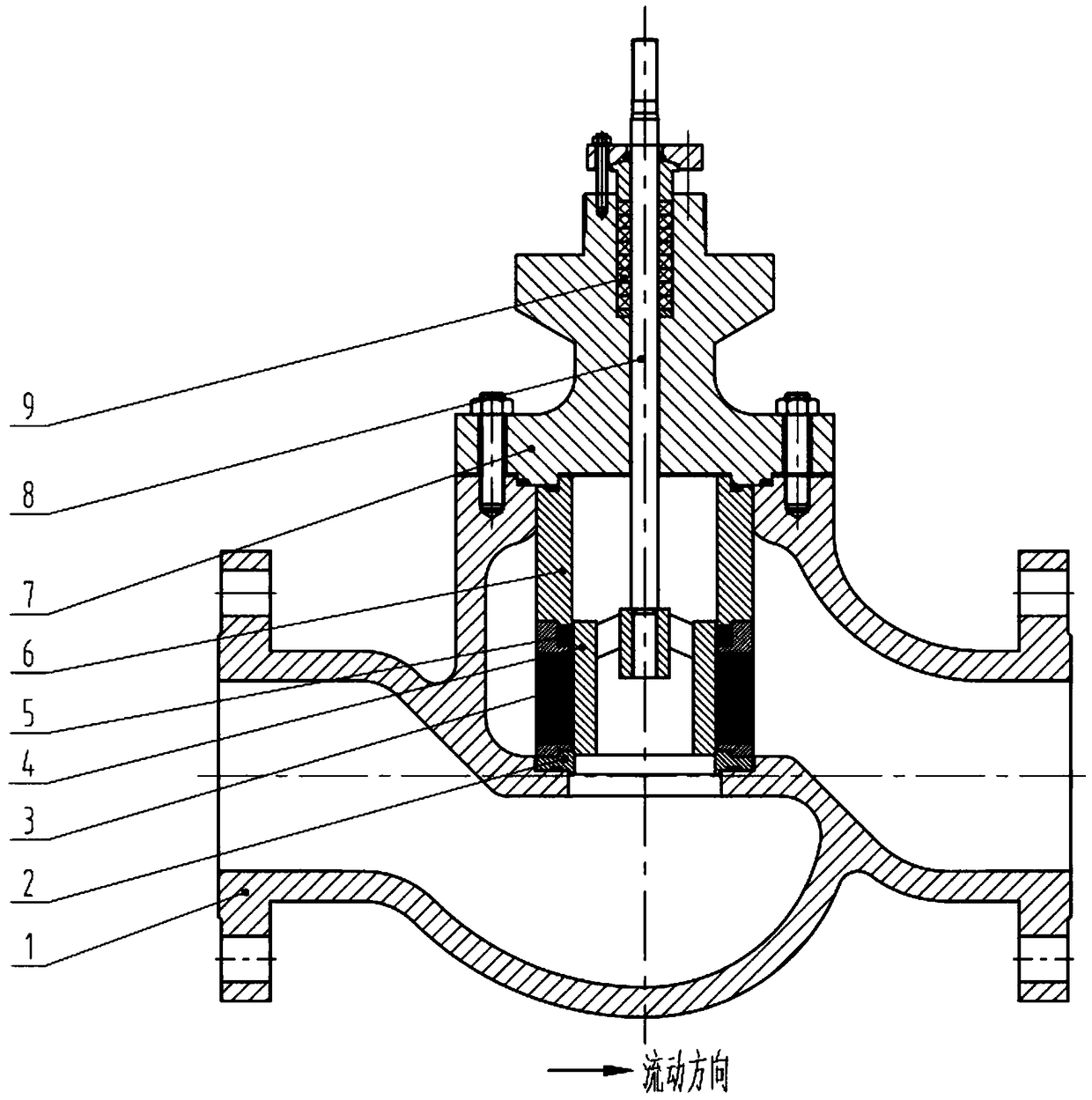

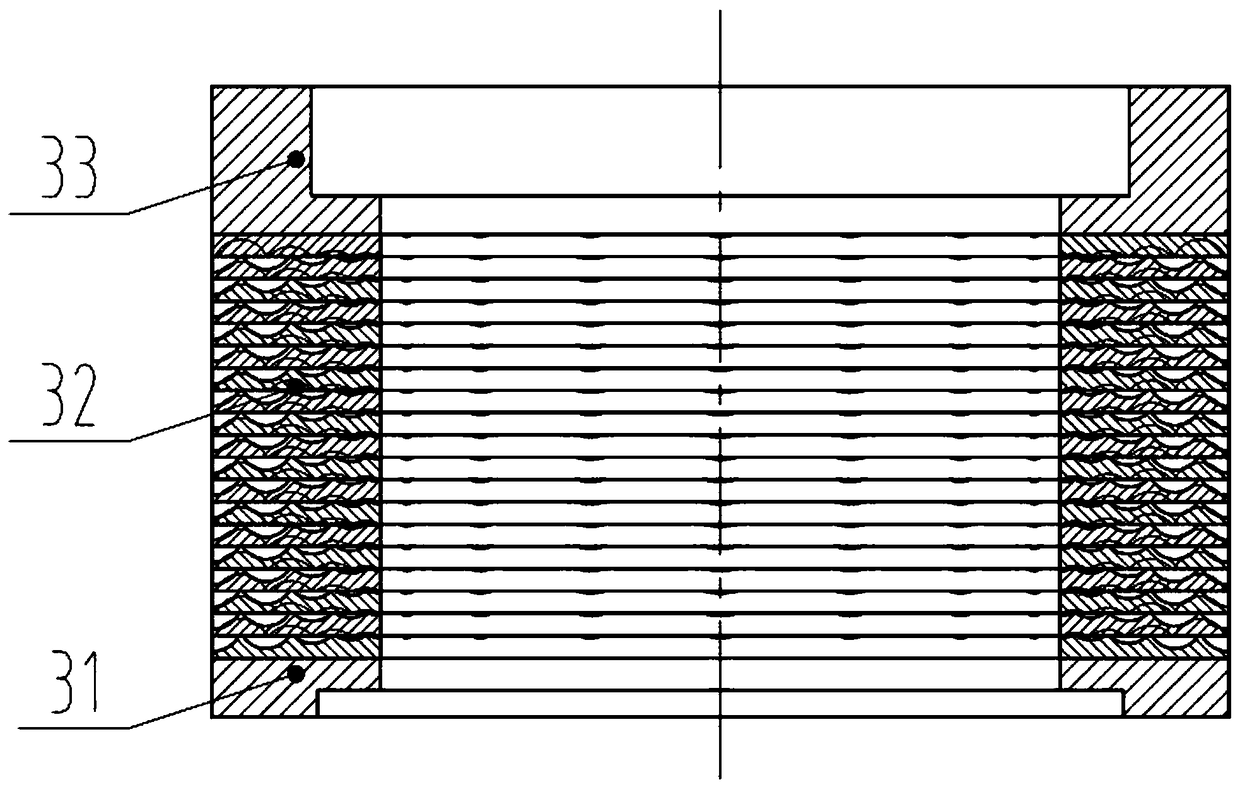

[0024] figure 1 and figure 2 This invention relates to a schematic structural diagram of a labyrinth sleeve regulating valve, which mainly consists of a valve body 1, a valve seat 2, a labyrinth assembly 3, a valve core 4, a balance seal ring 5, an upper sleeve 6, a valve cover 7, a valve Rod 8, sealing assembly 9, are made up of nine parts. Wherein, the labyrinth component 3 is made up of three parts of lower ring 31, disk 32, upper ring 33.

[0025] A gasket is installed between the valve body 1 and the valve seat 2, and a gasket is respectively installed between the valve cover 7, the valve body 1 and the upper sleeve 6, and a fixed connection is used between the valve body 1 and the valve cover 7.

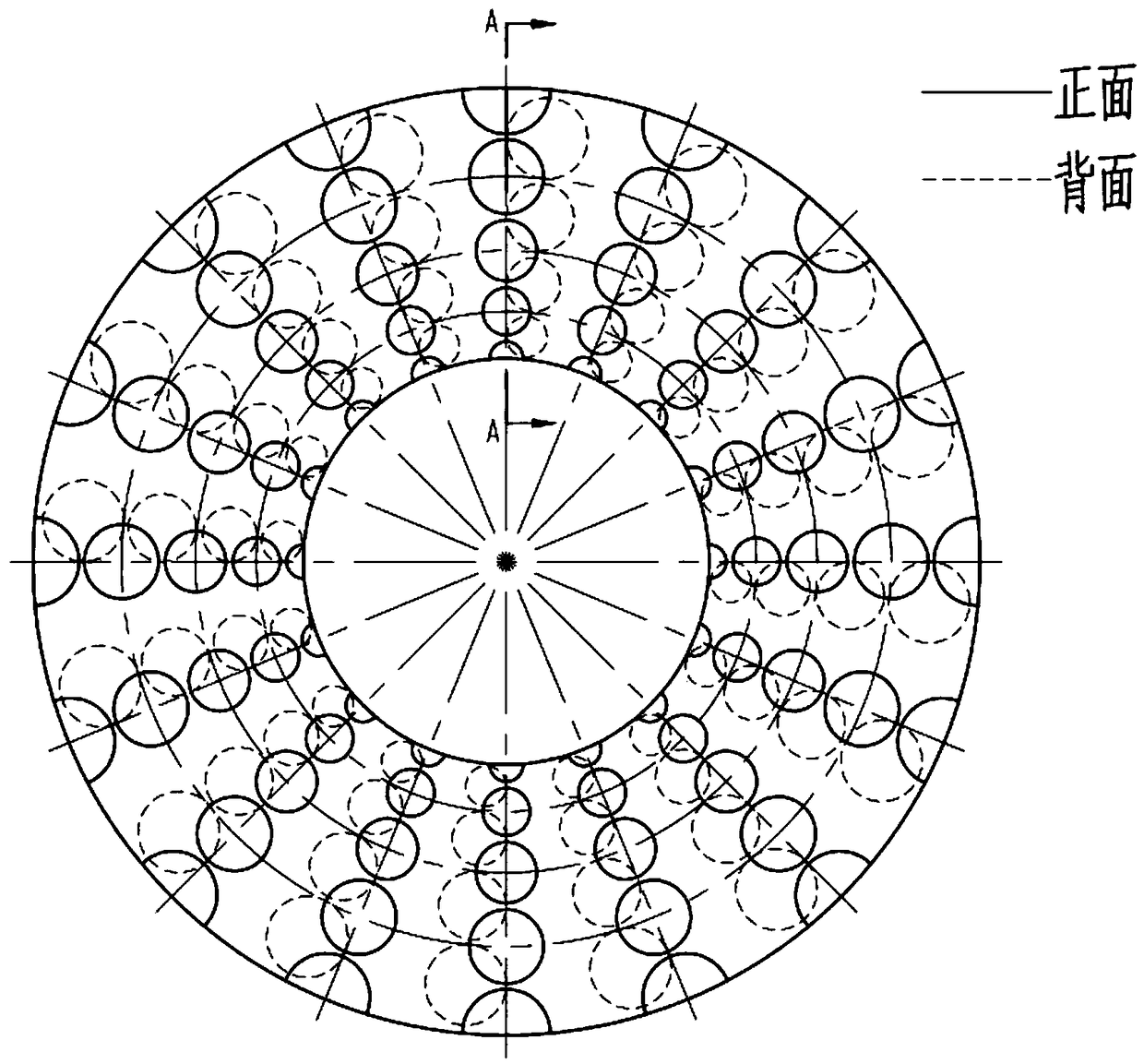

[0026] The labyrinth assembly 3 is composed of a lower ring 31 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com