Anti-cavitation centrifugal pump

A centrifugal pump and anti-cavitation technology, applied in the field of centrifugal pumps, can solve the problems of reduced pumping volume, low efficiency, impeller rupture, etc., and achieve the effects of avoiding vibration and noise, ensuring normal operation, and avoiding cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

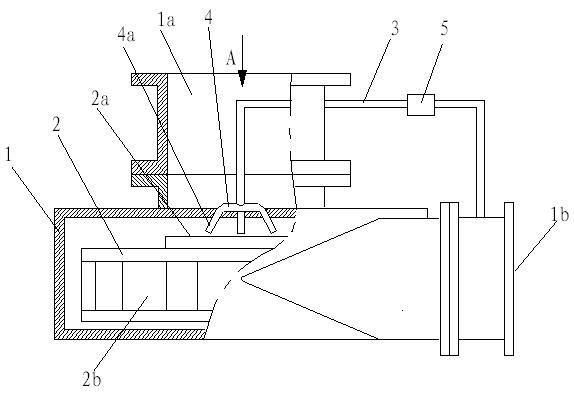

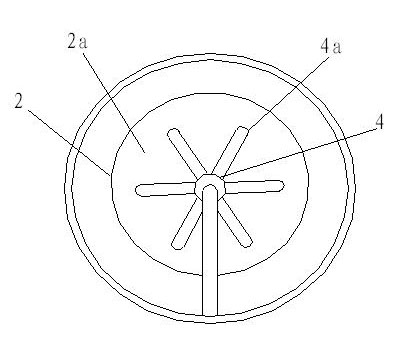

[0015] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the nozzle distribution of the injection device, as shown in the figure: the anti-cavitation centrifugal pump of this embodiment includes a pump casing 1 and an impeller 2, the pump casing 1 is provided with a pump inlet 1a and a pump outlet 1b, and the impeller 2 includes an impeller inlet 2a and the impeller outlet 2b, and also includes an ejection device, the ejection device includes an ejection pipe 3 and a nozzle 4a, the liquid inlet of the ejection pipe 3 is connected to the impeller outlet 2b, and the nozzle 4a is facing the impeller inlet 2a low-pressure area It communicates with the liquid outlet of the ejector pipe 3; the impeller inlet 2a low-pressure area is a specific area of the impeller, which refers to the part of the impeller with the lowest pressure when absorbing liquid. After the shape and structure of the impeller are determined, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com