Active hydraulic damper and hydraulic actuator

A hydraulic damper and hydraulic actuation technology, which is applied in the direction of liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve problems such as insufficient dynamics, low limit frequency, and complexity, and achieve improved dynamic characteristics and cost advantages Convenience and improved controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

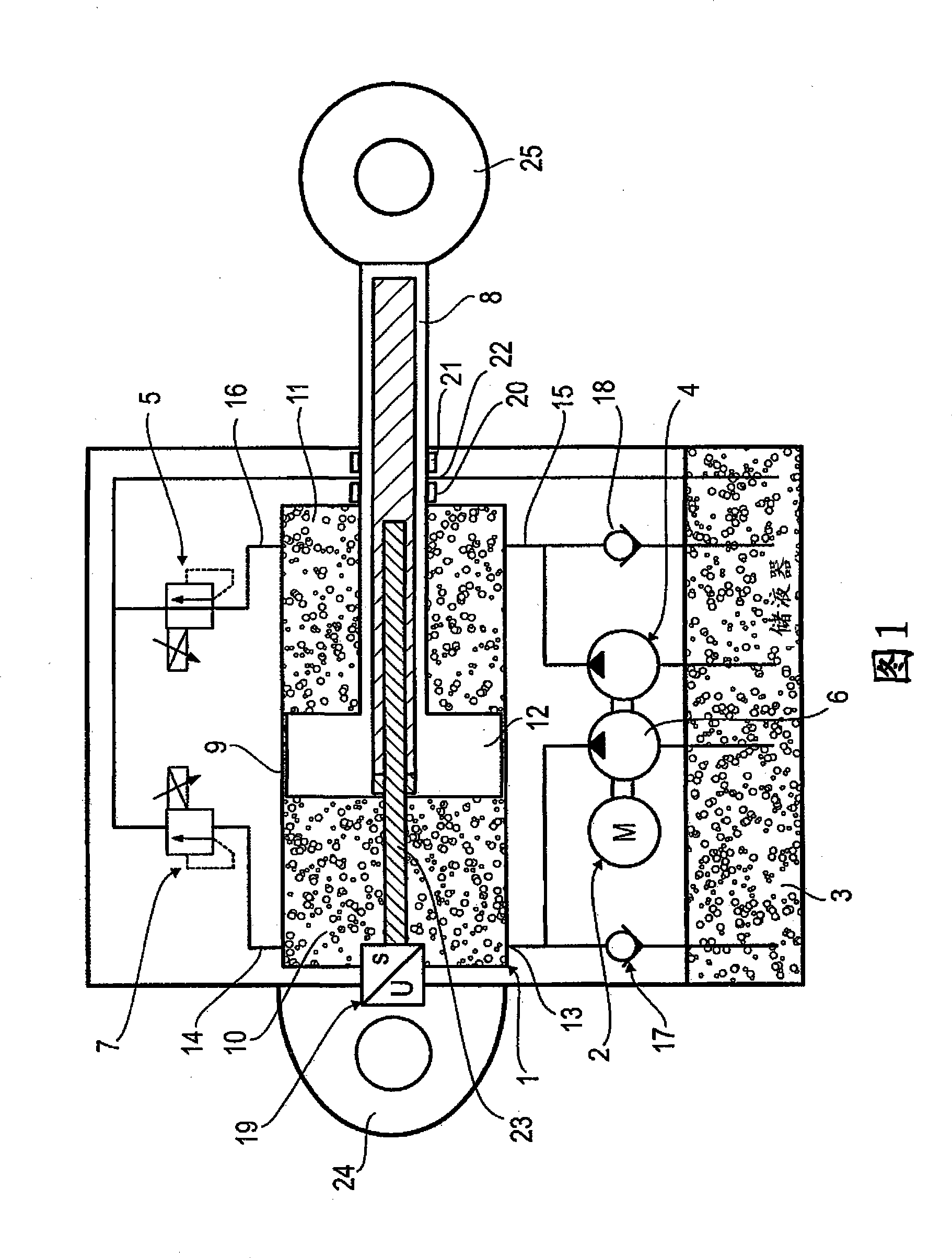

[0062] FIG. 1 shows an embodiment of the actuator of the invention in which all components of the hydraulic system are arranged at the hydraulic cylinder 1 . The hydraulic cylinder 1 is a double-acting cylinder with a cylinder space 9, a one-way piston rod 8 and a piston 12 movable in the cylinder space, which divides the cylinder space 9 into a first piston space 10 and a second piston space11. By applying a pressure difference between the first piston space 10 and the second piston space 11 , the pistons can move in opposite directions as directed by the pressure difference.

[0063] Furthermore, a position-measuring system 19 is provided, which is integrated in the hydraulic cylinder, wherein a position-measuring track 23 runs in a bore in the piston rod 8 . In this way, the movement of the piston and thus the position of the cylinder-side pivot point 24 relative to the piston-side pivot point 25 can be detected.

[0064] All components of the hydraulic system of the inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com